Page 1

I

nstallation, Operation and Maintenance Instructions

Model 3408

© 1999 Goulds Pumps

Page 2

Pump Safety Tips

Safety Apparel:

Insulated work gloves when handling hot bearings

•

or using bearing heater

Heavy work gloves when handling parts with sharp

•

edges, especially impellers

Safety glasses (with side shields) for eye

•

protection, especially in machine shop areas

Steel-toed shoes for foot protection when handling

•

parts, heavy tools, etc.

Other personal protective equipment to protect

•

against hazardous/toxic fluids

Coupling Guards:

Never operate a pump without a coupling guard

•

properly installed

Flanged Connections:

Never force piping to make a connection with a pump

•

Use only fasteners of the proper size and material

•

Operation:

Do not operate below minimum rated flow, or with

•

suction/discharge valves closed

Do not open vent or drain valves, or remove plugs

•

while system is pressurized

Maintenance Safety:

Always lock out power

•

Ensure pump is isolated from system and pressure

•

is relieved before disassembling pump, removing

plugs, or disconnecting piping

Use proper lifting and supporting equipment to

•

prevent serious injury

Observe proper decontamination procedures

•

Know and follow company safety regulations

•

Observe all cautions and warnings highlighted in

pump Installation, Operation and Maintenance

Instructions.

Ensure there are no missing fasteners

•

Beware of corroded or loose fasteners

•

Page 3

FOREWORD

3408 IOM 03/99 3

This manual provides instructions for the Installation, Operation, and Maintenance of the

Goulds Model 3408 Double Suction, Horizontally Split Case Pump. This manual covers the

standard product plus common options that are available. For special options, supplemental

instructions are supplied. This manual must be read and understood before installation

and maintenance.

The design, materials, and workmanship incorporated in the construction of Goulds pumps

make them capable of giving long, trouble-free service. The life and satisfactory service of any

mechanical unit, however, is enhanced and extended by correct application, proper

installation, periodic inspection, condition monitoring and careful maintenance. This instruction

manual was prepared to assist operators in understanding the construction and the correct

methods of installing, operating, and maintaining these pumps.

ITT Industries - Goulds Pumps shall not be liable for physical injury, damage or delays

caused by a failure to observe the instructions for Installation, Operation, and

Maintenance contained in this manual.

Warranty is valid only when genuine ITT Industries - Goulds Pumps parts are used.

Use of the equipment on a service other than stated in the order will nullify the warranty,

unless written approval is obtained in advance from ITT Industries - Goulds Pumps.

Supervision by an authorized ITT Industries - Goulds representative is recommended to

assure proper installation.

Additional manuals can be obtained by contacting your local ITT Industries - Goulds

representative or by calling 1-(800)-446-8537.

THIS MAN UAL EX PLAINS

Proper In stal la tion

n

Start- up Pro ce dures

n

Op era tion Pro ce dures

n

Rou tine Main te nance

n

Pump Over haul

n

Trou ble shoot ing

n

Or der ing Spare or Re pair Parts

n

Page 4

4 3408 IOM 03/99

Page 5

TABLE OF CONTENTS

3408 IOM 03/99 5

SECTION

PAGE

7 SAFETY

1

9 GENERAL INFORMATION

11 INSTALLATION

23 OPERATION

27 PREVENTIVE MAINTENANCE

35 DISASSEMBLY & REASSEMBLY

57 APPENDIX

2

3

4

5

6

7

Page 6

6 3408 IOM 03/99

Page 7

SAFETY

3408 IOM 03/99 7

DEFI NI TIONS .................................. 7

GEN ERAL PRE CAU TIONS ........................... 7

DEFINITIONS

1

This pump has been designed for safe and reliable

operation when properly used and maintained in

accordance with instructions contained in this manual.

A pump is a pressure containing device with rotating

parts that can be hazardous. Operators and

maintenance personnel must realize this and follow

safety measures. ITT Industries - Goulds Pumps

shall not be liable for physical injury, damage or

delays caused by a failure to observe the instructions

in this manual.

Throughout this manual the words WARNING ,

CAUTION , and NOTE are used to indicate

procedures or situations which require special

operator attention:

! WARNING

▲

Warning is used to indicate the presence of a

hazard which can cause severe personal injury,

death, or substantial property damage if the

warning is ignored.

▲!

Caution is used to indicate the presence of a

hazard which will or can cause minor pe rsonal

injury or property damage if the warning

is ignored.

NOTE: Operating procedure, condition, etc.

which is essential to observe.

CAUTION

EXAMPLES

! WARNING

▲

Pump shall never be operated without coupling

guard installed correctly.

▲!

Throttling flow from the suction side may

cause cavitation and pump damage.

NOTE: Proper alignment is essential for long

pump life.

CAUTION

GENERAL PRECAUTIONS

! WARN ING

▲

Personal injuries will result if procedures

outlined in this manual are not followed.

NEVER operate pump without coupling guard

•

correctly installed.

NEVER operate pump beyond the rated conditions

•

to which the pump was sold.

NEVER start pump without proper prime (sufficient

•

liquid in pump casing).

NEVER run pump below recommended minimum

•

flow or when no liquid is in pump.

ALWAYS lock out power to the driver before

•

performing pump maintenance.

NEVER operate pump without safety devices installed.

•

NEVER operate pump with discharge valve closed.

•

NEVER operate pump with suction valve closed.

•

DO NOT change conditions of service without

•

approval of an authorized Goulds representative.

! Warn ing

▲

If pump is to be used on process fluids above

120° F, pump surface temperatures could be

warm enough to cause burns. We recommend

pump surfaces be insulated. Failure to follow

these instructions could result in severe

personal injury.

Page 8

8 3408 IOM 03/99

Page 9

GENERAL INFORMATION

3408 IOM 03/99 9

PUMP DE SCRIP TION .............................. 9

NAME PLATE IN FOR MA TION ......................... 10

PUMP DESCRIPTION

2

This product line consists of 39 sizes of double

suction, horizontally split case pumps from size

2 x 3-11 through size 10 x 12-18.

Casing - The casing shall be (close-grained cast iron

for working pressures up to 175 psig), (ductile iron for

working pressures up to 400 psig), and shall be of

axially-split design with suction and discharge flanges

and mounting feet cast integral with the lower half

casing. Tapped and plugged holes shall be provided

for priming, vent drain and gauge connections. Upper

half casing shall be removable without disturbing

suction or discharge piping. Flanges shall be of (125#)

(250#) ASA Standard. Suction and discharge shall be

on a common centerline in both the horizontal and

vertical planes.

Impeller - The impeller shall be of the enclosed

double suction type made of bronze non-overloading

in operating characteristics and statically and

hydraulically balanced. The impeller shall be keyed to

the shaft and positioned axially by the shaft sleeves

which are, in turn, locked in place by shaft nuts. Hub

shall have sufficient metal thickness to allow

machining for installation of impeller rings.

Shaft - The shaft shall be made of ( SAE-1045 steel

(316 stainless steel

steel) of ample size to operate under load with a

minimum of deflection.

Shaft Sleeves - The Shaft Sleeves shall be made of

(bronze) (316 stainless steel) (cast iron) (420

stainless steel, 500 Brinnell ) and shall protect the

shaft from wear and from contact with the pumped

liquid. Shaft sleeves shall be locked in place by

threaded, bronze shaft sleeve nuts. An O-ring shall be

furnished under sleeve to prevent leakage.

•) (heat treated 416 stainless

•)

Stuffing Box Housing / Bearing Brackets - The

Stuffing Box Housing / Bearing Brackets shall be

made of cast iron separate from the casing mounted

in cylindrical fits in the casing. Stuff box/bearing

brackets will be drilled and tapped for drain

connection.

Casing Rings - The casing rings shall be made of

(bronze) (cast iron) ( Nitronic 60 stainless steel) and

shall be installed with an anti-rotation device and

designed to restrict leakage across the ring fit.

Bearings - The bearing shall be grease lubricated (oil

optional) ball type, single row inboard, double row

outboard, selected to carry radial and thrust loads.

The outboard bearing shall be retained by bearing

locknut and lockwasher.

Bearing Housings - The bearing housings shall be

bolted to the ends of the bearing bracket/stuffing box

and shall be male-female fitted for a full 360 degrees

to assure positive alignment. The housings shall

provide a fit for the inboard bearing that allows

freedom for thermal expansion while the outboard

bearing shall be clamped in place to take all thrust

loads and keep the rotating element in its proper axial

location. Openings for adding new grease and

draining old grease shall be provided.

Baseplate - The baseplate shall be steel, sufficiently

rigid to support the pump and driver.

Coupling - Coupling shall be of the flexible type.

Coupling hubs shall be secured to the driver and

driven shafts by a setscrew located over the key.

Coupling Guard - The coupling guard shall be the all

metal type.

Rotation - Pump shall have clockwise or

counterclockwise rotation when viewed from its

driven end.

• AISI 4140 Steel is standard on 4 x 6-11, 6 x 8-12M, and 8 x 10-20S & L, 10 x 12-18. 1045 & 316SS are no t available for these sizes.

Page 10

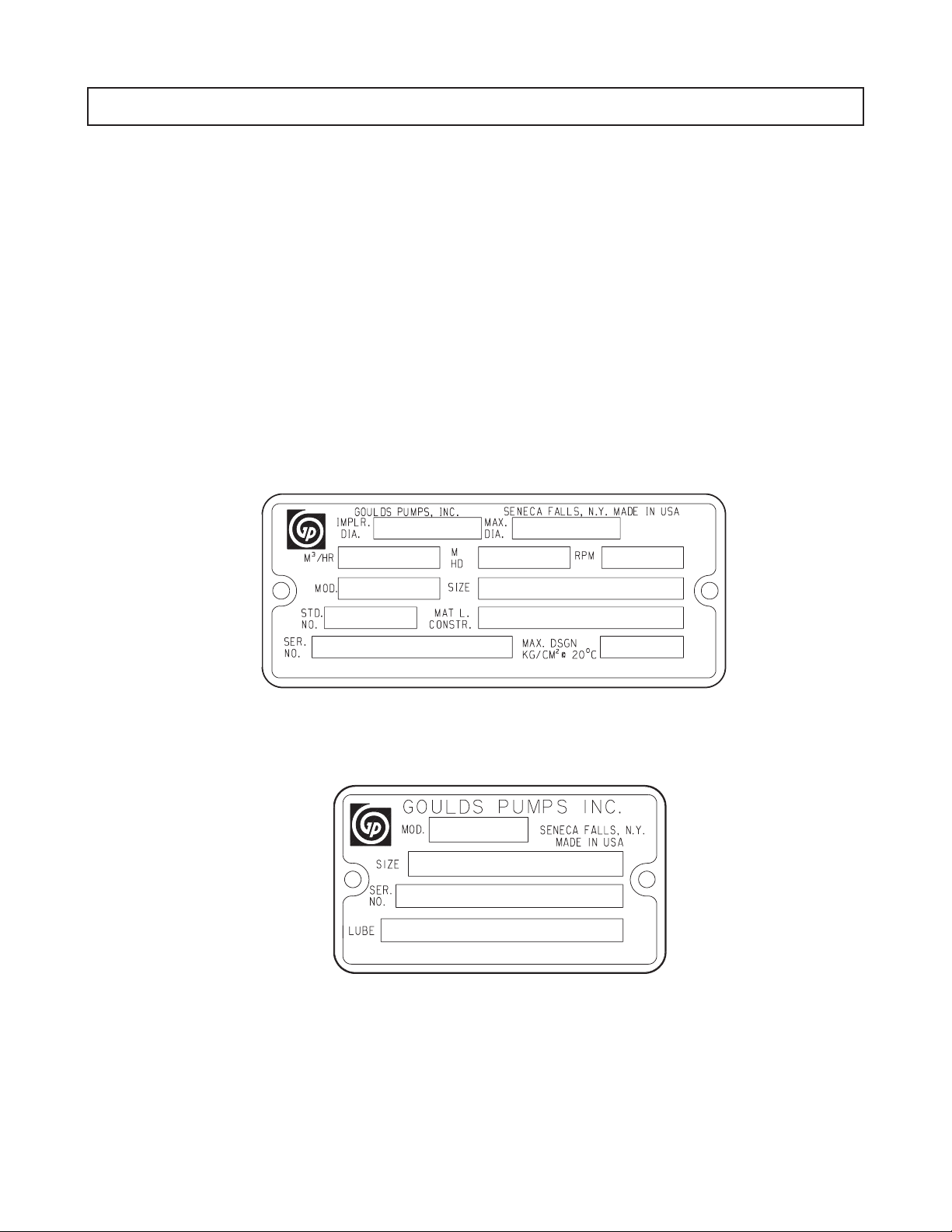

NAMEPLATE INFORMATION

Every pump has a Goulds nameplate that provides

information about the pump. The nameplate is located

on the pump casing.

Special tags which provide additional information

(mechanical seal data, etc.) and special tagging

required by customers are located on the pump

casing or on the bearing frame.

The standard nameplate (Fig. 1) provides information

about the pump size, type, serial number, rated head,

capacity, speed, impeller diameter, model number,

and maximum field hydrostatic test pressure.

The identification No. is a number which the end user

of pump requests to be put on the nameplate to

identify the pump in his operation.

The year indicates the year in which the pump was

built.

Rating and hydrostatic test pressure are expressed in

English units. Note the format of pump size:

Discharge x Suction - Nominal Impeller Diameter in

inches, for example, 2 x 3-11.

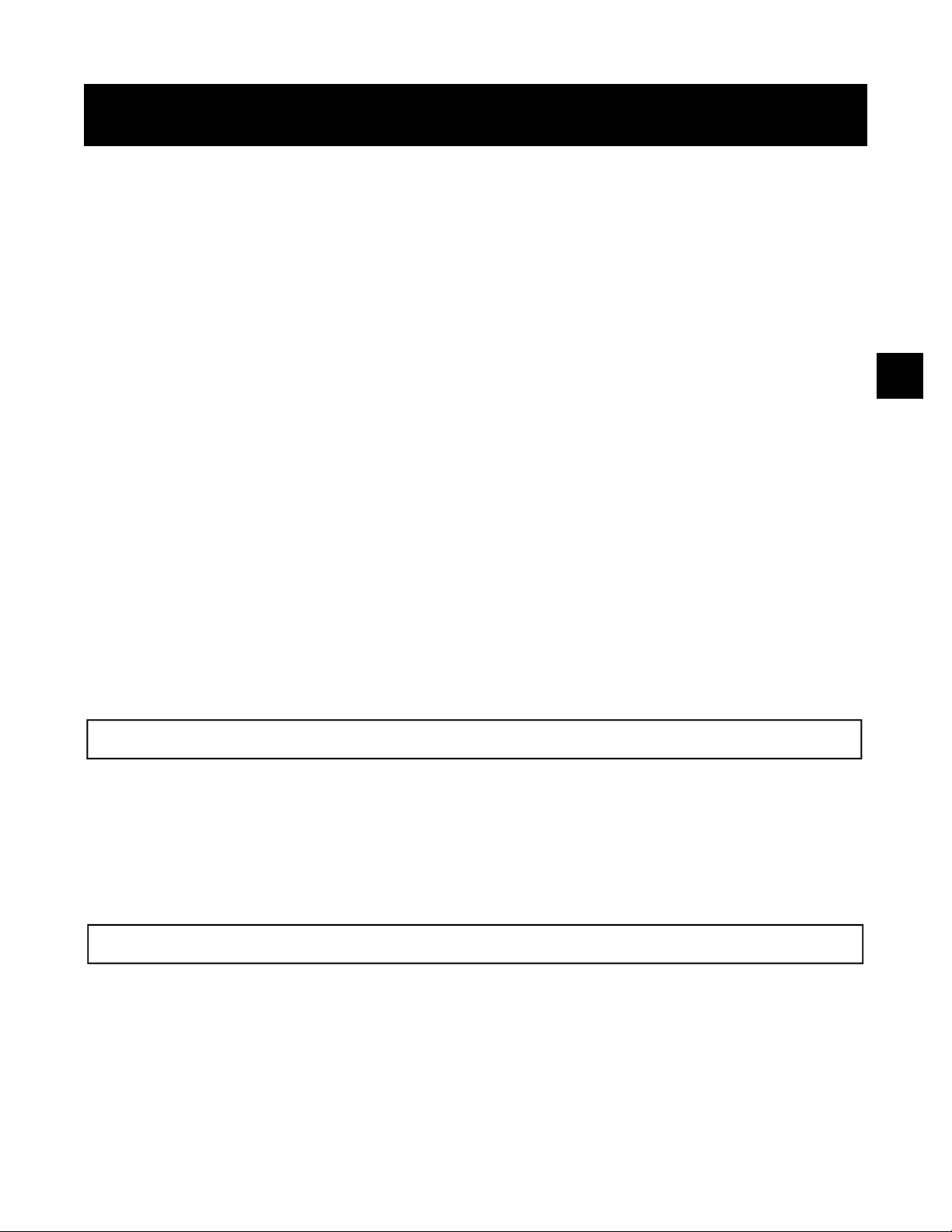

The frame plate (Fig. 2) provides information

concerning the bearings and their lubrication. The

inboard and outboard bearing numbers refer to the

bearing manufacturer’s numbers.

When ordering spare parts you will need to identify

pump model, size, serial number, and the catalog

number of required parts. Pump information can be

taken from the Goulds nameplate. Catalog numbers

can be found in this manual (Pg. 66).

Fig. 1

Fig. 2

10 3408 IOM 03/99

Page 11

INSTALLATION

3408 IOM 03/99 11

RE CEIVING THE PUMP ............................ 11

LIFTING THE PUMP .............................. 11

Hor i zon tal .................................. 11

Ver ti cal ................................... 12

STOR AGE ................................... 13

Tem po rary ................................. 13

Long Term ................................. 13

LO CA TION ................................... 14

FOUN DA TION ................................. 14

SETTING THE BASE PLATE ......................... 14

Grouting Pro ce dure ............................. 15

ALIGN MENT PRO CE DURE .......................... 15

Method One ................................. 16

Method Two ................................. 16

DOWELING .................................. 17

SUC TION AND DIS CHARGE PIPING ..................... 17

Suc tion Pip ing ................................ 17

Dis charge Pip ing .............................. 19

Pres sure Gauges .............................. 19

STUFFING BOX LU BRI CA TION ....................... 20

Packing ................................... 20

Me chan i cal Seals .............................. 21

Cartridge Seals ............................... 21

Cy clone Separators ............................. 21

3

RECEIVING THE PUMP

Check pump for shortages and damage immediately

upon arrival. (An absolute must!) Prompt reporting to

the carrier’s agent, with notations made on the freight

bill, will expedite satisfactory adjustment by the

carrier.

Pumps and drivers are normally shipped from the

factory mounted on a baseplate. Couplings may either

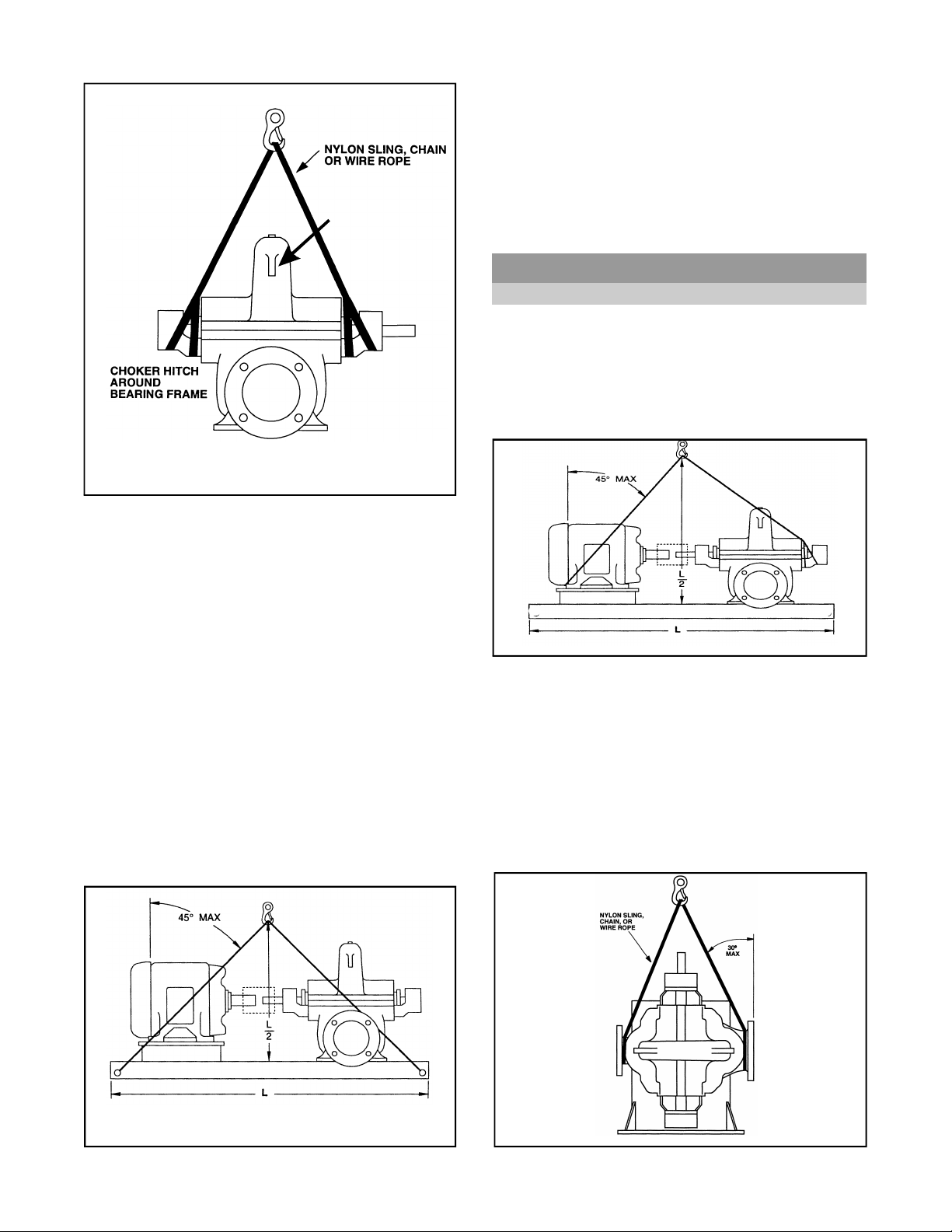

LIFTING THE PUMP

The following instructions are for the safe lifting of

your pump.

The unit should be unloaded and handled by lifting

equally at four or more points on the baseplate. The

lugs on the upper half casing are designed for lifting

the upper half casing only.

be completely assembled or have the coupling hubs

mounted on the shafts and the connecting members

removed. When the connecting members are

removed, they will be packaged in a separate

container and shipped with the pump or attached to

the baseplate.

HORIZONTAL

Bare Pump (Model 100)

1. Using a nylon sling, chain, or wire rope, hitch

around both bearing housings. (See Fig. 3)

Page 12

12 3408 IOM 03/99

DO NOT LIFT

ENTIRE PUMP

WITH THESE

LUGS.

Pump, Base, and Driver (Model 150)

2. Care must be taken to size equipment for

unbalanced loads which may exist if the driver is

not mounted on the base at the time of lifting.

Driver may or may not be mounted at the factory.

Fig. 3

Using ANSI/OSHA Standard “S” hooks, place the “S”

hooks in the holes provided in the four corners of the base.

Be sure the points of the hooks do not touch the bottom of

the pump base. Attach nylon slings, chains, or wire rope to

the “S” hooks. Size the equipment for the load, and so the

lift angle will be less than 45° from the vertical.

Bases supplied without lifting holes

Place one sling around the outboard bearing housing.

! WARN ING

▲

Do not use lugs on top half of casing.

Place the remaining sling around the back end of the driver

as close to the mounting feet as possible. Make certain

sling will not damage housing cover or conduit boxes.

Join the free ends of the slings together and place over

the lifting hook. Use extreme care when positioning sling

under the driver so it cannot slip off. (See Fig. 5)

3. Pump, base, and driver assemblies where the

base length exceeds 100 inches may not be safe

to lift as a complete assembly. Damage to the

baseplate may occur. If the driver has been

mounted on the baseplate at the factory, it is safe

to lift the entire assembly. If driver has not been

mounted at the factory and the overall baseplate

length exceeds 100 inches, do not lift entire

assembly consisting of pump, base, and driver.

Instead lift the pump and baseplate to its final

location without the driver. Then mount the driver.

Bases supplied with lifting holes

Large bases are supplied with lifting holes in the

sides or the ends of the base. (See Fig. 4)

Fig. 5

VERTICAL

Half Pedestal (Model 200)

1. Place nylon sling chain or wire rope around both

flanges. Use a latch hook or standard shackle and

end loops.

Be sure the lifting equipment is of sufficient length

to keep the lift angle less than 30° from the

vertical. (See Fig. 6)

Fig. 4

Fig. 6

Page 13

3408 IOM 03/99 13

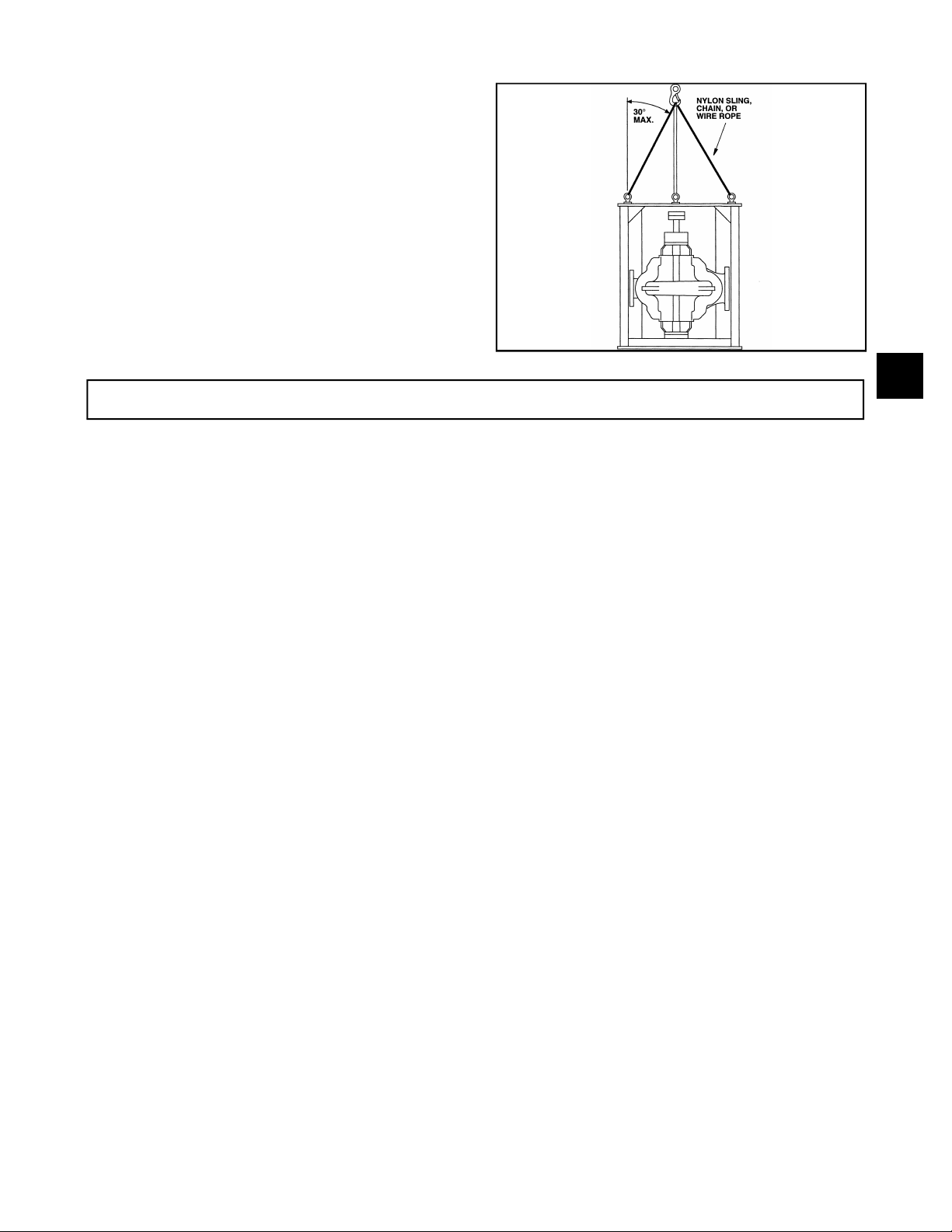

Full Pedestal (Model 300)

2. Install eyebolts in the three holes provided at the top of

the support, being sure to tighten securely. Attach

chain or wire rope using latch hook or standard shackle

and end loop.

Be sure to use shoulder eyebolts that are

manufactured per ANSI B18.15 and sized to fit the

holes provided.

Be sure lifting equipment is of sufficient length to

keep the lift angle less than 30° from the vertical.

(See Fig. 7)

STORAGE

Fig. 7

3

The following storage procedures apply to the pump

only. Other accessories such as motors, steam

turbines, gears, etc., must be handled per the

respective manufacturer’s recommendations.

TEMPORARY

Temporary storage is considered one month or less.

If the pump is not to be installed and operated soon

after arrival, store it in a clean, dry place having slow,

moderate changes in ambient temperature. Rotate the

shaft periodically to coat the bearings with lubricant

and to retard oxidation, corrosion, and to reduce the

possibility of false brinelling of the bearings. Shaft

extensions and other exposed machine surfaces

should be coated with an easily removable rust

preventative such as Ashland Oil Tectyl No. 502C.

For oil lubricated bearings, fill the frame completely

with oil. Before putting equipment into operation, drain

the oil and refill to proper level.

LONG TERM

Storage longer than one month is considered long

term storage. Follow the same procedure for

temporary storage with the following addition. Add

one half ounce of a corrosion inhibiting concentrated

oil such as Cortec Corp. VCI-329 (for both grease and

oil lubricated bearings). Seal all vents and apply a

water proof tape around the oil seals in the bearing

frame. Remember for oil lubricated bearings to drain

the oil from the frame and refill to the proper level

before running pump.

Page 14

14 3408 IOM 03/99

LOCATION

The pump should be installed as near the suction

supply as possible, with the shortest and most direct

suction pipe practical. The total dynamic suction lift

(static lift plus friction losses in suction line) should not

exceed the limits for which the pump was sold.

The pump must be primed before starting. Whenever

possible, the pump should be located below the fluid

level to facilitate priming and assure a steady flow of

liquid. This condition provides a positive suction head

on the pump. It is also possible to prime the pump by

pressurizing the suction vessel.

When installing the pump, consider its location in

relation to the system to assure that sufficient Net

Positive Suction Head (NPSHA) is available at the

pump inlet connection. Available NPSH must always

equal or exceed the required NPSH ( NPSHR ) of the

pump.

FOUNDATION

The foundation must be substantial enough to absorb

vibration. ( Hydraulic Institute Standards recommends

the foundation weigh at least five (5) times the weight of

the pump unit.) It must form a permanent and rigid

support for the baseplate. This is important in

maintaining the alignment of a flexibly coupled unit.

The pump should be installed with sufficient accessibility

for inspection and maintenance. A clear space with ample

head room should be allowed for the use of an overhead

crane or hoist sufficiently strong to lift the unit.

NOTE: Allow sufficient space to be able to

dismantle pump without disturbing the pump inlet

and discharge piping.

Select a dry place above the floor level wherever

possible. Take care to prevent pump from freezing during

cold weather when not in operation. Should the possibility

of freezing exist during a shut-down period, the pump

should be completely drained, and all passages and

pockets where liquid might collect should be blown out

with compressed air.

Make sure there is a suitable power source available for

the pump driver. If motor driven, the electrical

characteristics of the power source should be identical to

those shown on motor data plate.

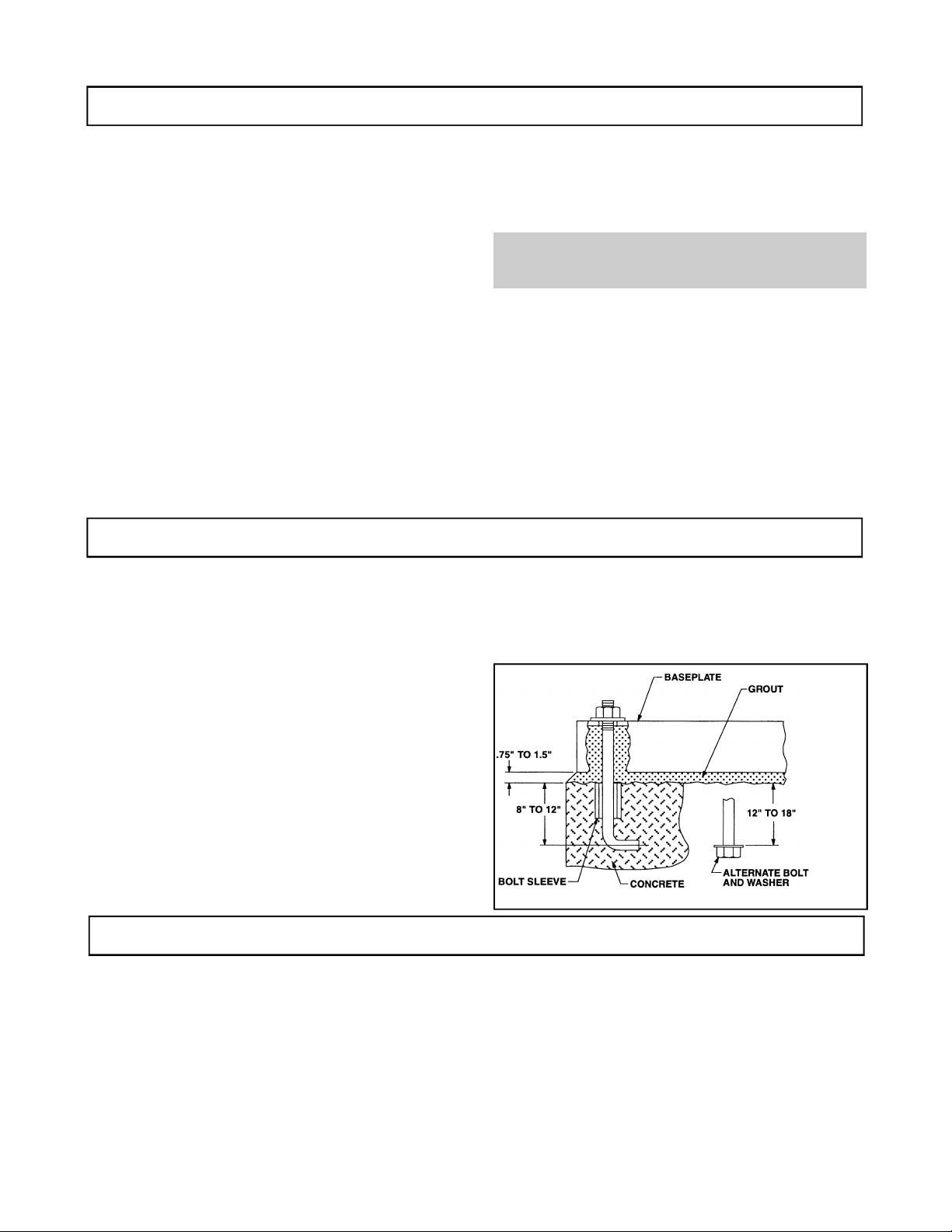

The foundation should be poured to within .75" - 1.5"

of the finished height. (See Fig. 8) Freshly poured

foundations should be allowed to cure for several

days before the unit is set in place and grouted.

Foundation bolts of the proper size should be embedded

in the concrete to a depth of eight (8) to twelve (12)

inches and locked with either a hook around a

reinforcing bar or alternatively, a nut and washer at the

bottom. The bolts should have a sleeve around them at

least six (6) times the bolt diameter in length and at least

two (2) bolt sizes larger in I.D. If a nut and washer are

used for locking, the washer should have an O.D. two

(2) sizes larger than the sleeve. Foundation bolts should

be sized .125" less than the anchor bolt holes in the

base.

SETTING THE BASEPLATE

Pump units are checked at the factory for align ability to

required tolerances.

Due to flexibility of an ungrouted base and handling in

shipment, it should not be assumed that the unit is in

alignment when it is placed on the rough foundation.

If these directions are followed, the required alignment

should be readily achieved.

Fig. 8

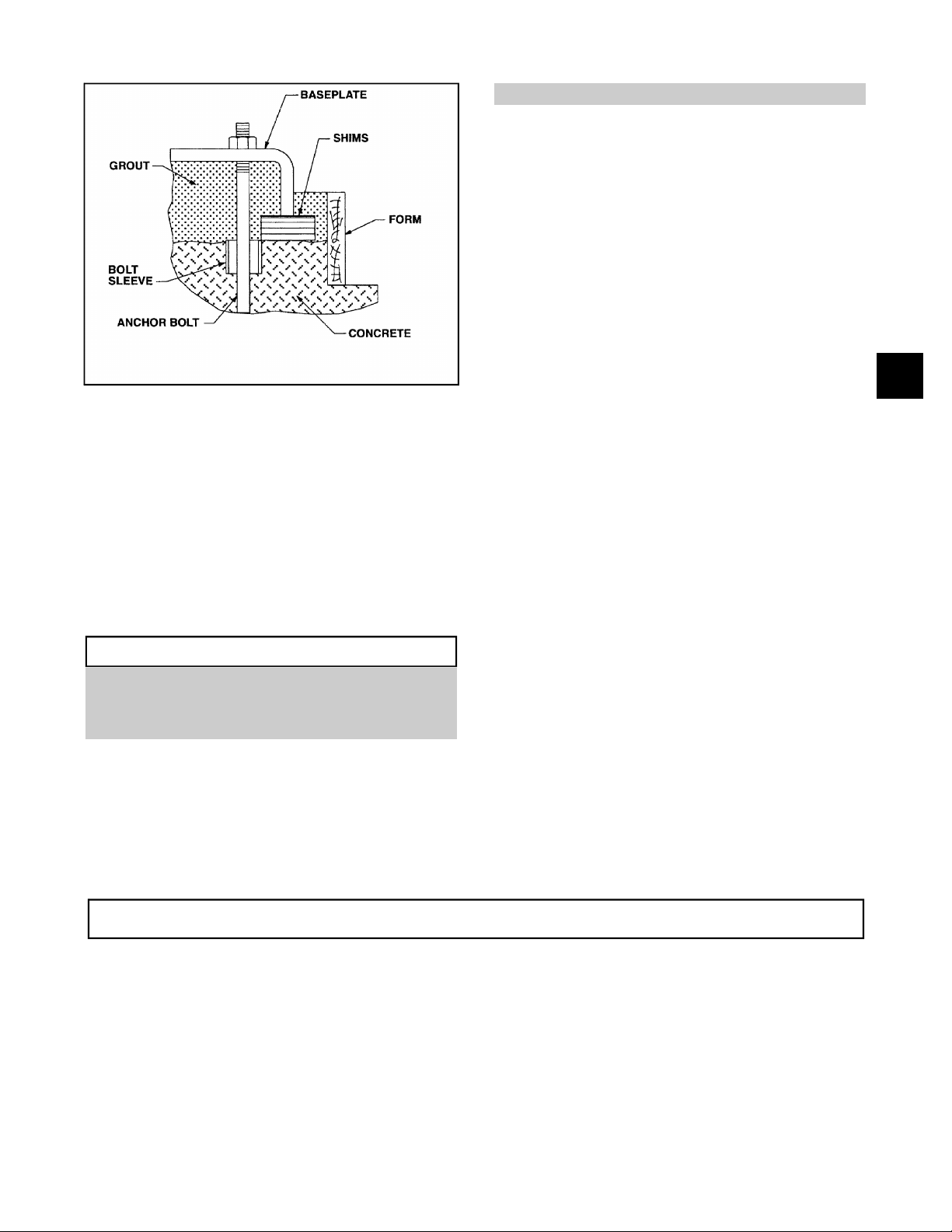

Initial or rough alignment must be done prior to grouting of

baseplate. Rough alignment is designated as .020" TIR

(Total Indicator Reading) parallel alignment and .009" TIR

per inch of radius angular alignment (See ALIGNMENT

PROCEDURE). Use blocks at anchor bolts and midway

between to position bottom of base at finished height

(See Fig. 9) with foundation bolts extending through holes

in the baseplate. Metal wedges with a small taper may be

used in lieu of blocks and shims.

Page 15

3408 IOM 03/99 15

NOTE: The baseplate does not have to be level.

After foundation bolts are lightly torqued , recheck

alignment requirements once more. Follow

requirements outlined at the beginning of this section.

If alignment must be corrected, add or remove shims

or wedges under the baseplate.

The unit can then be grouted. (See Fig. 9)

Grout compensates for the uneven foundation.

Together with the baseplate, it makes a very rigid

interface between the pump and the foundation

distributing the weight over the length of the base and

preventing shifting.

Fig. 9

If the unit has a non-flexible coupling (e.g. Falk Gear

coupling), the coupling halves should be disconnected;

this is generally not necessary on flexible type couplings

(e.g. Wood’s Sure-Flex coupling).

Tighten up all pump and motor bolts to assure they have

not loosened or a “soft foot” has occurred due to base

distortion in shipment. A “soft foot” causes a change in

the alignment when unloosening one bolt.

If the driver is being field installed, it should be centered in

its bolt holes with shims added to bring the driver into

rough alignment with the pump. (The pump may have to

be moved also.)

▲! CAUTION

Do not exceed six (6) shims, using as thick a

shim as possible, otherwise “sponginess” or

“soft foot” will result. Place thin shims in

between thick shims.

Level and plumb the pump shaft, coupling faces and

flanges by adding or removing shims between the blocks

and the bottom of the base. Hand tighten the anchor bolt

nuts at first. Being very careful not to distort the base,

snug down the nuts with a wrench. The non-flexible

coupling should not be reconnected until the alignment

operation has been completed.

Use an approved, non-shrinking grout such as

Embeco 636 or 885 by Master Builders, Cleveland,

Ohio or equivalent.

GROUTING PROCEDURE

1. Build a strong form around the foundation to

contain the grout.

2. Soak the top of the foundation thoroughly, then

remove surface water.

3. The baseplate should be completely filled with

grout and, if necessary, temporarily use air relief

tubing or drill vent holes to remove trapped air.

4. After the grout has thoroughly hardened

(approximately 24 hours), tighten the foundation

bolts fully.

5. Check the alignment after the foundation bolts

are tightened.

6. Approximately fourteen (14) days after the grout

has been poured and the grout has thoroughly

dried, apply an oil base paint to the exposed

edges of the grout to prevent air and moisture

from coming in contact with the grout.

3

ALIGNMENT PROCEDURE

Proper rough alignment must be made during unit

setting and grouting. See previous section.

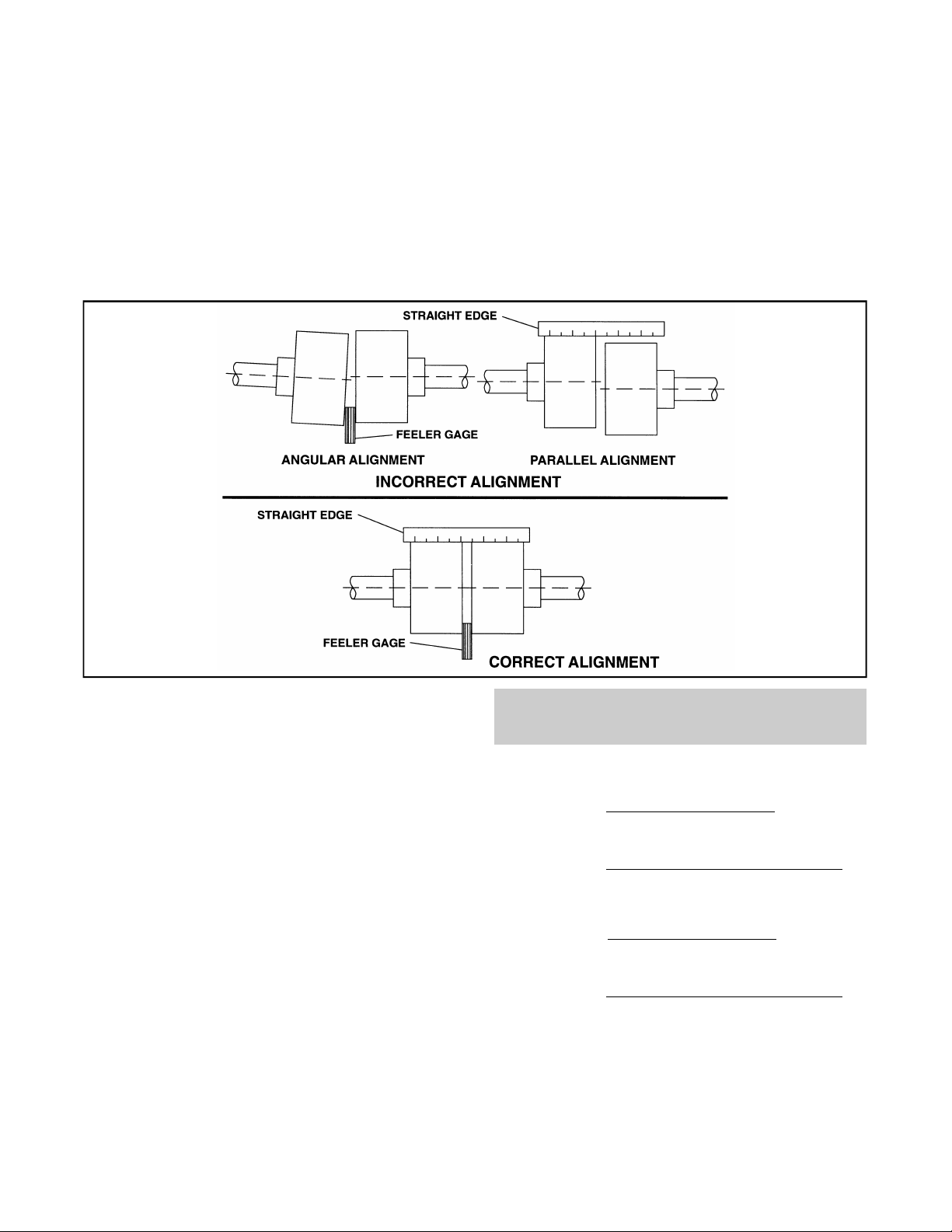

There are two forms of misalignment between the

pump shaft and the driver shaft as follows:

1. Angular misalignment — shafts have axis

concentric at intersection, but not parallel.

2. Parallel offset misalignment — shafts have axis

parallel, but offset.

The necessary tools for checking alignment are: (1) a

straight edge and a taper gauge or set of feeler gauges

or, (2) a dial indicator with mounting magnet and

extension bars.

Check and correct for angular misalignment before

correcting parallel alignment. Final alignment should be

made by moving and shimming the motor on its base until

the coupling hubs are within the recommended tolerances

measured in total run out. All measurements should be

Page 16

16 3408 IOM 03/99

taken with the pump and driver bolts tightened. Final

alignment check should be made after the unit has

attained its final operating temperature.

Method 1 - Using straight edge and taper gauges or

feelers (Fig. 10):

Proceed with this method only if satisfied that face

and outside diameters of the coupling halves are

square and concentric with the coupling bores. If this

condition does not exist or elastomeric couplings do

not make this method convenient, use Method 2.

Check for angular alignment by inserting the taper or

feeler gauges between the coupling faces at 90°

intervals. The unit is in angular alignment when these

four (4) measurements are the same, or within

recommended tolerances.

Check for parallel alignment by placing a straight

edge across both coupling rims on all four sides. The

unit is in parallel alignment when the straight edge

rests evenly across both coupling rims in all four (4)

positions.

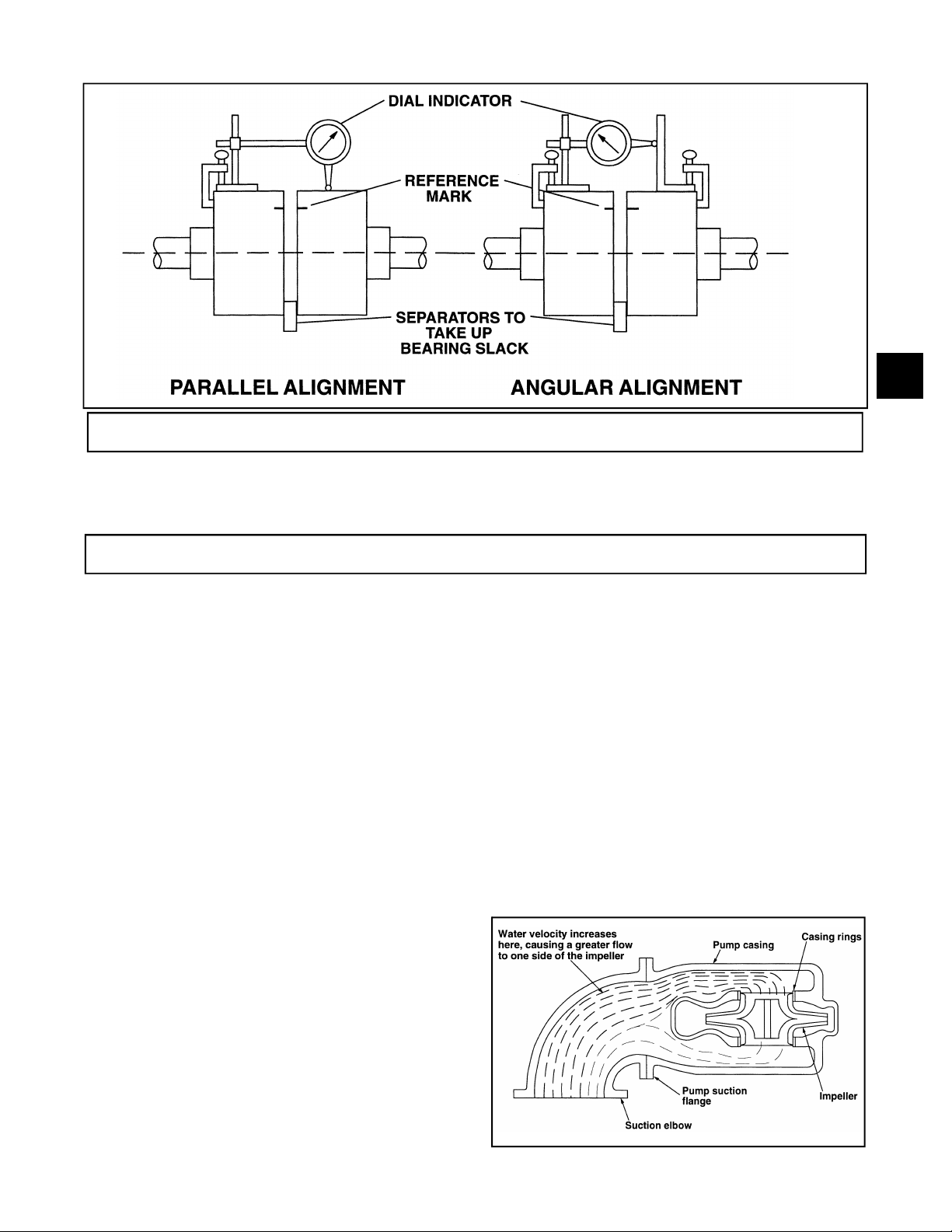

Method 2 - Dial Indicators (Fig. 11):

A dial indicator can be used to attain more accurate

alignment.

Fasten the indicator stand or magnetic base to the

pump half of the coupling and adjust the assembly

until the indicator button is resting on the other half

coupling periphery.

Set the dial to zero and chalk mark the coupling half

where the button rests. Also place a separator

between the coupling halves so bearing slack does

not affect the readings. (Chalk and separators are not

necessary on the elastomeric couplings that have not

been disconnected.) Rotate both shafts by the same

amount; i.e., all readings must be made with the

button on the chalk mark.

The dial readings will indicate whether the driver has

to be raised, lowered or moved to either side.

Accurate alignment of shaft centers can be obtained

with this method even where faces or outside

diameters of the coupling are not square or concentric

with the bores. After each adjustment, recheck both

parallel and angular alignments.

Fig. 10

NOTE: Gross deviations in squareness or

concentricity may cause rotation unbalance

problems and if so must be corrected.

Permissible Coupling Misalignment:

Parallel: Single element coupling:

.004" TIR (4 mils)

Double element (spacer) coupling:

.060" TIR per foot of spacer length

Angular: Single element coupling:

.004" TIP per inch of radius

Double element (spacer) coupling:

.002" TIR per inch of radius

Page 17

3408 IOM 03/99 17

DOWELING

Fig. 11

3

Pump units may, if desired, (or required in

specification) be doweled on diagonally opposite feet.

This should not be done until the unit has been run for

SUCTION AND DISCHARGE PIPING

The introduction of pumpage into a piping system which is

not well designed or adjusted may cause strain on the

pump, leading to misalignment or even impeller rubbing.

Since slight strain may go unnoticed, final alignment should

be done with the system full and up to final temperature.

Pipe flanges should not impose any strain on the pump.

This can be checked by a dial indicator. Any strain must be

corrected by adjustments in the piping system.

When installing the pump piping, be sure to observe the

following precautions:

Piping should always be run to the pump.

Do not move the pump to pipe. This could make final

alignment impossible.

Both the suction and discharge piping should be

independently anchored near the pump and properly

aligned so that no strain is transmitted to the pump when

the flange bolts are tightened. Use pipe hangers or other

supports at necessary intervals to provide support. When

expansion joints are used in the piping system they must be

installed beyond the piping supports closest to the pump.

Tie bolts and spacer sleeves should be used with

expansion joints to prevent pipe strain. Do not install

expansion joints next to the pump or in any way that would

cause a strain on the pump resulting from system pressure

changes. When using rubber expansion joints, follow the

recommendations of the Technical Handbook on Rubber

Expansion Joints and Flexible Pipe Connectors. It is usually

a sufficient length of time and alignment is within the

above alignment tolerance.

advisable to increase the size of both suction and discharge

pipes at the pump connections to decrease the loss of head

from friction.

Install piping as straight as possible, avoiding unnecessary

bends. Where necessary, use 45° or long radius 90° fittings

to decrease friction losses.

Make sure that all piping joints are air-tight.

Where flanged joints are used, assure that inside diameters

match properly.

Remove burrs and sharp edges when making up joints.

Do not “spring” piping when making any connections.

Provide for pipe expansion when hot fluids are to be

pumped.

Fig. 12

Page 18

Page 19

Page 20

18 3408 IOM 03/99

Suction Piping

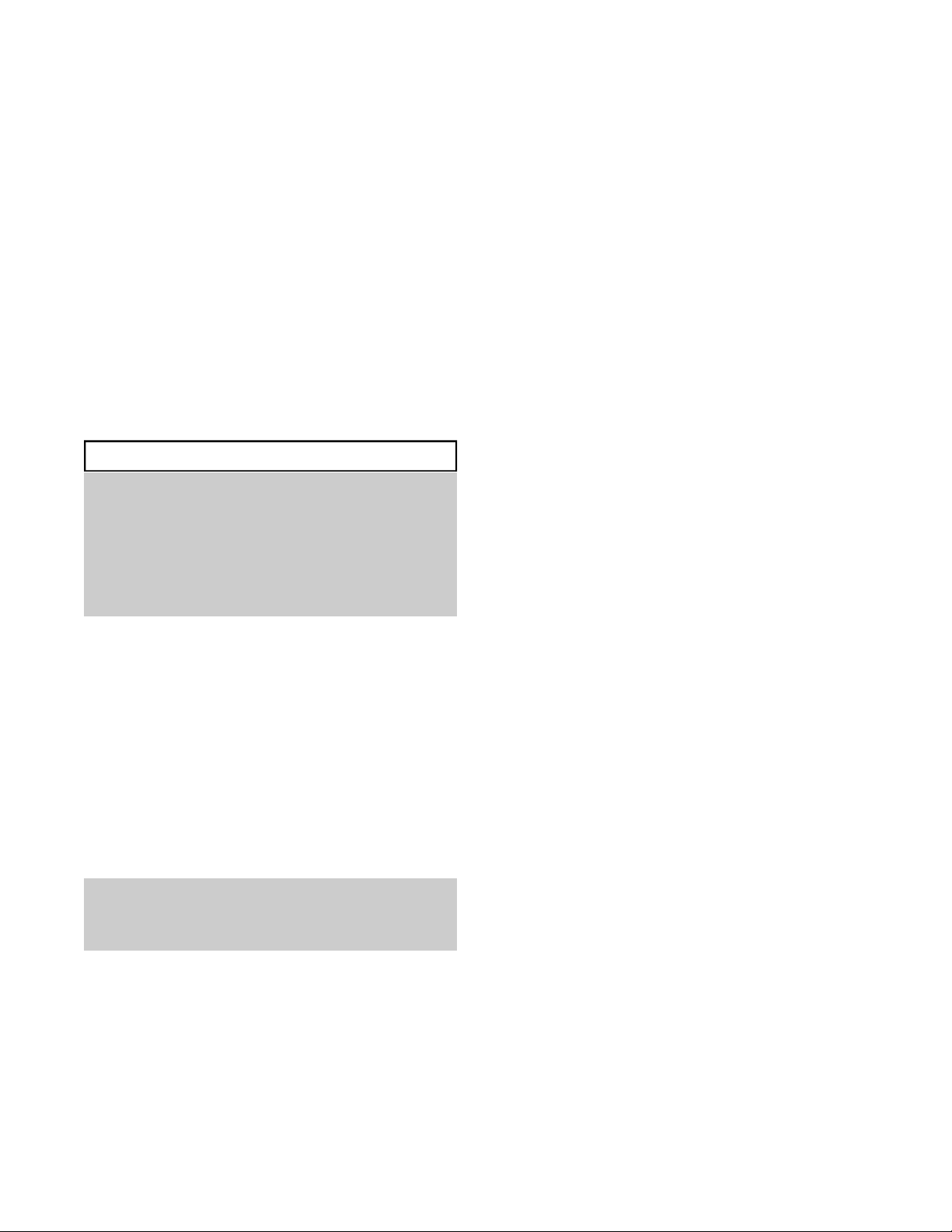

When installing the suction piping, observe the following

precautions. (See Fig. 13)

The sizing and installation of the suction piping is

extremely important. It must be selected and installed so

that pressure losses are minimized and sufficient liquid

will flow into the pump when started and operated.

Many NPSH (Net Positive Suction Head) problems

can be directly attributed to improper suction piping

systems.

When installing valves in the suction piping, observe

the following precautions:

1. If the pump is operating under static suction lift

conditions, a foot valve may be installed in the

suction line to avoid the necessity of priming each

time the pump is started. This valve should be of

the flapper type, rather than the multiple spring

type, sized to avoid excessive friction in the

suction line. (Under all other conditions, a check

valve, if used, should be installed in the discharge

line. See Discharge Piping.)

Suction piping should be short in length, as direct as

possible, and never smaller in diameter than the

pump suction opening. A minimum of five (5) pipe

diameters between any elbow or tee and the pump

should be allowed. If a long suction pipe is required, it

should be one or two sizes larger than the suction

opening, depending on its length.

▲! CAUTION

An elbow should not be used directly before the

suction of a double suction pump if its plane is

parallel to the pump shaft. This can cause an

excessive axial load or NPSH problems in the pump

due to an uneven flow distribution. (See Fig. 12) If

there is no other choice, the elbow should have

straightening vanes to help evenly distribute the

flow.

Eccentric reducers should be limited to one pipe size

reduction each to avoid excessive turbulence and

noise. They should be of the conical type. Contour

reducers are not recommended.

When operating on a suction lift, the suction pipe

should slope upward to the pump nozzle. A horizontal

suction line must have a gradual rise to the pump.

Any high point in the pipe can become filled with air

and prevent proper operation of the pump. When

reducing the piping to the suction opening diameter,

use an eccentric reducer with the eccentric side down

to avoid air pockets.

2. When foot valves are used, or where there are

other possibilities of “water hammer”, close the

discharge valve slowly before shutting down the

pump.

3. Where two or more pumps are connected to the

same suction line, install gate valves so that any

pump can be isolated from the line. Gate valves

should be installed on the suction side of all

pumps with a positive pressure for maintenance

purposes. Install gate valves with stems

horizontal to avoid air pockets. Globe valves

should not be used, particularly where NPSH is

critical.

4. The pump must never be throttled by the use of a

valve on the suction side of the pump. Suction

valves should be used only to isolate the pump

for maintenance purposes, and should always be

installed in positions to avoid air pockets.

3

NOTE: When operating on suction lift never

use a concentric reducer in a horizontal

suction line, as it tends to form an air pocket in

the top of the reducer and the pipe.

Fig. 13 shows some correct and incorrect suction

piping arrangements.

Page 21

3408 IOM 03/99 19

Discharge Piping

If the discharge piping is short, the pipe diameter can

be the same as the discharge opening. If the piping is

long, the pipe diameter should be one or two sizes

larger than the discharge opening. On long horizontal

runs, it is desirable to maintain as even a grade as

possible. Avoid high spots, such as loops, which will

collect air and throttle the system or lead to erratic

pumping.

A check valve and an isolating gate valve should be

installed in the discharge line. The check valve,

placed between pump and gate valve, protects the

pump from excessive back pressure, and prevents

liquid from running back through the pump in case of

power failure. The gate valve is used in priming and

starting, and when shutting the pump down.

Pressure Gauges

Properly sized pressure gauges should be installed in

both the suction and discharge nozzles in the gauge

taps provided. The gauges will enable the operator to

easily observe the operation of the pump, and also

determine if the pump is operating in conformance

with the performance curve. If cavitation, vapor

binding, or other unstable operation should occur,

widely fluctuating discharge pressure will be noted.

3

Fig. 13

Page 22

20 3408 IOM 03/99

STUFFING BOX LUBRICATION

Contaminants in the pumped liquid must not enter the

stuffing box. These contaminants may cause severe

abrasion or corrosion of the shaft, or shaft sleeve, and

rapid packing or mechanical seal deterioration; they

can even plug the stuffing box flushing and lubrication

system. The stuffing box must be supplied at all times

with a source of clean, clear liquid to flush and

lubricate the packing or seal. The most important

consideration is to establish the optimum flushing

pressure that will keep contaminants from the stuffing

box cavity. If this pressure is too low, fluid being

pumped may enter the stuffing box. If the pressure is

too high, excessive packing or seal wear may result;

and extreme heat may develop in the shaft causing

higher bearing temperatures. The most desirable

condition, therefore, is to use a seal water pressure

15-20 psig above the maximum stuffing box pressure.

If the pump system pressure conditions vary, packing

adjustment becomes difficult. Consideration should be

given to using a mechanical seal. (See Mechanical

Seals.)

Packing

Standard pumps are normally packed before shipment . If the pump is installed within 60 days after

shipment, the packing will be in good condition with a

sufficient supply of lubrication. If the pump is stored

for a longer period, it may be necessary to repack the

stuffing box. In all cases, however, inspect the

packing before the pump is started.

NOTE: Packing adjustment is covered in the

MAINTENANCE SECTION of this manual.

On some applications, it is possible to use internal

liquid lubrication (pumped liquid) to lubricate packing.

Only when all of the conditions prevail, can this be

done:

1. Liquid is clean, free from sediment and chemical

precipitation and is compatible with seal

materials.

2. Temperature is above 32° F and below 160° F.

3. Suction pressure is below 75 psig .

4. Lubrication (pumped liquid) has lubricating

qualities.

5. Liquid is non-toxic and non-volatile.

When the liquid being pumped contains solids or is

otherwise not compatible with packing materials, an

outside supply of seal liquid should be furnished. In

general, external-injection liquid (from an outside

source) is required when any of the above conditions

cannot be met.

The standard stuffing box consists of rings of packing

(see assembly section for number of rings), a seal

cage (optional), and a gland. A shaft sleeve which

extends through the box and under the gland is

provided to protect the shaft.

A tapped hole is supplied in the stuffing box directly

over the seal cage to introduce a clean, clear sealing

medium. The stuffing box must, at all times, be

supplied with sealing liquid at a high enough pressure

to keep the box free from foreign matter, which would

quickly destroy the packing and score the shaft

sleeve.

Only a sufficient volume of sealing liquid to create a

definite direction of flow from the stuffing box inward

to the pump casing is required, but the pressure is

important. Apply seal water at a rate of approximately

.25 GPM at a pressure approximately 15 to 20 psig

above the suction pressure. (Approximately one (1)

drop per second.)

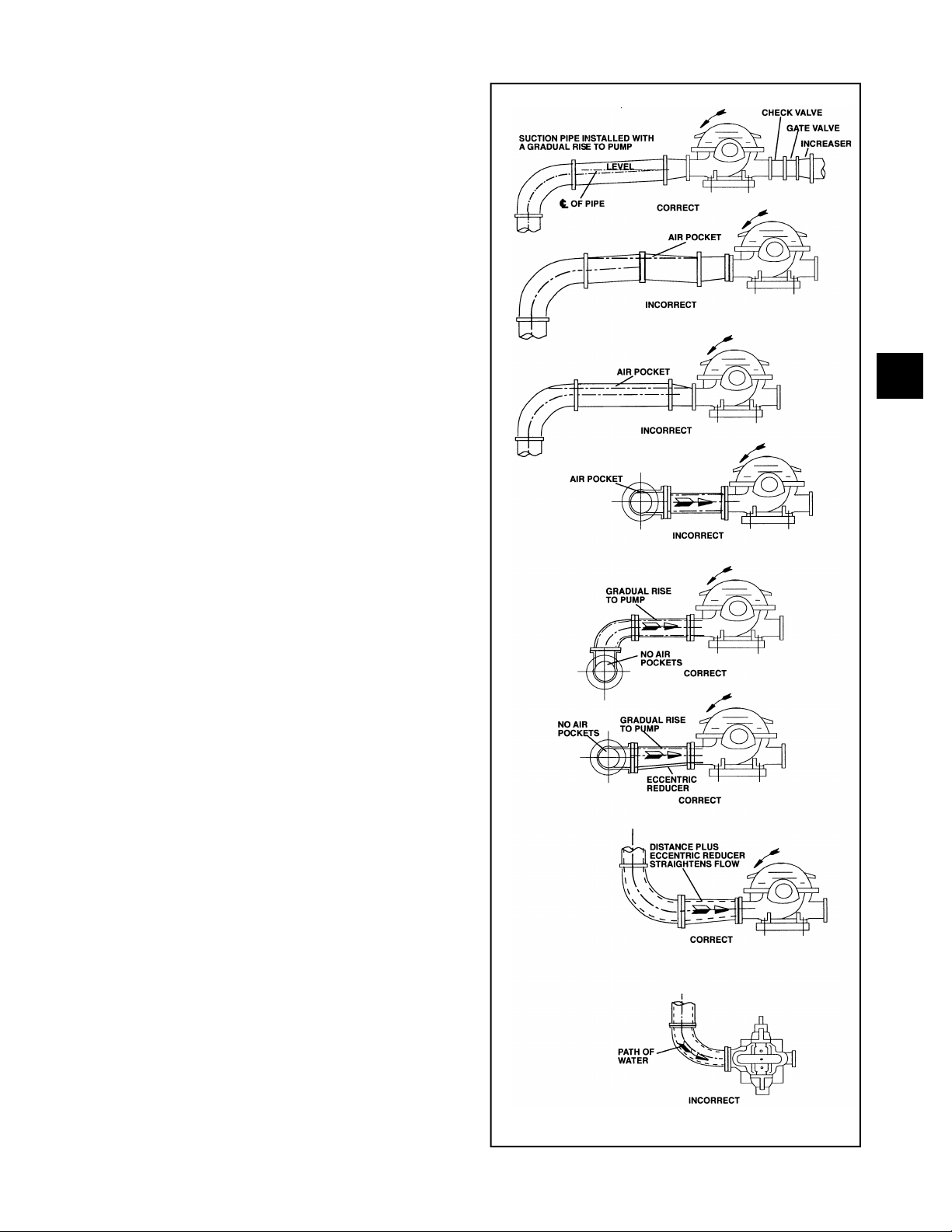

One recommended method to minimize error in

regulating flushing water is a “Controlled Pressure

System.” (Fig. 14) Most important is the pressure

reducing valve adjusted to a value slightly exceeding

the maximum stuffing box operating pressure

(assuming it is reasonably constant). A flow indicating

device will serve to indicate a failing of the bottom

packing rings allowing leakage in the pump.

External sealing liquid should be adjusted to the point

where the packing runs only slightly warm, with a very

slow drip from the stuffing box. Excess pressure from

an external source can be very destructive to packing.

More pressure is required, however, for abrasive

slurries than for clear liquids. Examination of the

leakage will indicate whether to increase or decrease

external pressure. If slurry is present in the leakage,

increase the pressure until only clear liquid drips from

the box. If the drippage is corrosive or harmful to

personnel, it should be collected and piped away.

A common error is to open the external piping valve

wide and then control the drippage by tightening the

packing gland. Actually, a combination of both

adjustments is essential to arrive at the optimum

condition. The life of packing and sleeve depends on

this careful control more than any other factor.

Page 23

3408 IOM 03/99 21

Pump

Casing

Fig. 14

Mechanical Seals

Mechanical seals are preferred over packing on some

applications because of better sealing qualities and

longer serviceability. Leakage is eliminated when a

seal is properly installed, and normal life is much

greater than that of packing on similar applications. A

mechanical shaft seal is supplied in place of a packed

stuffing box when specifically requested. The change

from packing to an alternate arrangement may be

made in the field by competent service personnel.

Conversion parts may be ordered from your Goulds

Pump Sales Representative.

Just as with packing, the mechanical seal chamber

must be supplied, at all times, with a source of clean,

clear liquid to flush and lubricate the seal. The most

important consideration is to establish the optimum

flushing pressure that will keep contaminants from the

seal cavity. If this pressure is too low, fluid being

pumped may enter the stuffing box. If the pressure is

too high, excessive seal wear may result.

When contaminants are present in the pumpage, an

external source of clean seal water must be supplied.

Supply approximately .25 GPM at a pressure

approximately 15 to 20 psig above the suction

pressure.

Fig. 14 shows the recommended “Controlled Pressure

System” for a mechanical seal. Seal water enters the

seal chamber, lubricates the seal face, and exits into

the pump itself. Positive flow in the seal water line

indicates adequate seal water pressure.

Cartridge Seals

Follow the appropriate lubrication directions for

mechanical seals given in this section. Most cartridge

seals provide flushing connections on their glands.

Use the cartridge seal gland flushing taps (if provided)

for your seal water connections instead of the stuffing

box tap. The quench taps on the glands (if present)

are normally only used in chemical applications.

Consult seal manufacturer’s literature for more

detailed information.

Cyclone Separator

If the fluid being pumped contains sediment and there

is no external, clean water source available to flush

the mechanical seals, a cyclone separator can be

used to remove most of the sediment from the liquid

being pumped so it can be used to flush the seals.

The separator is placed in the seal water piping line

and removes the sediment to an external drain

(normally back to the pump suction line).

3

Page 24

22 3408 IOM 03/99

Page 25

OPERATION

3408 IOM 03/99 23

PRE-START CHECKS ............................. 23

PRIMING .................................... 23

Flushing ................................... 23

Fill ing .................................... 23

STARTING ................................... 24

OP ER A TIONAL CHECK LIST ......................... 24

SHUT DOWN .................................. 25

FREEZE PRO TEC TION ............................ 25

FIELD TESTS ................................. 25

PRE-START CHECKS

Before the initial start of the pump, make the following

inspections:

1. Check alignment between pump and driver. See the

section on alignment for alignment requirements.

2. Check all connections to motor and starting device

with wiring diagram. Check voltage, phase, and

frequency on motor nameplate with line circuit.

3. Check suction and discharge piping and pressure

gauges for proper operation.

4. Turn rotating element by hand to assure that it rotates

freely.

5. Check stuffing box adjustment, lubrication, and

piping.

PRIMING

If the pump is installed with a positive head on the

suction, it can be primed by opening the suction

valve, and loosening the vent plug on the top of the

casing (Do not remove), allowing air to be purged

from the casing.

If the pump is installed with a suction lift, priming must

be done by other methods such as foot valves,

ejectors, or by manually filling the casing and suction

line.

▲! CAUTION

Under either condition, the pump must be

completely filled with liquid before starting. The

pump must not be run dry in the hope it will

prime itself. Serious damage to the pump may

result if it is started dry.

6. Check driver lubrication.

4

7. Assure that pump bearings are properly lubricated.

8. Assure that coupling is properly lubricated, if required.

9. Assure that pump is full of liquid and all valves are

properly set and operational, with the discharge valve

and the suction valve open. Purge all air from top of

casing.

10. Check rotation. Be sure that the driver operates in the

direction indicated by the arrow on the pump casing

as serious damage can result if the pump is operated

with incorrect rotation. Check rotation each time the

motor leads have been disconnected.

FLUSHING

New and old systems should be flushed to eliminate all

foreign matter. Heavy scale, welding splatter and wire or

other large foreign matter can clog the pump impeller.

This will reduce the capacity of the pump causing

cavitation, excessive vibration, and/or damage to close

clearance parts (wear rings, seals, sleeves, etc.)

FILLING

Vents should be located at the highest point so entrained

gases and air can escape. However, if the gases are

flammable, toxic, or corrosive they should be vented to an

appropriate place to prevent harm to personnel or other

parts of the system. Pipe hangers and anchors should be

checked to make sure they are properly set to take the

additional weight of the pumpage.

Page 26

24 3408 IOM 03/99

All drains should be closed when filling the system.

Filling should be done slowly so that excessive velocities

do not cause rotation of the pumping elements which

may cause damage to the pump or its driver. The

adequacy of the anchors and hangers may be checked

by mounting a dial indicator off of any rigid structure not

STARTING

tied to the piping and setting the indicator button on the

pump flange in the axial direction of the nozzle. If the

indicator moves, as the filling proceeds, the anchors and

supports are not adequate or set properly and should be

corrected.

1. Close drain valves.

2. Open fully all valves in the suction and discharge

lines.

3. Turn on seal water to the stuffing box. (If pumped

fluid is dirty or if leaking of air is to be prevented,

these lines should be always left open.)

4. Prime the pump.

NOTE: If the pump does not prime properly,

or loses prime during start-up, it should be

shutdown and the condition corrected before

the procedure is repeated.

OPERATIONAL CHECKLIST

1. Driver/Pump Rotation

Check rotation each time the motor leads have

been disconnected. Be sure that the driver

operates in the direction indicated by the arrow on

the pump casing. Rough operation and extreme

vibration can result if the pump is operated in the

wrong direction.

5. Start the pump driver (turbines and engines may

require warming up; consult the manufacturer’s

instructions).

6. When the pump is operating at full speed, check

to see that the check valve has opened up. Check

valve must open 5 seconds or less after start-up

to prevent damage to pump by operating at zero

flow.

7. Adjust the liquid seal valves to produce the

recommended pressure for either the mechanical

seal or packed stuffing box.

5. Temperature

Check and record bearing temperatures using a

thermometer. Temperature should not exceed

180° F.

NOTE: Just because bearing housings are too

hot to touch does not mean that they are

running too hot for proper operation.

2. Stuffing Box Adjustment

Make stuffing box packing gland and lubrication

adjustments.

3. Flow

An accurate measurement of flow rate

(volume/time) is difficult in the field. Venturi

meters, flow nozzles, orifice plates, or timing the

draw down in the wet well are all possible

methods. Record any reading for future reference.

4. Pressure

Check and record both suction and discharge

pressure gauge readings for future reference.

Also, record voltage, amperage per phase,

kilowatts if an indicating wattmeter is available,

and pump speed.

6. Vibration and Sound

The acceptable vibration level of a centrifugal

pump depends on the rigidity of the pump and the

supporting structure. Recommended values for

vibration can vary between .20 ips (inches per

second) velocity to .60 ips velocity depending on

the operating characteristics and the structure.

Refer to the Centrifugal Pump section of the

Hydraulic Institute Standards for a complete

description and charts on various pumps.

Field sound levels are difficult to measure

because of background noise from piping, valves,

drivers, gears, etc. Follow recommendations in

the Hydraulic Institute Standards.

Page 27

3408 IOM 03/99 25

SHUTDOWN

The following steps will take care of most normal

shutdowns of the pump, i.e. maintenance. Make any

further adjustments of process piping, valves, etc., as

required. If the pump is to be removed from service for

an extended period of time, refer to the sections on

storage and freeze protection.

1. Shut down the driver. (Consult manufacturer’s

instructions for special operations.)

FREEZE PROTECTION

Pumps that are shut down during freezing conditions

should be protected by one of the following methods.

1. Drain the pump; remove all liquid from the casing.

2. Keep fluid moving in the pump and insulate or

heat the pump to prevent freezing.

FIELD TESTS

A typical performance curve for a specific pump can

be obtained from Goulds Pumps. This can be used in

conjunction with a field test, if one is required. Goulds

Pumps tests and curves are based on the Hydraulic

Institute Standards . Any field test must be conducted

according to these Standards.

2. Close suction and discharge valves.

3. Close seal liquid valves. (If pumped liquid is dirty,

or if in leakage is to be prevented, these lines

should always be left open, except when the

pump is completely drained.)

4. Open drain valves as required.

▲! CAUTION

If heat is used to keep the pump from freezing,

do not let the temperature rise above 150° F.

4

Unless otherwise specifically agreed, all capacity,

head, and efficiencies are based on shop tests when

handling clear, cold, fresh water at a temperature not

over 85° F.

Appendix “C” contains a field test report sheet and

some useful equations, which can be used when

conducting a field test.

Page 28

26 3408 IOM 03/99

Page 29

PREVENTIVE MAINTENANCE

3408 IOM 03/99 27

GEN ERAL MAIN TE NANCE AND

PE RI ODIC IN SPEC TION ............................ 27

MAIN TE NANCE TIME TA BLE ......................... 27

MAIN TE NANCE OF FLOODED PUMPS ................... 28

LU BRI CA TION ................................. 28

Grease Lu bri ca tion of Bear ings ....................... 28

Pe ri odic Ad di tion of Grease ......................... 29

Bear ing Tem per a ture ............................ 29

Oil Lu bri ca tion of Bear ings ......................... 29

Cou pling Lu bri ca tion ............................ 30

SEALING IN FOR MA TION ........................... 30

Packing (Non-Asbestos) .......................... 30

Me chan i cal Seals .............................. 31

TROU BLE SHOOT ING ............................ 32

GENERAL MAINTENANCE & PERIODIC INSPECTION

Operating conditions vary so widely that to

recommend one schedule of preventative

maintenance for all centrifugal pumps is not possible.

Yet, some sort of regular inspection must be planned

and followed. We suggest a permanent record be

kept of the periodic inspections and maintenance

performed on your pump. This recognition of

maintenance procedure will keep your pump in good

working condition, and prevent costly breakdowns.

One of the best results to follow in the proper

maintenance of your centrifugal pump is to keep a

MAINTENANCE TIME TABLE

EVERY MONTH

Check bearing temperature with a thermometer, not by

hand. If bearings are running hot (over 180° F), it may

be the result of too much or too little lubricant. If

changing the lubricant and/or adjusting to proper level

does not correct the condition, disassemble and inspect

the bearings. Lip seals bearing on the shaft may also

cause the housing to run hot. Lubricate lip seals to

correct this condition.

record of actual operating hours. Then, after a

predetermined period of operation has elapsed, the

pump should be given a thorough inspection. The

length of this operating period will vary with different

applications, and can only be determined from

experience. New equipment, however, should be

examined after a relatively short period of operation.

The next inspection period can be lengthened

somewhat. This system can be followed until a

maximum period of operation is reached which should

be considered the operating schedule between

inspections.

whitish color. Wash out the bearings with a clean

industrial solvent and replace the grease with the proper

type as recommended.

EVERY 6 MONTHS

Check the packing and replace if necessary. Use the

grade recommended. Be sure the seal cages are

centered in the stuffing box at the entrance of the

stuffing box piping connection.

5

EVERY 3 MONTHS

Check the oil on oil lubricated units. Check grease

lubricated bearings for saponification . This condition is

usually caused by the infiltration of water or other fluid

past the bearing shaft seals and can be noticed

immediately upon inspection, since it gives the grease a

Take vibration readings on the bearing housings.

Compare the readings with the last set of readings to

check for possible pump component failure (e.g.

bearings).

Check shaft or shaft sleeve for scoring. Scoring

accelerates packing wear.

Page 30

28 3408 IOM 03/99

Check alignment of pump and driver. Shim up units if

necessary. If misalignment reoccurs frequently, inspect

the entire piping system. Unbolt piping at suction and

discharge flanges to see if it springs away, thereby indicating

strain on the casing. Inspect all piping supports for

soundness and effective support of load. Correct as

necessary.

EVERY YEAR

Remove the upper half of the casing. Inspect the pump

thoroughly for wear, and order replacement parts if

necessary.

Check wear ring clearances. Replace when clearances

become three (3) times their normal clearance or when a

significant decrease in discharge pressure for the same flow

rate is observed.

See Engineering Data Section for standard clearances.

MAINTENANCE OF FLOOD DAMAGED PUMPS

Remove any deposit or scaling. Clean out stuffing box

piping.

Measure total dynamic suction and discharge head as a

test of pump performance and pipe condition. Record the

figures and compare them with the figures of the last test.

This is important, especially where the fluid being pumped

tends to form a deposit on internal surfaces. Inspect foot

valves and check valves, especially the check valve which

safeguards against water hammer when the pump stops.

A faulty foot or check valve will reflect also in poor

performance of the pump while in operation.

NOTE: The above time table is based on the

assumption that after startup, the unit has been

constantly monitored and such a schedule was

found to be consistent with operation, as shown by

stable readings. Extreme or unusual applications

or conditions should be taken into consideration

when establishing the maintenance intervals.

The servicing of centrifugal pumps after a flooded

condition is a comparatively simple matter under

normal conditions.

Bearings are a primary concern on pumping units.

First, dismantle the frame, clean and inspect the

bearings for any rusted or badly worn surfaces. If

bearings are free from rust and wear, reassemble and

relubricate them with one of the recommended

lubricants. Depending on the length of time the pump

has remained in the flooded area, it is unlikely that

bearing replacement is necessary; however, in the

event that rust or worn surfaces appear, it may be

necessary to replace the bearings.

LUBRICATION

GREASE LUBRICATION

OF BEARINGS

Grease lubricated ball bearings are packed with grease

at the factory and ordinarily will require no attention

before starting, provided the pump has been stored in a

clean, dry place prior to its first operation. The bearings

should be watched the first hour or so after the pump

has been started to see that they are operating properly.

A lithium based NLGI-2 grade grease should be used for

lubricating bearings where the ambient temperature is

above -20° F. Grease lubricated bearings are packed at

the factory with Mobilux EP No. 2 grease. Other

recommended greases are Texaco Multifak EP-2 and

Shell Alvania EP-2.

Next, inspect the stuffing box, and clean out any foreign

matter that might clog the box. Packing that appears to

be worn, or no longer regulates leakage properly should

be replaced. Mechanical seals should be cleaned and

thoroughly flushed.

Couplings should be dismantled and thoroughly

cleaned. Lubricate the coupling with one of the coupling

manufacturer’s recommended lubricants where

required.

Any pump that is properly sealed at all joints and

connected to both the suction and discharge should

exclude outside liquid. Therefore, it should not be

necessary to go beyond the bearings, stuffing box, and

coupling when servicing the pump after flood damage.

Greases made from animal or vegetable oils are not

recommended due to the danger of deterioration and

forming of acid. Do not use graphite.

In greasing anti-friction bearings, the use of high

pressure equipment is not only unnecessary, but is

actually undesirable unless used with great care. High

pressure may damage the bearings or seals, cause

unnecessary loss of grease, create a danger of

overheating due to over greasing, and produce unsightly

conditions around the bearing. Excess grease is the

most common cause of overheating. Adequate

lubrication is assured if the level of grease is maintained

at about the capacity of the bearing and 1/3 to 1/2 of the

Page 31

3408 IOM 03/99 29

cavity between the bearing and grease fitting. Any greater

amount will, as a rule, be discharged by the seal or vent

and be wasted.

The importance of proper lubrication cannot be over

emphasized. Lubrication frequency depends upon the

speed, size and type of bearing, and operating

temperature or environmental conditions. Generally, the

smaller the bearing and faster the speed, the more

frequent the interval for relubrication with grease. It is

recommended that a certain amount of grease be added

at intervals of three to six months to replace the small

quantity of grease lost between grease flushing intervals.

For average bearing housing designs, one (1) ounce of

grease will be sufficient at these intervals. For larger or

smaller bearing housings this amount may have to be

adjusted.

Unfortunately, there is not a grease available which will

not harden over time and become less suitable for its

purpose due to oxidation. Therefore, it is good practice to

remove all the old grease about once a year and

thoroughly clean the bearings. This should be done

during major overhauls. After gaining experience with

each individual pump and its operating characteristics, the

relubrication and flushing intervals may be adjusted

accordingly. Keep good records and add grease at

regular intervals. Then adjustments can be made after the

first overhaul, if necessary.

OIL LUBRICATION OF BEARINGS

Oil lubrication on 3408 pumps is considered special.

Oil lubricated pumps are installed with Trico oilers.

(See Fig. 15) The oilers keep the oil level in the

housings constant at proper level.

After the pump has been installed, flush the housing

to remove dirt, grit, and other impurities that may have

entered the bearing housing during shipment or

installation. Then refill the housing with proper

lubricant. (The housing must be filled using the Trico

oiler.) The oil level will be maintained by the Trico

oiler. (See the SERVICE section for the proper

instructions.)

5

PERIODIC ADDITION OF GREASE

Grease lubricated ball bearings are packed with grease at

the factory. Store the pump in a clean, dry place prior to

its first operation.

If one is uncertain about the amount of grease in a

bearing at relubrication intervals, the safe rule is to add

grease slowly (one ounce at a time) as the bearing

operates (if this is safe). Remember, a ball or roller

bearing in most applications is assured of adequate

lubrication if the level of grease is maintained at about the

capacity of the bearing and 1/3 to 1/2 of the cavity

between the bearing and grease fitting. Any greater

amount will, as a rule, be discharged by the seals or vent

and be wasted. Excess grease is the most common

cause of overheating of the bearings. Remove vent plugs

for the first 24 hours of operation after regreasing .

BEARING TEMPERATURE

Normally the maximum desirable operating temperature

for ball bearings is 180° F. Special designs may have

higher limits. Should the temperature of the bearing frame

rise above the limit, the pump should be shut down to

determine the cause. A bearing frame which feels hot to

the touch of the hand is not necessarily running hot.

Check with an accurate temperature measuring device to

be sure.

Fig. 15

A Mobil Oil, DTE Medium, or equal, meeting the

following specification will provide satisfactory

lubrication. Similar oils can be furnished by all major

oil companies. It is the responsibility of the oil vendor

to supply a suitable lubricant.

(1) Saybolt viscosity at 100° F ........ 215 SSU-240 SSU

(2) Saybolt viscosity at 210° F ............. .49 SSU

(3) Viscosity index, minimum ................ 95

(4) API gravity ..................... .28-33

(5) Pour point, maximum ................ +20° F

(6) Flash point, minimum ................ 400° F

(7) Additives ............. Rust & Oxidation Inhibitors

(8) ISO viscosity ...................... 46

NOTE: Oils from different suppliers should not

be mixed. Engine oils are not recommended.

The oil should be a non-foaming, well refined, good

grade, straight cut, filtered mineral oil. It must be free

from water, sediment, resin, soaps, acid and fillers of

any kind.

Page 32

30 3408 IOM 03/99

In installations with moderate temperature changes,

low humidity, and a clean atmosphere, the oil should

be changed after approximately 1000 hours of

operation. The oil should be inspected at this time to

determine the operating period before the next oil

change. Oil change periods may be increased up to

2000-4000 hours based on an 8000 hour year. Check

the oil frequently for moisture, dirt or signs of

“breakdown”, especially during the first 1000 hours.

▲! CAUTION

Do not over oil; this causes the bearings to run

hot. The maximum desirable bearing housing

operating temperature for all ball bearings is

180° F. Should the temperature of the bearing

frame exceed 180° F (measured by

thermometer) shut down pump to determine

the cause.

SEALING INFORMATION

COUPLING LUBRICATION

Flexible couplings (Wood’s Sure-Flex or Falk Torus

coupling for instance) provide smooth transmission of

power. There is no rubbing action of metal against

rubber to cause wear. Couplings are not affected by

abrasives, dirt or moisture. This eliminates the need

for lubrication or maintenance, and provides clean

and quiet performance.

If other type couplings are used, follow maintenance

instructions of coupling manufacturer.

PACKING (NON-ASBESTOS)

On packed pumps the packing is installed prior to

shipment. All packings used are the highest grade

material. Before pump is put into operation check the

condition of the packing. If pump is installed within sixty

(60) days after shipment the packing will be in good

condition with a sufficient supply of lubrication. If pump is

stored for a longer period it may be necessary to repack

the stuffing box. In all cases, however, we recommend an

inspection of the packing before pump is started.

The standard 3408 pump packing is made from braided

acrylic yarn impregnated with graphite.

A soft, well-lubricated packing reduces stuffing box

resistance and prevents excessive wear on the shaft or

shaft sleeve. Many brands of packing on the market have

the desired qualities. Standard packing is John Crane

Style 1340, or equal.

When a pump with fiber packing is first started it is

advisable to have the packing slightly loose without

causing an air leak. As the pump runs in, gradually tighten

the gland bolts evenly. The gland should never be drawn

to the point where packing is compressed too tightly and

no leakage occurs. This will cause the packing to burn,

score the shaft sleeve and prevent liquid from circulating

through the stuffing box cooling the packing. The stuffing

box is improperly packed or adjusted if friction in the box

prevents turning the rotating element by hand. A properly

operated stuffing box should run lukewarm with a slow

drip of sealing liquid. After the pump has been in

operation for some time, and the packing has been in

operation for some time, and the packing has been

completely run-in, drippage from the stuffing boxes should

be at least 40 to 60 drops per minute. This will indicate

proper packing and shaft sleeve lubrication and cooling.

NOTE: Eccentricity of the shaft or sleeve

through the packing could result in excess

leakage that cannot be compensated for.

Correction of this defect is very important.

Packing should be checked frequently and replaced as

service indicates. Six months might be a reasonable

expected life, depending on operating conditions. It is

impossible to give any exact predictions. A packing tool

should be used to remove all old packing from the stuffing

box. Never reuse old and lifeless packing or merely add

some new rings. Make sure the stuffing box is thoroughly

cleaned before new packing is installed. Also check the

condition of the shaft or sleeve for possible scoring or

eccentricity, make replacements where necessary.

New packing (non-asbestos) should be placed carefully

into the stuffing box. If molded rings are used, the rings

should be opened sideways and the joints pushed into

the stuffing box first. The rings are installed one at a time,

each ring seated firmly and the joints staggered at about a

90° rotation from each preceding joint.

If coil packing is used, cut one ring to accurate size with

either a butt or mitered joint. An accurately cut butt joint is

superior to a poor fitting mitered joint. Fit the ring over the

shaft to assure proper length. Then remove and cut all

other rings to the first sample. When the rings are placed

around the shaft a tight joint should be formed. Place the

first ring in the bottom of the stuffing box. Then install

each succeeding ring, staggering the joints as described

above, making sure each ring is firmly seated.

Page 33

3408 IOM 03/99 31

If your pump is supplied with seal cages (optional)

make sure they are properly located in the stuffing

boxes under the sealing water inlets. The function of

the seal cage is to establish a liquid seal around the

shaft, prevent leakage of air through the stuffing box

and lubricate the packing. If it is not properly located it

serves no purpose.

MECHANICAL SEALS

General instructions for operation of the various

mechanical sealing arrangements are included below.

It is not feasible to include detailed instructions for all

mechanical seals in this booklet because of the

almost unlimited number of possible combinations

and arrangements. Instead, seal manufacturer’s

instructions will be included as a separate supplement

to this book, where required.

a. Mechanical seals are precision products and

should be treated with care. Use special care

when handling seals. Clean oil and clean parts

are essential to prevent scratching the finely

lapped sealing faces. Even light scratches on

these faces could result in leaky seals.

b. Normally, mechanical seals require no adjustment

or maintenance except routine replacement of

worn or broken parts.

c. A mechanical seal which has been used should

not be put back into service until the sealing faces

have been replaced or relapped. (Relapping is

generally economical only in seals two inches in

size and above.)

Four important rules which should always be followed

for optimum seal life are:

1. Keep the seal faces as clean as possible.

2. Keep the seal as cool as possible.

3. Assure that the seal always has proper

lubrication.

4. If seal is lubricated with filtered fluid, clean filter

frequently.

5

Page 34

32 3408 IOM 03/99

TROUBLE SHOOTING

Between regular maintenance inspections, be alert for signs of driver or pump trouble. Common symp toms are

listed below. Correct any trouble immediately and AVOID COSTLY REPAIR AND SHUTDOWN.

Prob lem Item s Prob a ble Cause Rem edy

1 Lack of prime. Fill pump and suction pipe completely with liquid.

Check for leaks in suction pipe joints and fittings; vent casing to remove

accumulated air. Check mechanical seal or packing.

If there is no obstruction at inlet and suction valves are open, check for pipe

friction losses. However, static lift may be too great. Measure with mercury

column or vacuum gauge while pump operates. If static lift is too high, liquid

to be pumped must be raised or pump lowered.

Check with factory to see if a larger impeller can be used; otherwise, cut pipe

losses or increase speed — or both, as needed. But be careful not to

seriously overload driver.

Check whether motor is directly across-the-line and receiving full voltage.

Frequency may be too low. Motor may have an open phase.

Check motor rotation with directional arrow on pump casing. If rotation is

correct with arrow, check the relationship of the impeller with casing. (This

will require removing casing upper half.)

Check pipe friction losses. Large piping may correct condition. Check that

valves are wide open.

If liquid pumped is water or other non-explosive and explosive gas or dust

is not present, test flanges for leakage with flame or match. For such

liq uids as gasoline, suction line can be tested by shutting off or plug ging

in let and putting line under pressure. A gauge will indicate a leak with a

drop of pressure.

Replace packing and sleeves if appropriate or increase seal lubricant

pressure to above at mo sphere.

a. Increase positive suction head on pump by lowering pump or in creas ing

suc tion pipe and fittings size.

b. Sub-cool suction piping at inlet to lower entering liquid temperature.

c. Pressurize suction vessel.

In spect im pel ler and wear rings. Re place if dam aged or vane sec tions

are badly eroded or if wear ring clear ance is 3 times normal.

Area through ports of valve should be at least as large as area of suc tion

pipe (pref er a bly 1.5 times). If strainer is used, net clear area should be

3 to 4 times area of suc tion pipe.

If in let can not be low ered or if ed dies through which air is sucked per sists

when it is low ered, chain a board to suc tion pipe. It will be drawn into

ed dies, smoth er ing the vor tex.

Symp toms are an over loaded driver and about one third rated ca pac ity from

pump. Com pare ro ta tion of mo tor with di rec tional ar row on pump cas ing.

If ro ta tion is cor rect with ar row, im pel ler may have to be turned 180º. (see

CHANGING RO TA TION)

Check to see if suc tion and dis charge valves are fully open. Dis man tle

pump and in spect pas sages and cas ing. Re move ob struc tion.

May be pos si ble to over rate pump to a point where it will pro vide ad e quate pres sure de spite con di tion. Better pro vide gas sep a ra tion cham ber on

suc tion line near pump and pe ri od i cally ex haust ac cu mu lated gas. See item 17.

No Liquid

Delivered

Not

Enough

Liquid

Delivered

Not

Enough

Pres sure

2 Loss of prime.

Suction lift too high (a negative suc tion

3

gauge reading).

4 System static head too high.

5 Speed to low.

6 Wrong direction of rotation.

7 No rotation. Check power, coupling, line shaft and shaft keys.

8 Impeller loose on shaft. Check key, locknut and set screws.

9 Impeller completely plugged. Dismantle pump and clean impeller.

System head or required discharge head

10

too high.

11 Air leaks in suction piping.

12 Air leaks in stuffing box.

13 Speed too low. See item 5.

14 Discharge head too high. See item 10.