Page 1

Installation, Operations, and Maintenance Instructions

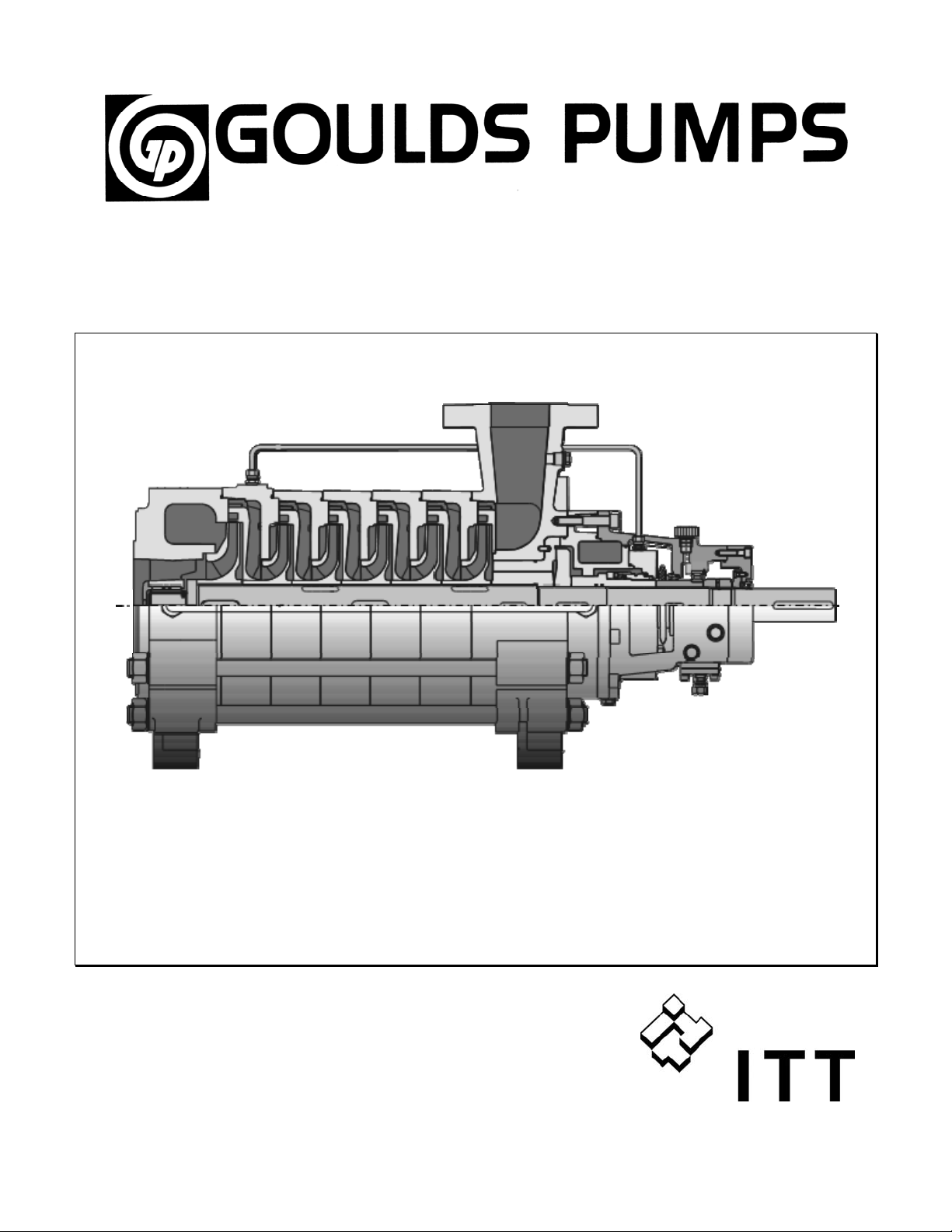

Model 3311

Page 2

TABLE OF CONTENTS

PAGE SECTION

3 SAFETY INSTRUCTIONS 1

5 APPLICATION 2

7 SYSTEM LAYOUT 3

12 UNPACKING, HANDLING, STORAGE 4

14 PUMP INSTALLATION 5

17 STARTING AND STOPPING PROCEDURES 6

19 MAINTENANCE, DISASSEMBLY, ASSEMBLY 7

30 LOCATING TROUBLES 8

31 SECTIONAL DRAWING / PARTS LIST 9

Please note: Only trained and skilled operating personnel are allowed to install and operate this

pump or pump set. Compliance with these operating instructions and all applicable

rules and regulations must be ensured.

If you fail to comply with these operating instructions:

• people may be put at risk

• the pump or pump set may be damaged

• the manufacturer shall not be held liable for damage caused by non-compliance.

2

Page 3

1 Safety Instructions

1.1 Safety instructions

This manual gives basic instructions which must be

observed during installation, operation and maintenance

of the pump.

It is therefore imperative that this manual be read by the

installer and the responsible personnel or operators prior

to installation and commissioning. It must always be

available on site.

Within this manual, safety instructions are marked with

safety symbols.

Safety symbol to ISO 3864-B.3.1

This general hazard symbol highlights information noncompliance with which could cause a risk to personal

safety.

Safety symbol to ISO 3864-B.3.6

This symbol refers to electrical hazards.

CAUTION

This word gives warning of a hazard to the machine.

Signs affixed to the machine, e.g.

- arrow indicating the direction of rotation

- symbols indicating fluid connections

must be visible and kept legible.

1.2 Qualification and training of

operating personnel

The personnel responsible for operation, maintenance,

inspection and assembly must be properly trained and

qualified.

The responsibilities of the operating personnel must be

exactly defined by the plant operator. If the staff does not

have the necessary knowledge, they must be trained and

instructed, which may be performed by the machine

manufacturer or the supplier on behalf of the plant

operator, if required. Moreover, the plant operator is to

make sure that the contents of this manual are fully

understood by the operating personnel.

1.3 Hazards in the event of non-

compliance with the safety

instructions

Non-compliance with the safety instructions may cause a

risk to personnel as well as to the environment and the

machine. Non-compliance may result in a loss of any

right to claim damages.

For example, non-compliance may involve the following

hazards:

- failure of important functions of the equipment;

- failure of specified maintenance and repair procedures;

- electrical, mechanical and chemical hazards affecting

personal safety;

- leakage of environmentally damaging substances.

1.4 Safety at work

When operating the pump, the safety instructions

contained in this manual, the relevant national accident

prevention regulations and any other service and safety

instructions issued by the plant operator must be

observed.

3

Page 4

1.5 Safety instructions relevant to

operation

- If hot or cold machine components involve hazards, the

customer must ensure these components are guarded

against accidental contact.

- Guards for moving parts (e.g. coupling) must not be

removed from the machine while in operation.

- Any leakage of hazardous (e.g. explosive, toxic, hot)

fluids (e.g. from the shaft seal) must be drained away

so as to prevent any risk to personal safety or the

environment. Statutory regulations must be complied

with.

- Hazards resulting from electricity must be prevented.

Local regulations must be complied with.

1.6 Safety instructions relating to

maintenance, inspection and assembly

work

It shall be the plant operator's responsibility to ensure that

all maintenance, inspection and assembly work is

performed by authorized and qualified personnel who

have adequately familiarized themselves with the subject

matter by studying this manual in detail.

Any work on the machine shall only be performed when it

is not operating and has been properly secured from

starting. Always lock out power to the driver before

performing pump maintenance. The procedure for

stopping the machine described in this manual must be

followed.

Pumps which handle hazardous fluids must be

decontaminated.

On completion of work all safety and protective

equipment must be re-installed and made operative again.

Prior to restarting the machine, the instructions listed

under sub-section 6.4 "Checks before first start-up" must

be observed.

1.7 Unauthorized alterations and

production of spare parts

Any modification to the machine is permissible only after

consultation with Gould’s Pumps.

Using genuine spare parts and accessories authorized by

the manufacturer is in the interest of safety. Use of other

parts may exempt the manufacturer from any liability.

1.8 Unauthorized use

Goulds Pumps, inc. will not be liable for any damages or

delay caused by failure to comply with the provisions of

this instruction manual. The pump is not to be operated at

speeds, working pressures, discharge pressures or

temperatures higher than, nor used with liquids other than,

stated in the original order acknowledgement or the

conditions of service for which it was quoted without

written permission from Goulds Pumps.

4

Page 5

2 Application

2.1 Limitation of use

Operation of the pump must be limited to the application

and operating conditions stated by the purchaser and

confirmed on the manufacturer's data sheet. The pump is

covered by warranty under Gould’s Pumps’ conditions of

sale.

2.2 Wrong use

• Operate the pump only for the application stated on

the data sheet. Operation outside these limits of

product application will increase the risk to personal

safety and the environment.

CAUTION

• Do not exceed the density stated on the data sheet as

this could cause a motor overload condition.

• Do not operate the pump outside its characteristic

curve so as to avoid pump or motor damage.

2.3 Accessories

The accessories supplied with the pump are indicated on

the data sheet. Other accessories may be mounted to the

pump or the pump set only after Gould’s Pumps' prior

consent.

2.4 Design and working principle

The 3311 high pressure pump of the Goulds multi-stage

line is a horizontal multi-stage ring-section type

centrifugal pump.

It meets the technical requirements according to DIN ISO

5199 / EN 25199.

The pump casings are held together by external tie bolts

and sealed against the atmosphere by O-rings.

The axial thrust is balanced by a hydraulic balancing

device consisting of a disc/drum combination. An

additional lift-off device is available and intended for

special applications. The balancing liquid flows back

through an external line to the suction casing.

Suction nozzle: axial or radial.

In the case of radial suction nozzle orientation, the suction

casing pump feet assembly allows adaptation to the

installation requirements by rotating the casing.

Bearings:

Oil-lubricated anti-friction bearing on the discharge side;

suction side sleeve bearing lubricated by the liquid

handled or oil-lubricated anti-friction bearing.

Shaft seal:

Packed stuffing box or mechanical seal according to DIN

24960.

Drive:

Depending on its design, the pump is either driven from

the discharge side or the suction side, by a customary

electric motor or turbine. The direction of rotation is

counter-clockwise for discharge side drive, and clockwise

for suction side drive, when viewed from drive end.

2.5 Applications

- M unici pal water supply:

Pumping stations, treatment plants, booster units.

- Water treatment:

Filtration, reverse osmosis.

- Pumps for industrial purposes:

General water supply, cold water, boiler feed

installations, hot water, pumping of organic and

inorganic solutions, high-pressure gas washing; power

water generation plants, purifying and cleaning plants,

desalinization plants.

- Power supply:

Small and medium-sized thermal stations, waste

incineration installations.

5

Page 6

2.6 Nameplate Information

Every pump has a Goulds nameplate that provides

information about the pump. The tags are located on the

pump casing.

When ordering parts, you will need to identify the pump

model, size, serial number, and the item number of the

required parts. Information can be taken from the pump

casing tags. Item numbers can be found later in this

manual.

Pump Casing Tag – provides information about the

pump’s hydraulic characteristics. Note the format of the

pump size: Discharge x Suction – Nominal maximum

Impeller Diameter in inches.

(Example: 2x3-7)

6

Page 7

3 System Layout

3.1 Pipework

3.1.1 General

In short discharge lines, the nominal diameter should be

such that the piping resistance is only a small proportion

of the discharge head. For long pipelines, the most costeffective solution should be determined on a case-by-case

basis.

Flow velocity guidelines:

Suction line: v

max. 3 m/s

Discharge line: v

Abrupt cross-section transitions or sharp bends should be

avoided. Flow disturbances must be kept to a minimum

when making necessary branches.

Unfavorable pipework layouts may impair the

performance of the pump, especially on the suction side

(e.g. bends in several planes in front of the suction

nozzle).

≈ 1.5 to 2.5 m/s

s

≈ 4 to 6 m/s

D

• The pipework must be independently supported and

positioned such that no excessive forces and moments

are exerted on the pump flanges.

• Excessive loads could result in leakage and be

hazardous to personnel.

CAUTION

• If hot water is handled, excessive pipework loads and

moments can cause a misalignment of the coupling

between pump and driver, thus reducing the operating

safety of the unit.

Once the flange bolts have been released, the flanges must

not yield more than the amount corresponding to the

gasket thickness, nor must they be out of parallel nor bear

against each other under stress. Check that the flange

gaskets do not extend into the interior of the pipe. All pipe

components, valves and fittings and the pump nozzles

should be thoroughly cleaned before assembly.

Air-relief valves and drain valves must be installed in the

suction and discharge lines.

In order to prevent the formation of air pockets,

- a feed line (supply source above the pump) should

slope gradually downward towards the pump;

- a suction line (supply source below the pump) should

gradually rise to the pump.

Shut-off valves must be installed in the suction and

discharge lines and in all pipelines connecting the pump

with the liquid system.

The valves enable the pump to be depressurized and

dismantled without having to drain the system. Flow

regulation at constant speed is permissible from the

discharge side only.

CAUTION

• The pipes should have at least the nominal diameter of

the pump nozzles. Where this is not possible, it should

be ensured that the flow velocity in the suction or feed

line does not exceed 2 - 3 m/s.

• Flange seals must not extend into the interior of the

pipework.

• Clean the pipework prior to pump installation.

• Support the pipelines so as to prevent distortion of

pump components.

• Avoid rough cross-section transitions and sharp bends.

• Eccentric reducers must be used in the event of

different nominal diameters.

• In the event of unfavorable suction conditions, stead y

flow should be ensured over a length of 15 x suction

nozzle diameter upstream from the suction nozzle.

• Shut-off valves in the suction or discharge line must

be fully open during operation and must never be

used to control the flow.

7

Page 8

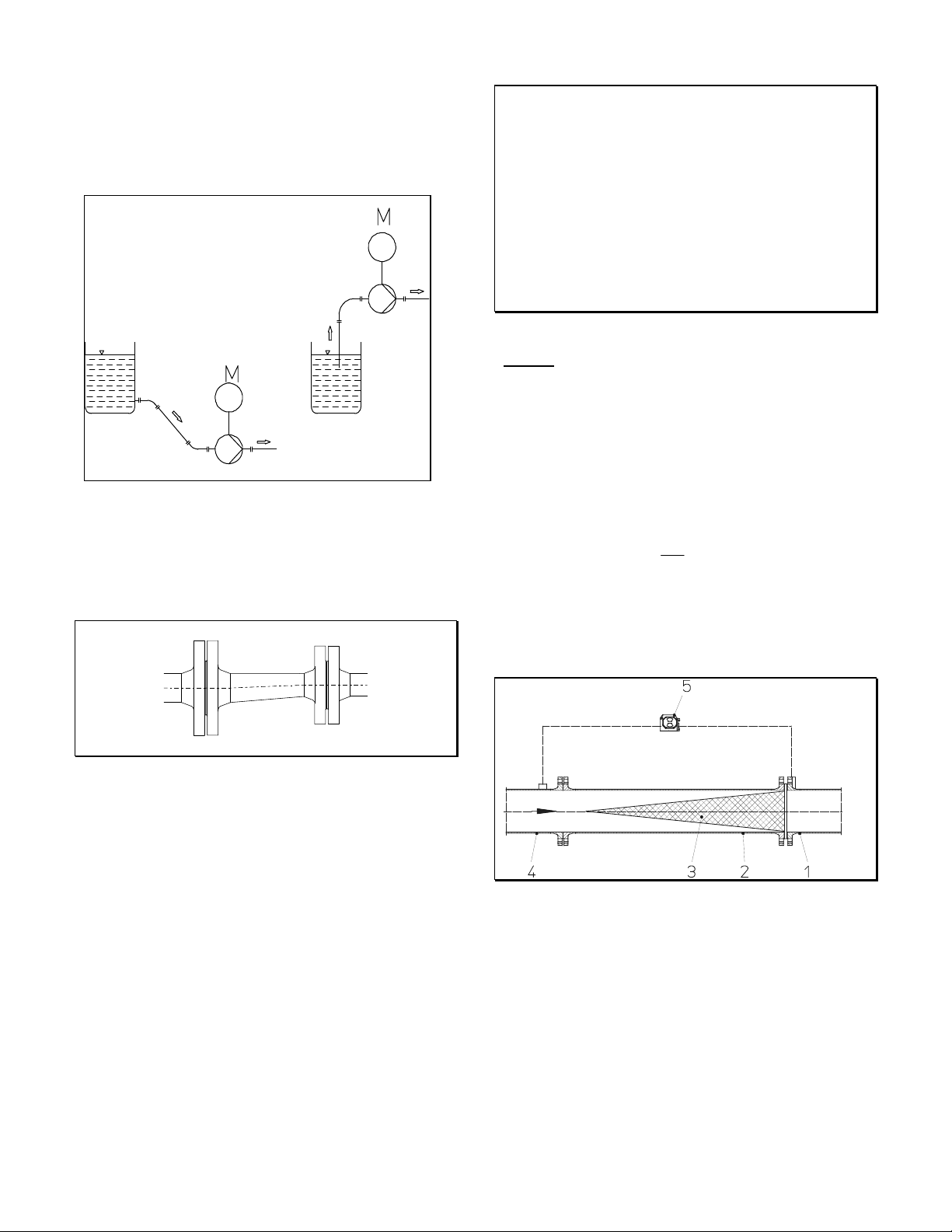

3.1.2 Suction or feed line

A suction line should rise to the pump and a feed line

should slope gradually downward towards the pump.

Feed operation suction operation

Reducers mounted must be eccentric to eliminate the

possibility of air pockets being formed.

CAUTION

• The strainer is for starting purposes only. Solids which

are smaller than the mesh size will not be retained by

the strainer.

• However, such small particles may collect in the

lateral area of the impeller near the clearances, in

particular if their concentration is high.

• In order to prevent clogging, it is recommended that

the customer provide a sedimentation tank or a larger

flushable fine strainer upstream from the pump.

Design:

Conical strainer with perforated plate support body with

external fine screen, mesh size 0.5 mm, of corrosionresistant material. The fine screen can be removed after

several months of operation, once there are no more

deposits.

For new conical strainers supplied by Gould’s Pumps the

pressure loss can be calculated as follows:

Hv

2

v

ζ

•=

g2

in m

v = medium flow velocity in reference cross-section,

in m/s

ζ = 4, loss coefficient for new conical strainers

Eccentric reducer

If the liquid is contaminated, a filter should be fitted

upstream from the pump whose free-space sectional area

should be three times the pipe cross-sectional area.

8

1 Pump suction nozzle / flange

2 Pipe section for strainer

3 Conical strainer

(installed with its tip against flow direction)

4 Feed line

5 Differential pressure measuring instrument

Feed line with conical strainer

Page 9

Determining the strainer pressure loss

Example:

Feed line = DN 125

Flow rate 80 m³/h

ζ = 4

v = 1.81 m/s in the feed line

Hv =

2

4

81.1

•

81.92

•

276.3

4

62.19

66.0

=•=

m

The suction line must be leak-proof and it must be

possible to release all air. The suction opening of the

suction line should be well below the liquid level, and a

foot valve with a strainer should be used. The foot valve

must be far enough from the bottom to avoid excessive

inlet losses which could impair performance.

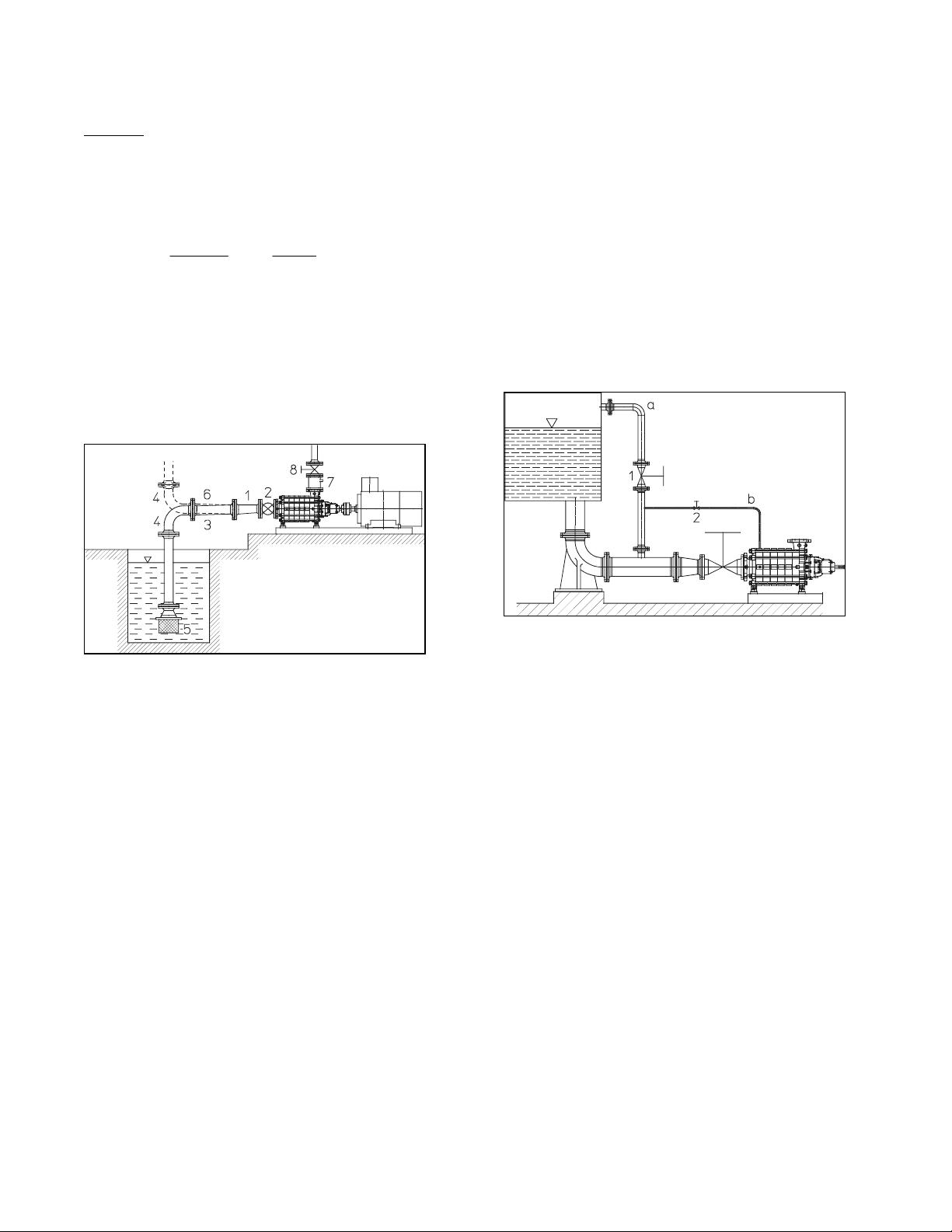

3.1.3 Vacuum equalizing pipe

If the pump draws from a system or tank under vacuum,

an equalizing pipe must be installed connecting the vent

connection at the suction casing or the highest point of the

suction line to a point above the maximum liquid level in

the suction tank.

- The line should be fitted with a shut-off valve which

should only be closed for maintenance work on the

pump.

To assist in starting the pump, we also recommend that a

pipeline, which can be shut off, be installed between the

first stage and the equalizing line.

1 Eccentric reducer (suction operation) or

concentric reducer (feed operation)

2 Shut-off valve

3 Suction line

4 Bend

5 Foot valve

6 Feed line

7 Non-return valve

8 Control valve

Pump installation

A shut-off valve should be installed in the feed line; it is

to be closed for maintenance work.

It should be installed such that air pockets cannot form in

the spindle cap, i.e. with the spindle in a horizontal

position or pointing vertically downward.

a Equalizing line

b Additional line

1 Shut-off valve

2 Shut-off valve (vacuum-tight)

Vacuum operation

3.1.4 Discharge line

For flow control, install a shut-off valve as close to the

pump nozzle as possible. It is recommended that a nonreturn valve be installed between pump nozzle and shutoff valve, thus protecting the pump against reverse

rotation and also the pump and the foot valve against

water hammer that may occur in the event of sudden shutdown.

9

Page 10

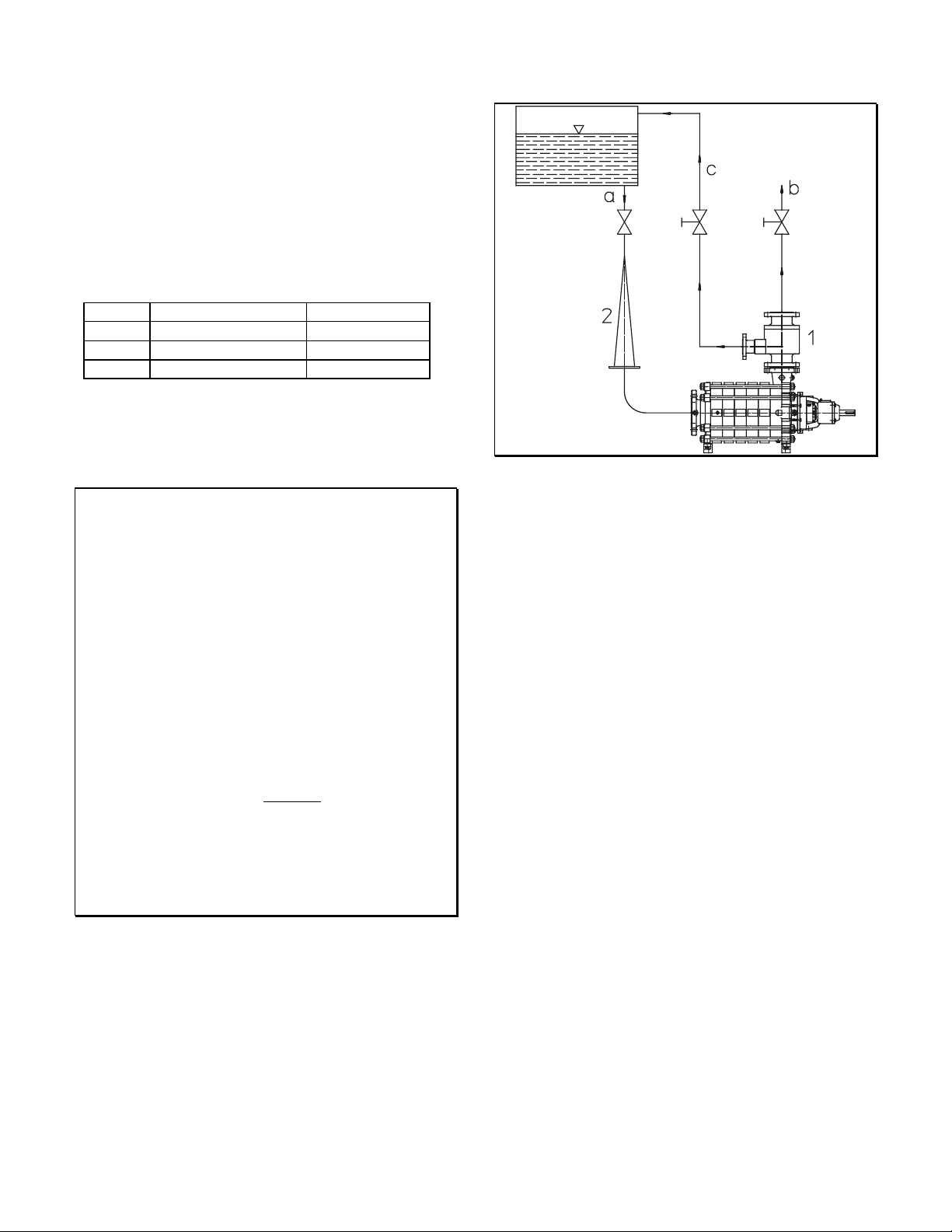

3.1.5 Minimum flow line

The minimum flow line (or bypass line) should be used if

operation with the discharge side shut-off valve closed is

possible. The minimum flow valve ensures that a

sufficient rate is automatically returned to the suction side

tank.

The minimum flow rate is shown on the curves or the data

sheet.

Size t = 140 °C or lower t > 140 °C

2x3-7 20 % of Q

2.5x4-8 20 % of Q

4x5-11 25 % of Q

25 % of Q

BEP

25 % of Q

BEP

25 % of Q

BEP

BEP

BEP

BEP

Should exact calculation be required, please contact

Gould’s Pumps.

CAUTION

• Up to the shut-off or non-return valve, the line should

be designed to suit the nominal pressure of the

discharge line, afterwards in accordance with the

design pressure of the feedwater/suction tank.

• Permissible velocity in the minimum flow line: 7 to 10

m/s.

• If an automatic device (bypass non-return valve) is

used, ensure that even in the case of trouble, liquid can

be returned through the minimum flow line.

• Frequent checks are recommended. Early replacement

of the minimum flow valve (which is exposed to

heavy wear) will prevent energy losses.

• The minimum flow valve should be installed near the

pump discharge nozzle, upstream from the discharge

shut-off valve.

• A non-return valve should be installed in the

minimum flow nozzle or the minimum flow line.

• For repair or overhaul work on the pump or the bypass

non-return valve, a shut-off valve must be installed in

the minimum flow line (c).

a Feed line

b Discharge line

c Bypass line

1 Bypass non-return valve

2 Conical strainer

Minimum flow control

3.1.6 Balancing line

The balancing line connects the discharge side shaft

sealing casing with the suction casing. There is no

throttling or shut-off device in this line, which serves to

hydraulically balance the pump.

The balancing line can also be returned by the customer to

the feed tank or the feed line.

3.1.7 Venting during pump priming

Before starting the set, the pump and the suction line must

be completely vented and filled with the liquid handled.

To bleed the air, several holes with plugs have been

provided. Similar holes may be used in the pip ework. The

shut-off valve in the suction or supply line must be fully

open.

10

Page 11

3.1.8 Cooling

Cooling is required if the temperature of the liquid

handled exceeds 110 °C, if a packed stuf fing box is used,

or 140 °C if a mechanical seal is installed. For this

purpose the pump is equipped with a shaft sealing casing

which can be cooled. The connecting points for the

cooling lines are on the shaft sealing casing. The customer

should provide either an open circuit, i.e. a cooling water

return line to the drain system, or a closed circuit

including a return to the cooling circuit to be provided.

3.1.9 Drain line, leakage water line

The pump has connections for leakage water and drain

lines.

3.1.10 Pressure monitoring

In order to monitor the pressures upstream and

downstream from the pump, the installation of measuring

points in the pipeline is recommended.

3.2 Electrical connections

The electrical connection for the driving motor must be in

compliance with the relevant rules and requirements.

11

Page 12

4 Unpacking, Handling, Storage

4.1 Safety measures

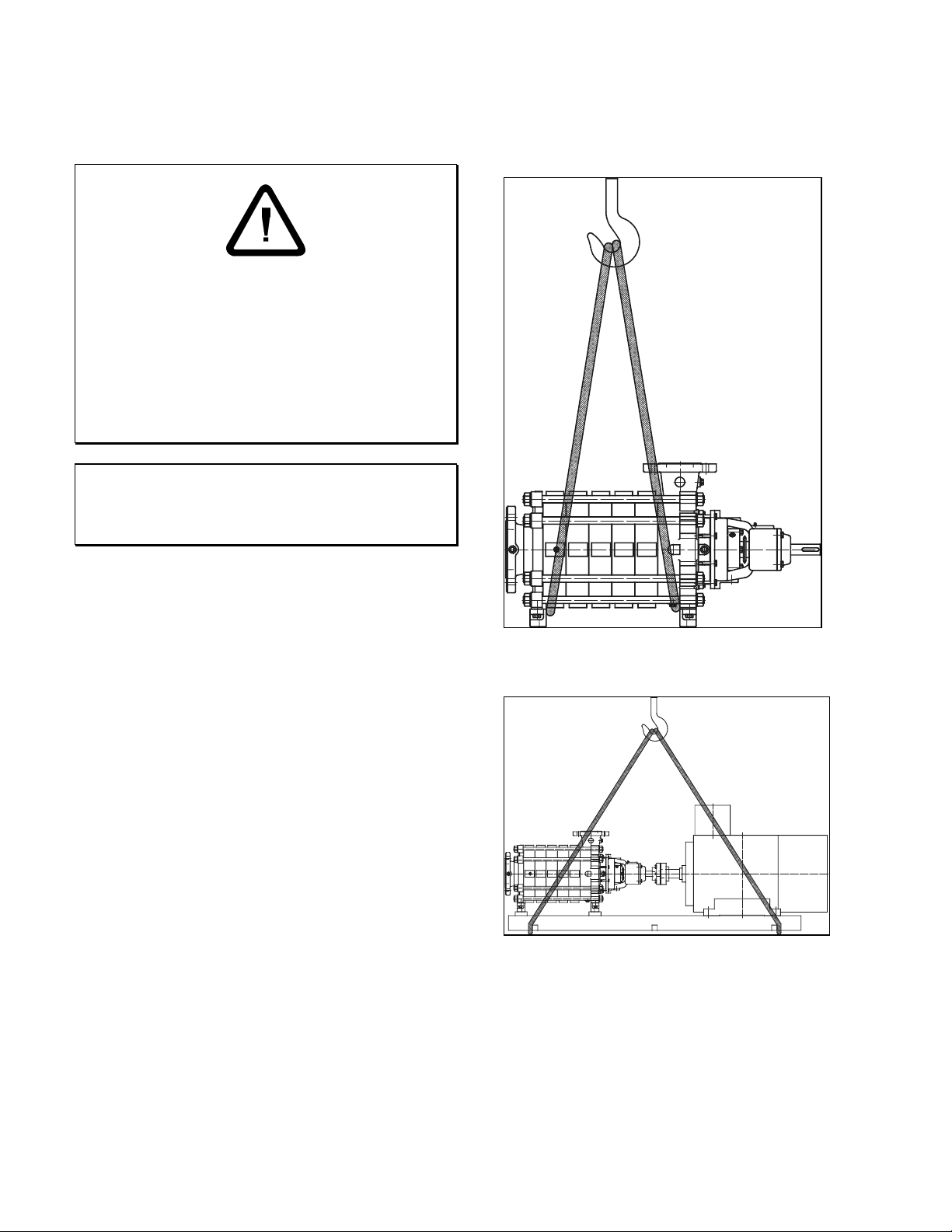

4.4 Handling

The pump or the pump set must be lifted as shown below:

• Do not lift heavy equipment overhead of personnel.

• A safe distance must be kept when lifting and moving

the equipment.

• Use only approved and suitable lifting equipment.

• The length of the lifting equipment should be such

that the pump or the set are lifted in horizontal

position.

• Do not attempt to lift the pump or the pump set using

eyebolts on pump components.

CAUTION

• Do not remove protection covers from the pump

nozzles, as they prevent contamination of the pump.

4.2 Unpacking

Do not unpack the pump until it has been carefully

checked for damage that may have occurred in transit.

Report any damage on the counterfoil or delivery note.

Claims must be made immediately on the carrier or the

transport insurance.

4.3 Intermediate storage

If the pump or the pump set is not to be installed

immediately it should be stored in a clean, dry and

vibration-free room.

The packing should be checked for damage on a monthly

basis.

Lifting the pump

Lifting the pump / motor / baseplate assembly

12

Page 13

4.5 Preservation

Usually, only iron pumps are preserved.

4.5.1 Removal of preservation

To remove the preservative coating, the pump should be

filled and drained several times using appropriate agents,

e.g. solvent naphta, diesel oil, or an alkaline detergent.

Flush with water, if necessary.

The pump must be installed and put into operation

immediately afterwards.

4.5.2 Re-preservation

If the pump has been supplied preserved and is to be

stored, a new preservative coating should be applied after

six months.

For suitable preservatives, contact Goulds Pumps.

13

Page 14

5 Pump Installation

5.1 Prerequisites

Prior to the installation of the pump, the storage and

handling instructions in Section 4 must have been

complied with.

5.2 Safety measures

• The pipework must be properly installed. Fluid

leakage during operation may cause health hazards or

environmental damage.

• The shut-off valves in the suction or feed line and in

the discharge line must be closed.

• All internal rules and guidelines must be complied

with.

• Hot components must have contact guards.

• Disconnect power to the equipment so as to eliminate

electrical shock hazards!

5.3 General

5.3.1 Fitting tools

Standard tools and lifting equipment are used. These

should be available at the customer's end.

5.3.2 Permissible environment

The ambient temperature range should be from

- 20 °C to + 60 °C.

The atmospheric humidity should be low in order to avoid

corrosion.

5.3.3 Space utilization

The space required by the pump or the pump set can be

seen from the table of dimensions and the arrangement

drawing.

Clear and easy access to the shut-off and regulating

valves and the measuring instruments must be ensured.

5.3.4 Installation position

3311 pumps are installed in horizontal position.

5.3.5 Preparatory checks

The foundation of the pump must be level and have a

minimum of vibration. The consistency of the concrete

should at least correspond to BN15, DIN 1045.

We recommend using a baseplate.

Prior to installation checks should be made with regard to:

- possible damage to the pump or the pump set that may

have occurred in transit

- ease of running (check that the shaft is free to rotate by

hand)

- the foundation dimensions.

5.3.6 Foundation

Prior to placing the pump set on the foundation which

should be well set, the following preparatory work must

be carried out:

- roughen and clean foundation surface

- remove shuttering/cores from the anchor holes

- clean and blow out the anchor holes

- check the positions and dimensions of the anchor holes

against the arrangement drawing.

Alternatively:

If the baseplate is fastened by means of heavy load plugs:

- Scribe and drill plug holes

- Clean plug holes and blow them out

- Inse rt heavy l oad plugs

14

Page 15

5.3.7 Installation of the set

4

The complete set mounted on the baseplate must be

placed on the foundation with its foundation bolts

suspended. If heavy load plugs are used, first screw in the

threaded rods in the plugs.

5.4 Motor

Prior to assembly the direction of rotation of the motor

must be checked (arrow on pump bearing housing).

5.5 Alignment of the set

- Place shims under the baseplate on both sides of the

foundation bolts (see Fig.).

- Use a spirit level to align the set.

- If the foundation bolts are more than 800 mm apart,

place additional shims between the foundation bolts to

prevent the baseplate from sagging. Care should be

taken to minimize distortion of the baseplate during

installation.

- The foundation bolts should be embedded in concrete

using quick-setting grout (this is not required if heavy

load plugs are used).

- Tighten the nuts of the foundation bolts in diagonal

sequence (after the grout has set).

- Re-check alignment with a spirit level.

Carry out the radial alignment of the coupling using a

knife-edge straight-edge and a feeler gauge.

1

Required dimensions:

a=a1 and b=b1, tolerance: ± 0.05 mm

1 knife-edge straight-edge

Aligning the coupling

The pumps are designed for high temperature foot

fastening as standard. Therefore, the pump feet must not

be fixed to the baseplate in order to avoid distortion

caused by high temperatures of the liquid handled and the

resulting expansion of the pump casing.

Stud bolts (1) and adjusting nuts (2) are used for the high

temperature foot fastening. Install adjusting nut (2) and

turn it finger-tight only (do not use a wrench), thus

installing the washer (3) free from play; however, the

washer (3) should still be movable by light hammer taps.

Lock the adjusting nut (2) in its position by tigh tening the

safety screw (4).

112 3

1

2

1 Shims

2 Additional shim, if foundation bolt distance ≥ 800 mm

Position of the shims

After aligning the set the axial clearance between the two

coupling halves measured at one point of the coupling

must be the same over the complete circumference of the

coupling, the permissible tolerance being ± 0.05 mm.

1 Stud bolt 3 Washer

2 Adjusting nut 4 Safety screw

15

Page 16

Guide pins (6) on the suction and discharge casing feet

prevent lateral movement of the pump. The drive side

guide pin is held in place by a guide casing which is

bolted to the baseplate (8). The opposite guide pin can

move in a guide casing.

5 Guide casing

6 Guide pin

7 Pump foot support

8 Baseplate

CAUTION

• Avoid distortions when finally tightening the bolts.

• The nuts of the foot fastening must be loosened so far

that the washers can be moved by light hammer

blows.

5.6 Grouting the baseplate

Prior to grouting the baseplate, carry out the following

preparatory work:

- Check the dimensions with regard to height and

alignment of flanges.

- Re-adjust baseplate, if necessary.

Ram earth-humid concrete under the baseplate or add

shrinkage-free grout until the entire space under the

baseplate is filled. Grouting should be a continuous

process so as to ensure that no air pockets form under the

baseplate.

When the grout is set re-tighten the foundation bo lts and

re-check the alignment of the coupling.

5.7 Pump installation in the piping system

CAUTION

• The pipework forces and moments acting on the pump

nozzles must not exceed the permissible pump nozzle

loads.

• The pump must not be used to clean the pipework

with chemicals.

- Remove the protection covers from the pump flanges

and the auxiliary pipeline connections.

- Insert the flange gaskets.

- Connect the suction or feed line.

- Connect the discharge line.

5.8 Hydrostatic test

• If the piping system is to undergo a hydrostatic

pressure test, the pump must be excluded from such

testing.

5.9 Cleaning, flushing and pickling of the

pipework

When the pipework is cleaned, flushed or pickled, the

pump must be excluded.

16

Page 17

6 Starting & Stopping Procedures

6.1 Prerequisites

The pump or the pump set must have been installed in

accordance with the instructions of Section 5.

6.2 Safety measures

• If there is no shaft seal, interrupt all further work and

install a shaft seal. Priming the pump with the liquid

handled in the absence of a shaft seal may present a

human-health or environmental hazard.

• Ensure that people and the environment are not put at

risk through explosive, toxic, hot, crystalline, or acid

liquids handled.

• Be sure that all electrical connections comply with the

local rules and regulations and that this work is done

by authorized personnel only.

CAUTION

• Fill bearing housings with oil.

• The pump must be completely primed and vented.

• Check the direction of rotation only with the pump

primed.

• If the liquid handled is hot, the pump should be filled

slowly so as to avoid distortions or heat shocks.

• The flow rate should be changed at constant speed

only on the discharge side. During operation the

regulating valve in the suction or feed line should

always be fully open.

• Do not run the pump with the regulating valve closed

for more than 30 seconds, if there is no minimum flow

bypass line.

• Safety measures should be taken at the customer's end

to ensure (for example by means of a relief valve) that

the permissible pump casing pressure is not exceeded

during operation.

• Repeat the alignment of the coupling at operating

temperature. Re-align the pump or the motor, if

necessary.

6.3 Electrical connection

Connect the electrical supply to the motor in accordance

with the connection diagram in the terminal box.

6.4 Checks before first start-up

- Are the pipelines connected and are the flange

connections tight?

- Is the pump incl. the pipework correctly primed?

- Is the shut-off valve in the discharge line closed?

- Is the shut-off valve in the suction or feed line fully

open?

- Is the motor ready?

- Is the direction of rotation of the motor correct? (Check

by momentarily switching on the motor.)

- Is the coupling correctly aligned (see Section 5)?

- Can the washers of the foot-fastening be moved? (see

subsection 5.5)

- Has the shaft seal been installed?

- Are the supply lines, if any, to the shaft seal open?

- Has the bearing housing been correctly filled with oil?

(see subsection 7.3.1).

CAUTION

• If the discharge pressure does not rise steadily as the

speed increases, stop the motor and re-vent and refill

the pump.

• Do not switch the pump on and off more often than

ten times per hour (this applies to a max. density of

1000 kg/m³ of the liquid handled). The motor

manufacturer's instructions must be followed.

17

Page 18

6.5 Starting procedure

- Check everything using the check list of sub-section

6.4.

- Switch on the motor.

- Check the pressure gauges at the pressure measuring

points.

- Open the discharge side regulating valve to adjust the

duty point of the pump.

CAUTION

• A fluid quantity of a few cm³ per hour will typically

leave the mechanical seal in the form of vapor, mist or

droplets. If there should be a considerable increase in

the leakage rate after the start-up phase, stop the pump

and check the mechanical seal.

• If a stuffing box is installed, the leakage rate after

start-up should be higher than during operation. After

about 1 hour, tighten the gland nuts gradually until

there is a slight drop leakage.

6.6 Particular information

The following parameters should be monitored during

operation:

- power consumption of the motor

- smoothness of pump operation (no vibrati on)

- bearing temperature

- leakage

6.7 Stopping procedure

- Cl ose the discharge side regulating valve.

- Switch off the m otor.

- Once the pump is at rest, close the shut-off valves of

the feed line and cooling line (if installed).

CAUTION

• If there is danger of freezing, the pump should be

drained down.

• Please note that there will always be some residual

liquid even if the pump is emptied in vertical position.

• Ensure that the pump does not contain any hazardous

substances when it is dismantled to be returned to the

manufacturer's factory.

• Ensure that during prolonged inactivity the pump is

operated for about five minutes every 1 to 3 months.

Follow the instructions under 6.5.

18

Page 19

7 Maintenance, Disassembly, Assembly

7.1 Prerequisites

The pump or the pump set must have been taken out of

operation in accordance with the instructions of Section 6.

7.2 Safety measures

Standard design with constant level oiler

- Pull oil bottle out of the screw-in elbow.

- Fill the bearing housing with oil until the oil becomes

visible in the screw-in elbow.

- Fill oil bottle through filler hole.

- Replace oil bottle. As long as there is oil in the bottle

the oil level in the bearing housing is sufficient.

• Flush the pump thoroughly before disassembly to

purge away the residual liquid left after draining the

pump.

• Ensure that people and the environment are not put at

risk through explosive, toxic, hot, crystalline, or acid

liquids handled.

CAUTION

• The workplace for disassembly or assembly must be

clean.

7.3 Maintenance and inspection

7.3.1 Oil-lubricated bearings

If the driver is on the discharge side, the pumps will be

equipped with oil-lubricated anti-friction bearings on the

drive side and a sleeve bearing lubricated by the liquid

handled on the suction side. If the driver is on the suction

side, the pump will have an oil-lubricated anti-friction

bearing on the suction side. An additional oil-lubricated

anti-friction bearing will be mounted on the discharge

side of pumps equipped with a lift-off device.

Pumps are shipped from the factory without oil in the

bearing housings.

The bearing housings must be filled with oil befo re initial

start-up.

CAUTION

• Use only very clean and non-ageing oil with good

water separating and corrosion protection properties.

If the bearings are new, change first oil after about 200

operating hours. Afterwards, change the oil in accordance

with the following table:

light service normal and severe service

Light contamination,

T < 50 °C

Annually every six months

Use the following lubricating oils:

Bearing temperature

< 80 °C

Lubricating oil acc.

to DIN 51517

Kin. viscosity

at 40 °C in mm²/s

Neutralization

number

Ash content,

weight-%

Water content,

weight-%

Oil consumption (l)

Size Lift-off device

without with

2x3-7 0.19 0.25

2.5x4-8 0.24 0.30

4x5-11 0.27 0.35

n ≤ 1500

rpm

CL 68 CL 46 CL 22

61.2 to

74.8

light contamination,

T > 50 °C

Ambient

temperature

< 0 °C

n > 1500

rpm

41.8 to

50.8

≤ 0.15 mg KOH/g

≤ 0.02

≤ 0.1

19.8 to 24.2

19

Page 20

7.3.2 Mechanical seal

Generally, virtually no maintenance is required on

mechanical seals. The mechanical seal should exhibit only

light visible leakage. In the case of heavy leakage, the

mechanical seal should be checked (see Section 6.6).

7.3.3 Packed stuffing box

With a packed stuffing box, there is always a leakage in

the form of drops. In the case of heavy leakage, the

packing and the shaft wearing sleeve should be checked

(for scores).

7.3.4 Driving motor

Maintenance of the driving motor should be in

compliance with the manufacturer's instructions.

7.4 Disassembly

Operating troubles involving pump disassembly are

unlikely in the event of careful monitoring and

maintenance of the pump.

However, if trouble occurs, the reason should be found

before disassembly, if possible. Repair and overhaul work

should be carried out by Goulds Pumps personnel or the

pump should be inspected at the manufacturer's factory.

Please note that any disassembly work to be performed

during the warranty period requires the approval of

Goulds Pumps.

If you disassemble the pump, all components should be

treated with utmost care.

All parts must be cleaned carefully, checked for wear and

reconditioned or replaced by spare parts, if necessary. It is

vital that the shaft is checked for concentricity. Use only

genuine spare parts.

7.4.1 Preparation for disassembly

- Disconnect power to the motor.

- Drain the system between suction side and discharge

side shut-off valves.

- Disconnect and dismantle existing sensors and

monitoring devices, if necessary.

- Dismantle coupling.

- Drain the liquid from the pump.

- Dismantle shaft seal supply lines, if any.

- Unbolt the pump from the pipe work.

- Dismantle balancing line.

- Drain the oil from the bearing housings.

7.4.2 Replacement parts

For re-assembly, replace all O-rings.

The item numbers of replacement parts are given in the

components list, section 9.

20

Page 21

7.4.3 Disassembly of the pump

Mark positions and sequence of the parts with a colored

pen or a scriber, for later re-assembly.

Measure and record shaft projection to bearing cover

(dimension X, section 7.6.2.2).

7.4.3.1. Discharge side drive

7.4.3.1.1. Dismantling of the bearings

a) Sleeve bearing, lubricated by the liquid handled

(non-drive side)

Axial suction nozzle

- R emove bearing cover 160.1

- Remove circlip 932.1

- Pull out bearing bush 545.1/545.2 with O-rings 412.1

- Remove bearing sleeve 529.1

CAUTION

• Anti-rotation grooved pin 561.1 must remain in the

shaft.

Radial suction nozzle

- Release hexagon head bolts 901.2

- R emove bearing cover 160.1 with O-rin g 41 2. 11

- Remove circlip 932.1

- Pull out bearing bush 545.1/545.2 with O-rings 412.1

- Remove bearing sleeve 529.1

CAUTION

• Anti-rotation grooved pin 561.1 must remain in the

shaft.

21

Page 22

b) Anti-friction bearing,

- oil-lubricated – drive side

- without lift-off device -

- If installed - remove cooling and/or circulation line

- R emove key 940.5

- Release bolts 914.5

- Remove bearing cover 360.1 with labyrinth ring 423.2

and limiting ring 380

- Release grub screw 904.2

- Remove circlip 932.2

- Support shaft 210 and key 940.5, and release shaft nut

921

- Release bolts 914.2

- Withdraw bearing housing 350.1, labyrinth ring 423.1,

bearing 322 and bearing sleeve 529.2

- R emove key 940.4

c) Anti-friction bearing,

- oil-lubricated - drive side

- with lift-off device -

- If installed - remove cooling and/or circulation line

- R emove key 940.5

- Remove suction side bearing cover 160.1 as described

under a) for axial or radial suction nozzle

- Fix shaft 210 axially on the suction side

- Release bolts 914.5

- Remove bearing cover 360.1 with labyrinth ring 423.2

and limiting ring 380

- Compress spring 950 by moving bearing carrier 382

- Remove circlip 932.3

- R emove bearing 321

- Release bolts 914.4

- Remove bearing housing 350.2 with bearing carrier

382 and spring 950

- Release grub screw 904.1

- Release bearing sleeve 529.3

- Remove circlip 932.2

- Pull spacer sleeve 525 from shaft 210

- Release bolts 914.2

- Withdraw bearing housing 350.1, labyrinth ring 423.1,

bearing 322, bearing sleeve 529.2

- R emove key 940.4

7.4.3.1.2. Dismantling of shaft seal

a) Stuffing box packing

22

Dismantle bearings in accordance with 7.4.3.1.1 b) or c)

- Release nuts 920.2

- Sli de bac k the st uf fi n g box gland 452

- Remove packing rings 461

- Remove balancing line

- Release bolts 914.1

- Dismantle sealing casing 441

- Withdraw shaft wearing sleeve 524

b) Mechanical seal

Page 23

7.4.3.1.4. Dismantling of hydraulic unit

Dismantle bearings in accordance with 7.4.3.1.1 b) or c)

- Release nuts 920.2

- Remove seal cover 471

- Remove balancing line

- Release bolts 914.1

- Withdraw sealing casing 441, mechanical seal 433 and

shaft sleeve 523

7.4.3.1.3. Dismantling of balancing device

Dismantle bearings in accordance with 7.4.3.1.1 b) or c)

Dismantle shaft seal in accordance with 7.4.3.1.2 a) or b)

Dismantle balancing device in accordance with 7.4.3.1.3

- R emove key 940.2

- Release nuts 920.1

- Remove tie bolts 905

- Support stage casing 108.1

- Dismantle delivery casing 107

- Remove, from stage to stage, impeller 230, key 940.1,

stage casing 108.1 with diffuser 171.1, in that order

Dismantle bearings in accordance with 7.4.3.1.1 b) or c)

Dismantle shaft seal in accordance with 7.4.3.1.2 a) or b)

- Pull balance disc 601 from shaft 210

- R emove key 940.3

- Dismantle balance disc seat 602

- Pull balance drum 603 from shaft 210

23

Page 24

7.4.3.2. Suction side drive

7.4.3.2.1. Dismantling the oil-lubricated anti-

friction bearing - drive side

7.4.3.2.2. Dismantling the shaft seal - drive side

a) Stuffing box packing

- If installed - remove cooling and/or circulation line

- R emove key 940.5

- Release bolts 914.7

- Dismantle bearing cover 360.1 with labyrinth ring

423.2

- Release grub screw 904.2

- Remove circlip 932.2

- Support shaft 210 and key 940.5, and release shaft nut

921

- Release bolts 914.2

- Withdraw bearing housing 350.1, labyrinth ring 423.3,

bearing 322 and bearing sleeve 529.2

- R emove key 940.4

Dismantle bearings in accordance with 7.4.3.2.1

- Release nuts 920.2

- Sli de bac k the st uf fi n g box gland 452

- Remove packing rings 461

- Release bolts 914.1

- Remove sealing casing 441

- Withdraw shaft wearing sleeve 524

b) Mechanical seal

24

Dismantle bearings in accordance with 7.4.3.2.1

- Release nuts 920.2

- Dismantle seal cover 471

- Release bolts 914.1

- Withdraw sealing casing 441, mechanical seal 433 and

shaft sleeve 523

Page 25

7.4.3.2.3. Dismantling of oil-lubricated anti-

friction bearing- non-drive side -

a) Without lift-off device

b) With lift-off device

- If installed - remove cooling and/or circulation line

- Release bolts 914.5

- Remove bearing cover 360.2 with limiting ring 380

- Release grub screw 904.2

- Remove circlip 932.2

- Support shaft 210 on the drive side with key 940.5, and

release shaft nut 921

- Release bolts 914.2

- Withdraw bearing housing 350.1, labyrinth ring 423.1,

bearing 322 and bearing sleeve 529.2

- R emove key 940.4

- If installed - remove cooling and/or circulation line

- Fix shaft 210 axially on the drive side

- Release bolts 914.5

- Remove bearing cover 360.2 with limiting ring 380

- Compress spring 950 by moving bearing carrier 382

- Remove circlip 932.3

- R emove bearing 321

- Release bolts 914.4

- Remove bearing housing 350.2 with bearing carrier

382 and spring 950

- Release grub screw 904.1

- Release bearing sleeve 529.3

- Remove circlip 932.2

- Pull spacer sleeve 525 from shaft 210

- Release bolts 914.2

- Withdraw bearing housing 350.1, labyrinth ring 423.1,

bearing 322 and bearing sleeve 529.2

- R emove key 940.4

25

Page 26

7.4.3.2.4. Dismantling of shaft seal- non-drive

side -

a) Stuffing box packing

Dismantle bearings in accordance with 7.4.3.2.3 a) or b)

- Release nuts 920.2

- Remove seal cover 471

- Remove balancing line

- Release bolts 914.1

- Withdraw sealing casing 441, mechanical seal 433 and

shaft sleeve 523

7.4.3.2.5. Dismantling of the balancing device

Dismantle bearings in accordance with 7.4.3.2.3 a) or b)

- Release nuts 920.2

- Sli de bac k the st uf fi n g box gland 452

- Remove packing rings 461

- Remove balancing line

- Release bolts 914.1

- Dismantle sealing casing 441

- Withdraw shaft wearing sleeve 524

b) Mechanical seal

Dismantle bearings in accordance with 7.4.3.2.3 a) or b)

Dismantle shaft seal in accordance with 7.4.3.2.4 a) or b)

- Pull balance disc 601 from shaft 210

- R emove key 940.3

- Dismantle balance disc seat 602

- Pull balance drum 603 from shaft 210

26

Page 27

7.4.3.2.6. Dismantling of hydraulic unit

Dismantle bearings in accordance with 7.4.3.2.3 a) or b)

Dismantle shaft seal in accordance with 7.4.3.2.4 a) or b)

Dismantle balancing device in accordance with 7.4.3.2.5

- R emove key 940.2

- Release nuts 920.1

- Remove tie bolts 905

- Support stage casing 108.1

- R emove delivery casing 107

- Remove, from stage to stage, impeller 230, key 940.1,

stage casing 180.1 with diffuser 171.1, in that order

7.5 Work after disassembly

- Clean all parts.

- Clean the clearances and sealing surfaces.

The following pump components, if existing, must be

checked:

Mechanical seal

If the running faces are damaged or worn, replace the

mechanical seal.

Clearances

The diameter difference between impeller clearance area

and casing or cover clearance area of a new pump is

between 0.3 and 0.6 mm, depending on size and material.

In the case of excessive wear in the clearance area, wear

rings must be installed.

Shaft

Carry out a concentricity check.

7.6 Assembly

CAUTION

• The assembly work must be based on good

engineering practice.

- Use no force.

- Heavy parts must be supported during assembly.

- Before assembly, apply a layer of an appropriate

erection substance on the fitting points. Observe

instructions with regard to cleanliness and safety.

- The properties of new pump components must not be

changed without our head office's consent.

- All parts must be clean and free from chips or dust.

- The unit may be re-assembled in the reverse manner to

disassembling.

- Observe the tightening torques specified.

- Quick-sticking glues are not permitted.

27

Page 28

7.6.1 Tightening torques

Size 2x3-7

No. of stages

Tightening

torque

Size 2.5x4-8

No. of stages

Tightening

torque

Size 4x5-11

No. of stages

Tightening

torque

≤ 12

710 Nm 850 Nm 900 Nm

≤ 8

610 Nm 920 Nm 980 Nm

≤ 4

790 Nm 1420 Nm 1570 Nm 1790 Nm

13 - 15 16 - 18

9 - 13 14 - 18

5 - 8 9 - 12 13 - 15

7.6.2 Pump assembly

- Installation starts on the suction side.

- The pump should be assembled in a vertical position, if

possible.

- Install the parts in their original position.

- Observe the sectional drawing with list of components.

- Lightly tighten the nuts of the tie bolts.

- Place pump on its feet, in horizontal position, on a flat

work surface.

- Tighten nuts of the tie bolts in several stages in

diagonal sequence (nominal tightening torque at last

stage).

7.6.2.1. Shaft seal

Packed stuffing box

CAUTION

• The packing rings must not be inserted until after the

pump, including the bearings, has been completely

installed.

- Only pre-compressed packing rings are permissible.

- Thoroughly clean the packing area and the stuffing box

gland.

- The first packing ring should now be laterally bent

open and pushed on the shaft wearing sleeve.

- Slide the packing ring into the packing chamber using

the stuffing box gland.

- Install the other packing rings in the same manner,

however with the gaps 180° apart.

- Tur n t he glan d nut s finger-tight.

- Check that the gland is not tightened at a slant.

CAUTION

• The pump rotating assembly must be free to rotate by

hand.

• The stuffing box leakage must not be adjusted until

start-up (see Section 6).

Dimensions Pump size

in mm 2x3-7 2.5x4-8 4x5-11

Packing cross-section 10 10 12.5

Number of rings 4 5

Shaft diameter 45 75 95

Mechanical seals

CAUTION

• Utmost care should be taken when mounting the

rotary and stationary seal rings so as to avoid

contamination and/or distortion on the sealing

surfaces.

• EPDM seals must not be exposed to oil or grease.

• In order to achieve the compression pressure required

for the operational reliability of the mechanical seal,

check the axial installation dimension against the

installation drawing.

- Install the mechanical seal in the reverse manner to

disassembling.

28

Page 29

7.6.2.2. Bearings

Discharge side drive

- Install sleeve bearing in the reverse manner to

disassembling.

- Install anti-friction bearing with or without lift-off

device in the reverse manner to disassembling.

Suction side drive

CAUTION

• Check axial position of the rotor. Dimension X must

be the same as before disassembly.

Install suction side anti-friction bearing in the reverse

manner to disassembling.

Install discharge side anti-friction bearing, without or with

lift-off device in the reverse manner to disassembling.

CAUTION

• Check axial position of the rotor. Dimension X must

be the same as before disassembly.

29

Page 30

8 Locating Troubles

8.1 Troubles and possible causes

Trouble Cause Remedial action

Insufficient liquid

delivered

Insufficient

suction

performance of

pump

Pump leakage

Temperature

increase in the

pump

Increase in bearing

temperature

Unsteady running

of pump, excessive

noise

Motor circuit

breaker switches

off

Wrong direction of rotation. Re-connect the motor.

Discharge pressure too high. Check the system for contaminants, re-adjust the duty

point.

Suction lift too high or insufficient NPSHA. Check liquid levels,

open suction side shut-off valves,

clean suction side filter / dirt trap.

Pump / pipeline insufficiently filled with liquid. Vent and re-fill the pump / pipeline.

Sealing clearances too great due to wear. Replace worn pump components, or install wear

rings.

Leakage in casing or suction pipework. Replace casing seal,

check flange connections.

Impellers or diffusers clogged. Disassemble the pump, clean the impellers or

diffusers.

Suction lift too high or insufficient NPSHA. Check liquid levels,

open suction side shut-off valves,

clean suction side filter / dirt trap.

Leakage in casing, shaft seal, foot valve or

suction pipework.

Loose or clogged parts in the pump. Open the pump and clean it.

Casing bolts not tight enough. Check tightening torque of the tie bolts.

Defective mechanical seal. Check the sealing surfaces and secondary seals of the

Damaged seals. Replace seals.

Discharge side valve closed. Open discharge side valve.

Suction lift too high or insufficient NPSHA Check liquid levels,

Pump / pipeline insufficiently filled with liquid. Vent and re-fill the pump / pipeline.

Internal components worn. Renew worn parts.

Excessive clearances. Install wear rings, diaphragm bushes.

Increase in axial thrust. Check clearances, throttling gap and balancing line.

Insufficient, too much, contaminated or

unsuitable lubricant.

Bearings worn. Replace bearings.

Shaft sealing area insufficiently cooled. Check cooling lines, remove any deposits in the

Coupling misaligned or coupling components

worn.

Pump distorted, or sympathetic vibrations in the

pipework.

Flow rate too low / too high. Ensure minimum flow / throttle discharge side shut-

Suction lift too high or insufficient NPSHA. Check liquid levels,

Pump / pipeline insufficiently filled with liquid. Vent and re-fill the pump / pipeline.

Base of the pump not level. Pump distorted. Check pump installation and adjustment.

Foreign substances in the pump. Open the pump and clean it.

Requirements as to pumping conditions not met. Check the pumping conditions against the data sheet.

Base of the pump not level. Pump distorted. Check the installation and alignment of the pump.

Foreign substances in the pump. Open the pump and clean it.

Replace casing seal, check shaft seal, check flange

connections.

mechanical seal, replace damaged components.

open suction side shut-off valves,

clean suction side filter / dirt trap.

Add, reduce or replace lubricant.

cooling liquid container.

Align or replace.

Check pump and pipework fastening. Install

vibration-absorbing pipework sup p ort .

off valve.

open suction side shut-off valves,

clean suction side filter / dirt trap.

30

Page 31

9 Sectional Drawing / Parts List

9.1 Sectional Drawing – Size: 2x3-7

Discharge side drive - with axial inlet, without lift-off device

31

Page 32

9.2 Sectional Drawing – Size: 2.5x4-8 & 4x5-11

Discharge side drive - with axial inlet, without lift-off device

32

Page 33

9.3 Sectional Drawing – Size: 2x3-7

Discharge side drive - with axial inlet, with lift-off device

33

Page 34

9.4 Sectional Drawing – Size: 2.5x4-8 & 4x5-11

Discharge side drive - with axial inlet, with lift-off device

34

Page 35

9.5 Sectional Drawing – Size: 2x3-7

Discharge side drive - with radial inlet, without lift-off device

35

Page 36

9.6 Sectional Drawing – Size: 2.5x4-8 & 4x5-11

Discharge side drive - with radial inlet, without lift-off device

36

Page 37

9.7 Sectional Drawing – Size: 2x3-7

Discharge side drive - with radial inlet, with lift-off device

37

Page 38

9.8 Sectional Drawing – Size: 2.5x4-8 & 4x5-11

Discharge side drive - with radial inlet, with lift-off device

38

Page 39

9.9 Sectional Drawing – Size: 2x3-7

Suction side drive - without lift-off device

39

Page 40

9.10 Sectional Drawing – Size: 2.5x4-8 & 4x5-11

Suction side drive - without lift-off device

40

Page 41

9.11 Sectional Drawing – Size: 2x3-7

Suction side drive - with lift-off device

41

Page 42

9.12 Sectional Drawing – Size: 2.5x4-8 & 4x5-11

Suction side drive - with lift-off device

42

Page 43

9.13 Parts list

Gould’s Item # Part number DIN Denomination

100S 106 Suction casing

100D 107 Delivery casing

100G 108/108.1 Stage casing

100T 108.2 Stage casing with extraction

109C 160.1 Bearing cover

119C 160.2 Oil room cover

150 171.1 Diffuser

150L 171.2 Diffuser last stage

239 182 Foot

122 210 Shaft

101 230 Impeller

301 231 Suction impeller

409 322 Bearing

228C / 134 350.1/.2 Bearing housing

109 360.1/.2 Bearing cover

458 380 Limiting ring

443B 382 Bearing carrier

360E 400 Gasket

351W 411.1/.2/.3 Joint ring

412 / 496 412.1/.2/.../.11 O-Ring

332 / 333 423.1/.2 Labyrinth ring

383 433 Mechanical seal

184 441 Sealing casing

107 / 250 452 Stuffing box gland

106 461 Packing ring

383 471 Seal cover

123 507 Thrower

126 / 258 523 Shaft sleeve

126 524 Shaft wearing sleeve

157 525 Spacer sleeve

157B / 521 529/.1/.2/.3 Bearing sleeve

197A / 408 545.1/.2 Bearing bush

437 550.1/.2 Disc

445 561.1 Grooved pin

469 / 819 561.2/.3/.4 Grooved pin

297 601 Balance disc

298 602 Balance disc seat

300 603 Balance drum

251 642 Oil level sight glass

113A 672 Venting device

370 901.1/.2 Hexagon head bolt

353 / 375 902.1/.2 Stud

492Q / 358X 903.1/.2 Screwed plug

228C 904.1/.2 Grub screw

356S 905 Tie bolt

113 913 Vent plug

341 / 370 / 371 / 372 914.1/.2.../.6 Hexagon socket head cap screw

355 / 357F 920.1/.2 Nut

124 921 Shaft nut

843 930 Safety device

361 932.1/.2/.3 Circlip

178 / 400 / 401 940.1/.2/.3/.4/.5 Key

708 950 Compress spring

43

Page 44

HOW TO ORDER

When ordering parts call

1-800-446-8537

or your local Goulds Representative

EMERGENCY SERVICE

Emergency parts service is available

24 hours/day, 365 days/year

Call 1-800-446-8537

Visit our website at www.gouldspumps.com

Form No. I3311 5/09

44

©2009 Goulds Pumps, Incorporated

a subsidiary of ITT Corporation

Loading...

Loading...