Page 1

Page 2

FOREWORD

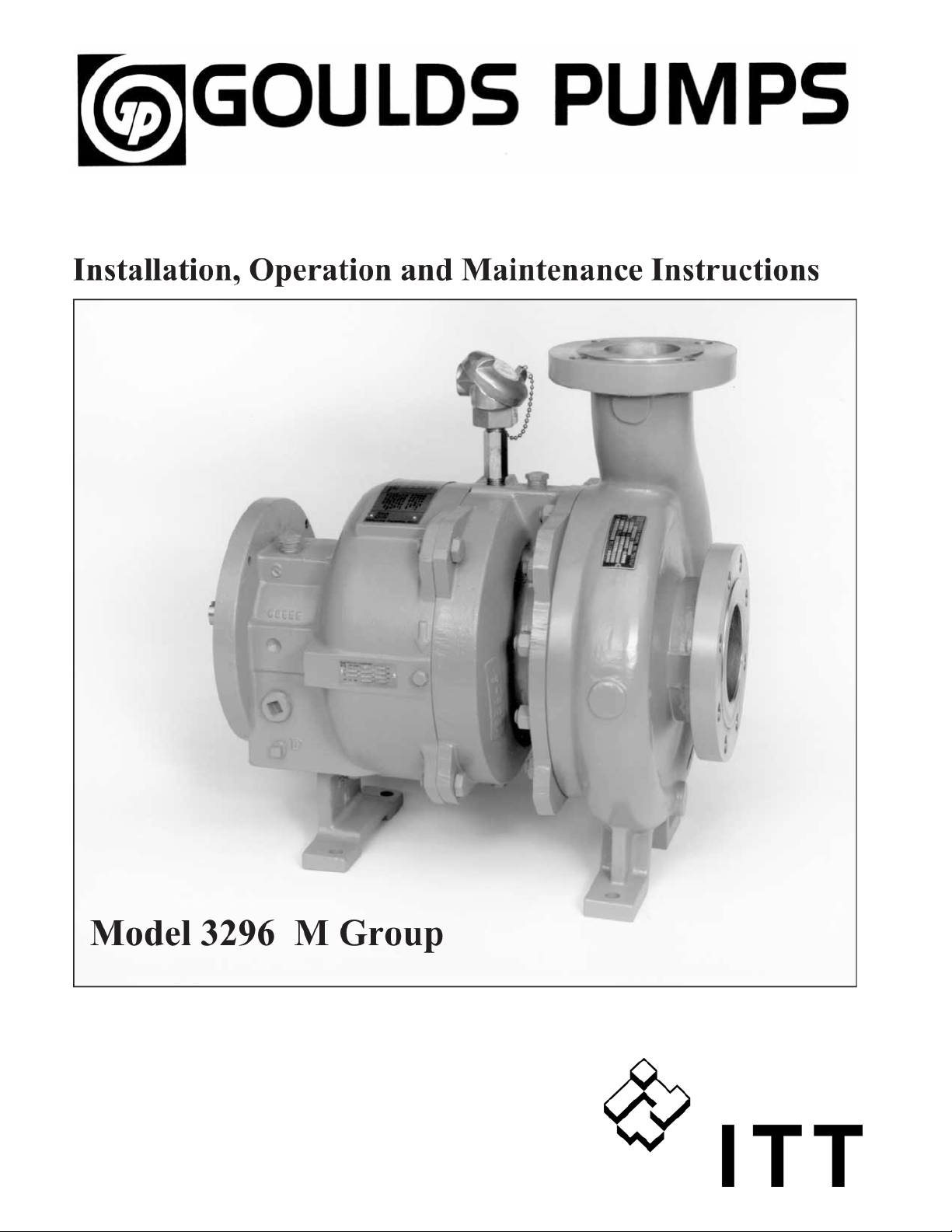

This manual provides instructions for the Installation, Operation, and Maintenance of the Goulds Model 3296 “M

Group” Magnetic Drive Process Pump. This manual must be read and understood before installation and start-up.

The design, materials, and workmanship incorporated in the construction of Goulds pumps makes them capable of

giving, trouble-free service. The life and satisfactory service of any mechanical unit, however, is enhanced and

extended by correct application, proper installation, periodic inspection, condition monitoring and careful

maintenance. This instruction manual was prepared to assist operators in understanding the construction and the

correct methods of installing, operating, and maintaining these pumps.

Goulds shall not be liable for physical injury, damage or delays caused by a failure to observe the instructions

for Installation, Operation, and Maintenance contained in this manual.

Warranty is valid only when genuine Goulds parts are used.

Use of the equipment on a service other than stated in the order could nullify the warranty, unless written approval

is obtained in advance from Goulds Pumps, Inc.

Supervision by an authorized Goulds representative is recommended to assure proper installation.

Additional manuals can be obtained by contacting your local Goulds representative or by calling 1-800-446-8537.

THIS MANUAL EXPLAINS

Proper Installation

n

Start Up Procedures

n

Operation Procedures

n

Routine Maintenance

n

Pump Overhaul

n

Troubleshooting

n

Ordering Spare or Repair Parts

n

3296 M Group 6/05 3

Page 3

TABLE OF CONTENTS

PAGE SECTION

7 SAFETY

9 GENERAL INFORMATION

11 INSTALLATION

19 OPERATION

23 PREVENTIVE MAINTENANCE

27 DISASSEMBLY & REASSEMBLY

1

2

3

4

5

6

55 SPARE AND REPAIR PARTS

61 APPENDIX

7

8

3296 M Group 6/05 5

Page 4

6 3296 M Group 6/05

Page 5

IMPORTANT SAFETY NOTICE

To: Our Valued Customers

User safety is a major focus in the design of our products. Following the precautions outlined in this

manual will minimize your risk of injury.

ITT Goulds pumps will provide safe, trouble-free service when properly installed, maintained, and

operated.

Safe installation, operation, and maintenance of ITT Goulds Pumps equipment are an essential end user

responsibility. This Pump Safety Manual identifies specific safety risks that must be considered at all

times during product life. Understanding and adhering to these safety warnings is mandatory to ensure

personnel, property, and/or the environment will not be harmed. Adherence to these warnings alone,

however, is not sufficient — it is anticipated that the end user will also comply with industry and corporate

safety standards. Identifying and eliminating unsafe installation, operating and maintenance practices is

the responsibility of all individuals involved in the installation, operation, and maintenance of industrial

equipment.

Please take the time to review and understand the safe installation, operation, and maintenance guidelines

outlined in this Pump Safety Manual and the Instruction, Operation, and Maintenance (IOM) manual.

Current manuals are available at

your nearest Goulds Pumps sales representative.

www.gouldspumps.com/literature_ioms.html or by contacting

These manuals must be read and understood before installation and star t-up.

For additional information, contact your nearest Goulds Pumps sales representative or visit our Web site at

www.gouldspumps.com.

S-1

Page 6

SAFETY WARNINGS

Specific to pumping equipment, significant risks bear reinforcement above and beyond normal safety precautions.

WARNING

A pump is a pressure vessel with rotating parts that can be hazard o us. An y press ure vessel can explode,

rupture, or discharge its contents if sufficiently ove r press u r i zed causi n g deat h, personal injury, property

damage, and/or damage to the environment. All necessary measures must be taken to ensure over

pressurization does not occur.

WARNING

Operation of any pumping system with a blocked suction and discharge must be avoided in all cases.

Operation, even for a brief period under these conditions, can cause superheating of enclosed pumpage and

result in a violent explosion. All necessary measures must be taken by the end user to ensure this condition is

avoided.

WARNING

The pump may handle hazardous and/or toxic fluids. Care must be taken to identify the contents of the pump

and eliminate the possibility of exposure, particularly if hazardous and/or toxic. Potential hazards include, but

are not limited to, high temperature, flammable, acidic, caustic, explosive, and other risks.

WARNING

Pumping equipment Instruction, Operation, and Maintenance manuals clearly identify accepted methods for

disassembling pumping units. These methods must be adhered to. Specifically, applying heat to impellers

and/or impeller retaining devices to aid in their removal is strictly forbidden. Trapped liquid can rapidly

expand and result in a violent explosion and injury.

ITT Goulds Pumps will not accept responsibility for physical injury, damage, or delays caused by a failure to

observe the instructions for installation, operation, and maintenance contained in this Pump Safety Manual or the

current IOM available at www.gouldspumps.com/literature.

S-2

Page 7

SAFETY

DEFINITIONS

Throughout this manual the words WARNING, CAUTION, ELECTRICAL, and ATEX are used to indicate

where special operator attention is required.

Observe all Cautions and Warnings highlighted in this Pump Safety Manual and the IOM provided with

your equipment.

WARNING

Indicates a hazardous situation which, if not avoided, could result in death or serious injury.

Example:

Pump shall never be operated without coupling guard installed correctly.

CAUTION

Indicates a hazardous situation which, if not avoi ded, could result in minor or moderate injury.

Example: Throttling flow from the suction side may cause cavitation and pump damage.

ELECTRICAL HAZARD

Indicates the possibility of electrical risks if directions are not followed.

Example: Lock out driver power to prevent electric shock, accidental start-up, and physical injury.

When installed in potentially explosive atmospheres, the instructions that follo w the Ex symbol must be

followed. Personal injury and/or equipment damage may occur if these instructions are not followed. If there

is any question regarding these requirements or if the equipment is to be modified, please contact an ITT

Goulds Pumps representative before proceeding.

Example:

parts, resulting in a spark and heat generation.

Improper impeller adjustment could cause contact between the rotating and stationary

S-3

Page 8

GENERAL PRECAUTIONS

WARNING

A pump is a pressure vessel with rotating parts that can be hazardous. Hazardous fluids may be contained by the

pump including high temperature, flammable, acidic, caustic, explosive, and other risks. Operators and

maintenance personnel must realize this and follow safety measures. Personal injuries will result if procedures

outlined in this manual are not followed. ITT Goulds Pumps will not accept responsibility for physical injury,

damage or delays caused by a failure to observe the instructions in this manual and the IOM provided with your

equipment.

WARNING

WARNING

General Precautions

NEVER use heat to disassemble pump due to risk of explosion from tapped liquid.

NEVER APPLY HEAT TO REMOVE IMPELLER. It may explode due to

trapped liquid.

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

NEVER operate pump without safety devices installed.

NEVER operate pump without coupling guard correctly installed.

NEVER run pump below recommended minimum flow when dry, or without

prime.

ALWAYS lock out power to the driver befo re per fo rming pump maintenance.

NEVER operate pump with discharge valve closed.

NEVER operate pump with suction valve closed.

DO NOT change service application without approval of an authorized ITT

Goulds Pumps representative.

Safety Apparel:

Insulated work gloves when handling hot bearings or using bearing heater

Heavy work gloves when handling parts with sharp edges, especial l y

impellers

Safety glasses (with side shields) for eye protection

Steel-toed shoes for foot protection when handli ng pa rts, heavy tools, etc.

Other personal protective equipment to protect against hazardous/toxic fluids

Receiving:

Assembled pumping units and their components are heavy. Failure to properly lift

and support equipment can result in serious physical injury and/or equipment

damage. Lift equipment only at specifically identified lifting points or as

instructed in the current IOM. Current manuals are available at

www.gouldspumps.com/literature_ioms.html or from your local ITT Goulds

Pumps sales representative. Note: Lifting devices (eyebolts, slings, spreaders, etc.)

must be rated, selected, and used for the entire load being lifted.

Alignment:

WARNING

Shaft alignment procedures must be followed to prevent catastrophic failure of

drive components or unintended contact of rotating parts. Follow coupling

manufacturer’s coupling installation and operation procedures.

S-4

Page 9

WARNING

CAUTION

General Precautions

Before beginning any alignment procedure, make sure driver power is locked out.

Failure to lock out driver power will result in serious physical injury.

Piping:

Never draw piping into place by forcing at the flan ged con necti on s of t he pump.

This may impose dangerous strains on the unit and cause misalignment between

pump and driver. Pipe strain will adversely effect the operation of the pump

resulting in physical injury and damage to the equipment.

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

CAUTION

CAUTION

WARNING

Flanged Connections:

Use only fasteners of the proper size and material.

Replace all corroded fasteners.

Ensure all fasteners are properly tightened and there are no missing fasteners.

Startup and Operation:

When installing in a potentially explosive environment, please ensure that the

motor is properly certified.

Operating pump in reverse rotation may result in contact of metal parts, heat

generation, and breach of containment.

Lock out driver power to prevent accidental start-up and physical injury.

The impeller clearance setting procedure must be followed. Improperly setting

the clearance or not following any of the proper procedures can result in sparks,

unexpected heat generation and equipment damage.

If using a cartridge mechanical seal, the centering clips must be installed and set

screws loosened prior to setting impeller clearance. Failure to do so could result

in sparks, heat generation, and mechanical seal damage.

The coupling used in an ATEX classified environment must be properly certified

and must be constructed from a non-sparking material.

Never operate a pump without coupling guard properly installed. Personal injury

will occur if pump is run without coupling guard.

Make sure to properly lubricate the bearings. Failure to do so may result in excess

heat generation, sparks, and / or premature failure.

The mechanical seal used in an ATEX classified environment must be properly

certified. Prior to start up, ensure all points of potential leakage of process fluid to

the work environment are closed.

Never operate the pump without liquid supplied to mechanical seal. Running a

mechanical seal dry, even for a few seconds, can cause seal damage and must be

avoided. Physical injury can occur if mechanical seal fails.

Never attempt to replace packing until the driver is properly locked out and the

coupling spacer is removed.

WARNING

WARNING

S-5

Dynamic seals are not allowed in an ATEX classified environment.

DO NOT operate pump below minimum rated flows or with suction and/or

discharge valve closed. These conditions may create an explosive hazard due to

vaporization of pumpage and can quickly lead to pump failure and physical injury.

Page 10

WARNING

WARNING

WARNING

WARNING

WARNING

CAUTION

CAUTION

WARNING

CAUTION

CAUTION

General Precautions

Ensure pump is isolated from system and pressure is relieved before

disassembling pump, removing plu gs, ope ni n g vent or drain valves, or

disconnecting piping.

Shutdown, Disassembly, and Reassembly:

Pump components can be heavy. Proper methods of lifting must be employed to

avoid physical injury and/or equipment damage. Steel toed shoes must be worn at

all times.

The pump may handle hazardous and/or toxic fluids. Observe proper

decontamination procedures. Proper personal protective equipment should be

worn. Precautions must be taken to prevent physical injury. Pumpage must be

handled and disposed of in conformance with applicable environmental

regulations.

Operator must be aware of pumpage and safety precautions to prevent physical

injury.

Lock out driver power to prevent accidental startup and physical injury.

Allow all system and pump components to cool before handling them to prevent

physical injury.

If pump is a Model NM3171, NM3196, 3198, 3298, V3298, SP3298, 4150, 4550,

or 3107, there may be a risk of static electric discharge from plastic parts that are

not properly grounded. If pumped fluid is non-conductive, pump should be

drained and flushed with a conductive fluid under conditions that will not allow

for a spark to be released to the atmosphere.

Never apply heat to remove an impeller. The use of heat may cause an explosion

due to trapped fluid, resulting in severe physical injury and property damage.

Wear heavy work gloves when handling impellers as sharp edges may cause

physical injury.

Wear insulated gloves when using a bearing heater. Bearings will get hot and can

cause physical injury.

S-6

Page 11

ATEX CONSIDERATIONS and INTENDED USE

Special care must be taken in potentially explosive environments to ensure that the equipment is properly

maintained. This includes but is not limited to:

1. Monitoring the pump frame and liquid end temperature.

2. Maintaining proper bearing lubrication.

3. Ensuring that the pump is operated in the intended hydraulic range.

The ATEX conformance is only applicable when the pump unit is operated within its intended use. Operating,

installing or maintaining the pump unit in any way that is not covered in the Instruction, Operation, and

Maintenance manual (IOM) can cause serious personal injury or damage to the equipment. This includes any

modification to the equipment or use of parts not provided by ITT Goulds Pumps. If there is any question

regarding the intended use of the equipment, please contact an ITT Goulds represe ntative before proceeding.

Current IOMs are available at

Pumps Sales representative.

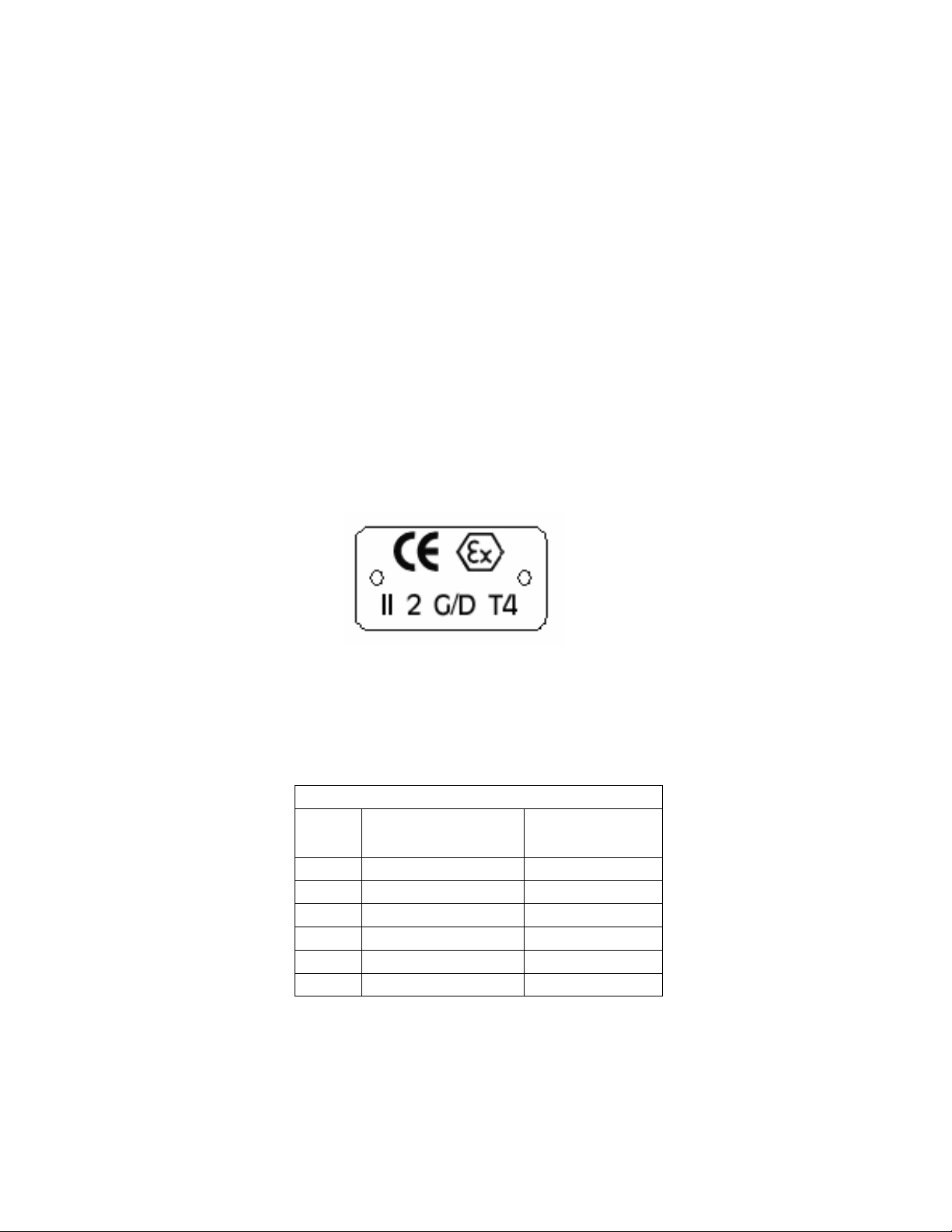

All pumping unit (pump, seal, coupling, motor and pump accessories) certified for use in an ATEX classified

environment, are identified by an ATEX tag secured to the pump or the baseplate on which it is mounted. A

typical tag would look like this:

www.gouldspumps.com/literature_ioms.html or from your local ITT Goulds

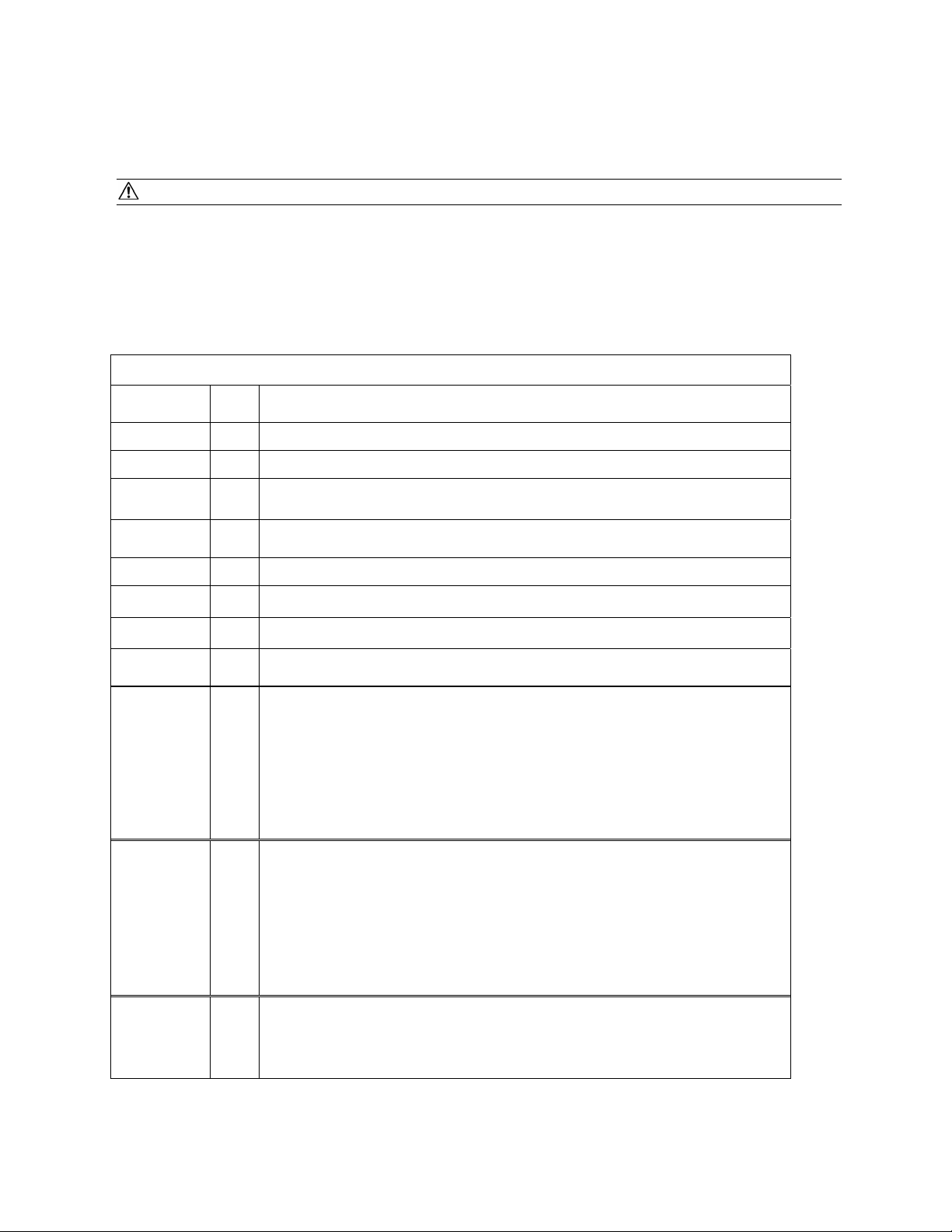

The CE and the Ex designate the ATEX compliance. The code directly below these symbols reads as follows:

II = Group 2

2 = Category 2

G/D = Gas and Dust present

T4 = Temperature class, can be T1 to T6 (see Table 1)

Table 1

Max permissible

surface temperature

Code

T1 842 (450) 700 (372)

T2 572 (300) 530 (277)

T3 392 (200) 350 (177)

T4 275 (135) 235 (113)

T5 212 (100) Option not available

T6 185 (85) Option not available

o

F (oC)

The code classification marked on the equipment must be in accordance with the specified area where the

equipment will be installed. If it is not, do not operate the equipment and contact your ITT Goulds Pumps sales

representative before proceeding.

Max permissible

liquid temperature

o

F (oC)

S-7

Page 12

PARTS

The use of genuine Goulds parts will provide the safest and

most reliable operation of your pump. ITT Goulds Pumps ISO

certification and quality control procedures ensure the parts are

manufactured to the highest quality and safety levels.

Please contact your local Goulds representative for details on

genuine Goulds parts.

S-8

Page 13

GENERAL INFORMATION

PUMP DESCRIPTION .............................9

NAMEPLATE INFORMATION ........................9

RECEIVING THE PUMP ...........................10

Storage Requirements ...........................................10

Handling .....................................................10

PUMP DESCRIPTION

2

The Model 3296 is a sealless frame-mounted

centrifugal pump with an enclosed impeller, that is

driven by a synchronous magnetic coupling, and meets

dimensional standards of ANSI B73.1.

Magnetic Coupling - is a coaxial synchronous type

using rare earth magnets. This concept results in a

compact design and allows the impeller to turn at the

same speed as the motor, (i.e.) there is no slip between

the drive and driven magnets.

Magnets - Two types of rare earth magnets are

available. Neodymium Iron (NdFe), which is used

when pumpage temperatures are less than 250°F

(120°C). For liquid pumpage between 250°F (120°C)

and 425°F (220°C) Samarium Cobalt (SmCo) magnets

are used.

Containment Shell - isolates the pumped liquid from

the atmosphere. Standard material is Hastelloy-C

which provides excellent corrosion and erosion

resistance.

NAMEPLATE INFORMATION

Sleeve Bearings and Thrust Bearings - Goulds

standard bearing material is Pure Sintered Alpha Grade

Silicon Carbide. The sleeve bearings are flexibly

mounted using O-rings.

Impeller - Model 3296 utilizes an enclosed impeller,

hydraulically balanced and keyed to the shaft.

Bearing Frame - the standard configuration is cast

ductile iron with flood oil lubricated ball bearings.

Pure oil mist systems are available as an option. For

protection and reliability of the bearings and the

lubricant, a carbon filled teflon non-contacting

labyrinth seal is provided. On the inboard side a lip

seal is used to prevent leakage of oil into the magnetic

drive assembly.

Casing - is top centerline discharge, self venting type

incorporates a fully confined gasket. 150 lb. ANSI

serrated raised face flanges are standard. The 3296 has

been designed such that there is a metal to metal fit

between the casing and frame adapter.

Every pump has 3 Goulds nameplates that provide

information on your pump. The tags are located on the

casing and bearing frame.

Pump Casing Tag - provides information relative to

the pumps characteristics. The format of pump size

information is: Discharge x Suction - Nominal

Impeller Diameter, (ex.1x1

Bearing Frame Tag - provides information relative to

the type of magnets being used.

3296 M Group 6/05 9

1

-6)

2

Pump Warning Tag - is permanently fastened to the

bearing frame. It contains precautions to be observed

during the operation, disassembly, maintenance and

reassembly of the pump.

When ordering spare parts you will need to know the

pump model, size, serial number, and the item number

of the required parts. Information can be taken from

the pump casing tag. Item number information can be

found in this manual.

Page 14

RECEIVING THE PUMP

Inspect the pump as soon as it is received. Make notes

of damaged or missing items on the receipt and freight

bill. File any claims with the transportation company

immediately.

STORAGE REQUIREMENTS

Short Term - (Less than 3 months) Goulds normal

packaging procedure is designed to protect the pump

during shipping. Upon receipt store in a covered and

dry location.

Long Term - (More than 6 months) Preservative

treatment of bearings and machined surfaces will be

required. Rotate shaft several times every 3 months.

Refer to driver and coupling manuals for their long

term storage procedures. Store in a dry covered

location.

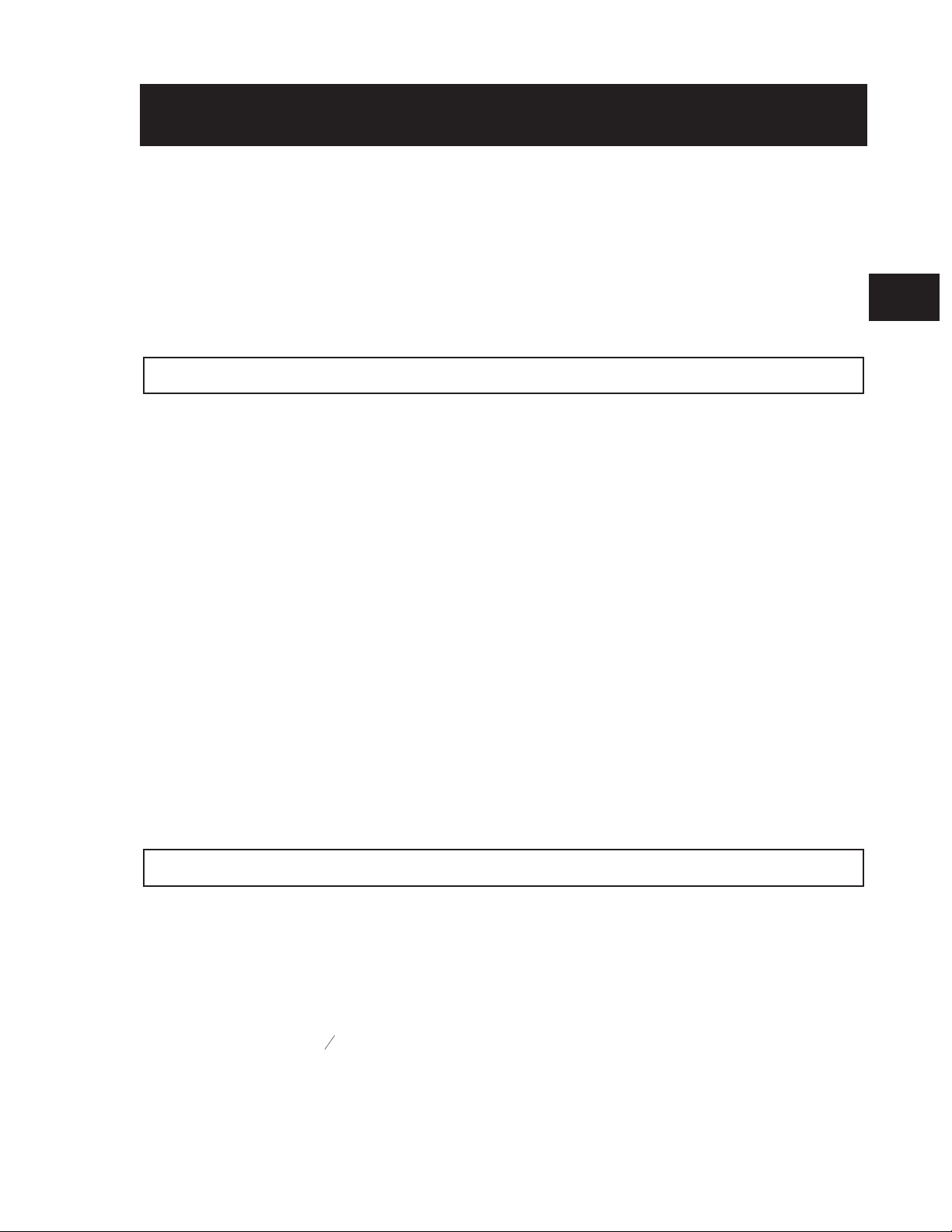

HANDLING

! WARNING

s

Failure to properly lift and support equipment

could result in serious injury or damage to pumps.

Use care when moving pumps. Lifting equipment must

be able to adequately support the entire assembly.

Hoist bare pumps, using a sling under the suction

flange and bearing housing.

the pump and driver.

Baseplate mounted units are moved with slings under

10 3296 M Group 6/05

Page 15

INSTALLATION

SITE/FOUNDATION..............................11

LEVEL BASEPLATE .............................12

ALIGNMENT AND ALIGNMENT PROCEDURE .............12

Alignment Checks..............................................12

Alignment Criteria .............................................13

SetUp.......................................................13

Measurement..................................................13

Angular Alignment .............................................13

Parallel Alignment .............................................14

Complete Alignment ............................................15

Alignment Troubleshooting ......................................15

GROUT BASEPLATE .............................15

PIPING......................................16

Suction Piping .................................................16

Discharge Piping ...............................................17

Final Piping Check .............................................17

3

SITE/FOUNDATION

A pump should be located near the supply of liquid

and have adequate space for operation, maintenance,

and inspection.

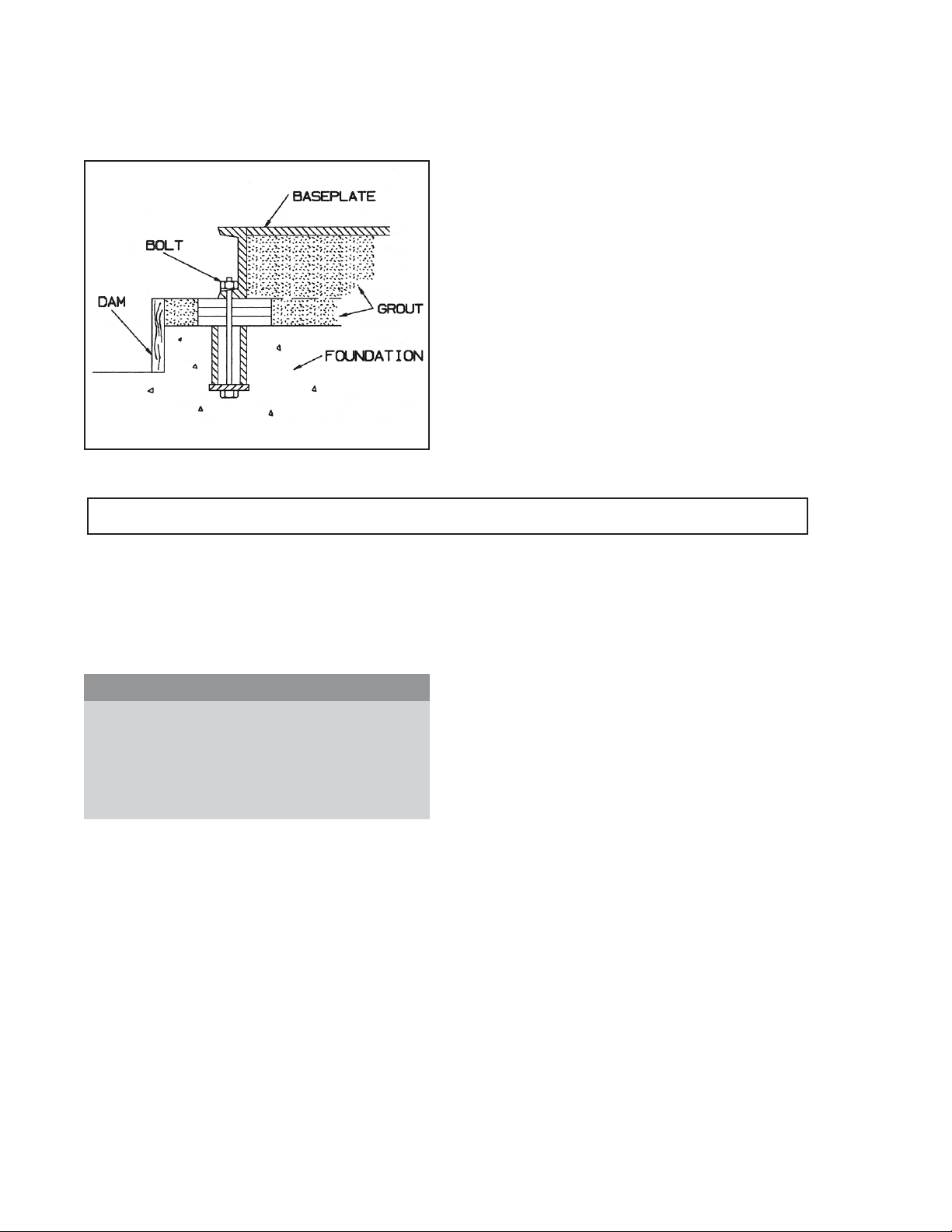

Baseplate mounted pumps are normally grouted to a

concrete foundation, which has been poured on a solid

footing. The foundation must be able to

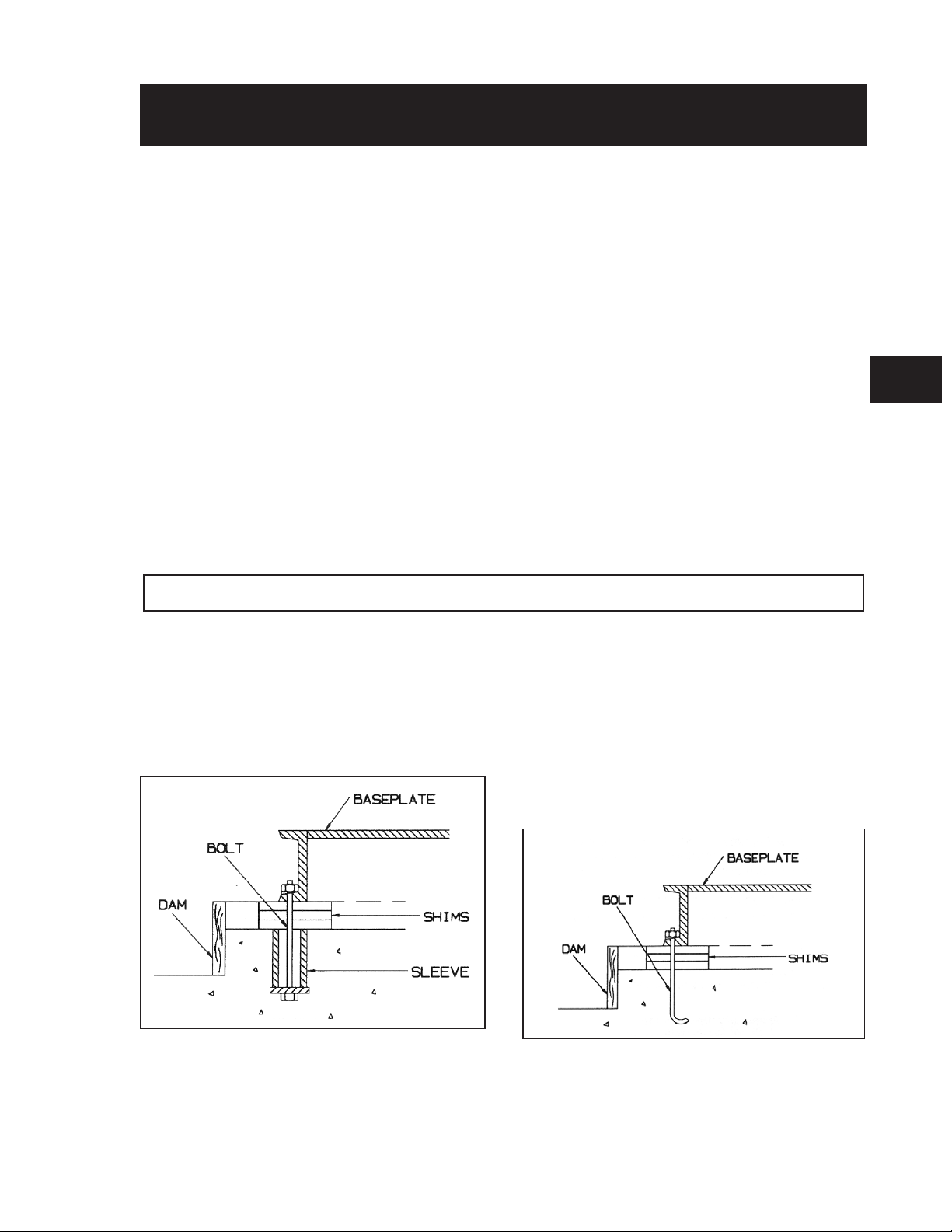

Fig. 4A

absorb any vibration and to form a permanent, rigid

support for the pumping unit.

The location and size of the foundation bolts are

shown on the outline assembly drawing, provided with

the pump data package.

Foundation bolts commonly used are sleeve type (Fig.

4A) and J type (Fig. 4B). Both designs permit

movement for final bolt adjustment.

Fig. 4B

3296 M Group 6/05 11

Page 16

LEVEL BASEPLATE

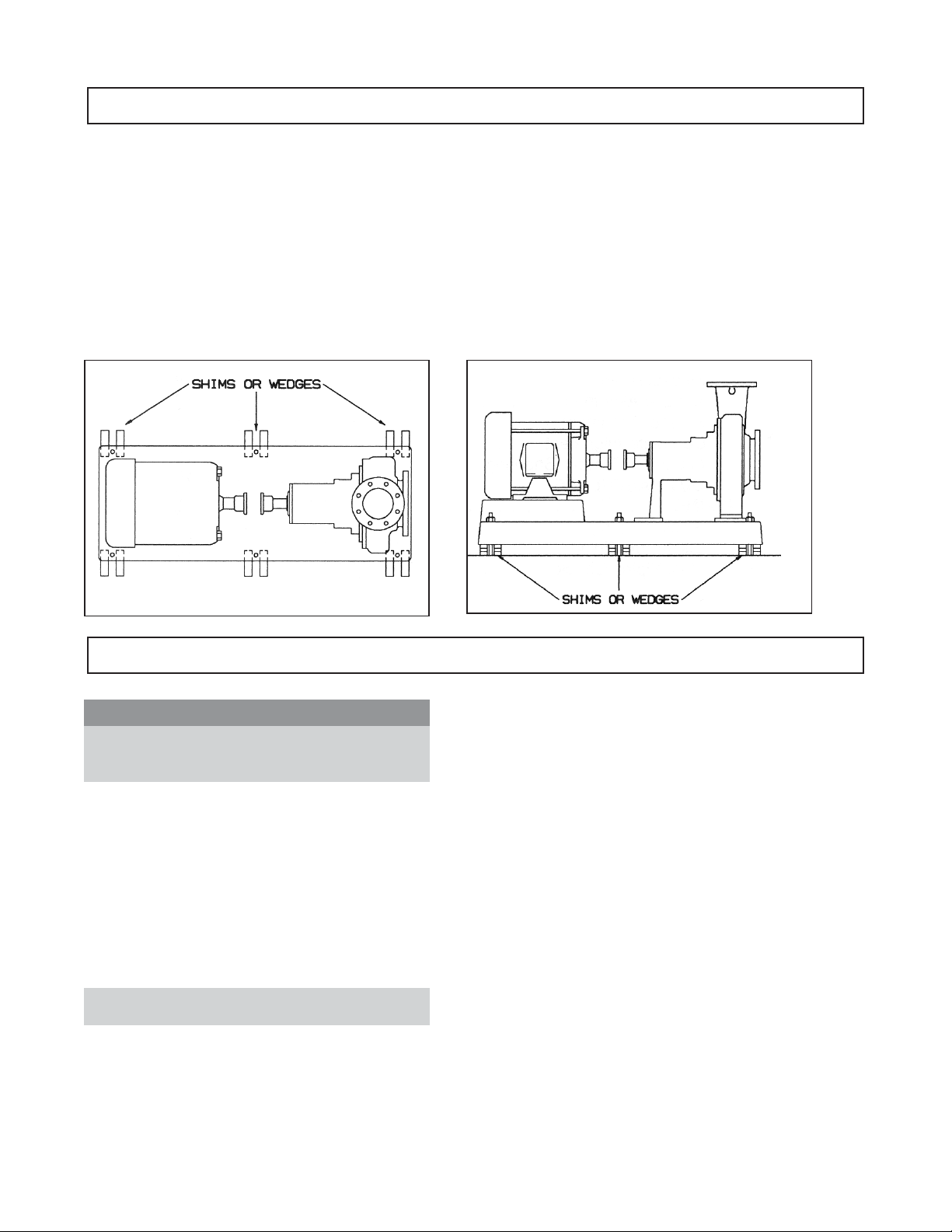

1. Place 2 sets of wedges or shims on the foundation,

one set on each side of every foundation bolt. The

wedges should extend .75 in. (20 mm) to 1.5 in.

(40 mm) above the foundation, to allow for

adequate grouting. This will provide even support

for the baseplate once it is grouted.

2. Remove water and/or debris from anchor bolt

holes/sleeves prior to grouting. If the sleeve

Fig. 5A

type bolts are being used, fill the sleeves with rags to

prevent grout from entering.

3. Carefully lower baseplate onto foundation bolts.

4. Level baseplate to within .125 in.(3mm) over the length of

the base and .062 in. (1.5 mm) over the width of the base

by adjusting shims or wedges.

5. Hand tighten bolts.

Fig. 5B

ALIGNMENT AND ALIGNMENT PROCEDURE

! WARNING

s

Before beginning any alignment procedure make

sure driver power is locked out. Failure to lock out

driver power can result in serious personal injury.

The points at which alignment is checked and adjusted

are:

l

Initial Alignment is done prior to operation when

the pump and the driver are at ambient temperature.

l

Final Alignment is done after operation when the

pump and driver are at operating temperature.

Alignment is achieved by adding or removing shims

from under the feet of the driver and shifting

equipment horizontally as needed.

NOTE: Proper alignment is the responsibility of

the installer of the unit.

Accurate alignment of the equipment must be attained.

Trouble-free operation can be accomplished by following these

procedures:.

ALIGNMENT CHECKS

Initial Alignment (Cold Alignment)

l

Before Grouting Baseplate- To ensure alignment can be

obtained.

l

After Grouting Baseplate - To ensure no changes to

alignment have occurred during grouting process.

l

After Connecting Piping -To ensure that pipe strains haven’t

altered alignment. If changes have occurred, alter piping to

remove pipe strains on pump flanges.

Final Alignment (Hot Alignment)

l

After First Run -To obtain correct alignment when both

pump and driver are at operating temperature. Thereafter,

alignment should be checked periodically in accordance with

plant operating and maintenance procedures.

12 3296 M Group 6/05

Page 17

ALIGNMENT CRITERIA

Good alignment is achieved when dial indicator

readings as specified in the alignment procedure are

.002 in. (.05 mm) Total Indicated Reading (T.I.R.) or

less when the pump and driver are at operating

temperature (Final Alignment).

MEASUREMENT

1. To ensure accuracy of indicator readings, always

rotate both coupling halves together so indicators

contact the same point on coupling half Y. This

will eliminate any measurement problems due to

runout on coupling half Y.

During the installation phase, however, it is necessary

to set the parallel alignment in the vertical direction to

a different criteria due to differences in expansion rates

of the pump and driver. Table 1 below shows

recommended cold settings for electric motor driven

pumps based on different pumpage temperatures.

Driver manufacturers should be consulted for

recommended cold settings for other types of drivers

(steam turbines, engines, etc.)

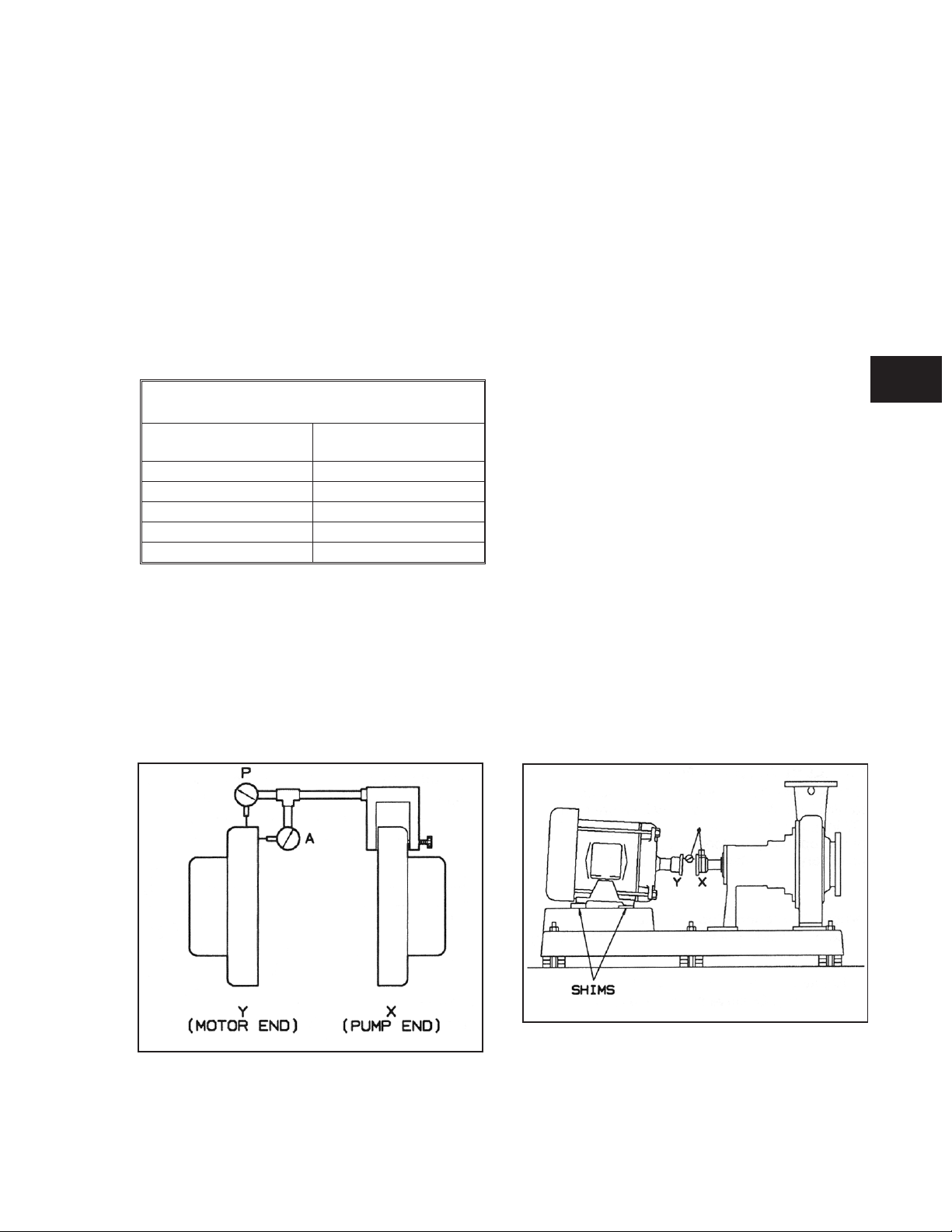

Table 1

Cold Settings of Parallel Vertical Alignment

PUMPAGE

TEMPERATURE

50°F (10°C) .002in. (.05mm) LOW

150°F (65°C) .001in. (.03mm) HIGH

250°F (120°C) .005in. (.12mm) HIGH

350°F (175°C) .009in. (.23mm) HIGH

425°F (218°C) .013in. (.33mm) HIGH

SET DRIVER SHAFT

SET UP

1. Mount two dial indicators on one of the coupling

halves (X) so they contact the other coupling half

(Y) (Fig. 6).

2. Check setting of indicators by rotating coupling

half X to ensure indicators stay in contact with

coupling half Y but do not bottom out. Adjust

indicators accordingly.

2. Take indicator measurements with driver feet hold

down bolts tightened. Loosen hold down bolts

prior to making alignment corrections.

3. Take care not to damage indicators when moving

driver during alignment corrections.

ANGULAR ALIGNMENT

A unit is in angular alignment when indicator A

(Angular indicator) does not vary by more that .002 in.

(.05 mm) as measured at four locations 90° apart.

Vertical Correction (Top to Bottom)

1. Zero indicator A at top dead center (12 o’clock) of

coupling half Y.

2. Rotate indicators to bottom dead center (6

o’clock). Observe needle and record reading.

3. Negative Reading - The coupling halves are

further apart at the bottom than at the top. Correct

by either raising the driver feet at the shaft end

(add shims) or lowering the driver feet at the other

end (remove shims) (Fig. 7A).

Positive Reading - The coupling halves are closer

at the bottom than at the top. Correct by either

lowering the driver feet at the shaft end (remove

shims) or raising the driver feet at the other end

(add shims).

3

Fig. 7A

Fig. 6

4. Repeat steps 1-3 until indicator A reads .002 in

(.05 mm) or less.

3296 M Group 6/05 13

Page 18

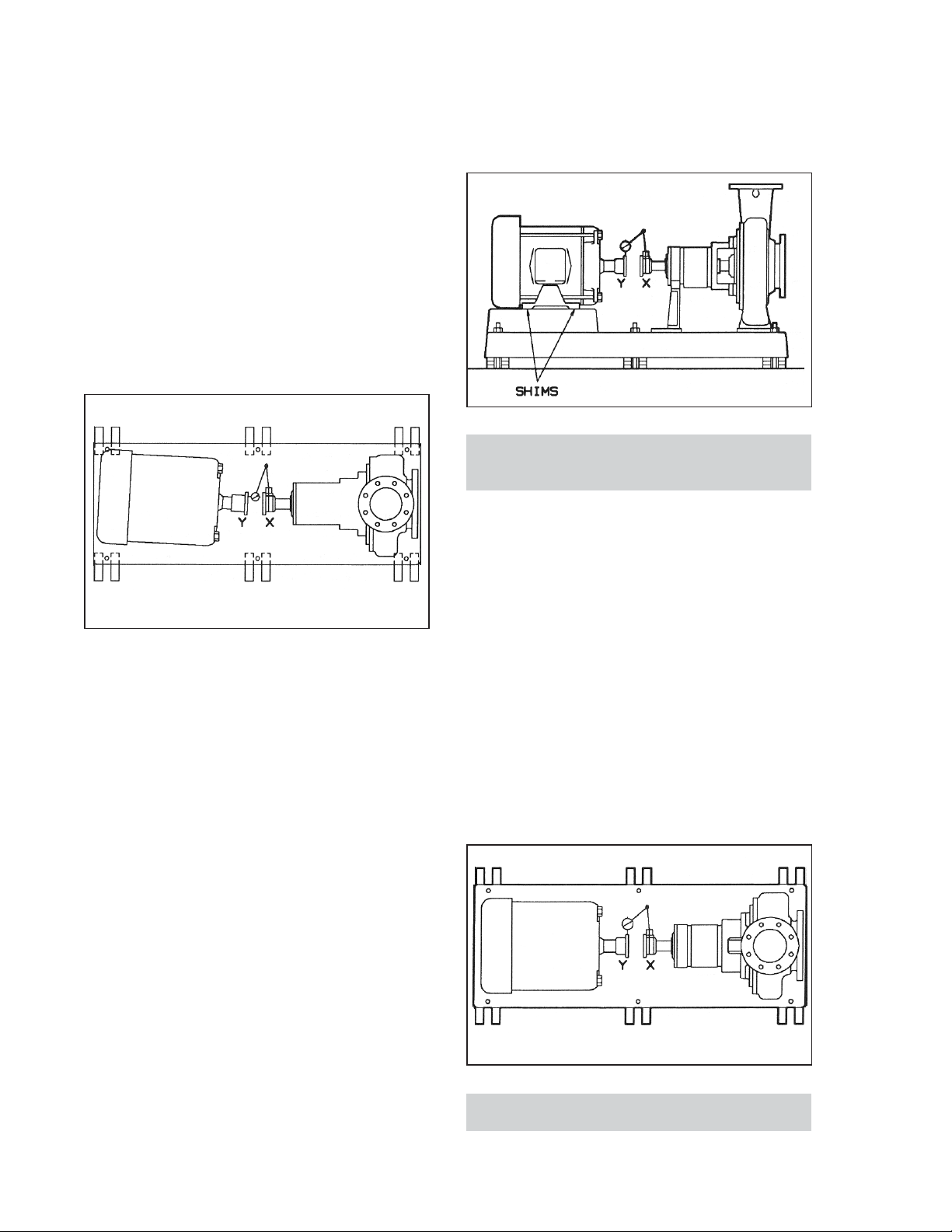

Horizontal Correction (Side to Side)

1. Zero indicator A on left side of coupling half Y,

90° from top dead center (9 o’clock).

2. Rotate indicators through top dead center to the

right side, 180° from the start (3 o’clock). Observe

needle and record reading.

3. Negative Reading - The coupling halves are

further apart on the right side than the left. Correct

by either sliding the shaft end of the driver to the

left or the other end to the right.

Positive Reading - The coupling halves are closer

together on the right side than the left. Correct by

either sliding the shaft end of the driver to the

right or the other end to the left (Fig. 7B).

Positive Reading - Coupling half X is higher than

coupling half Y. Correct by adding shims of

thickness equal to half of the indicator reading

from each driver foot (Fig. 8A).

Fig. 8A

NOTE: Equal amounts of shims must be added to

or removed from each driver foot. Otherwise the

vertical angular alignment will be affected.

4. Repeat steps 1 through 3 until indicator P reads

within .002 in. (.05 mm) or less when hot, or per

Table 1 when cold.

Fig. 7B

4. Repeat steps 1 through 3 until indicator A reads

.002 in. (.05 mm) or less.

5. Re-check both horizontal and vertical readings to

ensure adjustment of one did not disturb the other.

Correct as necessary.

PARALLELALIGNMENT

A unit is in parallel alignment when indicator P

(parallel indicator) does not vary by more than .002 in.

(.05 mm) as measured at four points 90° apart at

operating temperature. Note the preliminary cold

setting criteria, Table 1.

Vertical Correction (Top to Bottom)

1. Zero indicator P at top dead center of coupling (12

o’clock) half Y (Fig. 6).

2. Rotate indicator to bottom dead center

(6 o’clock). Observe needle and record reading.

3. Negative Reading - Coupling half X is lower than

coupling half Y. Correct by removing shims of

thickness equal to half of the indicator reading

under each driver foot.

Horizontal Correction (Side to Side)

1. Zero indicator P on the left side of coupling half

Y, 90° from top dead center (9 o’clock).

2. Rotate indicators through top dead center to the

right side, 180° from the start. Observe needle and

record reading (3 o’clock).

3. Negative Reading - Coupling half Y is to the left

of coupling half X. Correct by sliding driver

evenly in the appropriate direction (Fig. 8B).

Positive Reading - Coupling half Y is to the

right of coupling half X. Correct by sliding driver

evenly in the appropriate direction.

Fig. 8B

NOTE: Failure to slide motor evenly will affect

horizontal angular correction.

14 3296 M Group 6/05

Page 19

4. Repeat steps 1 through 3 until indicator P reads

.002 in. (.05 mm) or less.

5. Re-check both horizontal and vertical readings to

ensure adjustment of one did not disturb the other.

Correct as necessary.

COMPLETE ALIGNMENT

A unit is in complete alignment when both indicators

A (angular) and P (parallel) do not vary by more than

.002 in. (.05 mm) as measured at four points 90° apart.

Vertical Correction (Top to Bottom)

1. Zero indicators A and P at top dead center

(12 o’clock) of coupling half Y.

2. Rotate indicator to bottom dead center

(6 o’clock). Observe the needles and record the

readings.

Alignment Troubleshooting

PROBLEM PROBABLE CAUSE REMEDY

Cannot obtain horizontal

(Side-to-Side) alignment, angular

or parallel

Cannot obtain vertical (Top to

Bottom) alignment, angular or

parallel

Driver feet bolt bound

Baseplate not leveled

properly, probably twisted.

Baseplate not leveled

properly, probably bowed.

3. Make corrections as outlined previously.

Horizontal Correction (Side to Side)

1. Zero indicators A and P on the left side of

coupling half Y, 90° from top dead center

(9 o’clock).

2. Rotate indicators through top dead center to

the right side, 180° from the start (3 o’clock).

Observe the needle, measure and record the

reading.

3. Make corrections as outlined previously.

4. Recheck both vertical and horizontal readings to

ensure adjustment of one did not disturb the other.

Correct as necessary.

NOTE: With experience, the installer will

understand the interaction between angular and

parallel and will make corrections appropriately.

Table 2

Loosen pump hold down bolts and slide pump and driver

until horizontal alignment is achieved.

Determine which corner(s) of the baseplate are high or low

and remove or add shims at the appropriate corner(s) and

realign.

Determine if center of baseplate should be raised or lowered

and correct by evenly adding or removing shims at the center

of the baseplate.

3

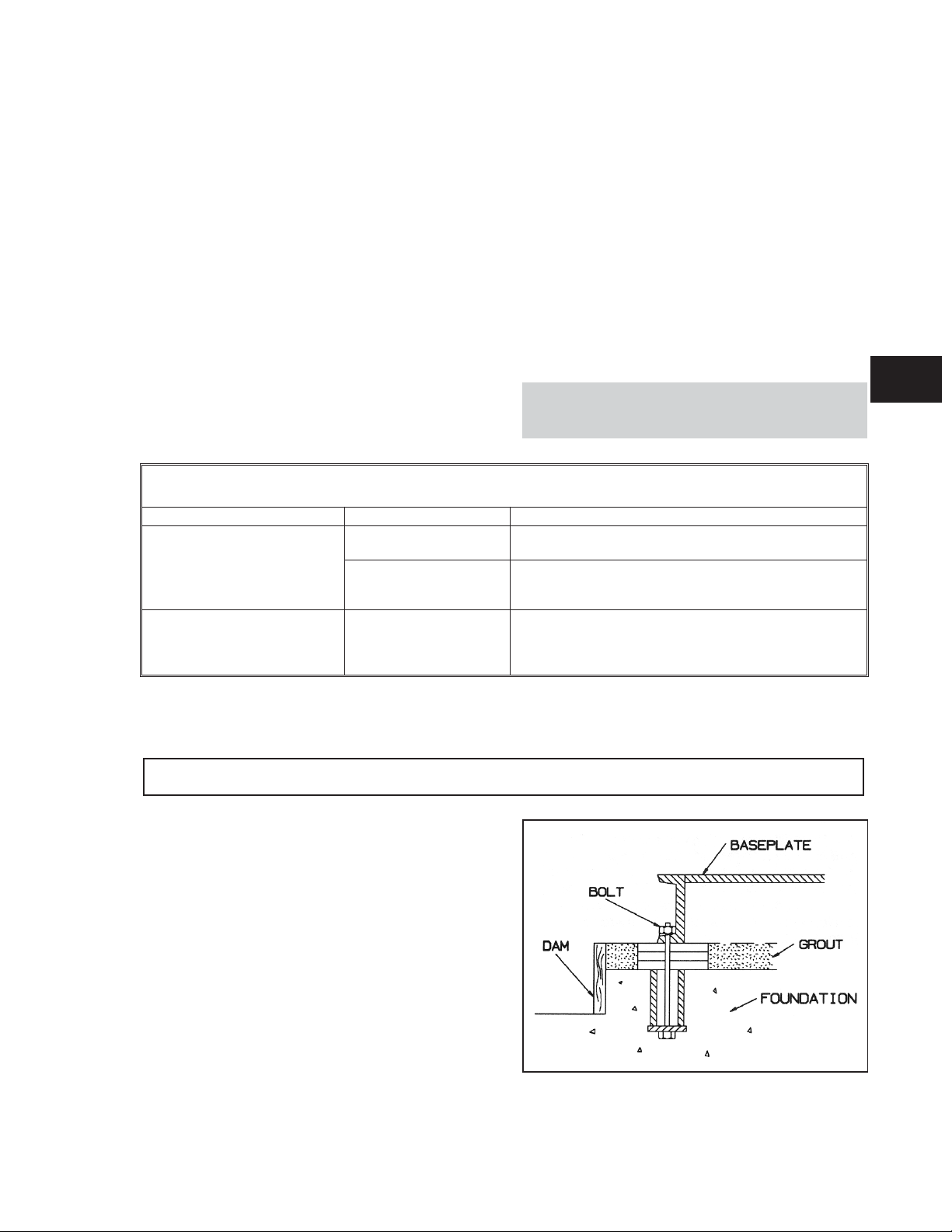

GROUT BASEPLATE

1. Clean areas of baseplate that will contact grout.

Do not use an oil-based cleaner because grout will

not bond to it.

2. Build a dam around foundation (Fig. 9A).

Thoroughly wet foundation.

3. Pour grout slowly through grout holes in

baseplate, until level with the top of the dam. The

use of non-shrink epoxy grout is recommended,

follow manufacturers recommendations. If

cementitious grout is used, remove air by puddling

or with a vibrator (Fig. 9A).

Fig. 9A

3296 M Group 6/05 15

Page 20

4. Allow grout to set.

6. Allow grout to set at least 48 hours.

5. Fill remainder of baseplate with grout. Remove air

as before (Fig. 9B).

Fig. 9B

PIPING

Guidelines for piping are given in the “Hydraulic

Institute Standards” (Edition 14, Centrifugal pump

section) and should be reviewed prior to pump

installation.

1. All piping must be supported independently and

must line up naturally with the pump flanges.

! WARNING

s

Never draw piping into place by forcing at the

flanged connections of the pump. This will impose

dangerous strains on the unit and cause

misalignment between pump and driver. Pipe

strain can adversely effect the operation of the

pump. That could result in serious personal injury

and damage to equipment.

2. Piping runs shall be designed to minimize friction

losses.

3. DO NOT make final connection of piping to pump

until grout has hardened and pump and driver

hold-down bolts have been tightened.

7. Tighten foundation bolts.

Alignment Check

Re-check alignment before continuing, using methods

previously described.

7. Gasket installation and materials must be suitable

for the service.

SUCTION PIPING

Properly installed suction piping is a necessity for

trouble free pump operation. Suction piping should be

flushed BEFORE connection to the pump.

1. Use of elbows close to the pump suction flange

should be avoided. There should be a minimum of

2 pipe diameters of straight pipe between the

elbow and suction inlet. Any elbows used should

be long radius.

2. Size suction pipe one or two sizes larger than

pump suction, with a reducer at suction flange.

Suction piping must never be of smaller diameter

than the pump suction.

3. Reducers, if used, must be eccentric at pump

suction flange with sloping side down.

4. Piping that handles hot liquids requires proper

installation of expansion loops/joints so that linear

expansion of piping will not cause mis-alignment.

5. Piping should be arranged to allow pump flushing

and draining prior to the removal of pump for

servicing.

6. System should be thoroughly cleaned prior to

installation.

4. Suction strainers, when used, must have a net

“free area” of at least three times the suction pipe

area.

5. Separate suction lines are recommended when

more than one pump is operating from the same

source of supply.

16 3296 M Group 6/05

Page 21

Suction Lift Conditions

1. Suction pipe must continuously slope upward

towards pump suction to eliminate air pockets.

2. All joints must be air tight.

FINAL PIPING CHECK

After Connecting Piping to the Pump

1. Rotate shaft several times by hand to be sure that

there is no binding and all parts are free.

3. A means of priming the pump must be provided,

such as a foot valve.

Suction Head/Flooded Suction Conditions

1. An isolation valve should be installed in suction

line to permit closing of the line for pump

inspection and maintenance.

2. Piping should be level or slope gradually

downward from source of supply.

3. No portion of piping should extend below pump

suction flange.

4. The suction pipe shall be submerged sufficiently

below the liquid surface to prevent vortices and air

entrainment at the supply.

DISCHARGE PIPING

1. Isolation and check valves should be installed in

discharge line. Locate check valve between

isolation valve and pump which will permit

inspection of check valve. An isolation valve is

required for isolating, priming, regulation of flow,

inspection and maintenance of the pump. A check

valve prevents pump damage due to reverse flow

when driver is turned off.

2. Check alignment, per the alignment procedure

outlined previously to determine absence of pipe

strain. If pipe strain exists, correct piping.

3

2. Increasers, if used, should be placed between

pump and check valves.

3. Cushioning devices should be used to protect

pump from surges and water hammer, if

quick-closing valves are installed in system.

3296 M Group 6/05 17

Page 22

18 3296 M Group 6/05

Page 23

OPERATION

PREPARATION FOR START-UP ......................19

Flushing Pump ................................................19

Checking Rotation .............................................19

Couple Pump and Driver ........................................20

Install Coupling Guard ..........................................20

Lubricating Bearings............................................20

Connect Condition Monitoring Devices .............................20

Priming Pump .................................................20

STARTING PUMP ...............................21

OPERATION ..................................21

General Considerations ..........................................21

Operating at Reduced Capacity ...................................21

Operating Under Freezing Conditions ..............................21

SHUTDOWN ..................................22

FINAL ALIGNMENT .............................22

4

PREPARATION FOR START-UP

FLUSHING PUMP

The 3296 is flushed with Ethylene Glycol Solution at

the factory to prevent accidental freezing during

shipping or storage at the customers site. Residual

amounts will remain in the pump but if this is a

problem, the 3296 can be flushed out following the

below procedure before pump is installed.

Procedure

3

1. Remove

flush liquid supply.

2. Devise a means of collecting flush liquid as it

drains out the suction nozzle or casing drain if

supplied.

3. Turn flush supply on and run for 5 minutes to

remove Ethylene Glycol residue.

4. When done, raise the coupling end of the pump

(suction flange down) to drain remaining flush

liquid from pump internals. Or, if pump is

equipped with a casing drain plug, remove it to

drain remaining liquid.

" NPT plug (408A) and connect clean

8

! WARNING

s

Failure to properly lift and support equipment

could result in serious injury or damage to pumps.

5. Replace any plugs removed and continue

preparation for start up.

CHECKING ROTATION

! CAUTION

l

Serious damage may result if pump is run in the

wrong rotation.

1. Lock out power to driver.

! WARNING

s

Lock out driver power to prevent accidental

start-up that could result in serious personal

injury.

2. Make sure coupling spacer is removed and

coupling hubs are fastened tightly to the shafts and

are not loose.

3296 M Group 6/05 19

Page 24

NOTE: Pump is shipped with coupling spacer

removed.

3. unlock driver power.

4. Make sure everyone is clear. Jog driver just long

enough to determine direction of rotation.

Rotation must correspond to arrow on bearing

frame.

Pure Oil Mist Lubrication - Pure oil mist is an

optional feature for the 3296. If your pump is equipped

with pure oil mist refer to oil mist generator

manufacturer’s instruction book for proper operation.

! WARNING

s

Operation of the unit without proper lubrication

will cause bearing failure, and pump seizure.

5. Lock out power to driver.

COUPLE PUMP AND DRIVER

! WARNING

s

Lock out driver power to prevent accidental

start-up that could result in serious personal

injury.

Lubricate coupling per manufacturer’s instructions and

install coupling spacer.

INSTALL COUPLING GUARD

Install coupling guard as defined in the appendix.

! WARNING

s

Never operate a pump without a coupling guard

properly installed. Operating pump without a

properly installed coupling guard can result in

serious personal injury.

LUBRICATING BEARINGS

Flood Oil Lubrication - Pumps are shipped without

oil. Fill bearing frame with oil, through filler

connection until oil level reaches center of sight-glass

(Fig A). A high quality turbine type oil, with rust and

oxidation inhibitors should be used as specified in

Table 5.

CONNECT CONDITION

MONITORING DEVICES

Always connect thermocouple to control panel and/or

temperature switch in driver starter. If unit is also

equipped with leak detection and vibration monitoring

systems, these must also be connected. (See Appendix

for wiring diagrams.)

PRIMING PUMP

Never start pump until properly primed (pump casing and

suction piping are full of liquid). Components such as

internal sleeve bearings depend on liquid for lubrication and

will quickly fail if run dry.

Your particular system conditions will dictate method

used to prime pump.

Fig. A

20 3296 M Group 6/05

Page 25

STARTING PUMP

1. Make sure suction valve and any recirculation or

cooling lines are open.

2. Fully close or partially open discharge valve as

dictated by system conditions.

3. Start driver.

! CAUTION

l

Immediately observe pressure gauges. If discharge

pressure is not quickly attained - stop driver,

reprime and attempt to restart.

4. Slowly open discharge valve until the desired flow

is obtained.

OPERATION

GENERAL CONSIDERATIONS

Always vary capacity with valve in discharge line.

NEVER throttle flow from suction side.

Driver may overload or magnets de-couple if pumpage

specific gravity (density) is greater than originally

assumed, or rated flow rate is exceeded.

Always operate the pump at or near the rated

conditions to prevent damage resulting from cavitation

or recirculation.

! CAUTION

l

Do not operate above rated temperature range of

magnets as this will weaken or ruin the magnets.

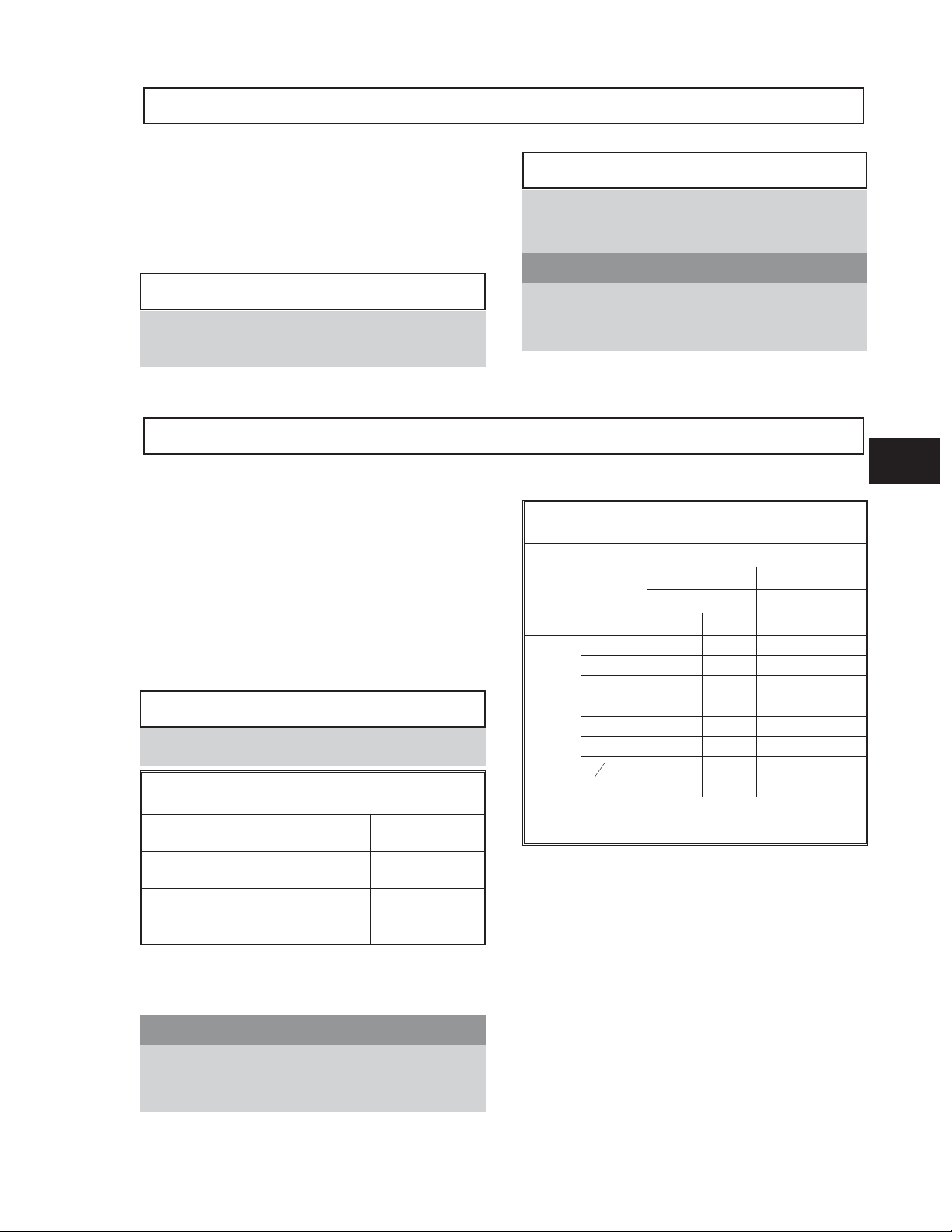

Table 3

Temperature Ratings

Magnetic Types

Neodymium Iron

NdFe

Samarium

Cobalt

SmCo

Drive

Designation

A,B,C,D,E,F 250°F (120°C)

AA,BB,CC,DD,

EE,FF

OPERATING AT REDUCED

CAPACITY

Rated

Temperature

425°F (220°C)

! CAUTION

l

Continuous operation against closed discharge

valve will cause pump to overheat. Overheating

the magnetic drive assembly will weaken or ruin

the magnets.

! WARNING

s

Continuous operation against closed discharge

valve may vaporize liquid creating an explosive

hazard due to confined vapor under high pressure

and temperature.

Table 4

Minimum Allowable Flow

Minimum Flow*

60 Hertz 50 Hertz

Pump

Group

M

* Based on water with a specific Gravity of 1.0 and

Specific Heat of 1.0

Size

2x3-8 60 32 11 6

3x4-8 - 112.5 40 23

3x4-8G 150 75 30 14

1x2-10 17 8.5 3 1.6

2x3-10 80 44 16 8

3x4-10H - 150 - 28

1

x3-13 - 41 - 8

1

2

2x3-13 - 80 - 15

GPM m

3600 1800 2900 1500

3

/h

OPERATING UNDER

FREEZING CONDITIONS

Exposure to freezing conditions, while pump is idle,

could cause liquid to freeze and damage the pump.

Liquid inside pump should be drained. Liquid inside

cooling coils, if supplied, should also be drained.

4

! WARNING

s

Do NOT operate pump below minimum rated flows or

with discharge valve closed. These conditions may

vaporize liquid creating an explosive hazard due to

confined vapor under high pressure and temperature.

3296 M Group 6/05 21

Page 26

SHUTDOWN

1. Slowly close discharge valve.

2. Shut down and lock out driver to prevent

accidental rotation.

FINAL ALIGNMENT

1. Run the unit under actual operating conditions for

a sufficient length of time to bring the pump and

driver up to operating temperature.

! WARNING

s

When handling hazardous and/or toxic fluids,

skin, eye and respiratory protection are required.

If pump is being drained, precautions must be

taken to prevent injury or environmental

contamination. Pumpage must be handled and

disposed of in conformance with applicable

environmental regulations.

2. Check and reset alignment per alignment

procedure outlined earlier.

3. Reinstall coupling guard per instruction in

appendix.

22 3296 M Group 6/05

Page 27

PREVENTIVE MAINTENANCE

GENERAL COMMENTS ...........................23

MAINTENANCE SCHEDULE ........................23

MAINTENANCE OF BEARINGS ......................24

TROUBLESHOOTING ............................25

GENERAL COMMENTS

A routine maintenance program can extend the life of your pump. Well maintained

equipment will last longer and require fewer repairs. You should keep maintenance

records, this will help pinpoint potential causes of problems. A sample form is in

the appendix that can be copied and used for this purpose.

MAINTENANCE SCHEDULE

5

Routine Maintenance

l

Bearing lubrication

l

Temperature monitoring

l

Vibration analysis

l

Discharge pressure

Routine Inspections

l

Check level and condition of oil through sight glass

on bearing frame.

l

Check for unusual noise, vibration, and bearing

temperatures.

l

Inspect pump and piping for leaks.

3 Month Maintenance

l

Check foundation hold down bolts of motor and

pump for tightness.

l

Change oil per section V-C.

l

Check alignment per section III-B.

Yearly Inspections

l

Check pump capacity, pressure, and power. If the

pump performance does not satisfy your process

requirements, the pump should be disassembled and

inspected. Worn parts should be replaced.

3296 M Group 6/05 23

Page 28

MAINTENANCE OF BEARINGS

OIL LUBRICATED BEARINGS

Oil level is measured through sight glass. Oil level

must not fall below center of site glass. An increase in

level may be noted after start up due to oil circulation

within the bearing frame. Change Oil after 200 hours

for new bearings, thereafter every 4000 operating

Bearing Frame Lubrication Requirement

Pumpage Temp. of

Oil Grades

ISO Grade VG 68 Synthetic VG 68

Approximate SSU

100°F (38°C)

DIN 51517 C 68 Synthetic C68

Kenematic Viscosity at 40°C

(105°F)

2

(mm

/sec)

Acceptable

less than 325°F (160°C)

Exxon Teresstic EP 68

Chevron GTS Oil 68

Mobil DTE 26

Gulf Harmony 68

Shell Tellus Oil 68

Phillips Mangus Oil 315

Phillips MM SAE 20-20W

Phillips HDS SAE 20-20W

hours or 6 months, which ever period is shorter.

Change oil every 2000 operating hours under severe

operating conditions, such as high temperature services

[pumpage temperatures in excess of 325°F (160°C)].

We recommend using Table 5 to help determine your

lubricating oil needs.

Table 5

Pumpage Temp. of

325° - 375°F

(160° - 190C°)

with bearing frame cooling

300 Synthetic 300

68 Synthetic 68

Pumpage Temp. of

greater than 375°F

(190°C)

with bearing frame cooling

Royal Purple Synfilm 68

NOTE: This is a list of oils that meet the lubrication requirements of this pump. It is not intended to be an

endorsement of products listed nor exclude other oils that meet these requirements.

24 3296 M Group 6/05

Page 29

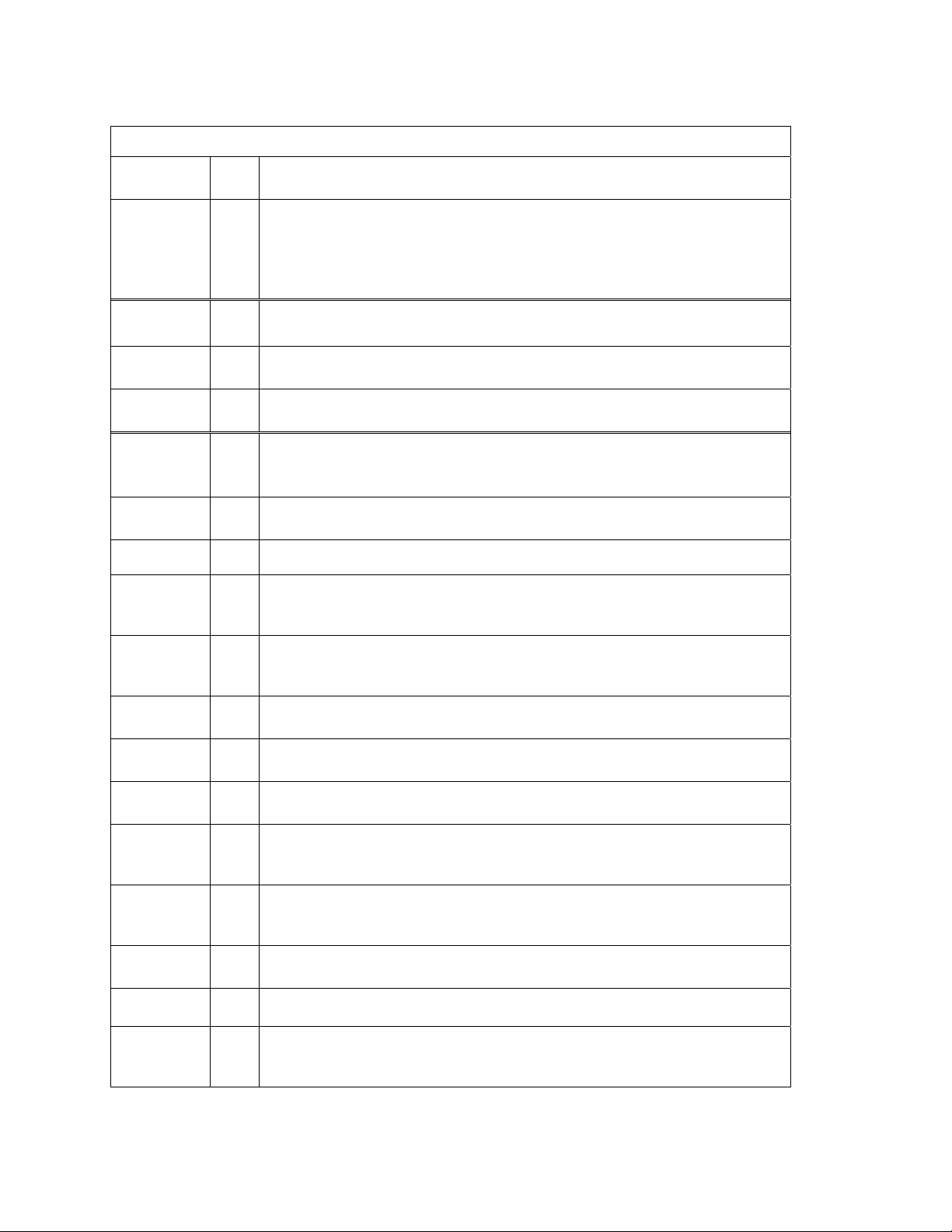

Table 6

Troubleshooting Pump

PROBLEM /

MALFUNCTION PROBABLE CAUSE REMEDY

No liquid delivered

Pump not

producing rated

flow or head

Pump starts then

stops pumping

Pump not primed.

Suction line clogged.

Impeller clogged with foreign material. Disassemble and remove blockage.

Magnet de-coupling

Air leak in suction line Check for leakage and correct.

Impeller partly clogged Back flush pump to clean impeller

Worn impeller rings Replace defective part as required

Insufficient suction head

Worn or broken impeller Inspect and replace if necessary

Improperly primed pump Reprime pump

Air leak in suction line Check for leakage and correct

Magnet de-coupling

Air or vapor pockets in suction line

Reprime pump, check that pump and

suction line are full of liquid.

Check suction line pressure. If low,

locate and remove obstructions.

Shut down. Check temperature and

viscosity of pumpage. Check magnets

with breakaway torque test.

Ensure that suction line shutoff valve is

fully open and line is unobstructed.

Check suction pressure

Shut down. Check temperature and

viscosity of pumpage. Check magnets

with breakaway torque test.

Rearrange piping as necessary, to

eliminate air pockets

Bearings run hot

Pump is noisy or

vibrates

Improper lubrication Check lubricant for suitability and level

Lube cooling Check cooling system

Improper alignment Check pump alignment

Improper pump/driver alignment Align shafts

Partly clogged impeller causing

imbalance

Broken or bent impeller or shaft Replace as required

Base not rigid enough

Worn bearings Replace

Suction or discharge piping not

anchored or properly supported

Pump is cavitating Increase NPSH available.

Disassemble and remove blockage

Tighten hold down bolts of pump and

motor or adjust stilts. Check grout.

Anchor per Hydraulic Institute Standards

recommendations (Edition 14, Centrifugal pump

section).

3296 M Group 6/05 25

Page 30

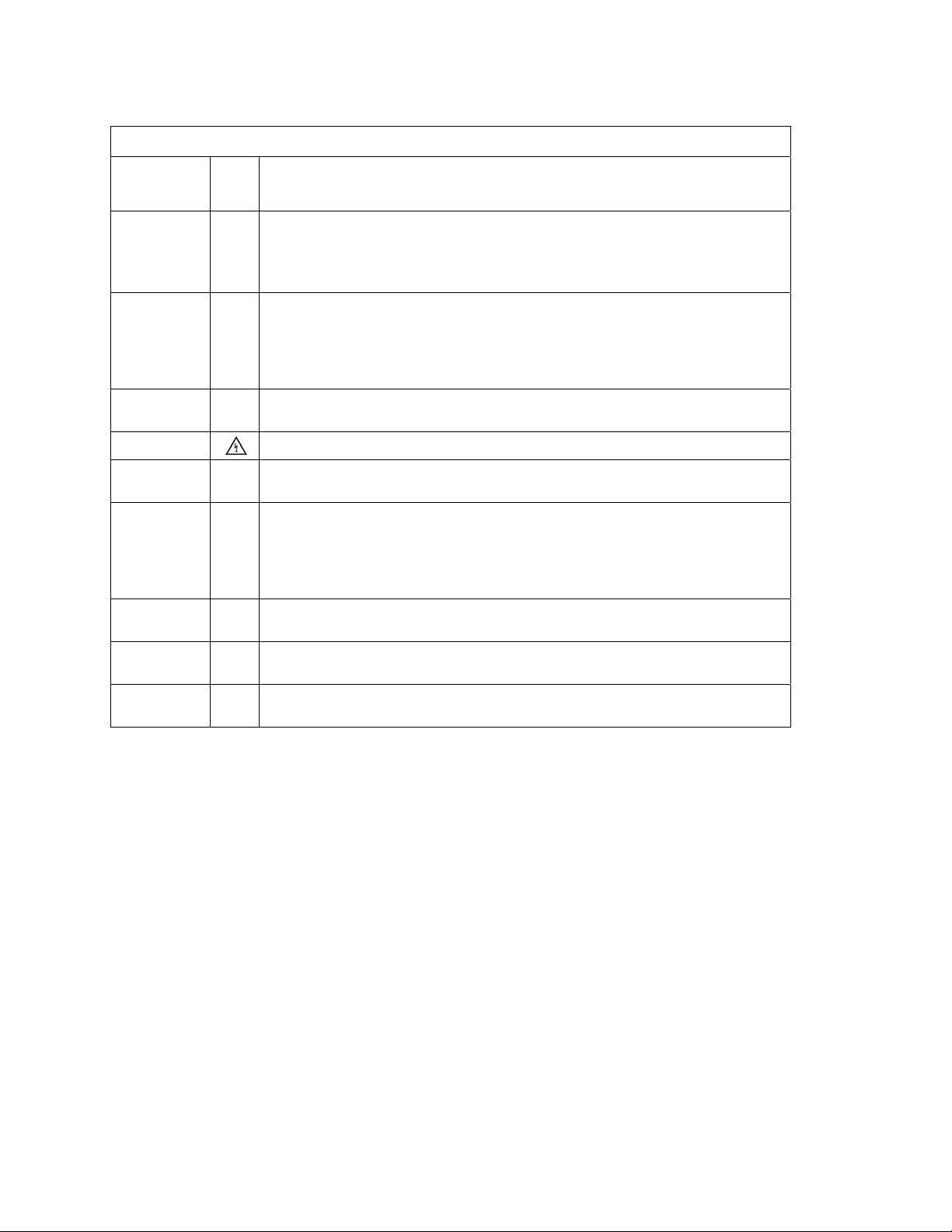

Table 6

Troubleshooting Pump

PROBLEM /

MALFUNCTION PROBABLE CAUSE REMEDY

Motor requires

excessive power

Condition

monitoring device

shuts down pump

Head lower than rating. Pumps too much

liquid

Liquid heavier than expected. Check specific gravity and viscosity.

Head higher than rating, capacity at

rating

Rotating parts binding or severly worn

Damaged sleeve & thrust bearings Replace as required.

Plugged recirculation circuit

Recirculation liquid vaporization

Damaged containment shell Replace as required.

Magnets decoupled

Pump run dry

Excessive motor power

Install throttle valve.

Check impeller diameter.

Check internal wearing parts for proper

clearances.

Disassemble and remove blockage. Determine and

correct cause of blockage.

Check actual liquid temperature versus design

temperature. Check actual NPSH available versus

design. Check minimum flow requirement for pump

size. Check recirculation circuit and flush screen for

blockage. Correct all as necessary.

Check temperature and viscosity of pumpage. Check

magnets with breakaway torque test.

Check control device for proper operation. Check

suction line for blockage. Reprime pump.

System head lower than rating. Pumps too much liquid.

Check rotating parts for binding and wear. Liquid

heavier than expected.

26 3296 M Group 6/05

Page 31

DISASSEMBLY & REASSEMBLY

REQUIRED TOOLS ..............................27

PREPARATION FOR DISASSEMBLY ...................29

DISASSEMBLY.................................29

INSPECTIONS .................................36

Casing .......................................................36

Wear Ring Clearances...........................................36

Impeller......................................................37

Flush Screen ..................................................37

Frame Adapter ................................................37

Silicon Carbide Bearings ........................................38

Containment Shell..............................................38

Magnets......................................................38

Bearing Frame.................................................38

REASSEMBLY .................................39

SECTIONALS, PARTS LIST, MATERIALS OF CONSTRUCTION ....50

REQUIRED TOOLS

! WARNING

s

This pump contains extremely strong magnets. The

use of non-magnetic tools and work surface are

required.

Non-Magnetic Tools

l

1-5/16" Socket wrench with 6" minimum extension

l

9/16" Socket wrench with speed handle

Tools

NOTE: Keep magnetic tools away from magnets.

l

3296 Tool Kit

l

Assorted Open end wrenches

l

3/4", 15/16" sockets

l

Socket wrench with minimum 4" minimum

extension

l

Needle nose pliers

l

Torque wrench

l

Screw drivers

l

1/2", 5/8" stud drivers

l

Lip seal driver

l

Non-metallic hammer

l

Hammer

l

Heat gun

l

Non-Magnetic Support blocks

3296 M Group 6/05 27

Page 32

Table 7

3296 M Tool Kit #R296TK01

Tool Use Qty Tool Number Mat’l

A

B O-ring Installation Tool 1 A03817A Nylon

C Shaft Wrench 1 A01676A 304SS

D

E Sleeve Bearing Driver 1 A03817A Nylon

Bearing Frame Jacking Screw

Drive Carrier Jacking Screws

Wear Ring Jacking Screw

Wear Ring Alignment Screw

End Cover Jacking Screw

4 A03777A02 304SS

3 49521 61 304SS

28 3296 M Group 6/05

Page 33

PREPARATION FOR DISASSEMBLY

! WARNING

s

The 3296 usually handles hazardous and/or toxic

fluids. Skin, eye and respiratory protection

required. Precautions must be taken to prevent

injury or environmental contamination.

! WARNING

s

If pump has failed, pumpage may be present in the

area between the adapter and the frame and also

inside of the bearing frame.

1. Lock out power to driver.

2. Shut off all valves controlling flow to and from pump.

3. Drain and decontaminate pump in accordance with

all Federal, State, local and company regulations.

The 3296 should be drained and thoroughly flushed

before it is removed from the piping. After isolating

the pump from the system flush the pump using a

compatible liquid.

DISASSEMBLY

! WARNING

s

Ensure pump is isolated from system and pressure

is relieved before any plugs are removed or piping

disconnected.

4. To decontaminate pump recirculation path,

remove plug 408A and inject flush into external

flush connection.

5. Disconnect all piping and auxiliary equipment.

6. Remove coupling guard.

7. Remove coupling.

NOTE: If the only service required is to change

the impeller, the flush screen or the wear ring,

please refer to the appendix “Changing the

Impeller”.

8. Remove casing foot and bearing frame foot bolts.

9. Remove bare pump from baseplate and take to shop.

! WARNING

s

Each component must be individually

decontaminated using procedures in accordance

with all federal, state, local and company

environmental regulations.

! WARNING

s

The magnets contained in this unit are extremely

powerful. Keep magnetic drive components and

magnetic tools apart from each other by a

minimum of six (6) feet [two (2) meters]. Serious

injury to fingers and hands will result.

NOTE: When working on pump use a bench with

a non-magnetic work surface such as wood with a

brass surface.

! CAUTION

l

The shop area must be clean and free of any

substances that would contaminate the magnets,

ex. ferrous metals.

1. Remove thermocouple (758B) (Fig. A).

2. Remove casing nuts (425). Remove casing (100)

(Fig. A).

3. Remove casing gasket (351) and discard

(Fig. A).

4. Place shaft wrench on coupling end as shown.

Remove impeller bolt (198), impeller lockwasher

(199A) and impeller washer (199) (Fig. B).

3296 M Group 6/05 29

Page 34

5. Place unit in vertical position resting on

non-magnetic blocks (Fig. C).

! WARNING

s

Pump and some individual components weigh

more than 50 lbs (23 kg). Care should be taken

when handling.

6. Remove frame adapter bolts (370) (Fig. C).

! WARNING

s

Do NOT attempt to remove bearing frame (228)

without using the jacking screws. Personal injury

and damage to the magnets will occur.

8. Evenly tighten bearing frame jacking screws until

bearing frame (228) is above containment shell

(750) as shown. Lift bearing frame (228) off

frame adapter (108) and set aside away from

attracting metals.

Use of a lifting device with a strap through two

opposite eyes in the jacking screws is

recommended.

Remove adapter to frame gasket (360W) and

discard (Fig. E).

! WARNING

s

The magnets contained in this unit are extremely

powerful. Keep magnetic drive components and

magnetic tools apart from each other by a

minimum of six (6) feet [two (2) meters]. Serious

7. Remove bearing frame using four (4) jacking

screws (Fig. D).

injury to fingers and hands will result.

! WARNING

s

This component can weigh more than

50 lbs (23 kg). Care should be taken when

handling.

30 3296 M Group 6/05

Page 35

9. Remove clamp ring screws (370B) and lock

washers (136A) (Fig. F).

NOTE: Place a folded clean cloth or cardboard

under frame adapter assembly to soften impact of

driven magnet assembly (740A) on work surface.

Shaft and magnet assembly should rest on work

surface.

13. Remove impeller (101) (Fig. H).

NOTE: It may be necessary to use a puller. Puller

must be placed under vanes so as not to damage

the impeller.

! WARNING

s

Use non-magnetic socket and speed wrench to

avoid personal injury or damage to parts.

10. Remove clamp ring (141C) and containment shell

(750) simultaneously (Fig. F).

11. Remove O-ring (412M) and discard (Fig. F).

12. Orient frame adapter assembly in vertical position

and support on blocks (Fig. G).

14. Press driven shaft (122A) out until it disengages

(Fig. I).

NOTE: Light tapping with a non-metallic

hammer may be necessary to disengage shaft.

3296 M Group 6/05 31

Page 36

! WARNING

s

The magnets contained in this unit are extremely

powerful. Keep magnetic drive components and

magnetic tools apart from each other by a

minimum of six (6) feet [two (2) meters]. Serious

injury to fingers and hands will result.

15. Lift frame adapter (108) off shaft (122). Set aside.

18. Press driven shaft (122A) out of driven magnet

assembly (740A). Remove key (178X) (Fig. K).

19. Wrap driven magnet assembly (740A) in a clean

cloth to keep clean and set aside away from

attracting metals.

! WARNING

s

The magnets contained in this unit are extremely

powerful. Keep magnetic drive components and

magnetic tools apart from each other by a

minimum of six (6) feet [two (2) meters]. Serious

injury to fingers and hands will result.

NOTE: Outboard rotary sleeve bearing will

remain on shaft.

! WARNING

s

This component can weigh more than 50 lbs (23

kg). Care should be taken when handling.

16. Remove thrust bearing holder key from shaft

(178S) (Fig. J).

17. Remove outboard rotary sleeve bearing (117C)

and two spacer gaskets (360). Discard spacer

gaskets (Fig. J).

178S

20. Remove and discard four shaft O-rings (497P)

(Fig. L). Set shaft aside.

21. Place frame adapter (108) on work bench as

shown. Remove wear ring bolts (353B) and flush

screen (187) (Fig. M).

32 3296 M Group 6/05

Page 37

22. Place wear ring jacking screws in threaded jacking

screw holes in wear ring (144) as shown. Tighten

bolts evenly and in sequence until wear ring (144)

can be removed (Fig. N).

NOTE: Do not over tighten jacking bolts. Tighten

until snug and move to next one in sequence.

23. Remove wear ring (144) and stationary bearing

key (178K) (Fig. N).

25. Set frame adapter (108) on blocks, impeller side

down, and place clean cloth underneath as shown

to absorb impact when bearings drop (Fig. P).

! CAUTION

l

The bearing material is extremely brittle. Take

every precaution necessary to avoid shock to the

bearings.

26. Press out thrust bearing assembly (212) and

inboard stationary sleeve bearing (117B) using

hand pressure and sleeve bearing driver oriented

as shown (Fig. P).

Jacking Screws

24. Remove inboard rotary sleeve bearing (117D) and

two spacer gaskets (360) (Fig. O). Discard

gaskets.

27. Set aside thrust bearing assemblies (212) and

outboard stationary sleeve bearing (117B).

28. Press outboard stationary sleeve bearing (117A)

out of frame adapter (108) using sleeve bearing

driver oriented as shown (Fig. Q).

Sleeve Bearing

Driver

29. Invert frame adapter (108), impeller end up, and set on

bench. Remove outboard stationary O-rings (496A)

and inboard stationary O-rings (496B). Discard

O-rings (Fig. R).

3296 M Group 6/05 33

Page 38

30. Bolt or clamp bearing frame (228A) to bench

(Fig. S).

31. Place shaft wrench on drive shaft (122B) and

loosen the drive magnet assembly hex nut (355A)

until it can be removed by hand. Leave nut on

shaft for now (Fig. T).

! WARNING

s

Use non-magnetic socket and extension to avoid

personnel injury or damage to parts.

Fig. R

Fig. T

32. Remove two rub ring retaining screws (372Y)

(Fig. U).

33. Thread two rub ring jacking screws into holes

provided in rub ring (144A) until they bottom

(Fig. U).

34. Tighten jacking screws until rub ring can be

removed.

Fig. S

Fig. U

35. Carefully invert bearing frame assembly, drive

magnet assembly up. Clamp firmly to work bench

(Fig. V).

! WARNING

s

This component can weigh more than 50 lbs (23

kg). Care should be taken when handling.

34 3296 M Group 6/05

Page 39

NOTE: A workbench with a two inch hole in the

surface to accommodate the coupling end of shaft

works well (Fig. V).

Fig. V

Fig. W

36. Remove drive magnet assembly nut (355A) from

shaft (Fig. W).

37. Thread the drive carrier jacking screws into holes

provided in drive magnet assembly (740B) until

screws bottom against frame (Fig. W).

38. Tighten jacking screws evenly and in sequence

until drive magnet assembly is free from shaft.

Using a lifting strap through the eyebolts and a

lifting device, raise drive magnet assembly.

Remove from frame and set aside away from

attracting metals (Fig. W).

! WARNING

s

This component can weigh more than 50 lbs (23

kg). Care should be taken when handling.

! WARNING

s

The magnets contained in this unit are extremely

powerful. Keep magnetic drive components and

magnetic tools apart from each other by a

minimum of six (6) feet [two (2) meters]. Serious

injury to fingers and hands will result.

40. Remove bearing end cover bolts (370C) (Fig. X).

41. Install jacking screws in jacking screw holes,

tighten evenly to back off bearing end cover

(109A) (Fig. X).

42. Slide bearing end cover (109M) back. Labyrinth

oil seal (332A) will slide back with end cover

(Fig. X).

43. Remove labyrinth seal (332A) (Fig. X).

44. Remove bearing end cover (109A). Remove

gasket (360A) and discard (Fig. X).

39. Remove drive magnet assembly key (178Y)

(Fig. W).

Fig. X

3296 M Group 6/05 35

Page 40

45. Remove bearing wavewasher (529) from bearing

bore (Fig. Y).

46. Remove drive shaft (122B) with ball bearings

(112) from bearing housing (228) (Fig. Y).

Fig. Y

INSPECTIONS

47. Press bearings (112) off shaft and discard.

48. Remove lip seal (333D) as shown and discard

(Fig. Z).

Fig. Z

Model 3296 parts must be inspected to the following

criteria before reassembly to ensure pump will run

properly. Any part not meeting required criteria should

be replaced.

NOTE: Various tolerances specified on the 3296

are held extremely close, measure parts at standard

temperature 68°F(20°C) to ensure accurate

measurement.

CASING (100)

Casing (100) should be inspected for excessive wear or

pitting. It should be repaired or replaced if it exceeds

the following criteria.

Table 8

Minimum Casing

Thickness

Minimum

Thickness Inches

Group Pump Size

2x3-8

3x4-8

3x4-8G

M

1x2-10

2x3-10

3x4-10H

1

1

x3-13

2

2x3-13

(mm)

0.31 (7.9)

0.31 (7.9)

0.31 (7.9)

0.37 (9.4)

0.37 (9.4)

0.37 (9.4)

0.37 (9.4)

0.37 (9.4)

WEAR RING CLEARANCES

Refer to Table 9 to check wear ring clearances.

36 3296 M Group 6/05

Page 41

Group Size

2x3-8

3x4-8

3x4-8G

1x2-10

M

2x3-10

3x4-10H

1

1

x3-13

2

2x3-13

Table 9

Diametrical Wear Ring Clearance

LOCATION

Ê

Impeller to casing

in. (mm)

New Replace New Replace New Replace New Replace

.024 - .028

(.61 - .71)

.026- .030

(.66 - .76)

.026 - .030

(.66 - .76)

.022 - .026

(.56 - .66)

.026 - .030

(.66 - .76)

.027 - .031

(.69 - .79)

.026 - .030

(.66 - .76)

.026 - .030

(.66 - .76)

.048 (1.22)

.052 (1.32)

.052 (1.32)

.044 (1.12)

.052 (1.32)

.054 (1.37)

.052 (1.32)

.052 (1.32)

Impeller to wear ring

.024 - .028

(.61 - .71)

.026 - .030

(.66 - .76)

.026 - .030

(.66 - .76)

.026 - .030

(.66 - .76)

.026 - .030

(.66 - .76)

.026 - .030

(.66 - .76)

.026 - .030

(.66 - .76)

.026 - .030

(.66 - .76)

Ë

in. (mm)

.048

(1.22)

.052

(1.32)

.052

(1.32)

.052

(1.32)

.052

(1.32)

.052

(1.32)

.052

(1.32)

.052

(1.32)

Driven magnet

to adapter

in (mm)

.024 - .028

(.61 - .71)

Ì

.048 (1.22)

Drive Magnet

to Rub Ring

in (mm)

.067 - .073

(1.70 -

1.85)

Í

.090 (2.29)

IMPELLER (101)

1. Inspect wear ring surface for signs of pitting.

2. Inspect front and back wear ring clearance per

wear ring clearance Table 9.

3. Inspect leading and trailing edges of vanes for

pitting, and erosion or corrosion damage.

4. Check impeller bore and keyway. Bore should

measure .7490 to .7505 in. (19.025 to 19.063 mm).

If oversize, replace impeller.

5. Check impeller balance per Table 10. Values are

based on ISO - 1940/1 grade 2.5 at 3000 RPM.

Table 10

Impeller Balance Specification

Part # Pattern # Part Name oz-inches

C03333A 68455 2x3-8 Impeller .04

C03363A 68491 3x4-8 Impeller .06

C03362A 68490 3x4-8G Impeller .05

C03335A 68456 1x2-10 Impeller .06

C03172A 68325 2x3-10 Impeller .06

C03367A 68457 3X4-10H Impeller .07

C03360A 68358 1.5x3-13 Impeller .09

C03265A 68383 2x3-13 Impeller .09

FLUSH SCREEN (187)

1. Must be clean and free from holes or tears.

2. Inspect for erosion and corrosion.

FRAME ADAPTER (108)

1. Inspect wear ring clearances per clearance Table

9.

2. Check all internal recirculation passages to make

sure they are open and free from excessive wear

due to erosion or corrosion.

3296 M Group 6/05 37

Page 42

SILICON CARBIDE BEARINGS

(117A-D)

Sleeve Bearings

1. Inspect bearings for cracks and chips.

2. Inspect dimensions per Table 11.

Table 11

Bearing Clearances

Group Location

Shaft to Bearing

M

Thrust Bearings (237)

1. Inspect for cracks or chips.

Bearing to

Bearing

Bearing to

Adapter

New Clearance

in. (mm)

.0045 - .0065

(.114 - .165)

.003 - .006

(.076 - .152)

.0015 - .0035

(.038 - .089)

Replace

in. (mm)

.0085

(.216)

.008

(.203)

.0055

(.140)

CONTAINMENT SHELL (750)

1. Wall thickness .050 in. (1.3 mm) minimum.

2. Must be free from pitting or cracks.

3. Grooves in excess of .005 in. (.13 mm) require

containment shell replacement.

MAGNETS (740A & B)

Driven Magnet Assembly (740A)

! WARNING

s

The magnets contained in this unit are extremely

powerful. Keep magnetic drive components and

magnetic tools apart from each other by a

minimum of six (6) feet [two (2) meters]. Serious

injury to fingers and hands will result otherwise.

Drive Magnet Assembly (740B)

! WARNING

s

The magnets contained in this unit are extremely

powerful. Keep magnetic drive components and

magnetic tools apart from each other by a

minimum of six (6) feet [two (2) meters]. Serious

injury to fingers and hands will result otherwise.

NOTE: The magnets are extremely brittle. It is

normal to have chips (up to 10% of the magnet

at

surface) per MMPA standard no. 0100-90.

1. Magnets must be free of major cracks (extending

over 50% of surface) and also free of

imperfections that create loose particles.

2. If magnets and drive magnet carrier were exposed

to product, they should be replaced.

3. Inspect drive magnet carrier for cracks and replace

if any are found.

4. Drive magnet carrier hub O.D. must be free from

grooves and scratches greater than .005 in. (.13

mm).

5. Inspect magnets for proper bonding to metal

carrier.

BEARING FRAME (228)

1. Visually inspect frame and frame foot for cracks.

2. Inspect for corrosion or pitting if frame has been

exposed to pumpage

3. Inspect frame bearing bores. The maximum

acceptable bore is 3.1506 in. (80.025 mm).

4. Inspect ball bearings for contamination and

damage.

1. Must be free from bulges.

2. Must be free of pits and scratches exceeding .005

in. (.13 mm) deep.

3. Must be free of erosion or corrosion exceeding

.005 in. (.13 mm) deep.

4. Inspect wear ring clearance per wear ring

clearance Table 9.

5. Check pump-out vanes for cracks or corrosion.

6. Ensure circulation holes are open.

5. Make sure gasket surfaces are clean.

6. Visually inspect bearing end cover (109A) for

cracks and pits. Gasket surface must be clean.

7. Inspect labyrinth seal O-rings (332A) for cuts and

cracks.

8. Replace lip seal.

38 3296 M Group 6/05

Page 43

REASSEMBLY

Please refer to the Appendix for assembly and

inspection checklist for your convenience. Make a

copy and checkoff parts as they are assembled.

Refer to Table 12 for torque values while reassembling

pump.

Table 12

*Bolt Torque Table

Ft-Lbs (Nm)

Location

Drive Magnet Assy Nut (355A)

Wear Ring Screw (353B)

Clamp Ring Screws (370B)

Impeller Nut (198)

Adapter to Frame Srews (370)

Casing Nuts (425)

* Torque values based on Dry Threads

! WARNING

s

The magnets contained in this unit are extremely

powerful. Keep magnetic drive components and

magnetic tools apart from each other by a

minimum of six (6) feet [two (2) meters]. Serious

injury to fingers and hands will result.

Dry

Threads

120 (160)

17 (25)

12 (16)

45 (60)

50 (70)

45 (60)

3. Place the first spacer gasket (360) over driven

shaft (122A) (Fig. B) and shoulder against driven

magnet assembly.

NOTE: Use new spacer gaskets when

reassembling.

NOTE: Spacer gaskets require care when

handling to avoid damage.

4. Place O-ring installation tool on driven shaft

(122A) and install impeller washer (199) and bolt

(198), hand tighten. Install two outboard shaft

O-rings (497P) (Fig. B).

NOTE: Cover first three O-ring (497P) grooves

with tape before installing O-rings. Remove tape

as necessary to install O-rings (497P). O-rings

may have to be heat shrunk to be fully seated in

O-ring grooves. Do not overheat O-rings

Fig. B

1. Install key (178X) on driven shaft (112A) (Fig.

A).

NOTE: Ensure shaft O-ring, grooves, shaft

keyways and keyway in driven carrier are free of

burrs.

2. Install driven shaft (122A) into driven magnet

assembly (740A) (Fig. A).

5. Put lube on O-rings.

6. Install outboard rotary sleeve bearing (117C) on

driven shaft (122A) using bearing driver (Fig. C).

7. Place the second spacer gasket (360) over driven

shaft (122A). Shoulder against outboard rotary