Page 1

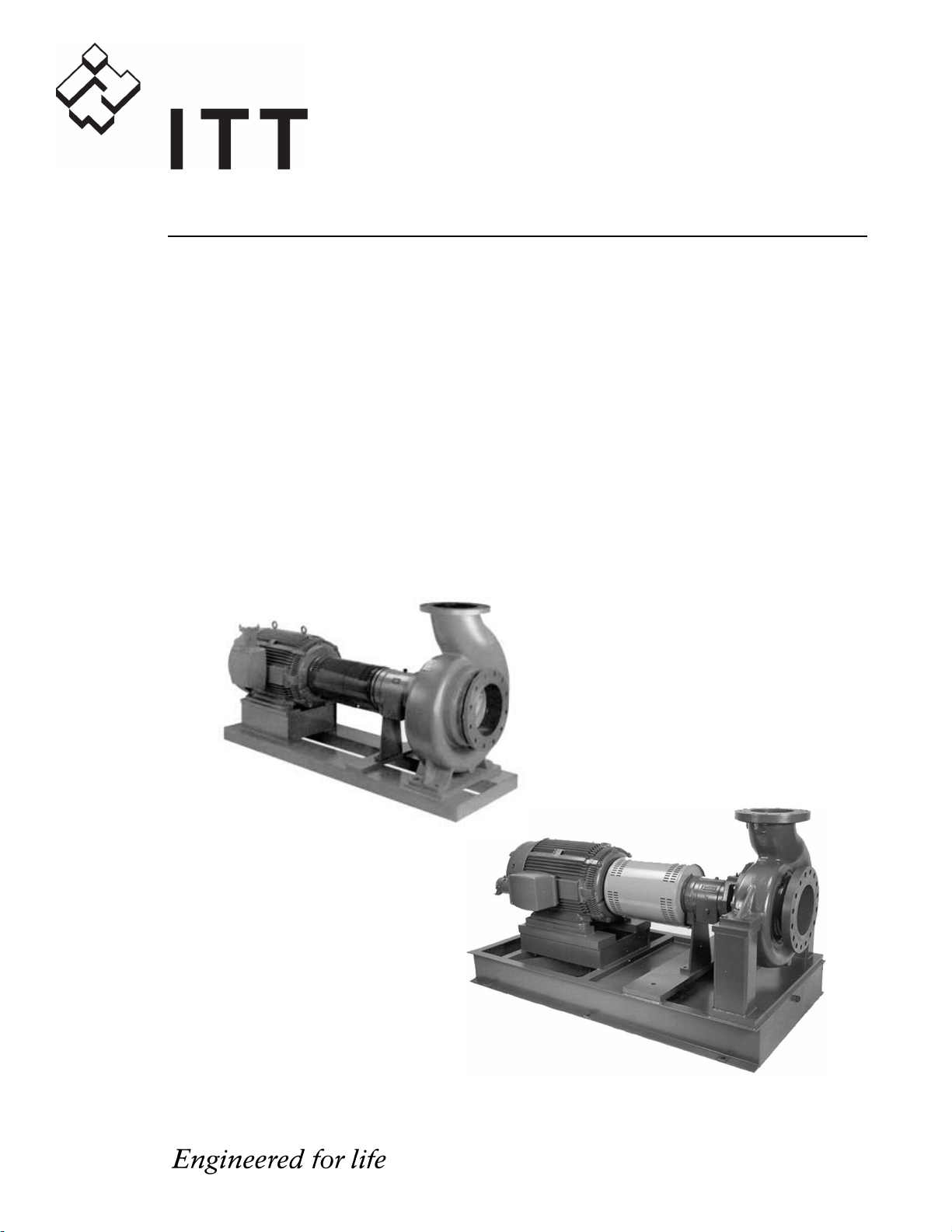

Goulds Pumps

3180 / 3185

3181 / 3186

Installation, Operation, and

Maintenance Manual

Models 3180, 3181, 3185, and 3186

Page 2

Page 3

Table of Contents

Introduction and Safety...................................................................................................................................................4

Introduction.......................................................................................................................................................................4

Requesting other information......................................................................................................................................4

Safety...................................................................................................................................................................................4

Safety terminology and symbols..................................................................................................................................5

Environmental safety.....................................................................................................................................................5

User safety.......................................................................................................................................................................6

Safety regulations for Ex-approved products in potentially explosive atmospheres...........................................8

Product approval standards.............................................................................................................................................9

Product warranty.............................................................................................................................................................10

Transportation and Storage..........................................................................................................................................11

Inspect the delivery.........................................................................................................................................................11

Inspect the package.....................................................................................................................................................11

Inspect the unit.............................................................................................................................................................11

Transportation guidelines...............................................................................................................................................11

Precautions....................................................................................................................................................................11

Pump handling.............................................................................................................................................................11

Lifting methods............................................................................................................................................................11

Storage guidelines............................................................................................................................................................13

Storage location............................................................................................................................................................13

Pump storage requirements........................................................................................................................................13

Frostproofing................................................................................................................................................................14

Table of Contents

Product Description........................................................................................................................................................15

General description.........................................................................................................................................................15

Part description............................................................................................................................................................15

General description i-ALERT™ Condition Monitor................................................................................................18

Nameplate information..................................................................................................................................................18

Installation.........................................................................................................................................................................21

Preinstallation...................................................................................................................................................................21

Pump location guidelines............................................................................................................................................21

Foundation requirements............................................................................................................................................22

Baseplate-mounting procedures....................................................................................................................................22

Prepare the baseplate for mounting..........................................................................................................................22

Install the baseplate using shims or wedges.............................................................................................................23

Install the baseplate using jackscrews.......................................................................................................................23

Spring mounted installation........................................................................................................................................25

Baseplate-leveling worksheet......................................................................................................................................30

Install the pump, driver, and coupling.........................................................................................................................31

Pump-to-driver alignment..............................................................................................................................................31

Alignment checks.........................................................................................................................................................31

Permitted indicator values for alignment checks....................................................................................................32

Alignment measurement guidelines..........................................................................................................................32

Attach the dial indicators for alignment...................................................................................................................32

Pump-to-driver alignment instructions....................................................................................................................33

Grout the baseplate.........................................................................................................................................................36

Bypass-piping considerations........................................................................................................................................36

Piping checklists..............................................................................................................................................................37

General piping checklist..............................................................................................................................................37

Suction-piping checklist..............................................................................................................................................38

Models 3180, 3181, 3185, and 3186 Installation, Operation, and Maintenance Manual 1

Page 4

Table of Contents

Discharge piping checklist..........................................................................................................................................40

Auxiliary-piping checklist............................................................................................................................................41

Final piping checklist...................................................................................................................................................42

Commissioning, Startup, Operation, and Shutdown............................................................................................43

Preparation for startup...................................................................................................................................................43

Remove the coupling guard...........................................................................................................................................43

Check the rotation...........................................................................................................................................................44

Impeller-clearance check................................................................................................................................................44

Impeller axial clearances.............................................................................................................................................44

Check the Shearpeller™ axial clearance....................................................................................................................45

Impeller-clearance setting..............................................................................................................................................45

Set the impeller clearance - dial indicator method .................................................................................................45

Set the impeller clearance - feeler gauge method ...................................................................................................46

Couple the pump and driver..........................................................................................................................................46

Install the coupling guard...........................................................................................................................................47

Bearing lubrication..........................................................................................................................................................49

Oil volumes...................................................................................................................................................................50

Lubricating oil requirements......................................................................................................................................50

Acceptable oil for lubricating bearings.....................................................................................................................50

Lubricate the bearings with oil...................................................................................................................................50

Greased-for-life bearing lubrication..........................................................................................................................51

Shaft-sealing options.......................................................................................................................................................51

Mechanical seal options..............................................................................................................................................51

Connection of sealing liquid for mechanical seals..................................................................................................52

Packed stuffing box option.........................................................................................................................................52

Connection of sealing liquid for a packed stuffing box.........................................................................................52

Seal the shaft with a packed stuffing box.................................................................................................................53

Dynamic-seal option (3180 and 3185 S, M, L, and XL groups only)..................................................................54

Pump priming..................................................................................................................................................................55

Prime the pump with the suction supply above the pump...................................................................................55

Prime the pump with the suction supply below the pump...................................................................................56

Other methods of priming the pump.......................................................................................................................57

Start the pump.................................................................................................................................................................57

Activate the i-ALERT™ Condition Monitor..............................................................................................................58

i-ALERT™ Condition Monitor routine operation....................................................................................................59

Pump operation precautions.........................................................................................................................................59

Shut down the pump......................................................................................................................................................60

Deactivate the i-ALERT™ Condition Monitor..........................................................................................................60

Reset the i-ALERT™ Condition Monitor...................................................................................................................60

Make the final alignment of the pump and driver......................................................................................................60

Maintenance......................................................................................................................................................................62

Maintenance schedule.....................................................................................................................................................62

Bearing maintenance.......................................................................................................................................................63

Lubricating oil requirements......................................................................................................................................63

Lubricating-grease requirements...............................................................................................................................64

Lubricate the bearings after a shutdown period......................................................................................................65

Shaft-seal maintenance...................................................................................................................................................65

Mechanical-seal maintenance.....................................................................................................................................65

Packed stuffing-box maintenance..............................................................................................................................66

Dynamic seal maintenance (3180 and 3185 S, M, L, and XL groups only) .......................................................66

Disassembly......................................................................................................................................................................68

Disassembly precautions.............................................................................................................................................68

Tools required...............................................................................................................................................................68

Drain the pump............................................................................................................................................................68

Remove the back pull-out assembly..........................................................................................................................69

2 Models 3180, 3181, 3185, and 3186 Installation, Operation, and Maintenance Manual

Page 5

Table of Contents

Remove the casing wear ring (S, M, L, and XL)......................................................................................................71

Remove the casing wear ring (for XL1, XL2-S, and XL2)....................................................................................71

Remove the suction sideplate.....................................................................................................................................72

Impeller removal..........................................................................................................................................................73

Remove the stuffing box cover..................................................................................................................................76

Remove the TaperBore PLUS™ seal chamber........................................................................................................78

Remove the dynamic seal............................................................................................................................................80

Remove the frame adapter from the frame (XL1, XL2-S, and XL2)...................................................................81

Disassemble the bearing frame..................................................................................................................................81

Guidelines for i-ALERT™ Condition Monitor disposal.......................................................................................83

Disassemble the spring-mounted baseplate (second generation).........................................................................83

Preassembly inspections.................................................................................................................................................85

Replacement guidelines...............................................................................................................................................85

Bearing-frame inspection............................................................................................................................................85

Reassembly.......................................................................................................................................................................85

Assemble the bearing frame.......................................................................................................................................85

Assemble the frame adapter to the frame (XL1, XL2-S, and XL2).....................................................................91

Assemble the TaperBore PLUS™ seal chamber.....................................................................................................92

Assemble the stuffing-box cover...............................................................................................................................93

Install the dynamic seal (S, M, L, and XL)...............................................................................................................95

Impeller installation.....................................................................................................................................................97

Install the suction sideplate......................................................................................................................................100

Install the casing wear ring (S, M, L, and XL enclosed impeller).......................................................................100

Install the casing wear ring (XL1, XL2-S, and XL2 enclosed impeller)............................................................101

Install the back pull-out assembly...........................................................................................................................101

Attach the i-ALERT™ Condition Monitor to the pump....................................................................................103

Post-assembly checks................................................................................................................................................104

Assembly references..................................................................................................................................................104

Troubleshooting.............................................................................................................................................................113

Operation troubleshooting..........................................................................................................................................113

Alignment troubleshooting..........................................................................................................................................114

Assembly troubleshooting...........................................................................................................................................114

i-ALERT™ Condition Monitor troubleshooting.....................................................................................................115

Parts Listings and Cross-sectional Drawings.......................................................................................................116

Parts list .........................................................................................................................................................................116

Assembly drawings (exploded views).........................................................................................................................126

Envelope drawings for packed box and seal chamber............................................................................................132

Certification: CE or CE ATEX..................................................................................................................................146

Certificates of conformance........................................................................................................................................146

Other Relevant Documentation or Manuals.........................................................................................................152

For additional documentation.....................................................................................................................................152

Local ITT Contacts.......................................................................................................................................................153

Regional offices.............................................................................................................................................................153

Models 3180, 3181, 3185, and 3186 Installation, Operation, and Maintenance Manual 3

Page 6

Introduction and Safety

Introduction and Safety

Introduction

Purpose of this manual

The purpose of this manual is to provide necessary information for:

• Installation

• Operation

• Maintenance

CAUTION:

Read this manual carefully before installing and using the product. Improper use of the product can cause

personal injury and damage to property, and may void the warranty.

NOTICE:

Save this manual for future reference, and keep it readily available at the location of the unit.

Requesting other information

Special versions can be supplied with supplementary instruction leaflets. See the sales contract for any

modifications or special version characteristics. For instructions, situations, or events that are not

considered in this manual or in the sales documents, please contact the nearest ITT representative.

Always specify the exact product type and identification code when requesting technical information or

spare parts.

Safety

WARNING:

• The operator must be aware of safety precautions to prevent physical injury.

• Any pressure-containing device can explode, rupture, or discharge its contents if it is over-pressurized.

Take all necessary measures to avoid over-pressurization.

• Operating, installing, or maintaining the unit in any way that is not covered in this manual could cause

death, serious personal injury, or damage to the equipment. This includes any modification to the

equipment or use of parts not provided by ITT. If there is a question regarding the intended use of

the equipment, please contact an ITT representative before proceeding.

• This manual clearly identify accepted methods for disassembling units. These methods must be

adhered to. Trapped liquid can rapidly expand and result in a violent explosion and injury. Never apply

heat to impellers, propellers, or their retaining devices to aid in their removal.

• Do not change the service application without the approval of an authorized ITT representative.

• Never operate the pump below the minimum rated flow, when dry, or without prime.

• Never operate the pump without safety devices installed.

• Never operate the pump with the discharge valve closed.

• Never operate the pump with the suction valve closed.

Observe all safety messages highlighted in other sections of this manual.

4 Models 3180, 3181, 3185, and 3186 Installation, Operation, and Maintenance Manual

Page 7

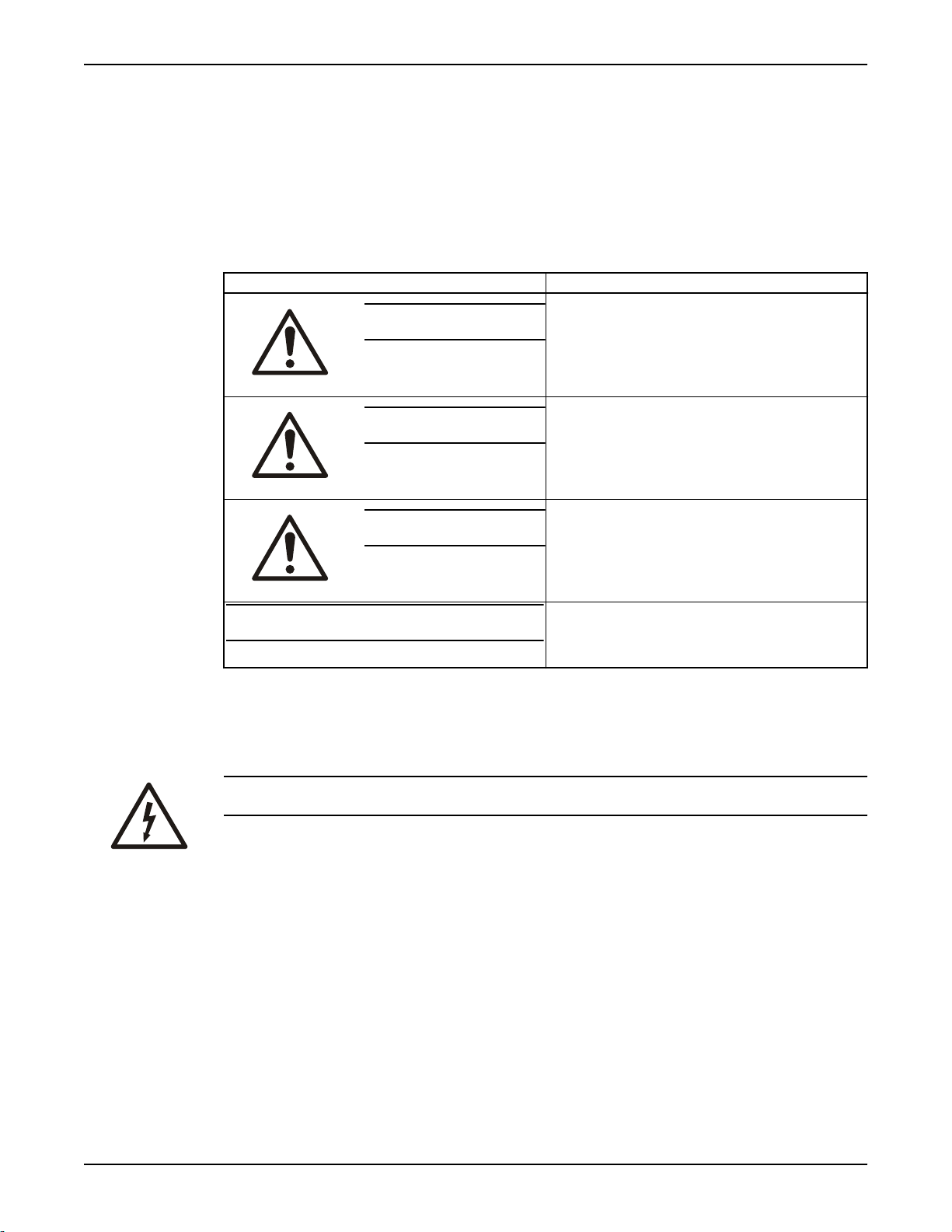

Safety terminology and symbols

About safety messages

It is extremely important that you read, understand, and follow the safety messages and regulations

carefully before handling the product. They are published to help prevent these hazards:

• Personal accidents and health problems

• Damage to the product

• Product malfunction

Hazard levels

Hazard level Indication

DANGER:

WARNING:

Introduction and Safety

A hazardous situation which, if not avoided, will

result in death or serious injury

A hazardous situation which, if not avoided, could

result in death or serious injury

Hazard categories

A hazardous situation which, if not avoided, could

CAUTION:

NOTICE:

Hazard categories can either fall under hazard levels or let specific symbols replace the ordinary hazard

level symbols.

Electrical hazards are indicated by the following specific symbol:

Electrical Hazard:

These are examples of other categories that can occur. They fall under the ordinary hazard levels and may

use complementing symbols:

• Crush hazard

• Cutting hazard

• Arc flash hazard

result in minor or moderate injury

• A potential situation which, if not avoided,

could result in undesirable conditions

• A practice not related to personal injury

Environmental safety

The work area

Always keep the pump station clean to avoid and/or discover emissions.

Recycling guidelines

Always recycle according to these guidelines:

Models 3180, 3181, 3185, and 3186 Installation, Operation, and Maintenance Manual 5

Page 8

Introduction and Safety

1. If the unit or parts are accepted by an authorized recycling company, then follow local recycling laws

and regulations.

2. If the unit or parts are not accepted by an authorized recycling company, then return them to the

nearest ITT representative.

Waste and emissions regulations

Observe these safety regulations regarding waste and emissions:

• Dispose appropriately of all waste.

• Handle and dispose of the pumped fluid in compliance with applicable environmental regulations.

• Clean up all spills in accordance with safety and environmental procedures.

• Report all environmental emissions to the appropriate authorities.

Reference for electrical installation

For electrical installation requirements, consult your local electric utility.

Recycling guidelines

Always follow local laws and regulations regarding recycling.

User safety

General safety rules

These safety rules apply:

• Always keep the work area clean.

• Pay attention to the risks presented by gas and vapors in the work area.

• Avoid all electrical dangers. Pay attention to the risks of electric shock or arc flash hazards.

• Always bear in mind the risk of drowning, electrical accidents, and burn injuries.

Safety equipment

Use safety equipment according to the company regulations. Use this safety equipment within the work

area:

• Helmet

• Safety goggles, preferably with side shields

• Protective shoes

• Protective gloves

• Gas mask

• Hearing protection

• First-aid kit

• Safety devices

NOTICE:

Never operate a unit unless safety devices are installed. Also see specific information about safety

devices in other chapters of this manual.

Electrical connections

Electrical connections must be made by certified electricians in compliance with all international, national,

state, and local regulations. For more information about requirements, see sections dealing specifically with

electrical connections.

Precautions before work

Observe these safety precautions before you work with the product or are in connection with the product:

• Provide a suitable barrier around the work area, for example, a guard rail.

• Make sure that all safety guards are in place and secure.

• Make sure that the equipment is properly insulated when it operates at extreme temperatures.

• Allow all system and pump components to cool before you handle them.

• Make sure that you have a clear path of retreat.

6 Models 3180, 3181, 3185, and 3186 Installation, Operation, and Maintenance Manual

Page 9

• Make sure that the product cannot roll or fall over and injure people or damage property.

• Make sure that the lifting equipment is in good condition.

• Use a lifting harness, a safety line, and a breathing device as required.

• Make sure that the product is thoroughly clean.

• Make sure that there are no poisonous gases within the work area.

• Make sure that you have quick access to a first-aid kit.

• Disconnect and lock out power before servicing.

• Check the explosion risk before you weld or use electric hand tools.

Precautions during work

Observe these safety precautions when you work with the product or are in connection with the product:

• Never work alone.

• Always wear protective clothing and hand protection.

• Stay clear of suspended loads.

• Always lift the product by its lifting device.

• Beware of the risk of a sudden start if the product is used with an automatic level control.

• Beware of the starting jerk, which can be powerful.

• Rinse the components in water after you disassemble the pump.

• Do not exceed the maximum working pressure of the pump.

• Do not open any vent or drain valve or remove any plugs while the system is pressurized. Make sure

that the pump is isolated from the system and that pressure is relieved before you disassemble the

pump, remove plugs, or disconnect piping.

• Never operate a pump without a properly installed coupling guard.

• Always bear in mind the risk of drowning, electrical accidents, and burn injuries.

• Never heat the condition monitor to temperatures in excess of 300°F (149°C).

• Never expose the condition monitor to open flames.

• Do not use the condition monitor in atmospheres containing acetic acid.

• Always wear protective gloves. The pump and condition monitor can be hot.

Introduction and Safety

Hazardous liquids

Wash the skin and eyes

The product is designed for use in liquids that can be hazardous to your health. Observe these rules when

you work with the product:

• Make sure that all personnel who work with biologically hazardous liquids are vaccinated against

diseases to which they may be exposed.

• Observe strict personal cleanliness.

Do the following if chemicals or hazardous fluids have come into contact with your eyes or your skin:

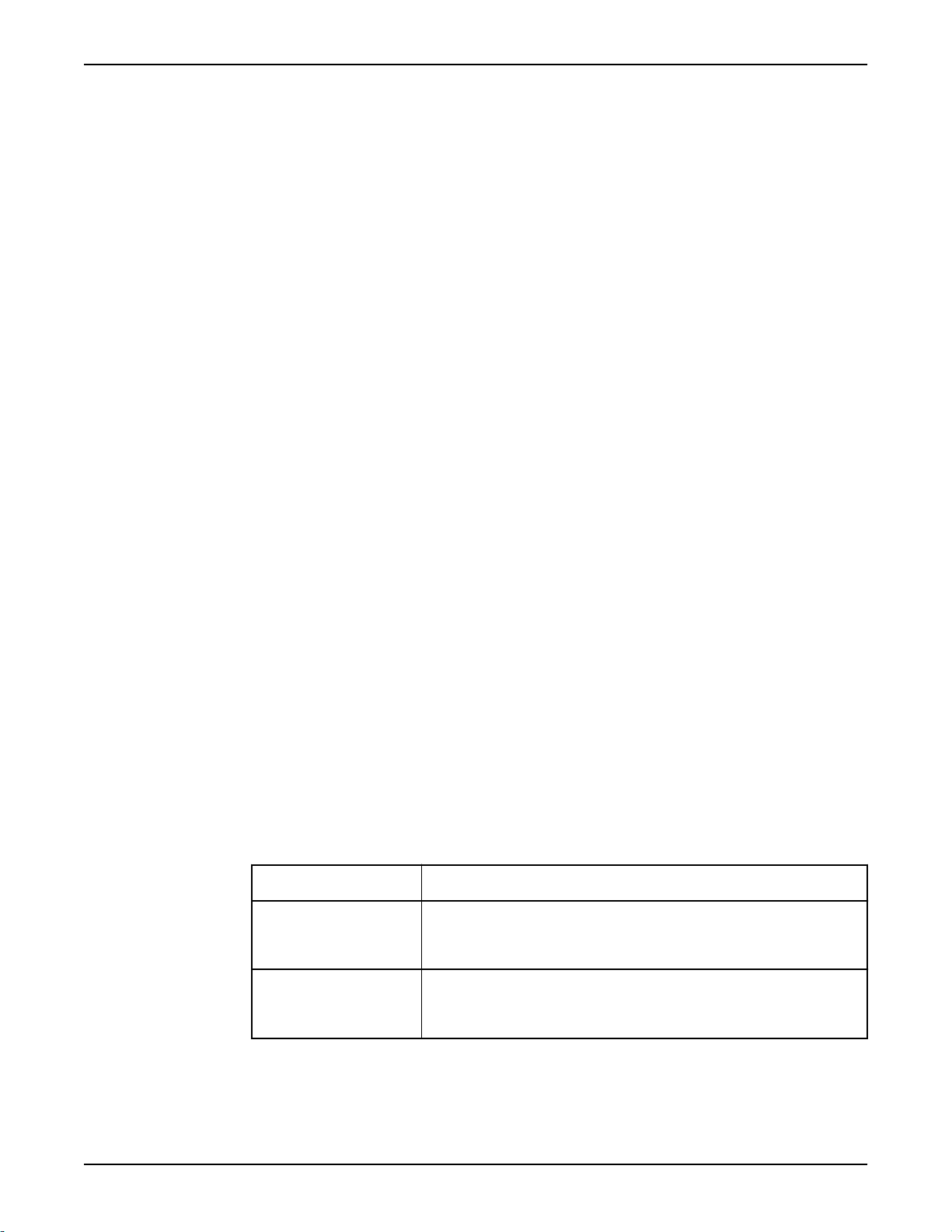

If you need to wash

your...

Eyes

Skin

Then...

1. Hold your eyelids apart forcibly with your fingers.

2. Rinse the eyes with eyewash or running water for at least 15 minutes.

3. Seek medical attention.

1. Remove contaminated clothing.

2. Wash the skin with soap and water for at least one minute.

3. Seek medical attention, if required.

Models 3180, 3181, 3185, and 3186 Installation, Operation, and Maintenance Manual 7

Page 10

Introduction and Safety

Safety regulations for Ex-approved products in potentially explosive atmospheres

Description of ATEX

The ATEX directives are a specification enforced in Europe for electrical and non-electrical equipment.

ATEX deals with the control of potentially explosive atmospheres and the standards of equipment and

protective systems used within these atmospheres. The relevance of the ATEX requirements is not limited

to Europe. You can apply these guidelines to equipment installed in any potentially explosive atmosphere.

Guidelines for compliance

Compliance is only fulfilled when the pump is operated within its intended use, for example within its

intended hydraulic range. The conditions of the service must not be changed without approval of an

authorized ITT representative. When installing or maintaining explosion-proof pumps, follow these

guidelines:

• Always install ATEX-approved equipment in compliance with the directive and applicable standards

(IEC/EN 60079–14).

• Do not install explosion proof products in locations that are classified as hazardous in the national

electric code, ANSI/NFPA 70–2005.

WARNING:

This manual clearly identify accepted methods for disassembling units. These methods must be adhered to.

Trapped liquid can rapidly expand and result in a violent explosion and injury. Never apply heat to

impellers, propellers, or their retaining devices to aid in their removal.

If there are any questions regarding these requirements, the intended use, or if the equipment requires

modification, contact an ITT representative before you proceed.

Personnel requirements

ITT disclaims all responsibility for work done by untrained and unauthorized personnel.

These are the personnel requirements for Ex-approved products in potentially explosive atmospheres:

• All work on the product must be carried out by certified electricians and ITT-authorized mechanics.

Special rules apply to installations in explosive atmospheres.

• All users must know about the risks of electric current and the chemical and physical characteristics of

the gas and/or vapor present in hazardous areas.

• Any maintenance for Ex-approved products must conform to international and national standards

(for example IEC/EN 60079-17).

Product and product handling requirements

These are the product and product handling requirements for Ex-approved products in potentially

explosive atmospheres:

• Only use the product in accordance with the approved motor data stated on the nameplates.

• The Ex-approved product must never run dry during normal operation. Dry running during service

and inspection is only permitted outside the classified area.

• Never start a pump without the proper priming.

• Before you start working with the product, make sure that the product and the control panel are

isolated from the power supply and the control circuit, so they cannot be energized.

• Do not open the product while it is energized or in an explosive gas atmosphere.

• Make sure that thermal contacts are connected to a protection circuit according to the approval

classification of the product.

• Intrinsically safe circuits are normally required for the automatic level-control system by the level

regulator if mounted in zone 0.

• The yield stress of fasteners must be in accordance with the approval drawing and the product

specification.

8 Models 3180, 3181, 3185, and 3186 Installation, Operation, and Maintenance Manual

Page 11

• Make sure that the equipment is properly maintained:

2D Barcode Here

• Monitor the pump components and the end temperature of the liquid.

• Maintain proper bearing lubrication.

• Do not modify the equipment without approval from an authorized ITT representative.

• Only use parts that have been provided by an authorized ITT representative.

Equipment for monitoring

For additional safety, use condition-monitoring devices. Condition-monitoring devices include but are not

limited to these devices:

• Pressure gauges

• Flow meters

• Level indicators

• Motor load readings

• Temperature detectors

• Bearing monitors

• Leak detectors

• PumpSmart control system

Product approval standards

Regular standards

All standard products are approved according to CSA standards in Canada and UL standards in USA. The

drive unit degree of protection follows IP68. See the nameplate for maximum submersion, according to

standard IEC 60529.

All electrical ratings and performance of the motors comply with IEC 600341.

Introduction and Safety

Explosion-proofing standards

All explosion-proof products for use in explosive atmospheres are designed in compliance with one or

more of the following approvals:

• EN, ATEX Directive 94/9/EC

• FM According to NEC

• Class 1 Div 1 Groups “C”, and “D”

• Class 2 Div 1 Groups “E”, “F”, and “G”

• Class 3 Div 1 Hazardous Locations

ATEX/IECEx:

• Group: IIC

• Category: Ex ia

• Temperature Class: T4 (for ambients up to 100ºC)

• ATEX Marking: Ex II 1 G

CSA certification

Intrinsically safe for:

• Class I, Div. 1, Groups A, B, C, D

• Class II, Div. 1, Groups E, F, G

Models 3180, 3181, 3185, and 3186 Installation, Operation, and Maintenance Manual 9

Page 12

SERIAL NO.

& YEAR OF

MANUFACTURE HERE.

Introduction and Safety

• Class III

• Certified to Canadian and US requirements

Product warranty

Coverage

ITT undertakes to remedy faults in products from ITT under these conditions:

• The faults are due to defects in design, materials, or workmanship.

• The faults are reported to an ITT representative within the warranty period.

• The product is used only under the conditions described in this manual.

• The monitoring equipment incorporated in the product is correctly connected and in use.

• All service and repair work is done by ITT-authorized personnel.

• Genuine ITT parts are used.

• Only Ex-approved spare parts and accessories authorized by ITT are used in Ex-approved products.

Limitations

Warranty claim

The warranty does not cover faults caused by these situations:

• Deficient maintenance

• Improper installation

• Modifications or changes to the product and installation made without consulting ITT

• Incorrectly executed repair work

• Normal wear and tear

ITT assumes no liability for these situations:

• Bodily injuries

• Material damages

• Economic losses

ITT products are high-quality products with expected reliable operation and long life. However, should the

need arise for a warranty claim, then contact your ITT representative.

10 Models 3180, 3181, 3185, and 3186 Installation, Operation, and Maintenance Manual

Page 13

Transportation and Storage

Inspect the delivery

Inspect the package

1. Inspect the package for damaged or missing items upon delivery.

2. Note any damaged or missing items on the receipt and freight bill.

3. File a claim with the shipping company if anything is out of order.

If the product has been picked up at a distributor, make a claim directly to the distributor.

Inspect the unit

1. Remove packing materials from the product.

Dispose of all packing materials in accordance with local regulations.

2. Inspect the product to determine if any parts have been damaged or are missing.

3. If applicable, unfasten the product by removing any screws, bolts, or straps.

For your personal safety, be careful when you handle nails and straps.

4. Contact your sales representative if anything is out of order.

Transportation and Storage

Transportation guidelines

Precautions

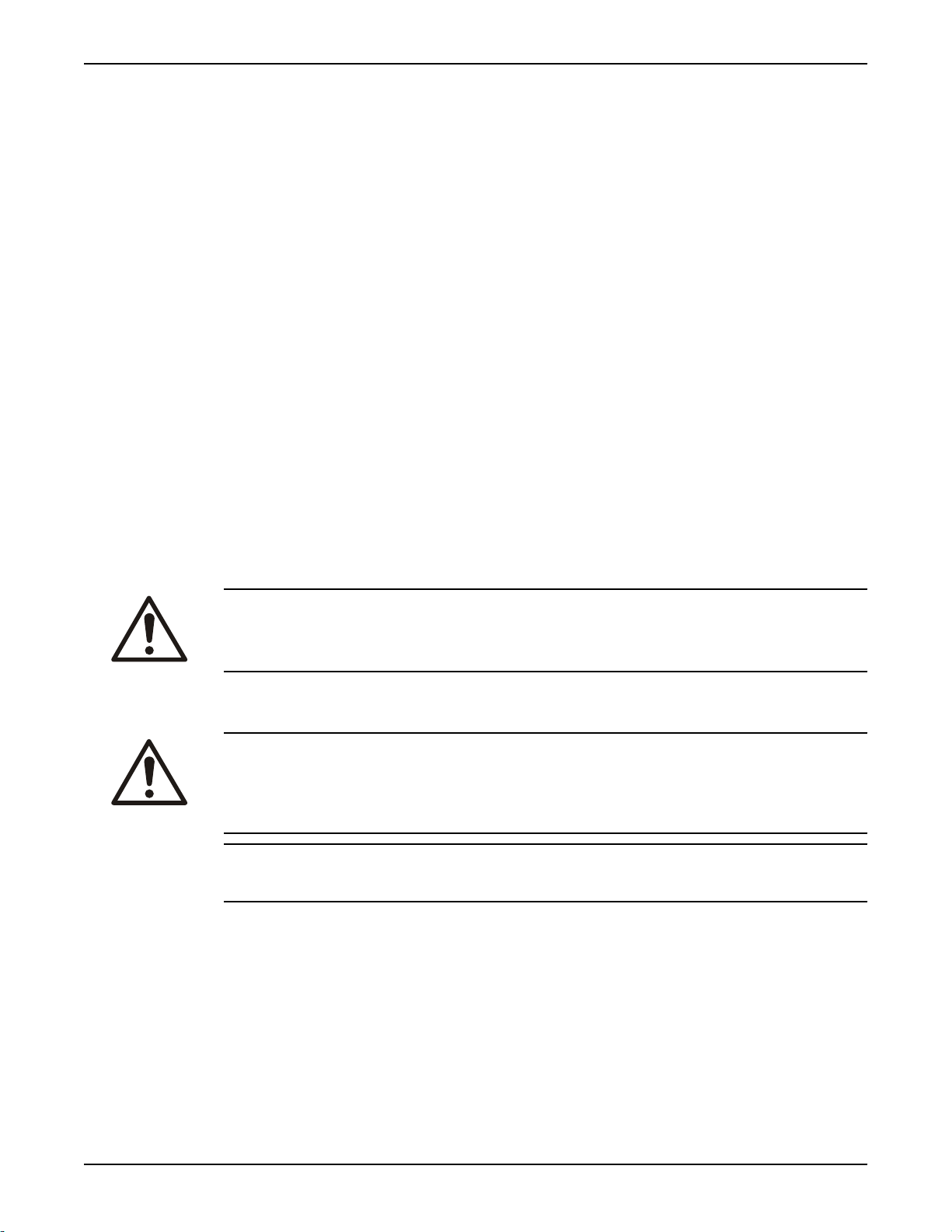

WARNING:

• Stay clear of suspended loads.

• Observe accident prevention regulations in force.

Pump handling

WARNING:

• Make sure that the pump cannot roll or fall over and injure people or damage property.

• These pumps might use carbon or ceramic silicon carbide components. Do not drop the pump or

subject it to shock loads as this can damage the internal ceramic components.

NOTICE: Use a forklift truck or an overhead crane with sufficient capacity to move the pallet with the

pump unit on top. Failure to do so can result in equipment damage.

Lifting methods

Models 3180, 3181, 3185, and 3186 Installation, Operation, and Maintenance Manual 11

Page 14

Transportation and Storage

WARNING:

• Assembled units and their components are heavy. Failure to properly lift and support this equipment

• Crush hazard. The unit and the components can be heavy. Use proper lifting methods and wear steel-

• Do not attach sling ropes to shaft ends.

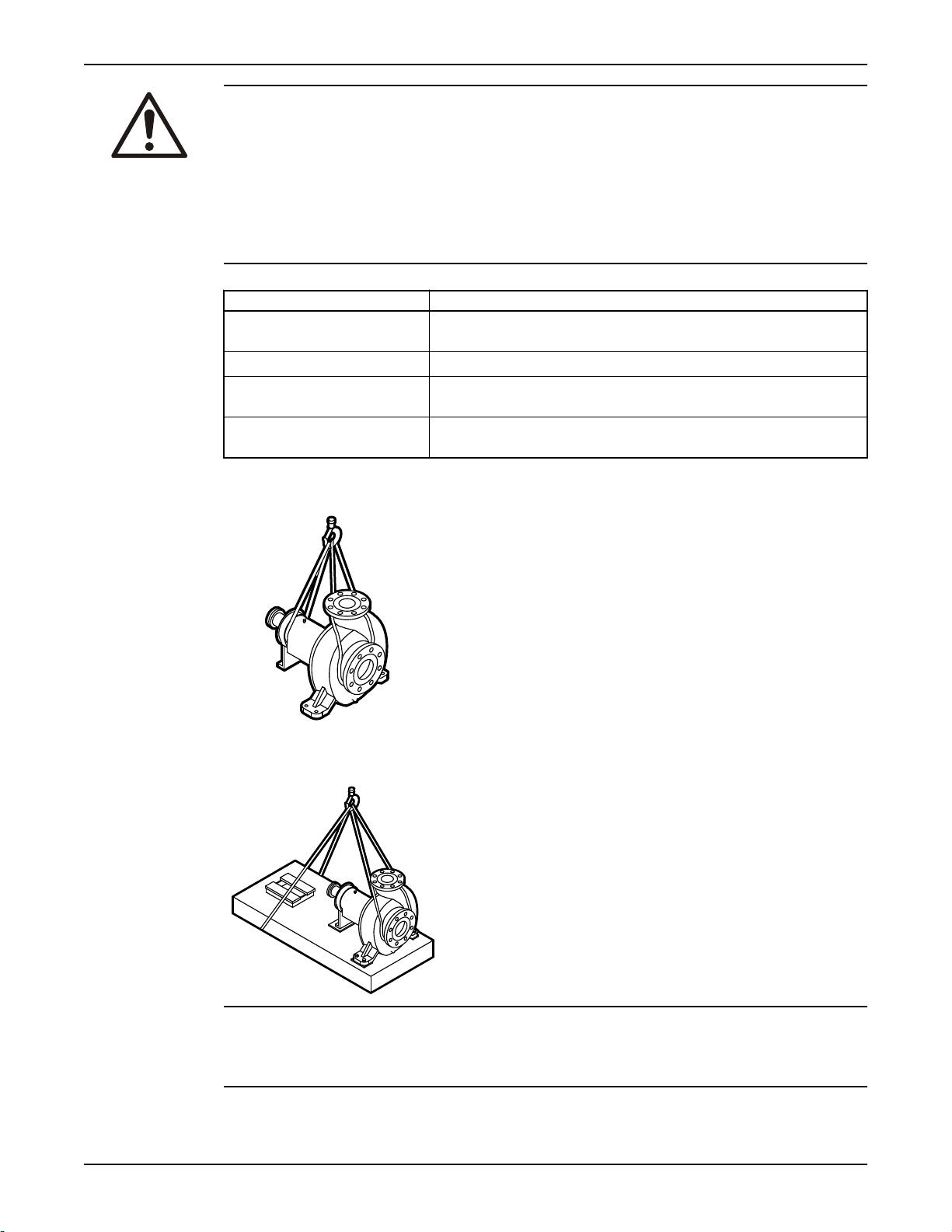

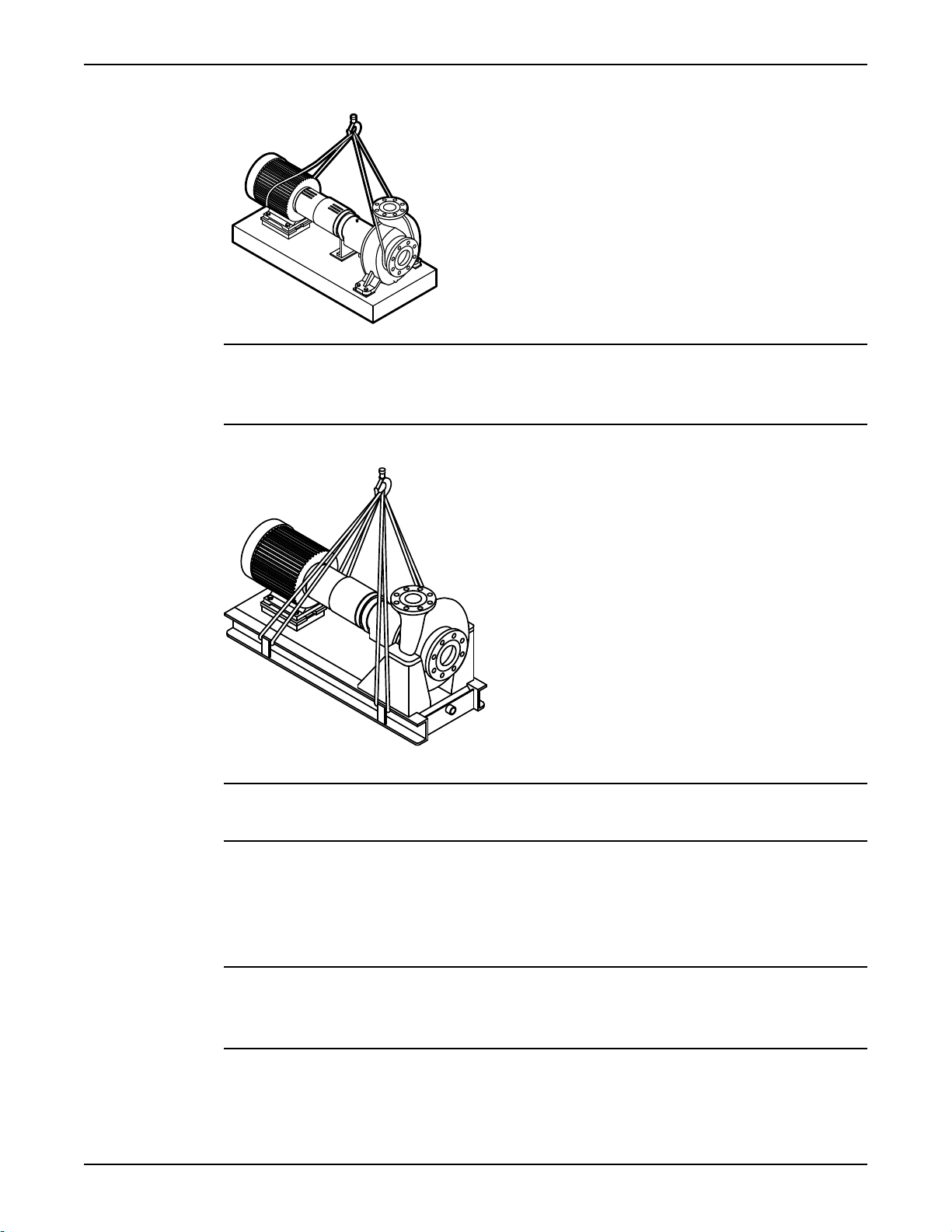

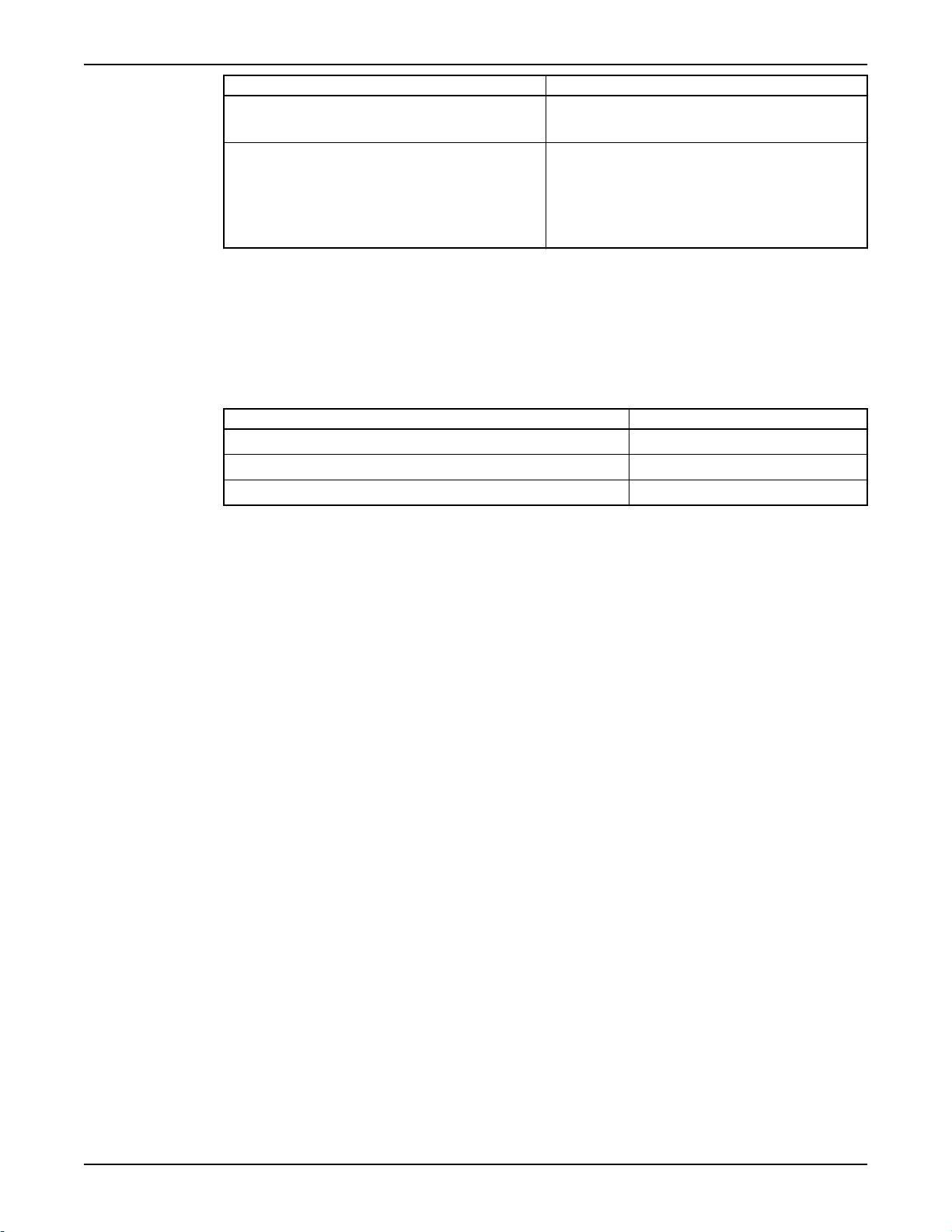

Table 1: Methods

Pump type Lifting method

A bare pump without lifting

handles

A bare pump with lifting handles Lift the pump by the handles.

A base-mounted pump Use slings under the pump casing and the drive unit, or under the base

A base-mounted pump with

baseplate lifting lugs

Examples

can result in serious physical injury and/or equipment damage. Lift equipment only at the specifically

identified lifting points. Lifting devices such as eyebolts, slings, and spreaders must be rated, selected,

and used for the entire load being lifted.

toed shoes at all times.

Use a suitable sling attached properly to solid points like the casing, the

flanges, or the frames.

rails.

Use slings through the baseplate lifting lugs.

Figure 1: Example of a proper lifting method

NOTICE:

Do not use this lifting method to lift a Polyshield base with the pump and motor mounted. Doing so may

result in equipment damage.

Figure 2: Example of a proper lifting method

12 Models 3180, 3181, 3185, and 3186 Installation, Operation, and Maintenance Manual

Page 15

Transportation and Storage

NOTICE:

Do not use this lifting method to lift a Polyshield base with the pump and motor mounted. Doing so may

result in equipment damage.

Figure 3: Example of a proper lifting method

Figure 4: Example of a proper lifting method

NOTICE: When lifting a unit that does not have a way to secure the strap on the suction flange, you must

secure the strap around the frame adapter. Failure to do so may result in equipment damage.

Storage guidelines

Storage location

The product must be stored in a covered and dry location free from heat, dirt, and vibrations.

NOTICE:

• Protect the product against humidity, heat sources, and mechanical damage.

• Do not place heavy weights on the packed product.

Pump storage requirements

Storage requirements depend on the amount of time that you store the pump. The normal packaging is

designed only to protect the pump during shipping.

Models 3180, 3181, 3185, and 3186 Installation, Operation, and Maintenance Manual 13

Page 16

Transportation and Storage

Length of time in storage Storage requirements

Upon receipt/short-term (less than six months)

Long-term (more than six months)

Treat bearing and machined surfaces so that they are well preserved. Refer to drive unit and coupling

manufacturers for their long-term storage procedures.

You can purchase long-term storage treatment with the initial pump order or you can purchase it and

apply it after the pumps are already in the field. Contact your local ITT sales representative.

Frostproofing

This table shows to what degree the pump is frostproof:

When the pump is... Then...

Operating The pump is frostproof.

Immersed in a liquid The pump is frostproof.

Lifted out of a liquid into a temperature below freezing The impeller might freeze.

• Store in a covered and dry location.

• Store the unit free from dirt and vibrations.

• Store in a covered and dry location.

• Store the unit free from heat, dirt, and

vibrations.

• Rotate the shaft by hand several times at least

every three months.

14 Models 3180, 3181, 3185, and 3186 Installation, Operation, and Maintenance Manual

Page 17

Product Description

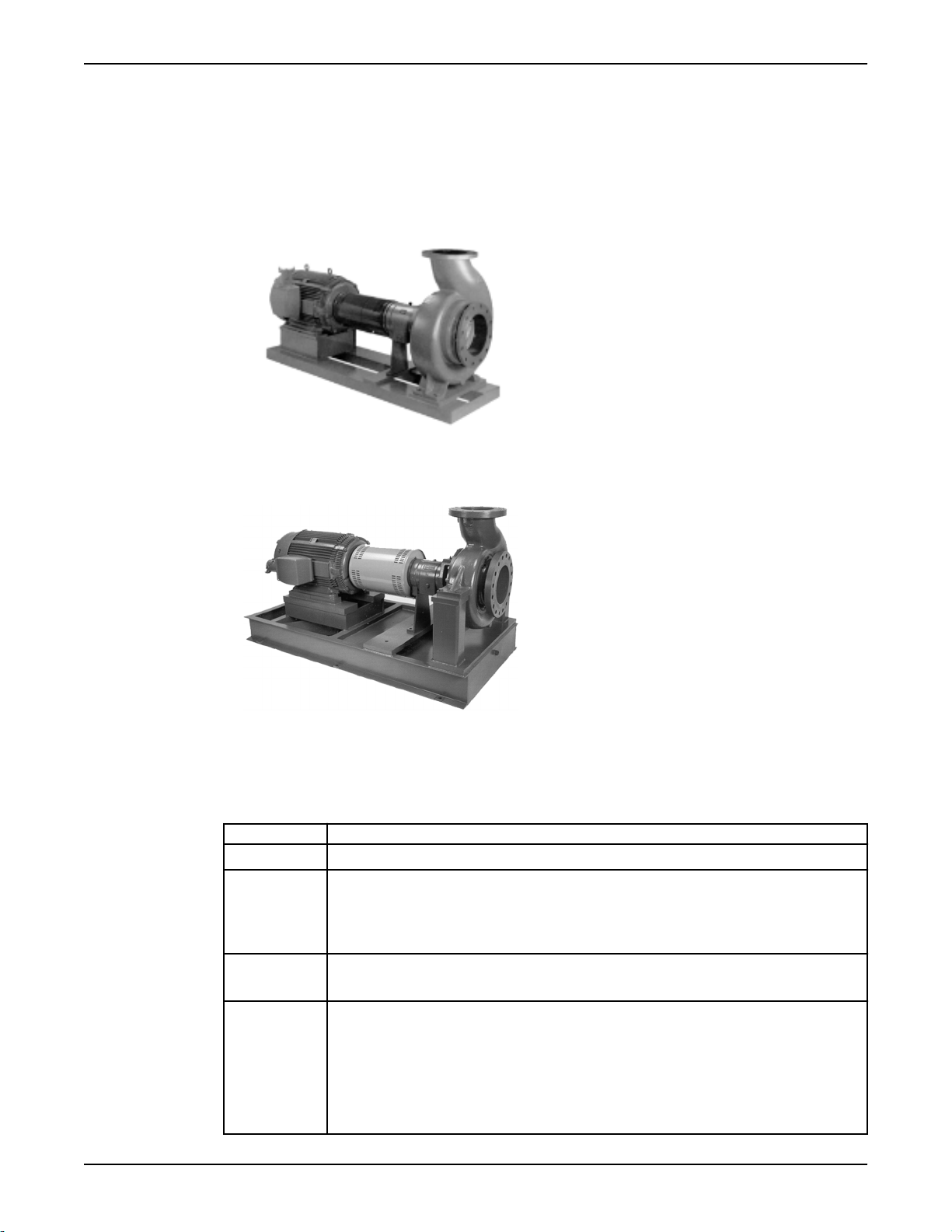

General description

The 3180 models are horizontal, end-suction, centrifugal pumps designed for heavy-duty process

applications.

Figure 5: Model of 3180 and 3185

Product Description

Figure 6: Model of 3181 and 3186

Part description

Casing

Feature Description

Discharge This discharge has top centerline for ease in handling air-entrained liquids.

Gasket The gasket is fully confined between the casing and the stuffing box cover and is

composed of this material:

• 3180 and 3185: aramid fiber

• 3181 and 3186: spiral-wound metallic

Mounting

method

Flange drilling For the S, M, L, and XL groups, the flange drilling meets these standards:

Models 3180, 3181, 3185, and 3186 Installation, Operation, and Maintenance Manual 15

• 3180 and 3185: foot mount

• 3181 and 3186: centerline mount

• 3180: ANSI class 125/150

• 3181: ANSI class 300

• 3185: ISO or JIS 16 bar

• 3186: ISO NP40 or JIS 40K

For the XL1, XL2-S, and XL2 groups, the flange drilling is ANSI class 150.

Page 18

Product Description

Impeller

Impeller option Description

Open with suction

sideplate (not available

on XL1, XL2-S, and

XL2)

• Provided as standard with models 3180 and 3185 (except on XL1, XL2-S,

and XL2)

• Provided as optional with models 3181 and 3186

• Available for all sizes of pumps (except on XL1, XL2-S, and XL2)

• Is fully open, end-suction type

• Contains Francis or radial design inlet

• Constructed with large balance holes and back pump-out vanes that reduce

stuffing box pressure and axial thrust

• Keyed to the shaft and held in position by an impeller locknut

• Sealed by a Viton O-ring

• Sealed on the sleeve side by a Teflon O-ring for a dry shaft design

• Handles the tough paper stock and process services

The suction sideplate has these benefits:

• Protects against casing wear

• Removed easily

• Secured to the casing with corrosion-resistant studs and capnuts

• Sealed with a gasket and O-ring

Enclosed with wear rings

(standard on XL1, XL2S, and XL2)

• Standard with the 3181 and 3186

• Optional with selected sizes of the S, M, L, and XL 3180 and 3185. Standard

on XL1, XL2-S, and XL2 3180 and 3185.

• Uses replaceable impeller wear ring and casing wear ring

• Wear ring configuration allows for axial impeller adjustment to renew and

maintain proper wear ring clearances

• Can handle fine solids

TM

Shearpeller

suction sideplate

with

• Provided as optional with eight sizes of models for 3180 and 3185

• Is fully open, end-suction type

• Constructed with radial design inlet

• Has scalloped shroud and back pump-out vanes that reduce axial thrust

• Can handle the tough recycle mill applications

• Can handle long, stringy solids without plugging or clogging

Stuffing box cover/seal chamber

The cover functions both as a way to seal the chamber and as a replaceable wear part. It is secured with a

series of clamping lugs at the outside diameter of models 3180 and 3185, and it is through-bolted with

capscrews on models 3181 and 3186. XL1, XL2-S, and XL2 sizes are through-bolted using a frame adapter

to secure the stuffing box cover or seal chamber.

The table shows the four available design options:

Seal chamber option Description

Packed box

• Uses five rings of 1/2 in. (12.5 mm) packing, plus a lantern ring

• Has a single flush connection at the lantern ring

• Has an optional second connection at the lantern ring and the stuffing box

throat

• Has a plain split gland

• Has a throat bushing

TaperBore™ PLUS

• Used with mechanical seals

• Uses an optional Vane Particle Ejector (VPE) ring for increased seal life

16 Models 3180, 3181, 3185, and 3186 Installation, Operation, and Maintenance Manual

Page 19

Power end

Seal chamber option Description

TaperBore™ PLUS with

packing conversion sleeve

Dynamic seal (not available

on XL1, XL2-S, and XL2)

• Only used with the 3181 and 3186

• Used with packing during startup, then converted to mechanical seal

• Only used with the S, M, L, and XL 3180 and 3185

• Used for tough applications where conventional mechanical seals or

packing require outside flush

• Contains a repeller mounted between the impeller and stuffing box cover

to pump the liquid out of the stuffing box while the pump is running

• Provides a static seal to prevent pumped fluid from leaking when the pump

is shut down

Part Description

Bearing

frame and

housing

For the S, M, L, and XL groups:

• The bearing frame and housing are constructed of cast iron.

• The frame is bolted and rabbeted to the stuffing box cover.

• The frame is sealed with labyrinth seals.

• No special parts are required to convert from grease to oil lubrication.

• The bearing frame cooling can be supplied as an option with oil lubrication.

• The bearing locknut and coupling extension are dimensioned in inches for models 3180 and

in millimeters for models 3185 and 3186.

For the XL1, XL2-S, and XL2 groups:

• The bearing frame and housing are constructed of cast iron.

• The frame is bolted and rabbeted to the frame adapter.

• The frame is sealed with labyrinth seals.

• Grease lubrication and bearing frame cooling are not available.

• The bearing locknut is in millimeters.

• The coupling extension is in inches.

Shaft

sleeve

For the S, M, L, and XL groups:

• The shaft sleeve is a renewable hook type, positively driven by the impeller key.

• One end is free to expand with possible temperature variations.

• A Teflon O-ring prevents leaks under the sleeve.

• The sleeve is dimensioned in inches for models 3180 and 3181 and in millimeters for

models 3185 and 3186.

For the XL1, XL2-S, and XL2 groups:

• The shaft sleeve is a renewable hook type, positively driven by the impeller key.

• One end is free to expand with possible temperature variations.

• A Teflon O-ring prevents leaks under the sleeve.

• The packing sleeve is dimensioned in millimeters, and the mechanical seal sleeve is

dimensioned in inches.

Bearings

• The inboard bearing carries only radial loads.

• The inboard bearing is free to float axially in the frame.

• The outboard bearings are a 40° angular-contact, duplex set, mounted back-to-back.

• The outboard bearings carry both radial and axial loads.

• The outboard bearings are locked onto the shaft by a threaded locknut.

Product Description

Hardware

All fasteners and tapped connections are metric.

Direction of rotation

The direction of rotation is clockwise (right hand) when viewed from the driver end.

Models 3180, 3181, 3185, and 3186 Installation, Operation, and Maintenance Manual 17

Page 20

Product Description

ISO 2858 conformance

The Models 3185 and 3186 conform to the ISO 2858 Standard where applicable. The ISO standard allows

for 125 mm flanges, which are nominal 5 in. flanges. Because ANSI standards no longer permit 5 in.

flanges, they are not used on models 3185 and 3186.

General description i-ALERT™ Condition Monitor

Description

The i-ALERT Condition Monitor is a compact, battery-operated monitoring device that continuously

measures the vibration and temperature of the pump power end. The condition monitor uses blinking red

LEDs to alert the pump operator when the pump exceeds pre-set vibration and temperature limits. This

allows the pump operator to make changes to the process or the pump before a catastrophic failure

occurs. The condition monitor is also equipped with a single green LED to indicate when it is operational

and has sufficient battery life.

Alarm mode

The condition monitor enters alarm mode when either vibration or temperature limits are exceeded over

two consecutive readings within a ten minute period. Alarm mode is indicated with two red flashing LEDs

within two second intervals.

Temperature and vibration limits

Variable Limit

Temperature 195°F (91°C)

Vibration 100% increase over the baseline level

Battery life

The i-ALERT Condition Monitor battery is not replaceable. You must replace the entire unit once

the battery runs out of power.

The battery life is not covered as part of the standard five-year pump warranty.

This table shows the average condition monitor battery life under normal and alarm-mode operating

conditions.

Condition monitor operational state Battery life

Normal operating and environmental conditions Three to five years

Alarm mode One year

Nameplate information

Important information for ordering

Every pump has nameplates that provide information about the pump. The nameplates are located on the

casing and the bearing frame.

When you order spare parts, identify this pump information:

• Model

• Size

• Serial number

• Item numbers of the required parts

Refer to the nameplate on the pump casing for most of the information. See Parts List for item numbers.

18 Models 3180, 3181, 3185, and 3186 Installation, Operation, and Maintenance Manual

Page 21

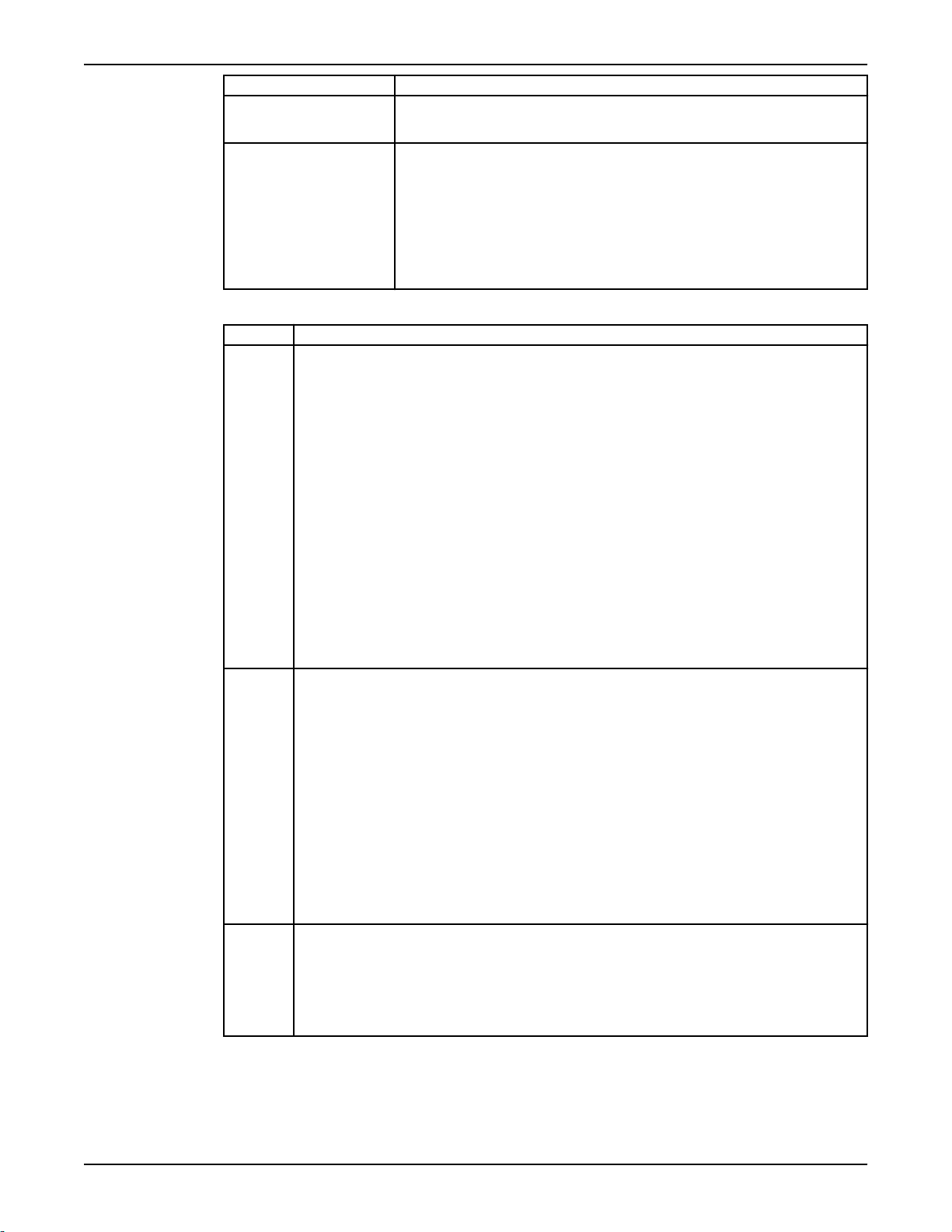

Nameplate on the pump casing using English units

Table 2: Explanation of nameplate on the pump casing

Nameplate field Explanation

IMPLR. DIA. Impeller diameter, in inches

MAX. DIA. Maximum impeller diameter, in inches

GPM Rated pump flow, in gallons per minute

FT HD Rated pump head, in feet

RPM Rated pump speed, revolutions per minute

MOD. Pump model

SIZE Size of the pump

STD. NO. Does not apply

MAT L. CONST. Material of which the pump is constructed

SER. NO. Serial number of the pump

MAX DSGN PSI

Maximum pressure at 100ºF according to the pump design

@ 100F

Product Description

Nameplate on the pump casing using metric units

Table 3: Explanation of the nameplate on the pump casing

Nameplate field Explanation

IMPLR. DIA. Impeller diameter

MAX. DIA. Maximum impeller diameter

M3/HR Rated pump flow, in cubic meters per hour

M HD Rated pump head, in meters

RPM Rated pump speed, in revolutions per minute

MOD. Pump model

SIZE Size of the pump

STD. NO. Does not apply

Models 3180, 3181, 3185, and 3186 Installation, Operation, and Maintenance Manual 19

Page 22

Product Description

Nameplate field Explanation

MAT L. CONST Material of which the pump is constructed

SER. NO. Serial number of the pump

MAX. DSGN KG/

CM2@20°C

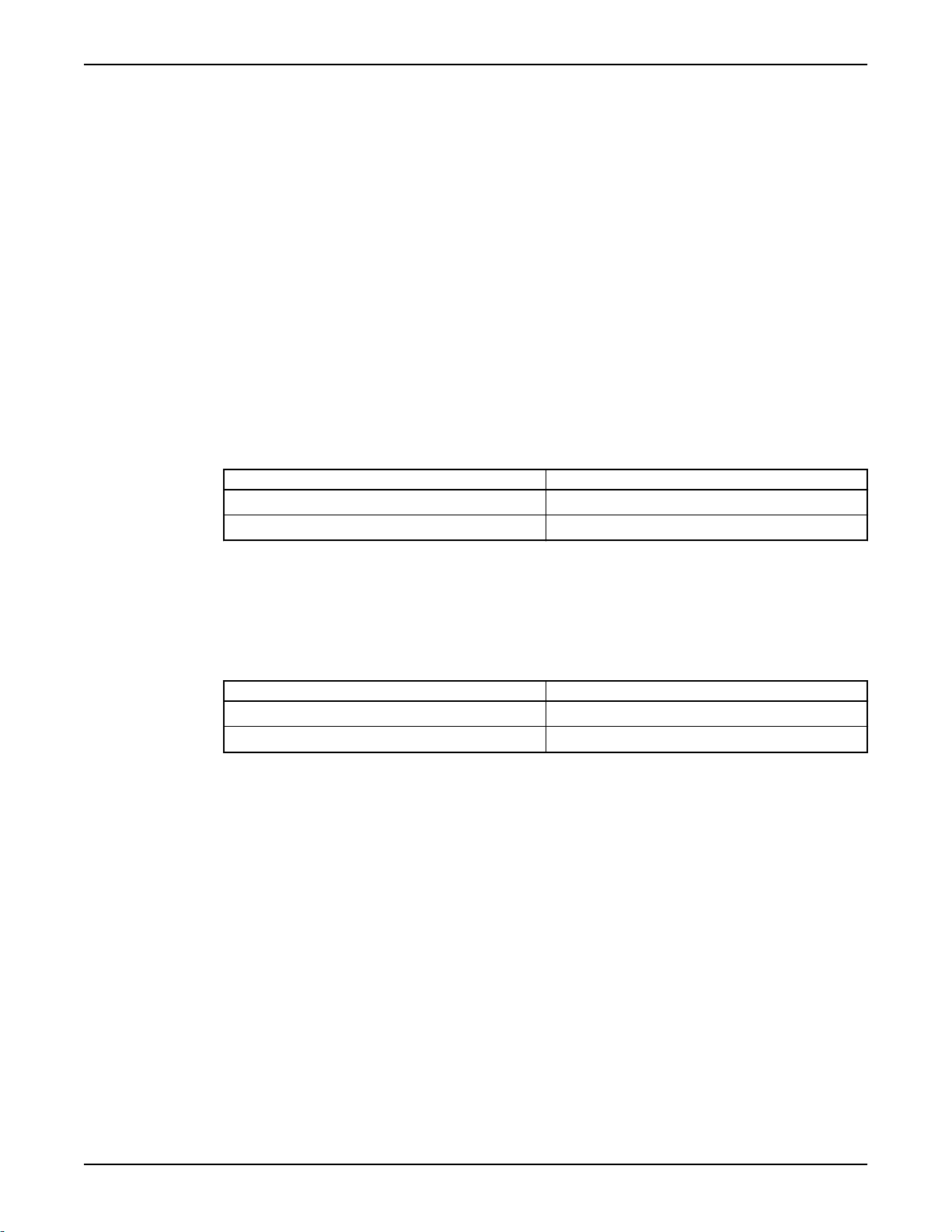

Nameplate on the bearing frame

Table 4: Explanation of the nameplate on the bearing frame

Nameplate field Explanation

MOD. Pump model

SIZE Size of the pump

SER. NO. Serial number of the pump

LUBE Lubricant, oil or grease

Kilograms per square centimeter at 20°C

ATEX nameplate

Nameplate field Explanation

II Group 2

2 Category 2

G/D Pump can be used when gas and dust are present

T4 Temperature class

NOTICE: Make sure that the code classifications on the pump are compatible with the specific

environment in which you plan to install the equipment. If they are not compatible, do not operate the

equipment and contact your ITT representative before you proceed.

20 Models 3180, 3181, 3185, and 3186 Installation, Operation, and Maintenance Manual

Page 23

Installation

Preinstallation

Precautions

WARNING:

• When installing in a potentially explosive environment, make sure that the motor is properly certified.

• You must earth (ground) all electrical equipment. This applies to the pump equipment, the driver, and

any monitoring equipment. Test the earth (ground) lead to verify that it is connected correctly.

NOTICE: Supervision by an authorized ITT representative is recommended to ensure proper installation.

Failure to do so may result in equipment damage or decreased performance.

Pump location guidelines

WARNING:

Assembled units and their components are heavy. Failure to properly lift and support this equipment can

result in serious physical injury and/or equipment damage. Lift equipment only at the specifically identified

lifting points. Lifting devices such as eyebolts, slings, and spreaders must be rated, selected, and used for

the entire load being lifted.

Installation

Guideline Explanation/comment

Keep the pump as close to the liquid source as

practically possible.

Make sure that the space around the pump is

sufficient.

If you require lifting equipment such as a hoist or

tackle, make sure that there is enough space above

the pump.

Protect the unit from weather and water damage

due to rain, flooding, and freezing temperatures.

Do not install and operate the equipment in

closed systems unless the system is constructed

with properly-sized safety devices and control

devices.

Take into consideration the occurrence of

unwanted noise and vibration.

This minimizes the friction loss and keeps the suction

piping as short as possible.

This facilitates ventilation, inspection, maintenance,

and service.

This makes it easier to properly use the lifting

equipment and safely remove and relocate the

components to a safe location.

This is applicable if nothing else is specified.

Acceptable devices:

• Pressure relief valves

• Compression tanks

• Pressure controls

• Temperature controls

• Flow controls

If the system does not include these devices, consult

the engineer or architect in charge before you operate

the pump.

The best pump location for noise and vibration

absorption is on a concrete floor with subsoil

underneath.

If the pump location is overhead, undertake

special precautions to reduce possible noise

transmission.

Models 3180, 3181, 3185, and 3186 Installation, Operation, and Maintenance Manual 21

Consider a consultation with a noise specialist.

Page 24

1

2

3

4

5

6

1

3

2

4

5

Installation

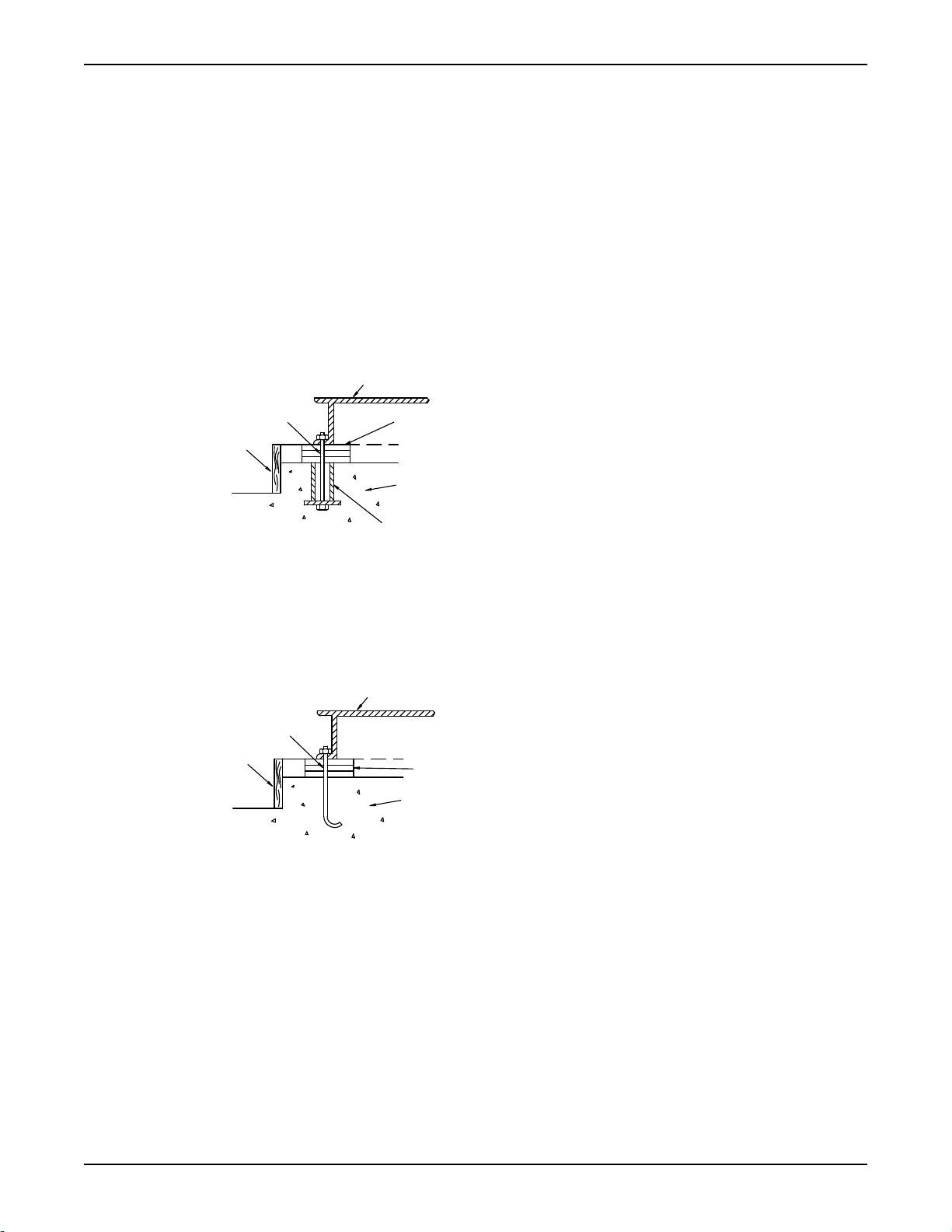

Foundation requirements

Requirements

• The foundation must be able to absorb any type of vibration and form a permanent, rigid support for

the pump unit.

• The location and size of the foundation bolt holes must match those shown on the assembly drawing

provided with the pump data package.

• The foundation must weigh between two and three times the weight of the complete pump, baseplate,

and drive assembly.

• Provide a flat, substantial concrete foundation in order to prevent strain and distortion when you

tighten the foundation bolts.

• Sleeve-type and J-type foundation bolts are most commonly used. Both designs allow movement for

the final bolt adjustment.

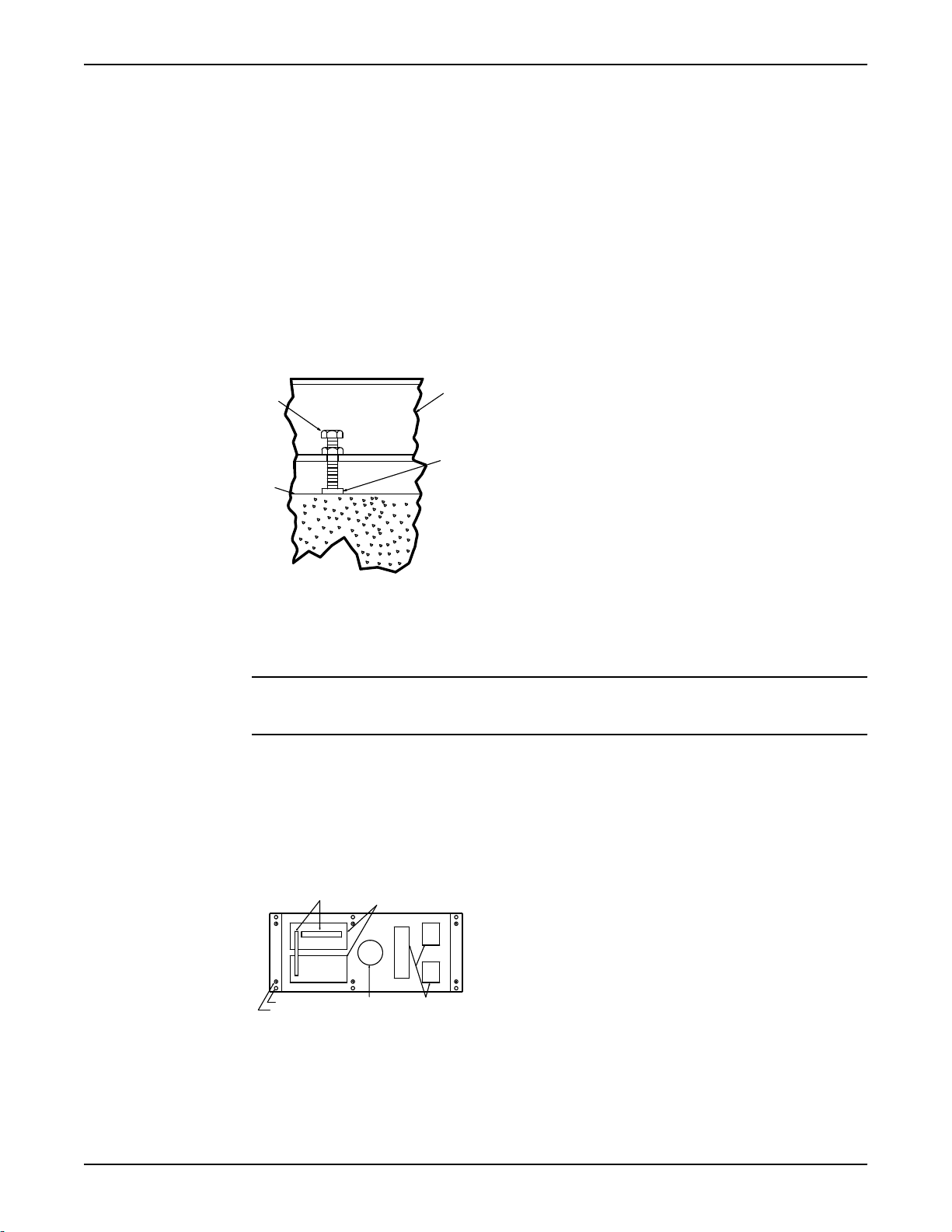

Sleeve-type bolts

1. Baseplate

2. Shims or wedges

3. Foundation

4. Sleeve

5. Dam

6. Bolt

J-type bolts

1. Baseplate

2. Shims or wedges

3. Foundation

4. Dam

5. Bolt

Baseplate-mounting procedures

Prepare the baseplate for mounting

1. Remove all the attached equipment from the baseplate.

2. Clean the underside of the baseplate completely.

22 Models 3180, 3181, 3185, and 3186 Installation, Operation, and Maintenance Manual

3. If applicable, coat the underside of the baseplate with an epoxy primer.

Use an epoxy primer only if you used an epoxy-based grout.

4. Remove the rust-proofing coat from the machined mounting pads using an appropriate solvent.

5. Remove water and debris from the foundation-bolt holes.

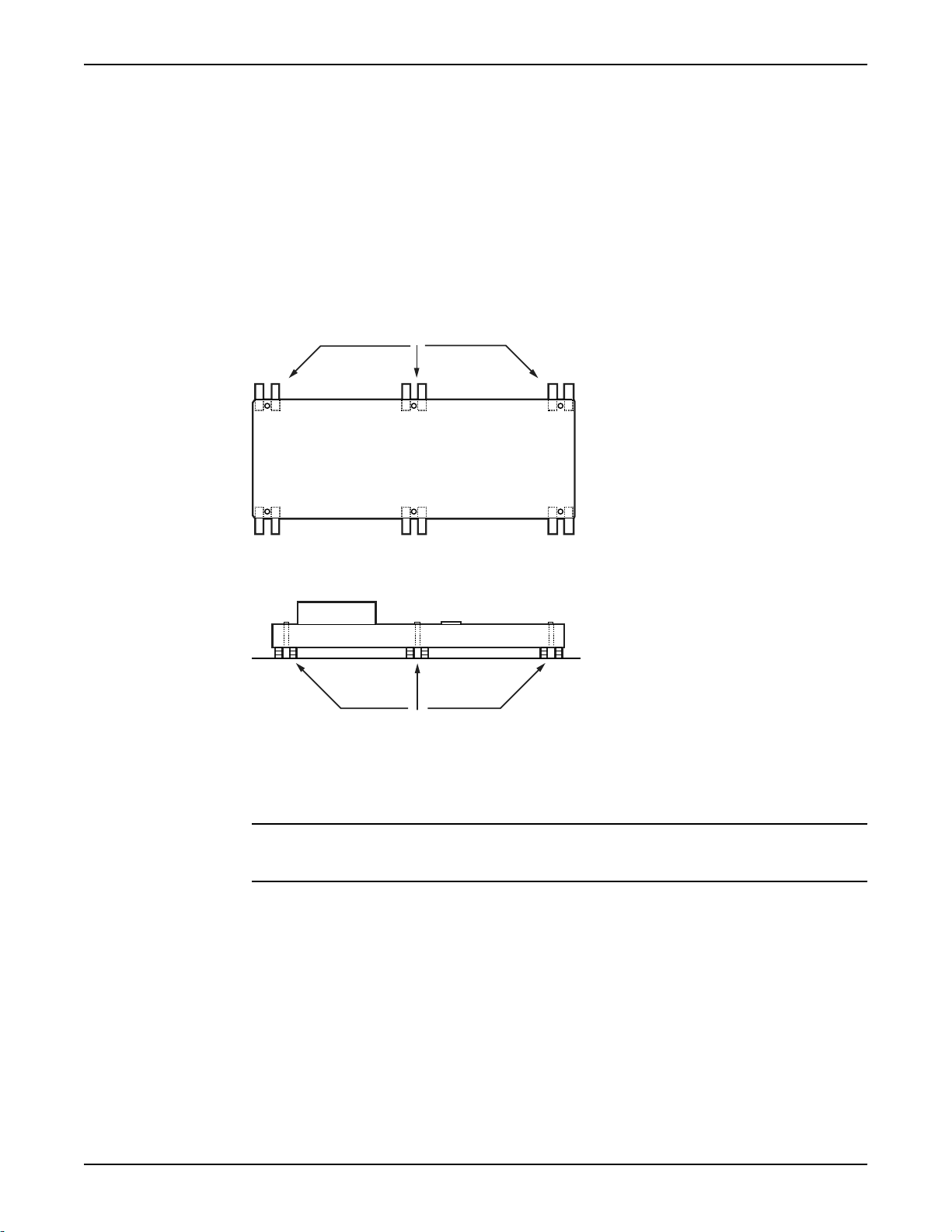

Page 25

Install the baseplate using shims or wedges

1

1

Required tools:

• Two sets of shims or wedges for each foundation bolt

• Two machinist's levels

• Baseplate-leveling worksheet

This procedure is applicable to cast iron and fabricated steel baseplates.

1. If you use sleeve-type bolts, fill the bolt sleeves with packing material or rags to prevent grout from

entering the bolt holes.

2. Put the sets of wedges or shims on each side of each foundation bolt.

The sets of wedges should have a height of between 0.75 in. (19 mm) and 1.50 in. (38 mm).

Installation

1. Shims or wedges

Figure 7: Top view

1. Shims or wedges

Figure 8: Side view

3. Lower the baseplate carefully onto the foundation bolts.

4. Put the machinist's levels across the mounting pads of the driver and the mounting pads of the pump.

NOTICE: Remove all dirt from the mounting pads in order to make sure that you achieve the

correct leveling. Failure to do so can result in equipment damage or decreased performance.

5. Level the baseplate both lengthwise and across by adding or removing shims or moving the wedges.

These are the leveling tolerances:

• A maximum difference of 0.125 in. (3.2 mm) lengthwise

• A maximum difference of 0.059 in. (1.5 mm) across

You can use the baseplate-leveling worksheet when you take the readings.

6. Hand-tighten the nuts for the foundation.

Install the baseplate using jackscrews

Models 3180, 3181, 3185, and 3186 Installation, Operation, and Maintenance Manual 23

Tools required:

• Anti-seize compound

• Jackscrews

• Bar stock

Page 26

1

2

3

4

1

2

3

4

5

6

Installation

• Two machinist's levels

• Baseplate-leveling worksheet

This procedure is applicable to the feature-fabricated steel baseplate and the advantage base baseplate.

1. Apply an anti-seize compound on the jackscrews.

The compound makes it easier to remove the screws after you grout.

2. Lower the baseplate carefully onto the foundation bolts and perform these steps:

a) Cut the plates from the bar stock and chamfer the edges of the plates in order to reduce stress

concentrations.

b) Put the plates between the jackscrews and the foundation surface.

c) Use the four jackscrews in the corners in order to raise the baseplate above the foundation.

Make sure that the distance between the baseplate and the foundation surface is between 0.75 in.

(19 mm) and 1.50 in. (38 mm).

d) Make sure that the center jackscrews do not touch the foundation surface yet.

1. Jackscrew

2. Baseplate

3. Foundation

4. Plate

3. Level the driver mounting pads:

NOTICE: Remove all dirt from the mounting pads in order to make sure that you achieve the

correct leveling. Failure to do so can result in equipment damage or decreased performance.

a) Put one machinist's level lengthwise on one of the two pads.

b) Put the other machinist's level across the ends of the two pads.

c) Level the pads by adjusting the four jackscrews in the corners.

Make sure that the machinist's level readings are as close to zero as possible, both lengthwise and

across.

Use the baseplate-leveling worksheet when you take the readings.

1. Machinist's levels

2. Driver's mounting pads

3. Foundation bolts

4. Jackscrews

5. Grout hole

6. Pump's mounting pads

4. Turn the center jackscrews down so that they rest on their plates on the foundation surface.

24 Models 3180, 3181, 3185, and 3186 Installation, Operation, and Maintenance Manual

Page 27

1

2

3

4

5

6

Installation

5. Level the pump mounting pads:

NOTICE: Remove all dirt from the mounting pads in order to make sure that you achieve the

correct leveling. Failure to do so can result in equipment damage or decreased performance.

a) Put one machinist's level lengthwise on one of the two pads.

b) Put the other level across the center of the two pads.

c) Level the pads by adjusting the four jackscrews in the corners.

Make sure that the machinist's level readings are as close to zero as possible, both lengthwise and

across.

1. Driver's mounting pads

2. Machinist's levels

3. Foundation bolts

4. Jackscrews

5. Grout hole

6. Pump's mounting pads

6. Hand-tighten the nuts for the foundation bolts.

7. Check that the driver's mounting pads are level and adjust the jackscrews and the foundation bolts if

necessary.

The correct level measurement is a maximum of 0.002 in./ft (0.0167 mm/m).

Spring mounted installation

WARNING:

Springs can store energy that can launch parts at a high velocity. Before you perform any tasks, make sure

that all springs are positively locked against free expansion.

NOTICE: The spring-mounted baseplate is designed only to support piping loads from thermal

expansion. You must support the suction and discharge piping individually. Failure to do so may result in

equipment damage.

Determine which spring-mounted baseplate you are working with:

If... Then...

The springs are of equal lengths with some mounted

above the baseplate and some mounted below the

baseplate.

The springs are of different lengths and mounted

below the baseplate.

Install the baseplate using spring mounting (first generation)

Check these items before you start this procedure:

• All springs in the first-generation spring-mounted baseplate are identical and have the same spring

constant.

• The foundation pads are not provided with the baseplate. Make sure that the foundation pads are 316

stainless steel plates, which have a 63 to 125 micro-inch surface finish.

• Make sure that the foundation pads are correctly installed on the foundation/floor. See the

instructions from the manufacturer.

Complete the steps in Install the baseplate using

spring mounting (first generation).

Complete the steps in Install the baseplate using

spring mounting (second generation).

Models 3180, 3181, 3185, and 3186 Installation, Operation, and Maintenance Manual 25

Page 28

1

2

3

4

5

6

7

Installation

1. Put the baseplate on a support above the foundation/floor.

Make sure that there is enough space between the baseplate and the foundation/floor in order to

install the spring assemblies.

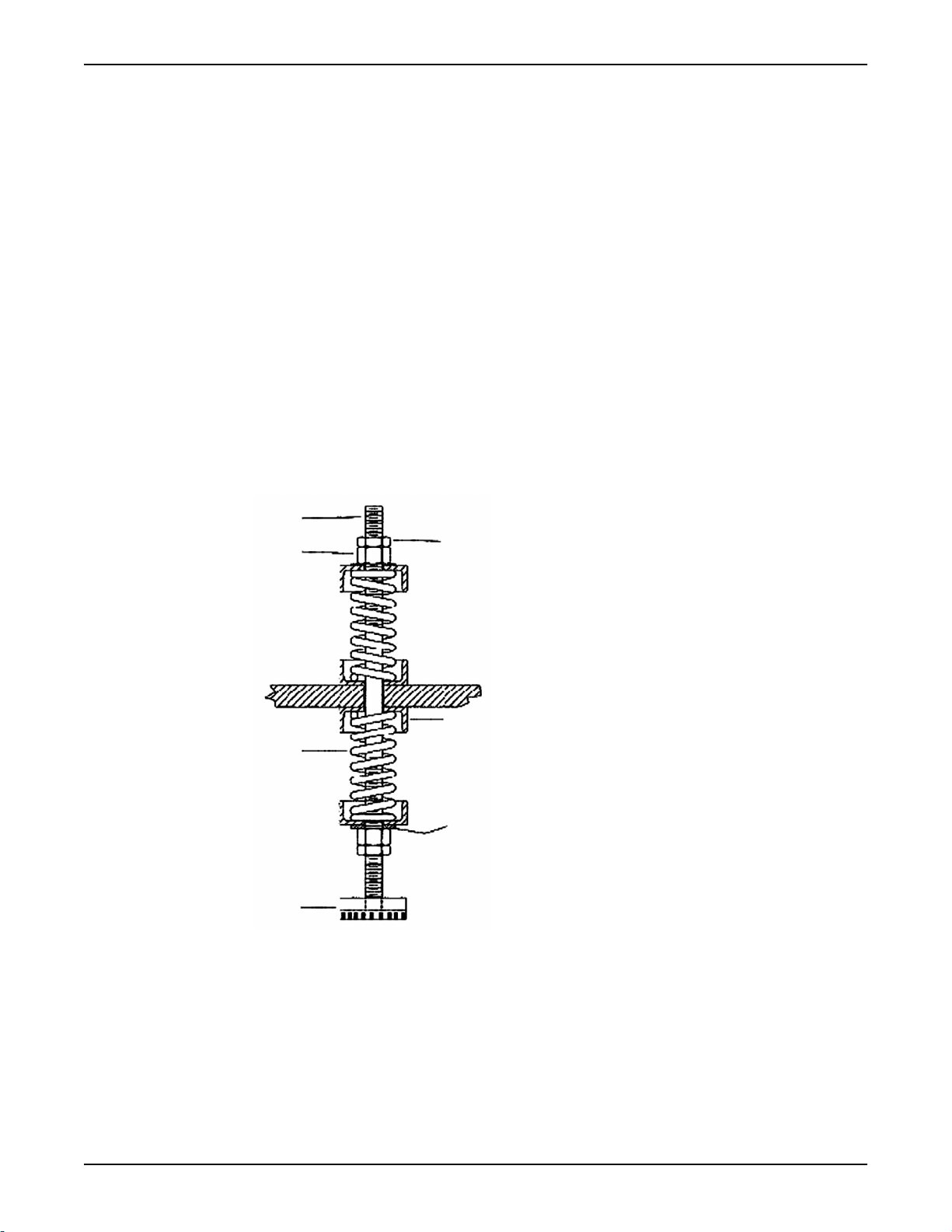

2. Assemble the spring assemblies:

a) Set a hex jam nut and a hex nut on a spring stud to the height of 2.00 in. (5.00 cm).

b) Install a bearing pad on the stud.

c) Hand-tighten the stud to the bearing pad.

d) Set the bottom adjusting nuts on the stud to the height (X) indicated on the certified GA

dimension drawing.

e) Install a flat washer on the stud.

f) Install a spring follower on the stud with the flat bottom facing downward.

g) Install a spring on the stud.

h) Install another spring follower with the flat bottom facing upward.

i) Install this subassembly from under the baseplate, pushing the stud up through the mounting

bracket.

j) Install a spring follower on the stud with the flat bottom facing downward.

k) Install another spring on the stud.

l) Install a spring follower with the flat bottom facing upward.

m) Install a flat washer on the stud.

n) Install a hex nut and a hex jam nut on the stud.

1. Hex jam nut

2. Follower

3. Flat washer

4. Bearing assembly

5. Spring

6. Hex nut

7. Stud

3. Repeat step 2 for each spring assembly.

4. Lower the baseplate so that the spring assemblies fit into the foundation pads.

5. Level the baseplate and make the final height adjustments:

a) Loosen the upper hex jam nuts and hex nuts.

26 Models 3180, 3181, 3185, and 3186 Installation, Operation, and Maintenance Manual

b) Adjust the height and level the baseplate by moving the lower adjusting nuts.

Page 29

c) When the baseplate is level, tighten the upper hex nuts so that the upper springs are not loose in

the spring followers.

6. Fasten the lower and upper jam nuts on each spring assembly.

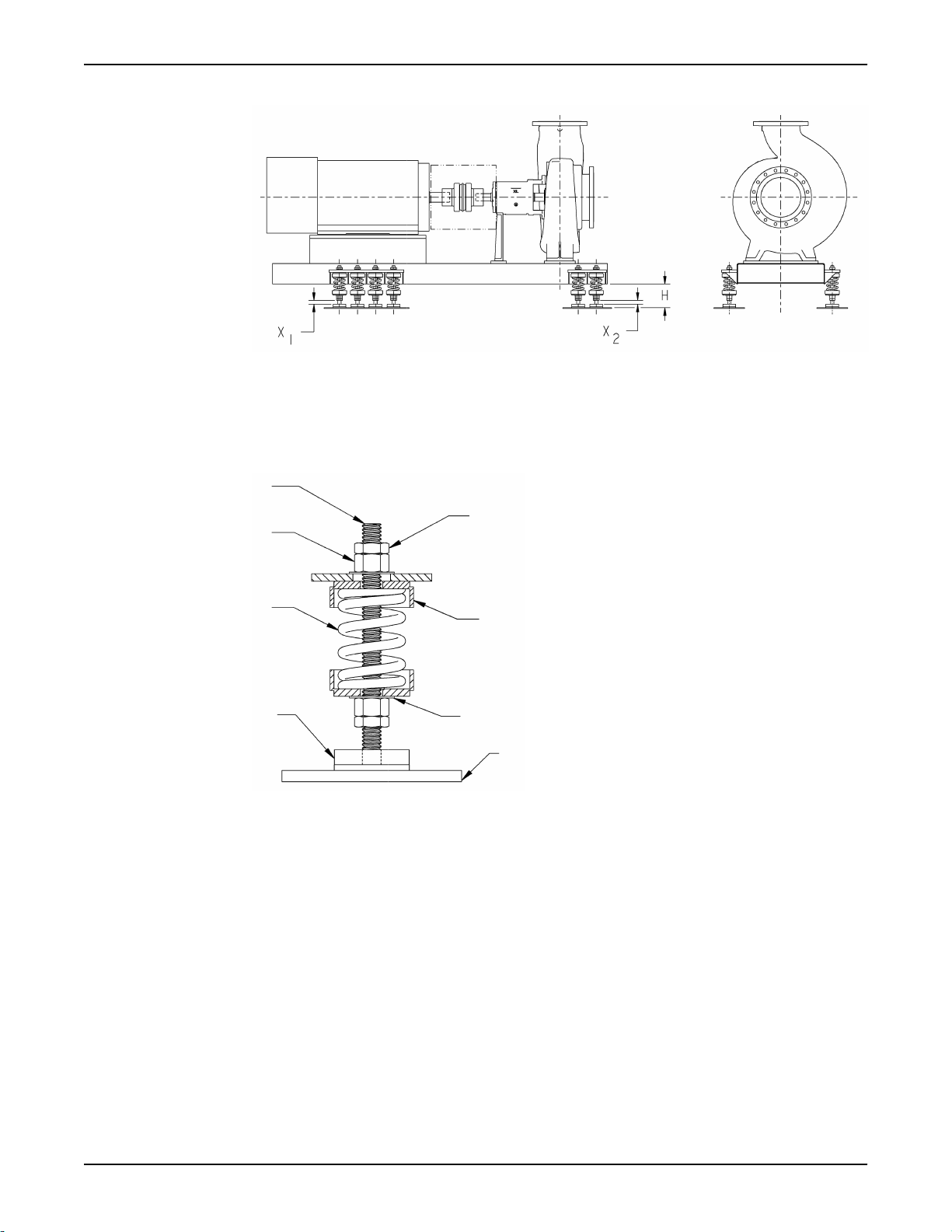

Install the baseplate using spring mounting (second generation)

Check these items before you start this procedure:

• The foundation pads are not provided with the baseplate. Make sure that the foundation pads are 316

stainless steel plates, which have a 63 to 125 micro-inch surface finish.

• Make sure that the foundation pads are correctly installed on the foundation/floor. See the

instructions from the manufacturer.

Installation

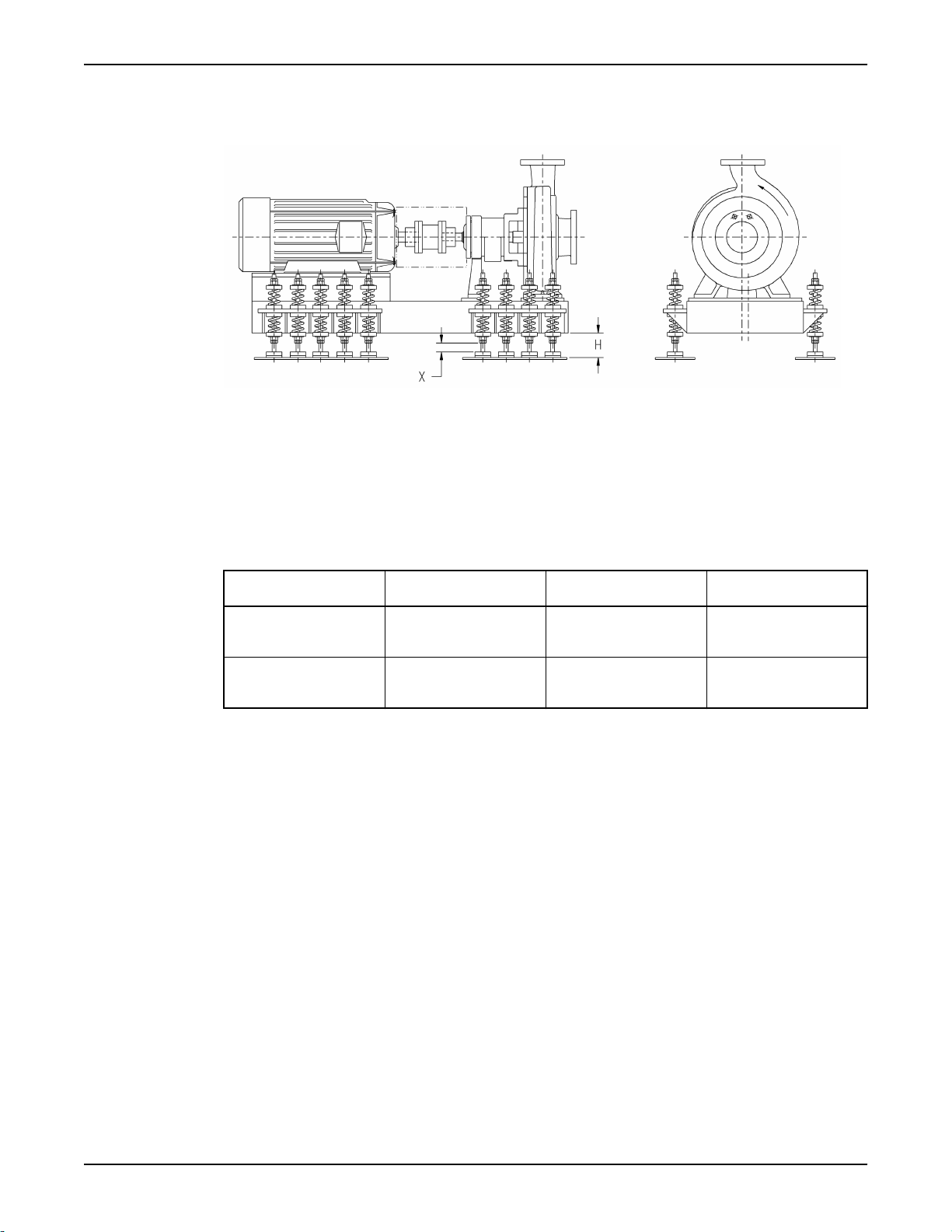

The springs in the second-generation spring-mounted baseplate are supplied in two sizes:

Free length of spring Spring rate Location Length of stud used

with the spring

7.125 in. (181 mm) 885 lbs/in.(149.72

newtons/mm)

11 in. (280 mm) 176 lbs/in.(30.82

newtons/mm)

1. Put the baseplate on a support above the foundation/floor.

Make sure that there is approximately 16 in. (406 mm) between the baseplate and the foundation/

floor in order to provide enough space to install the spring assemblies.

2. Apply an anti-galling compound to the threads of the studs, nuts, and bearing pads.

3. Assemble the spring assemblies:

a) Set a hex nut and a hex jam nut on a spring stud and thread it down 1 in. (25 mm).

b) Insert the stud from the top of the mounting bracket on the baseplate.

Refer to the GA outline dimension drawing in order to determine the correct length of the studs

for each location.

c) Install a follower with the flat side facing up.

d) Install a spring.

Refer to the GA outline dimension drawing in order to determine the correct spring for each

location.

e) Install a follower with the flat side facing down.

f) Install a flat washer, a hex nut, and a hex jam nut and thread them up 2 in. (54 mm).

g) Install a bearing pad on the lower end of the stud.

h) Hand-tighten the stud to the bearing pad.

The depth of the thread in the bearing pad is 1 in. (25 mm).

i) Set the bottom adjusting nuts on the stud to the heights (X1 and X2) indicated on the certified

GA dimension drawing.

Mounted under the

baseplate below the

pump

Mounted under the

baseplate below the

motor

16 in. (406 mm)

22 in. (559 mm)

Models 3180, 3181, 3185, and 3186 Installation, Operation, and Maintenance Manual 27

Page 30

1

2

3

4

5

6

7

8

Installation

Adjust distances by moving the hex nut and the hex jam nut up or down.

4. Repeat step 3 for each stud and spring assembly.

5. Check the X1 and X2 dimensions again.

6. Lower the baseplate so that the spring assemblies fit into the foundation pads.

The weight of the baseplate compresses the springs, which leaves the upper nuts loose. You might

have to level the baseplate.

1. Hex jam nut

2. Follower

3. Flat washer

4. Foundation pad

5. Bearing assembly

6. Spring

7. Hex nut

8. Stud

7. Level the baseplate and make the final height adjustments:

a) Thread each of the upper hex nuts down to the baseplate mounting bracket.

b) Turn the upper hex nuts on the studs that hold the larger springs under the motor. This allows

you to compress each spring until the baseplate is level.

c) Hand tighten the upper hex nuts on the studs that hold the smaller springs under the pump.

Hand tighten only in cold setting.

28 Models 3180, 3181, 3185, and 3186 Installation, Operation, and Maintenance Manual

Page 31

• Make sure the distance (H) from the bottom of the baseplate to the floor mounting pads is equal

to the dimension shown on the certified GA dimension drawing.

• Make sure the height of the centerline of the suction flange is equal to the dimension shown on

the certified GA dimension drawing

• In order to level the baseplate, the X1 and X2 dimensions can vary slightly from the dimensions

shown on the certified GA dimension drawing.

8. Fasten the lower and upper hex jam nuts against the hex nuts on each spring assembly.

NOTICE: Do not cut off the additional length of the studs. The additional length is needed in order

to remove the springs safely. Keep the additional threads lubricated with grease or a rust inhibitor.

Installation

Models 3180, 3181, 3185, and 3186 Installation, Operation, and Maintenance Manual 29

Page 32

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

1)____________________

2)____________________

3)____________________

4)____________________

5)____________________

6)____________________

7)____________________

8)____________________

9)____________________

10)___________________

11)___________________

12)___________________

13)___________________

14)___________________

15)___________________

16)___________________

17)___________________

18)___________________

Level measurements

Installation

Baseplate-leveling worksheet

30 Models 3180, 3181, 3185, and 3186 Installation, Operation, and Maintenance Manual

Page 33

Install the pump, driver, and coupling

1. Mount and fasten the pump on the baseplate. Use applicable bolts.

2. Mount the driver on the baseplate. Use applicable bolts and hand tighten.

3. Install the coupling.

See the installation instructions from the coupling manufacturer.

Pump-to-driver alignment

Precautions

WARNING:

• Follow shaft alignment procedures in order to prevent catastrophic failure of drive components or

unintended contact of rotating parts. Follow the coupling installation and operation procedures from

the coupling manufacturer.

• Always disconnect and lock out power to the driver before you perform any installation or

maintenance tasks. Failure to disconnect and lock out driver power will result in serious physical

injury.