Page 1

054001

OUTPUT UNIT

Instruction Manual

-} GOULD ADVANCE

Telephone 01-5001000

Telegrams Attenuate Ilford

Telex 263785

Page 2

SECTION 1

SECTION 2

SECTION

SECTION

Introduction

Specification

Operating Instructions

3

General

3.1

Chart recorder speed

3.2

Driving a chart recorder 5

3.3

The Read-out cycle 5

3.4

Remote start

3.5

Function Generation

3.6

3.7 Digital Outputs

Circuit Description

4

4.1 General

D-A Converter

4.2

Latches and latch control 9

4.3

4.4

X-ramp counter 9

4.5 Data Selector

4.6 Clock delay

10

3

SECTION 5

4

5

Maintenance

Fitting the 4001 to the OS4000

5.1

5.2 Access

Fault finding

5.3

Setting up Procedure

5.4

12

12

13

14

15

5

5

SECTION

Circuit Diagrams and Components

6

Schedules 17

5

SECTION

7

7

8

8

9

Fig. 1

Fig. 2

Fig. 3 Block diagram

Fig. 4

Fig. 5

9

Fig. 6

Fig. 7

Fig. 8

Guarantee and Service Facilities

7

ILLUSTRATIONS

Typical read-out cycle

Connections to back panel socket

Data Selector - mechanical

equivalent

Clock delay - timing diagram

Internal view of 4001

Fixing details

Circuit diagram

21

6

7

8

10

11

12

13

19

Page 3

Introduction

The 400 I option is designed to be added to a standard

OS4000 Digital Storage Oscilloscope to enable the infor-

mation in store to be retransmitted in both analogue and

digital form. Two analogue outputs are provided, and

these are intended primarily to drive strip chart and X-V

recorders. Channel I and 2 signals are available simultan-

eously at a read-out rate which can be varied to suit the

chart recorder, with a slowest time of 200 seconds

representing the 10 division display. In addition, a

corresponding X-ramp signal is provided for X-Y recorder

use. The unit also incorporates relay contacts for pen lift

or chart motor control. There is a variable delay between

the closing of these contacts and the start of read out

which can be preset to allow a chart drive motor to

accelerate.

.A socket on the rear panel presents the output infor-

mation in digital form as two eight bit parallel signals for

Y and one ten bit parallel signal for the X ramp. Control

facilities for remote start and continuous readout are also

provided. The latter can be used for continuous

generation of a recorded transient or frequency shift of

recorded waveforms.

Page 4

Specification

Section 2

ANALOGUE OUTPUTS Via B.N.C. connectors

Channels 1 and 2

Amplitude lOOmV per cm of screen height.

Bipolar with OV corresponding to

middle of screen

Accuracy Output voltage per cm of display±3%

Output to input voltage (ca!)

X Ramp

Amplitude

Time output accuracy of Y Channel outputs±1%

(Record to replay ratio)

Output Impedance CHI, CH2 and X-ramp

DIGITAL OUTPUTS Via back panel socket

Channels I and 2

X Ramp

Accuracy

lOOmV per cm of screen width.

Positive ramp resetting to OV

Output voltage/cm of display±J%

Output voltage/unit time recorded±3%

100H/0.IJ.lF

Continuous short circuit protected

All outputs true binary from open

collector T.T.L. buffers

8 bit parallel, negative logic

10 bit parallel, negative logic

Y Channel full scale=9cm of display±5%

X Ramp full scale=II.3cm of display ± 5%

±

3%

Remote continuous read-out by T.T.L. low or contact

closure to ground.

Delay between start command and

initiation of read-out cycle set by front

panel preset control from <20msec to

> I sec.

(lOJ.lsec. to lOsec. by internal component

change)

Front panel access via 4mm sockets to

isolated single pole contact which closes

from start command to end of read-out

cycle

Contact rating 200V D.C. 0.5 A D.C.

IOWD.C. Isolation 400V max.

OUTPUTS

Oocks I and 2

Negative T.T.L. pulses, 100nsec.

duration marking the change of

each digital word.

T.T.L. low, commencing at the end

of delay, for the duration of the

read-out cycle.

READ OUT RATE

Set on OS4000 time base range switch

Range 20sec/cm to

Read-out bandwidth D.C. - 16kHz (-3dB)

CONTROLS

Front panel start button to initiate single read-out cycle.

Remote start by T.T.L.low or contact closure to ground.

200J.ls/cm

DIMENSIONS 3.75cm extra height to OS4000

WEIGHT 570gm extra (l

ACCESSORIES 36 way plug Ampheno157-30360

%

Ib) to OS4000 approx.

2 x 4mm plugs

Handbook PN 36896

Page 5

Operation

3.1

ANALOGUE OUTPUTS

The 4001 may be used to drive strip-chart, T-Y or X-V

recorders. Both Y channels are available simultaneously

for chart recorders with two pens. Alternatively, the two

channels may be reproduced sequentially on single pen

recorders. A synchronised X-ramp is available to drive

X-V recorders as Y-t. Alternatively, the CHI and CH2

outputs can drive an X-Y display directly.

The internal contacts can be used to control chart motor

and/or pen lift if required.

3.2

CHART RECORDER SPEED

The 4001 offers a very wide range of read-out rates to suit

the recorder being used. The rate should be chosen by

considering the following:

1) A slow read-out rate, while faithfully reproducing

the stored signal, will also show the discrete levels

in the output waveform, (there is no dot-joining on

the 4001 outputs). A faster read-out rate and chart

recorder speed will tend to smooth the output wave·

form.

2) If too high a read-out rate is chosen, the chart

recorder may be unable to follow any large ampli-

tude fast change of the signal. This is slew-rate

limitation of the recorder.

The optimum read out speed for any particular

stored waveform is thus the maximum at which the

chart recorder is capable of tracking the signal. This

may be determined by increasing the readout/chart

recorder speed each sweep until waveform degrad-

ation can be observed.

The bandwidth of the output amplifier is d.c. to

16kHz (-3d B) which is well above the limitation of

most chart recorders. However this limitation may

be reached if the output is required for other

purposes when the replay frequency is a function

of recorded waveform and replay rate.

(See Function Generator)

3.3

DRIVING A CHART RECORDER

1) Connect to the CHI, CH2 and X-ramp sockets as

reqUired. In single trace operation, the same signal

will be present at CHI and CH2 outputs.

Set the sensitivity of the chart recorder inputs to

accommodate±400rn V f.s. on CHI and CH2 and

o

to 1V on the X-ramp.

When the 4001 is not reading out, the CHI and 2

and the X-ramp outputs return to

V-channel output corresponds to mid-screen on the

OS4000 display and thus the chart recorder pen

should be set to mid-scale unless specifically

required otherwise.

The X-ramp moves positive fromOVand thus the

OV.

Ov on the

pen should be positioned to allow at least 1V

positive travel.

2) Connect, if required for remote start/pen lift.

NOTE: The relay contacts are unprotected and

inductive loads should be suppressed to stay within

the contact rating.

3) The delay time (from closing of relay contacts to

start of read-out) is set by a front panel screwdriver

preset. The minimum delay time of < 20rns is

sufficiently short for recorders for which no delay

is required. The preset control range allows the

delay time to be set to a maximum of 1 second but

this can be increased to approx. 10 sec. by increasing

the internal capacitor C80I to I5tlF.

4) Obtain the required trace on the OS4000 and

STORE or LOCK it. If the 50% hold facility is

being used, the trace stored by the 50% hold will

appear at the CH2 output, the other trace appearing

at CHI.

5) Set the required read-out rate on the timebase range

switch.

6) Press the start switch to initiate the read-out cycle.

Note the display is inhibited during read-out. At

slow read-out rates, this will result in a blank screen

for considerable periods. Similarly the OS4000 is

prevented from accepting new data into the store

during this period.

7) At the end of the read-out cycle, reset the timebase

range switch as required to record subsequent data.

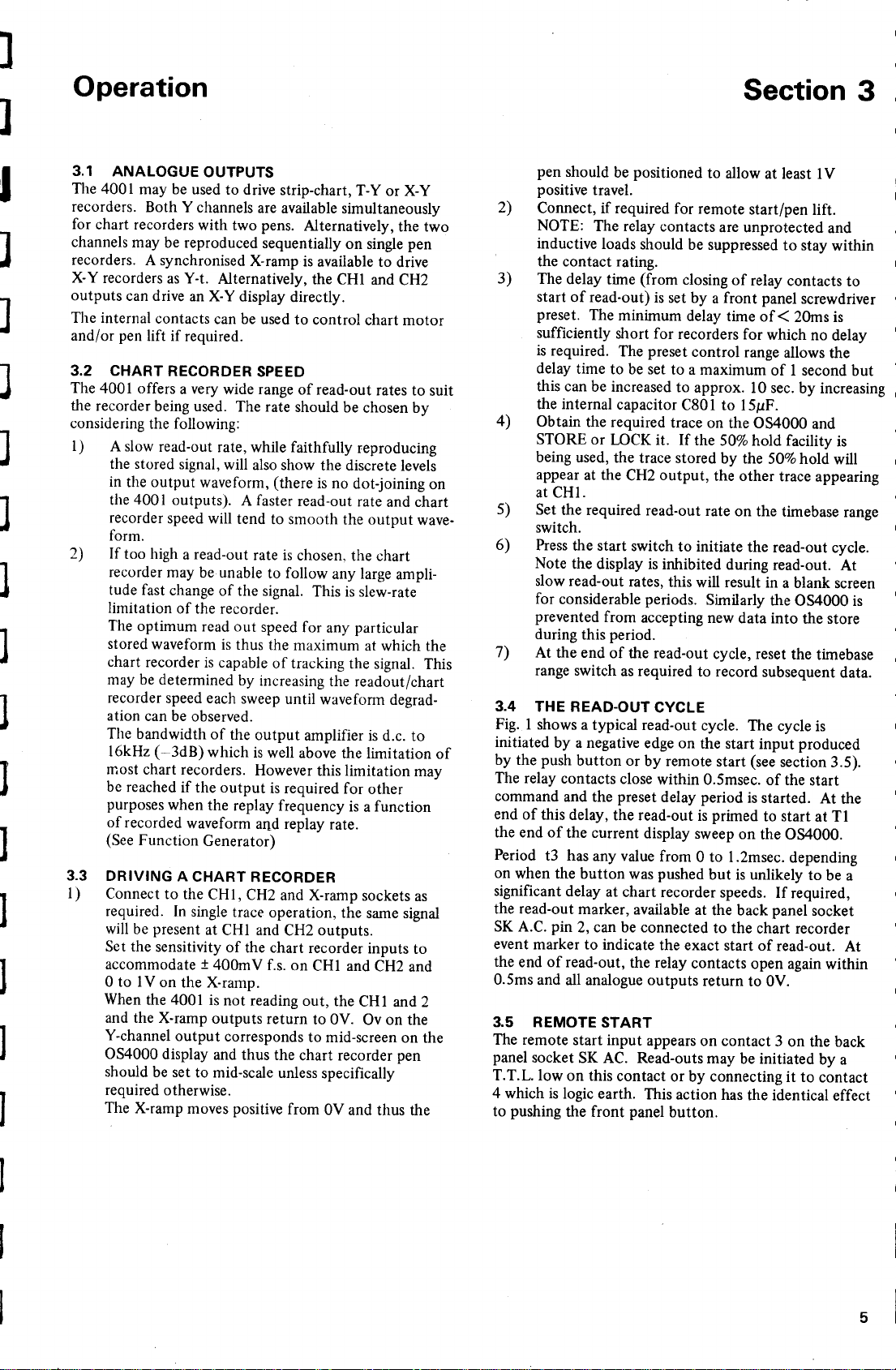

3.4

THE READ-OUT CYCLE

Fig. 1 shows a typical read-out cycle. The cycle is

initiated by a negative edge on the start input produced

by the push button or by remote start (see section 3.5).

The relay contacts close within 0.5msec. of the start

command and the preset delay period is started. At the

end of this delay, the read-out is primed to start at T1

the end of the current display sweep on the 0S4000.

Period t3 has any value from 0 to I.2msec. depending

on when the button was pushed but is unlikely to be a

significant delay at chart recorder speeds. If required,

the read-out marker, available at the back panel socket

SK A.C. pin 2, can be connected to the chart recorder

event marker to indicate the exact start of read-out. At

the end of read-out, the relay contacts open again within

0.5ms and all analogue outputs return to

3.5

REMOTE START

The remote start input appears on contact 3 on the back

panel socket SK AC. Read-outs may be initiated by a

T.T.L.low on this contact or by connecting it to contact

4 which is logic earth. This action has the identical effect

to pushing the front panel button.

OV.

Page 6

Operation

DELAY

OIP

START

COMMAND

,~:--------j-----<\~:

1__

11

----.j

',~,------I

I I

10.5msec I

----~Ft2

1--------<\1----1 ----

i

I

I

I

I I

Section 3

SINGLE

TRACE

CLOCKS

1 AND 2

CHl AND

CH2 DATA

CHl AND CH2

ANALOGUE

OUTPUTS

CH'

ANALOGUE

OUTPUT

CH2

ANALOGUE

OUTPUT

X-RAMP

ANALOGUE

OUTPUT

'~', -- -- _I~

'0'

'1'

'0'

Dv

...-- OUTPUTS HELD AT --------.: .- OUTPUTS CLEARED TO

'" ID;:

'0' 1000 0000 '. . _

". I I

..---- OUTPUTS HELD AT

_Ov II- ----

'1'

f- __

'0' LOW i~~ (LOW)

1000 0000 I

ALL OUTPUTS HELD---,~r-y-y--y-y ALL OUTPUTS CLEARED TO

9~---------<\1-----

I

,

I

14 -+I

I

I

I

,

I

I

: Qv

j~

iUlJ

lJlr~

I

, I

l~

---1-----. ~

I I

I :

I

: :1

I

I

i

I I

I

STEP'

___________________ ..L _

J~

~Ir-,

STEP 1023 :

~

I

I

I

I

I

I

r---

I

LJ

I

i

: ~o}Jsec

I

1000 0000

OUTPUTS CLEARED TO

1000 0000

90%-10%

FALL TIME

approx

Dv

Dv

Page 7

Operation

3.6 FUNCTION GENERATION

Although primarily intended to be used to drive chart

recorders, the analogue outputs can be used for other

applications. In the continuous run mode, the 4001 acts

as a function generator, continuously repeating the one or

two waveforms stored.

Thus a single transient can be recorded at one speed and

regenerated continuously at another faster or slower

speed, within the available stepped range of timebase

sweep speeds. (20 sec/cm to 200~s/cm.) As the scan

length is approx. 11.5 cm, this range is equivalent to 230

seconds to 2.3ms for a full cycle. For example a slow

stimulus into a servo system could be recorded and

replayed faster for analysis in an electrical analogue of

the servo.

Alternatively functions can be "written" manually on the

screen of the OS4000 by use of the shift control or

externally controlled input during a very slow scan in the

refreshed mode.

Such a single scan can be started by operation of the

trigger level control and frozen at any point by the 'Lock

Store' button. The latter is necessary at some point

during a scan for operation of the X shift control so that

the end of scan can be brought on screen. When the

'Lock Store' button is released the scan continues from

the point at which it was frozen. To write a second trace

in this mode, the Lock Alt. Samples button should be

pressed and the writing process repeated. The two

patterns will be generated simultaneously from the CHI

and CH2 outputs. Such outputs could be used for XY

display on another oscilloscope or chart recorder.

Continuous readout is obtained by shorting Pin 1 on the

rear panel socket to Pin 4 (ground).

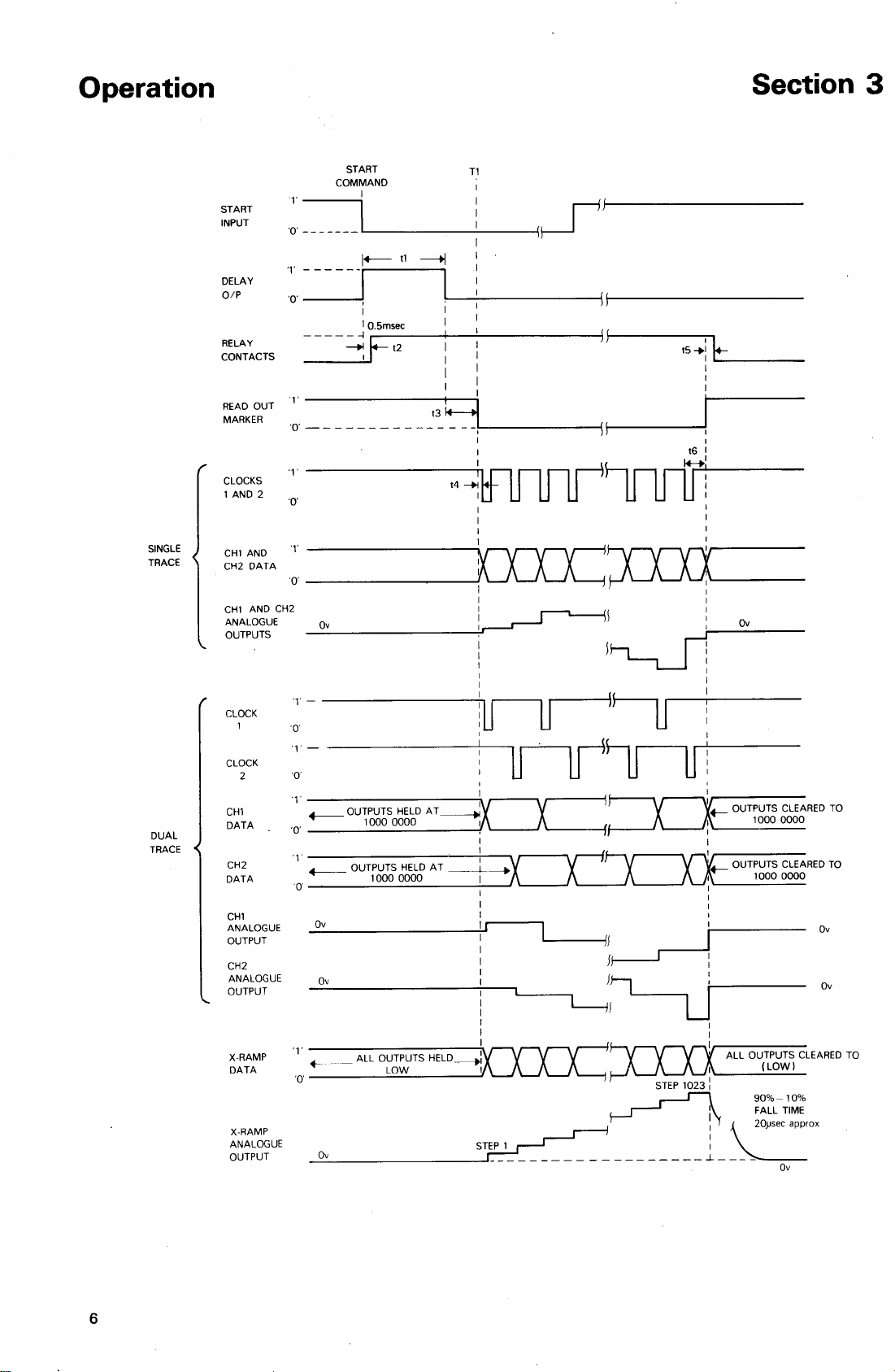

3.7

DIGITAL OUTPUTS

The chart in Fig.2 shows the'digital outputs and controll-

ing inputs available at back panet socket SKAC. These

outputs come from open collector T.T.L. buffers without

pull-up resistors.

Fig.l shows a typical read-out cycle. The read-out cycle

is initiated by a negative edge on the start input, which

triggers the delay period t1. This delay may be set in the

range 20ms to 1 sec. by the front panel control or if

required it can be reduced to less than 50~sec.by changing

C801 to 1000pF.

Read-out will commence at Tl, the end of the current

display sweep on the OS4000. Thus there will be a period

t3, after the end of the initial delay, of 0 to 1.2msec.

approx. according to the relative timing of the start

command and the OS4000 sweep before the read-out is

enabled.

There will be a further delay, t4, between the read-out

enable and the first clock pulse, where t4 is dependent

upon the read-out rate chosen. For a read-out rate of

N sec./cm, t4 will be in the range 0 to N x 11 X

10-3sec,

Section 3

Th~ problems due to the uncertainty of these delays are

reduced (or removed) by clocks 1 and 2, whose negative

edges indicate when the data is updated in channels 1 and

2 respectively. These clocks may be used to latch the

data at the receiving digital equipment.

CHI data is shown as changing first when in dual channel

operation. This is only in the case when the 084000 is in

the 'Refreshed' mode. In the 'Roll' mode, each sweep

does not start at the beginning of store (see 0S4000

handbook). This results in an uncertainty as to which

channel output will appear first. Again, recourse should

be made to clocks 1 and 2.

Pin No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

Connection

Continuous read-out input

Read-out marker

Remote start input

Logic earth (OV)

Clock 1

Clock 2

Dl (Most Significant)

D2

D3

D4

D5

D6

D7

D8

D9

DlO (Least significant)

Not connected

Not connected

Dl (Most significant)

D2

D3

D4

D5

D6

D7

D8 (Least significant)

D1 (Most significant)

D2

D3

D4

D5

D6

D7

D8 (Least significant)

Not connected

Not connected

Page 8

Circuit Description

4.1 GENERAL

Fig.8 shows the full circuit detail0f the 4001.

References of components on the P.C.B. are in the range

800 to 899.

Components in the range 80 to 89 are on the front panel

of the 4001.

Interconnection between the 0S4000 and the 4001 is

obtained by breaking the direct links SKK to SKD and

SKA to SKH in the OS4000 and reconnecting SKA to

SKAA, SKD to SKDD etc. (see Fig.26 of 0S4000 hand-

book). This provides access to the Y-Channel data and

permits 0S4000 control signals to be modified by the

4001.

+

5V WRITE

RELAY RATE

x::::::::::=:

GATE

&

DELAY

Section 4

PULSES

BUFFERS

[>0

START BUTION ~

.l

READ-OUT WRITE

ENABLE RATE

B-BIT DATA

\ IN

In essence, operation of the start button initiates the

delay period. At the end of this period the control

circuitry is primed to start a read-out at the end of the

current display sweep of the OS4000. During read-out,

the clock to the OS4000 read address counter is changed

to the slower rate determined by the timebase range

switch. At the end of the slow read-out scan, the control

circuit is reset and the OS4000 returns to normal

operation.

(a) CH1 and CH2

Y channel data is obtained from the OS4000 in the form

of an 8 bit word as read out from the stores.

Consider the circuit when operating in dual trace mode.

Channel 1 information is contained in odd store locations

and Channel 2 information in even locations. In order to

PULSES

j

BUFFERS

[>0

1

separate the two channels and present them simultan-

eously, the incoming data is held in two sets oflatches,

one clocked on even addresses, the other on odd. The

latched information is then passed on to the digital to

analogue converters (D to A) and also to the buffers,

which protect the internal data from external effects

such as short circuits or line reflections. At the end of

read-out, the latches are cleared to binary 1000,0000

which produces

(b) X Ramp

The X-ramp is produced digitally by a 10 bit counter

clocked at each change of data input. The counter is

cleared to all zeros at the end of read-out. The output of

this counter feeds a third D to A and is buffered as is the

Y data for the digital output.

av

(mid range) at the analogue outputs.

CHl

OUT

CH2

OUT

Page 9

Circuit Description

(c)

Timing

The start of read-out is initiated by triggering the delay.

This immediately energises the relay. At the end of the

delay period, the start latch is set, holding the relay and

putting a '1' on the D of the enable latch. The next

sweep reset from the OS4000 clocks this' l' to the out-

put and enables the read-out.

The start latch is cleared after two clock pulses putting a

'0' on the D of the enable latch. The relay is now held on

by theQof the enable latch. When the next 'sweep reset'

pulse arrives at the end of the slow scan, this '0' is clocked

to the output and the read-out enable goes low clearing

the Y channel latches and resetting the X-ramp, thus

terminating read-out.

The NORM input inhibits read-out when the OS4000 is in

the normal mode, by putting a '0' on the D input of the

start latch and on the clear input of the enable latch.

4.2 D/A CONVERTERS

The D/ A converters, IC821, 822, 823, are similar to those

used in the OS4000. The output current produced at

Pin 4 is converted into an output voltage by the following

operational amplifiers, IC 824, 825, 826. The current

injected into Pin 14 of the D to A defines the output

scaling, and the external current injected into Pin 4 of the

D to A, sets the zero. Each has a preset control to com-

pensate for component tolerances. Both pins are virtual

earth points and so the currents can be completely

defined by a reference voltage and a series resistor. The

reference voltage is provided by regulator, IC827. The

resistor and capacitor on the output remove any high

frequency pick up. Each channel has a half scale offset

current introduced by R848, 849 and R841, 842 such

that mid-screen on the display produces OV out.

The X-ramp operates on 10 bits. The least significant

eight are converted to an analogue current by IC821.

The two most significant bits are generated separately for

current summation at the input of IC824.

These additional binary weighted currents are provided

by R822, R823 and R824 representing bit Dl, and R832,

R833 and R834 representing bit D2.

Transistors, TR802 and TR803, when switched on,

reverse bias diodes, D807 and D805/D806 respectively,

diverting the current from the summing junction. D804

is included in series with R854 to ensure thermal tracking

between the current from IC821 and the two additional

currents. IC821 draws a current toward -6V from the

summing junction, proportional to the digital input.

Correspondingly the two additional currents are normally

on when their digital inputs are zero and their total

current is balanced by that through R825 and R827.

R824 and R834 adjust the currents representing D2 and

Dl respectively. R829 adjusts the overall scaling without

changing the matching between the three currents.

4,3

LATCHES AND LATCH CONTROL

Refer to the circuit diagram, Fig.8.

The incoming data stream enters two 4-bit latches in each

Channel, IC819, 815 and IC814, 818. TheQoutputs are

used for all but the most significant bit, which arrives

inverted by IC804 (d) and is taken out from theQoutput.

This ensures that at the end of read-out when the clear is

taken low and all the latches cleared, the digital infor-

mation presented to the D/A is binary 1000,0000 which

is half full scale (OV at the analogue output).

IC807 gates the clock pulses such that:-

(a) In dual trace or 'Lock alternate samples' mode,

information from odd and even locations is clocked into

CHI and CH2 latches respectively.

(b) Information from all store locations is clocked into

both channels when in single trace operation.

The operation is as follows:-

The signal arriving at Pins 13 and 2 of IC807 is the clock

to be gated. The signal arriving at Pins 5 and 9 is the read-

out enable. When low it inhibits clocks to both latches

and clears them. When high, it enables clocks.

The input 'dual trace' is inverted by IC802 (b). In single

trace operation it puts a '0' on IC805 Pins 13 and 9 which

in turn puts a '1' on IC807 Pins 12 and 1. This allows

clocks to reach both Y Channel latches simultaneously,

fulfilling condition (b) above.

In dual trace operation or 'lock alt. samples', IC802 Pin 4

is high, enabling the read address LSB to arrive at IC807

Pin 1 and its inverse at Pin 12. Thus when the LSB is

High, the CHI latches receive clocks, when it is low CH2

receive clocks. This fulfils conditions (a).

4.4 X

IC817 and IC820 are each four bit synchronous binary

counters and with IC816 are cascaded to form a 10 bit

divider. They are cleared to zero at the end of each sweep

and stepped with each change of Y Channel data, Le.

following the read address through the read-out cycle.

4.5

Switches shown with '0' on select.

The data selector, IC808 functions as 4 changeover

switches as shown in FigA.

The OS4000 normally reads out from the stores at a fixed

RAMP COUNTER

DATA SELECTOR

Page 10

Circuit Description

rate. Switch (a) changes this rate to one set by the Time-

base switch, i.e. the write-rate pulses. The flip-flop,

IC805 (a) and (b), retimes the write-rate pulses from P2

to PI to drive the read address counter. (See Fig.5.)

In dual trace operation, the OS4000 normally reads even

store locations only on one sweep and odd only on the

next. (See section 4.5.4 of 0S4000 handbook.)

In the read-out mode, switch (c) ensures that the LSB

address is taken from Cl rather than Cl', retaining read-

out from all the store location. Switch (b) sends logic '0'

to the dot-joiner gating circuitry of the OS4000 in place

of Cl during read-out, while (d) sends logic to the read/

write control to inhibit writing into store.

4.6

CLOCK DELAY

Fig.5 shows the retimed write rate pulses which arrive at

IC803 Pin 3. These are sent to step the read address

counter but there is an inherent delay within the OS400C

before the data changes. Because of this delay of data it

is necessary to delay the start of clock pulses to the X-

ramp counter and to the Y-Channellatches by three P4

pulses.

The write-rate pulses are entered at the serial i.!l.Putof the

shift register, IC812, and clocked through by P4. Using

the output from the third stage of the register produces

the required delay. At the end of read-out, the shift

register is cleared to zero by parallel loading.

Page 11

Circuit Description

T

ORIGINAL READ

COUNTER PULSE

'0'

t

WRITE RATE PULSE

SLOW READ

COUNTER PULSE

IC808

pin

3

1ST STAGE CLOCK

DELAY

READ STORE

ADDRESS

DATA FROM STORE

P4

TJl

'0'

TJ

'Q'

T

0'

0

T

'Q'

T

'0

t

n

X

n

~

n

n n

r1

Fig.

NEW DATA

AT

alP

LATCH

2ND STAGE CLOCK

DELAY

3RD STAGE CLOCK

DELAY

IC812

pin

11

CLOCK TO RAMP

COUNTER

LA TCH GA TING

X DATA alP

5

Clock Delay - Timing Diagram

&

T

'0

T

'0'

T

'0'

T

'Q'

'1'

'Q'

~

U

~

Page 12

Section 5

5.1 FITTING THE 4001 TO THE 084000

The 4001 kit to be fitted to an OS4000 comprises:

Part Number

1 4001 assembly

2 Cable and plug assy 'A'

2 Cable and plug assy 'B'

4 Nut special

4 Pillar clamping

10 Washer 4-40 'Wavey'

1 Cover Bottom

6 Screws 4-40 x ~" Pan Head

A3/36892

A3/36893

A4/36827

A4/36826

4591

A2/36823

22694

Taptite

Fitting procedure

(1) Disconnect the OS4000 from the supply and

stand it on the back cover.

(2) Remove both covers of the OS4000, plus 4 feet.

(3) Unplug the ribbon cables connecting SKA to

SKH and SKK to SKD and plug in the four

ribbon cables supplied to each of the above

sockets as shown in Figs. 6 and 7b. (Long cables to

sockets A and H, short to K and D.) It is possible

to achieve this without removing the store and

timing logic boards, but if any difficulty is

encountered refer to the OS4000 handbook

section 5.2.2 to remove these boards.

(4) Place the special nuts on the OS4000 frame

extrusion, with the threaded hole inside as shown

in Fig.7a.

(5) Place the 4001 chassis in position and insert the

threaded pillars.

(6) Connect the power supplies as shown in Fig.7c.

The connectors are a push fit onto the supply pins.

(7) Plug in the four ribbon cables to the sockets on the

4001, connecting

SK A to SK AA

SK D to SK DD

SK H to SK HH

SK K to SK KK

POWER SUPPLY

CONNECTIONS

(SEE F;g 7)

DELAY

TIMING

COMPONENTS

C80l

• CHASSIS FIXINGS

• BOARD FIXING SCREWS

R 825

X ZERO

R 829

X CAL

Page 13

(8) The 4001 is now ready for setting up as detailed in

section 5.4. It should not be necessary to make any

adjustment to the OS4000.

(9) Fit the bottom cover to the 4001 with the ventil-

ation holes at the rear. The original bottom cover

of the OS4000 is not required when the 4001 is

fitted.

(l0) Fit 4 feet to the 4001.

4001

BACK/FRONT

PANEL

5;2 ACCESS

Access to the 4001 is obtained by unscrewing the six

retaining screws and removing the bottom cover. Fig.6

shows the location of the preset controls and test points.

Access to both sides of the board and to the preset

controls in the OS4000 may be obtained in the following

manner.

(l) Unplug PLC and PLG.

(2) Remove the three screws marked (.) in Fig.6.

The board is now free to hinge about the central bar.

OUTPUT UNIT

4001

,

.-

OS 4000

STORE LOGIC

BOARD

METHOD FOR CONNECTING

CABLES DD AND AA

TIMING LOGIC

BOARD

STORE LOGIC

BOARD

METHOD FOR CONNECTING

CABLES HH AND KK

TIMING LOGIC

BOARD

Page 14

+170V

Section E

+20V

~ b

GREY

5.3 FAULT FINDING

(a) All voltage measured with respect to OV as in Table 1

Supply

+5.V +4.8 to +5.2V Pin 1 with respect to

+12V

-6V

6.2V ref. 5.9 to 6.5V

With the exception of the 6.2V reference, the supplies are

derived from the 084000. If any disagreement with

Table 1 is encountered, disconnect the supplies at Pins 1,

2 and 11, 12 and 13 and check the incoming supplies. If

the fault lies with the main frame, refer to section 5 of

the OS4000 manual.

(b)

logic Levels

le's with the exception of IC's 802, 809, 810, 811, 813.

Logic '1', 2 to 4.5V

Logic '0', 0.15 to 0.7V

1C's 802, 809, 810, 811, 813 have open collector outputs

which require a pull-up resistor to +5V to attain the levels

indicated above.

(c) Fault Location

The following guide assumes that there is no fault in the

0S4000. This can be checked by by-passing the 4001

completely as follows:-

Measured

Voltage

11.5 to 12.5V Pin 12 w.r.t. Pin 13

5.75 to 6.25V

~!

BOTTOM EDGE

Location

Pin 2

Pin 11 w.r.t. Pin 13

Wiper of R834 w.r.t.

Pin 13

(a) Disconnect the four ribbon cables between the

4001 and the OS4000.

(b) Use two of these cables to connect SK A

directly to SK Hand SK K directly to SK D.

First check the supplies, then set the delay period to

maximum.

The following chart offers guidance on fault localisation;-

(i)

Digital read-out

but one or more

analogue outputs

inoperative.

(ii)

No read-out cycle

(OS4000 display

not interrupted)

but the L.E.D.

comes on for the

delay period.

(iii) L.E.D. perman-

ently on, no SKDD/KK Pin 1.

0S4000 display.

(1) +12V and -6V supplies.

(2) D/ A convertors.

(3) Operational Amplifiers.

(1) Sweep reset pulse on

SKDD/KK Pin 16 and

1C806 Pin 11.

(2) Clear inputs of

IC808.

(1) P4 clock pulses on

(2) Write rate pulses

(related to timebase

switch setting) on in-

put Pin 3 and output

Pin 4 of IC808.

(3) Check clocks to ramp

counter and ensure

count. Read-out

cannot terminate

untilQofIC816 (b)

clears IC806 (a).

Page 15

(iv) Both CH1 and

CH2 outputs

chopping between

CHI and CH2

signals at approx.

100 cycles per

displayed cm.

(v) Discontinuities in

the X-ramp.

SETTING UP PROCEDURE

Test Equipment

1. Calibrated dual trace oscilloscope.

2. Square wave generator.

Channels 1 and 2

Set the square-wave generator to 1kHz and the

0S4000 to CHI, 0.2ms/div. X expansion Xl.

Adjust the generator frequency and amplitude

display an 8 div peak to peak waveform with two

cycles occupying 10 div. Press "Full Store Lock".

Connect the 4001 CHI output to an oscilloscope

via the front panel BNC connector. Set the OS4000

timebase switch to 2ms/div. Connect TPl or its

remote on SK AC Pin 3, to logic earth to produce a

continuous read-out. Adjust R846 to produce an

800mV pk-pk output. Remove the earth on TPl

(1) SKDD/KK Pin 3 is

LO in dual trace

mode.

(1) Data bits missing.

(2) Mis-match between

IC821 current and

additional currents

see 5Ad.

and adjust R849 to produce OV d.c. out. Connect

the oscilloscope to the CH2 output and repeat

adjusting R839 and R842.

X-ramp

With the same stored display as in 5A(b) connect

an oscilloscope to the X-ramp output. Earth TPl

to produce continuous read-out. Connect the

second channel of the oscilloscope to the Channel

1 output. One cycle of the stored square wave,

representing 5 Div. of displayed trace, should also

correspond to 500m V of X ramp. Adjust R829 to

this effect.

Remove the earth on TPl and adjust R825 to

produce OV d.c. out.

X-ramp current matching

If any discontinuity is visible at the 14and/or72and

%

way points of the ramp, this means that the two

additional currents are no longer matched to the

current from IC821.

On one channel of an oscilloscope, display the

X-ramp in continuous read-out as in 5A(c).

Connect the other channel to R812.

R824 should be used to remove any step at the

quarter way point (coincident with the first positive

edge of D2) expanding the trace to view it if

possible. Adjust R834 to remove any step at the

half way point (negative edge of D2). When these

two are correctly adjusted there should be no

discontinuity at the three-quarter way point

(coincident with the second positive edge ofD2).

Repeat (c) above.

Page 16

Component List and Illustrations

ABBREVIATIONS USED FOR COMPONENT DESCRIPTIONS

Section 6

RESISTORS

CC

Carbon Composition

CF Carbon Film

MO Metal Oxide

MF

WW

CP

Metal Film

Wire Wound

Control Potentiometer

PeP Preset Potentiometer

CAPACITORS

CE(l)

CE(2)

SM

PF

Ceramic

Ceramic

Silver Mica

Plastic Film

PS Polystyrene

PE Polyester

Pe Polycarbonate

E

T

Electrolytic (aluminium)

Tantalum

1/

W

2

l/

W

S

1/

W

2

1/4W

6W

500V

10%

5%

2%

1%

5%

20%

20%

+

80%

- 25%

±

10%

10%

±

±

10%

+

50%

-

10%

+

50%

-

10%

unless otherwise stated

unless otherwise stated

unless otherwise stated

unless otherwise stated

unless otherwise stated

unless otherwise stated

unless otherwise stated

unless otherwise stated

unless otherwise stated

unless otherwise stated

Page 17

Component List and Illustrations Section 6

OUTPUT UNIT 4001

Ref Value DescriPtion Tol

RESISTORS

%±

Part No.

R81 1M CP A4/37898

R801 6k8 CF 21807

R802 4k7 CF

R803 lOk

R804

1M CF

R805 lOk

R806

4k7

CF

CF

CF 21805

R807 4k7 CF

R808

R809 4k7

470 CF

CF 21805

21805

21809

31840

21809

21805

21797

R810

R811 4k7

R812

8k2 CF

R813 8k2

R814

10

R815 2k7

R816 3k3

R817

10 CF

R818 3k3

R819

10 CF 21793

R820 3k3

R821

10

R822 180 CF

R823

3k MO

R824 220 PCP

R825 220 PCP

R826

R827

4k7

lkl

CF

21805 C809 lOnF

21808 C810

CF

CF

21808 C811 lOnF

21793

CF 28726

CF

21803

21793

CF

CF

CF

21803

21803

21793

21795

26727

35881

35881

CF

MO

21805

28791

R828 120 CF 28718

R829 100 PCP

R830

R831 2k7

100 CF

CF

R832 100 CF

R833

1k5 MO

R834 100 PCP

R835 680 CF

R836

R837

R838

R839

560 CF

560 CF

100 CF

lk CP

R840 3k3 CF

R841

R842

R843

R844

R845

R846

R847

6k8 CF

2k2 PCP

560

CF 21798

560 CF

100 CF

lk

3k3

PCP

CF

R848 6k8 CF

R849

2k2 PCP

36958

21794

28726

21794

26733

36958

28723

21798

21798

21794

35880

21803

21807

36868

21798

21794

35880

21803

21807

36868

R850.

R851

R852 4k7

R853

180 CF

R854 3k3

CF

MO

21805

21795

26726

Ref Value Description Tol

CAPACITORS

C81

.C82

C83

C801

C802

C803 lOnF

C804

C805 lOnF

C806

C807 1nF

C808 lOnF

.1J.lF

.1J.lF

.1J.lF

1.5J.lF

.68J.lF

2n2F

lOnF

CE(2)

CE(2)

CE(2)

PE

E 63V

CE(2) 250V 22395

CE(2)

CE(2) 250V 22395

CE(2)

CE(2) 500V 22387

CE(2) 250V 22395

CE(2) 250V 22395

33J.lF

E 16V

CE(2) 250V

C812

C813 lOnF

C814 lOnF

C815

C816 lOnF

C817

C818 lOnF

C819 lOnF

C820 100nF

C821 100nF

C822 100nF

INTEGRATED CIRCUITS

IC801

IC802'

IC803

IC804

IC805

IC806

33J.lF

10nF

lOnF

E 16V 32173

CE(2)

CE(2)

CE(2)

CE(2) 250V 22395

CE(2)

CE(2)

CE(2)

CE(2)

CE(2) 36709

CE(2)

555V

74LS05

74LSlO

74LS04

74LSOO

74LS74

IC807 74LSOO

IC808

IC809

IC810

IC811

IC812

IC813

IC814

IC815

IC816

IC817

IC818

IC819

IC820

IC821

IC822

IC823

IC824

IC825

IC826

IC827

74S157

74LS05

74LS05

74LS05

74LS95 36734

74LS05

74LS175

74LS175

74LS76

74LS161 36727

74LS175

74LS175

74LS161

1408-8

1408-8

1408-8

741

741

741

78L06

%±

Part No.

25V 36709

25V 36709

25V 36709

63V 31365

500V 22389

250V 22395

250V 22395

250V 22395

250V 22395

250V 22395

250V 22395

250V 22395

36813

36879

36867

36731

36730

36732

36730

36735

36879

36879

36879

36879

36728

36728

36733

36728

36728

36727

35683

35683

35683

36736

36736

36736

36959

32162

32173

22395

36709

36709

Page 18

Component List and Illustrations

OUTPUT UNIT 4001 (Contd.l

Ref

TRANSISTORS

Value

TR801

TR802

TR803

Description Tol%±

BC182B

2N2369

2N2369

Part No. Ref

33205

23307

23307

Value

MISCELLANEOUS

S81

RL801

Description

REED RELAY

Section 6

Tol

%±

Part No.

A4/35341

26755

DIODES

D81

D801

D802

D803

D804

D805

D806

D807

D808

L.E.D. TIL209A

IN4148

IN4148

IN4148

IN4148

IN4148

IN4148

IN4148

35202

23802

23802

23802

23802

23802

23802

23802

SKAC

SKAD

SKAE

SKAF

SKAG

SKAH

Ampheno157-40360

27513

26587

26587

26587

36946

36946

Page 19

Guarantee and Service Facilities

Section 7

This instrument is guaranteed for a period of two years

from its delivery to the purchaser, covering faulty work-

manship and replacement of defective parts other than

cathode ray tubes and batteries (where fitted). Cathode

ray tubes are subject to the manufacturers guarantee.

This assumes fair wear and tear and usage in the specified

environment and does not cover routine recalibrations

and mechanical adjustments.

Wemaintain comprehensive after sales facilities and the

instrument should be returned to our factory for servicing

if this is necessary. The type and serial number of the

instrument should always be quoted, together with full

details of any fault and service required.

Equipment returned for servicing must be adequately

Service Dept.,

Roebuck Road,

Hainault,

Essex,

IG63UE

Tel: 01-500 1000

Telex: 263785

Telegrams: Attenuate Ilford

packed, preferably in the box in which the instrument

was supplied and shipped with transportation charges

prepaid. We accept no responsibility for instruments

arriving damaged. Should the cause of failure during the

guarantee period be due to misuse or abuse of the instru-

ment, or if the guarantee has expired the repair will be

put in hand without delay and charged unless other

instructions are received.

Our Sales, Service and Engineering Departments are ready

to assist you at all times.

The Service Department can provide maintenance and

repair information by telephone or letter, if required.

Note: Please check fuses before returning instruments

for service.

Loading...

Loading...