Page 1

Gould 400 Series

Digital Storage Oscilloscopes

Operators Manual

Page 2

Gould 400 Series

Digital Storage Oscilloscopes

Operators Manual

Copyright@1990 Gould lnc., Instruments Division

(Gould Electronics Ltd.)

Page 3

400 Operators Manual

A

Contents

Introduction

Getting Started

Advanced Features

The Menus

Performance Checking

Waveform Processing

1

2

3

4

5

Battery Unit Operat io n

Alphabetical Summary

Appendix 1 Error Messages

Appendix 2 Specification

Appendix 3 Remote

Operation

ppendix 4 Front & Back

Pictures

I

Service Facilities

6

7

A1

A2

A3

Page 4

Contents

400 Operators Manual

Introduction

Getting Started

1.

1.1 Safety and Power Requirements

1.1.1

International Safety Warning

1.1.2

Grounding

1.1.3

Live Parts

1.1.4

Ventilation and Dust

1.1.5

Operating Temperatures

1.1.6

Power & Frequency

Requirements

1.1.7

1.2 Using the Buttons

1.3 Start-Up Display

1.4 Obtaining a Trace

1.5 Horizontal Adjustments

1.6 Vertical Adjustments

Fuse Requirements

1.4.1

AUTO SETUP

1.4.2

Channel Selection (Off/On/lnv)

1.4.3

Coupling (AC/DC/Gnd)

1.5.1

TIME/DIVISION

1.5.2

Aliases

1.5.3

Position

1.5.4

Magnification

1.6.1

VOLTS/DIVISION

1.6.2

Position

1.6.3

Variable/Uncalibrated

1.6.4

Add

1.7 Manually Obtaining a Trace

1.8 Operating Hints

1.8.1

1.8.2

Advanced Features

2.

2.1 Trigger Control

2.2 Captu e Facilities

2.3 Display Modes

2.4 Cursor Measurements

1.8.3

1.8.4

1.8.5

2.1.1

2.1.2

2.1.3

2.1.4 Slope

2.1.5

2.1.6

r

2.2.1

2.2.2

2.2.3

2.4.1

2.4.2

2.4.3

Intensities too low

Trace off the top or bottom

Trace not being acquired

Trace unstable

Trace has flat top or bottom

Selecting Source and Coupling

Level

Trigger Point (T)

Trigger Mode (Norm/Auto)

Trigger Delay

Trace Hold

S/Shot and Run

Acquisition Status-AFTS

Cursor and Datum Selection

Making Measurements

of screen

(+/-)

The Cursor& Datum Lines

Plot

2.5

2.5.1

2.5.2

2.5.3

2.5.4

2.5.5

2.5.6

2.5.7

2.5.8

Internal Colour Plotter

Pens

Pen Changing

Paper Selection

Paper Loading

Internal plotting

External plots

Plot positioning and scaling

Data Transfer

2.6

2.6.1

2.6.2

2.6.3

Syntax

Receiving Data

Error Status

Real Time Clock

2.7

3.

The Menus

Additional Buttons

3.1

3.1.1

3.1.2

3.1.3

3.1.4

The Numeric Buttons

Menu Traces

Control

Post Store

Control Master Menu

3.2

Status Menu

3.3

3.3.1

3.3.2

3.3.3

3.3.4

3.3.5

3.3.6

Mode

Max/Min

V/Div

Probe set

Timebase

Trigger

Display and Trigger Menu

3.4

3.4.1

3.4.2

3.4.3

3.4.4

3.4.5

Probe ratio

Max/Min

Dot Join

Averaging

Trig Pos'n

Display Intensity

3.5

Reference Trace

3.6

RS423 Interface Menu

3.7

3.7.1

RS423 Plot Connections

3.7.2

RS423 Data Connections

Special Functions Menu

3.8

Post Store Master Menu

3.9

3.10 Save Trace Menu

Recall Memory Menu

3.11

3.12 Plot Menu

Performance checking

4.

Risetime

4.1

Bandwidth

4.2

Trigger sensitivity

4.3

Trigger bandwidth

4.4

Timebase calibration

4.5

Vertical Calibration

4.6

Max-Min (Alias Detector)

4.7

Page 5

400 Series Operators Manual

Contents

Waveform Processing Functions

5.

5.1 Cursor Measurements

5.1.1 Voltage and Time

5.1.2 Peak-Peak

5.1.3 Max-Min

5.1.4 Risetime (falltime)

5.1.5 Overshoot (preshoot)

5.1.6 Pulse Width

5.1.7 Frequency, Period, Duty Cycle

5.1.8 RMS

5.1.9 Area

5.2 Trace Manipulation

5.2.1 Filter Frequency

5.2.2 Filter Current Trace

5.2.3 Invert Current Trace

5.2.4 Integrate Signal

5.2.5 Integrate Current Trace

5.3 Trace arithmetic

5.4 Persistence/Limits Testing

5.4.1 Limits

5.4.2 Persistence

Battery Unit Operation

6.

Alphabetical Summary of controls

7.

Appendix 1: Error Messages

Appendix 2: Specification

Appendix 3: Remote DC operation of the DSO

Appendix 4: Front and Back Pictures

Service Facilities

Figure List

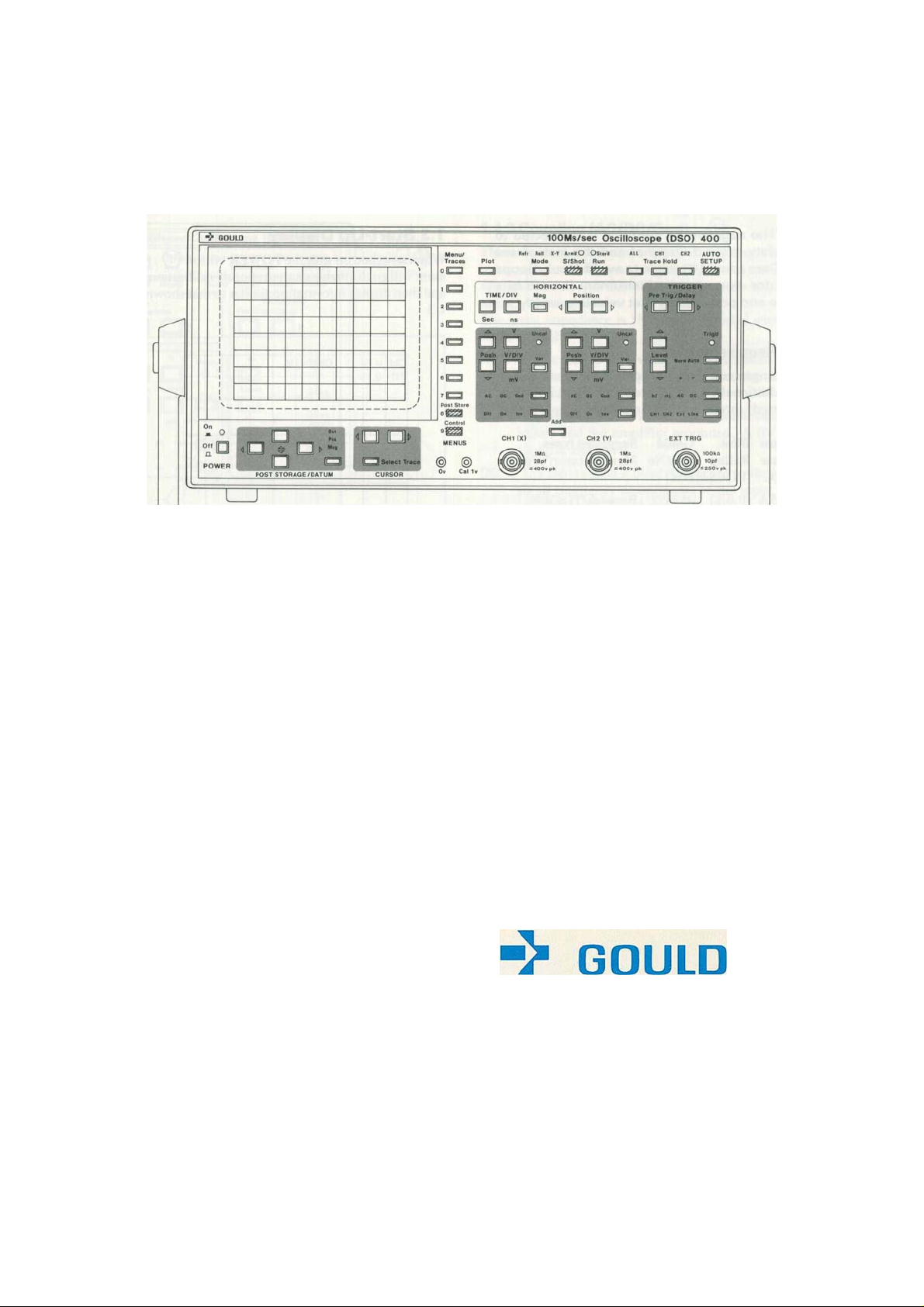

1.2a Single Function Buttons

1.2b The Toggles

1.2c

Pressure Sensitive Buttons

1.3

Start-Up Display

1.4

Obtaining a trace

1.4.1 An AUTO SETUP Display

1.5

Horizontal Controls

1.5.2 Alias Generation

1.6

Vertical Controls

2.1

Trigger Controls

2.1.6 Trace Capture with Delay

2.2

Capture Controls

2.4

The Cursor and Datum Line Controls

2.4.2 The Cursor and Datum Lines

2.5.5 Paper Loading

2.5.8a Relative Plot Positions

2.5.8b Plot Dimensions

3

3.1

3.2

3.3

3.4

3.5

3.6

3.7

3.7.1 400to Gould 6120 or HP7475 Connections

3.7.2a 400 to IBM-PC/XT Connections

3.7.2b 400 to IBM-PC/AT Connections

3.8

3.9

3.10 Save Trace Menu

3.11 Recall Trace Menu

3.12 Plot Menu

5.1a Cursor Measurements Menu

5.1b Example of Calculations on trace

5.1.1 Voltage and Time Measurement

5.1.2 Peak to Peak Measurement

5.1.3 Max-Min Measurement

5.1.4 Risetime Measurement

5.1.5 Overshoot Measurement

5.1.6 Pulse Width Measurement

5.1.7 Freq. Period and Duty Cycle Measurement

5.1.9 Area Measurement

5.2

5.4

6

6.2

A2

A3.2 DC Power Connections

A4a

A4b

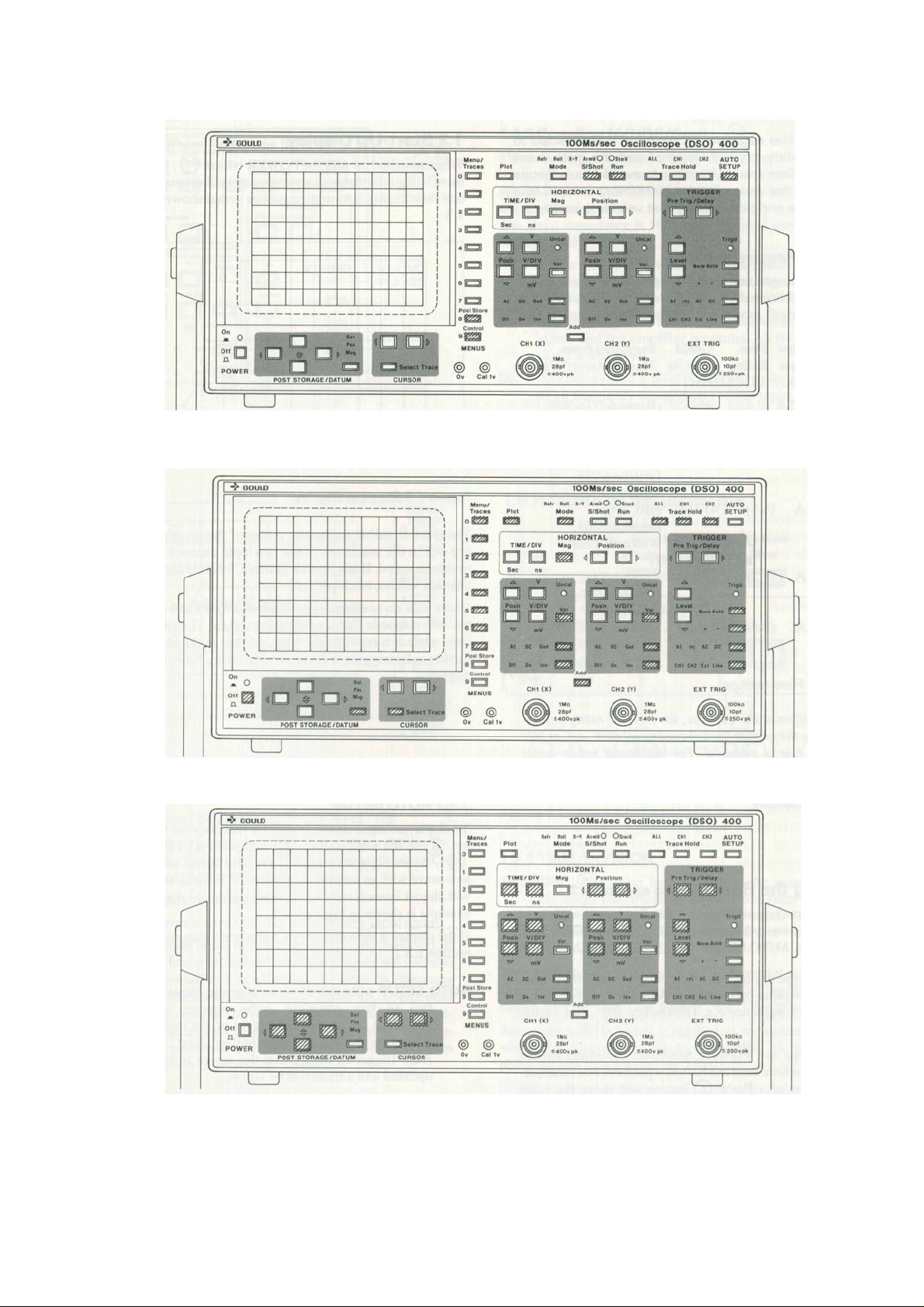

Menu Overview

Numeric Buttons

Control Master Menu

A Status Menu

A Display and Trigger Menu

Display Intensity Menu

Reference Trace Menu

An RS423 Interface Menu

Special Functions Menu

Post Storage Master Menu

Trace Manipulation Menu

Persistence/Limits Testing Menu

Battery Unit Interconnections

Battery Unit Front Panel Indicators

400 Series Dimensions

Rear View

RS423 Connections

Page 6

400 Operators Manual

Introducti

N

on

Introduction

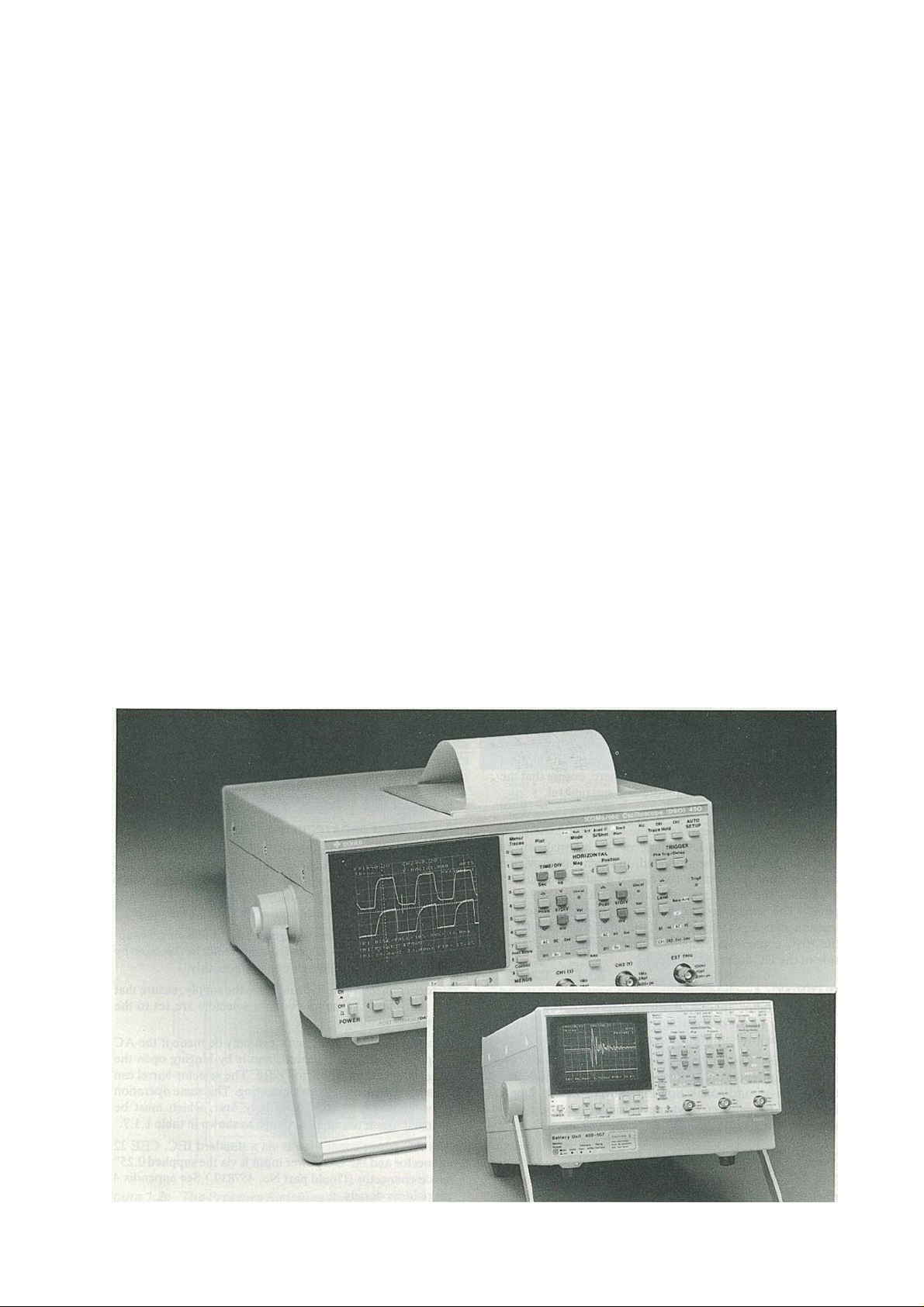

The Gould 400 series instruments are Digital Storage

Oscilloscopes (DSOs). They include all the features

expected of advanced modern oscilloscop es designed for

the professional engineer, whilst retaining the userfriendliness essential for those learning to use such

instruments for the first time.

The 400 range consists of three basic models; the 400 the

420 and the 450. All versions can be fitted with a battery

unit which provides the instrument with a fully automatic

built in Nickel Cadmium battery and charger which

allows uninterrupted operation of the DSO in the even t

of an AC supply failure and complete operation

independent of an AC supply.

Obtaining a trace is especially simple - just connect the

signal and press the Auto Setup button - the 400 does the

rest. Having obtained a trace, readily accessible datum

lines and a cursor make it easy to take automatic timing

and voltage measurements directly from the display. On

the 420 and 450 models, the waveform processing

function increases the power of the cursor measurements

in terms of both capture and post storage analysis and

measurement functions.

The innovative use of ergonomically designed pressure

sensitive push button controls provides a combination of

precision and flexibility for ease of operation.

More advanced features of the 400 series include a comprehensive range of menu-controlled functions. For

example, the Display and Trigger menu operates features

such as the trigger delay and pre-trigger display

functions. The pre-trigger display function allows the

signal prior to the trigger point to be captured and

displayed.

Three complete traces can be stored for future use and

recalled to the display via the Save Trace and Recall

Trace menus respectively. With the built in battery back

up facility, these will be retained even when the

instrument is switched off.

In addition to the above features, the 420 and 450 instruments have a built in 4 colour plotter and a battery

backed Real Time Clock. This provides a simple and

convenient method of obtaining permanent hard copy

plots of the screen display. The plots will contain the date

and time of acquisition together with the date and time of

plotting.

The 450 has all the features of the 420 and has a signal

bandwidth of 50MHz and an extra timebase range of

50ns/div.

umbers circled in the text refer to the controls shown

on the front panel picture in Appendix 3.

Page 7

Getting Started 1.1-1.1.6

400 Series Operators Manual

1.1 Safety and Power Requirements

1.1.1 International Safety Warning

(as required for I.E.C. 348 Cat I)

This instrument has been designed and tested in accordance

with IEC publication 348, and has been supplied in a safe

condition. This manual contains information and warnings

which must be observed to keep the instrument in a safe

condition. The instrument should not be switched on if it is

damaged and it should not be used under wet conditions.

For the correct and safe use of this instrument it is essential that

both operating and service personnel follow generally accepted

safety procedures in addition to the safety precautions specified

in this manual.

Whenever it is likely that safety-protection has been impaired,

the instrument must be made inoperative and be secured against

any unintended operation. Qualified maintenance or repair

personnel should be informed. Safety protection is likely to be

impaired if, for example the instrument shows visible damage

or fails to perform the intended measurements correctly.

1.1.2 Grounding

THE INSTRUMENT MUST BE GROUNDED.

AC

The instrument must be operated with a protective ground

connected via the yellow/green conductor of the supply cable.

This is connected to the instrument before the line and neutral

connections when the supply plug is inserted into the socket on

the back of the instrument. If the final connection to the supply

is made elsewhere, ensure that the ground connection is made

before line and neutral.

DC

If the unit is disconnected from the AC supply, and powered

from an isolated DC source or the internal battery unit, the unit

will not be grounded. Independent provision must be made to

maintain the case at a safe potential, by grounding the safety

ground terminal on the DSO rear panel. The safety ground

terminal is connected to the instrument case, to the ground of

the input signals (outer of the BNC connectors), and also

internally to the negative side of the DC supply.

WARNING: Any interruption of the protective ground

conductor inside or outside the instrument is likely to

make the instrument dangerous. Intentional

interruption is prohibited.

Signal connections to the instrument should be connected after

the ground connection is made and disconnected before the

ground connection is removed, i.e. the supply lead must be

connected whenever signal leads are connected.

1.1.3 Live Parts

The instrument should not be operated with covers removed.

The covers protect the user from live parts and

they should be removed only by suitably qualified personnel

for maintenance and repair purposes.

WARNING: Removing the covers may expose voltages in

excess of 8000V at the side of the display tube; these

may be present for up to one minute after the

instrument has been disconnected from the power

source.

1.1.4 Ventilation and Dust

The instrument relies on forced air cooling via a fan and

ventilation slots. Adequate ventilation can usually be achieved

by leaving a 75mm (3" gap) around the instrument.

The instrument should not be operated in dusty environments.

If the CRT filter requires cleaning it can be easily removed by

pressing in its right hand edge as shown by the moulded arrow.

1.1.5 Operating Temperatures

The instrument is designed to be operated in an environment

having an ambient temperature of between 0 and 50 degrees C,

(0 to 45 degrees if the battery unit is fitted) and to operate with

full accuracy between 15 and 35 degrees C.

Note: Direct sunlight, radiators and other heat sources

should be taken into account when assessing the ambient

temperature.

The instrument may occasionally be subjected to temperatures

between 0

and -10ºC without degradation of its safety.

1.1.6 Power and Frequency Requirement s

The instrument uses less than 85V A (200V A if battery unit

fitted) and operates from line voltages of 90V to 130V, and

190V to 265V, at 45 to 400Hz. Under the extreme conditions of

90V and 45Hz, the instrument will still operate correctly even if

there is a half cycle dropout in the line supply.

The instrument may be powered from a direct current supply in

the range 12V to 33V. The unit cannot be damaged by applying

power to both inputs simultaneously.

Before connecting the instrument to the supply, ensure that the

rear panel AC supply voltage selectors are set to the appropriate

voltage.

Access to the voltage selector can only be made if the AC

supply connector is removed, and is by hinging open the panel

connector from its top edge. The selector barrel can then be

moved to the required setting. This same operation provides

access to the AC supply fuse, which must be changed to suit

the supply voltage as shown in table 1.1. 7.

The AC power connection is via a standard IEC, CEE 22

connector and the DC power input is via the supplied 0.25"

spade connector (Gould part No. 457839.) See appendix 4 for

polarity details.

Page 8

400 Operators Manual

Figure 1.2a Single Function Buttons

Getting Started

Figure 1.2b The Toggles

Figure 1.2c The Pressure Sensitive Buttons

Page 9

Getting Started 1.1.7-1.4.1

pply

gg

yp

P

y

400 Series Operators Manual

CAUTION: The negative DC terminal is connected to the

safety ground terminal and the instrument case.

Care should be taken to avoid ground loops when,

for example, the instrument is used in a vehicle and

powered by that vehicle's supply.

1.1.7 Fuse Requirements

The fuse arrangement shown in table 1.1. 7 must be followed,

and additionally in the UK, a 3A fuse (5A if the battery unit is

fitted) should be fitted in the line supply plug .

Su

Slow Blow Gould Su

Voltage Fuse Rating Part No Manufacturer/Type No

IEC (ULlCSA) DSO

230V 0.5A (0.6A) 457452 BeswickrrDC488,

115V lA (1.2A) 457454 BeswickrrDC488,

12VDC 5A (6A) 457979 HRC type

BATTERY UNIT

230V lA (1.2A) 457454 BeswickrrDC488,

115V 2A (2.5A) 457455 BeswickrrDC488,

Table

1.1.7

Fuse ratings

ested t

es.

Littlefuse/239,

Schurter/FSP

Littlefuse/239

Schurter/FSP

Beswick/S505,

Wickman 19181

Littlefuse/239,

Schurter/FSP

Littlefuse/239,

Schurter/FS

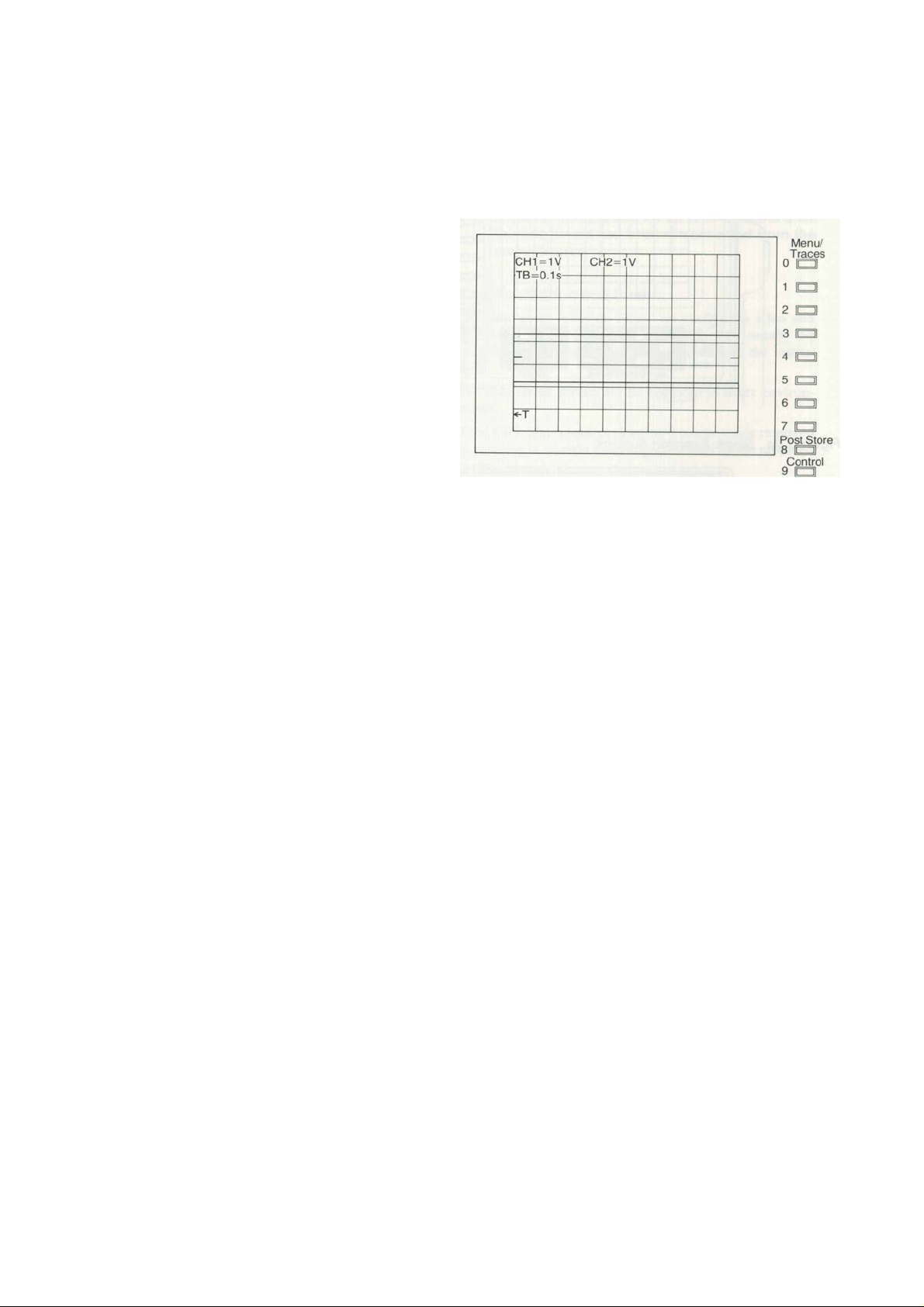

1.3 Start-Up Display

When switched on with the POWER button

will go through its automatic self-calibration sequence and then

display information similar to that shown in Figure

Figure

1.3

Start-Up Displa

The trace is visible across the centre of the screen. At the top

will be the sensitivity of the two input channels and the

timebase speed. It any input is inactive, information for that

channel will not be displayed.

Users with no previous experience of a DSO will find that the

400 responds like a conventional Real Time Oscilloscope while

it is repetitively triggered, but in the absence of further valid

triggers, it retains the last trace for continuous display.

(1)

.

the instrument

1.3.

Note: For different DC voltages, the DC fuse rating multiplied

by the voltage used should equal60W. e.g. at 30V a 2A

is required. For additional safety under extreme

fuse

fault conditions, the DC fuse

(HRC) type. This fuse should have a 1500A break

capacity.

1.2 Using the Buttons

There are three types of buttons. The first type usually have

only one function: when pressed, that one function will be

(

activated e.g. AUTO SETUP

The second type are toggles: each press of the button either

switches something on or off e.g. Add

next item in a sequence e.g. Off/On/lnv

1.2b.

The third type are Pressure Sensitive: the effect caused depends

upon how hard the button is pressed. For example, a gentle

press of a Pos'n (8) button will move the trace slowly. If the

button is pressed harder, the trace will move more quickly. See

Figure 1.2c.

24)

is

a high rupture current

see appendix 3

.

See Figure 1.2a.

(10) , or selects the

(13) . See Figure

1.4 Obtaining a Trace

1.4.1 AUTO SETUP

To display an input signal, connect it via either the CHI socket

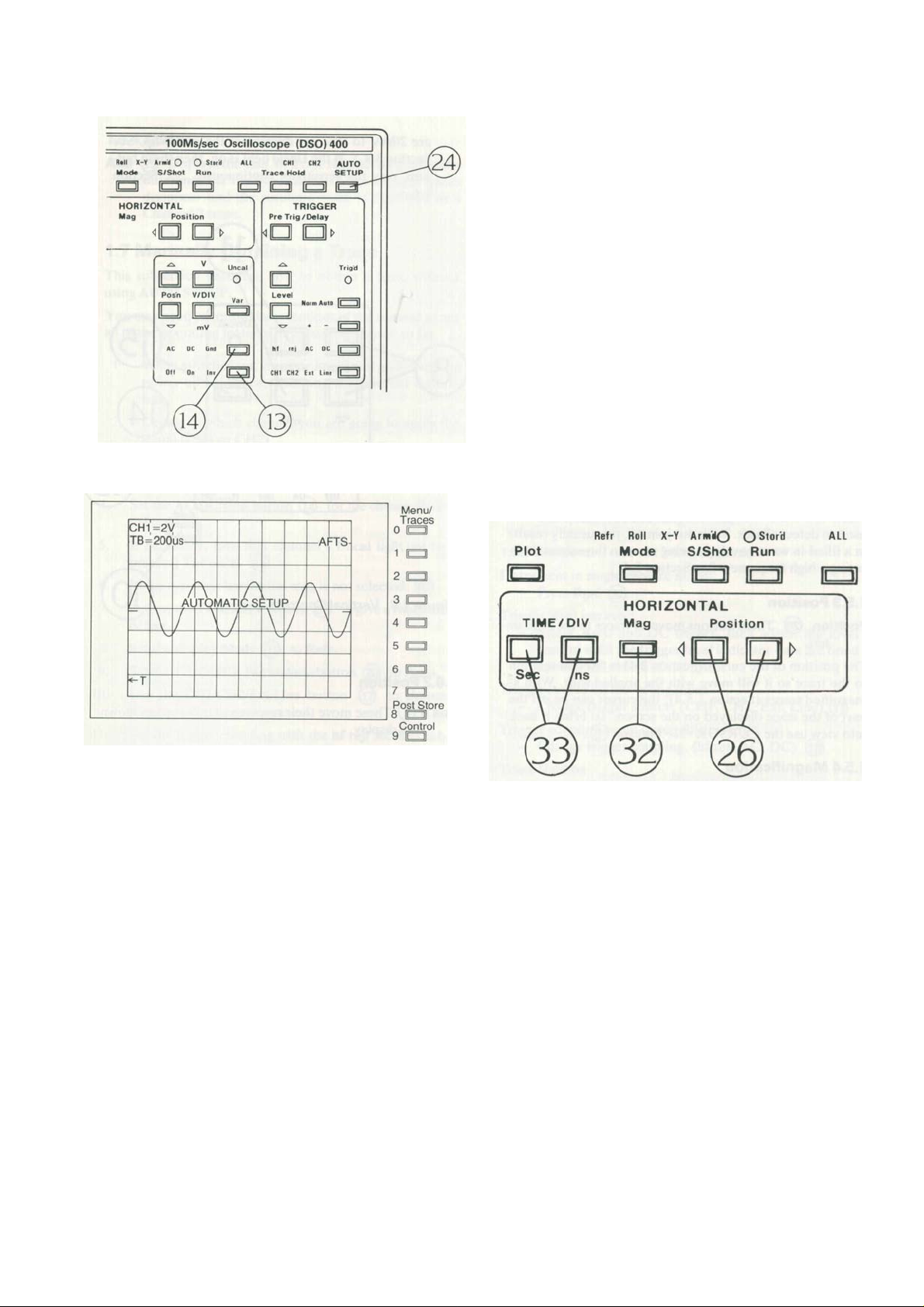

See Figure 1.4

(9) or the CH2 socket (12) and press AUTO SETUP (24) .

Assuming you've applied a regular signal, say a 2kHz sinewave with an amplitude of perhaps 5V peak to peak, it will

almost immediately be represented on the display. An example

is shown in Figure 1.4.1.

It the display is very dim or has completely disappeared see

section 1.8.1.

AUTO SETUP will attempt to arrange the display so that two

to five complete cycles appear, with the amplitude set so

that the height of the trace is between two and five

screen divisions. Also, it selects Auto trigger to ensure

that the screen is frequently updated and a trace will be

visible.

If signals are connected to both channels, the

highest amplitude takes priority.

Page 10

A

400 Series Operators Manual

Getting Started 1 .4.2-1 .5.1

Figure

1.4

Obtaining a Trace

1.4.3 Coupling (AC/DC/Gnd)

These buttons control the type of coupling between the input signal

and the instrument. DC is the most generally applicable, and

AUTO SETUP will normally set this control to DC, where

possible.

The input impedance is I M ohm in parallel with a capacitance of

28pF.

(14)

AC This is used to remove any DC component from input

signals. Suitable input signals (i.e. the bandwidth) are from

4Hz to 20MHz.

Gnd The input signal is internally disconnected from the inputs and

the amplifier grounded. A OV reference signal is displayed.

DC The input signal is directly coupled to the instrument so all

frequency components of the input signal will be displayed.

The bandwidth will be from DC to 20MHz.

1.5 Horizontal Adjustments

Figure

1.4.1

n AUTO SETUP Display

1.4.2

Channel Selection (Off/On/lnv)

A channel may be switched on or off with its Off/On/Inv button. If

the channel is on, its trace can be displayed in either normal or

inverted mode.

Off The channel is deactivated.

On The trace is a true representation of the input signal. Inv The

input signal is inverted before being displayed. If

there is any DC component in the signal this will also be

inverted and could cause the trace to disappear from the

screen. Such an unwanted DC component can be removed

by selecting AC coupling. Any vertical shift applied to the

trace is not inverted. The trigger point remains at the same

point on the waveform regardless of inversion.

(13)

Figure

1.5

Horizontal Controls

1.5.1

TIME/DIVISION

TIME/DIV

With a timebase of say 200/Ls, each horizontal screen division

represents 200/Ls worth of signal. The timebase is shown near the

top of the display - e.g. TB=200/Ls.

Assuming a 2kHz signal is applied as mentioned earlier, when the

timebase is set to 500ms/div, an interesting phenomenon may

appear: an 'alias'.

(33) These buttons control the sweep rate of the trace.

The timebase can be varied from 100ns/div to 50s/div in a I,

2, 5 sequence of values. The button marked 'ns' decreases

the time/div, the button marked 'sec' increases the time/div.

Page 11

Getting Started 1 .5.2-1 .6.3

400 Series Operators Manual

1.5.2 Aliases

An alias is a false image. The instrument is a digital oscilloscope

and so takes frequent samples of the input signal in order to update

the trace. Thus, if the signal frequency is higher than the sample

frequency, one sample will be taken from a particular point on the

waveform and the next sample may be taken from a point slightly

further along on a subsequent cycle. It will then display the wave

as being much slower than it really is. See Figure 1.5.2. This effect

is only likely to occur if there are more than 100 cycles of

waveform across the screen.

Figure

1.5.2

Alias Generation

There is a 'Max/Min' glitch detection feature which can be used to

detect aliases. With dot join on, this usually results in a filled-in

wave envelope being seen on the screen, indicating a high

A.

frequency. See Section 3

are 20mV to 50V per division at the probe tip. See Section

3.4.1

.

If the Uncal light is on, then these buttons vary the

1.6.3.

sensitivity continuously. See Section

1.5.3 Position

Position (26) These buttons move all traces to the right or

left.

The position of the cursor (Section

trace so it will move with the applied shift. With x-magnified

1.5.4),

traces (Section

displayed on the screen. To bring it back into view use the

CURSOR < > buttons

the cursor can be off the part of the trace

(5).

2.4)

is fixed in relation to the

1.5.4 Magnification

Mag (32) Switches horizontal magnification on or off When

switched on, a xl0 expansion is applied to any displayed

trace, which will expand around the centre of screen. The

timebase setting is adjusted to reflect the expansion.

The instrument displays 50 dots (samples) per screen division, each

plotted dot value being obtained from the 512 byte acquisition

memory. At an expansion of x 10. there are five dots per division.

1.6 Vertical Adjustments

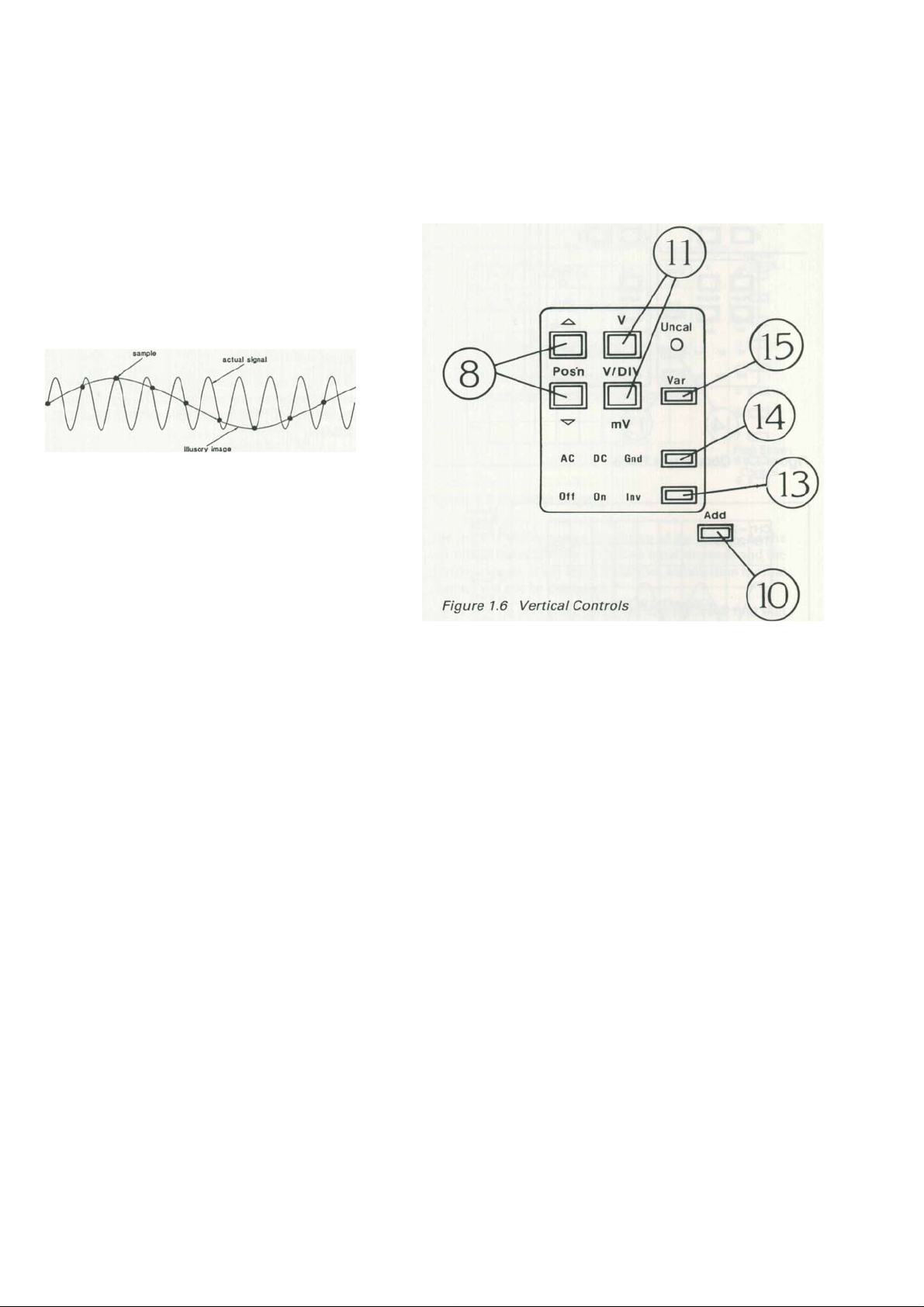

Each channel has its own set of vertical controls. See Figure

1.6.1 VOL TS/DIVISION

V/DIV

(11) Adjusts the sensitivity of the instrument over discrete

calibrated ranges from 2m V to 5V per screen division in

1,2,5 steps. With a x10 probe the ranges

1.6.

1.6.2 Position

(8) These move their respective traces up and down

Pos'n

the display.

If Trace Hold is on (Section 2.2) or a S/Shot capture has been

made, any part of the trace which was captured off-screen

vertically will be shown by a horizontal line.

1.6.3 Variable/Uncalibrated

Var (15) When this is set to 'Uncal', the coarse setting of the

attenuator remains unchanged, but a variable attenuation is

004.

applied to the input signal in the range of 1 to

with an initial setting of IV, the actual sensitivity of the

channel could be set by this control to anywhere between I

V and 2.5V per division. The V/DIV buttons are used to

vary the uncalibrated sensitivity.

Thus,

Example screen display:

CH1 =5V Channel is set to a sensitivity of 5 Volts per screen

division.

CH2>20mV Channel 2 is uncalibrated and the attenuator is set to a

sensitivity greater than 20m V per screen division.

Page 12

400 Series Operators Manual Getting Started 1.6.4 - 1.8.5

1.6.4 Add

Add (10) Displays the sum, or if one channel is inverted the

difference, of the input signals. The original traces

disappear and the resultant trace is displayed as a

Channel 2 trace.

1.7

Manually Obtaining a Trace

This subsection describes how to obtain a trace without using

AUTO SETUP.

You may need to consult later sections of the manual as not all

of the operating features have been discussed so far.

1. When switched on, the instrument will go through its

power-up sequence, checking the internal calibration.

2. Decide to which channel you are going to apply the

signal (CH1 or CH2).

3. Make sure the chosen channel is active by setting the

Off/On/lnv

4. Set the AC/DC/Gnd button

nel to Gnd.

5. If necessary, turn that channel's Uncal light out by

pressing Var once.

6. Make sure that horizontal mag is not selected. (32)

7. Adjust the TIME/DIV setting

of

5μs.

8. Set the display Mode (31) to Refr.

9. Set the TRIGGER Norm/Auto button

10. Use the CHl/CH2/Ext/Line button (17) to choose the

source for trigger signals.

11. Set the trigger coupling with the hf rej/AC/DC button.

(13) for that channel to On.

(14) for the chosen chan-

(15)

(33) to give a timebase

(20) to Auto.

(18)

12. If necessary adjust the position of the trace using the

Position and Pos’n buttons.

13. Ensure that Trace Hold (25) is not selected.

14. Select Run.

15. Apply the signal through a BNC connector to the chosen

CH input socket. (9) or (12)

16. Set the AC/DC/Gnd button

either DC or AC, as appropriate.

17. Adjust the gain of the chosen channel using the V/ DIV

buttons

by pressing the Var button once.

18. Adjust the timebase setting using the TIME/DIV but-

tons.

19. If the display is unstable, adjust the trigger Level. (22)

1.8

Operating Hints

The following list gives some of the more commonly met

problems in operating digital oscilloscopes, how to correct

them, and a brief explanation of what was wrong.

(27)

(11) . For intermediate settings, set Uncal on

(33)

(26)

&

(8)

(14) for the channel to

(15)

You may need to consult later sections of the manual as not all

of the operating features have been discussed so far.

1.8.1 Problem: Traces and Alphanumerics very dim or

completely disappeared.

Intensities too low

- Press the control button

menu, then press numeric button 3 to select the intensity

menu. Further presses of numeric button 3 will increase

the brightness of the alphanumerics on the display. The

traces can now be intensified using numeric button I.

Note:- The display may not become visible until the numeric

3

button

1.8.2 Problem: Trace off the top or bottom of the screen. Too

much vertical shift

Input has large DC offset

1.8.3 Problem: Trace not being acquired.

Instrument in single capture mode

Trigger level incorrect

Trigger source on the wrong input

Trigger coupling on an unsuitable setting

Trace Hold on

Timebase on very slow acquisition

1.8.4 Problem: Trace is unstable even when triggered.

Alias

Noisy input

Trigger on Auto

1.8.5 Problem: Trace has a very flat top or bottom.

Trace captured when off screen vertically and Pos’n shift has

been used

has been pressed several times.

- correct with that channel's Pos’n buttons.

- AC couple input signal.

- Correct with Pos’n buttons.

- Use a less sensitive range.

- Press Run.

- Select Auto and DC trigger, then adjust the level

control until the trigger level indicator bars are lined up

with the centre of the trace.

- Change trigger source. (CH1, CH2, Ext, Line) (17)

- Change trigger coupling. (hf rej, AC, DC) (18)

- Release Trace Hold.

-Adjust TIME/DIV.

- Check for alias using Max/Min (glitch

detection), and select a faster timebase range.

- Select hf rej trigger coupling. (18)

- Adjust trigger Level.

- With low frequency inputs (below 20Hz), Auto trigger

will initiate triggers overriding the input triggers. Select

Norm trigger.

- Use less sensitive V/DIV range when acquiring trace. (11)

- Re-position trace prior to capture.

(27)

(20)

(7) to get the control master

(8)

(8)

(25)

(33)

(22)

Page 13

A

dvanced Features 2.1-2.1.5

p

2 Advanced Features

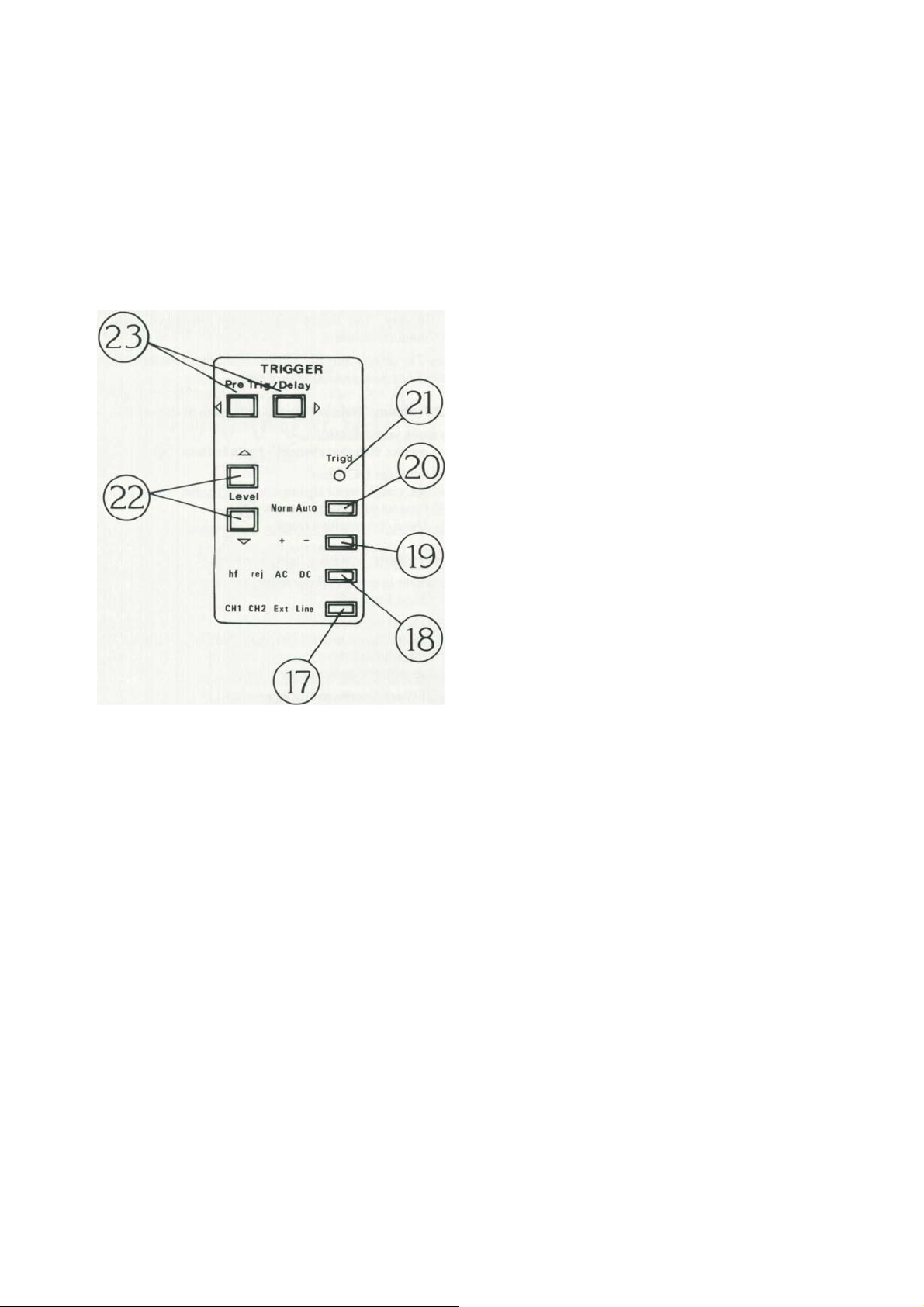

2.1 Trigger Control

Trigger facilities discussed here are controllable directly from

the front panel. For the more advanced menu-controlled

facilities see Section 3.4.

The power-down trigger setting will be retained on future

ower-up.

400 Series Operators Manual

Table

2. 1. 1

Useful Frequency Ranges

Types

Coupling

hfrej 10Hz to 15kHz

AC 4Hz to 20M Hz

DC DCt020MHz

2.1.2 Level

The trigger level is the threshold at which the instrument will

respond to potential triggers; the trace actually has to pass

through the level indicated for a trigger to be valid. See Section

2.1.3.

The level is indicated on the display by two bars, one on each

side. of the screen, and is adjusted by the level buttons.

For an internal trigger the range is approximately

divisions and on external approximately

signal is AC coupled, the level bars will be offset from the

actual trigger position on the screen by any DC offset present.

2.1.3 Trigger Point (T)

Input

of

Coupling

+/

- 3V. If the trigger

+/-

(22)

10

Figure

2. 1

Trigger Controls

2.1.1 Selecting Source and Coupling

The lowest button in the TRIGGER section of the front panel

selects the source of the trigger.

CH1/CH2/Ext/line

of trigger signals. When Ext is selected, the source is the

'EXT TRIG' socket (16) in the lower right corner of the

front panel.

Selecting line is meaningful only if the instrument is

powered from the mains. Triggering is then from an

internal pulse having a fixed phase relation to the mains

voltage waveform. To change this phase relationship,

use the trigger delay buttons. See Section 2.1.6.

(17) Steps through the possible sources

The trigger point is indicated on the display by a 'T' near the

bottom of the screen underneath the trigger. An arrow next to

the T indicates that the trigger point is off the screen.

2.1.4 Slope

A trigger is generated when the selected source signal passes

through the chosen trigger level. This transition may be either

on a rising or a falling edge. The rising edge is considered to be

a positive slope and the falling edge a negative slope.

+/-

(19)This button selects positive

slope triggers.

2.1.5 Trigger Mode (Norm/Auto)

The trigger system operates in either Normal or Auto mode.

In Normal mode, display captures can only occur when a valid

trigger input has been received.

In Auto mode, if no valid trigger has been received for some

time the instrument will generate its own trigger and initiate a

capture. This ensures that the screen is constantly updated

irrespective of the input signal. However, if valid input triggers

are received at a rate of 20Hz or more, the instrument will start

all captures with these triggers and not generate its own.

Auto/Norm (20)This button selects which trigger mode the

instrument is operating in.

Trig'd

receiving valid trigger signals.

(+/-)

(+)

or negative (-)

(21) This LED lights up when the instrument is

hf rej/

AC/DC

(18) Steps through the available trigger cou-

pling options; hf rej is a 15kHz low-pass filter ('high

frequency reject'). All the couplings can be used with

any source except Line, with which the input coupling is

not selectable.

Page 14

400 Series Operators Manual Advanced Features 2.1.6-2.2.1

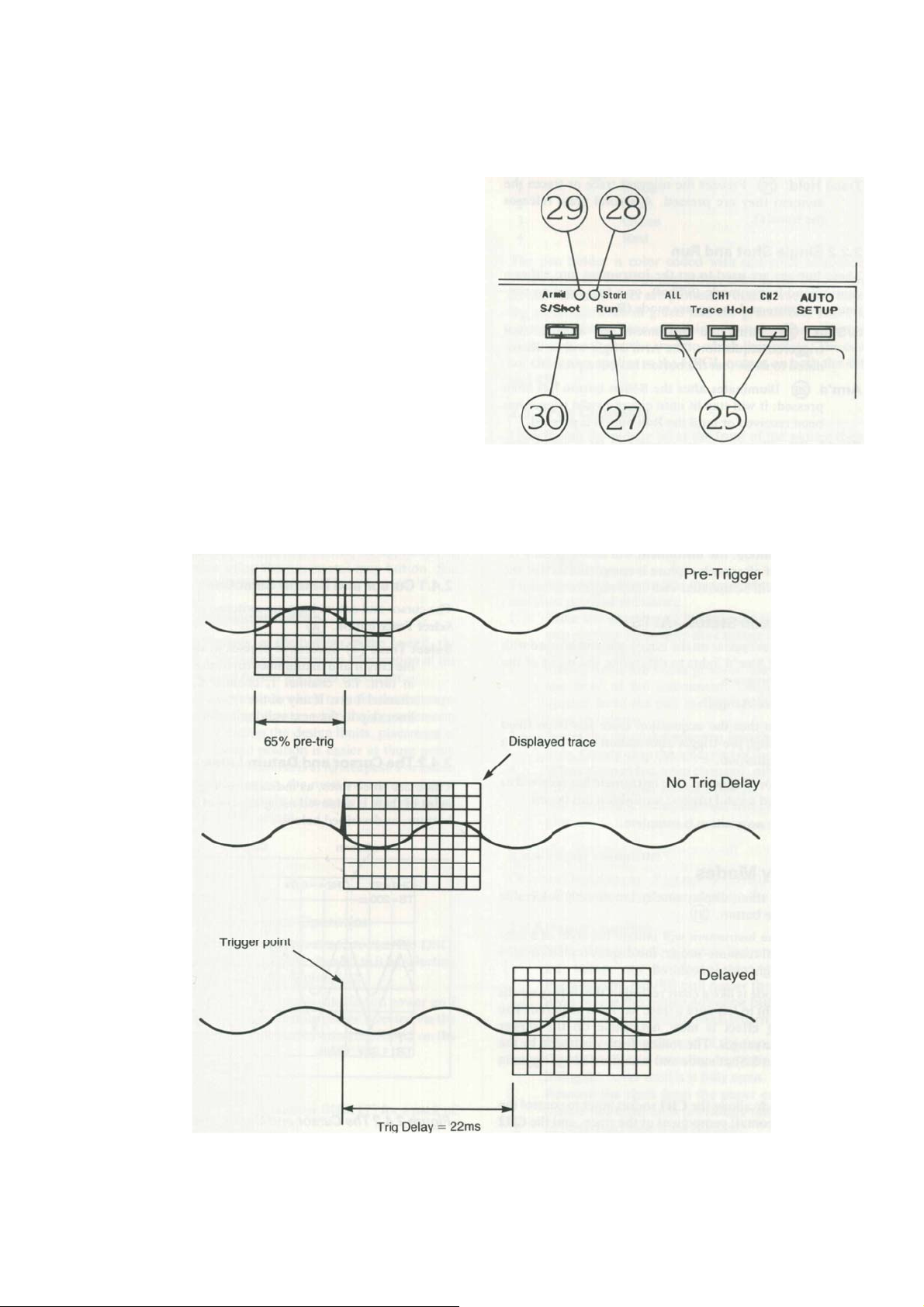

2.1.6

Trigger Delay

The amount of data which is acquired for display before or

after the trigger is determined by the pre or post trigger delay

selected, see figure 2.1.6. The value of this delay is shown in

the bottom right hand of the trace display.

Pretrig This allows a section of the trace that occurred

before the trigger point to be included in the display. The

amount of pre-trigger visible can be set with the front

panel PreTrig/Delay buttons.

set anywhere between 0% and 100% of screen width, in

steps as small as 0.4%.

Trig Delay With this set, the oscilloscope will acquire a trace

following both the specified trigger and a specified

delay. The amount of delay is shown beside the 7 key.

Delay is controlled by the PreTrig/Delay keys.

The size of the steps by which the delay can be

incremented or decremented is controlled by the

TIME/DIV keys, i.e., step size is 0.04 x the time/ div

setting. This can be demonstrated by varying both the

timebase and delay settings, while observing the last two

lines of the Display and Trigger Menu (See section 3.4).

Once set, the delay time remains the same regardless of

the selected timebase range.

(23) Pre-trigger can be

(23)

2.2 Capture Facilities

The capture facilities allow the traces to be frozen.

Figure

2.2

The Capture Controls

2.2.1

Trace Hold

There are two ways to freeze the display: a single-shot capture

whereby a full trace is acquired then frozen (Section

Figure 3.4a Trace Capture with Delay

Page 15

Advanced Features 2.2.2-2.4.2

s

400 Series Operators Manual

2.2.2), or by pressing one of the buttons labelled Trace Hold.

Trace Hold:

(25) Freezes the relevant trace or traces the moment

they are pressed. A second press releases the trace( s).

2.2.2 Single Shot and Run

These buttons are used to set the instrument into either a captureand-freeze mode (S/Shot), or a free running continuous capture

and re-capture mode (Run).

S/Shot

(30) Arms the instrument for a single-shot triggered

acquisition. The Arm'd light will be illuminated to show

that the button has been pressed.

Arm'd

(29) Illuminates after the S/Shot button has been pressed;

it will stay lit until either a valid trigger has been received

or until the Run button is pressed.

Stor'd

Run

(28) Illuminates on completion of a single-shot

acquisition. This is after the instrument has been Arm'd,

triggered and a complete trace acquired. The light will stay

on until the instrument is re-armed by pressing S/Shot again

or Run is pressed.

(27) This button puts the instrument in continuous capture

mode: the instrument will automatically rearm itself after

each capture is completed so that the display will be

updated with each triggered sweep.

2.2.3 Acquisition Status - AFTS

These characters appear on the screen and can be used with the

Arm'd and Stor'd lights to determine the 'status of the acquisition

in progress.

A Stands for 'Armed'.

F Indicates that the acquisition store has been filled with

enough pre-trigger information to be ready for a fresh

acquisition.

T Stands for 'Triggered': the instrument has received or

generated a valid trigger; acquisition has begun.

S 'Stored': acquisition is complete.

2.3 Display Modes

socket input to control the Y (vertical) component. It

provides an X- Y display of the data captured by the time

base and trigger systems. The timebase should be set slow

enough to capture the whole of the signal of interest. This

mode is not available with magnified traces (Mag).

2.4 Cursor Measurements

The instrument allows you to take direct measurements from the

screen display automatically, using inbuilt datum lines and cursor.

Figure

2.4

The Cursor and Datum Line Control

2.4.1 Cursor and Datum Selection

The cursor and datum lines are switched on or off using the Select

Trace button.

Select Trace

2.4.2 The Cursor and Datum Lines

There are three lines, as indicated in Figure 2.4.2. Movement of

them is aCH1eved using the DATUM and CURSOR buttons, as

described below.

(4)

(4) Successive presses of this button places the

cursor and datum lines on to the displayed traces in turn. i.e.

channel, channel 2, reference, off, channel etc. If any of the

traces are not in use the lines skip to the next valid

selection.

The following three display modes are directly selectable using the

Mode button.

Refreshed The instrument will imitate the style of a conventional

Roll This mode is like a chart recorder: the display scrolls from

(31)

realtime 'scope: the display is plotted from left to right as it

is acquired.

right to left until a trace has been acquired. The scrolling

effect is most noticeable on the slower timebase ranges. The

rolling display is frozen by the trigger in S/Shot mode and is

unaffected by trigger in Run.

X-V This mode allows the CH1 socket input to control the X

(horizontal) component of the trace, and the CH2

Figure

2.4.2

The Cursor and Datum lines

Page 16

400 Series Operators Manual

A

r

d

dvanced Features 2.4.3-2.5.5

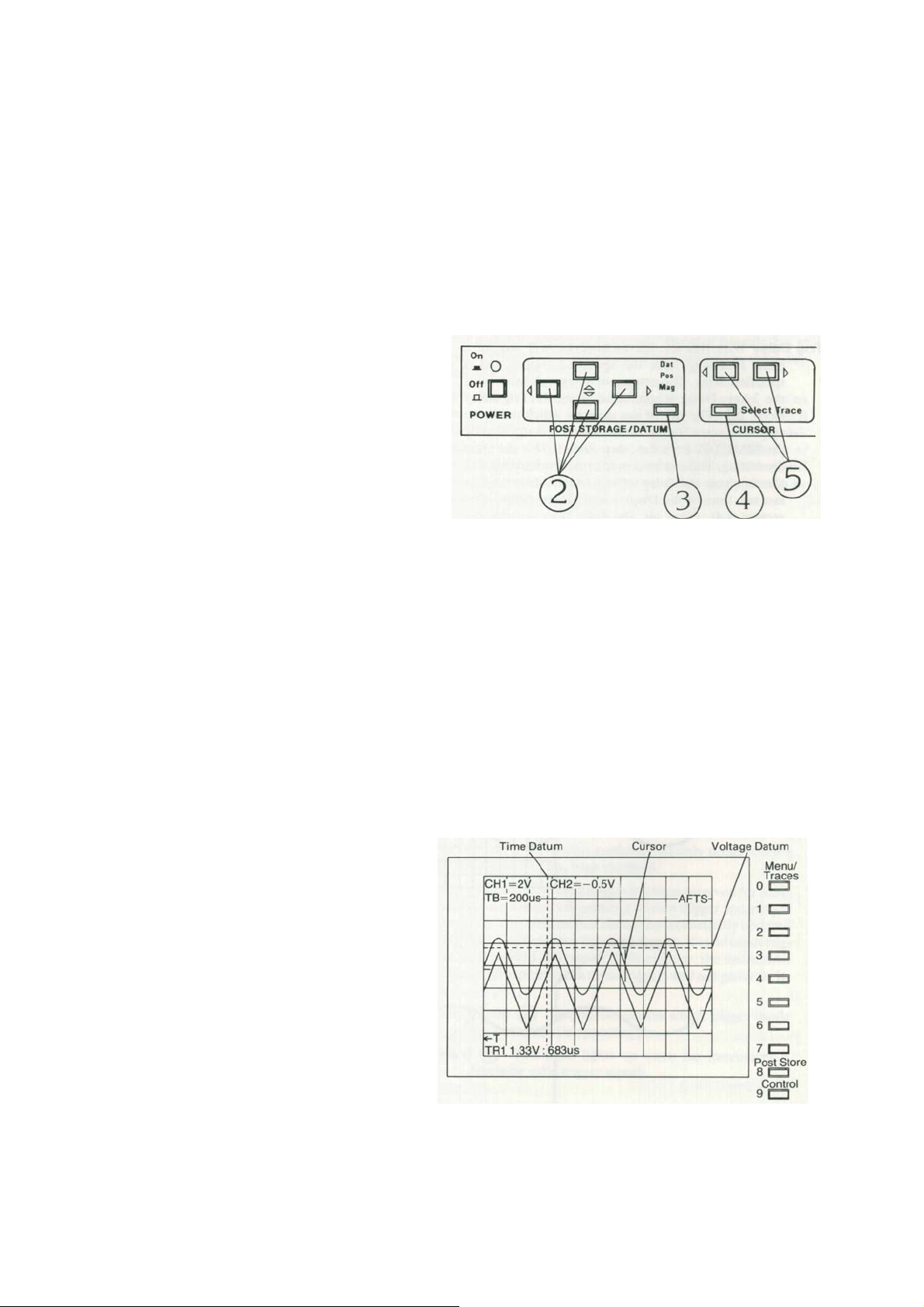

Dat Selecting this option on the Dat/Pos/Mag button (3)

allows the position of the datum lines to be controlled

using the DATUM buttons. (2)

DATUM

(5) Moves the cursor to the right and left along the trace.

Pos/Mag These selections on the Dat/pos/mag button

Pos This option on the Dat/Pos/Mag button (3)

Mag The vertical magnitude of the selected trace can be varied

2.4.3 Making Measurements

The instrument displays, at the bottom of the screen, the time

and voltage difference between the intersection of the

horizontal and vertical datum lines and the cursor.

The choice of points between which to make the measurements

can influence the accuracy: while the measurements made will

always be within the design limits, placement of the cursor at

the desired position is easier at those points where the slope of

the waveform is at its steepest. For example, on a standard sine

wave, the most accurate measurements of wavelength are likely

to be made if they are taken between two OV crossing points.

(2)

Used for moving the two datum lines. CURSOR

(3)

allow the DATUM buttons to control post storage

position and magnitude. They can only be used with

stored waveforms. Pressing menu button 1 (opposite the

restore message) will cancel the effect of pos and mag

on the selected trace i.e. the one with the cursor

X and Y shift to be applied to the trace on which the

cursor is placed, using the POST STORAGE/ DATUM

keys. (2)

from X4 to XO.062, using the POST STOR-

AGE/DATUM keys.

displayed near the top centre of the CRT.

No horizontal magnification is available using this

control, but x10 magnification may be applied to all

stored traces using the horizontal mag button. See

Section 1.5.4).

(2)

The magnification factor is

on

it.

allows both

The normal pen sequence is:

Pen No. Colou

1 Black

2 Blue

3 Green

4 Re

The pen holder is colour coded with this colour sequence.

When pens are fitted in this order, trace 1, the border and all the

alphanumerics are plotted in black, trace 2 in blue, the reference

trace in green and the graticule in red. The cursor and datum

lines and their measurements are plotted in the same colour as

the trace to which they relate. The cursor colour also applies to

the HPGL output on both the 420 and 450.

2.5.3 Pen Changing

Underneath the plotter lid at the front of the plotter there are

two small blue buttons. The right hand button when viewed

from the front of the OSO is the Pen change button, and the left

hand one is the paper advance button.

CAUTION: When changing a pen, extreme care should

be taken not to damage any of the plotter mechanism.

NEVER

move the pen carriage by hand.

To change a pen, ensure that the instrument is switched on and

then proceed as follows:

1. Press the pen change button once. This rotates the pen

carriage and moves the carriage to the right hand side of

the plotter.

2. Gently press the white grooved eject lever towards the

front of the instrument. The top pen will be ejected from

the pen carriage and can be removed from the plotter.

3. Insert the tip of the new pen into the carriage guide hole.

Gently snap the other end of the pen into place.

4. When the pen has been changed, press the left hand

button - the paper advance button - and the carriage will

move back to the left hand side ready for the next plot.

2.5

Plot

2.5.1 Internal Colour Plotter Operation

When the internal colour plotter is fitted to the 400 OSO, plots

of the instrument's display can be sent to it by selecting internal

on the Plot Menu, see section 3.12.

The internal plotter is automatically selected on power up if it

is fitted. If required the plot output can be directed via the

RS423 port to an external plotter by selecting RS423 on the

Plot Menu, see section 3.12.

2.5.2 Pens

Only use Gould pens - part number 04101175 for a pack of 4; 1

of each colour.

2.5.4 Paper selection

Only use Gould paper - Part number 04101165 for a pack of 8

rolls. Other paper types may damage the mechanism.

2.5.5 Paper Loading

CAUTION: When loading paper, extreme care should be taken

not to force any of the plotter mechanism.

paper through by hand, always use the paper advance

button to prevent damage to the plotter mechanism.

1. With scissors, cut the end of the paper square.

2. Open the plotter cover by depressing the catch and

lifting the cover until it is fully open.

3. Remove the shaft from the paper cradle and if the plotter

has been used previously remove the plastic or

cardboard tube from the shaft.

NEVER

pull

Page 17

A

dvanced Features 2.5.6-2.5.8 400 Series Operators Manual

4. Insert the shaft through the paper roll and fit the roll into

the paper cradle.

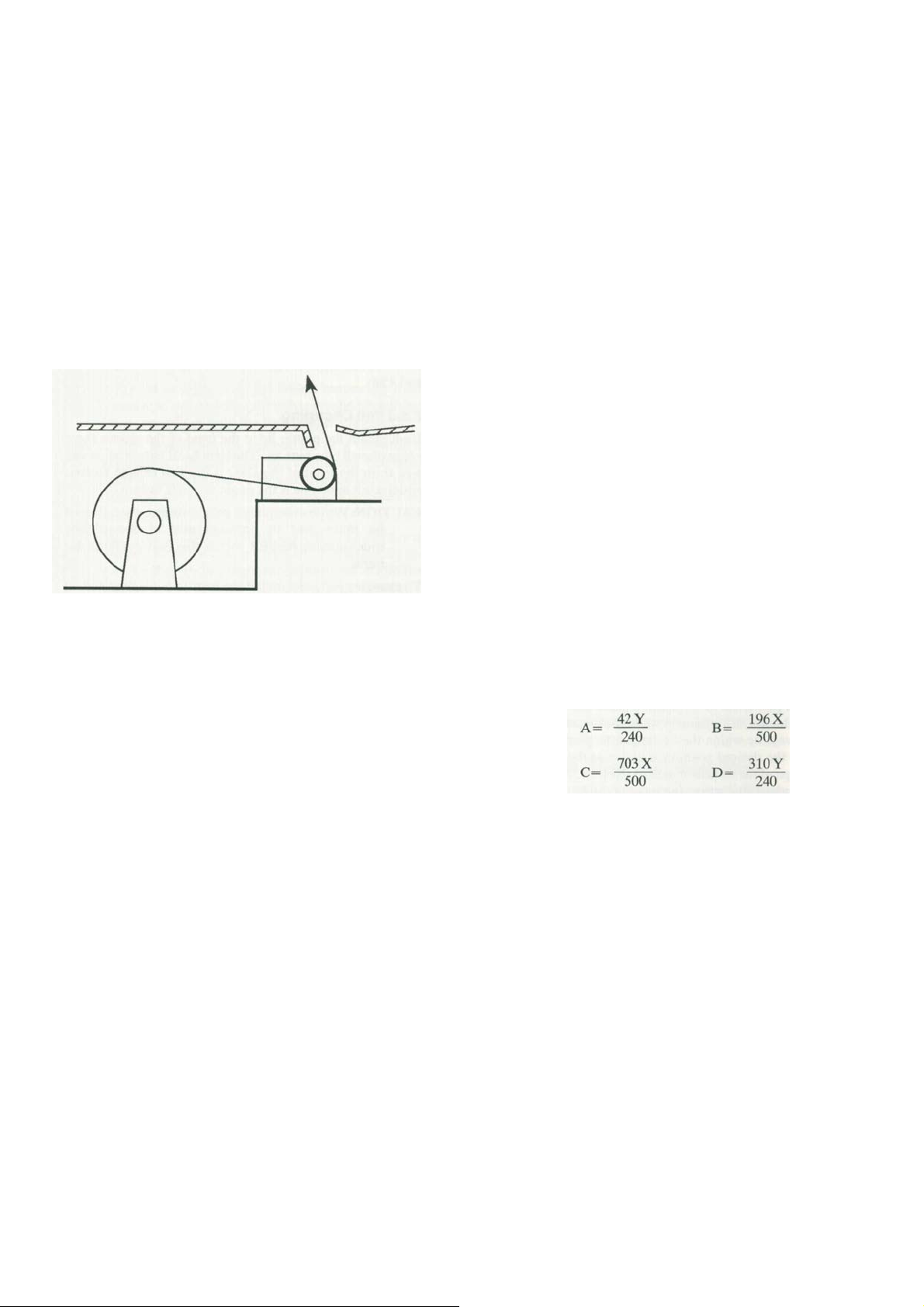

5. Feed the paper from the top of the roll as shown in

figure 2.5.5 below and push it through the slot in the rear

of the printer mechanism.

6. Press the paper advance button - the left hand blue

button at the front of the printer assembly - until the

paper reappears at the front.

7. Feed enough paper through to pass through the top

cover, ensure that it is running around the mechanism

smoothly and that it is straight.

7. Close the plotter cover and ensure that it latches shut.

Figure

2.5.5.

Paper Loading

2.5.6

Internal Plotting

When a plot is initiated, the Hold All lamp lights and the

message "PLOTTING - PRESS PLOT TO ABORT" appears

on the screen. After about 9 seconds the hold All lamp goes out

indicating that the data has been transferred to the plot buffer

and that the instrument can be used again. The plotting

message will remain on the screen until the plot is complete

when it will disappear.

In Auto Plot Mode, the instrument is re-armed after the plot

data has been transferred to the plot buffer, but the front panel

controls will remain in-active during plots.

If the plot button is pressed while the plot is in progress, the

plot will be aborted. Any changes to the instrument status

during a plot will have no effect on the plot as the data has

already been transferred and stored in the plot buffer.

2.5.7 External plots

A plot of the display can be sent to an external plotter by

pressing the plot button @ . The parameters for the plotter

and the plot format can be set as described in section 3.7 and

3.12.

The display is held while a plot is in progress.

Plots can be aborted by a second press of the plot button. If the

plot is aborted, the pen will be left in a random position and the

external plotter may need to be reset to restore the pen to its

start position.

2.5.8

Plot positioning and scaling

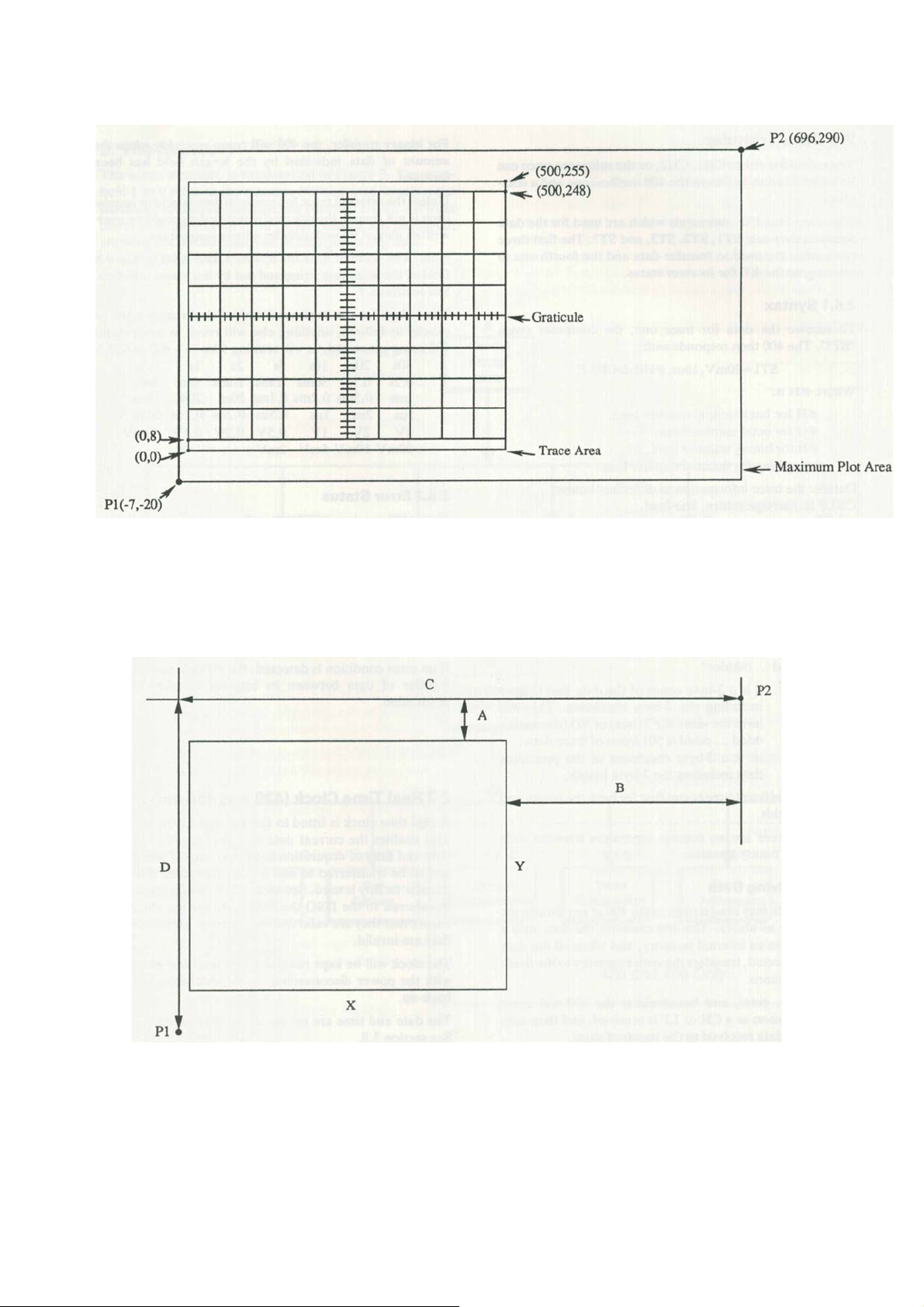

The output plot from the 400 has the relative positions shown in

figure 2.5.8a. These may be shifted and scaled to position the

plot exactly over a pre-defined grid using the following

procedure with reference to figure 2.5.8b.

The sides of the pre-defined grid are X and Y, the exact

positions of PI and P2 are found by calculating the dimensions

A, B, C and D:

Measure the vertical dimension of the required grid, note

this as Y.

Measure the horizontal dimension of the required grid,

note this as X.

U sing these values of X and Y, A, B, C and D can be

calculated as follows:

Measure and mark the exact positions of PI and P2 from the

grid edges using figure 2.5.8b and the values obtained above.

The PI and P2 points can now be set on the plotter, refer to the

plotter manual for details.

Page 18

400 Series Operators Manual

s

Advanced Features

Figure 2.5.8a Relative Plot Positions

Figure 2.5.8b Plot Dimension

Page 19

A

dvanced Features 2.6-2.7

400 Series Operators Manual

2.6 Data Transfer

Trace data for either CH1, CH2, or the reference trace can be

transferred to and from the 400 oscilloscope and a computer.

There are four I/O commands which are used for the data

transfer, they are: ST1, STI, ST3, and ST? The first three

commands are used to transfer data and the fourth one to

interrogate the 400 for its error status.

2.6.1 Syntax

To receive the data for trace one, the computer sends "STl".

The 400 then responds with:

STl =20m V, 10us, # HdataCRLF

Where #H is:

#H for hexadecimal number base, #0

for octal number base,

#B for binary number base,

or nothing for decimal number base.

Data is: the trace information as described below.

CRLF is: carriage return, line feed.

If the 400 receives ST3 and the reference trace is unused, the

400 will respond with "ST3=UNUSED"

Note: When data is being sent to the 400 #D may be used for

decimal number base.

For decimal, octal and hexadecimal, the "data" field consists of

501 data points separated by commas.

For binary transfer, the "data" field is as follows:

"lldddd ... ddddcc"

Where:

II

is a 2-byte count of the data that follows including

the 2-byte checksum. This will have the value

01F7 (hex) or 503 (decimal). dddd ... dddd is

501 bytes of trace data.

cc is a 2-byte checksum of the preceding data

including the 2-byte length.

The most significant byte is sent first for both the length and

checksum fields.

Note that there are no comma separators between data bytes

during binary transfer.

2.6.2 Receiving Data

The computer may send strings to the 400 at any time in the

same syntax as above. The 400 converts the data into a binary

form in an internal memory, and when all the data has been

collected, transfers the entire memory to the destination trace

store.

For decimal, octal, and hexadecimal the 400 will cease

receiving as soon as a CR or LF is received, and then only

transfer the data received to the required store.

For binary transfer, the 400 will cease receiving when the

amount of data indicated by the length field has been received.

Unless the selected trace for received data is held or acquisition

is not armed, the selected memory data could be overwritten

almost immediately by a fresh acquisition.

Note: The number base for received data is set by the #X field

of the incoming string and not by the menu selection. See

section 3.7

The strings for the horizontal and vertical ranges must be

exactly as follows, anything else will result in error status 102

being generated, as will sending 50ns to a 400 or 420.

50s 20s 10s 5s

0.2s

0.ls 50ms 20ms10ms 5ms 2ms

1ms 0.5ms 0.2ms 0.1ms 50us 20us 10us

5us 2us 1μs 0.5μs 0.2μs 0.1μs 50ns

5V 2V IV O.SY 0.2V 0.1V 50mV

20mV 10mV 5mV 2mV

2s Is 0.5s

2.6.3 Error Status

If the 400 receives "ST?", it will respond with a decimal error

status string as follows:

o

No error

96 Invalid command

102 Syntax error

103 Number out of range

104 Length error - Binary transfer only 105

Checksum error - Binary transfer only

If an error condition is detected, the 400 will not make the

transfer of data between its internal memory and the

destination.

2.7 Real Time Clock (420 and 450 only)

A real time clock is fitted to the 420 and 450 instruments. This

enables the current date and time together with the date and

time of acquisition to appear on any screen plot, and to be

transferred to and from a computer if the data transfer facility is

used. See section 2.6. When trace data is transferred to the DSO

the date and time are checked to ensure that they are valid and

syntax error 102 is returned if they are invalid.

The clock will be kept running for at least ten years, even with

the power disconnected, by its own internal battery back-up.

The date and time are set via the special functions menu. See

section 3.8.

Page 20

400 Series Operators Manual

3. The Menus

The menu structure is summarised in Figure 3. The numbers 1

to 9 refer to the numeric buttons used to select the particular

menus and menu items (Section 3.1.1). All front panel controls

remain "live" when menus are displayed, allowing the control

status to be changed at any time.

The Menus 3

Figure 3 Menu Overview

Page 21

The Menus 3.1-3.2

400 Series Operators Manual

3.1 Additional Buttons

3.1.1 The Numeric Buttons

The buttons 1 to 7 (36) are used in conjunction with the menu

system to provide a large number of extra functions not

otherwise available directly from the front panel. Pressing these

buttons when the menus are displayed operates the menu

functions described in Sections 3.2 to 3.12. Buttons

have extra functions described below.

0, 8

and 9

Figure

3. 1

The Numeric Buttons

3.1.2 0: Menu/Traces

Menu/Traces: (35)Toggles the display between the traces and

the last used menu.

3.1.3 9: Control

Control: (7)

3.1.4 8: Post Store

Post Store: (6) Brings the Post Storage Master Menu onto the

The current display, whatever it may be, is

replaced with the Control Master Menu.

display.

3.2 Control Master Menu

Each entry on the Control Master Menu is also a menu, covering one set of functions. The text is lined up with the numeric

buttons 1-7 on the side of the display. To obtain any secondary

menu simply press the relevant button.

Figure 3.2 Control Master Menu

The options available on the Control Master Menu are as

follows:

STATUS Displays information about the present setup of the

instrument. See section 3.3.

DISPLAY AND TRIGGER Controls probe sensitivity,

averaging, interpolation, the glitch detect function, and

trigger delay. See section 3.4.

DISPLAY INTENSITY The brightness of

the

alphanumerics, graticule, cursor and traces can all be

adjusted independently. See section 3.5.

REFERENCE TRACE Either one of the currently displayed

traces can be copied to the reference trace. See section

3.6.

RS423 INTERFACE Setting the RS423 output protocol.

See section 3.7.

SPECIAL FUNCTIONS Enables the user to disable the auto-

calibration, calibrate either channel, or force a full

calibration. See section 3.8.

Page 22

400 Series Operators Manual

The Menus 3.3

3.3 Status Menu

This menu allows the various horizontal, vertical and trigger

settings of the instrument to be viewed. A typical display is

shown in Figure 3.3.

Figure

3.3

A Status Menu

3.3.1 Mode:

There are three possible display modes:

Refresh, Roll and X- Y. They are described in Section

2.3.

3.3.4 Probe Set: The probe gain settings are shown as x l ,

x10 or x100. These may be set using the Display and

Trigger Menu. See Section 3.4.

3.3.5 Timebase: The sweep rate of the timebase is shown in s,

ms,

/-LS

or ns per division.

3.3.6 Trigger This section of the display shows the selected

trigger options. The choices of source are CH1, CH2,

Ext and Line. The available couplings are AC, DC and

high frequency reject. These are discussed in Section

2.1.

The trigger level is shown in terms of the number of

screen divisions above the bottom of the graticule. The

trigger slope is shown as either +ve (rising edge) or -ve

(falling edge).

Following this is the trigger delay setting, given in s, ms,

/-LS

or ns as appropriate. For pre-trigger operation, the

figure is given as a percentage; 0% places the trigger

point at the left-hand edge of the screen and 100% on the

right-hand edge.

3.3.2 Max/Min: The glitch detector is selected using the

Display and Trigger Menu. See Section 3.4.

3.3.3 V/Div:

The input sensitivity of the channels is shown in

volts per division. The range is 2mV to 5V per division.

If Add mode is selected, a + sign is shown between the

channels.

Along with the input sensitivity of the channels, other

information is also shown. The symbols used are as

follows:

-

Trace inverted

Uncalibrated

>

AC coupled

~

=

Calibrated

Trace off top of display

↑

Trace off bottom of display

↓

Page 23

The Menus 3.4 400 Series Operators Manual

)

f

d

atest value at

3.4

Display and Trigger Menu

This menu controls probe ratios, maximin detection, interpolation, and the trigger delay function.

3.4.1

Probe Ratio:

can be set for each of the two input channels with

successive presses of buttons 1 and 2. The ratios

available are xl, x10 and x100. Thereafter, probes of the

chosen ratios may be attached to the appropriate inputs;

the new sensitivities at the probe tip will be displayed

correctly.

3.4.2

MaxiMin: Using the number 3 key, the maximin or glitch

detection function can be switched on or off.

The Max-Min function is designed to detect narrow

glitches which may occur between samples. It operates

on the signal before it is placed in the acquisition store

and can detect very narrow glitches, down to

Any glitches detected will at least be displayed as a

spike. They will be detected whether they are positive

(max) or negative (min). The function works in the

timebase ranges of 100 microseconds per division down

to 50s per division.

An independent probe attenuation ratio

2f.Ls

wide.

Figure

3.4

Display and Trigger Menu with

Trigger Delay Selected.

3.4.3

Dot Join

On some X-magnified or high speed traces, gaps can be

visible between the sample points; if Off is selected, the

points alone will be displayed. Selecting On causes the

data to be automatically joined by straight lines.

3.4.4

Averaging

ratio of repetitive signals by averaging them. This

function, which converts the display into a weighted

average of previous acquisitions is toggled On and Off

by button 5. Button 6 is used to determine the averaging

factor to be used in the algorithm

Button 4 selects the dot-joining function.

It is possible to improve the signal to noise

Where: n =The data point (1 to 501

A =New value at n

an

=

averaging factor (2 to 256)

=

L

=

e.g. In continuous mode, if 8 acquisitions are selected,

any single acquisition that deviates from an otherwise

consistent level, contributes 1/8 of its deviation to the

display. In S/Shot

acquisitions contribute to the resultant held display.

only the selected number of

Old value at n

n

3.4.5

Trig Pos’n:

pretrigger percentage or the post trigger delay time. The

value can be altered as described in section 2.1.6. Figure

2.1.6 shows the display relative to the trigger position

for both pre and delay trigger values.

This displays the current value of either the

Page 24

400 Series Operators Manual

The Menus 3.5-3.6

3.5 Display Intensity

This menu allows independent control over the brightness of

various display features.

TRACES/CURSOR: The brightness of the cursor, datum lines

and all traces will be adjusted. The number 1 key

increases the intensity and the number 2 key decreases

it.

Figure

3.5

Display Intensity Menu

ALPHA: The brightness of all the alphanumerics will be

adjusted. The number 3 key increases the intensity and

the number 4 key decreases it.

GRAT: The brightness of the graticule (or grid) will be

adjusted. The number 5 key increases the intensity and

the number 6 key decreases it.

3.6 Reference Trace

The menu provides the option of temporarily storing a trace for

comparison with the two Channels. It will be lost when it is

replaced with an alternative trace.

Figure

3.6

Reference Trace Menu

To copy a currently displayed and held trace into the reference

trace, simply press either button 2 or button 3 depending on

whether the held trace is in Channel or Channel 2 respectively.

A copy of the trace will then be automatically taken. If the trace

is not held prior to pressing the button, a fresh acquisition will

be made before the copy is taken.

To display a previously stored reference trace, use the button

to toggle the selection to On.

Page 25

The Menus 3.7

s

400 Series Operators Manual

3.7 RS423 Interface Menu

This menu allows the parameters of the RS423 output to the

remote plotter or other data handling device to be set.

Figure

3.7 An RS423 Interface Menu

Data is always output with no parity, one start bit, eight data

bits and one stop bit.

The data that is output is the complete waveforms, including

the reference trace, plus information about the timebase and

volts per division. The data is output in a form suitable for

HPGL plotters, such as the Gould 6120. See section 3.12.

FF represents the top of the screen.

The maximum number of characters per trace

transfer is 1522

Binary:

Each data point is sent as a single byte.

00000000 represents the bottom of the screen,

10000000 represents the middle of the screen, and

11111111 represents the top of the screen.

The maximum number of characters per trace

transfer is 525

BLOCK LENGTH: Successive press of button 4 changes the

block length from 0 to 80 in steps of 10 i.e. the sequence

0, 10,20,30,40,50,60,70,80, 0 ... A block length of 0

selects infinite length blocks.

During data output from the 400, if the next value to be

sent would exceed the block length, then a CRLF is sent

instead of the comma. Block length has no effect on

binary transfers, all bytes of data are always sent.

3.7.1 RS423 Plot Connections

The RS423 port is configured at the factory as shown in table

3.7.1. The instrument can be connected to a Gould colorwriter

6120 or a HP7475 plotter using the Gould plotter cable part

number 0409-1232. The connections of this cable are shown in

figure 3.7.1.

SPEED: This is selected with button 1. The data rate may be

75,150,300,600, 1200,2400,4800 or 9600 baud.

HANDSHAKE: Key 2 is used to select from handshaking Off,

or

XON-XOFF,

NUMBER BASE: Button 3 sequentially selects from decimal,

hexadecimal, octal, and binary as the number base to be

used in any data transmission from the 400. See section

2.6

The value range for the data points for each number base

is as follows:

Decimal:

Each data point is sent as a signed decimal number. 128 represents the bottom of the screen,

o

represents the middle of the screen, and

128 represents the top of the screen.

The maximum number of characters per trace

transfer is 2522

Octal:

Each data point is sent as three unsigned octal digits.

000 represents the bottom of the screen,

200 represents the middle of the screen, and

377 represents the top of the screen.

The maximum number of characters per trace

transfer is 2023

Hexadecimal:

Each data point is sent as two unsigned hex digits. 00

represents the bottom of the screen,

80 represents the middle of the screen, and

CTS-RTS.

Pin No. Name Description

1

2 RXD Receive Data

3

4 CTS Clear to send

5 RTS Request to send

7

9

Table 3.7. 1 Standard RS423 Pin Connections

Figure 3.7.1 400

3.7.2 RS423 Data Connections

To connect the 400 to a computer use the connections shown in

figure 3.7 .2a or figure 3.7 .2b. A prewired cable for each of

these arrangements is available; part number 0410-9248 for the

PC/XT and part number 0410-1247 for the

OV

TXD Transmit Data

OV

OV

to

Gould 6120

Protective Ground

Signal Ground

Ground

or

HP7475 Connection

AT.

Page 26

400 Series Operators Manual

The Menus 3.8

Figure

Figure

3.

7.2a 400

3.

7.2b 400

to

IBM-PC/XT Connections

to

IBM-A T Connections

3.8 Special Functions

This menu controls the selection of auto calibration and can

force the instrument to perform a full calibration.

Figure

3.8

Special Functions Menu

AUTO-CAL: successive presses of button I enables and

disables the instrument's automatic re-calibration

procedure.

When Auto-cal is enabled, the change of any vertical or

timebase range will, after a 2 second pause, initiate a

calibration of the new operating conditions. If the

operating conditions are not changed, a recalibration is

initiated at 15 minute intervals, alternating between

channels 1 and 2. Each calibration takes about one

second.

If the occasional interruption of the normal function of

the instrument is unacceptable to the user the Auto-cal

facility can be disabled as described above. Recalibration

is then recommended 30 minutes after switch on from

cold, and additionally if there is a significant change in

the ambient operating temperature.

CALIBRATE CURRENT SETUP: Pressing button 2 forces the

instrument to recalibrate for the vertical range and mode

and the timebase range that it is currently set at. The

actual calibration occurs approximately 2 seconds are

pressing the button. This feature does not operate when

the instrument is in Roll mode.

FULL CALIBRATION: Button 3 forces the instrument to

perform a complete internal recalibration ignoring

existing information. All internal memories are cleared

including the instrument status data and any stored

traces. To obtain the best results from this calibration,

the instrument must have been operating for a minimum

1/

hour. This calibration should only be required if

of

2

there have been repairs to the signal processing sections

of the unit or if the internal battery maintaining the status

memories has been totally discharged or disconnected.

Page 27

The Menus 3.9

400 Series Operators Manual

REAL TIME

Note: No channel calibrations will be performed if the

instrument is armed, in a data capture cycle, in continuous roll

mode or if Auto-cal is disabled, they will simply be postponed

until these conditions end. Full calibration is always available.

If the unit is unable to complete any of the above self calibrations. an error message will appear. See appendix 1. These

messages should only occur if there is a major fault requiring

the unit to be serviced.

When performing a full calibration connect a

to the Ext Trig input. This ensures that the trigger input is

correctly calibrated for a

CLOCK (420 and 450 only):

clock is set using buttons Menu. The entire date and

time is displayed, with one section highlighted. The

highlighted element is selected using button 5 and can

then be increased or decreased using button 4 or 6 as

appropriate.

Once the correct date and time has been set, pressing

button 7 enters the data. This makes it easy to set a time

that is a few seconds in advance of real time and then

press button 7 at a time signal. If the menu is exited

without pressing button 7, then the date and time will

remain unchanged.

The clock is kept running even with the power disconnected for at least ten years by its own internal battery

back-up.

son

source signal.

The real time

son

termination

3.9

Post Storage Master Menu

The Post Storage Master Menu provides access to three further

menus which control the operation of the three battery-backed

trace memories, and the plotter.

Figure

3.9

Post Storage Master Menu

Lines 4 to 7 only appear on a 420 or 450 instrument and are the

waveform processing functions. Their operation is fully

described in section 5.

Page 28

400 Series Operators Manual

The Menus 3.10-3.11

3.10 Save Trace Menu

This menu allows you to store up to three traces, including the

reference trace, to the battery-backed memories.

Figure

3.

10 Save Trace Menu

Because these memories are battery-backed, the traces stored in

them will not be lost even when the instrument is powered down.

SAVE TRACE: Using the 1, 2 or 3 keys selects either Trace

Trace 2 or the Reference Trace respectively to be saved.

Once the trace has been selected, a fresh option will appear,

described below.

SAVE TRACE TO MEMORY: Any of the three battery backed

memories may be selected.

1,

3.11 Recall Memory Menu

Traces previously saved using the Save Trace menu can be recalled

using this menu.

Figure

3. 11

Recall Memory Menu

RECALL MEMORY One of the three memories may be recalled

by pressing the button 1,2 or 3. Having chosen a memory,

you will be asked into which display trace you would like to

place it.

RECALL MEMORY TO TRACE Pressing button 5, 6 or 7 will

cause the trace data from the previously selected memory to

be displayed on trace 1, trace 2, or the reference trace.

NOTE:

is not armed, the selected memory data could be over-

written soon after it

Unless the selected trace is held, or acquisition

is displayed.

Page 29

The Menus 3.12

3.12 Plot menu

This menu allows the user to set the format of the plot sent to

the internal colour plotter or to the external plotter via the

RS423 interface. Refer to Section 3.7 for RS423 connections.

400 Series Operators Manual

Figure

3.12

Plot Menu

PLOT MODE: This can be set to either Single or Auto with

successive presses of the number 1 button. In Single plot

mode one press of the Plot button wil1 produce one plot

output. In Auto mode, a press of the plot button will

initiate a plot. The sequence thereafter continues

automatically. At the end of the plot the trigger circuit is

rearmed for the next acquisition, and at the end of an

acquisition, the plot is started. An external plotter must

have an auto feed facility to function correctly in this

mode. If it does not, then the feed command from the

400 may confuse the plotter.

PLOT WITH GRATICULE: The user has the option of

including the screen grid in the plots with On or

excluding it with Off.

GRAT LINE TYPE: A solid or broken graticule can be

selected for the plot, by successive presses of button 3.

PLOT WITH CURSORS: If On is selected, then any plots

made will include the cursor and datum lines. Otherwise,

they will be omitted.

PLOT OUTPUT: This line only appears if the instrument is

fitted with an internal colour plotter. The internal plotter

is automatical1y selected on power up if it is fitted. If

required the plot output can be directed, via the RS423

port, to an external plotter by selecting RS423 with

button 5.

ADVANCE PAPER: Pressing button 6 when the internal

plotter is selected causes the paper to be advanced

approximately 15mm per press. This line only appears if

the internal plotter is selected on line 5.

Page 30

400 Series Operators Manual

Performance Checking 4.1-4.5

4. Performance Checking

The aim of this section is to allow the user of a 400 oscillos-

cope to verify the major analogue performance parameters.

Should any of these fail to be within specification then it is

recommended that the instrument be re- calibrated. A skilled

technician with the aid of the service manual should be able to

perform this task; alternatively return the instrument to your

Gould distributor.

4.1 Risetime

Equipment required:

Fast edge pulse generator <Ins: Bradley oscilloscope

calibrator type 192 or Tektronix PG506 or similar; 50

Ohm precision coaxial cable;

50 Ohm precision terminator.

Connect the pulse generator to a channel input through the coax

cable and the terminator, which should be at the 400 end of the

cable.

1. Select 100mY per division on the input channel and set

the timebase to

2. Set the generator to give 600mY peak to peak at a

repetition rate of 1 MHz and adjust the trigger level to

give a stable trace.

3. Select the cursor and change the time base to 500ns per

division.

4. Apply x10 trace magnification using the Mag button to

give 50ns per division, and adjust the horizontal Position

buttons to centre the fast edge.

5. Position the cursor and datum lines on the edge such that

the cursor is 60m Y below the high level and the datum

lines cross 60m Y above the low level.

The rise time can now be read from the cursor line on the

bottom row of text. This figure should not be greater than 18ns.

Suss per division.

4.2 Bandwidth

Equipment required:

Levelled signal generator: Tektronix SG503 or

similar;

50 Ohm coaxial cable;

50 Ohm terminator.

Connect the signal generator to a channel input through the

coax cable and the terminator, which should be at the 400 end

of the cable.

1. Select 5mY per division on the input channel and set the

50jLs

timebase to

2. Set the amplitude of the signal generator to give six

divisions at 50kHz or similar reference frequency.

3. Change the timebase range to 500ns per division.

per division.

4. Increase the frequency on the signal generator until

the peak to peak amplitude reduces to 4.2 divisions.

The measured frequency should be greater than 20MHz.

4.3 Trigger Sensitivity

Equipment required:

Signal generator: Tektronix SG503 or similar; 50

Ohm coaxial cable;

50 Ohm terminator.

Connect the signal generator to a channel input through the

coax cable and the terminator, which should be at the 400 end

of the cable.

1. Select 100mY per division on the input channel and set

50jLs

the timebase to

2. Select Auto trigger.

3. Set the signal generator to 50kHz or similar reference

frequency and adjust the amplitude to give 0.3 of a

division peak to peak.

4. Select AC Coupling and Norm on the trigger con-

trols.

It should be possible to find a suitable trigger level to obtain a

stable triggered picture.

per division.

4.4 Trigger Bandwidth

Equipment required:

Levelled signal generator: Tektronix SG503 or

similar;

50 Ohm coaxial cable;

50 Ohm terminator.

Connect the signal generator to a channel input through the

coax cable and the terminator, which should be at the 400 end

of the cable.

1. Select 100m Y per division on the input channel and

500ns per division on the timebase.

2. Set the signal generator to 20MHz and adjust its

amplitude to give one and one half divisions on the

screen.

It should be possible to adjust the trigger level to give a stable

triggered trace.

4.5 Timebase Calibration

Equipment required:

Time calibrator: Bradley oscilloscope calibrator type 192

or Tektronix TG501 or similar;

50 Ohm coaxial cable;

50 Ohm terminator.

Connect the calibrator to a channel input through the coax cable

and the terminator, which should be at the 400 end of the cable.

Page 31

Performance Checking 4.6-4.7

400 Series Operators Manual

1. Select a suitable timebase range to view the signal and

set the channel attenuator to give between two and five

vertical divisions of signal.

2. Select DC Coupling and Norm on the trigger con-

trols.

3. Adjust the trigger level to give a stable trace.

4. Change the timebase to 500ns per division.

5. Set the calibrator to produce markers every 500ns.

6. Select the cursors.

With the cursor and time datum on identical positions on any

two markers, the time difference should read in multiples of

500ns to within 1 %.

Note: Failure of this specification point is indicative of a

major system fault and the instrument should be serviced immediately.

4.6 Vertical Calibration

Equipment required:

Oscilloscope calibrator: Bradley type 192 or similar;

Coaxial cable.

Connect the vertical calibration output of the oscilloscope

calibrator to the 400 through the coax cable.

500ILs

1. Set the timebase to

per division for the input channel.

2. Set the calibrator to give 25mV peak to peak, i.e. 5

screen divisions.

3. Adjust the trigger level to give a stable picture.

4. Switch the cursor on.

per division and select 5m V

The peak to peak measurement should be 25m V to within 3%

and the trace should be 5 divisions high to

These measurements should be repeated on all the attenuator