User Manual

Easy Clean Cleanflow, series SECE

The descriptions in this manual may differ from your version.

GOUDSMIT Magnetic Systems B.V.

P.O. Box 18 5580 AA Waalre

Petunialaan 19 5582 HA Waalre

The Netherlands

Tel. (+31) (0)40 2213283

Internet www.goudsmitmagnets.com

E-mail info@goudsmitmagnets.com

Disclaimer

© Copyright 2019 Goudsmit Magnetics Group B.V.

All rights reserved.

This manual is protected by copyright.

It is prohibited to copy any content, images or other components it contains.

This manual may not be duplicated in any manner, except with the prior written permission of Goudsmit

Magnetics Group B.V.

Contents

Disclaimer ................................................................................................................................................................................. 2

Contents .................................................................................................................................................................................... 2

Safety ......................................................................................................................................................................................... 3

General ................................................................................................................................................................................ 3

Safety regulations ................................................................................................................................................................. 3

Lock Out Tag Out (LOTO) .................................................................................................................................................... 3

Danger of magnetic field ....................................................................................................................................................... 4

Identification plate .................................................................................................................................................................... 5

Removal of ferromagnetic particles in Easy Clean Cleanflows ............................................................................................. 6

Construction and functioning of Cleanflow magnet .............................................................................................................. 7

Installation, start-up and servicing .......................................................................................................................................... 8

The information we supply may only be used for service or operation of the product.

It may not be disclosed to any third parties without our prior written permission.

Our products and the data in our documentation may be subject to later amendment without any

obligation to previously supplied equipment.

Please ensure that anyone working with the device has access to all the necessary documentation.

SECE Easy Clean Cleanflow manual, version 07/2019

2

• Read and observe the warnings and

They are applied for your safety!

• Goudsmit recommends a maximum lifting

• The activities described in this manual can

personnel.

• Always observe the locally applicable safety

• Apply protective cream to the body, if

necessary.

• Remain a safe distance from rotating and

moving components.

• To prevent the risk of fire, the Cleanflow and

fluids.

• Wear clean protective clothing, goggles and

• Follow all safety and warning regulations

provided in this manual!

Safety

General

The machine is provided with safeguards where necessary. Make sure every person who comes in contact

with the machine, or enters the area around it, wears adequate personal protection (overalls, safety

glasses, ear protectors, helmet, steel-toed safety shoes etc.). Areas of the machine considered dangerous

are marked with warning pictograms.

If the machine remains easily accessible to persons, extra safety precautions (e.g. safeguards) must be

installed. When safeguards are not possible, make sure clear instructions are given to people using the

machine.

Safety regulations

instructions given on stickers and labels on

the Cleanflow.

Do not ignore them.

only be done by trained, competent certified

surrounding area must be free of flammable

weight of 23 kg per person.

For the heavier components use a lifting

machine or ask a colleague to assist.

and environmental regulations.

safety shoes when working on the Cleanflow.

Lock Out Tag Out (LOTO)

Lock Out Tag Out (LOTO) is an internationally agreed safety procedure to make sure that dangerous

machines are properly shut off, and that they cannot be started again prior to the completion of

maintenance or repair work.

The Cleanflow is prepared for LOTO, Goudsmit recommends use of the LOTO procedure for every

activity performed on the SRCP.

This will reduce the risk of personal injuries.

3

!

!

!

Danger of magnetic field

The magnets generate a powerful magnetic field that strongly attracts ferromagnetic (Fe) materials.

Always take into account that these materials may suddenly be powerfully drawn towards the magnet.

This applies to steel workbenches and steel tools, but also to Ferromagnetic materials carried on your

person, such as coins in your wallet or your keys. Wherever possible make use of non-magnetic tools

and workbenches fitted with a wooden worktop and preferably a non-Fe frame (for instance stainless

steel).

Remember that ferromagnetic items, including personal items, will be attracted if you are closer

than 0.3 metres to a magnet.

Danger - strong magnetic field!

People fitted with pacemakers should on no account enter the magnetic field

(within a radius of at least 1 metres).

Prohibited for people with pacemakers!

Credit cards, chip cards, computer disks/tapes, computer screens, watches, etc. may be damaged

or destroyed if they enter the magnetic field (within a radius of at least 0.5 metres).

Danger for magnetic cards!

Warning Pictograms

Ensure that all warning pictograms are legible. Replace if lost or damaged.

General Protection

Wear all the personal safety equipment necessary for safe operation or maintenance.

This may include; overalls, safety glasses, ear protection, helmet, safety shoes, etc.

Keep all screens and safeguards in place

4

Identification plate

If you need to correspond about your device, make a note of the numbers on the identification

plate. On smaller Cleanflows there may not be an identification plate.

5

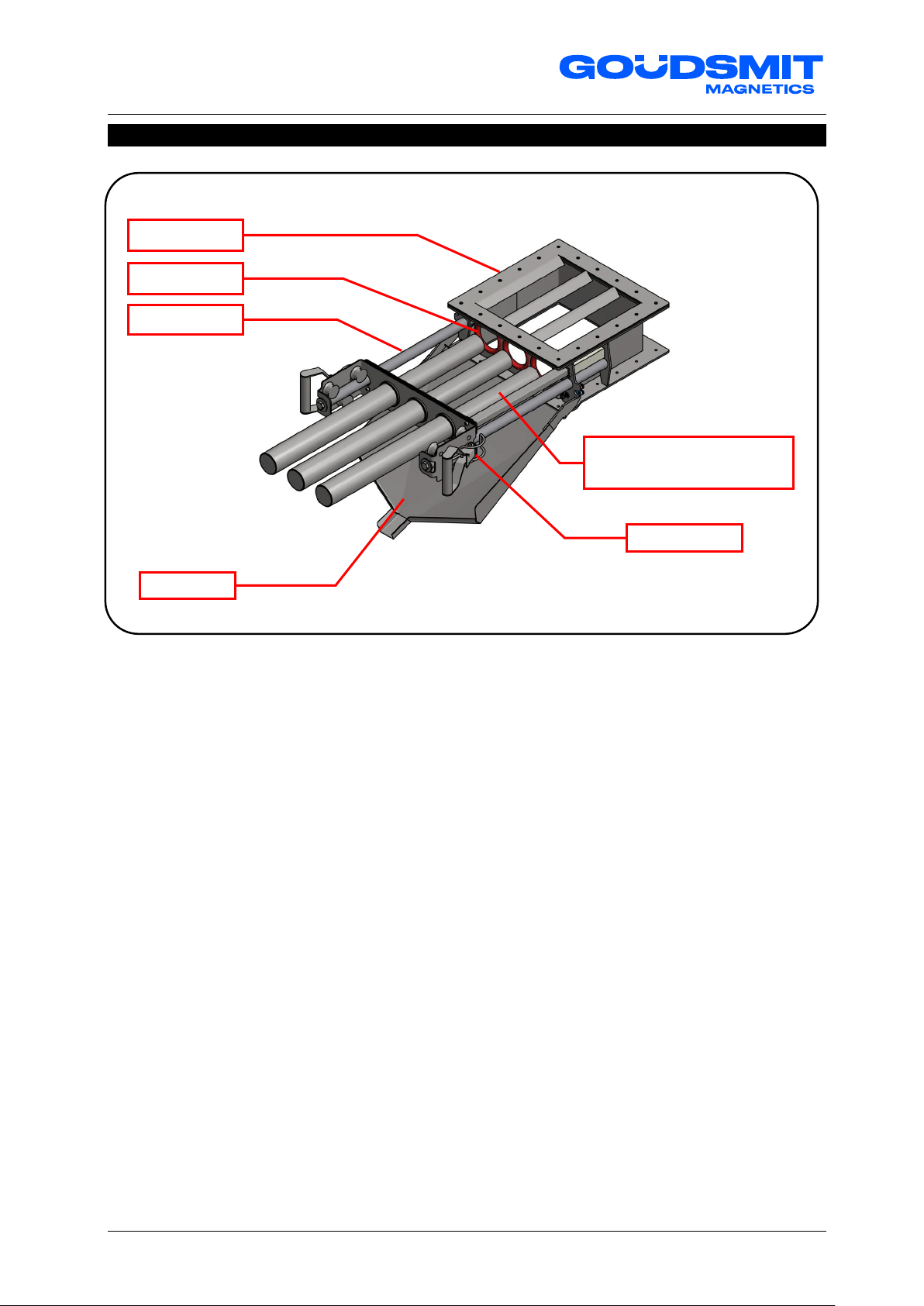

Pneumatic rods

Fasteners

Seal

Guiding rod

Tray

Flange

Removal of ferromagnetic particles in Easy Clean Cleanflows

Contains the Magnets

When cleaning the pneumatic cleanflows of ferromagnetic particles

1. Stop product flow.

2. Loosen clamps and slide extractor unit out of the housing.

3. The magnet unit inside the extractor, will slide out of the front section automatically.

4. Clean the ferromagnetic particles from the extractor with a clean soft brush.

5. Dispose of ferromagnetic debris. Use tray for sampling.

6. Slide the extractor unit back into the housing and refasten.

7. The magnet unit will slide back automatically back into the extractor unit.

8. Resume product flow.

6

Flange

Guided extractor

Pneumatically

activated

Fasteners

Construction and functioning of Cleanflow magnet

and magnet unit

Function

The function of the device is to capture ferromagnetic particles in the product stream.

The product flows through the pipe and around the magnets.

These capture ferromagnetic particles.

Features

The manual pneumatic Cleanflows have a telescopic assembly. Whereby the pneumatic components

automatically move the magnet unit in and out of the front section of the extractor if it is pulled in or out

of the housing.

7

Installation, start-up and servicing

Installation

• Only allow qualified personnel to work on the installation.

• Handle the Cleanflow with great care. The extractor tubes are very fragile.

• Remember that any ferromagnetic tools and components are attracted to the magnet and may

damage it.

• Connect joints or flanges correctly to the inlet and outlet joint.

• Use a pressure of 4 bar on the pneumatic connection. Press connection hose in remaining

connection.

• Install the Cleanflow correctly and at the proper work height.

Leave 100 mm free space underneath

Start-up

Ensure that:

1. The device has no damages or malfunctions. Test the pneumatic bar operation with a paperclip.

It should react if the magnet is operated.

2. All connections, whether mechanical or pneumatic, are made properly.

Servicing

If the extractor or magnet bars are damaged or dented, check that they still operate correctly.

Spare parts include the pneumatic bar magnet and the seals. The seals must be replaced every year.

Goudsmit Magnetic Systems can offer a yearly inspection with a replacement of seals and magnetic

inspection report and certificate.

Storage and dismantling

When recycling the device at the end of its technical life, dispose of correctly and according to local

regulations.

8

Loading...

Loading...