Page 1

INSTALLATION INSTRUCTIONS

SQP, SQDLW, SQPH,

SQDLWH, SQTH, SQDLWTH,

SQDLV, SQDMRH Mounting Frame

Upon receipt, thoroughly inspect for any freight

damage which should be brought to the attention of

the delivery carrier. Compare the catalog des cription

listed on the packing slip with the label on the carto n

to ensure you have received the correct

merchandise.

IMPORTANT SAFETY INFORMATION

For Your Protection, Read Carefully

WARNING: Risk of fire. Do not install insulation

within 3 inches of fixture sides or wiring compartment,

nor above the fixture in such a manner as to entrap

heat.

This product must be installed by a person familiar

with the construction and operation of the product

and the hazards involved, in accordance with the

applicable installation code.

1. Electric current can cause painful shock or

serious injury unless handled properly. For you

safety, always remember the following:

•Turn off the supply power.

•Ground the fixture to avoid potential electrical

shocks.

•Do not handle an energized fixture or ener gize

any fixture with wet hands, when standing on a

wet or damp surface, or in water.

2. Specific safety information concerning

lamps:

•Match wattage of fixture and lamp exactly.

•Do not remove or insert lamp when power is

on.

•Do not scratch glass or subjec t lamp to undue

pressure as either may cause lamp breakage.

•Protect operating lamp from sources of

moisture.

• If lamp is marked it contains mercury.

Follow disposal laws. See:

www.lamprecycle.org

.

Open

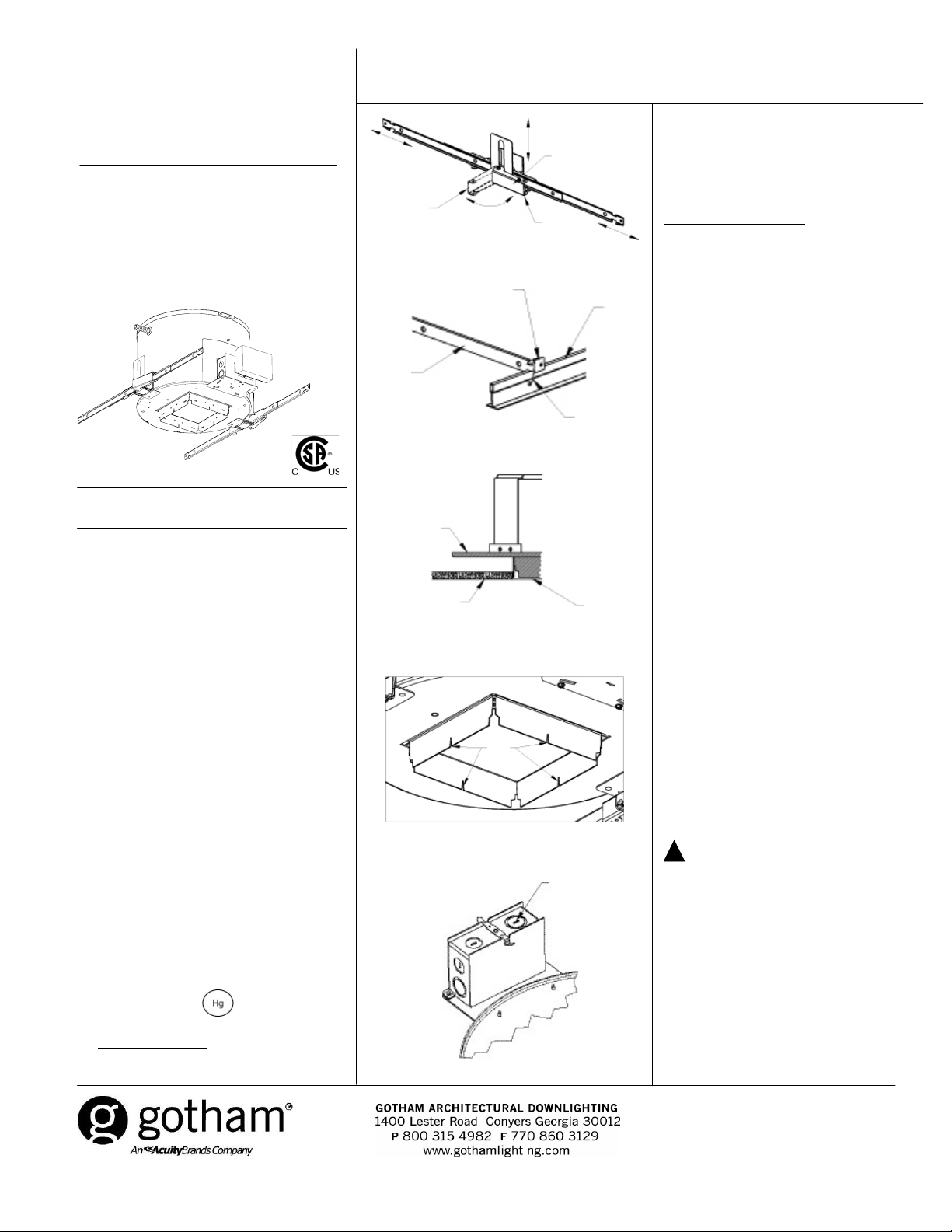

Figure 1

Channel

bar

Figure 2

Mounting

Figure 3

Figure 4

Figure 5

SAVE THESE INSTRUCTIONS

NEW INSTALLATION FOR SQ SERIES

IMPORTANT! For wallwash housing

orientation installation details see

page 2.

Lay-in panel T-bar ceiling:

1. Cut ceiling opening slightly larg er than the

outside opening of the mounting frame.

2. Position mounting frame through openin g in

ceiling. Release clamping latch arms and

adjust channel bars to the correct spacing

between T-bar (see Figure 1). Secure channel

bars to T-bar by means of wire ties, screws or

by bending ends onto T-bar (see Figure 2).

3. Once mounting frame has been secured in

structure, adjust the mounting frame vertic ally

to align the bottom edge to either flush or

slightly above (1/8" max) the ceiling line (see

Figure 3). Secure mounting frame into position

by closing the clamping latc h arm. The notch

located in the draw-down flange of the ho us ing

can be used to assist with alignment of

multiple fixtures (see Figure 4).

4. If additional security is required, a No. 8

sheet metal screw, wire tie or wire (not

supplied) may be used to tie the latc h arm to

the mounting frame (see Figure 1).

5. Remove knockouts on junction box to feed

power supply to fixture (see Figure 5). Supp ly

wire must meet applicable electrical co des an d

be rated for a minimum of 90°C. Junctio n bo x

is thru-wire rated for 8-No. 12 AWG

conductors (4 in-4 out).

6. Complete necessary wire connections.

Snap the door onto the junction box.

7. To adjust housing alignment after

installation, see “Post Installation

Adjustment.”

!

CAUTION! For T4/T6 and low voltage

MR16 downlights, lens must be in place in

front of lamp before fixture is energized.

frame

Ceiling

Clamping

latch arms

Closed

Bent tab

T-Bar

Wire tie

Flush or

slightly

above

ceiling line

Sight

Notches

Remove

knockouts

as needed

CJ5200903 Rev. B

6/10 1 of 2

©2009, 2010 Acuity Brands Lighting, Inc.

All Rights Reserved.

Page 2

SQP, SQDLW, SQPH, SQDLWH, SQTH, SQDLWTH, SQDLV, SQDMRH Mounting Frame Installation Instructions

NEW INSTALLATION FOR SQ SERIES

Non-accessible ceiling

1. For microflange (MFLG) installation, an

additional component (shipped separately) is

required to be installed PRIOR TO drywall

installation and vertical alignment of this

fixture.

2. Release clamping latch arms and adjust c hannel

bars to the correct spacing between joists (see

Figure 1).

Mounting Channel Bar-Flexible Wiring Method

3. Bend ends of channel bars 90° and adjustment at

its lowest point on the mounting frame. Mak e sure

bottom of the flange is flush with the bottom of the

joists. Secure mounting frame into position by

closing the clamping latch arm. Channel bars will

accommodate up to 24” O.C. joists. The notch

located in the draw-dow n flange of the housing c an

be used to assist with alignment of multiple fixtures.

Non-Flexible Wiring Method

If non-flexible wiring methods are used, follow

procedure for Flexible Wiring Method, then lower

mounting frame equal to the thickness of the

finished ceiling or slightly abov e, (1/8” max. - se e

Figure 3). The notch located in the draw-down

flange of the housing can be used to assist with

alignment of multiple fixtures.

4. Remove knockouts on junction box to feed power

supply to fixture (see Figure 5). Supply wire must

meet applicable electrical code s and be rated for a

minimum of 90°C. Junction box is thru- wire rated

for 8-No. 12 AWG conductors(4in-4out).

(plaster, drywall, etc.):

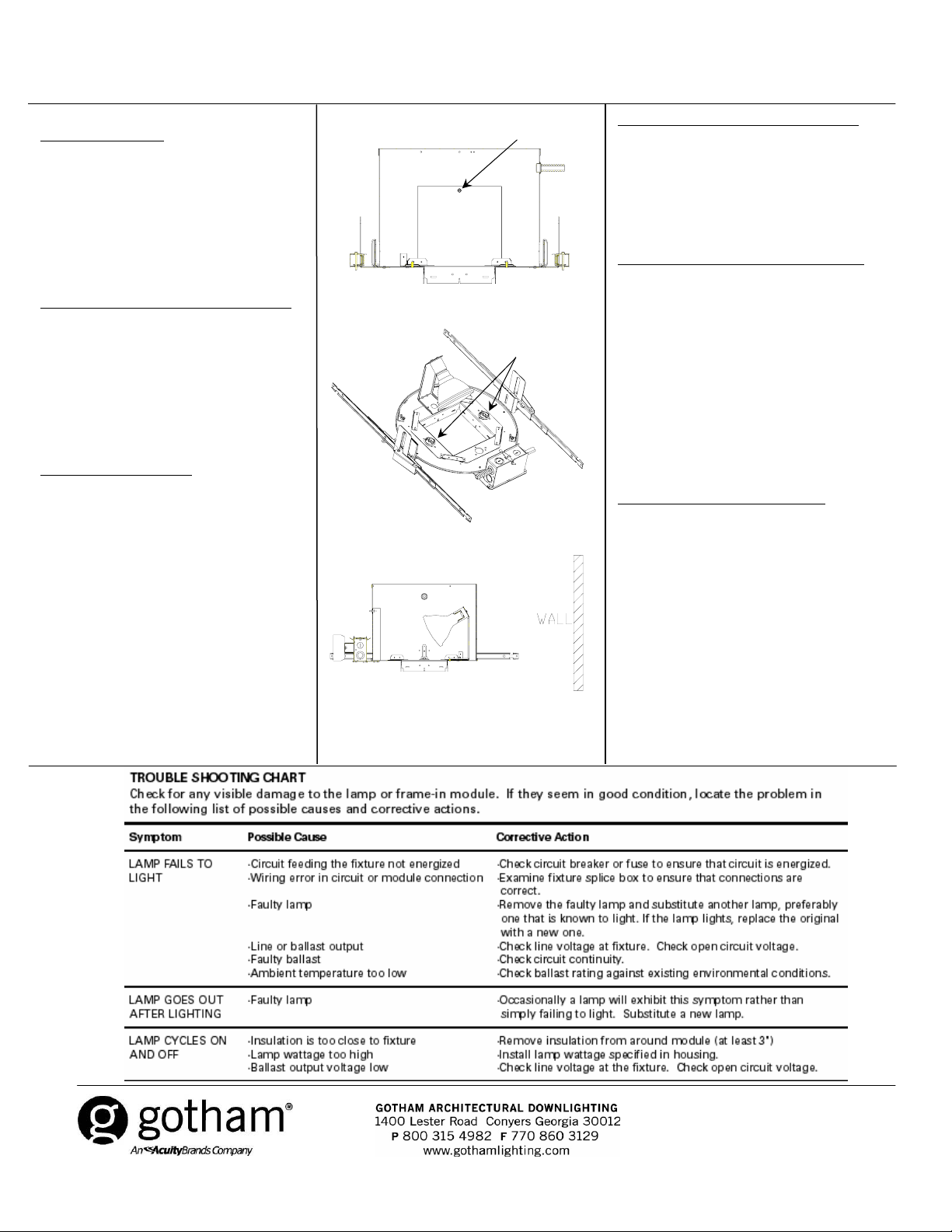

Figure 6

Figure 7

Figure 8

Thumb screw

Speed nuts

ACCESSING JUNCTION BOX FROM BELOW

To gain access to junction box from below ceiling.

1. Remove trim.

2. Remove lamp. (PAR lamps only)

3. Loosen thumb screw to remove door from

housing and set aside. (see Figure 6).

POST INSTALLATION HOUSING ALIGNMENT

In the event that the trim is in need of alignment

after installation, adjustments can be made to the

housing.

1. Remove trim by gripping edge of flange and

pulling it out of housing.

2. To adjust housing for trim alignment, reach

through aperture and loosen two speed nuts (see

Figure 7). Adjust housing as required and retighten

nuts.

3. Reinstall trim. If needed, refer to trim installation

instructions.

WALLWASH HOUSING ORIENTATION

WALLWASH HOUSING ONLY:

(SQDLW, SQDLWH, SQDLWTH, SQDLV

wallwash and SQDMRH wallwash)

1. Install wallwash housing so that lamp is aimed

away from the wall (see Figure 8). If housing is

installed incorrectly with lamp aimed towards wall,

reach through aperture and r emove two (2) speed

nuts. Rotate socket mounting bracket so that it is

aimed away from wall and reinstall speed nuts.

CJ5200903 Rev. B

6/10 2 of 2

©2009, 2010 Acuity Brands Lighting, Inc. All

Rights Reserved.

Loading...

Loading...