Page 1

MOUNTING BRACKET

CENTER HOLE

FRAME MOUNTING

BRACKET

MOUNTING PAN

INSTALLATION INSTRUCTIONS

GRS Recessed Mount

PDPA/PDPF/PDPH

Upon receipt, thoroughly inspect for any

freight damage which should be brought

to the attention of the delivery carrier.

Compare the catalog description listed on

the packing slip with the label on the carton to ensure you have received the correct merchandise.

IMPORTANT SAFETY INFORMATION

For Your Protection, Read Carefully

WARNING: Risk of fire. Do not install

insulation within 3 inches of fixture sides

or wiring compartment, nor above the

fixture in such a manner as to entrap

heat.

1. Electric current can cause painful

shock or serious injury unless handled

properly. For your safety, always

remember the following:

• Turn off the power supply.

• Ground the fixture to avoid poten-

tial electrical shocks.

• Do not handle an energized fixture

or energize any fixture with wet

hands, when standing on a wet or

damp surface, or in water.

2. Specific safety information concerning

lamps:

• Match wattage of fixture and lamp

exactly.

• Do not remove or insert lamp when

power is on.

• Do not scratch glass or subject lamp

to undue pressure as either may

cause lamp breakage.

• Protect operating lamp from sources

of moisture.

SA VE THESE INSTRUCTIONS

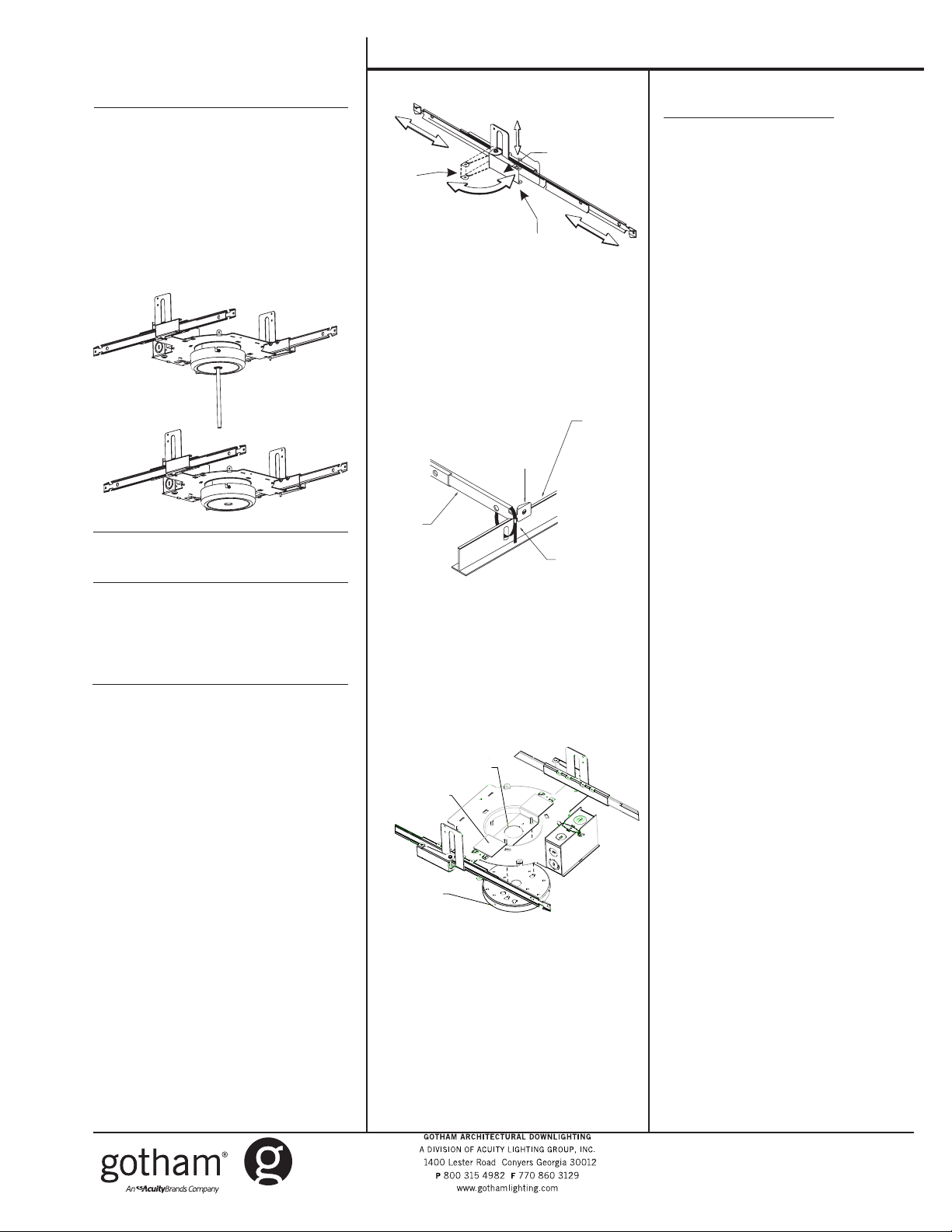

NEW INSTALLATION FOR GRS

Lay-in panel T-bar ceiling:

1. Cut ceiling opening slightly larger

than the outside diameter of the

mounting frame.

2. Position mounting frame through

opening in ceiling. Release clamping latch arms and adjust channel

bars to the correct spacing between T-bar as shown in Figure 1.

Secure channel bars to T-bar by

means of wire ties, screws or by

bending ends onto T-bar as shown

in Figure 2.

3. Once mounting frame has been

secured in structure, adjust the

mounting frame vertically to align

the bottom edge to either flush or

slightly above (1/8" max) the ceiling

line. Secure mounting frame into

position by closing the clamping

latch arm.

4. If additional security is required, a

No. 8 sheet metal screw, wire tie or

wire (not supplied) may be used to

tie the latch arm to the mounting

frame as shown in Figure 1.

5. Remove knockouts on junction box to

feed power supply to fixture as

shown in Figure 4. Supply wire must

meet applicable electrical codes

and be rated for a minimum of 75

Junction box is thru-wire rated for 8No. 12 AWG conductors (4 in-4 out).

6. Complete necessary wire connections. Snap the door onto the junc-

tion box.

Note 1: For fluorescent applicationsDimming: Make necessary wire

connections per ballast type.

EL and HID F-Can: Allow for 9-1/2” head

space above for ballast maintenance.

Pivot ballast tray onto spacer brackets

as shown in Figure 5. Thermal protector

assembly must be plugged into the

appropriate power supply voltage (120V,

227V or 347V). Snap door onto the

junction box.

Note 2: For incandescent 277V SDT

applications, make sure a minimum of

9-1/2” head space is available for yoke

height.

7. Pull flex through center hole of

bracket as shown in Figure 3.

8. Center mounting bracket in frame

aperture, and loosen screws until

1/2” from surface (Do Not Remove).

Part No. CJ520709

Page 1 of 2 2/07

Open

Figure 1

Channel

Bar

Figure 2

Mounting Bracket

Center hole

Frame Mounting

Bracket

Mounting

Pan

Figure 3

Clamping

Latch Arms

Closed

T-Bar

Bent Tab

Wire Tie

o

C.

Page 2

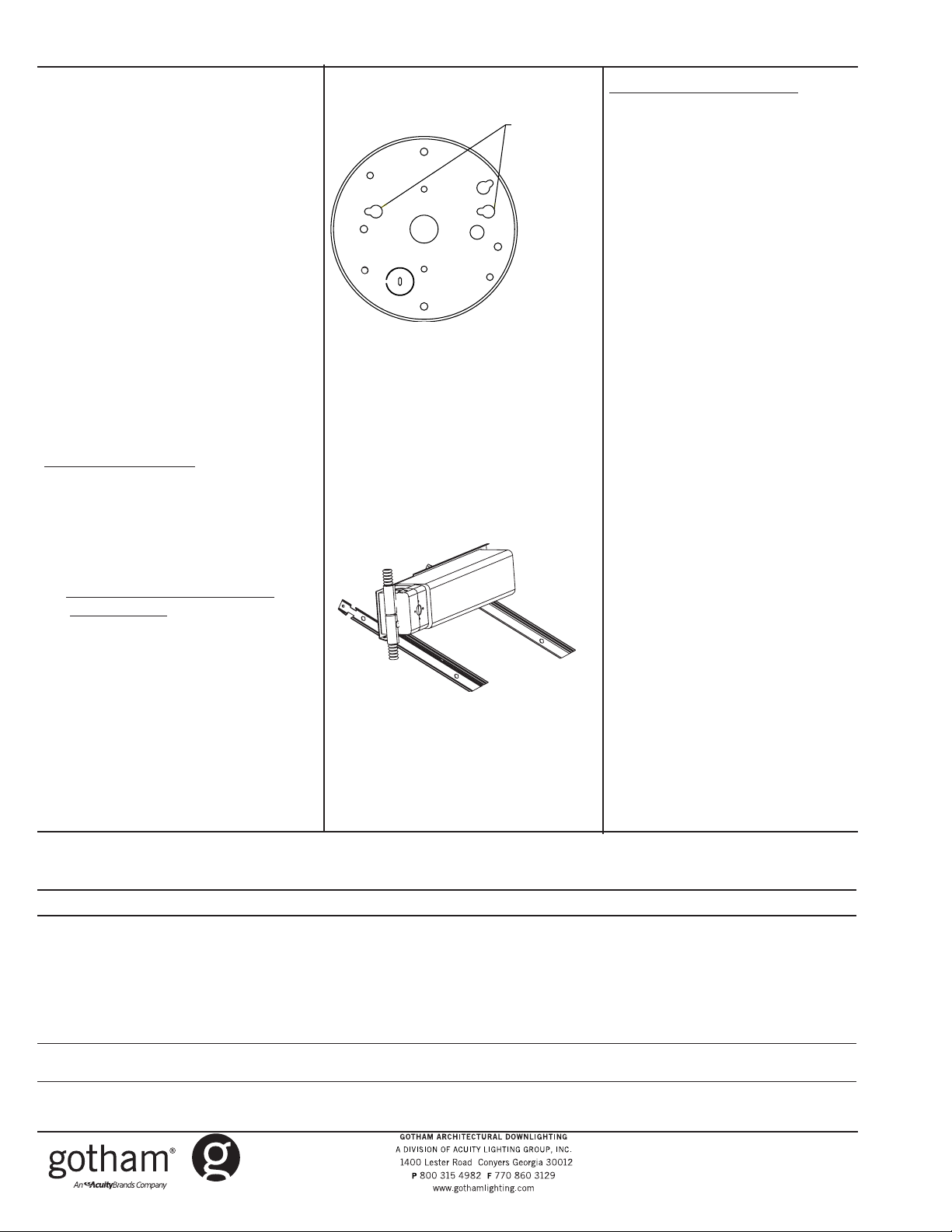

GRS Recessed Mount PDPA/PDPF/PDPH Installation Instructions

3.5 INCH SPACED

KEYHOLES

BACK OF MOUNTING PAN

VIEW

9. Connect flex to back of mounting

pan with end connector. Secure

flex with nut on inside of pan. Wires

should be inside of pan.

10. Orientate pan’s 3-1/2” spaced key holes with screws on mounting

bracket (Pan View).

11. Insert screws into pan keyhole

slots, and shift pan sideways to seat

into slots.

12. Tighten screws in slots to capture

pan to frame assembly. Make sure

screws are seated properly to cen ter pan.

13. Once pan is secured and centered,

installation of frame ASM is complete.

14. Mount canopy ASM per installation

instructions.

NEW INSTALLATION FOR GRS

Non-accessible ceiling (plaster, dry-

wall, etc.):

1. Release clamping latch arms and

adjust channel bars to the correct

spacing between joists as shown in

Figure 1.

2. Mounting Channel Bar- Flexible

Wiring Method

Bend ends of channel bars 90° and

adjustment at its lowest point on the

mounting frame. Make sure bottom

of the flange is flush with the bottom

of the joists. Secure mounting frame

into position by closing the clamping

latch arm. Channel bars will accom modate mount to joists with vertical

up to 24” O.C. joists

Back of Mounting Pan View

Figure 4

Figure 5

3.5 Inch Spaced

Keyholes

Non-Flexible Wiring Method

If non-flexible wiring methods are

used follow procedure for flexible

wiring methods. Then lower mounting

frame equal to the thickness of the

finished ceiling or slightly above.

3. Remove knockouts on junction box

to feed power supply to fixture.

Supply wire must meet applicable

electrical codes and be rated for a

minimum of 75°C. Junction box is

thru-wire rated for 8-No. 12 AWG

conductors (4 in - 4 out).

4. Complete necessary wire connec-

tions. Snap the door onto junction

box. Note 1. For fluorescent appli-

cations. Dimming- Make necessary wire connections per ballast

type. EL HID F-can- Allow for 9-1/2”

head space above for ballast

maintenance. Pivot ballast tray

onto spacer brackets as shown in

Figure 5. Thermal protector assembly must be plugged into the

appropriate power supply voltage

(120V, 277V or 347V). Snap door onto

junction box.

Note 2. For incandescent 277V SDT

applications, make a minimum of 9 1/2” head space available for yoke

height.

5. Follow steps 6-14 in previous

section.

Ballast Access: To access ballast

and/or J-box, first remove canopy

assembly from mounting bracket.

Remove mounting bracket and reach

through aperture to access J-box and

ballast

.

motpmySesuaCelbissoPnoitcAevitcerroC

THGIL

FFODNA

OTSLIAFPMAL

ivynarofkcehC

TUOSEOGPMAL

GNITHGILRETFA

NOSELCYCPMAL

TRAHCGNITOOHSELBUORT

.snoitcaevitcerrocdnasesuacelbissopfotsilgniwollofeht

omrotiucricnirorregniriW·

pmalytluaF·

tuptuotsallabroeniL·

tuodenrubtsallaB·

wolooterutarepmettneibmA·

pmalytluaF· n

erutxifotesolcootsinoitalusnI·

hgihootegattawpmaL·

wolegatlovtuptuotsallaB·

dezigrenetonerutxifehtgnideeftiucriC·

noitcennocelud

.tcerroc

.enowenahtiw

ckcehC·

lovenilkcehC·

thgilotnwonksitahteno

.ytiunitnoctiucri

.pmalwenaetutitsbuS.thgilotgniliafylpmis

)"3tsaelta(eludomdnuoramorfnoitalusnievomeR·

.gnisuohnideificepsegattawpmalllatsnI·

Part No. CJ520709

nimelborpehtetacol,noitidnocdoognimeesyehtfI.eludomni-emarfropmalehtotegamadelbis

.dezigrenesitiucrictahterusneotesufrorekaerbtiucrickcehC·

erasnoitcennoctahterusneotxobecilpserutxifenimaxE·

ylbareferp,pmalrehtonaetutitsbusdnapmalytluafehtevomeR·

lanigiroehtecalper,sthgilpmalehtfI.

.egatlovtiucricnepokcehC.erutxiftaegatlovenilkcehC·

.snoitidnoclatnemnorivnegnitsixetsniagagnitartsallabkcehC·

ahtrehtarmotpmyssihttibihxelliwpmalayllanoisaccO·

.egatlovtiucricnepokcehC.erutxifehttaegat

CJ520709

02/07

Page 2 of 2

Loading...

Loading...