Page 1

INSTALLATION INSTRUCTIONS

Directional

Lensed Wallwash

Housing

DLWF 6 & 8

Upon receipt, thoroughly inspect for any

freight damage which should be brought to

the attention of the delivery carrier. Compare

the catalog description listed on the packing

slip with the label on the carton to ensure you

have received the correct merchandise.

IMPORTANT SAFETY INFORMATION

For Your Protection, Read Carefully

WARNING - Risk of fire. Do not install insulation within 3 inches of fixture sides or wiring compartment, nor above the fixture in

such a manner as to entrap heat.

1. Electric current can cause painful shock

or serious injury unless handled properly.

For your safety, always remember the

following:

• Turn off the power supply.

• Ground the fixture to avoid potential

electrical shocks.

• Do not handle an energized fixture or

energize any fixture with wet hands,

when standing on a wet or damp surface, or in water.

• Double check all electrical connections

to be sure they are tight and correct.

2. Specific safety information concerning lamps:

• Match wattage of fixture and lamp ex-

actly.

• Do not remove or insert lamp when power

is on.

• Do not scratch glass or subject lamp to

undue pressure as either may cause

lamp breakage.

• Protect operating lamp from sources

of moisture.

SAVE THESE INSTRUCTIONS

PRIOR TO INSTALLATION

Read and familiarize yourself with the nomenclature and instructions before starting

installation.

Turn off electricity at the breaker panel or

fuse box and follow National Electrical Code

regulations.

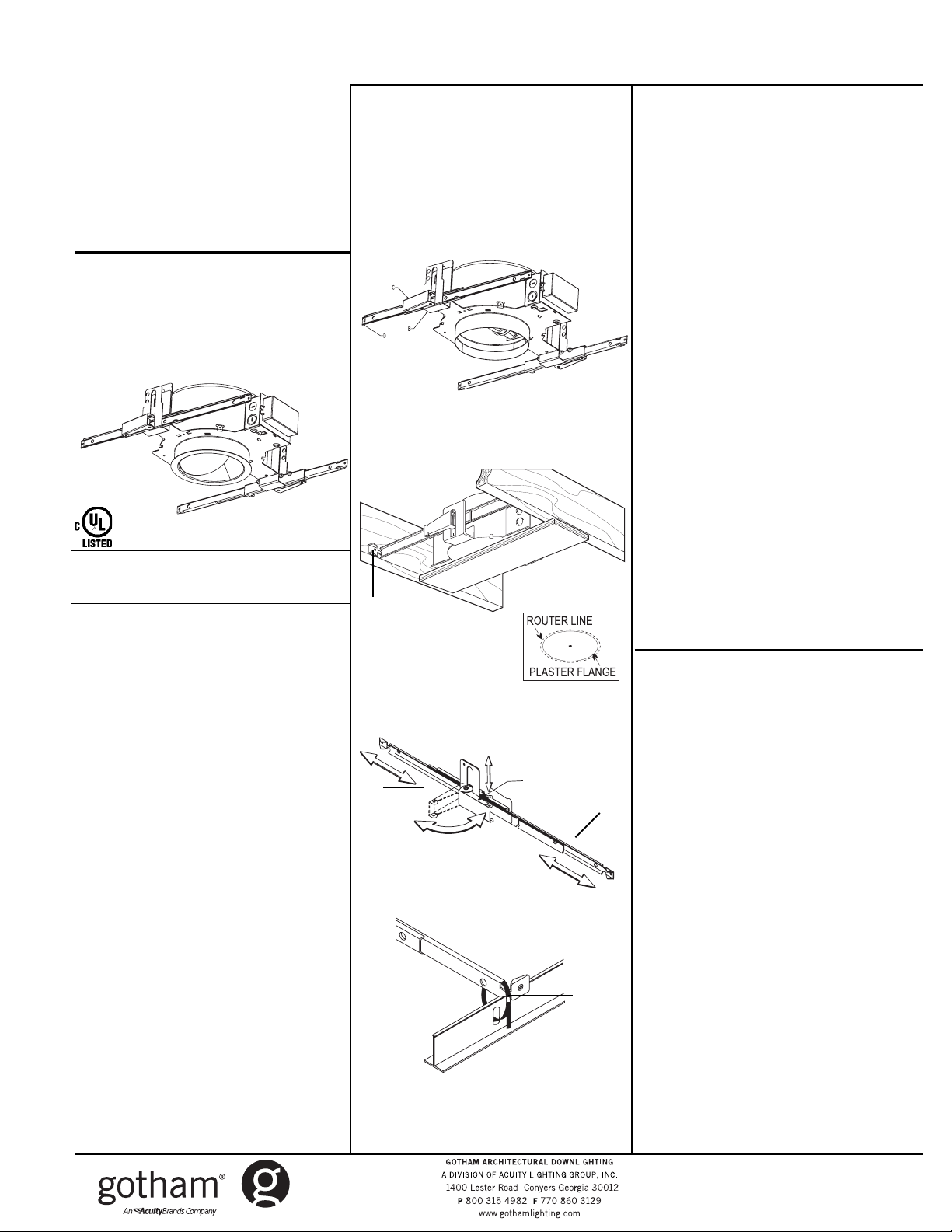

Figure 1

E

F

Figure 2

G

A

Figure 3

A

Figure 4

WOOD OR STEEL JOIST CONSTRUCTION

On 24” centers (16” or 24” O.C. for 4” fixture)

utilizing solid type (non-accessible) ceiling

(drywall, plaster, etc.).

USING ROUTER FOR CEILING CUTOUT

1. Open lever (C) securing bar hangers bend ends of hangers 90° (D) to be used

as nailing tabs, center in the vertical slot,

and close lever (C) to lock; repeat on

opposite side.

2. Secure a piece of plywood (E) to temporarily span the bottom of the joists to

support the fixture housing while

attaching the bar hangers (F) to the

joists. This will position the housing

correctly for drywall installer to provide

pilot hole (G) to locate fixture after ceiling

has been installed.

3. PROCEED TO “FEED WIRE CONNECTION

TO FIXTURE J-BOX” ON NEXT PAGE.

Return and complete following steps

after feed wire connections have been

made.

4. Using 1/8” router follow outside of plaster

frame to cut hole in ceiling.

5. Loosen (2) 5/16” screws (A) 180° apart,

allowing fixture to drop down so bottom

edge of plaster flange will be slightly

above edge of ceiling material.

FOR CEILING THICKNESS OVER 3/4” REFER

TO FIGURE 5.

T-BAR CEILING INSTALLATION

1. Install ceiling panel in t-bar with ceiling

opening pre-cut. Ceiling opening must be

slightly larger than the outside diameter

of the plaster flange.

2. Open lever (A), expand bar hangers (B) to

approximately 24” and close lever to

lock. Refer to Figure 3.

B

3. Through an adjacent opening, position

the mounting frame with the plaster

flange passing through the pre-cut

opening with the notches on the bar

hangers engaging the t-bar.

4. Secure the bar hangers to the t-bar by

wire or wiretie (by others) or bending end

of bar hanger. Refer to Figure 4.

5. Open lever and adjust mounting frame

vertically so that the bottom edge of the

plaster flange is flush or slightly above

the bottom edge of the ceiling panel.

6. PROCEED TO “FEED WIRE CONNECTION

TO FIXTURE J-BOX” ON NEXT PAGE.

7.

If fine tune adjustment from below ceiling

is required:

180° apart, allowing fixture to drop down

so bottom edge of plaster flange will be

slightly above edge of ceiling material.

Refer to Figure 1.

Refer to Figure 2.

Loosen (2) 5/16” screws (A)

Part No. CJ52009

Page 1 of 2 - 5/06

Page 2

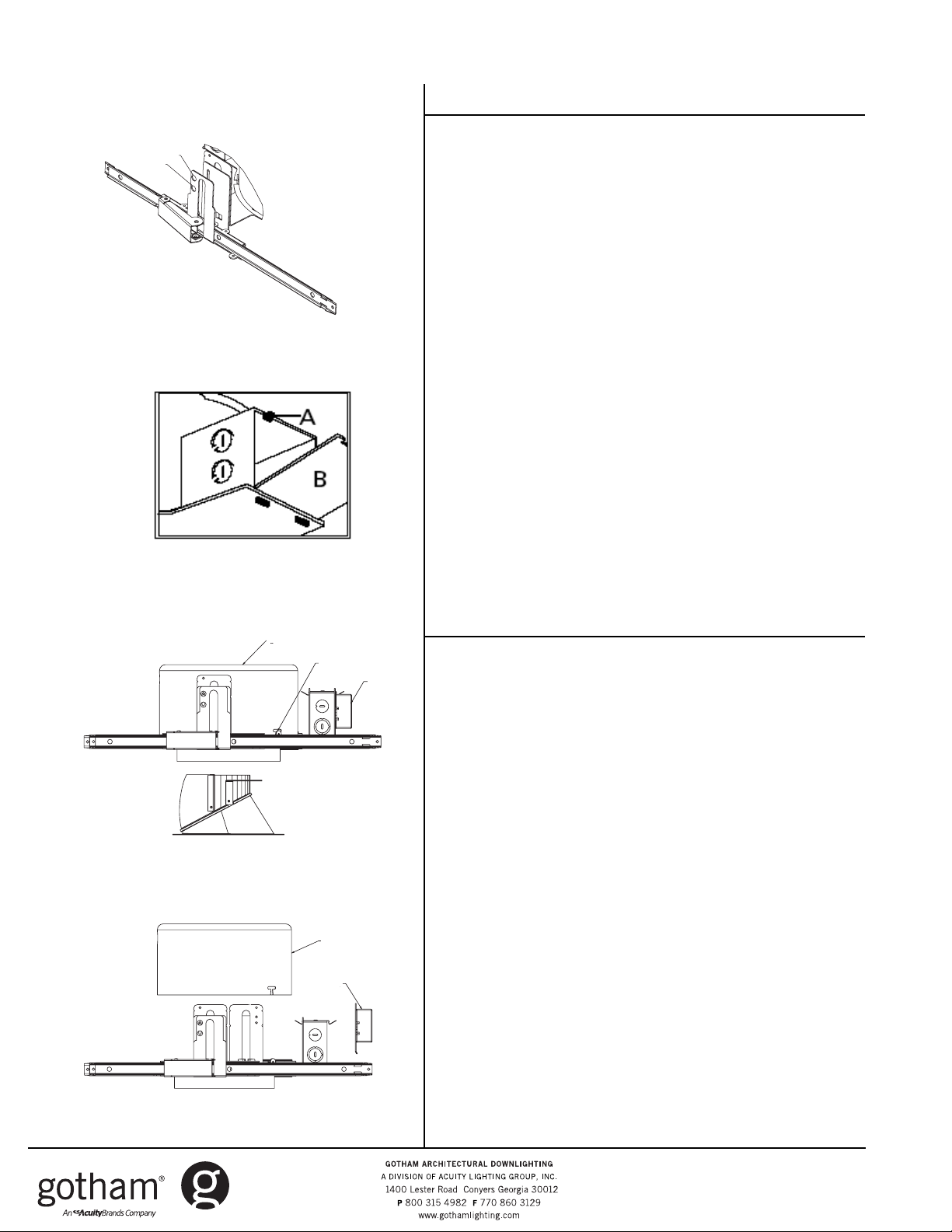

NON-STANDARD CEILING THICKNESS

HOUSING INSTALLATION

A

B

SAVE THESE INSTRUCTIONS

IMPORTANT INSTALLATION INFORMATION

Fixture ships configured for T-grid and standard ¾” drywall. For

thicknesses exceeding ¾” up to 1 ½” inches, adjust mounting bar

brackets by loosening screw through hole (A), sliding bracket to

upper position and tightening through hole (B).

Figure5

Figure 6

FEED WIRE CONNECTION TO FIXTURE J-BOX Refer to Figure 6

J-box is approved for through wiring with eight No. 12 AWG

conductors (4in/4out), rated 90°C or higher.

1. Remove J-box cover by releasing spring clip (A) at top and

allowing cover (B) to hinge open.

2. Select knockout, remove and install appropriate box connector.

3. Install feed wire applicable to NEC and/or local requirements.

4. Complete wiring.

5. Reinstall J-box cover (B) and the wiring is complete.

BALLAST REPLACEMENT Refer to Figures 7 & 8

1. Remove trim.

2. Using a ¼” nut driver or flat head screwdriver, loosen two

screws (A) located inside of housing above galvanized frame

aperture.

3. Twist black housing (B) and lift off of galvanized mounting

frame.

4. Through aperture, remove ballast assembly (C), unwire

ballast.

5. Install replacement in reverse order.

B

A

C

Figure 7

Figure 8

B

C

Part No. CJ52009

Page 2 of 2 - 5/06

Loading...

Loading...