Page 1

INSTALLATION INSTRUCTIONS

"APR"

Reflector

Upon receipt, thoroughly inspect for any

freight damage which should be brought to

the attention of the delivery carrier. Compare the catalog description listed on the

packing slip with the label on the carton to

ensure you have received the correct merchandise.

IMPORTANT SAFETY INFORMATION

For Your Protection, Read Carefully

WARNING - Risk of fire. Do not install insulation within 3 inches of fixture sides or

wiring compartment, nor above the fixture

in such a manner as to entrap heat.

1. Electric current can cause painful shock

or serious injury unless handled properly.

For your safety, always remember the following:

· Turn off the power supply.

· Ground the fixture to avoid potential

electrical shocks.

· Do not handle an energized fixture or

energize any fixture with wet hands,

when standing on a wet or damp surface, or in water.

· Double check all electrical connections

to be sure they are tight and correct.

2. Specific safety information concerning lamps:

· Match wattage of fixture and lamp ex-

actly.

· Do not remove or insert lamp when power

is on.

· Do not scratch glass or subject lamp to

undue pressure as either may cause

lamp breakage.

· Protect operating lamp from sources

of moisture.

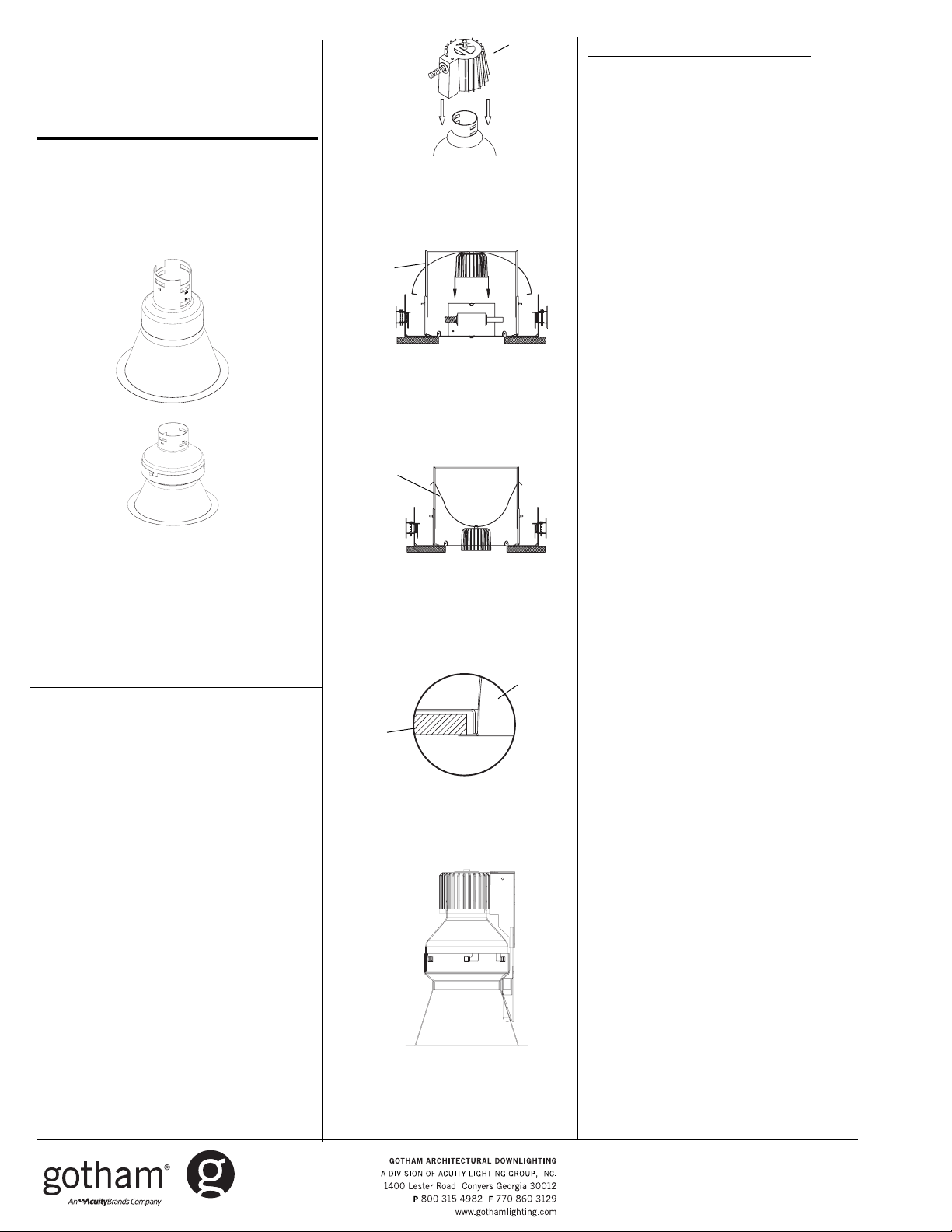

Figure 1

Flat

Spring

Up

Figure 2

Flat

Spring

Down

Figure 3

Ceiling

Figure 4

Figure 5

Socket

cup

Reflector

New Installation for APR Reflector

1. The GRS mounting frame utilizes an adjustable, flatspring, yoke assembly to retain the reflector into the ceiling as

shown in Figure 2. The yoke assembly

must be properly installed onto the

mounting frame. Refer to the INSTALLATION INSTRUCTIONS included in the

mounting frame for proper yoke installation.

2. The yoke assembly is preset at the factory for a ceiling thickness up to 1-5/8".

For other ceiling thickness, adjust the

yoke assembly by loosening the screws

on the yoke and moving the yoke downward equal to the difference of the ceiling thickness minus 1-5/8" (ex. 3" ceiling

thickness minus 1-5/8" = 1-3/8"). Refer to

scale on the yoke assembly for ease of

adjustment.

3. The socket cup is factory installed to

the flat spring. Pull socket cup down

into the ceiling opening until the flat

spring is fully extended as shown in Figures 2 and 3.

4. Attach socket cup to top of reflector by

aligning and engaging spring in socket

cup with slots in top of reflector as

shown in Figure 1. Lamp type markings

are located near the slots in top of reflector for proper positioning of socket

cup for optimum light distribution. If QRS

is included, install socket cup and neck

so that lamp bracket aligns with reflector slot as shown in Figure 5.

5. Install appropriate lamp as determined

by position of the socket cup/lamp type

marking on the reflector. For APR4 PAR30

and APR6 PAR38, remove reflector trim

from trim neck by twisting reflector

clockwise. Install lamp. Reverse procedure for re-assembly of reflector. Because reflector must be removed for relamping, a re-lamping pole cannot be

used. WARNING: Do not exceed the

wattage restrictions. If socket cup

adjustment is required: reach inside of

reflector, compress springs in socket cup

and move to appropriate reflector slot.

6. Push reflector through the ceiling opening until the flat spring pulls it up to the

ceiling as shown in Figure 4.

7. If reflector does not rest tightly against

the ceiling, remove the reflector (See

step 8), adjust the yoke assembly upward and re-attach reflector.

8. To remove the reflector: pull reflector

downward until the flat spring is fully

extended, remove lamp, reach inside of

reflector, compress springs in socket cup

and remove socket cup from reflector.

Part No. CJ520347

8/04

Page 2

APR, Reflector Installation Instructions

TROUBLE SHOOTING CHART

Check for any visible damage to the lamp or frame-in module. If they seem in good condition, locate the problem in the following list

for possible causes and corrective actions.

Symptom Possible Cause Corrective Action

Lamp will not start •Incorrect lamp or ballast •Compare ballast/lamp label against lamp type.

or starts slowly •Lamp is loose in socket •Back lamp out and retighten.

•Incorrect or loose wiring •Power off, check for proper connections. Connect fixture lead marked for proper voltage

to voltage supply lead. Connect white or lead marked COM to neutral supply.

•Lamp at or near end of life •Replace with new lamp. HPS lamp will cycle on and off as lamp reaches end of life. MH lamp

will suffer severe color change as lamp nears end of life.

•Line or ballast output •Check line voltage at fixture. Check open circuit voltage.

•Faulty ballast •Check circuit continuity.

•Starter circuit failed •Replace lamp with known good lamp.

•Ambient temperature too low •Check ballast rating against existing environmental conditions.

Cycling (lamp turns •Lamp at end of life •Replace with new lamp.

on and off) •Incorrect lamp or ballast •Compare fixture and lamp label for matching wattage and

source. Compare fixture and system voltage rating.

•Ballast output voltage low •Check line voltage at the fixture. Check open circuit voltage.

•Incorrect lamp operating •Check lamp specifications for proper operating position.

position (Metal Halide)

•Line voltage variations •Check incoming voltage with recording voltmeter (if this is the problem, check other

equipment on same circuit).

Low Lamp Output •Lamp end of life •Replace with new lamp.

•Line voltage or ballast •Check line voltage at fixture. Check open circuit voltage.

output voltage

•Incorrect lamp or ballast •Compare fixture and lamp label for matching wattage and source. Compare fixture and

system voltage rating.

Short Lamp Life •Incorrect lamp or ballast •Compare fixture and lamp label for matching wattage and

source. Compare fixture and system voltage rating.

•Line voltage or ballast output •Check line voltage at the fixture. Check open circuit voltage

voltage too low

•Lamp operates less than 10 hrs. •Rated lamp life is based on 10 hours of operation per start. General rule for expected lamp

life is 50% reduction in burn time per start results in 25% reduction in lamp life.

Part No. CJ520347

08/04

Loading...

Loading...