Gossen MetraWatt SSP 240 Series, SSP 120 Series, SSP 320 Series, SSP 240-20, SSP 120-80 Operating Instructions Manual

...Page 1

Operating Instructions

SSP-KONSTANTER 32 N

Series SSP 120, SSP 240 and SSP 320

Programmable Power Supplies

3-349-267-03

12/10.18

Page 2

2 GMC-I Messtechnik GmbH

Page 3

Contents Page

Contents Page

I Initial Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

II Warnings and Safety Precautions . . . . . . . . . . . . . . . . . . . . .4

1 Technical Description. . . . . . . . . . . . . . . . . . . . . . . . . . . .5

1.1 Features and Range of Applications . . . . . . . . . . . . . . . . . . .5

1.2 Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

1.3 Options and Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . .6

1.4 Functional Principle. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

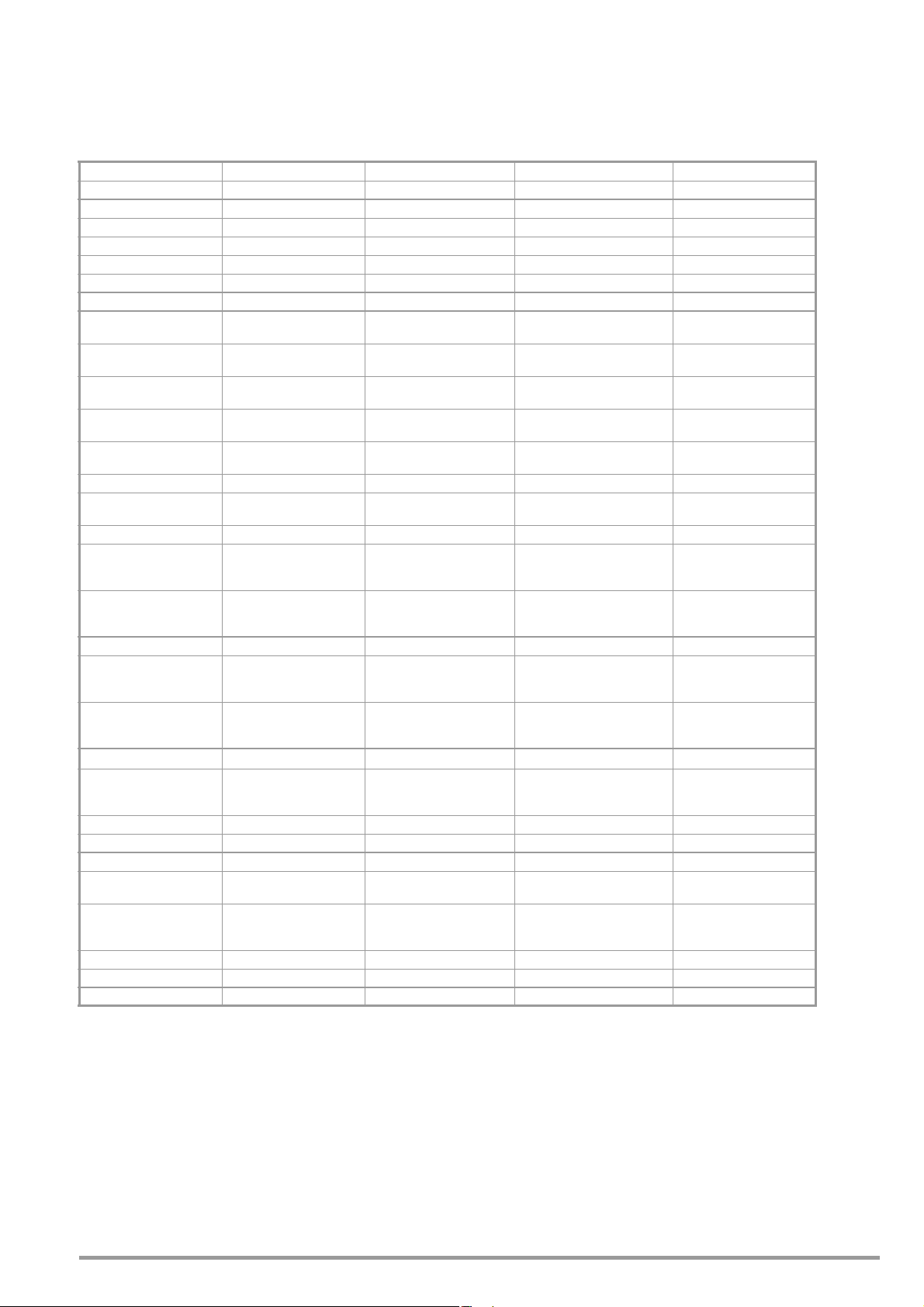

1.5 Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

1.5.1 General Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

1.5.2 Mechanical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

1.5.3 Electrical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

2 Initial Start-Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

2.1 Preparing for Operation . . . . . . . . . . . . . . . . . . . . . . . . . . .12

2.1.1 Installing the IEEE 488 Interface Module . . . . . . . . . . . . .12

2.1.2 Installation to 19'' Device Racks . . . . . . . . . . . . . . . . . . .12

2.1.3 Combining Benchtop Devices . . . . . . . . . . . . . . . . . . . . .13

2.1.4 Connection to the Mains . . . . . . . . . . . . . . . . . . . . . . . . .13

2.1.5 Connecting Power Consumers. . . . . . . . . . . . . . . . . . . . .13

2.1.6 Connection to Computer Interfaces . . . . . . . . . . . . . . . . . 13

2.2 Switching the Instrument On . . . . . . . . . . . . . . . . . . . . . . .14

4.14 INCR <> and DECR <> Keys . . . . . . . . . . . . . . . . . . . .47

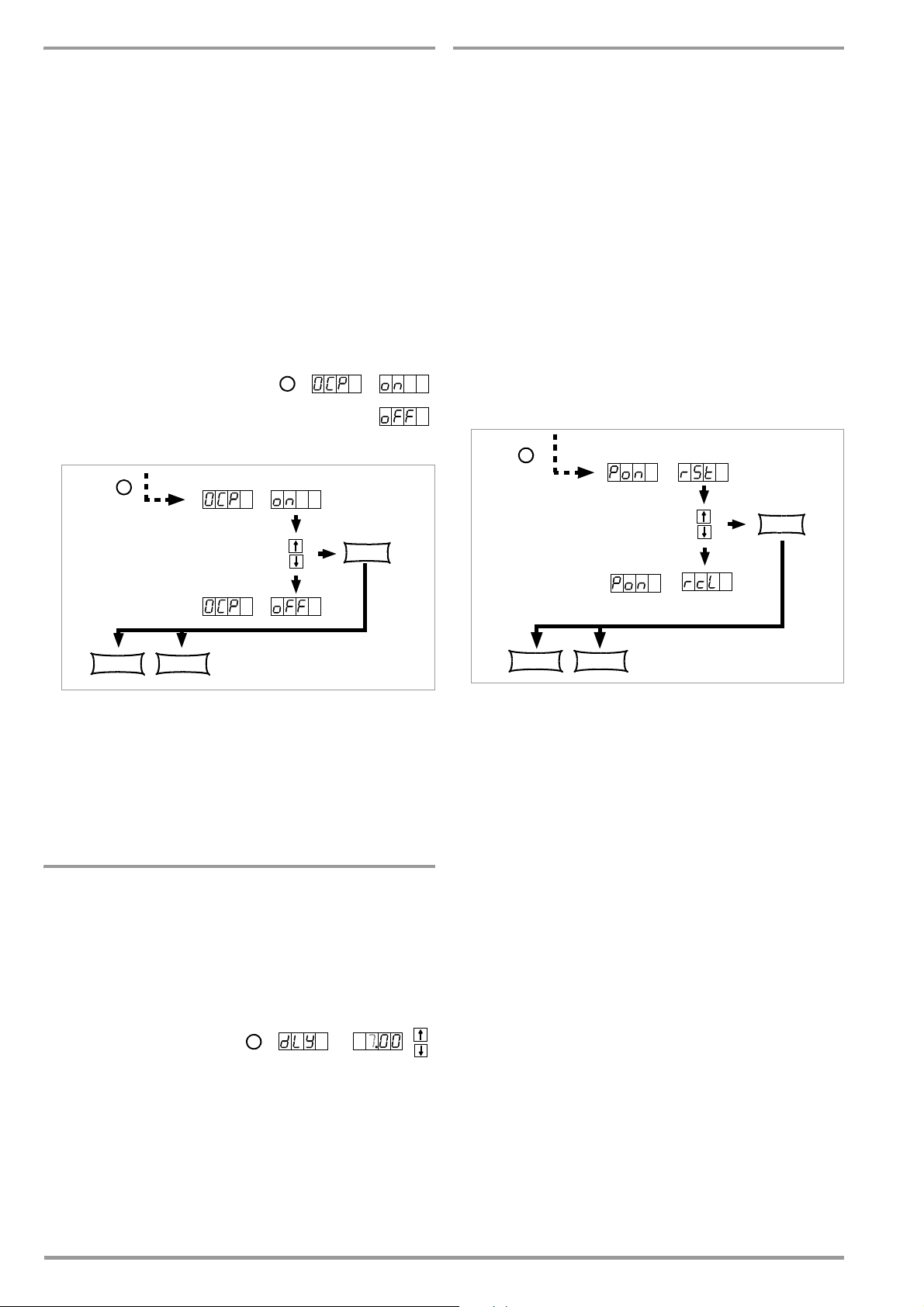

4.15 Device RESET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

Selecting Remote and Local Control Modes . . . . . . . . . . . . . . . . . 47

4.16

5 Analog Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

5.1 Connector Pin Assignments . . . . . . . . . . . . . . . . . . . . . . . .48

5.2 Auto-Sensing Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

5.3 Status Signal Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

5.4 Regulating Output Voltage . . . . . . . . . . . . . . . . . . . . . . . .50

5.5 Regulating Output Current . . . . . . . . . . . . . . . . . . . . . . . .50

5.6 Voltage Monitoring Output . . . . . . . . . . . . . . . . . . . . . . . .51

5.7 Current Monitoring Output . . . . . . . . . . . . . . . . . . . . . . . .51

5.8 Trigger Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

5.9 Parallel Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

5.9.1 Direct Parallel Connection . . . . . . . . . . . . . . . . . . . . . . . .52

5.9.2 Master-Slave Parallel Connection . . . . . . . . . . . . . . . . . .54

5.10 Series Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

5.10.1 Direct Series Connection. . . . . . . . . . . . . . . . . . . . . . . . .55

5.10.2 Master-Slave Series Connection . . . . . . . . . . . . . . . . . . .56

5.11 Varying the Internal Output Resistance Value . . . . . . . . . . .57

3 Controls, Display Elements and Terminals . . . . . . . . . . . 16

4 Manual Operation and Device Functions . . . . . . . . . . . .20

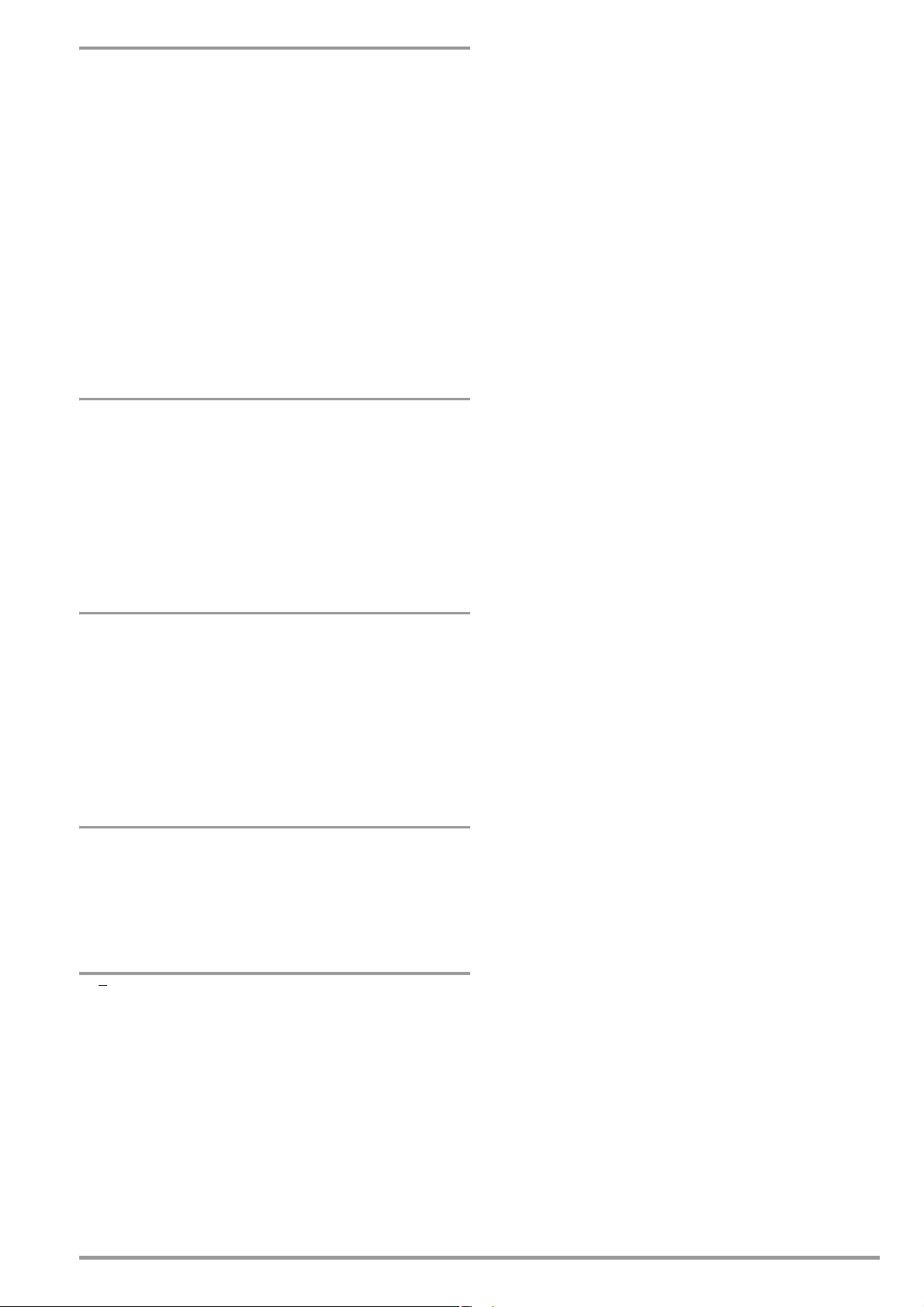

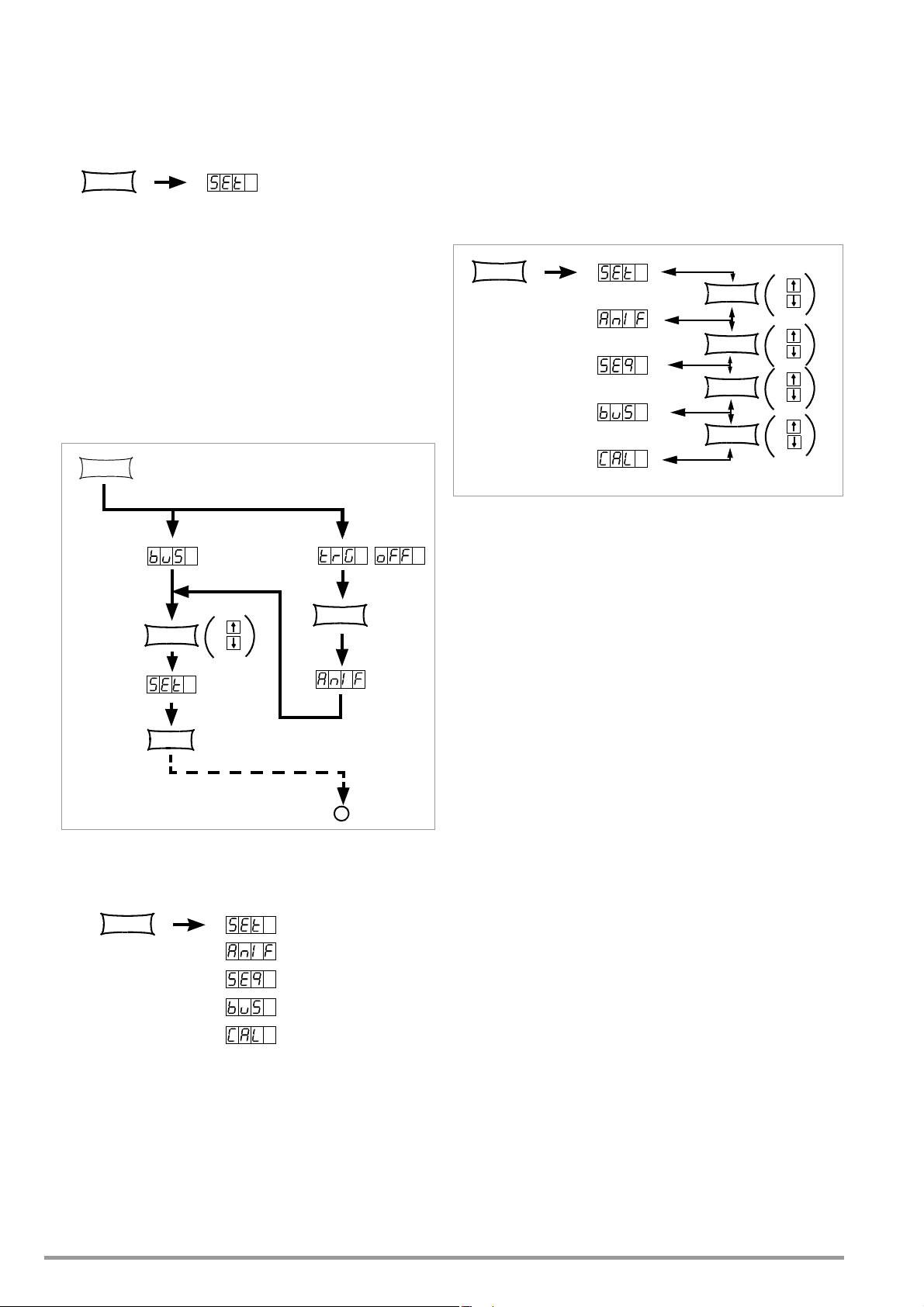

4.1 Menu Structure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

4.2 Setting Output Voltage and Output Current . . . . . . . . . . . . . 20

4.2.1 Direct Selection (rotary knobs and scroll keys) . . . . . . . . .20

4.2.2 Pre-selected Setting (ENTER, scroll keys) . . . . . . . . . . . .21

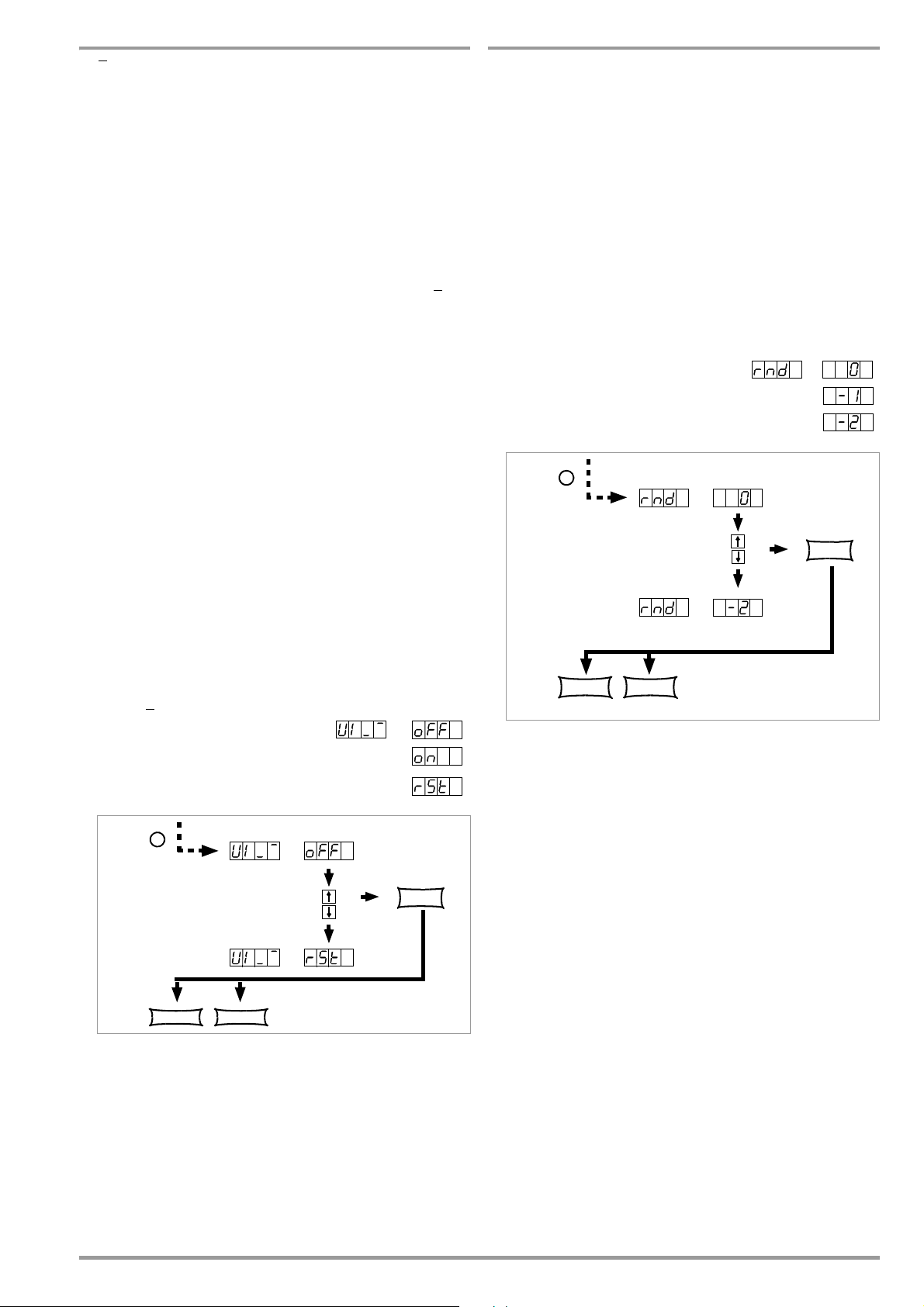

Switching the Power Output On and Off . . . . . . . . . . . . . . . . . . . .21

4.3

4.4

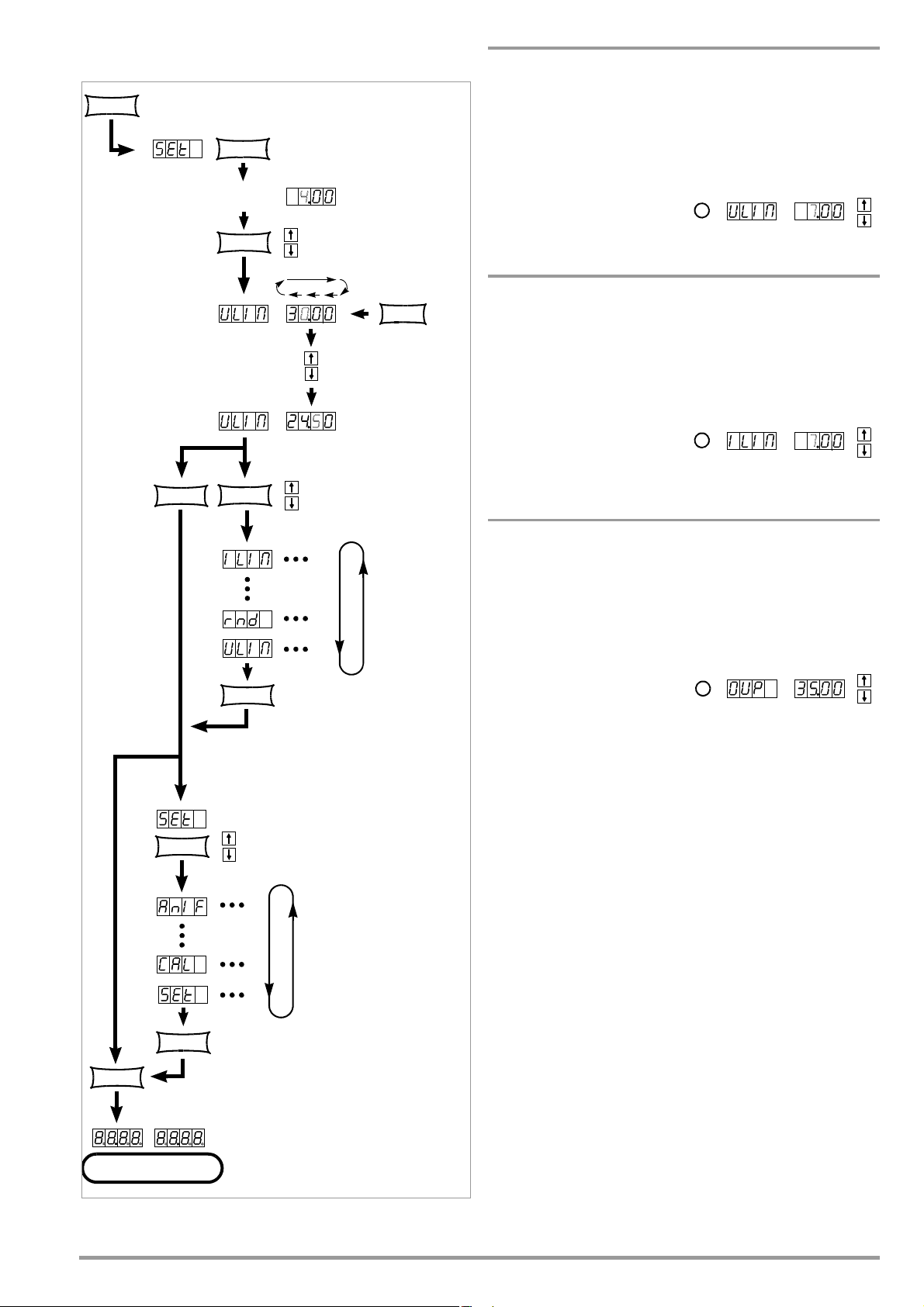

Limiting the Allowable Working Range: Ulim, Ilim . . . . . . . . . . . . .22

4.5 Description of OVP and OCP Protection Functions. . . . . . . .22

4.6 Display of Momentary Output Values Uout, Iout and Pout. . .23

4.7 Operating Menu via the FUNCTION Key . . . . . . . . . . . . . . .23

4.7.1 SET – “Setup” Function Group . . . . . . . . . . . . . . . . . . . .25

4.7.2 AnIF – “Analog Interface” Function Group . . . . . . . . . . . .28

4.7.3 SEq – The Sequence Function Group. . . . . . . . . . . . . . . .30

4.7.4 buS – The “Interface” Function Group . . . . . . . . . . . . . . .38

4.8 Settings with the <SELECT> Key

4.8.1 In the Basic Function . . . . . . . . . . . . . . . . . . . . . . . . . . .40

4.8.2

4.8.3

4.8.4 Setting Resolution with the <SELECT> Key . . . . . . . . . . .41

4.9 Storing Data with the <SAVE> Key . . . . . . . . . . . . . . . . . .41

4.9.1 Saving Basic Device Settings. . . . . . . . . . . . . . . . . . . . . .41

4.9.2 Saving Data to a Memory Location. . . . . . . . . . . . . . . . . .41

4.9.3

4.9.4 Inserting a Memory Location . . . . . . . . . . . . . . . . . . . . .43

4.9.5 Deleting a Memory Location . . . . . . . . . . . . . . . . . . . . . .44

4.9.6 Deleting the Contents of a Memory Location . . . . . . . . . .45

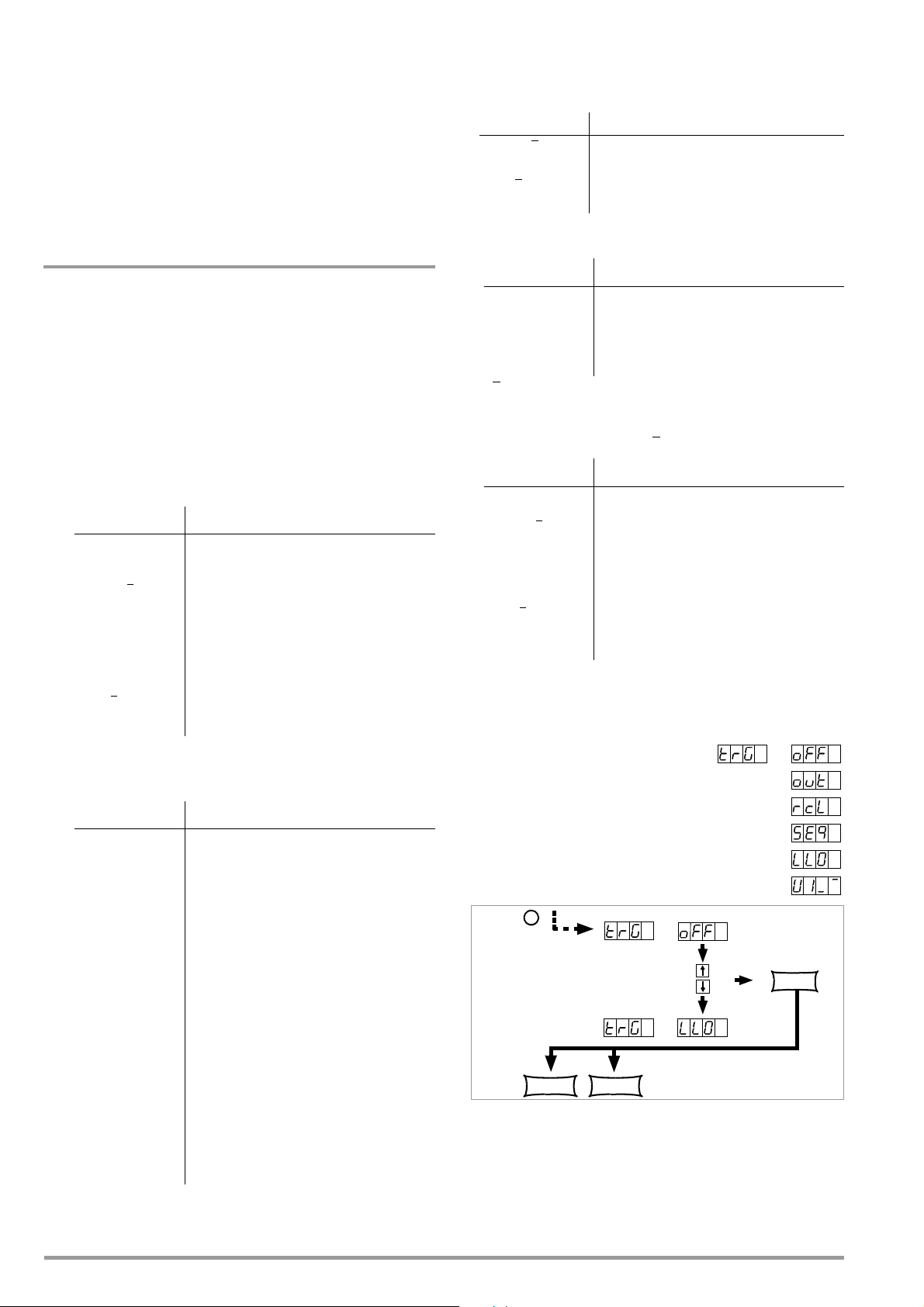

4.10 Memory Recall with the <RCL> Key. . . . . . . . . . . . . . . . . .45

4.10.1 Recall from SETUP Memory. . . . . . . . . . . . . . . . . . . . . . .45

4.10.2 Recall from SEQUENCE Memory . . . . . . . . . . . . . . . . . . .46

4.11 Disabling Front Panel Controls . . . . . . . . . . . . . . . . . . . . .46

4.12 <The ENTER> Key . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

4.13 The <CE/LOCAL> Key . . . . . . . . . . . . . . . . . . . . . . . . . . .46

During a Sequence Run and with Step-by-Step Control. . . . . . . .40

Display of Stored Data Upon Execution of <RCL>. . . . . . . . . . . .40

Clearing the Contents of a Defined Memory Range . . . . . . . . . . 42

. . . . . . . . . . . . . . . . . . . . . .40

6 Operating Commands . . . . . . . . . . . . . . . . . . . . . . . . . . .58

6.1 Syntax . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

6.2 IEEE 488 Functions . . . . . . . . . . . . . . . . . . . . . . . . . . .60

6.3 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

6.4 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

6.5 Status and Events Management. . . . . . . . . . . . . . . . . . . . .77

7 Adjusting the SSP KONSTANTER

CAL – “Calibration” Function Group . . . . . . . . . . . . . . . .79

7.1 General Information and Definition of Terms . . . . . . . . . . . .79

7.2 Adjusting Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . .80

7.3 Self-Test Triggering . . . . . . . . . . . . . . . . . . . . . . . . . . . . .82

8 Appendix. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .83

8.1 Adjustable Functions and Parameters . . . . . . . . . . . . . . . .83

8.2 Queriable Functions and Parameters . . . . . . . . . . . . . . .85

8.3 Query Commands for Status and Events Management . .86

8.4 Overview of Menu Functions . . . . . . . . . . . . . . . . . . . . .87

8.5 Memory Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . .88

8.6 Indication of Operating States . . . . . . . . . . . . . . . . . . . . . .89

8.7 System Messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .90

8.6 Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .91

9 Order Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .92

10 Repair and Replacement Parts Service,

Calibration Center* and Rental Service . . . . . . . . . . . . .92

11 Product Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .92

GMC-I Messtechnik GmbH 3

Page 4

I Initial Inspection

!

Important Warnings

Immediately after receipt, unpack the KONSTANTER and all

included accessories, and inspect for damage and completeness.

Unpacking

Great care must be exercised when removing the electronic

device from the package.

☞ Pull the KONSTANTER from its package.

☞ In doing so, do not grasp rotary knobs, terminals or jacks in

order to avoid damage.

☞ Do not allow the KONSTANTER to fall out of the packaging.

Controls, displays, terminals and internal components might

otherwise be damaged.

☞ Do not, under any circumstances, touch the KONSTANTER’s

electrical terminals before grounding yourself to the housing

in order to neutralize potential differences. Sensitive

electronic circuitry might otherwise be damaged as a result

of electrostatic discharge.

☞ The KONSTANTER is delivered in recyclable packaging, which

provides for adequate protection during transport as

substantiated by testing. If the instrument is repacked at a

later point in time, the same packaging or its equivalent must

be used.

Visual Inspection

Compare the order number or type designation included on

☞

the packaging and/or the serial plate with the particulars

shown in the shipping documents.

☞ Make sure that all accessory components have been

included

(see chapter 1.3, “Options and Accessories”).

☞ Inspect the packaging, as well as mechanical instrument

and accessory components for possible transport damage.

Complaints

If damage is discovered, immediately file a claim with the

freight forwarder (save the packaging!). If other defects are

detected, or in the event that service is required, inform your

local representative, or contact us directly at the address

included in the last page of this handbook.

II Warnings and Safety Precautions

The KONSTANTER has been manufactured and tested in

accordance with the electrical safety regulations listed under

“Technical Data” as a safety class I device, and has been shipped

from the factory in flawless technical safety condition. In order to

maintain this condition and to assure safe operation, users must

observe all notes and warnings included in these operating

instructions. These are identified with the following headings:

ATTENTION!

A note concerning operation, practical advice or other information

which must be adhered to in order to prevent damage to the

KONSTANTER, and to assure correct operation.

WARNING!

An operating procedure, practical advice or other information

which must be adhered in order to assure safe operation of the

KONSTANTER, and to prevent personal injury.

The most important warnings are summarized below.

Reference is made to these warnings at appropriate points

within the operating instructions.

WARNING I – Protective Grounding

The KONSTANTER may only be placed into operation after the

protective conductor has been connected. Interruption of the

protective conductor, either inside or outside of the

KONSTANTER, or disconnection of the protective conductor

terminal may transform it into a source of danger. Intentional

interruption is prohibited.

The device is connected to the mains by means of a 3 conductor

cable with mains plug. The plug may only be inserted into a

suitable outlet with earthing contact. This safety precaution must

not be defeated though the use of an extension cable without

protective conductor.

WARNING II – Impaired Safety

If it can be assumed that safe operation is no longer possible, the

KONSTANTER must be removed from service and secured against

inadvertent use. It must be assumed that safe operation is no longer

possible:

☞ If the KONSTANTER demonstrates visible damage

☞ If the KONSTANTER no longer functions

☞ After lengthy periods of storage under conditions which deviate

from specified storage conditions

☞ After extraordinary stressing due to transport

WARNING III – Opening Housing Panels

Voltage conducting parts may be exposed when housing panels

are opened, as long as the KONSTANTER is connected to supply

power.

Any contact with these exposed conductive parts is life

endangering.

For this reason, housing panels may only be opened and/or

removed by trained personnel who are familiar with the dangers

involved.

WARNING IV – Repair by Trained Personnel

Voltage conducting parts may be exposed when housing panels

are opened, as long as the KONSTANTER is connected to supply

power.

Maintenance and repair work, as well as internal balancing, may

only be performed by trained personnel who are familiar with the

dangers involved.

The KONSTANTER must be disconnected from all external

voltage sources before work of this type is performed, in as far as

this is possible. A five minute waiting period must be observed

after disconnection in order to allow internal capacitors to

discharge to safe voltage levels.

WARNING V – Fuse Replacement

Only specified fuse types with the specified nominal current rating

may be used to replace blown fuses (see “Technical Data” and

specifications on the serial plate).

Tampering with fuses or fuse holders is prohibited (“repairing”

fuses, short-circuiting fuse holders etc.).

Significance of Symbols

Indicates EC conformity

Observe EGB directives

Warning concerning a source of danger

(attention: observe documentation!)

4 GMC-I Messtechnik GmbH

Page 5

1 Technical Description

1.1 Features and Range of Applications

Depending upon where they are used and prevailing local

conditions, electrical and electronic devices may be subject to

significant supply power fluctuation in the absence of stabilizing

and back-up systems.

Automotive electrical system voltage characteristics during starter

motor operation offer a typical example.

R&D, production and test departments must be able to assure

that electrical equipment is capable of executing all required

functions under these types of conditions.

Type SSP 120, SSP 240 and SSP 320 KONSTANTER power

supplies from GMC-I Messtechnik GmbH support users in fulfilling

this objective.

In particular in automated test systems for routine testing,

SSP KONSTANTERs are capable of high throughput rates. Short

response times assure accurate emulation of rapidly changing

voltage and current characteristics.

Power consumer characteristics relative to dynamic supply power

can thus be tested and simulated very easily.

The integrated calibration procedure and the included calibration

certificate are especially important for use in production and testing

departments which are certified in accordance with ISO 9000.

SSP KONSTANTERs (single output system power supplies are

programmable, voltage and current regulated DC power supplies

with 120, 240 or 320 W of output power.

They are microprocessor controlled, and are furnished with an

addressable RS 232C serial interface as standard equipment. Up

to 30 KONSTANTERs can thus be controlled from a single PC

port.

An IEEE 488 interface can be integrated as an option. Complete

control of all device functions, as well as querying of measured

values, setting parameters and device statuses is possible via

both interfaces.

Manual adjustment of voltage and current is accomplished by

means of two rotary pulse encoders with selectable adjusting

sensitivity.

Two 4-place multifunction displays are used for precision read-out

of measured values (V, A and W), as well as for menu-driven

configuration of numerous additional functions such as limiting

setting ranges, overvoltage protection, overcurrent shutdown

delay and programmable, digital signal inputs and outputs.

Up to 243 settings can be saved to memory and recalled either

individually or sequentially, for example in order to generate

specific voltage or current characteristics. And innovative circuit

technology allows for nearly load independent response times of

less than 1 ms.

Output parameters can thus be superimposed with AC signal

right up into the kHz range via the analog interface which is

furnished as standard equipment.

The measuring function includes a Min-Max value memory, limit

monitoring signals and a HOLD function.

1.2 Functions

Adjustable functions:

❑ Voltage and current setpoint values

❑ Voltage and current limit values (soft-limits)

❑ Activate / deactivate the output

❑ Overvoltage protection trigger value

❑ Overcurrent response (limiting with or without shutdown)

❑ Delay time for overcurrent shutdown

❑ Start-up performance (power-on status)

❑ Reset device settings

❑ Save / recall device settings

❑ Save / recall setting sequences

❑ Sequence definition

❑ Trigger input function selection

❑ Function selection for digital control inputs

❑ Operating parameters for the measuring function (Min-Max

value memory, limit monitoring, display resolution)

❑ Initialize calibration procedure

❑ Initialize self-test

❑ Operating parameters for computer interfaces (device

address, SRQ masks, transmission speed etc.)

Display functions:

❑ Momentary measured voltage, current and power values

❑ Minimum and maximum measured voltage and current

values

❑ Current device settings (individual or complete)

❑ Current operating status (control mode, overtemperature,

busy)

❑ Occurred events (mains or phase failure, overtemperature,

overvoltage, overload, programming error)

❑ Memory contents

❑ Device ID

❑ Calibration date

Protective Functions and Additional Functions

❑ Sensing terminals protected against polarity reversal and

automatic switching to auto-sensing

❑ Control panel disabling

❑ Output overvoltage protection

❑ Output protected against reverse polarity

❑ Overtemperature protection

❑ Backup battery for device settings memory

❑ Master-slave series operation

❑ Inrush current limiting

❑ Temperature controlled fans (with 240 and 320 W models)

GMC-I Messtechnik GmbH 5

Page 6

1.3 Options and Accessories

1.4 Functional Principle

Options

(See order information on last page.)

Devices can be equipped with an IEEE 488 plug-in interface

module for integration of SSP KONSTANTERs into IEC bus

controlled systems.

The interface is in compliance with requirements set forth in the

IEEE488.2 standard (IEC 625-2), and is frequently designated

as a GPIB (general purpose interface bus) or an HP-IB (Hewlett

Packard interface bus).

Programming of all device functions, as well as querying

measured and configured parameters, is possible via the

interface. Several specific interface functions are also provided.

The interface option is supplied as a separate plug-in module for

easy, subsequent installation to the KONSTANTER.

Included accessories:

The following accessories are included with the

SSP KONSTANTER:

❑ These operating instructions

❑ 1 mains power cable with earthing contact plug

(approx. 1½ meters)

Additionally available accessories:

(See order information on last page.)

❑ 19" rack adapter, 1 x 32 N

required for installation of one series SSP 32 N or SLP 32 N

KONSTANTER to a 19" rack

❑ 19" rack adapter, 2 x 32 N

required for installation of two series SSP 32 N or SLP 32 N

KONSTANTERs to a 19" rack

❑ Mains jumper cable, 0.4 meters

The cable is equipped with a 10 A inlet plug and a 10 A inlet

socket. It is used for looping mains power through when

several KONSTANTERs are mechanically combined into a

multi-channel unit. In this way, the complete unit requires

only one mains power cable.

❑ RS 232 bus cable, 2 meters

For connecting one KONSTANTER to an RS 232 interface.

(extension cable, 9-pin socket / 9-pin plug connector)

Power Supply

Required DC supply power is generated for each respective

circuit from mains power which has been fed to the power pack

via an interference suppression filter, a wire fuse, the mains switch

and inrush current limiting.

The Central Processing Unit (CPU)

Overall control of the SSP KONSTANTER is accomplished by

means of the CPU on PCB A. It uses an 80C32 8-bit

microcontroller with 64 kilobytes of program memory and 32

kilobytes of battery-backed CMOS RAM.

An 11 MHz pulse generator establishes the clock frequency for

the processor, and creates a time reference for the serial

interface.

A watchdog circuit monitors processor activity and disables

access battery-backed RAM in the event of supply power failure.

Operation

Generally speaking, all of the functions of the SSP KONSTANTER

can be controlled with the adjusting elements at the front panel,

via the RS 232 interface or via the optional IEEE 488 plug-in

interface module.

Displays and Control Panel

Both 4-place 7-segment displays and the individual LEDs are

controlled statically by the processor via the registers. Front panel

key operations are processed by means of a group interrupt and

subsequent direct querying. The rotary pulse encoders control

the increment and decrement counters depending upon the

direction of rotation. Each time an adjusting element is activated,

an interrupt occurs at the CPU which then causes an appropriate

response.

Interface Option

The SSP KONSTANTER with installed interface module allows for

control via the IEEE 488 bus in addition to serial operation.

Remote Control

Device messages received by the interface are forwarded to the

CPU where they are first saved to RAM. After receiving an end-ofmessage character, data are checked for correct syntax,

plausibility and limit values. Valid commands are subsequently

executed.

6 GMC-I Messtechnik GmbH

Page 7

Setup Procedure

Setup data are processed and forwarded to the respective I/O

controller of the respective function unit. Each setting value for

output voltage, output current or overvoltage protection triggering

is converted to a proportional control voltage by a 12 bit DAC,

and is fed to the respective controller or comparator as a setpoint

or a reference quantity.

Actual output voltage is ascertained by a voltage monitor, whose

automatic sensor switching inputs are connected either to the

output terminals or the sensing terminals.

Actual output current is acquired as a voltage drop at a shunt

situated in the negative output conductor, and is amplified by the

current monitor to a scaled signal.

In order to achieve rapid downward adjustment of output voltage

even with minimal output load, the device is equipped with a

limited sink function (limited to approximately 15 W continuous

power). The sink function is implemented by means of BET

technology (bidirectional energy transfer). This technology assures

charging and discharging of the output capacitor within an equally

short period of time, even at no-load operation. The sink function

is activated as soon as, and for as long as output voltage exceeds

the current setpoint value (also in the event of energy recovery

from a parallel connected voltage source).

The source and sink functions are enabled when the output On /

Off status is set to ON, and the source function is disabled when

the status is set to Off, in which case the sink function is

deactivated after approximately 300 ms (highly resistive output).

Measuring Procedure

Monitor-amplifier output signals, which are proportional to actual

output voltage and current, are fed to an analog multiplexer (MUX)

which switches one of the two signals to the input of the analogdigital converter (ADC) depending upon the desired measured

quantity. The converter, controlled directly by the CPU, functions in

accordance with the dual-slope principle and traces measured

value acquirement back to a time measurement (meter reading).

The actually measured decimal value is calculated based upon this

data, and is stored to RAM. Depending upon the circumstances,

the measured value display is refreshed, an extreme value

comparison is performed for the Min-Max function or the measured

value is made available at the computer interfaces’ data output

buffer.

Monitoring Functions

– Control Mode Recognition and Overload

An electrically isolated digital signal is derived from the output

signals of the voltage and current regulators, which indicates

the currently active control mode (constant voltage or constant

current mode), as long as overload operation is not active.

“Overload” indicates that power limiting has been triggered as a

result of selected parameter settings and prevailing load. These

operating conditions are evaluated by the CPU (e.g. for OCP

function), are indicated with LEDs and are used to generate

status and event registers for computer control.

– Overvoltage Monitoring

After bypassing the voltage monitor, device output voltage is

additionally compared to an adjustable limit value within a range

of 3 V to 120% nominal voltage by a comparator, and the

output is deactivated if the limit value is exceeded and an OVP

message is generated (“CV” LED blinks, status and events

registers).

– Overcurrent Monitoring

Overcurrent monitoring can be activated and deactivated.

Response time is defined with the delay parameter. If, with

activated OCP function, the device is in the current regulating

mode for at least the duration of the selected delay time (“CC”

LED is illuminated), the power output is switched off and an

OCP message is generated (“CC” LED blinks, status and

events registers).

–Temperature Monitoring

Temperature is acquired by means of PTC resistors at

representative points (circuit breaker heat sink), and is

converted into a proportional electrical signal. As of an initial

threshold temperature of approximately 70C, fan voltage is

increased in a linear fashion as temperature increases. The

device can be operated at any output load up to the maximum

specified operating temperature after the fan has been

activated. If ventilation is impeded, or at excessive ambient

temperatures, temperature at the sensor may reach the upper

threshold of approximately 90C. If this is the case, an

overtemperature message is entered to the status and event

registers. The output is deactivated by the CPU after 5

seconds, and OTP triggering is indicated by the blinking

“Pmax” LED. After sufficient cooling has occurred, the status

message is cleared and a ready for operation message is

entered to the event register. If the POWER-ON function is set

to “Recall”, the output is reactivated automatically. If the

POWER-ON function is set to “Standby” or “Reset”, the output

remains deactivated and can only be reactivated by pressing

the OUTPUT key, or by means of a command from the control

computer. After actual temperature has fallen to below the

lower threshold value, fan speed is reduced automatically.

GMC-I Messtechnik GmbH 7

Page 8

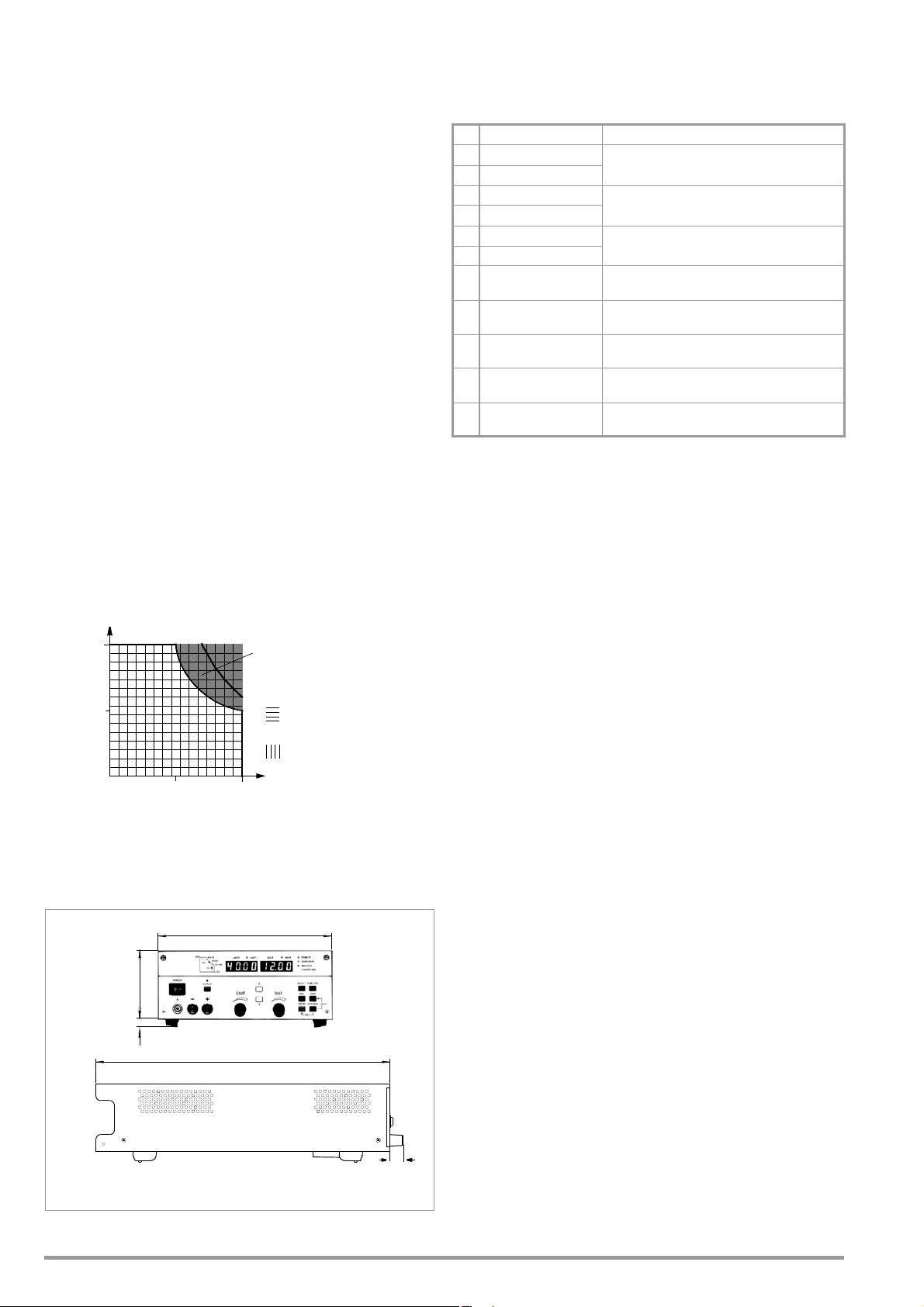

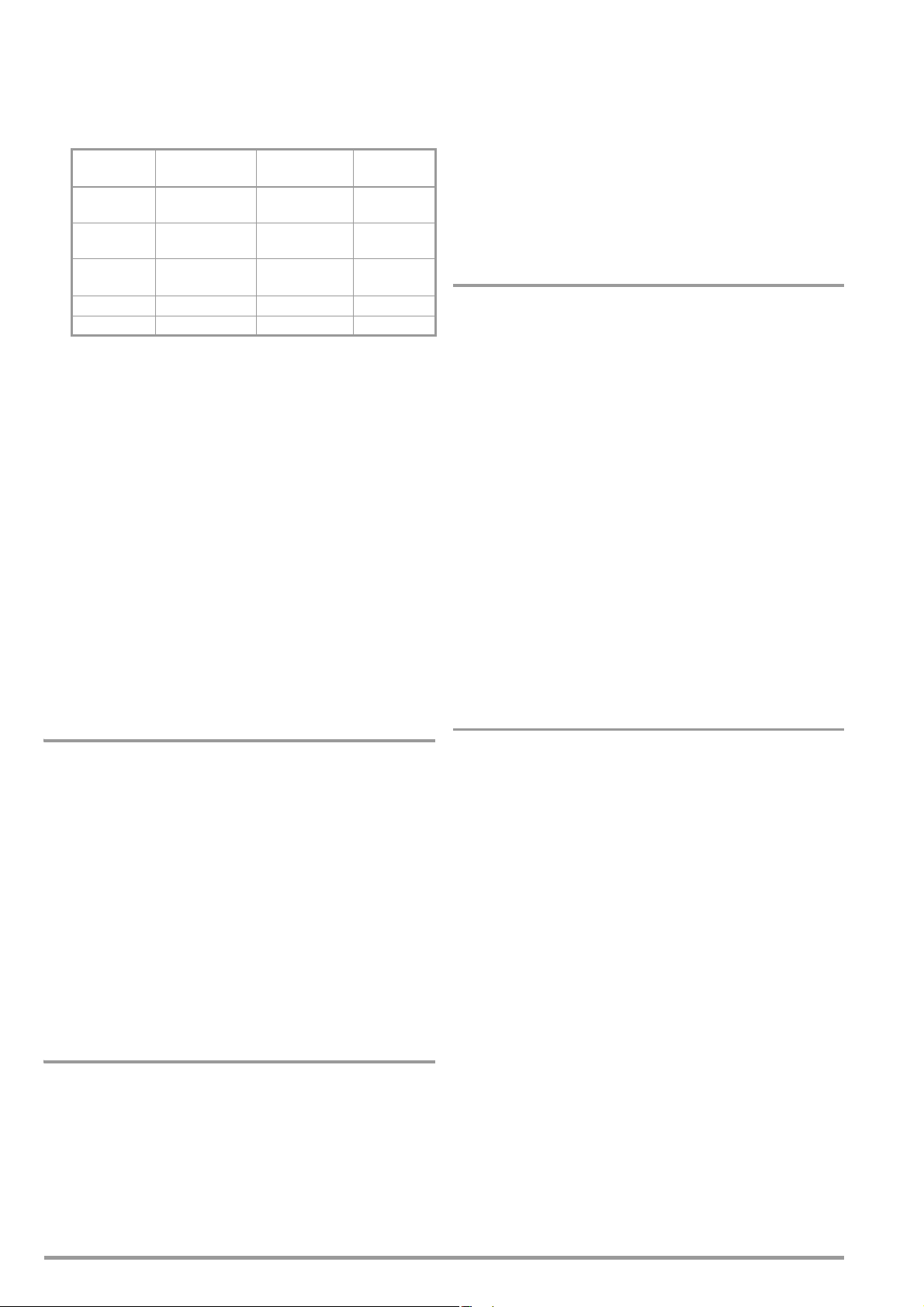

1.5 Technical Data

U/V

U

nom

I / A

I

nom

0

0.5 I

nom

P

nom

Short-Term

Working Range

Voltage Setting

Current Setting

0.5

U

nom

Range

Range

380.5

17

14 88

221.5

Dimensions in millimeter

1.5.1 General Data

Power Supply

Connection Input: 10 A IEC inlet plug

Output: 10 A IEC inlet socket,

Line voltage 230 V ~ +10 -15%, 47 to 63 Hz

Power consumption See chapter 1.4.3

Inrush Current Max. 50 A

Mains fuse 1 ea. T 4 A / 250 V (6.3 x 32 mm, UL)

internal: 1 ea. T 5 A 250 V (5 x 20 mm)

Output

Connection

Output Front panel, 2 ea. 4 mm safety jacks

Rear , 6-pole plug-in screw terminal block

Sensor Rear panel, included in 6-pole plug-in

screw terminal block

Analog interface Rear, 11-pole plug-in screw terminals

Regulator type Primary switched-mode regulator with

BET technology

Operating modes Adjustable constant voltage / constant

current source with automatic sharp

transition

Output isolation Floating output with “safe electrical

separation” from the mains input and

computer interfaces

Max. allowable potential, output–ground:

120 V, capacitance, output–ground

(housing) 60 nF

Output operating range

without switch,

without fuse

S

Analog Interface

Connection 11-pole plug-in screw terminal block

Reference potential Output minus pole, floating TRG input

Connector pin assignments:

Pin Designation Function

1SIG1 OUT

2SIG2 OUT

3TRG IN –

4TRG IN +

5 +15 V

6AGND

– Analog, inverting voltage control input

7U

set

+ Analog voltage control input

8U

set

+ Analog current control input

9I

set

10 U-MON Output voltage measuring output

11 I-MON Output current measuring output

Digital, programmable, open-collector outputs (max.

30 V / 20 mA)

Digital, programmable control input

(low: < 1.0 V, high: 4 ... 26 V), potential-free

Auxiliary voltage, +15 V / max. 50 mA

reference point, connected to -output

(0 ... –5 V correspond to 0 ... U

(0 ... +5 V correspond to 0 ... U

(0 ... +5 V correspond to 0 ... I

(0 ... 10 V correspond to 0 ... U

(0 ... 10 V correspond to 0 ... I

, Ri = 10 k)

nom

, Ri = 10 k)

nom

, Ri = 10 k)

nom

, Ri = 9.8 k)

nom

, Ri = 9.4 k)

nom

Addressable V.24 – RS 232C Interface

Input 9-pin subminiature socket connector

Output 9-pin subminiature plug connector

Operating mode half-duplex, asynchronous, XON / XOFF

Transmission speed adjustable from 50 to 19,200 bits per second

Device address selectable from 0 to 30 or UNL (unlist)

Max. Setting Rate approx. 15 settings per second

Max. Sampling Rateapprox. 7 measurements per second

IEC 625 – IEEE 488 Interface (optional)

Connection 24-pin socket connector

per IEC 625.1, IEEE488.1

Interface SH1 SOURCE HANDSHAKE

functions handshake source function

AH1 ACCEPTOR HANDSHAKE

handshake sink function

T6 TALKER

talker function with serial polling

and automatic unlisting,

no secondary address and no

Short-term range:

If lengthy operation in the short-term

range occurs, overtemperature protection may be triggered resulting in output

shutdown (see also short-term power in

chapter 1.5.3).

talk-only operation

L4 LISTENER

listener function with automatic

unlisting, no secondary

address and no listen-only operation

SR1 SERVICE REQUEST

service request function

RL1 REMOTE / LOCAL

remote to local switching

function with disabling

DC1 DEVICE CLEAR

reset function including selected

device clear

PP1 PARALLEL POLL

parallel polling function with remote

configuring

DT1 DEVICE TRIGGER

trigger function

C0 No controller function

E1/2 Open collector driver

Codes / formats Per IEEE 488.2

Device address Selectable from 0 to 30 or UNL (unlist)

Figure 1.5 Dimensional Drawing (benchtop device)

Max. setting rate Approx. 40 settings per second

Max. sampling rate Approx. 15 measurements per second

8 GMC-I Messtechnik GmbH

Page 9

Electrical Safety

Safety class I

Overvoltage

category II for mains input

I for output and interfaces

Fouling factor 2

Earth leakage

current 2.5 mA, typ.

IEC 61010-1:1990 + A1:1992 / DIN EN 61010-1: 1993 /

VDE 0411-1:1994

DIN VDE 0160:1988 + A1:1989 class W1

EN 60950:1992 / VDE 0805:1990

Protection IP 20 for housing per

IEC 529:1989,

EN 60529:1991,

VDE 0470-1:1992

Electrical isolation Test voltage

Mains/output–PE 1.35 kV~

Mains–output 2.7 kV~ (type test: 3.7 kV ~)

Electromagnetic Compatibility (EMC)

Product standard EN 61326-1:1997 + A1: 1998

Interference

emission EN 55022:1998 class A

Interference

immunity EN 61000-4-2:1995, feature A

EN 61000-4-3:1996 + A1:1998,

feature B

EN 61000-4-4:1995, feature B

EN 61000-4-5:1995, feature B

EN 61000-4-6:1996, feature B

EN 61000-4-11:1994, feature B

Ambient Conditions

IEC 68-2-6 (’90) Vibration resistance

10 ... 55 Hz, 0.3 mm, 1 octave / min.,

3 x 30 min.

IEC 68-2-27 (’89) Impact resistance

(15 g, 11 ms, semi-sinusoidal,

3 x 6 shocks)

Temperature Operation: 0 to 50° C,

range current derating at > 40° C

(see also chapter 1.5.3)

Storage: -25 to +75° C

Relative humidity Operation:

75%, no condensation allowed

Cooling With integrated fan

Inlet vent: side panel

Outlet vent: rear panel

1.5.2 Mechanical Data

Type Benchtop device, suitable for rack

Dimensions See also dimensional drawing in

(W x H x D) Benchtop device:

Weight Approx. 2.8 kg

mounting

Figure 1.5

221.5 x 102 x 397.5 mm

For 19" rack: ½19" x 2 standard height

units x 400 mm

IEEE 488 interface (optional):

approx. 0.1 kg

GMC-I Messtechnik GmbH 9

Page 10

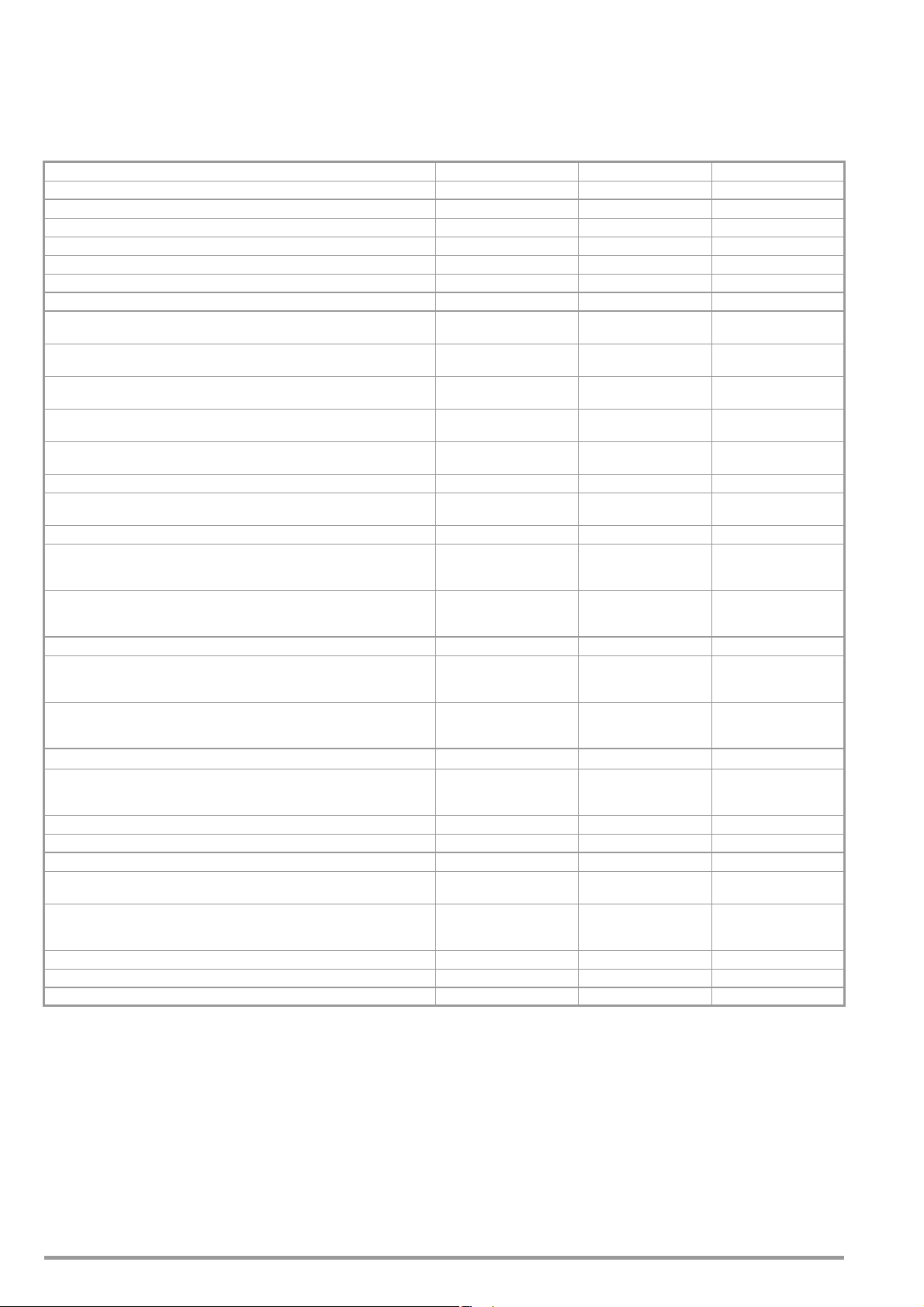

1.5.3 Electrical Data

Electrical Data for 120 W Models

Unless otherwise specified, all entries are maximum values and apply within an operating

temperature range of 0 to 50C, within the nominal power range and the nominal line

voltage range of 230 V

Percentages make reference to the respective setting value or measured value.

Description (abbreviated name) SSP 120-20 SSP 120-40 SSP 120-80

Typ e 32 N 20 RU 10 P 32 N 40 RU 6 P 32 N 80 RU 3 P

Nominal Output Data Voltage setting range 0 ... 20 V 0 ... 40 V 0 ... 80 V

Output Characteristics

Setting resolution

[display (< 10.00 / 10.00), remote]

Overall setting accuracy at 23 ± 5° C

including system deviation (load / mains)

Static system deviation

with 100% load fluctuation

Static system deviation

with 10% line voltage fluctuation

Residual ripple

Ua > 5% U

Common mode noise (10 Hz ... 1 MHz) 0.5 mA

Settling time (voltage)

with load step of 10 ... 90% I

Under and overshooting with load step of 50 A / ms (Typical values) I = 80% 400 mV 400 mV 800 mV

Response time (voltage)

with setpoint jump from 0 100%

with setpoint jump from 100% 0

Response time (current)

with setpoint jump from 0 100%

with setpoint jump from 100% 0

Measured Value Displays (4-place)

Measuring resolution

[display (< 10.00 / 10.00), query]

Measuring accuracy at 23 ± 5° C

for values > 0.1% of the nominal value

Protective Functions

Output overvoltage protection, trigger value Setting Range

Reverse polarity protection load capacity Continuous 10 A 6 A 3 A

Reverse voltage withstand capacity Continuous 40 V 80 V 100 V

General

Power supply

Power consumption At nominal load

Efficiency At nominal load > 70% > 80% > 80%

Switching frequency Typical 200 kHz 200 kHz 200 kHz

Article Number K320A K321A K322A

1)

Specified values are increased by a factor of approximately 1.2 within the functional range for line voltage, namely -10% to -15%.

nom

1)

10% after a warm-up period of 30 minutes.

Short-term power where t < 90 s / Tu 25° C max. 200 W max. 240 W max. 240 W

1)

1

1)

1

1)

nom

Current setting range 0 ... 10 A 0 ... 6 A 0 ... 3 A

Continuous power at Tu 40° C

max. 120 W max. 120 W max. 120 W

Current derating where Tu > 40° C -0.25 A / K -0.15 A / K -0.07 A / K

Voltage

Current

Voltage

Current

Voltage

Current

Voltage

Current

Voltage (10 Hz ... 10 MHz)

Current (10 Hz ... 1 MHz)

To le ra n ce

(Typical values) I = 80%

To le ra n ce

No-load / nominal load

No-load / nominal load

To le ra n ce

short-circuit / nominal load

short-circuit / nominal load

Voltage

Current

Power

Voltage

Current

Power

Setting resolution

Setting accuracy

Line voltage 230 V~ +10 / 15%

In standby mode

With maximum short-term power

5 mV / 10 mV, 5 mV

2.5 mA

0.15% +30 mV

0.4% +35 mA

15 mV

20 mA

5 mV

8 mA

10 mV

eff

25 mA

eff

eff

40 mV

200 s

40 mV

1 ms / 1 ms

1 ms / 1 ms

100 mA

< 5 ms / < 5 ms

< 5 ms / < 5 ms

2 mV / 10 mV, 2 mV

1 mA, 1 mA

0.1 W, 0.1 W

0.15% + 30 mV

0.4% + 25 mA

0.55% + 0.5 W

0 ... 25 V

0.1 V

2% + 0.2 V

47 ... 63 Hz

280 VA, 180 W

45 VA, 15 W

450 VA

10 mV

2 mA

0.15% +40 mV

0.5% +20 mA

10 mV

10 mA

5 mV

5 mA

10 mV

eff

20 mA

eff

0.5 mA

eff

80 mV

200 s

80 mV

1 ms / 1 ms

1 ms / 1 ms

60 mA

< 5 ms / < 5 ms

< 5 ms / < 5 ms

10 mV, 4 mV

0.6 mA, 1 mA

0.1 W, 0.1 W

0.15% + 40 mV

0.5% + 15 mA

0.65% + 0.6 W

0 ... 50 V

0.2 V

2% + 0.4 V

230 V~ +10 / 15%

47 ... 63 Hz

280 VA, 170 W

45 VA, 15 W

500 VA

20 mV

1 mA

0.15% +80 mV

0.5% +10 mA

10 mV

10 mA

5 mV

5 mA

10 mV

eff

10 mA

eff

0.5 mA

eff

160 mV

200 s

160 mV

4 ms / 4 ms

4 ms / 4 ms

30 mA

< 10 ms / < 10 ms

< 10 ms / < 10 ms

10 mV, 8 mV

0.5 mA, 1 mA

0.1 W, 0.1 W

0.15% + 80 mV

0.5% + 10 mA

0.65% + 0.8 W

0 ... 100 V

0.4 V

2% + 0.8 V

230 V~ +10 / 15%

47 ... 63 Hz

280 VA, 170 W

45 VA, 15 W

500 VA

10 GMC-I Messtechnik GmbH

Page 11

Electrical Data for 240 and 320 W Models

Unless otherwise specified, all entries are maximum values and apply within an operating

temperature range of 0 to 50C, within the nominal power range and the nominal line

voltage range of 230 V

10 % after a warm-up period of 30 minutes.

Percentages make reference to the respective setting value or measured value.

SSP 240-20 SSP 240-40 SSP 240-80 SSP 320-32

32 N 20 RU 20 P 32 N 40 RU 12 P 32 N 80 RU 6 P 32 N 32 RU 18 P

0 ... 20 V 0 ... 40 V 0 ... 80 V 0 ... 32 V

0 ... 20 A 0 ... 12 A 0 ... 6 A 0 ... 18A

max. 240 W max. 240 W max. 240 W max. 320 W

max. 320 W max. 360 W max. 360 W max. 430 W

-0.5 A / K -0.3 A / K -0.15 A / K -0.5 A / K

5 mV / 10 mV, 5 mV

5 mA / 10 mA, 5 mA

0.15% +40 mV

0.5% +70 mA

25 mV

30 mA

5 mV

8 mA

15 mV

eff

50 mA

eff

0.5 mA

eff

40 mV

600 s

10 mV

3.33 mA / 10 mA, 3.33 mA

0.15% +45 mV

0.5% +45 mA

18 mV

30 mA

5 mV

8 mA

15 mV

eff

25 mA

eff

0.5 mA

eff

80 mV

300 s

20 mV

2 mA

0.15% + 80 mV

0.5% +25 mA

18 mV

15 mA

5 mV

5 mA

15 mV

eff

20 mA

eff

0.5 mA

eff

160 mV

200 s

50 mA

450 mV 450 mV 800 mV 450 mV

40 mV

1 ms / 1 ms

1 ms / 1 ms

200 mA

< 5 ms / < 5 ms

< 5 ms / < 5 ms

2 mV / 10 mV, 2 mV

2 mA, 10 mA, 2 mA

0.15% +40 mV

0.5% +70 mA

0.65% +1.4 W

80 mV

1 ms / 1 ms

1 ms / 1 ms

120 mA

< 5 ms / < 5 ms

< 5 ms / < 5 ms

10 mV, 4 mV

2 mA / 10 mA, 1.2 mA

0.15% +40 mV

0.5% +25 mA

0.65% +1 W

160 mV

4 ms / 4 ms

4 ms / 4 ms

60 mA

< 10 ms / < 10 ms

< 10 ms / < 10 ms

10 mV, 8 mV

0.6 mA, 1 mA

0.15% + 80 mV

0.5% +15 mA

0.65% +1.2 W

10 mV

5 mA / 10 mA, 5 mA

0.15% +50 mV

0.5% +70 mA

30 mV

40 mA

10 mV

20 mA

30 mV

eff

(Ua > 10%U

eff

0.5 mA

eff

64 mV

500 s

64 mV

1 ms / 1 ms

1 ms / 1 ms

180 mA

< 5 ms / < 5 ms

< 5 ms / < 5 ms

10 mV, 4 mV

2 mA, 10 mA, 2 mA

0.1 W, 0.1 W

0.15% +40 mV

0.5% +70 mA

0.65% +1.4 W

nom

)

0 ... 25 V

0.1 V

2% +0.2 V

0 ... 50 V

0.2 V

2% +0.4 V

0 ... 100 V

0.4 V

2% + 0.8 V

20 A 12 A 6 A 18 A

40 V 80 V 100 V 64 V

230 V~ +10 / 15%

47 ... 63 Hz

510 VA, 350 W

45 VA, 15 W

620 VA

230 V~ +10 / 15%

47 ... 63 Hz

500 VA, 340 W

45 VA, 15 W

690 VA

230 V~ +10 / 15%

47 ... 63 Hz

500 VA, 340 W

45 VA, 15 W

690 VA

> 68% > 70% > 70% > 69%

200 kHz 200 kHz 200 kHz 200 kHz

K330A K331A K332A K334A

1)

Specified values are increased by a factor of approximately 1.2 within the functional range for line voltage, namely -10% to -15%.

0 ... 40 V

0.2 V

2% +0.4 V

230 V~ +10 / 15%

47 ... 63 Hz

650 VA, 460 W

50 VA, 15 W

770 VA

GMC-I Messtechnik GmbH 11

Page 12

2 Initial Start-Up

Warning!

Attention!

!

ANALOG INTERFACE OUTPUT

OUTIN RS 232

230V 5

FUSE T4

➁

➂

➁

Interface

Module

Ribbon

Cable

➁

➀

➀

➁

19“ Dummy Plate

19“ Abutment

➃

19'' Connector Plate

19'' Abutment

➃

➃

2.1 Preparing for Operation

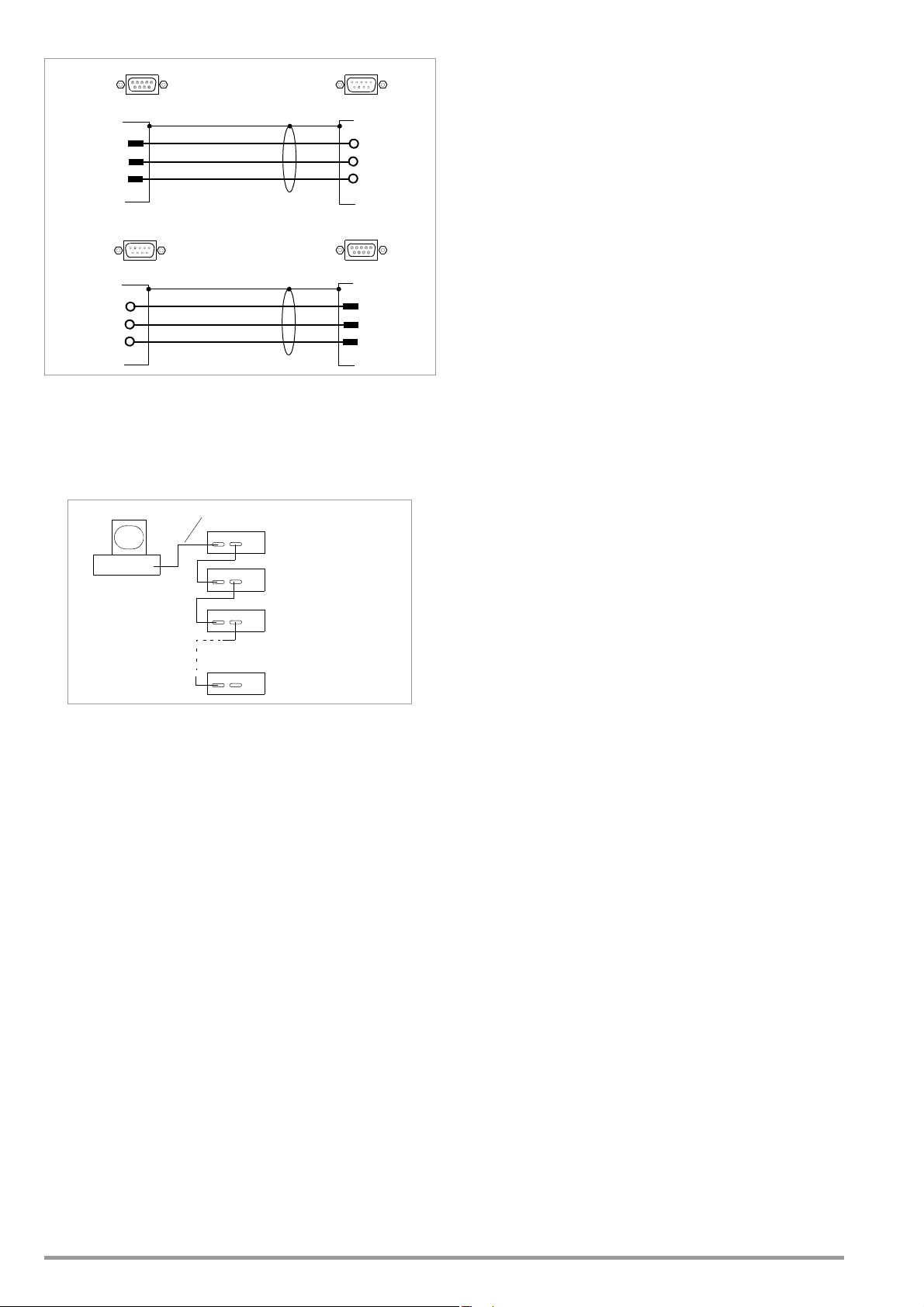

2.1.1 Installing the IEEE 488 Interface Module

2.1.2 Installation to 19'' Device Racks

The SSP KONSTANTER housing allows for use as a benchtop

instrument, as well as for installation to a 19'' rack. One

KONSTANTER and a cover plate, or two devices next to each

other can be installed to the rack.

The benchtop instrument can be quickly retrofitted for rack

mounting.

The KONSTANTER must be disconnected from the

mains before installing the interface module. Switch the

KONSTANTER off, and then pull the mains plug from the

outlet. Wait at least 5 minutes before opening the

KONSTANTER, in order to assure that the capacitors

have been discharged to a safe voltage level.

Capacitors may otherwise be charged with life

endangering voltage, and coming into contact with them

may result in severe injury.

The interface module may be damaged by electrostatic

discharge. Observe guidelines for handling electrostatic

sensitive devices. Do not touch electrical contacts or PCB

components.

➀ Disconnect the KONSTANTER from the mains, and pull the

mains plug from the outlet. Wait for at least 5 minutes in

order to assure that the capacitors have been adequately

discharged.

➁ Loosen the 4 screws in the housing cover and lift the cover

off.

➂ Unscrew the cover plate at the left-hand side of the rear

housing panel. Save the screws for use in the next step..

Retrofit for Rack Mounting a Single Device

Use the accessory adapter: 19'' adapter 1 x 32 N.

This accessory components includes a 19'' abutment and a 19''

blanking plate.

➀ Loosen the 4 screws at the KONSTANTER front panel.

➁ Pull out the filler strips from the left and right sides.

Figure 2.1.2 aRack Installation of a Single KONSTANTER

➂ Replace the filler strips with the 19'' abutment on one side,

and with the 19'' blanking plate on the other side, and

secure them with the four screws.

➃ Unscrew the feet from the bottom of the housing. Remove

the rubber inserts from the feet to this end. The screws are

then exposed.

➄ Now install the KONSTANTER to the rack. Save all loose

parts for possible future use.

Figure 2.1.1 a Opening the KONSTANTER Housing

the rack. The guide rails, as well as the front panel mounting

screws used to secure the KONSTANTER, are rack-specific and

The KONSTANTER must be attached to guide rails at one side of

➃ The interface module:

must be procured from your rack supplier.

With the ribbon cable facing forward, push the interface module

through the housing rear panel and into the device interior.

Securely screw the sheet metal cover on the interface

module to the housing rear panel from the outside. Use the

two screws referred to in step➂.

➄ Insert the plug connector from the interface module into the

connector strip on the primary printed circuit board. Do not

twist the ribbon cable.

Retrofit for Rack Mounting Two KONSTANTERs

Use the accessory adapter: 19'' adapter 2 x 32 N.

This accessory component includes two 19'' abutments and one

19'' connector plate.

➀ Loosen the 8 screws at the KONSTANTER front panels.

➁ Pull out the filler strips from the left and right sides of each

device.

Figure 2.1.2 b Rack Installation for Two KONSTANTERs

➂ Replace the filler strips with the 19'' abutments at the far left

and far right, and with the 19'' connector plate in the middle,

and secure them with the eight screws.

Figure 2.1.1 b Installing the Interface Module

➅ Return the housing cover and secure it with the four screws.

The KONSTANTER can now be connected as usual.

12 GMC-I Messtechnik GmbH

Screw both housings to the through-holes and threads in

the plug protector at the rear.

Page 13

➃ Unscrew the feet from the bottom of the housing. Remove

Attention!

!

Warning!

the rubber inserts from the feet to this end. The screws are

then exposed.

➄ If you would like to electrically connect the two

KONSTANTERs, use the “mains jumper cable” and “RS 232

bus cable” accessories.

➅ Install the two devices to the rack. Save all loose parts for

possible future use.

The KONSTANTERs must be attached to guide rails at both sides

of the rack. The guide rails, as well as the front panel mounting

screws used to secure the KONSTANTERs, are rack-specific and

must be procured from your rack supplier.

2.1.3 Combining Benchtop Devices

Up to 3 benchtop KONSTANTERs can be stacked in combination

(see also chapter 5 for electrical connection options via the analog

interface).

➀ Unscrew the feet from the bottom of the housing. Remove

the rubber inserts from the feet to this end. The collar screws

are then exposed.

Four oblong slots now become visible at the bottom of the

housing.

➁ Turn the 4 collar screws from the feet into the 4 threaded

holes on the top of the other device housing. Save the 4

retaining washers and feet for possible future use.

➂ Set the KONSTANTER without feet onto the top of the other

KONSTANTER. The screws from the bottom KONSTANTER

must protrude through the oblong slots in the base of the

other KONSTANTER. Carefully push the top KONSTANTER

back until the screws snap into place.

➃ Screw the two KONSTANTERs together via the through-

holes and threads in the plug protector at the back. The top

KONSTANTER is thus secured against shifting.

➄ If you would like to electrically connect the two

KONSTANTERs, use the “mains jumper cable” and “RS 232

bus cable” accessories.

2.1.4 Connection to the Mains

Observe WARNING I!

Before switching the KONSTANTER on, is must be

assured that available mains power complies with the

supply power values specified at the mains connection

on the back of the device.

The KONSTANTER requires 230 V ~ supply power. Connect the

mains inlet plug at the rear panel to a mains outlet with earthing

contact using the included power cable.

Rated power consumption is specified on the serial plate at the

bottom of the KONSTANTER.

A mains outlet is included above the mains inlet plug for looping

mains power through to an additional KONSTANTER.

This mains outlet can neither be switched on and off, nor is it protected

with a fuse.

If mains power is looped through, make sure that overall

current consumption does not exceed 10 A at the

incoming supply lines!

Suitable “mains jumper cables” are available as

accessories (see order information on last page).

2.1.5 Connecting Power Consumers

The output leads are connected either at the front panel with

4 mm safety plugs to the “” and “” safety jacks, or at the rear

panel to the “” and “” outputs at the 6-pole screw terminal.

If loads are connected to both the front and the rear panel (not

allowed in the event of parallel connection due to danger of

overload!), constant voltage regulation applies to the terminals at

the rear panel. There are two terminals each for “” and “” for

load connection at the rear panel.

In the case of load current of greater than 10 A, these terminals must

be parallel connected due to the specified contact rating.

Make sure that the utilized cables have an adequate cross-section,

and that polarity is not reversed. It is advisable to twist the output

leads and to identify polarity at both ends.

The yellow-green safety jack at the front panel is connected to

PE, and can be used to connect ground cables or cable shield, or

can be used as an earth connection point for one of the output

poles.

2.1.6 Connection to Computer Interfaces

If the KONSTANTER is used within computer controlled systems,

one of the two connections described below must be established

via the appropriate interface.

Comments

The KONSTANTER cannot be remote controlled via both

interfaces simultaneously. The interface which first initiates

action after mains power has been switched on is activated,

and the other remains inactive.

In order to assure that existing bus activity is not interfered

with, all affected KONSTANTERs should be switched off while

establishing the bus connection.

Both interfaces are equipped with a common ground (GND),

and are electrically isolated from the output in accordance with

specified electrical safety regulations.

Interface configuration is described in chapter 4.7.4.

RS 232C Interface

Most controllers include two serial ports, which are commonly

designated COM1 and COM2, and which are equipped with 25 or

9-pin subminiature plug connectors.

A suitable cable with a length of approximately 2 meters is

available as an accessory for connecting the KONSTANTER and

the controller. Cables with other lengths are commercially

available. Appropriate adapters are available as well, in the event

that your controller is equipped with a 25-pin plug connector.

If you would like to fabricate the connector cable yourself, you’ll

need a 3-conductor shielded cable in order to establish

connection as shown in Figure 2.1.6 a.

GMC-I Messtechnik GmbH 13

Page 14

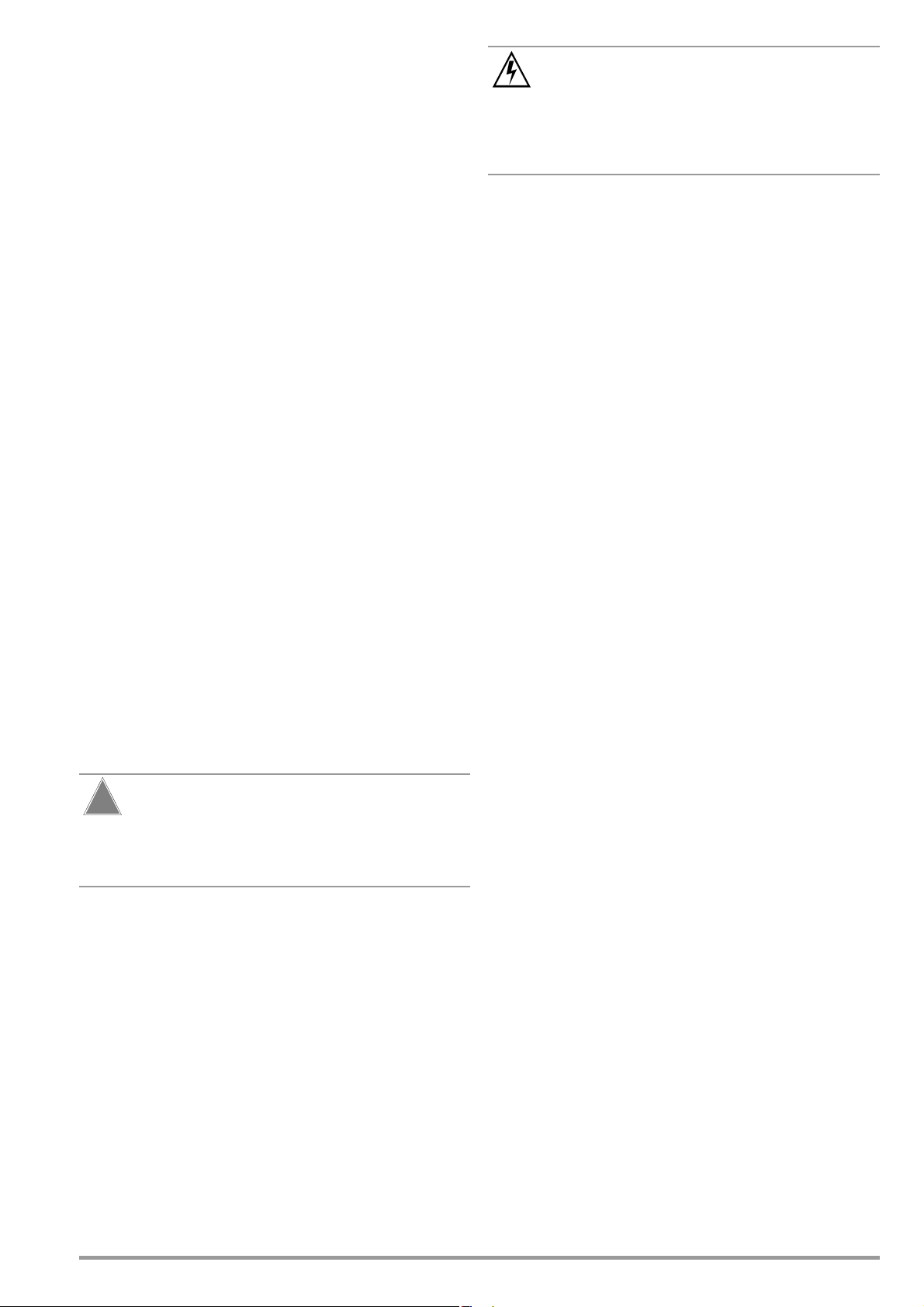

Figure 2.1.6 a Pin Assignments for 9-Pin Plug and

TxD_IN 2

3

5

RxD_IN

GND_IN

2 RxD

3 TxD

5 GND

SSP

9-pin Plug9-pin Socket Connector

RxD_OUT 2

3

5

TxD_OUT

GND_OUT

2 TxD_IN

3 RxD_IN

5 GND_IN

9-pin Plug 9-pin Socket Connector

SSP

OUT

IN

RS 232

RS 232

PC/Controller

SSP

IN

RS 232

COM1/COM2

IN OUT

IN OUT

IN OUT

IN OUT

Accessory:

RS 232 Bus Cable, 0.4 meters

Accessory: RS 232 Bus Cable, 2 meters (for example)

Socket Connectors

The serial interface furnished with this KONSTANTER series is

addressable. Up to 30 KONSTANTERs can be addressed via this

interface.

Data Queries

If a device (slave) is requested to return data to the controller, it

may not be addressed in the interim. In other words, the controller

must wait until all requested data have been fully received. No

data may be transmitted to any other devices during this period of

time.

In the case of multiple device serial operation, good timing must be

assured. Data collision is thus avoided, which may result in

interruption of data transfer and deletion of output buffer

contents.

If the slave does not respond within a specified period of time

(TIMEOUT), the controller can try to synchronize the device with a

universal command, or execute a reset and request the required

data once again.

IEEE 488 Interface

Up to 15 IEC bus controlled devices (including the controller)

can be interconnected to create a system.

These devices are connected to the bus with suitable,

commercially available cables with 24-pin plug connectors.

If your IEC bus system is equipped with the previously

common 25-pin subminiature plug connectors, you’ll need a

suitable adapter cable.

In order to assure reliable data transfer, the cable length

between any two devices should not exceed 2 meters, and

overall length should not exceed 15 meters.

Double shielded connector cable is recommended if the

KONSTANTERs are operated in proximity to strong sources of

interference or their power cables.

2.2 Switching the Instrument On

After the described preparations have been completed, the

device can be switched on.

Press the mains switch [1] at the front panel until it snaps into

place in order to turn the device on.

Power-Up Test

The microprocessor included in the device then starts a power-up

Figure 2.1.6 b Interconnection via the Serial Interface

If RS 232 communication is to be expanded to several

KONSTANTERs, additional arrangements must be made

regarding data protocols.

Addressing

A separate address is assigned to each interconnected

KONSTANTER. If the KONSTANTER receives its own address, it

is switched to the “addressed” status after which it accepts all

subsequent commands and data, until it is unlisted upon receipt

of a different device address.

In compliance with IEEE 488, an address range of 0 to 31 is used,

although address 31 is reserved as a general unlist command

(UNL). The serial interface’s device address is thus identical to the

address of the optional IEEE 488 interface (if included).

Universal Commands

In addition to the command

Addr xxDevice address,

other general commands can be used which are accepted

without previous addressing.

*TRG Trigger command, synchronization

DCL Device clear

IFC Interface clear

Explanations of these commands and their syntax are included in

chapter 6.

14 GMC-I Messtechnik GmbH

test. The following operations are performed during the test

routine (duration approximately 8 seconds):

– Reset all functional units (except battery-backed setup

memory)

– ROM test

–RAM test

– Initialize computer interfaces if installed

– Ascertain device type

– Check the A-D converter timer

– Recall last settings if required

The “LOCKED/SEQ” LED [12] blinks while this routine is running,

and all other LEDs and all digital display segments light up

(display test). If the device has been equipped with the optional

“IEEE 488 computer interface”, the selected IEC bus device

address then appears briefly at the display (e.g. “Addr 12”).

After successful completion of the self-test, the READY lamp is

continuously illuminated and the display is switched to measured

value indication for voltage (Uout) and current (Iout).

If this status is not achieved despite correctly selected device

address (0 to 30), even after repeatedly switching the device on

and off with abbreviated self-test, the device is probably

defective. If this is the case, contact your local representative.

Page 15

Abbreviated Power-Up Test

In order to shorten power-up time, or if problems occur with the

normal power-up test, an abbreviated power-up test can be

used:

With the device switched off, press and hold the <ENTER>

key.

Turn the mains switch on.

Release the <ENTER> key after approximately 1 second.

If this procedure is used, only essential initialization steps are run

during power-up.

After initial power-up, the device has the following basic

configuration:

Interface functions Standard “pon” status

Device functions

– Output status Inactive

– Voltage setpoint 0 V

– Current setpoint 0 A

– Voltage setting limit Nominal output voltage

– Current setting limit Nominal output current

– OVP trigger value 25 V (for 20 V models)

50 V (for 40 V models)

100 V (for 80 V models)

– Current limiting mode Limiting without shutdown

– Shutdown delay 0 ms

– TRIGGER input Inactive

– Min-Max measured value memory Off

– Power ON mode Reset configuration

– Manual operation Enabled

– Memory contents Deleted

The desired settings can be selected starting with this basic

configuration.

After a warm-up period of approximately 30 minutes, the

instrument operates at maximum accuracy.

When the device is powered up again at a later point in time, active

device configuration depends upon the last setting selected for

the POWER_ON function (—> page 69):

– Default settings or

– Last used device settings or

– Last used device settings with inactive output

Power-Up with RESET

In order to assure that the connected power consumer is not

endangered by any previous device settings, the device can be

initialized with the “POWER_ON RST” function by pressing and

holding the <CE/LOCAL> key during the power-up routine.

In order to switch the device off, activate the mains switch one again.

The device is then disconnected from mains power and the

output is deactivated. The last device configuration, as well as any

settings which have been saved to battery-back configuration

memory, are retained.

Caution!

Avoid switching the device on and off in a rapid, repeated fashion. This

temporarily impairs the effectiveness of the inrush current limiting

function, and may result in a blown fuse.

GMC-I Messtechnik GmbH 15

Page 16

3 Controls, Display Elements and Terminals

12356 89 12

171615141311 1074 18

Note: Numbers in brackets make reference to the figures included below.

[1] Mains Switch <POWER>

For turning the KONSTANTER on and off

After switching the KONSTANTER on, a self-test is performed

with a duration of approximately 8 seconds. After successful

completion of the self-test, the KONSTANTER briefly displays

its interface address and the version number of the installed

firmware, one after the other. The POWER-ON function then

configures the device with predetermined settings and the

device is ready for use.

When the KONSTANTER is switched off, it is disconnected from

mains power and the output is immediately deactivated. The last

device configuration, as well as any settings which have been

saved to battery-backed setup memory, are retained.

[2] Output On-Off Key <OUTPUT>

The power output can be activated and deactivated by

pressing the <OUTPUT> key. The red LED above the <OUTPUT>

key is illuminated as long as the output is active.

No significant output voltage overshooting occurs when the

output is activated and deactivated.

Activation sequence:

If the power output is activated, current and voltage are initially

set to “0” for transition from the “highly resistive” state.

Setpoints do not become active until after this transition has

been completed.

Deactivation sequence:

Current is set to 0 A and voltage to 0 V for approximately

350 ms. A sink is thus activated which discharges the output

capacitors to the greatest possible extent. The sink is then

deactivated and the output becomes highly resistive. However,

the output terminals are not electrically isolated.

[3] Control Mode, Protective Function and Status Displays

No LEDs light up: Output has not been activated

LEDs lights up:

Indicates the output’s operating status (control mode) if it has

been activated:

Green CV LED Constant voltage regulation (Uout = Uset)

Green CC LED Constant current regulation (Iout = Iset)

Blinking LED:

Indicates the reason for automatic deactivation of the output

Green CV LED OVP (overvoltage protection)

Overvoltage protection has been triggered,

because output voltage has exceeded the

selected trigger value OVP / OVSET.

Possible causes:

☞ Voltage setpoint USET has been set too high manually,

memory recall, programming error or Uset control signal to

the analog interface

☞ Voltage transients caused, for example, by switching

inductive power consumers (perhaps too little difference

between selected USET and OVSET values)

☞ Unipolar power recovery from the connected consumer

(e.g. DC motor)

16 GMC-I Messtechnik GmbH

Page 17

☞ During auto-sensing: Sensing lead polarity is reversed, or an

output lead is/was interrupted or was not taken into

consideration when adjusting OVSET, so that the voltage at

the output terminals which is relevant for the OVP function is

increased by the amount to be compensated for at both leads,

and is higher than USET voltage as controlled by the

sensors at the load side (too little difference between

selected USET and OVSET values).

☞ Parallel connected voltage sources

Green CC LED OCP (overcurrent protection)

Overcurrent protection is active.

If the OCP ON function has been activated,

the output was operated for a duration of

t > DELAY in the current limiting mode

(current regulation). The output has been

deactivated.

Possible causes:

☞ Current setpoint ISET has been set too low manually, memory

recall, programming error or Iset control signal to the

analog interface

☞ Current transients caused by switching inductive

consumers (DELAY time may be set too low)

Yellow Pmax LED OTP (overtemperature protection)

Electronic power limiting has been

(overload! Pout > Pnom).

Possible causes:

triggered

☞ Impaired cooling, e.g. air inlet or exhaust vents are

obstructed.

☞ Excessive ambient temperature

The KONSTANTER is capable of continuously supplying

nominal power at ambient temperatures of up to 50 °C

(measured at the air inlet vents). Approximately 120 to

130% nominal power can be drawn intermittently

(triggering point for electronic power limiting). Continuous

operation at these levels may cause triggering of the

overtemperature protection function.

☞ The fan has failed.

☞ A device error or defect has occurred.

After the cause of triggering has been eliminated, the output can be

reactivated.

[4] Output

Selected constant voltage or constant current is available from

the safety jacks at the front panel.

blue Negative output pole

red Positive output pole

yellow-green Earth connection point for the output or

shield terminal if shielded output leads are

used. The ground terminal is connected to

the housing and the earthing contact at the

mains connection.

The power consumer can also be connected to the OUTPUT

interface [22] at the rear panel.

[5] Left-Hand Display with [7]

[6] Display Parameter Indicators (LEDs)

As a default setting, the measured output voltage value Uout

appears in volts at the left-hand display.

The display can be switched to the momentary measured voltage

value Uset by slightly turning the voltage adjusting knob [5], or by

pressing the <ENTER> key.

The LEDs allocated to the display indicate which value is being

displayed (green LED = measured value, yellow LED = setting

value).

Uout / V (gr) = Measured output voltage value in V

Uset / V (ye) = Output voltage setpoint in V (blinking

indicates that the displayed value has not

yet been set)

If no adjustment is made for a period of 10 seconds during the

display of a setting value, the display returns to Uout

automatically.

Additional KONSTANTER functions can be selected with the

<SELECT>, <FUNCTION>, <RCL> and <SAVE> keys. The function

code or the parameter name appears at the left-hand display

in this case.

[7] Rotary Knob for Voltage Adjustment <Uset>

Voltage is adjusted in the usual fashion with the rotary knob.

However, the adjusting element is not a potentiometer, but

rather a rotary pulse encoder which generates 24 pulses per

revolution, whose setting resolution (step size per pulse) can

be set to either coarse, medium or fine with the <SELECT>

function. This allows for convenient, precise adjustment on the

one hand, and also assures that no change occurs to the

selected value when switching between remote control and

manual operation.

When the voltage adjusting knob is turned, the left display is

first switched to the Uset display and the current voltage

setpoint appears. After approximately 0.4 seconds, one of the

decimal places starts blinking at the display in order to indicate

selected adjusting sensitivity. From this point on, turning the

rotary knob changes the display value, and thus the setpoint

value, at the selected decimal place.

Clockwise rotation increases the value, and counterclockwise

rotation decreases the value.

If no adjustment is made for a period of 10 seconds, the

display automatically returns to the measured voltage value

Uout. The display can be immediately switched to the Uout

value by pressing the <CE/LOCAL> key.

☞ Detailed explanations are included in chapter 4.6.

[8] Right-Hand Display with [10]

[9] Display Parameter Indicators (LEDs)

As a default setting, the measured output current value Iout

appears in amperes at the right-hand display.

The display can be switched to the momentary current setpoint

Iset by slightly turning the current adjusting knob [8], or by

pressing the <ENTER> key twice.

The LEDs allocated to the display indicate which values are

being displayed (green LED = measured value, yellow LED =

setting value).

Iout/A (gr) = Measured current value in A

Iset / A (ye) = Current setpoint in A (blinking indicates that

the displayed value has not yet been set)

If no adjustment is made for a period of 10 seconds during the

display of a setting value, the display returns to Iout

automatically.

GMC-I Messtechnik GmbH 17

Page 18

Additional KONSTANTER functions can be selected with the

Attention!

!

<SELECT>, <FUNCTION>, <RCL> and <SAVE> keys. The

respective measured value or setting parameter appears at the

right-hand display in this case.

[10] Rotary Knob for Adjusting Current <Iset/A>

The same applies to this rotary knob, with reference to output

current, as is also the case with the voltage adjusting knob [5].

[11] Parameter Adjusting Keys and

The <> (increment) and <> (decrement) keys are used to

select or adjust all KONSTANTER functions and their

parameters.

☞ Detailed explanations are included in chapters 4.6, 4.7

and 4.14.

[12] Interface Displays: REMOTE, ADDR, SRQ, LOCKED

The respectively illuminated LED indicates the current

operating state of the computer interface:

REMOTE on: The KONSTANTER is being remote

controlled, front panel controls are

disabled.

ADDR/DATA on: The KONSTANTER has been addressed

and is receiving or transmitting data

(applies to IEC bus operation only).

SRQ/STS on: The KONSTANTER is transmitting a service

request.

LOCKED/SEQ on: Indicates that manual controls are disabled:

Front panel controls are disabled and

protected against unauthorized or

inadvertent change.

This display only applies to disabling of the

front panel controls by means of manual

operation or a control signal applied to the

TRIGGER input (for T_MODE LLO). It does not

indicate disabling of manual switching to

local control by means of the IEC bus LOCAL

LOCKOUT command.

blinking: Sequence mode display in

disabled and enabled state:

– Slow blinking: sequence in hold status

– Fast blinking: sequence in run status

Sequence mode display

LLO is displayed when any key or rotary

knob is activated (

and disabling:

l

ocal lockout).

[13] Function Selection Key <SELECT>

Selection of displayable measured values

Resolution of display values and setting values

☞ Detailed explanations are included in chapters 4.6, 4.7

and 4.8.

[14] Recall Key <RCL>

Recall of stored KONSTANTER settings, value pairs (Uset and

Iset) and any associated dwell time setting for possible

readjustment.

☞ Detailed explanations are included in chapter 4.10.

[15] <ENTER> Key

The <ENTER> key is used for several functions:

Execute selected functions

Acknowledge selected text parameters

Go to the next lowest function menu level

Switch the display from Uout / Iout to Uset / Iset with active

cursor

Setpoint changes are acknowledged with the <ENTER> key

in this mode.

Move cursor back and forth between Uset and Iset in the

Uset / Iset display

Activate the recalled memory location

☞ Detailed explanations are included in chapters 4.6, 4.7

and 4.12.

[16] <CE/LOCAL> Key

This key has several functions:

Abort an operation

Switching from remote to local control

Disable front panel controls

In combination with special functions

☞ Detailed explanations are included in chapter 4.13.

[17] Save Key <SAVE>

Saves device settings, value pairs (Uset and Iset) and any

associated dwell time. In the manual mode, this key also

fulfills the function of the STORE computer command.

Disabling of front panel controls in order to prevent

inadvertent or unauthorized changes to settings is only

possible in combination with the <CE/LOCAL> key.

☞ Detailed explanations are included in chapter 4.9.

[18] Function Selection Key <FUNCTION>

No special key is assigned to device functions which are

normally seldom adjusted or used. These functions are

controlled in a menu-driven fashion.

☞ A description of the menu and the procedure for setting all

functions and parameters is included in chapter 4.7.

[19] RS 232 Interface

☞ Detailed explanations regarding remote control of

KONSTANTER functions via the RS 232 serial interface are

included in chapter 2.1.3.

☞ Interface-specific commands are included in chapter 6.4.

[20] IEEE 488 Bus Connection

Connection for remote control of KONSTANTER functions:

☞ Detailed explanations are included in chapter 2.1.1.

☞ Interface-specific commands are included in chapter 6.4.

The electrical contacts of all interfaces are connected to

components which may be damaged by electrostatic

discharge. Neutralize potential differences between

yourself and the device by grasping the housing before

touching these contacts!

18 GMC-I Messtechnik GmbH

Page 19

[21] Analog Interface

Attention!

!

Attention!

!

Attention!

!

Warning!

GOSSEN METRAWATT

IEC 625/IEEE 488 INTERFACE F. SSP-KONSTANTER BEST.NR. K380A

+

-

+

+

-

+

-

+

SENSE

-

+

SENSE

I-MON

U-MON

Iset

Uset

Uset

AGND

15V

TRG IN

TRG IN

SIG2 OUT

SIG1 OUT

ANALOG INTERFACE OUTPUT

OUT

IN

RS 232

230V 50-60Hz

FUSE T4/250V

19 20

21 22

23 24 25

The analog interface facilitates the following functions:

Remote adjustment of output voltage and current with

analog control voltages ranging from 0 to 5 V, or 5 to 0 V

☞ chapter 5.8 / chapter 5.4

External measurement or recording of output voltage and

current based on monitor signals, 0 to 10 V

☞ chapter 5.4 / chapter 5.5

Supply external controllers with +15 V auxiliary power

Linking of several devices for master-slave operation

☞ chapter 5.9 / chapter 5.10

Varying the internal output resistance value

☞ chapter 5.8

Control of a selected device function via the floating trigger

input

☞ chapter 5.7

The electrical contacts of this interface are connected to

components which may be damaged by electrostatic

discharge. Ground yourself by grasping the housing

before touching these contacts!

All of the control cables connected to the analog

interface should be shielded. Ground the shield directly

to the device using the shortest possible connection

lead. One of the threaded holes for the plug protector at

the rear panel can be used for this connection. Use a

suitable screw and washer to secure the connection and

assure good contact.

[22] OUTPUT Interface

The output interface offers two options:

Take constant voltage or constant current from the terminal

strip at the rear panel of the KONSTANTER.

Connect sensing leads for compensation of voltage drops in

the output leads

☞ chapter 5.3

[23] Exhaust Vents

The exhaust vents are required for regulating the temperature

inside the device. Warm air generated during operation of the

device is discharged via these vents with the help of a

temperature controlled fan.

The exhaust vents may not be closed or obstructed,

because heat accumulation inside the device may result

in malfunctioning, failure or damage to the

KONSTANTER.

[24] Mains Input

Mains input with looped through mains outlet for inlet plug. The

looped through mains outlets make it possible to directly

connect up to three devices using two short power cables with

inlet plugs. In this way, only one mains power cable is required

to operate all three devices.

[25] Mains Fuse

Fusing for the 230 V mains power input

All devices: T 4.0 A / 250 V (6.3 x 32 mm)

Only fuses of the type and nominal current rating

specified here may be used when replacing blown fuses.

Tampering with fuses or fuse holders is absolutely

prohibited (“repairing” fuses, short-circuiting fuse holders

etc.).

GMC-I Messtechnik GmbH 19

Page 20

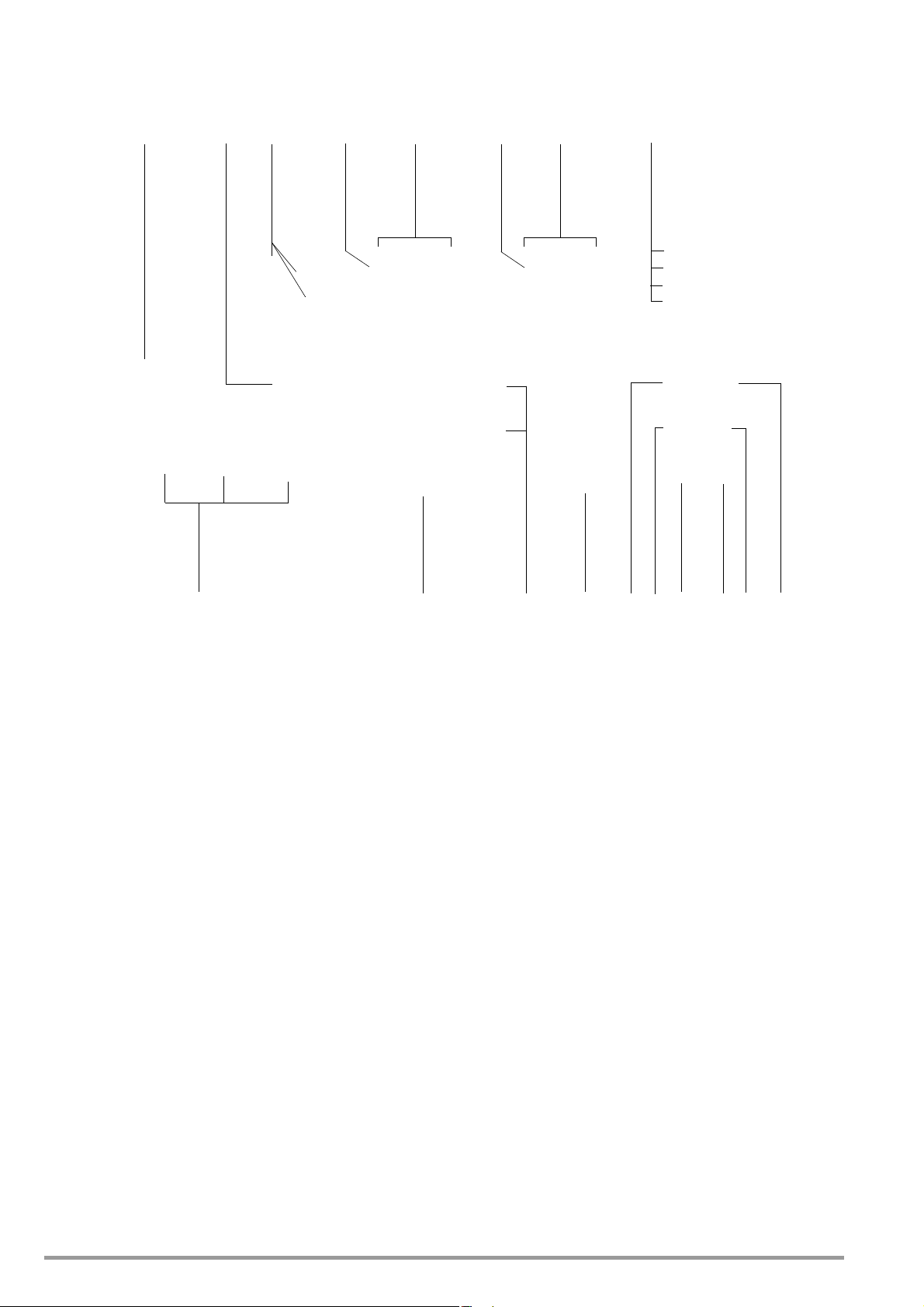

4 Manual Operation and Device Functions

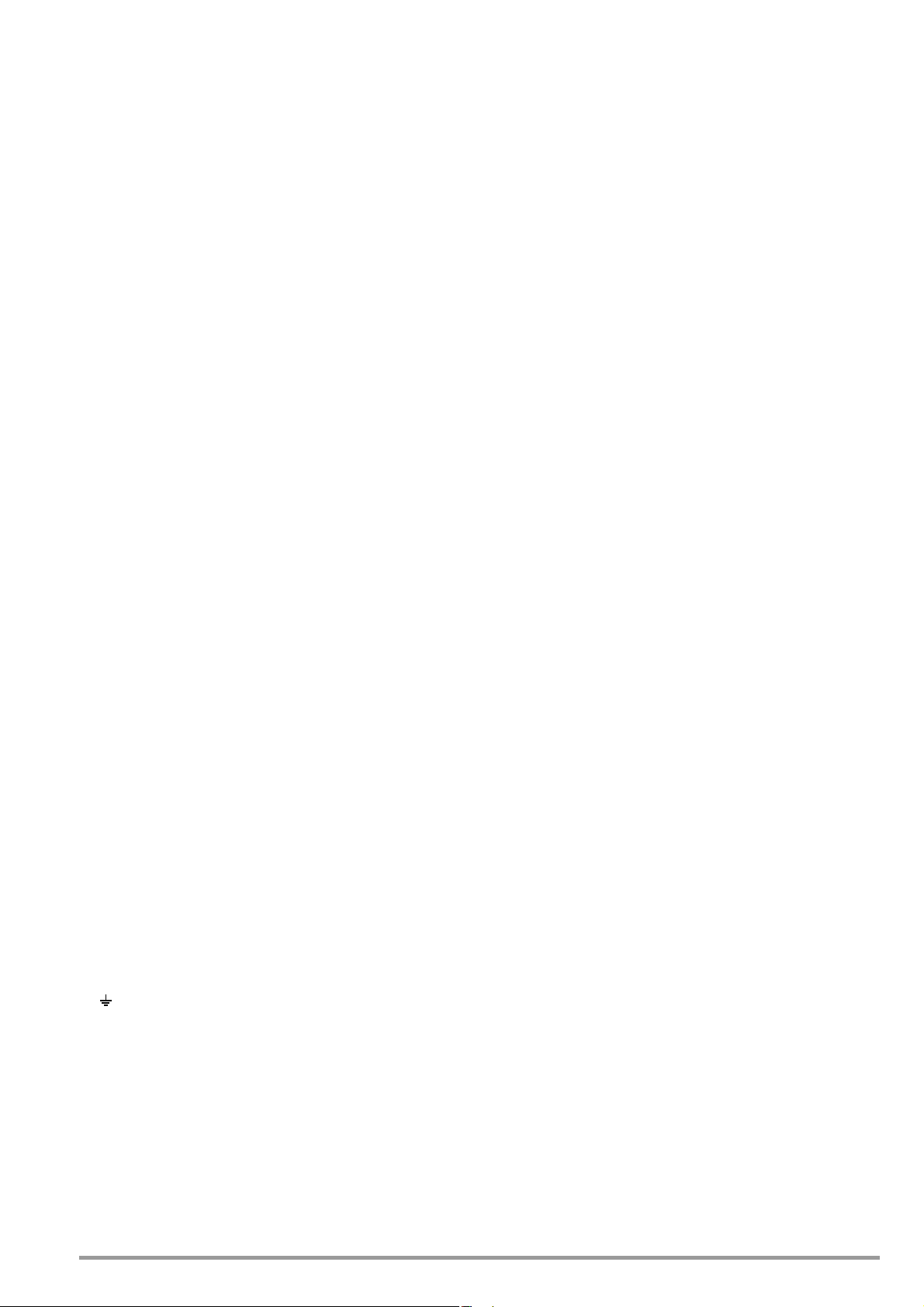

Uset / V

Uout

t

(1)

(2)

(3)

4.1 Menu Structure

After the power-up sequence has been completed, the device is

switched to the basic operating mode by means of which the