Gossen Metrawatt SLP 120-20, SLP 120-40, SLP 120-80, 32 N 20 R 10, 32 N 40 R 6 User guide

...Page 1

Operating Instructions

13025

11/5.15

SLP-KONSTANTER 32N

Series SLP 120 /SLP 240 / SLP 320

Analog Controlled Laboratory Power Supplies

Page 2

2 GMC-I Messtechnik GmbH

Page 3

Contents

Page

Receiving Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Warnings and Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Important Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

1 Technical Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

1.1 Range of Applications and Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

1.2 Functional Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

1.3 Options and Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

1.4 Technical Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.4.1 General Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

1.4.2 Electrical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

1.4.3 Mechanical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

2 Preparation for Operation and Initial Start-Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

2.1 Connection to the Mains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.2 Connection to the Consuming Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

2.3 Sensing Mode Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

2.4 Installation to a 19" Rack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

2.5 Multiple Benchtop Device Combination . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

3 Controls, Displays and Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4 Adjusting Output Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

4.1 Output Voltage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

4.1.1 Uout – Presently Measured Voltage Value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

4.1.2 Ulim – Limit Value for Uset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

4.1.3 Uset – Voltage Setpoint Value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

4.2 Output Current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.2.1 Iout – Presently Measured Current Value. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

4.2.2 Ilim – Limit Value for Iset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

4.2.3 Iset – Current Setpoint Value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.3 OUTPUT – Switching the Power Output On and Off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

5 Control via the Analog Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.1 Connector Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

5.2 Status Signal Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

5.3 Trigger Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

5.4 Controlling Output Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.5 Controlling Output Current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.6 Voltage Monitoring Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

5.7 Current Monitoring Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

5.8 Parallel Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

5.8.1 Direct Parallel Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

5.8.2 Parallel Master-Slave Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5.9 Series Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

5.9.1 Direct Series Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

5.9.2 Series Master-Slave Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5.10 Varying Internal Output Resistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

6 Accessories. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

7 Order Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

8 Repair and Replacement Parts Service

Calibration Center and Rental Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

9 Product Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

GMC-I Messtechnik GmbH 3

Page 4

Receiving Inspection

Important Warnings

Immediately upon receipt, unpack the KONSTANTER and all included

accessories, and inspect for completeness and possible damage.

Unpacking

☞ Other than the usual degree of care required for the handling of

electronic devices, no special care must be exercised when

unpacking the instrument.

☞ The KONSTANTER is shipped in recyclable packaging which

provides for adequate protection during transport. If the

instrument needs to be repacked, the original packaging, or

equivalent packaging, must be used.

Visual Inspection

☞ Compare the order number or type designation found on the

packaging and/or the serial plate with the specifications

printed in the shipping documents.

☞ Make sure that all accessory components have been included

(→ 1.3 Options and Accessories).

☞ Inspect the packaging as well as instrument mechanisms for

possible transport damage.

Complaints

If damage is detected, file a damages report immediately with the

freight forwarder (save the packaging!). In the event of any other

defects or if service is required, please contact your service representative, or contact us directly at the address included in the last

page of these instructions.

Warnings and Safety Precautions

The KONSTANTER has been manufactured and tested in accor-

dance with the safety regulations specified in the technical data

section included in this chapter as a safety class I device. It has left

the factory in flawless technical safety conditions. In order to maintain this condition, and to assure safe use, the user must observe

all notes and warnings included in these operating instructions.

These are identified with the following headings:

CAUTION!

Operating instructions or practical information etc., which must be

observed in order to prevent damage to the KONSTANTER, and to assure

correct operation.

WARNING I – Protective Ground

The

KONSTANTER may only be operated with a connected protec-

tive conductor. Any interruption of the protective conductor, either

inside or outside of the KONSTANTER or disconnection of the pro-

tective conductor terminal, may render the KONSTANTER hazardous.

Intentional interruption is prohibited.

Mains connection is accomplished with a 3-conductor cable with

mains plug. The plug may only be inserted into a suitable mains

outlet with an earthing contact. The resulting protection must not

be rendered ineffective through the use of an extension cable

without protective conductor.

WARNING II – Impaired Safety Protection

If it may be assumed that safe operation is no longer possible, the

KONSTANTER must be removed from service and secured against

unintentional use. It must be assumed that safe operation is no

longer possible if:

KONSTANTER demonstrates visible damage

• The

KONSTANTER no longer functions

• The

• After lengthy periods of storage if specified storage conditions

have not been observed

• After excessive stress due to transport

WARNING III – Opening Housing Covers

Voltage conducting part may be exposed when housing covers

are opened, as long as the KONSTANTER is connected.

Touching these exposed voltage conducting parts is extremely life

endangering.

Housing covers may thus only be opened or removed by qualified

personnel who are familiar with the dangers involved.

WARNING IV – Repairs Performed by Qualified Personnel Only

Voltage conducting part may be exposed when housing covers

are opened, as long as the

Maintenance and repairs, as well as internal instrument balancing,

may only be performed by qualified personnel who are familiar with

the dangers involved.

In as far as possible, the KONSTANTER must be disconnected from

all external voltage sources before such work is performed. A 5

minute waiting period must be observed after disconnection, in

order to allow internal capacitors to discharge to safe voltage

levels.

KONSTANTER is connected.

WARNING!

Operating instructions or practical information etc., which must be

observed in order to maintain the safety features included with the

KONSTANTER, and to prevent personal injury.

The most important warnings are summarized below. Reference is made

to these warning at all appropriate points throughout the operating

instructions.

4 GMC-I Messtechnik GmbH

WARNING V – Replacing Fuses

When replacing blown fuses, use only specified fuse types with the

specified current ratings (see technical data or serial plate).

Tampering with the fuses or fuse holders (“mending” fuses, shortcircuiting fuse holders etc.) is prohibited.

Page 5

1 Technical Description

1.2 Functional Characteristics

1.1 Range of Applications and Features

The SLP-KONSTANTER is a single channel laboratory power supply

for universal use in R&D, production, training and service.

The KONSTANTER maintains either constant current or constant voltage

and is capable of delivering 120 W or 240 W of nominal power

over a broad range thanks to the auto-ranging output.

Precise manual settings for voltage and current are accomplished

with the help of ten-turn potentiometers. The setting range can be

reduced with a screwdriver, in order to prevent inadvertent

adjustment to unwanted, excessively high values.

Output voltage and current appear at two large-format 3½ place

digital LED displays, which can also be switched for the display of

setpoint values. Control mode displays indicate the respective

operating status.

The floating output at the front and rear panels can be activated and

deactivated by pressing a key, or with a signal to the analog interface which is provided as standard equipment. The instrument is

automatically switched to remote sensing as soon as sensor cables

are connected.

The sturdy metal housing is sealed at top and bottom, and is

equipped with rubber feet and a cable spacer at the rear panel.

With a minimum of effort, several housings can be mechanically

combined into a multi-channel unit. This unit requires only one

mains outlet which is looped through with the help of a mains

jumper cable (accessory) via the integrated mains outlet socket.

Installation to a 19" rack is also possible with the appropriate

adapter.

Adjustable functions

❏ Voltage and current setpoints

❏ Limit values for voltage and current setting ranges

❏ Output activation and deactivation

Display functions

❏ Measured voltage and current values

❏ Voltage and current setpoints

❏ Current control mode (CC/CV)

Protective and additional functions

❏ Reverse polarity protection for sensor terminals

with automatic activation (auto-sensing)

❏ Protection against excessive temperature

❏ Protection against output polarity reversal

❏ In-rush current limiting

❏ Temperature controlled fan

❏ Master-slave link

1.3 Options and Accessories

Options

No options are available for the KONSTANTER, above and beyond

the included standard equipment.

Included Accessories:

The following accessories are included with the KONSTANTER:

❏ These operating instructions

❏ 1 power cable (approx. 1.5 m long) with earthing contact plug

Additionally available accessories:

(see last page for order information)

❏ 19" adapter (1x32N) for installing 1 series SLP KONSTANTER to

a 19" rack

❏ 19" adapter (2x32N) for installing 2 series SLP KONSTANTERs to

a 19" rack

❏ Mains jumper cable, 0.4 m long

used for looping through mains power, equipped with a 10 A

plug and a 10 A socket for non-heating apparatus

GMC-I Messtechnik GmbH 5

Page 6

1.4 Technical Data

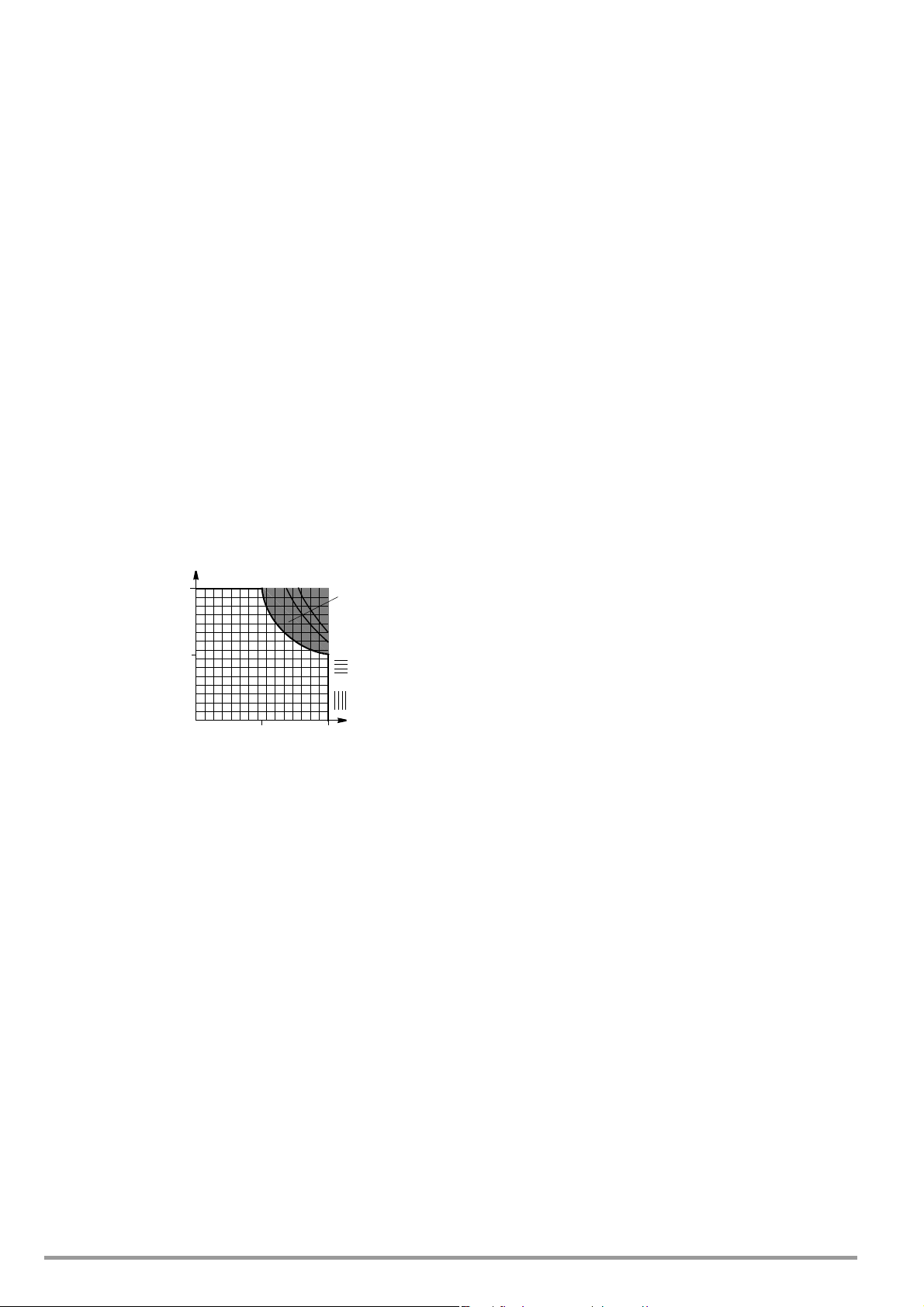

U/V

U

Nom

I/A

I

Nom

0

0.5 I

Nom

P

Nom

Intermittent

Working Range

Voltage Adj.

Current Adj.

Range

Range

0.5

U

Nom

1.4.1 General Data

Power Supply

Connection Input: 10 A IEC plug

Output: 10 A IEC socket,

Line Voltage 230 V~, +10 / –15%, 47 … 63 Hz

Power Consumption see 1.4.2

In-Rush Current max. 50 A

Mains Fuse 1 x T 4 A / 250 V (6.3 x 32 mm, UL)

internal: 1 x T 5 H / 250 V (5 x 20 mm)

Output

Connection

Output front panel, 2 ea. 4 mm safety socket

rear panel, 6-pole plug-in screw terminal

block

no switch, no fuse

S

10 U-MON Output voltage measurement output

(0 ... 10 V corres. to 0 ... U

, Ri = 9.8 kΩ)

nom

11 I-MON Output current measurement output

(0 ... 10 V corres. to 0 ... I

, Ri = 9.4 kΩ)

nom

Electrical Safety

Safety class I

Overvoltage

category II for mains input

I for output and interfaces

Fouling factor 2

Earth leakage

current 2.5 mA, typ.

IEC 61010-1:1990 + A1:1992 / DIN EN 61010-1: 1993 /

VDE 0411-1:1994

Sensor rear panel, 6-pole plug-in screw terminal

block

Regulator Type primary switched mode with BET

DIN VDE 0160:1988 + A1:1989 class W1

EN 60950:1992 / VDE 0805:1990

technology

Operating Modes adjustable constant voltage / constant cur-

rent source with automatic sharp transition

Output Isolation Floating output with “safety isolation” from

the mains input,

max. allowed potential output

-

earth:

120 V,

capacitive output-earth (housing): 60 nF

Output Working Range

Protection IP 20 for housing per

IEC 529:1989,

EN 60529:1991,

VDE 0470-1:1992

Electrical isolation Test voltage

Mains/output–PE 1.35 kV~

Mains–output 2.7 kV~ (type test: 3.7 kV ~)

Electromagnetic Compatibility (EMC)

Product standard EN 61326-1:1997 + A1: 1998

Interference

emission EN 55022:1998 class A

Interference

immunity EN 61000-4-2:1995, feature A

EN 61000-4-3:1996 + A1:1998,

feature B

EN 61000-4-4:1995, feature B

EN 61000-4-5:1995, feature B

EN 61000-4-6:1996, feature B

Intermittent Working Range:

Overtemperature protection may be

triggered, and the output deactivated, if

operated for lengthy periods of time in the

intermittent working range (see also

intermittent power, 1.4.2).

Analog Interface

Connection 11-pole plug-in screw terminal block

Reference Potential negative output pole,

floating TRG input

Connector Pin Assignments:

Pin Designation Function

1 SIG1 OUT Status signal output for output ON/OFF

(open collector, max. 30 V − / 20 mA)

2 SIG2 OUT Control mode status signal output CV / CC

Ambient Conditions

IEC 68-2-6 (’90) Resistance to Vibration

IEC 68-2-27 (’89) Impact Resistance

Temperature Range Operation: 0 ... 50 °C

Atmospheric Humidity Operation: ≤ 75% relative humidity,

Cooling With integrated fan

EN 61000-4-11:1994, feature B

(10 ... 55 Hz, 0.3 mm, 1 octave / min,

3 x 30 min)

(15 g, 11 ms, half-sine, 3 x 6 shocks)

current derating at > 40 °C

(see also 1.4.2.)

Storage: –25 ... +75 °C

no condensation

Air inlet: at side panels

Air outlet: at rear panel

(open collector, max. 30 V − / 20 mA)

3TRG IN + Digital control input for output ON/OFF

4TRG IN − (low: < 1 V, high: 4 ... 26 V), floating

5 +15 V Auxiliary voltage +15 V / max. 50 mA

6 AGND Reference point connected to − output via

automatic resetting fuse

7U

8U

9I

6 GMC-I Messtechnik GmbH

− Analog, negated voltage control input

set

+ Analog voltage control input

set

+ Analog current control input

set

(0 ... −5 V corres. to 0 ... U

(0 ... +5 V corres. to 0 ... U

(0 ... +5 V corres. to 0 ... I

non

nom

nom

, Ri = 10 kΩ)

, Ri = 10 kΩ)

, Ri = 10 kΩ)

Page 7

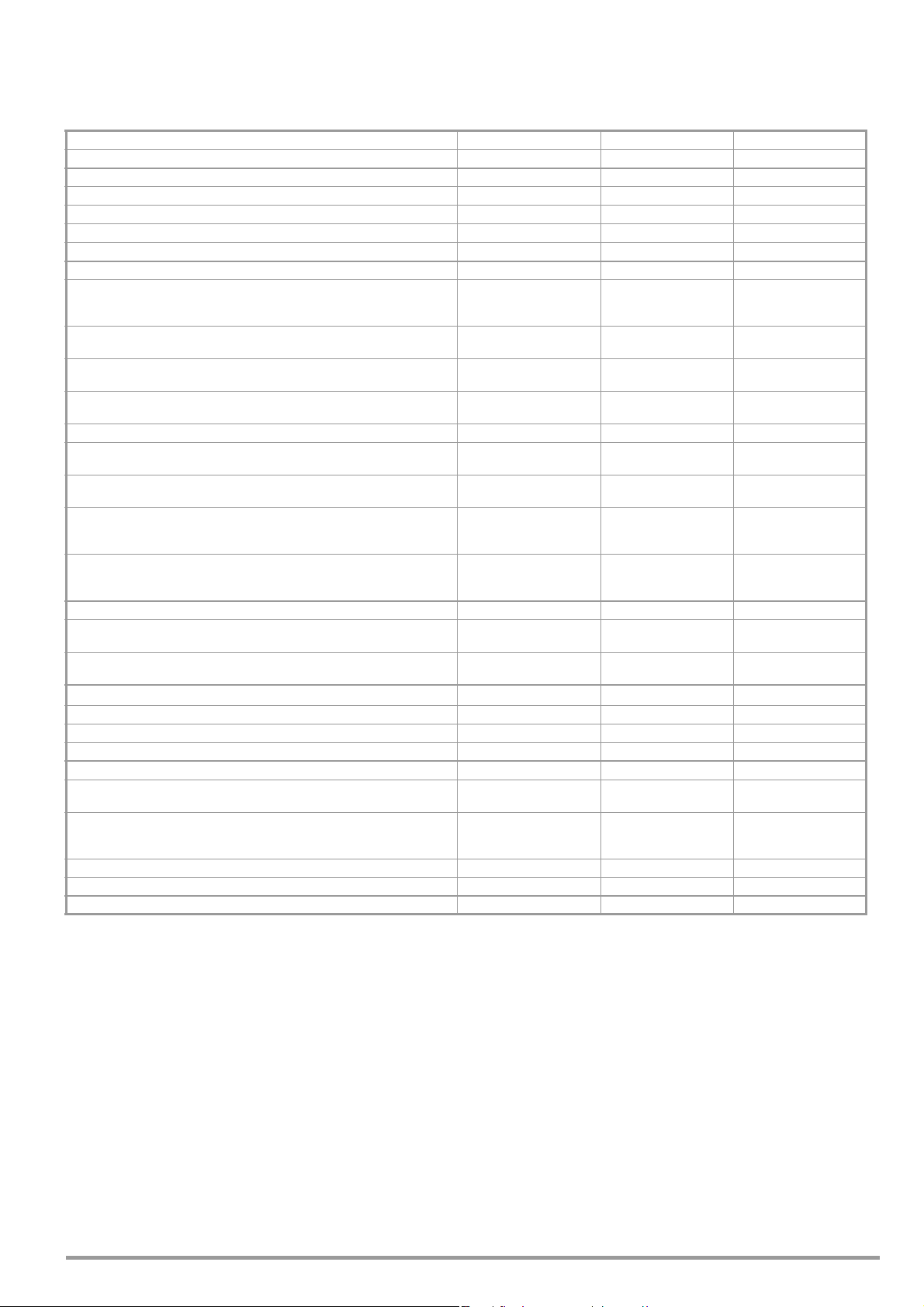

1.4.2 Electrical Data

Electrical Data, Series 120 W

If not otherwise specified, all entries are maximum values and are valid for an operating temperature range of 0 to 50 °C,

nominal power range and a line voltage range of 230 V ± 10% after a warm-up period of 30 minutes.

Description (abbreviated designation) SLP 120-20 SLP 120-40 SLP 120-80

Typ e 32 N 20 R 10 32 N 40 R 6 32 N 80 R 3

Nominal Output Data Voltage setting range 0 ... 20 V 0 ... 40 V 0 ... 80 V

Current setting range 0 ... 10 A 0 ... 6 A 0 ... 3 A

Continuous power where Tu ≤ 40 °C max. 120 W max. 120 W max. 120 W

Intermittent power where t < 90 s / Tu ≤ 25 °C max. 200 W max. 240 W max. 240 W

Current derating where Tu > 40 °C – 0.25 A / K – 0.15 A / K – 0.07 A / K

Output Operating Characteristics

Overall setting accuracy at 23 ± 5 °C

with reference to 3½ place setpoint display

including system deviation, load / mains

Static system deviation

at 100% load variation

Static system deviation

at 10% line voltage variation

Residual ripple

Ua > 5% U

nom

1)

1)

1)

1)

1)

Voltage (10 Hz ... 10 MHz)

Current (10 Hz ... 1 MHz)

Common-mode noise (10 Hz ... 1 MHz) 0.5 mA

Settling time (voltage)

with sudden load variation of 10 ... 90% I

nom

Under and overshooting with sudden load variation of

(Typical values) Δ I = 80%

(Typical values) Δ I = 80% 400 mV 400 mV 800 mV

50 A / ms

Settling time (voltage)

with setpoint jump: 0 → 100%

with setpoint jump: 100% → 0

no load / nominal load

no load / nominal load

Settling time (current)

with setpoint jump: 0 → 100%

with setpoint jump: 100% → 0

short-circuit / nominal load

short-circuit / nominal load

Measured Value Displays (3½ place)

Measurement resolution Voltage

Measuring accuracy at 23 ± 5 °C

with reference to the respective measured value

Protective Functions

Output overvoltage protection Threshold 25 ± 1 V 50 ± 2 V 100 ± 4 V

Reversed polarity protection – overload capacity Continuous 10 A 6 A 3 A

Reverse flow resistance Continuous 40 V 80 V 100 V

General

Power supply

1)

Power Consumption At nominal load

At max. intermittent power

Efficiency At nominal load > 70% > 80% > 80%

Switching frequency Typical 200 kHz 200 kHz 200 kHz

Article number K220A K221A K222A

1) Typical values are increased by a factor of approximately 1.2 in the functional line voltage input range of –10% to –15%.

Voltage

Current

Voltage

Current

Voltage

Current

0.2% + 50 mV

0.5% + 45 mA

15 mV

20 mA

5 mV

8 mA

10 mV

25 mA

To le ra nc e

40 mV

200 μs

To le ra nc e

40 mV

1 ms / 1 ms

1 ms / 1 ms

To le ra nc e

100 mA

< 5 ms / < 5 ms

< 5 ms / < 5 ms

10 mV

Current

Voltage

Current

10 mA

0.15% + 25 mV

0.5% + 30 mA

Line voltage 230 V~ +10 / −15%

47 ... 63 Hz

280 VA, 180 W

In standby mode

45 VA, 15 W

450 VA

0.2% + 150 mV

0.5% + 35 mA

10 mV

10 mA

5 mV

5 mA

eff

eff

eff

10 mV

20 mA

0.5 mA

eff

eff

eff

80 mV

200 μs

80 mV

1 ms / 1 ms

1 ms / 1 ms

60 mA

< 5 ms / < 5 ms

< 5 ms / < 5 ms

100 mV

10 mA

0.2% + 120 mV

0.5% + 25 mA

230 V~ +10 / −15%

47 ... 63 Hz

280 VA, 150 W

45 VA, 15 W

500 VA

0.2% + 250 mV

0.5% + 20 mA

10 mV

10 mA

5 mV

5 mA

10 mV

10 mA

0.5 mA

80 mV

200 μs

160 mV

4 ms / 4ms

4 ms / 4ms

30 mA

< 10 ms / < 10 ms

< 10 ms / < 10 ms

100 mV

10 mA

0.2% + 150 mV

0.5% + 20 mA

230 V~ +10 / −15%

47 ... 63 Hz

280 VA, 170 W

45 VA, 15 W

500 VA

eff

eff

eff

GMC-I Messtechnik GmbH 7

Page 8

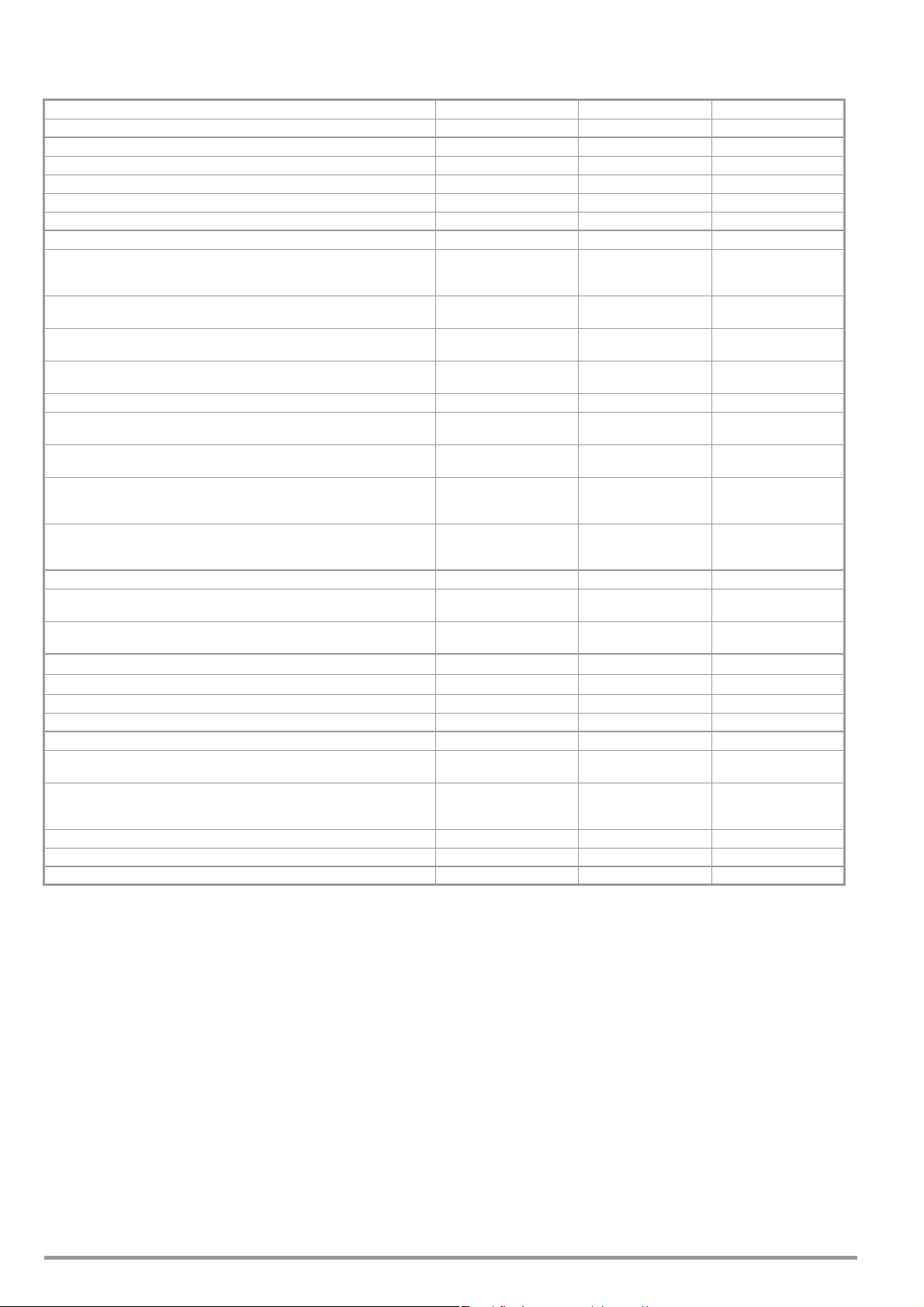

Electrical Data, Series 240 W

If not otherwise specified, all entries are maximum values and are valid for an operating temperature range of 0 to 50 °C,

nominal power range and a line voltage range of 230 V ± 10% after a warm-up period of 30 minutes.

Description (abbreviated designation) SLP 240-20 SLP 240-40 SLP 240-80

Typ e 32 N 20 R 20 32 N 40 R 12 32 N 80 R 6

Nominal Output Data Voltage setting range 0 ... 20 V 0 ... 40 V 0 ... 80 V

Current setting range 0 ... 20 A 0 ... 12 A 0 ... 6 A

Continuous power where Tu ≤ 40 °C max. 240 W max. 240 W max. 240 W

Intermittent power where t < 90 s / Tu ≤ 25 °C max. 320 W max. 360 W max. 360 W

Current derating where Tu > 40 °C – 0.5 A / K – 0.3 A / K – 0.15 A / K

Output Operating Characteristics

Overall setting accuracy at 23 ± 5 °C

with reference to 3½ place setpoint display

including system deviation, load / mains

Static system deviation

at 100% load variation

Static system deviation

at 10% line voltage variation

Residual ripple

Ua > 5% U

nom

1)

1)

1)

1)

1)

Voltage (10 Hz ... 10 MHz)

Current (10 Hz ... 1 MHz)

Common-mode noise (10 Hz ... 1 MHz) 0.5 mA

Settling time (voltage)

with sudden load variation of 10 ... 90% I

nom

Under and overshooting with sudden load variation of

(Typical values) Δ I = 80%

(Typical values) Δ I = 80% 450 mV 450 mV 800 mV

50 A / ms

Settling time (voltage)

with setpoint jump: 0 → 100%

with setpoint jump: 100% → 0

no load / nominal load

no load / nominal load

Settling time (current)

with setpoint jump: 0 → 100%

with setpoint jump: 100% → 0

short-circuit / nominal load

short-circuit / nominal load

Measured Value Displays (3½ place)

Measurement resolution Voltage

Measuring accuracy at 23 ± 5 °C

with reference to the respective measured value

Protective Functions

Output overvoltage protection Threshold 25 ± 1 V 50 ± 2 V

Reversed polarity protection – overload capacity Continuous 20 A 12 A 6 A

Reverse flow resistance Continuous 40 V 80 V 100 V

General

Power supply

1)

Power Consumption At nominal load

At max. intermittent power

Efficiency At nominal load > 68% > 70% > 70%

Switching frequency Typical 200 kHz 200 kHz 200 kHz

Article number K230A K231A K232A

1) Typical values are increased by a factor of approximately 1.2 in the functional line voltage input range of –10% to –15%.

Voltage

Current

Voltage

Current

Voltage

Current

0.2% + 100 mV

0.5% + 55 mA

25 mV

30 mA

5 mV

8 mA

15 mV

50 mA

To le ra n ce

40 mV

600 μs

To le ra n ce

40 mV

1 ms / 1 ms

1 ms / 1 ms

To le ra n ce

200 mA

< 5 ms / < 5 ms

< 5 ms / < 5 ms

10 mV

Current

Voltage

Current

10 mA

0.2% + 50 mV

0.5% + 25 mA

Line voltage 230 V~ +10 / −15%

47 ... 63 Hz

510 VA, 350 W

In standby mode

45 VA, 15 W

620 VA

0.2% + 150 mV

0.5% + 45 mA

18 mV

30 mA

5 mV

8 mA

eff

eff

eff

15 mV

25 mA

0.5 mA

eff

eff

eff

80 mV

300 μs

80 mV

1 ms / 1 ms

1 ms / 1 ms

120 mA

< 5 ms / < 5 ms

< 5 ms / < 5 ms

100 mV

10 mA

0.2% + 120 mV

0.5% + 30 mA

0.2% + 250 mV

0.5% + 35 mA

18 mV

15 mA

5 mV

5 mA

15 mV

20 mA

0.5 mA

160 mV

200 μs

160 mV

4 ms / 4ms

4 ms / 4ms

60 mA

< 10 ms / < 10 ms

< 10 ms / < 10 ms

100 mV

10 mA

0.2% + 120 mV

0.5% + 25 mA

100 ± 4 V

230 V~ +10 / −15%

47 ... 63 Hz

500 VA, 340 W

45 VA, 15 W

690 VA

230 V~ +10 / −15%

47 ... 63 Hz

500 VA, 340 W

45 VA, 15 W

690 VA

eff

eff

eff

8 GMC-I Messtechnik GmbH

Page 9

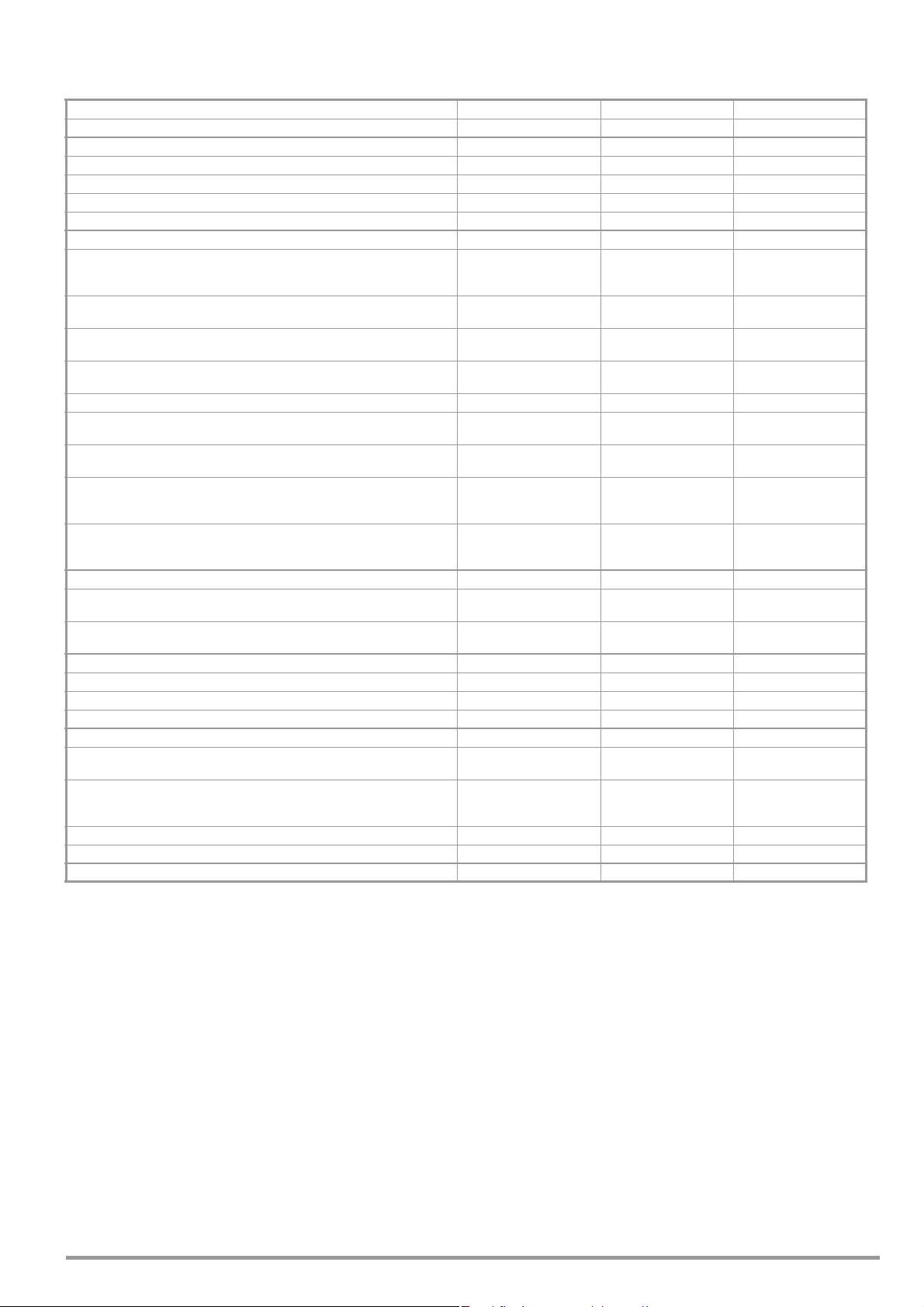

Electrical Data, Series 320 W

If not otherwise specified, all entries are maximum values and are valid for an operating temperature range of 0 to 50 °C,

nominal power range and a line voltage range of 230 V ± 10% after a warm-up period of 30 minutes.

Description (abbreviated designation) SLP 320-32

Typ e 32 N 32 R 18

Nominal Output Data Voltage setting range 0 ... 32 V

Current setting range 0 ... 18 A

Continuous power where Tu ≤ 40 °C max. 320 W

Intermittent power where t < 90 s / Tu ≤ 25 °C max. 430 W

Current derating where Tu > 40 °C – 0.5 A / K

Output Operating Characteristics

Overall setting accuracy at 23 ± 5 °C

with reference to 3½ place setpoint display

including system deviation, load / mains

Static system deviation

at 100% load variation

Static system deviation

at 10% line voltage variation

Residual ripple

Ua > 5% U

nom

1)

1)

1)

1)

1)

Voltage (10 Hz ... 10 MHz)

Current (10 Hz ... 1 MHz)

Common-mode noise (10 Hz ... 1 MHz) 0.5 mA

Settling time (voltage)

with sudden load variation of 10 ... 90% I

nom

Under and overshooting with sudden load variation of

(Typical values) Δ I = 80%

(Typical values) Δ I = 80% 450 mV

50 A / ms

Settling time (voltage)

with setpoint jump: 0 → 100%

with setpoint jump: 100% → 0

no load / nominal load

no load / nominal load

Settling time (current)

with setpoint jump: 0 → 100%

with setpoint jump: 100% → 0

short-circuit / nominal load

short-circuit / nominal load

Measured Value Displays (3½ place)

Measurement resolution Voltage

Measuring accuracy at 23 ± 5 °C

with reference to the respective measured value

Protective Functions

Output overvoltage protection Threshold 40 ± 1 V

Reversed polarity protection – overload capacity Continuous 20 A

Reverse flow resistance Continuous 64 V

General

Power supply

1)

Power Consumption At nominal load

At max. intermittent power

Efficiency At nominal load > 69%

Switching frequency Typical 200 kHz

Article number K234A

1) Typical values are increased by a factor of approximately 1.2 in the functional line voltage input range of –10% to –15%.

Voltage

Current

Voltage

Current

Voltage

Current

0.2% + 150 mV

0.5% + 50 mA

30 mV

40 mA

10 mV

20 mA

30 mV

50 mA

(Ua > 10%U

eff

To le ra nc e

64 mV

500 μs

To le ra nc e

64 mV

1 ms / 1 ms

1 ms / 1 ms

To le ra nc e

180 mA

< 5 ms / < 5 ms

< 5 ms / < 5 ms

100 mV

Current

Voltage

Current

10 mA

0.2% + 120 mV

0.5% + 40 mA

Line voltage 230 V~ +10 / −15%

47 ... 63 Hz

650 VA, 460 W

In standby mode

50 VA, 15 W

770 VA

eff

)

nom

eff

GMC-I Messtechnik GmbH 9

Page 10

1.4.3 Mechanical Data

All dimensions in mm

CC

CV

DISPLAY

Volt

Amp

Iset

Uset

POWER

OFF

ON

Uset/Iset

240W

40V

12A

20V/12A

40V/6A

OUTPUT

Ulim Ilim

230V 50-60Hz

FUSE T4/250V

OUTPUTANALOG INTERFACE

SIG1 OUT

SIG2 OUT

TRG IN

TRG IN

15V

AGND

Uset

Uset

Iset

U-MON

I-MON

SENSE

+

-

SENSE

+

-

+

-

+

+

-

+

397.5

221.5

380.5

88

14

Mechanical Design

Benchtop instrument, suitable for rack mounting

Dimensions See also dimensional drawing

(W x H x D) 221.5 x 102 x 397.5 mm

For 19" rack ½19" x 2 standard height units x 400 mm

Weight approx. 2.8 kg

Dimensional Drawing

10 GMC-I Messtechnik GmbH

Page 11

2 Preparation for Operation and

Initial Start-Up

2.1 Connection to the Mains

Observe WARNING I!

CAUTON!

Before switching the KONSTANTER on, make sure that your local mains

voltage corresponds with the operating voltage specified on the

instrument’s rear panel.

The KONSTANTER requires 230 V~ supply power. Connect the

recessed mains plug at the back of the device to a mains outlet

with earthing contact with the included power cable.

Power consumption is specified on the serial plate at the back of

the KONSTANTER.

A mains outlet socket is located above the recessed plug and

can be used for looping mains power through to additional

instruments.

This mains outlet is neither switched nor fused.

increasing voltage as required at the output jacks.

☞ Voltage limiting remains uninfluenced by output current as well

during constant current operation.

☞ The voltage value determined by the measuring function

corresponds to voltage acquired by the sensing leads. Load

parameters such as power consumption and load impedance

can thus be more precisely determined.

• The parameters and limit values listed in figure 2.3 apply for

operation with sensing leads.

WARNING!

If mains power is looped through, make sure that overall power

consumption does not exceed 10 A at the point from which power is

drawn from the mains!

Suitable “mains jumper cables” are available as an accessory (see

order information on last page).

2.2 Connection to the Consuming Device

Supply power to the consuming device is connected either at the

front panel with 4 mm safety plugs to the safety jacks identified

with the “+” and “−” markings, or to the “+” and “−” outputs at the

6-pole terminal strip at the rear panel.

Connections for the consuming device at the

“+” and

These must be connected in parallel for load currents of greater than 10 A

due to contact ratings.

Be certain to use conductors with an adequate cross-section and observe

correct polarity. It is advisable to twist the power leads to the consuming

device, and to identify polarity with markings at their ends.

If connections are made simultaneously at the front and the rear

panel, constant voltage regulation applies to the terminals at the

rear panel. This is not permitted for parallel connection because the

internal connection might otherwise be overloaded.

The yellow-green safety jack at the front panel is connected to PE,

and can be used to connect earthing cables or cable shields, or as

an earth connection point for one of the output terminals.

two “−

” terminals.

rear panel

include

two

2.3 Sensing Mode Operation

In order to take advantage of highly constant output voltage, even

if long leads are used for connection to the consuming device,

voltage drops at the power leads can be compensated for with

additional sensing leads.

Function

• Sensing terminals: +SENSE / −SENSE

Output voltage, which is decisive for the voltage measuring and

regulating circuits, is acquired directly at the consuming device

(instead of at the output terminals).

• Sensing mode operation (remote sensing) offers the following

advantages:

☞ Voltage at the consuming device remains largely uninfluenced

by current-dependent voltage drops at the power supply leads

during constant voltage operation.

Voltage drops are compensated for by automatically

Figure 2.3 Connection to Consumer for Sensing Mode Operation

• Cs+, Cs-typically ... 220 μF

s+,Us-

≤ 1 V

− Us+ / 81 Ω

Us– / 81 Ω

• U

• I

s+

• I

s-

Connection

• The +SENSE and –SENSE leads from the output plug connector at

the rear panel should be connected as close as possible to the

corresponding terminals at the power consuming device.

• Interference injection can be minimized as follows:

☞ Twist the sensing leads and/or

☞ Shield the sensing leads.

(Connect shield to ground/housing or neg. output terminal.)

• Impedance resulting from long power and sensing leads may lead to

control oscillation at the output.

Capacitance at the consumer promotes this problem as well.

• Control oscillation can be counteracted by connecting

capacitors (C

(see figure 2.3).

• Twisting the power leads reduces their impedance as well.

• Incorrect connection of the sensing leads does not cause any damage

to the KONSTANTER, although it results in the following reversible

events:

, Cs-) between the SENSE and the output terminals

s+

☞ Sensing lead polarity reversal or power lead interruption

If output voltage from the KONSTANTER is not limited with the

current regulator, it rises to well above the setpoint value.

Overvoltage protection is then immediately triggered and the

output is deactivated.

☞ Sensing lead interruption

If one of the sensing leads is interrupted, the device is

switched automatically to local sensing for the

corresponding output terminal.

• If the sensing leads are connected incorrectly, voltage present

at the output terminals or consuming device is not displayed.

Activating Sensing Mode Operation

• Sensing mode operation is activated automatically after

connecting the SENSE terminal to the consumer which has

been connected to the output terminals.

• Sensing mode operation is deactivated as soon as this

connection has been interrupted.

GMC-I Messtechnik GmbH 11

Page 12

2.4 Installation to a 19" Rack

➁

➀

➀

➁

½19“ Blanking Plate

19“ Limit Stop

➃

➂

19" Joiner

19" Limit Stop

➃

➃

➂

The housing included with the KONSTANTERs has been designed for

use as a benchtop device, as well as for installation to a 19" rack.

Two KONSTANTERs can be installed next to one another, or a single

device can be installed along with a blanking plate. Benchtop

devices can be quickly converted for installation to a 19" rack.

Installing a Single KONSTANTER to a 19" Rack

Use the 19" adapter set accessory 1x32N.

It includes an 19" limit stop and a ½19" blanking plate.

➀ Loosen the 4 screws at the front panel of the

KONSTANTER.

➁ Pull out the two filler strips from the left and right-hand sides at

the front of the side panels.

Figure 2.4 Rack Conversion for a Single Device

➂ Replace the filler strips with the 19" limit stop on one side, and

the ½19" blanking plate on the other side. Fasten the limit stop

and the blanking plate with the 4 screws.

➃ Unscrew the feet from the bottom of the device. Remove the

rubber inserts from the feet first, behind which the screws are

concealed.

➄ Install the KONSTANTER into the rack. Keep all remaining parts in

a safe place for possible future use.

➅ The KONSTANTER must be supported in the rack at one side with

slide rails. The slide rails, as well as the screws required for

securing the KONSTANTER’s front panel are rack-specific, and

must thus be obtained from your rack supplier.

➂ Replace the filler strips with the 19" limit stops at the right and

left-hand sides, and with the 19" joiner in the middle. Fasten

the limit stops and the joiner with the 8 screws.

Screw the housings together at the threaded through-holes in

the cable spacers at the back of the devices.

➃ Unscrew the feet from the bottom of the devices. Remove the

rubber inserts from the feet first, behind which the screws are

concealed.

➄ If the two KONSTANTERs are to be electrically connected to one

another, use the accessory “mains jumper cable”.

➅ Install the KONSTANTERs into the rack. Keep all remaining parts

in a safe place for possible future use.

➆ The KONSTANTERs must be supported in the rack at both sides

with slide rails. The slide rails, as well as the screws required

for securing the KONSTANTER’s front panels are rack-specific,

and must thus be procured from your rack supplier.

2.5 Multiple Benchtop Device Combination

Up to 3 KONSTANTERs can be stacked to create a multiple bench-

top device combination (see also chapter 5 regarding possible

electrical connections via the analog interface).

➀ Unscrew the feet from the bottom of the device. Remove the

rubber inserts from the feet first, behind which the screws are

concealed.

Four large slotted holes are now visible at the bottom of the

device.

➁ Turn the four collar screws from the device feet into the threads

at the top of the other device housing. Keep the 4 lock

washers and device feet in a safe place.

➂ Set the KONSTANTER without feet on top of the other KONSTAN-

TER. The screws from the bottom device must protrude

through the enlarged openings in the bottom of the top device.

Push the top device back slightly, until the screws snap into

place.

➃ Screw the housings together at the threaded through-holes in

the cable spacers at the back of the devices. This secures the

top device against slipping.

➄ If the two KONSTANTERs are to be electrically connected to one

another, use the accessory “mains jumper cable”.

Conversion for Installing Two

Use the 19" adapter set accessory 2x32N.

It includes two 19" limit stops and one 19" joiner.

KONSTANTERs to a 19" Rack

➀ Loosen the 8 screws from the front panels at the KONSTANTERs.

➁ Pull out the two filler strips from the left and right-hand sides of

the front of the side panels at each device.

Figure 2.4 Rack Conversion for Two Devices

12 GMC-I Messtechnik GmbH

Page 13

3 Controls, Displays and Connectors

123 4 5

101196

87

Figure 3.1 Front Panel Controls, Displays and Connectors

[1] Mains Switch <POWER>

For switching the KONSTANTER on and off.

After mains power has been switched on, the KONSTANTER

adjusts itself to all of the values which have been predetermined by manual control settings or signals received at the

analog interface. It is then switched to the standby mode

and is ready for operation.

When the KONSTANTER is switched off, it is disconnected at

both poles from the mains and the output is deactivated.

CAUTION!

Do not switch the device on and off repeatedly at short intervals.

Effectiveness of in-rush current limiting may be impaired in such

cases, which may cause the mains fuse to blow!

[2] Output ON/OFF key <OUTPUT>

The power output is activated and deactivated by

pressing the <OUTPUT> key.

If the output is active, one of the control mode displays lights

up, namely CV or CC [3].

No significant output voltage overshooting occurs during

activation and deactivation of the power output.

When the device is switched off, an electronic sink is activated for approximately 300 ms, which rapidly discharges

the output capacitors. The output then becomes “highly

resistive” (R

> 50 kΩ II 250 μF).

i

[4] Left-Hand Display

The measured value for output voltage Uout in volts appears as

the standard display value at the left-hand display.

As long as the <DISPLAY Uset/Iset> key [9] is depressed, the

manually selected voltage setpoint Uset appears at the display.

Type / Nom.Voltage Display Resolution / Range

20 V 0.01 (max. 19.99)

32/40/80 V 0.1 (xx.x)

[5] Right-Hand Display

The measured value for output current Iout in amperes appears

as the standard display value at the right-hand display.

As long as the <DISPLAY Uset/Iset> [9] key is depressed, the

manually selected current setpoint Iset appears at the display.

Display Resolution / Range 0.01 (max. 19.99)

☞ Refer to chapter 4.3 for detailed information.

[6] Front Panel Output

The selected constant voltage or constant current is made

available at the safety jacks at the front panel, or at the

terminals on the rear panel [13].

– (blue) Negative output terminal

+ (red) Positive output terminal

(yellow-green) The output can be grounded here if

☞ Refer to chapter 4.3 for detailed information.

CAUTION!

The output terminals are not electrically isolated when the output is

deactivated.

desired, or the shield can be connected here if shielded power leads

are used. The ground terminal is connected to the housing and the mains

connection earthing contact.

[3] Control Mode Displays

The three LEDs indicate the current operating status (control

mode) of the output.

“CV” illuminated Constant voltage mode (Uout = Uset)

“CC” illuminated Constant current mode (Iout = Iset)

“Pmax” illuminated Overload limiting / overtemperature

protection has been triggered.

The output is deactivated as a result.

GMC-I Messtechnik GmbH 13

☞ Refer to chapter 2.2 for detailed information.

Page 14

Figure 3.2 Controls and Connectors at the Rear Panel

+

-

+

+

-

+

+

SENSE

-+

SENSE

I-MON

U-MON

Iset

Uset

Uset

AGND

15V

TRG IN

TRG IN

SIG2 OUT

SIG1 OUT

ANALOG INTERFACE OUTPUT

230V 50-60Hz

FUSE T4/250V

12 13

14

15

16

[7] Limit Value Adjustment <Ulim>

The upper limit value Ulim for the voltage setting range is

selected with this trimming potentiometer. Use a size 3

screwdriver only for this adjustment.

☞ Refer to chapter 4.1.2 for detailed information.

[8] Rotary Knob for Voltage Setpoint Adjustment <Uset>

Output voltage can be set with this rotary knob. Adjustment

is accomplished with a ten-turn potentiometer and allows for

precise adjustment of the voltage setpoint Uset, selected

within the range defined by means of Ulim [7].

Press the key [9] in order to display the setpoint value Uset.

☞ Refer to chapter 4.1.3 for detailed information.

[9] Display Switching Key <Uset/Iset>

The two displays [4/5] can be switched from Uout/Iout to

Uset/Iset by pressing the key [9].

The key must be pressed and held in order to continuously

monitor changes to Uset/Iset or Ulim/Ilim during adjustment.

[10] Rotary Knob for Current Setpoint Adjustment <Iset>

This rotary knob functions just like the rotary knob for voltage setpoint adjustment [8].

The display can be switched to the present current setpoint

value Iset by pressing the key [9] <DISPLAY Uset/Iset>.

☞ Refer to chapter 4.2.3 for detailed information.

[11] Limit Value Adjustment <Ilim>

The upper limit value Ilim for the current setting range is

selected with this trimming potentiometer. Use a size 3

screwdriver only for this adjustment.

☞ Refer to chapter 4.2.3 for detailed information.

[12] Analog Interface

CAUTION!

The contacts at the analog interface are connected to electronic

components which may be damaged by electrostatic discharge.

Before touching any contacts, neutralize the potential difference

between yourself and the KONSTANTER by touching the housing!

The analog interface provides for the following functions:

• Remote setting of output voltage and current with analog

control voltages ranging from 0 to 5 V or −5 to 0 V

☞ Refer to chapters 5.4 and 5.5 for detailed information.

• External measurement or recording of output voltage

and current by means of monitor signals ranging from

0 to 10 V

☞ Refer to chapters 5.6 and 5.7 for detailed information.

• +15 V auxiliary power supply to the trigger input or

external control devices

• Linking of several KONSTANTERs for master-slave operation

☞ See chapters 5.8.2 and 5.9.2 for detailed information.

• For varying internal output resistance

☞ Refer to chapter 5.10 for detailed information.

• For activating and deactivating the output via the floating

TRIGGER input

☞ Refer to chapter 5.3 for detailed information.

[13] Rear Panel Output

The OUTPUT interface can be used for two different

functions:

• Pick off constant voltage or constant current from the

rear panel of the KONSTANTER via the terminal strip

• Connect the sensing leads for the compensation of

voltage drops at the power leads

☞ Refer to chapters 2.2 and 2.3 for detailed information.

[14] Air Outlet

The air outlet vents regulate temperature inside the KONSTANTER. Warm air generated during operation is exhausted via

the air outlet vents with the help of a temperature controlled

fan.

CAUTION!

The air outlet may not be closed off and, it must be possible for

warm air to be exhausted freely via the air outlet vents. Nonobservance may trigger overtemperature protection and deactivate

the output (see chapter 4.3).

[15] Mains Power Input

Mains power input with looped through mains outlet for

connection to inlet connectors for non-heating apparatus.

The looped through mains outlet allows for direct connection

of up to 3 KONSTANTERs with two short power cables with

inlet connectors for non-heating apparatus. Only one power

cable is thus required for operation of three devices.

☞ Refer to chapter 2.1 for detailed information.

[16] Mains Fuse

Fusing at the mains power input:

All device types: T 4.0 A / 250 V (6.3 x 32 mm)

The second mains input pole is fused internally with:

T 5.0 A / 250 V (5 x 20 mm)

WARNING!

When replacing blown fuses, use only fuses of the specified type

with the specified current rating.

Any tampering with fuses or the fuse holder (“mending” fuses or

short-circuiting the fuse holder etc.) is strictly prohibited.

14 GMC-I Messtechnik GmbH

Page 15

4 Adjusting Output Values

4.1 Output Voltage

4.1.1 Uout – Presently Measured Voltage Value

• The left-hand digital display [4] <Volt> indicates the measured

value Uout for voltage present at the output terminals.

• During sensing mode operation, the displayed value

corresponds to voltage acquired from the sensing leads

at the consuming device.

• The 3½ place measured value display is refreshed approxi-

mately 3 times per second. Overflow is indicated for measured

values of greater than 19.99 at 20 V devices.

• If output voltage is superimposed with an alternating voltage,

the arithmetic mean value is displayed.

☞ Refer to chapter 1.4.3, Electrical Data, regarding measuring

range, measuring resolution and measuring accuracy.

4.1.2 Ulim – Limit Value for Uset

Function

• Defines the voltage adjustment setting range <Uset> [8]

• Prevents inadvertent, excessively high voltage setpoint values

(Uset) during manual operation.

• If Ulim is set to 0 V (full left), the voltage adjusting

potentiometer <Uset> is disabled (e.g. for adjustment of output

voltage by means of the analog interface).

Setting Ulim

• Ulim is adjusted with the left-hand trimming potentiometer [7]

<Ulim>.

• Use a size 3 screwdriver only in order to avoid damaging the

potentiometer.

• Deactivate the output: <OUTPUT> ”OFF”.

• First set Uset to its maximum value (turn potentiometer [8] <Uset>

clockwise as far as it will go).

• Press the key [9] <DISPLAY Uset/Iset>.

• The left-hand display [4] <Volt> is switched from the presently

measured voltage value Uout to the manually selected voltage

setpoint Uset.

• Hold this key depressed.

• At the same time, turn <Ulim> [7] with the screwdriver until <Volt>

appears at the display [4] as the selected voltage for Ulim.

• To increase voltage:Turn clockwise

• To decrease voltage:Turn counterclockwise

• The selected voltage is now the maximum voltage value to which

Uset can be adjusted manually.

4.1.3 Uset – Voltage Setpoint Value

Function

• Predefined voltage at which the consuming device is to be

operated

Adjusting Uset

• Uset is adjusted with the left-hand rotary knob [8] <Uset>.

• First press the key [9] <DISPLAY Uset/Iset>.

• The left-hand display [4] <Volt> is switched from the presently

measured voltage value Uout to the manually adjusted voltage

setpoint Uset.

• Hold this key depressed.

• At the same time, turn the rotary knob [8] <Uset>.

• To increase voltage:Turn clockwise

• To decrease voltage:Turn counterclockwise

• If the output is activated <OUTPUT> “ON”, output voltage is

adjusted directly by turning rotary knob.

• If the output is deactivated <OUTPUT> “OFF”, no voltage is present

at the output during adjustment. Voltage is not applied to the

output until it is activated <OUTPUT> “ON”.

• After releasing the key [9] <DISPLAY Uset/Iset>, the display [4] is

switched back to the measured value for output voltage Uout.

CAUTION!

The Uset value can also be changed when the KONSTANTER is not in

operation.

Setting Range

• The rotary knob can be turned 10 revolutions.

• The 10 revolutions which are possible with the <Uset>

potentiometer [8] always correspond to a range of 0 V to Ulim.

• The selection of a low value for Ulim allows for “finer” adjustment

of the Uset value.

The setting accuracy specified in chapter 1.4.3 makes reference

to the respectively displayed setpoint value.

• 19.99 is the highest value which can be displayed for Uout and

Uset with 20 V devices.

The A-D converter generates an overflow display for values

beyond this limit:

Setting Range

• The <Ulim> potentiometer can be turned 270°, which

corresponds to a setting range of 0 V

• The 10 revolutions which are possible with the <Uset> rotary knob

[8] always correspond to a range of 0 V to Ulim.

GMC-I Messtechnik GmbH 15

≤ Ulim ≤ Unom.

Page 16

4.2 Output Current

4.3 OUTPUT – Switching the Power Output On and Off

4.2.1 Iout – Presently Measured Current Value

• The right-hand digital display [5] <Amp> indicates the measured

value Iout for current at the output.

• If output current is superimposed with an alternating current,

the arithmetic mean value is displayed.

• The 3½ place measured value display is refreshed approxi-

mately 3 times per second. Overflow is indicated for measured

values of greater than 19.99 at 20 A devices.

☞ Refer to chapter 1.4.3, Electrical Data, regarding measuring

range, measuring resolution and measuring accuracy.

4.2.2 Ilim – Limit Value for Iset

Function

• Defines the current adjustment setting range <Iset> [8].

• Prevents inadvertent, excessively high Iset values.

• If Ilim is set to 0 V (full left), the current adjusting

potentiometer <Iset> is disabled (e.g. for adjustment of output

current by means of the analog interface).

Setting Ilim

• The procedure for adjusting the Iset limit value is identical to the

procedure used to adjust the Uset limit value (4.1.2).

• The following controls and displays do however vary:

Left trimmer [7] <Ulim> → Right trimmer <Ilim> [11]

Left rotary knob [8] <Uset> → Right rotary knob <Iset> [10]

Left display [4] <Volt> → Right display <Amp> [5]

Setting Range

• The <Ilim> potentiometer can be turned 270°, which

corresponds to a setting range of 0 A ≤ Ilim ≤ Inom.

• The 10 revolutions which are possible with the <Iset> rotary knob

[10] always correspond to a range of 0 A to Ilim.

4.2.3 Iset – Current Setpoint Value

Function

• Predefined current at which the consuming device is to be

operated.

Adjusting Iset

• The procedure for adjusting the current setpoint is identical to

the procedure used to adjust Uset (4.1.3).

• The following controls and displays do however vary:

Left rotary knob [8] <Uset> → Right rotary knob <Iset> [10]

Left display [4] <Volt> → Right display <Amp> [5]

CAUTION!

The Uset value can also be changed when the KONSTANTER is not in

operation.

Setting Range

• The 10 revolutions which are possible with the <Iset> rotary knob

[10] always correspond to a range of 0 A to Ilim.

• The selection of a low value for Ilim allows for “finer” adjustment

of the Iset value.

The setting accuracy specified in chapter 1.4.3 makes reference

to the respectively displayed setpoint value.

• Overflow display

for settings of greater than 19.99 at 20 A devices:

• The power output is switched on and off with the red detented

key [9] <OUTPUT>.

• Pressing the <OUTPUT> key activates or deactivates the power

output.

OUTPUT OFF → OUTPUT ON

OUTPUT ON → OUTPUT OFF

• The power output can be deactivated for adjustments to Uset,

Ulim, Iset and Ilim in order to prevent damage to the consuming

device due to inadvertent, excessively high settings.

• If the power output is deactivated, “OUTPUT OFF”, the control

mode displays are switched off.

• If the power output has been deactivated by means of overtem-

perature protection, the yellow “Pmax” LED in the control mode

display [3] lights up. The output cannot be reactivated until the

KONSTANTER has cooled back down to its normal operating tem-

perature.

• Additional functions which may deactivate the power output:

✗ External control signal to TRG IN at the analog interface

(see also chapters 5.1 and 5.3)

✗ Overvoltage protection is triggered as soon as voltage at the

output terminals exceeds approximately 125% of Unom.

Cause:

– Excessively high setting for output voltage by means of

Uset control signal to the analog interface

– Voltage transient while switching an inductive consumer

– Unipolar power recovery from interconnected

consumers (e.g. DC motors) or from parallel

connected voltage sources

– Sensing mode operation: sensing leads connected with

reversed polarity or a power lead is/was interrupted

The “CV” display for constant voltage operation remains

illuminated. However, the display for output voltage or output

current drops to zero. At the same time, SIG1OUT indicates

“OUTPUT OFF”.

After eliminating the cause of triggering, the output can be

reactivated.

✗ Overtemperature protection is triggered

Cause:

– Impaired cooling, e.g. closed off air inlet

or air outlet vents

– Excessively high ambient temperature or load:

The device is able to deliver nominal power during

continuous operation at a maximum ambient

temperature of 40 °C (measured at air inlet vents)

– Defective fan

After the device has cooled sufficiently, the output is

reactivated automatically.

CAUTION!

The output terminals are not electrically isolated when the output is

deactivated.

16 GMC-I Messtechnik GmbH

Page 17

SIG1 OUT

SIG2 OUT

TRG IN -

TRG IN +

+ 15 V

AGND

Uset -

Uset +

Iset +

U MON

I MON

− SENSE

− OUT

− OUT

+ SENSE

20

OUT

IN

ADJ

1,5 k

−

+

10 k

10 k

10 k

−

9k8

9k4

+T

110 mA

+ OUT

+ OUT

−

-+-

81

81

120k

120k

R

a

R

b

−

+

OUTPUT Status

Control Mode CV/CC

OUTPUT Control

+18 V

U-Reg.

I-Reg.

U-Reg.

I-Reg.

R

a

= Rb = 60 k for 20 V devices

37.5 k for 32 V devices

30 k for 40 V devices

ANALOG INTERFACE

OUTPUT

5 k

+

+

15 k for 80 V devices

5 Control via the Analog Interface

5.1 Connector Assignments

SIG1 OUT, SIG2 OUT (output)

• Digital status signal outputs with reference to AGND

I-MON (output)

• Analog voltage output proportional to actual output current Iout

(0 ... 10 V 0 ... Iout

nom

)

• This output, with reference to AGND, has an internal resistance

of 9.4 kΩ and is short-circuit proof.

☞ Refer to chapter 5.7 for detailed information.

• SIG1 OUT indicates the status of the power output

• SIG2 OUT indicates the current control mode

• Signal type open collector

• Max. switching voltage 30 V DC

• Max. switching current 20 mA

☞ Refer to chapter 5.2 for detailed information.

TRG IN+, TRG IN- (input)

• Floating digital control input for switching the power output on

and off

• Low signal: –26 V ≤ Us ≤ +1 V

• High signal: +4 V ≤ U

= (Us - 2 V) / 1.5 kΩ

I

s

≤ +26 V

s

☞ Refer to chapter 5.3 for detailed information.

+15 V (output)

• This auxiliary voltage output (14 ... 17.5 V DC with reference to

AGND) can be used to control the trigger input or to supply

external consumers with power (e.g. reference component for

the generation of control voltages).

• The output is equipped with electronic current limiting to

approximately 60 mA, and is short-circuit proof to AGND.

AGND (analog ground = reference point)

• Reference point for analog control inputs and outputs

• This terminal is internally connected to the negative pole of the

power output via an automatic resetting fuse (110 mA rating).

Uset-, Uset+ (input)

• Analog (differential) voltage input with reference to AGND for

controlling output voltage. The following applies when the

output is active:

• Uout = USET + U

Uout: output voltage during constant voltage operation

USET: manually selected voltage setpoint value

: external control voltage (0 ... 5 V 0 ... Uout

U

su

: voltage control coefficient = Uout

k

su

: input impedance Uset+: 10 kΩ

R

su

⋅ k

su

su

☞ Refer to chapter 5.4 for detailed information.

Iset+ (input)

• Analog voltage input with reference to AGND for controlling output

• Iout = ISET + U

☞ Refer to chapter 5.5 for detailed information.

U-MON (output)

• Analog voltage output, proportional to output voltage Uout

current. The following applies when the output is active:

⋅ k

si

si

Iout: output current during constant current operation

ISET: manually selected current setpoint value

Usi: external control voltage (0 ... 5 V 0 ... Iout

: current control coefficient = Iout

k

si

Rsi: input impedance: 10 kΩ

which is acquired by the sensing leads

(0 ... 10 V 0 ... Uout

nom

).

• This output, with reference to AGND, has an internal resistance

of 9.8 kΩ and is short-circuit proof.

☞ Refer to chapter 5.6 for detailed information.

GMC-I Messtechnik GmbH 17

nom

Uset–: 15 kΩ

nom

/ 5 V

/ 5 V

nom

nom

)

)

Figure 5.1 Internal connection to the analog interface and

the output (simplified schematic)

Page 18

5.2 Status Signal Outputs

SLP-KONSTANTER

Settings

USET = Uset

ISET = Iset

+SENSE

-OUT

-OUT

-SENSE

Analog Interface

SIG1 OUT

SIG2 OUT

TRG IN –

TRG IN +

+ 15 V

AGND

Uset Uset +

Iset +

U-MON

I-MON

+OUT

+OUT

Uout

Load

Iout

Output

R

PU

OUTPUT ON

+5 V

Usig

SLP-KONSTANTER

SLP-KONSTANTER

Settings

USET = Uset

ISET = Iset

+SENSE

-OUT

-OUT

-SENSE

Analog Interface

SIG1 OUT

SIG2 OUT

TRG IN –

TRG IN+

+ 15 V

AGND

Uset -

Uset +

Iset +

U-MON

I-MON

+OUT

+OUT

Uout

Load

Settings

USET = Uset

ISET = Iset

Uout

+SENSE

-OUT

-OUT

-SENSE

Analog Interface

SIG1 OUT

SIG2 OUT

TRG IN –

TRG IN +

+ 15 V

AGND

Uset -

Uset +

Iset +

U-MON

I-MON

+OUT

+OUT

Iout

Load

Iout

Output

Output

I

s

U

s

OUTPUT ON

OUTPUT ON

Is approx. 10 mA

5.3 Trigger Input

Function

• The KONSTANTER includes two digital open collector outputs

with reference to AGND for the generation of status signals.

• SIG1 OUT – indicates activation status of the power output

OUTPUT ON = passive high (= OFF)

OUTPUT OFF = active low (= ON)

– If this output is connected to the trigger input of a second

KONSTANTER, the power outputs of both devices can be activated and deactivated simultaneously (see also chapters

5.8.2 and 5.9.2).

–As a message signal for transmission to monitoring equipment

– For the control of external output relays

Due to the fact that output voltage drops off very quickly

when the output is switched off (< 1 ms), the relay can be

released load-free with resistive consumers.

• SIG2 OUT – indicates the active power output control mode.

– Constant current (CC) or overload (Pmax) = active low (= ON)

– Constant voltage (CV) or OUTPUT OFF = passive high (= OFF)

–As a message signal to monitoring equipment

Connection

• Connected load values

Max. switching voltage 30 V DC

Max. switching current 20 mA

Low level < 1 V at I

≤ 20 mA

s

• In order to generate an “active high” signal of + 15 V, the status

signal outputs can be connected to the +15 V terminal with

pull-up resistors R

with a value of at least 1 kΩ.

PU

Function

• The floating optocoupler input “TRG IN” allows for remote control of

a the OUTPUT function with a binary control signal.

• The trigger input is only active as long as the OUTPUT key is

depressed (ON).

• If this input is connected to the signal of a second KONSTANTER,

the power outputs of both devices can be activated and deactivated simultaneously (see also chapters 5.8.2 and 5.9.2).

• The OUTPUT ON/OFF function can be controlled by means of

user-specific signals to the trigger input in automated testing

systems.

Connection

• Connect the control signal between TRG IN + and TRG IN -.

Appropriate signal levels are listed in the following table.

Signal U

s

High 4 ... 26 V DC (U

I

s

− 2 V) / 1.5 kΩ OFF

s

Output

Low 0 ... 1 V DC 0 mA ON

• The TRIGGER can be controlled with the + 15 V output at the

analog interface via any desired switch (see figure 5.3 a).

WARNING

Trigger input TRG IN is a floating input and is functionally isolated from the

output current circuit.

This functional isolation is not to be construed with “protective

separation” as set forth in electrical safety regulations.

Figure 5.2 Wiring examples for the status signal outputs

Figure 5.3 a Controlling the

trigger input with

a switching element

18 GMC-I Messtechnik GmbH

Figure 5.3 b Controlling the

trigger input with

an external signal

Page 19

5.4 Controlling Output Voltage

SLP-KONSTANTER SLP-KONSTANTER

Settings

USET = 0

ISET = Isoll

OUTPUT on / off

+SENSE

-OUT

-OUT

-SENSE

Analog Interface

SIG1 OUT

SIG2 OUT

TRG IN –

TRG IN +

+ 15 V

AGND

Uset Uset +

Iset +

U-MON

I-MON

+OUT

+OUT

Settings

USET = 0

ISET = Isoll

OUTPUT on / off

+SENSE

-OUT

-OUT

-SENSE

Analog Interface

SIG1 OUT

SIG2 OUT

TRG IN –

TRG IN +

+ 15 V

AGND

Uset Uset +

Iset +

U-MON

I-MON

+OUT

+OUT

Last

Uout

Iout

Uout

Last

a)

I

out

I

su

b)

REF 02

IN

OUT

+5V

2k

Output

Output

U

su

USET+

USET-

AGND

ISET+

AGND

SLP-KONSTANTER SLP-KONSTANTER

Settings

USET = Uset

ISET = 0

OUTPUT ON/OFF

+SENSE

-OUT

-OUT

-SENSE

Analog Interface

SIG1 OUT

SIG2 OUT

TRG IN –

TRG IN +

+ 15 V

AGND

Uset -

Uset +

Iset +

U-MON

I-MON

+OUT

+OUT

Uout

Load

Settings

USET = Uset

ISET = 0

OUTPUT ON/OFF

Uout

+SENSE

-OUT

-OUT

-SENSE

Analog Interface

SIG1 OUT

SIG2 OUT

TRG IN –

TRG IN +

+ 15 V

AGND

Uset −

Uset +

Iset +

U-MON

I-MON

+OUT

+OUT

I

si

Iout

U

si

REF 02

IN

OUT

+5V

2k

Load

Iout

Output

Output

5.5 Controlling Output Current

Function

• Output voltage Uout can be controlled via control inputs Uset+

(non-inverting) and Uset− (inverting) with an external control

voltage U

.

su

• The following applies during constant voltage operation:

Uout = USET + U

⋅ k

su

su

USET: manually selected voltage setpoint value

ksu: voltage control coefficient = Uout

– Max. setting error: ± 0.05% of U

± 2% of setting value

nom

nom

/ 5 V

• The voltage control input has been designed as a differential

voltage input:

Uset+: non-inverting input:

= 0 ... +5 V for Uout = 0 V ... Uout

U

su

nom

,

input impedance: 10 kΩ

Uset−: inverting input:

= 0 ... −5 V for Uout = 0 V ... Uout

U

su

nom

,

input impedance: 15 kΩ

Notes

• The control inputs are not floating inputs, the reference point AGND

is connected to the negative pole of the power output.

• Connecting grounded current circuits to the control input may

lead to erroneous settings due to leakage current or earth loops.

• If control voltage U

is applied to the output’s negative pole with its

su

reference point at the load side, the inverting input must be

connected to this point (connection b in figure 5.4 a).

Influences caused by voltage drops at the load conductor are

thus avoided.

• If control voltage is electrically isolated from the output, connect

Uset− to AGND (connection a in figure 5.4 a).

• If remote control of output voltage is to be accomplished by means

of a potentiometer, wiring can be implemented in accordance

with figure 5.4 b.

can be applied as an alternating voltage, e.g. in order to

• U

su

superimpose the selected direct voltage USET with fault

signals.

The cut-off frequency of the modulated output voltage depends

upon voltage amplitude.

However, the cut-off frequency remains largely independent

of load and the selected current limit thanks to special circuit

technology.

Function

• Output current Iout can be controlled with an external control

voltage Usi via the control input Iset+.

• The following applies during constant current operation:

Iout = ISET + U

⋅ k

si

si

ISET: manually selected current setpoint value

ksi: current control coefficient = Iout

Max. setting error: ±0.1% v. I

± 2% of setting value

nom

nom

/ 5 V

• Current Control Input

Iset+: non-inverting input:

= 0 ... +5 V for Iout = 0 A ... Iout

U

si

nom

,

• Input impedance is equal to 10 kΩ.

Notes

• The control input is not a floating input, the reference point AGND is

connected to the negative pole of the power output.

• Connecting grounded current circuits to the control input may

lead to erroneous settings due to leakage current or earth loops.

• Control voltage U

may not be connected to the input’s negative

si

pole at the load side (see figure 5.5 a).

• If remote control of output current is to be accomplished by means

of a potentiometer, wiring can be implemented in accordance

with figure 5.5 b.

can be applied as an alternating voltage, e.g. in order to

• U

si

superimpose the selected direct current ISET with fault signals.

The cut-off frequency of the modulated output current depends

upon the load-related voltage amplitude.

CAUTION!

Control inputs Uset +, Uset – and Iset + should only be connected with

shielded cable.

Connect the shield to reference point AGND.

Figure 5.4 a Wiring for control

GMC-I Messtechnik GmbH 19

of output voltage

with an external

voltage

Figure 5.4 b Wiring for control

of output voltage

with an external

potentiometer

Figure 5.5 a Wiring for control

of output current