Page 1

Operating Instructions

SECUTEST SI+

3-349-613-15

5/4.17

Page 2

5

6

1

2

4

3

7

8

9

10

11

12

13

14

6

SECUTEST SI+

MENU

without Function

Standard Equipment

1 Input and memory module

SECUTEST SI+,

1 USB connector cable,

1 Operating instructions

The Driver Control software for installing

the USB device driver is available from

our website.

2 GMC-I Messtechnik GmbH

Page 3

ENTER

STORE

,

-

MENU

1

STORE

0

1

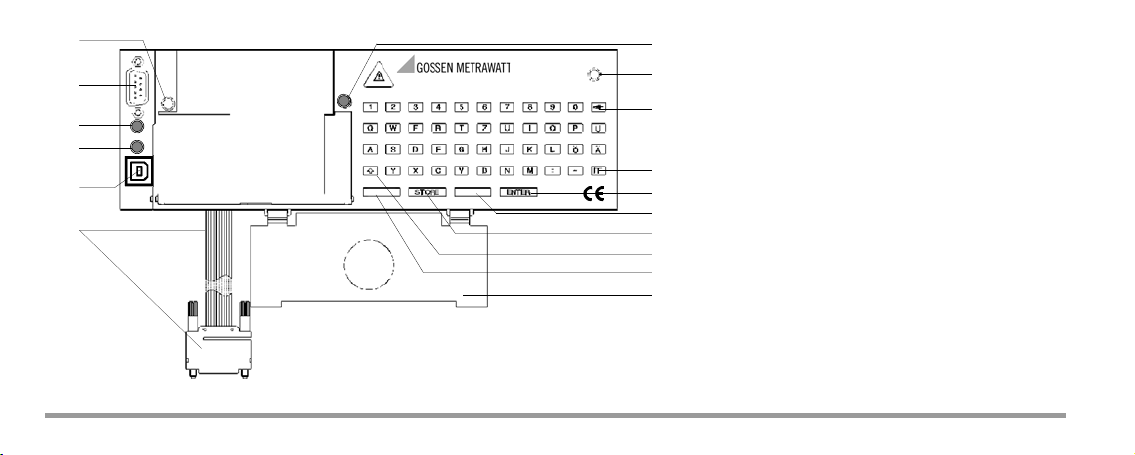

Ribbon cable with RS232 plug for connection of the SI module to the tester

2 USB socket connector for the transmission of stored data to the PC

LED signal lights up green when USB interface is active

3

provided the USB device driver has been installed to the connected PC

4

LED signal lights up green when RS232 interface is active

5 RS232 connection socket for PC, barcode reader or RFID scanner

6 Knurled screw

Signal LED, lights up briefly when connected with the test instrument and remains

7

deactivated afterwards

8 Clear key to delete single characters or

complete lines in connection with the shift key

Shift key to shift the keyboard from small letters to capital letters and vice versa

12

Key shifts to full stop ( . )

Key shifts to underline ( _ )

13 Key to activate the SI module

14 Flap to fix the probe lead in the lid of the SECUTEST...

Combined keyboard instructions for report entry

(only for SECUTEST... test instrument)

Deletes the line on which the cursor is positioned.

All text entries are deleted,

provided the cursor is positioned in an active text entry section

9 Enter key to conclude the entry and go to the next entry prompt

10 Space key to enter spaces

11 Storage key to store the last test report

+ The report stored last is deleted,

provided no SI module window is active.

+ A reset is done, the SI module is initialized, all stored data are

deleted!

This is only possible in the

GMC-I Messtechnik GmbH 3

Setup

menu under

Clear memory

.

Page 4

Contents Page Page

1 Applications .................................................................................6

1.1 Application SECUTEST... ..............................................................................6

1.2 Application PROFITEST 204 and METRISO 5000 D-PI ....................................7

1.3 Meaning of the Symbols on the Unit .............................................................7

5 How to Display and Store Reports .............................................12

5.1 How to Display Reports, Enter and Store Texts ............................................ 12

5.2 Automatic Report Storage ......................................................................... 14

5.3 Quick Report Storage ................................................................................ 15

5.4 Requesting Stored Reports ........................................................................ 16

2 Safety Features and Safety Precautions .....................................8

6 Statistics ....................................................................................17

3 Getting Started ............................................................................9

3.1 Installing the SI Module ................................................................................9

3.2 Activating the SI Module ..............................................................................9

6.1 Getting Started for Statistics Recording ......................................................17

6.2 View Statistic Data .................................................................................... 18

6.3 Delete Statistic Data ................................................................................. 19

4 Presettings ................................................................................10

4.1 Setting the Clock .......................................................................................10

4.2 Enter and Delete Top and Bottom Lines ......................................................11

4.3 Clear Memory ...........................................................................................11

7 Operation with Barcode Reader .................................................20

7.1 Connecting the Barcode Reader ................................................................ 20

7.2 Configuring the Barcode Reader ................................................................ 20

8 Data exchange with a PC ...........................................................21

4 GMC-I Messtechnik GmbH

Page 5

Contents Page Page

9 Error Message ........................................................................... 21

10 Technical Data ........................................................................... 22

11 Maintenance .............................................................................. 25

11.1 How to Reset the SI Module ...................................................................... 25

11.2 Housing ................................................................................................... 25

11.3 Device Return and Environmentally Compatible Disposal ............................. 25

12 Repair and Replacement Parts Service ..................................... 26

13 Product Support ........................................................................ 26

GMC-I Messtechnik GmbH 5

Page 6

1 Applications

Note

Note

The SI (Storage Interface) module SECUTEST SI+ is a special accessory

for the the following test instruments:

SECUTEST..., SECULIFE ST, PROFITEST 204 and METRISO 5000 D-PI.

It is installed in the lid of the tester and fastened with two knurled screws.

The test results determined with the test instrument are directly transferred to the SI module via the ribbon line.

1.1 Application SECUTEST...

All measured values for approximately 300 reports (amount of one working day) can be stored in this memory.

Via a serial RS232 port or an USB interface, the stored measured values

can be transferred from the SECUTEST SI+ to the PC, archived and pro-

cessed there with our software packages (e.g. for the preparation of

invoices), or printed directly into a pre-made form.

6 GMC-I Messtechnik GmbH

Transmission of the data from the memory of the SI module to the

PC via the RS232 or USB interface is only possible when the SI

module is connected to the test instrument.

Data transmission from the memory of the SI module to the PC

via USB interface is only possible if you have installed the

required device driver to your PC via the Driver Control software.

Page 7

USB Device Driver

!

The Driver Control software for installing the USB device driver including

the operating instructions are available for download from our website

http://www.gossenmetrawatt.com

Products Software Software for Testers

Utilities Driver Control

Free of Charge Starter Programs

An overview of the up-to-date report generating software with and without database for testers (free starter programs and demo software for

data management, report and list generation) is provided on our website.

These programs can be downloaded either directly or after registration.

http://www.gossenmetrawatt.com

Products Software Software for Testers

GMC-I Messtechnik GmbH 7

1.2 Application PROFITEST 204 and METRISO 5000 D-PI

Operation with these test instruments is limited to the function „Entry of

comments via the alphanumeric keyboard.“ Only the following chapters

are relevant in this context:

chap. 2 Safety Features and Safety Precautions

chap. 3.1 Installing the SI Module

chap. 10 Technical Data (without memory function)

chap. 11, 12 and 13 Maintenance and Addresses

1.3 Meaning of the Symbols on the Unit

Warnung concerning a point of danger

(Attention: observe documentation!)

indicates EC conformity

This device may not be disposed of with the trash. Further information

regarding the WEEE mark can be accessed on the

www.gossenmetrawatt.com by entering the search term WEEE.

Internet at

Page 8

2 Safety Features and Safety Precautions

!

!

When the SECUTEST SI+ is properly used, the safety of both the user and

the unit is assured.

In order to meet the legal regulations for electromagnetic compatibility

(EMC), an electrically conductive plastic material is used for the housing for

shielding. Touching of the SI module under normal operation causes no danger as contact-hazardous voltages do not occur in the

Attention!

The housing of the SI module has electrically conductive characteristics that are similar to those of metal. It must not come

into connection with live parts.

Read the operating instructions carefully and completely before you use your unit

and follow them in all respects.

8 GMC-I Messtechnik GmbH

SECU

TEST SI+

.

Data Backup (only instruments of the SECUTEST... series)

The measurement, report and entry data can be safely stored in the

RAM of the SECUTEST SI+ storage module.

We advise you to regularly transmit your stored data to a PC in order to

prevent potential loss of data in the storage module.

We assume no liability for any data loss.

For data processing and management we recommend our software

packages, see page 7.

Page 9

!

MENU

0

3 Getting Started

3.1 Installing the SI Module

➭ SECUTEST... only: Remove the cover from the lid of the SECUTEST.... For

this purpose, press the cover to the side.

➭ Insert the SI module into the lid and fasten it with the two knurled re-

taining screws.

➭ Connect the module to the connection socket of the RS232 interface

of the test instrument via the ribbon cable.

➭ SECUTEST... only: Below the SI module there is a compartment provided

in the lid for the storage of the probe lead. Lock the flap inserted in the

module on the hinge of the lid so that the probe lead will not fall out

when the lid is closed.

3.2 Activating the SI Module

To activate the SI module, a connection to the RS232 interface of the

SECUTEST... must be established and the test instrument must be connected to the mains.

GMC-I Messtechnik GmbH 9

Initial Start-up – Clear memory

For initial start-up, the memory should be completely cleared by means

of a reset:

➭ Activate the menu function by pressing .

➭ Select the Setup menu and then the menu Clear memory.

➭ Press + simultaneously.

➭ Reset date and time after initialization.

Attention!

As long as the signal lamp lights up at the SI module, a synchronization between the test instrument and the SI module is

being performed during which no test data may be imported

from the SI module. Do not press any key at the test instrument.

Page 10

Request menu

MENU

10%

Press 1x

4 Presettings

Upon selection of the menu item „Setup“

you can perform the following settings:

Selection and execution of the functions listed

in the menu is done by means of the corresponding keys on the test instrument.

The other operating controls and connectors

should remain unchanged while the SI module

is active so that the data traffic will not be disturbed.

The menu item "Return" causes a return to the LC display presented

prior to activating the SI module.

The display shows that 10 % of the storage capacity are already

occupied. When 99% of the memory are filled, the data should be trans-

4.1 Setting the Clock

Note:

Please ensure that the same date and time are

set in the connected test instrument.

mitted to a PC and stored there. Subsequently, the existing data must

be deleted before new data can be stored to memory. Otherwise, the

messages „Memory full“ and „Clear memory in setup“ appear.

10 GMC-I Messtechnik GmbH

Page 11

4.2 Enter and Delete Top and Bottom Lines

Note

ENTER

ENTER

0

➭ You will get to the next line by pressing the key

➭ You can delete the top and bottom lines with the and keys

4.3 Clear Memory

To clear the memory, press the key

on the SI module.

From the keyboard, you can enter optional texts which – before and/or

after the test result – are to be automatically included in the report printout. For top and bottom lines, 5 lines of 24 characters each are available.

The top and bottom lines are the same for all test results in the memory.

Enter the texts via the keyboard.

Data entry is also possible via barcode reader (see chapter 7, page 20).

GMC-I Messtechnik GmbH 11

To stop, press the key on the SECUTEST....

With the „Clear memory“ function, text information that has

been entered consisting of headline and bottom line, device

type, manufacturer, prototype as well as details on customer,

repair work and statistics are preserved. These data can only

be deleted by performing a reset ( + ).

Page 12

5 How to Display and Store Reports

Note

STORE

MENU

The test report automatically contains the test result including the measured and limit values as well as information on the visual inspection.

Storage of the results of the safety and function tests as well as their

entry into reports and statistics is only possible after tests have been

performed.

Exception: the function switch is in the „MENUE“ position (older

versions: also „FUNCTION-TEST“). In this position only the

result of the last function test can be stored.

You can load the result of the last test into the SI module and store it

there under an Ident Number. The report of the last test can be printed

out several times.

The results of a complete working day (approximately 300 reports) can

be stored in the memory of the SI module. Pressing the key

several times makes for the same data record to be overwritten again

and again.

12 GMC-I Messtechnik GmbH

Further specific information on device under test, customer and repair

can be integrated in the test report by entries via the keyboard or a barcode reader (see chapter 7, page 20).

The report is presented on the LCD in several windows.

5.1 How to Display Reports, Enter and Store Texts

➭ Request the SI menu via the key

➭ Select Protocol and confirm with

First, the test result including measured and

limit values is shown. The display contains

available data only.

In further windows that can be selected with the

and keys, you can display information on the

visual inspection as well as enter texts via the keyboard, and barcodes via the barcode reader (see

chapter 7, page 20). A maximum of 24 characters

can be entered into one line.

Page 13

End the text entry of a line by pressing the

ENTER

STORE

key. At the same time, this brings you

to the next line.

➭ To store, press the key.

returns you to the SI menu.

When storing the report, the consecutive ident

number is output between date and time.

Figure at left:

Info on DUT

max. 24 charact. each

Figure at right:

Info on customer

max. 24 charact. each

Results of the function test

Information on

e.g. repair

max. 10 lines

of max.

24 characters each

GMC-I Messtechnik GmbH 13

Page 14

If there are no data available in the test instrument when the menu item Protocol is called up,

the following message appears:

➭ SECUTEST... test instrument:

Select the desired test at the function selector switch of the test instrument.

➭ older versions SECUTEST 0701/0702S:

Set the function selector switch of the test instrument to the MENUE

position.

➭ Move the cursor to Setup and confirm with .

➭ Move the cursor to Configureand confirm with .

5.2 Automatic Report Storage

➭

Move the cursor to

Autostore

: activate or deactivate the function with .

All test results are automatically allocated a consecutive ident number*

provided the Autostore function is active. After the safety test as well as

after the function test, a note is displayed indicating that the test data are

being stored.

When the SI module is deactivated, proceed as follows to activate the

Autostore function in the test instrument:

* It consists of max. 24 digits. Counting starts with the first four digits in

each case, beginning with 0000.

14 GMC-I Messtechnik GmbH

Page 15

Note

STORE

ENTER

STORE

5.3 Quick Report Storage

If many measurements are to be made successively and the results are

to be evaluated later, the function "Quick report storage" presents itself.

This function can only be performed after a test (safety test and/or function test).

If a reset has been made accidentally after the test, e.g. by

changing the position of the function switch or pulling the interface cable off, the ident number must again be entered in the

report. The data are preserved.

➭ Activate the SI module with .

This brings you directly to the enter field for

the ident number. Here you can enter a

maximum of 24 digits and confirm with

.

➭ To store, press the key once more.

The report is stored in the data base of the SI

module together with all available data. Empty

data fields are ignored. At the same time you

return to measuring mode to immediately start

the next measurement.

GMC-I Messtechnik GmbH 15

Page 16

5.4 Requesting Stored Reports

i

A list of all stored reports can be requested at any time in order to display

and print out the contents of individual reports at a later date. The first

column contains the consecutive numbers, the second one the ident

numbers. The first 14 characters of the ident number are shown as a

maximum.

➭ Choose Protocol and confirm with .

➭ Press the help key i on the SECUTEST....

A list of the stored reports appears.

➭ Select the desired report using the and keys and confirm

with .

A maximum of 10 stored reports is displayed. The next 10 reports are

selected by browsing through with the cursor.

In the presentation of the archived report, an on the right-hand side of

the first bottom line informs you that the measured data have been

stored under a consecutive number and consequently no more data can

be entered.

16 GMC-I Messtechnik GmbH

Page 17

6 Statistics

Altogether, statistic data of a maximum of eight equipment classes can

be recorded. The statistic data include the number of the errors occurred

as well as their percentage of the total measurement within one class.

The statistics menu appears provided Statistics has been selected in the

main menu, see chapter 3.2, page 9.

6.1 Getting Started for Statistics Recording

Where statistic data are to be recorded, the associated class designation

must be defined prior to a measurement by selection of Class. If a class

name is already entered, it must be activated.

➭ Move the cursor to Class and , set menu is displayed.

➭ Move the cursor to the respective class name and ,

an underline appears at the end of the text.

➭ If you want another class name: delete existing characters with ,

or complete lines with

and enter a maximum of eight charac-

ters via the alphanumeric keyboard.

➭ Confirm with , the cursor moves to the error column.

➭ Determine with or whether only the first or all errors are to be

considered. Confirm with . A lightning symbol appears behind the

activated class name.

➭ Repeat Return until the SI LCD no longer appears.

GMC-I Messtechnik GmbH 17

Page 18

The safety tests as well as the function tests can now be performed for

the selected class.

After the start of a report recording, the setting First or All in the statistics

menu can no longer be changed.

After each complete measurement, consting of safety test and function

test, the measured data must be stored so that they will be available for

statistic evaluation. See „How to Display and Store Reports“ on page 12.

If, after the measurement, First or All is followed by a symbol, statistic

6.2 View Statistic Data

Select the Statistics menu to request statistic data:

➭ With or move the cursor to Display and confirm with , View

menu is shown.

➭ Select the class the statistic data of which you wish to see, confirm

with . The statistic data of the selected class are listed.

Moreover, in this mode you can browse through the statistic data of all

classes with the or keys.

data have been stored for the respective class.

All following measurements expand the statistics of the class activated at

the time by the additional measured results. If new statistic data are to

be recorded for an existing class, the stored statistic data can be

deleted, see chap. 6.3 Delete Statistic Data.

18 GMC-I Messtechnik GmbH

Page 19

6.3 Delete Statistic Data

➭ With or , move the cursor to Delete and press .

➭ Select the class the data of which is to be deleted

or

➭ Select Delete: all to delete the stored statistic data of all classes!

After all classes are deleted, class A is set active and the error type of

each class is set to First.

GMC-I Messtechnik GmbH 19

Page 20

7 Operation with Barcode Reader

The barcode reader Z720A (as accessory) allows for all information available in barcode form to be quickly, easily and safely entered into the test

reports. This type of data entry permits time-saving and low-cost acquisition of large amounts of information, e.g. for series measurements of

devices provided with barcodes.

7.2 Configuring the Barcode Reader

The barcode reader Z720A is configured for the following barcodes:

CODE 39 / CODE 128 / EAN13 (12 digits) *

The barcode reader is immediately ready for operation when connected

to a SECUTEST... or SECUTEST SI+ test instrument.

7.1 Connecting the Barcode Reader

➭ Connect the reader to the RS232 interface of the SI module.

An SI LCD window must not be active!

The barcode reader confirms the correct connection with a double

For operation with PROFITEST 204, the barcode reader has to be configured with the code indicated in the operating instructions of the barcode reader adapter. For these test instruments, only Code 128 is possible.

acoustic signal.

If you wish to use other codes for the SECUTEST..., please consult our

Product Support Hotline, see chapter 13, page 26

* Z720A has the appropriate scanning width to be programmed to the EAN 128

barcode.

20 GMC-I Messtechnik GmbH

Page 21

8 Data exchange with a PC

STORE

Transmission of the data to the PC is only possible when the SI module is

connected to the test instrument, which, in turn is connected to the

mains.

➭ Connect the PC to the RS232 connection socket of the SI module via

an interface cable.

9 Error Message

Message when the key has been

pressed although there is no free memory.

GMC-I Messtechnik GmbH 21

Page 22

10 Technical Data

Note

Connection elements

Fasteners on test instrument

2 knurled screws for fastening in the lid of

Data Memory

RAM (data) 100 kbytes

Real-time clock with date battery-backed by embedded Lithium cell

the test instrument; transmission of measured data and power supply via ribbon

cable and 9-pin D-SUB connector, to be

connected to the RS232 interface of the

test instrument

Interfaces RS232, bidirectional, 9-pin D-SUB socket,

e.g. for connection to a PC or a barcode

reader, or RFID Scanner

USB, 4 pin USB1.1 type B,

for connection to a PC

(only for transmission of measured data)

RS232 Interface

Type RS232, serial, per DIN 19241

Operating voltage

6.5 V ... 12 V for connection to test instrument

Current consumption 40 mA typical

Baud rate 9600 bauds

Parity none

Data bits 8

Stop bit 1

A comprehensive description of the interface protocole can be

downloaded from our website www.gossenmetrawatt.com.

Assignment of the Interfaces: see following page

22 GMC-I Messtechnik GmbH

Page 23

The 9-pin D-SUB connector for connection of the SI module to the

1: Enable remote control „Plus“

2: RXD

3: TXD

4: NC

5: GROUND

6: Enable remote contr. "GROUND"

7: NC

8: NC

9: +9 V

9876

54

3

21

1: NC

2: TXD

3: RXD

4: Switching input

5: GROUND

6: +5 V

7: CTS

8: RTS

9: NC

6789

12

3

45

SECUTEST 0701S tester has the following pin assignment:

USB Interface

Ty pe

USB 1.1

Operating voltage 5 V DC 10 % from the RS232 interface of

the test instrument

Current consumption 40 mA typical

Baud rate 9600 bauds

Parity none

Data bits 8

The 9-pin D-SUB connection socket for connection to PC, barcode reader,

etc., has the following pin assignment:

GMC-I Messtechnik GmbH 23

Stop bit 1

Terminal assignment Type B 4 pin,

1: VCC, 2: D–, 3: D+, 4: GND

Page 24

Reference Conditions

Operating voltage for

connection to test instrument

9V 0.5 V DC or 8 V 0.5 V rectified

Ambient temperature +23

Relative humidity 40

C 2K

60 %

Electromagnetic Compatibility (EMC)

Interference emission EN 61326-1:2013 class B

Interference immunity EN 61326-1:2013

Mechanical Design

Ambient Conditions

Operating temperature 0

Storage temperature

C ... +40 C

20 C ... +60 C

Humidity max. 75 % RH; no condensation

24 GMC-I Messtechnik GmbH

Protection type IP 20 for the housing

Dimensions 240 mm x 81 mm x 40 mm

(without knurled screws and ribbon cable)

Weight approx. 0.4 kg

Page 25

11 Maintenance

0

Pb Cd Hg

11.1 How to Reset the SI Module

Should the SI module no longer react, e.g. due to incorrect operation, it

must be initialized:

➭ Pull the line plug of the test instrument and restart it. Stored data are

preserved

or

➭ If stored data are to be deleted at the same time:

Select the Setup menu and then the menu item Clear memory.

Press + simultaneously.

Check the preset time after a reset!

11.2 Housing

No special maintenance is required for the housing. Keep outside surfaces clean. Use a slightly dampened cloth for cleaning. Avoid the use of

cleansers, abrasives or solvents.

11.3 Device Return and Environmentally Compatible Disposal

The instrument is a category 9 product (monitoring and control instrument) in accordance with ElektroG (German Electrical and Electronic

Device Law). This device is subject to the RoHS directive.

We identify our electrical and electronic devices in accordance

with WEEE 2012/19/EU and ElektroG with the symbol shown to

the right per DIN EN 50419. These devices may not be disposed with the trash. Please contact our service department regarding

the return of old devices, address see chap. 12.

If you use batteries or rechargeable batteries in your instrument or

accessories which no longer function properly, they must be duly disposed of in compliance with the applicable national regulations.

Batteries or rechargeable batteries may contain harmful substances or

heavy metal such as lead (PB), cadmium (CD) or mercury (Hg).

They symbol shown to the right indicates that batteries or

rechargeable batteries may not be disposed of with the trash,

but must be delivered to collection points specially provided for

this purpose.

GMC-I Messtechnik GmbH 25

Page 26

12 Repair and Replacement Parts Service

When you need service, please contact:

GMC-I Service GmbH

Service Center

Thomas-Mann-Straße 20

90471 Nürnberg • Germany

Phone +49 911 817718-0

Fax +49 911 817718-253

E-Mail service@gossenmetrawatt.com

www.gmci-service.com

This address is only valid in Germany. Please contact our representatives

or subsidiaries for service in other countries.

Edited in Germany Subject to change without notice A pdf version is available on the internet

13 Product Support

When you need support, please contact:

GMC-I Messtechnik GmbH

Product Support Hotline

Phone +49 911 8602-0

Fax +49 911 8602-709

E-Mail support@gossenmetrawatt.com

GMC-I Messtechnik GmbH

Südwestpark 15

90449 Nürnberg •

Germany

Phone +49 911 8602-111

Fax +49 911 8602-777

E-Mail info@gossenmetrawatt.com

www.gossenmetrawatt.com

Loading...

Loading...