Page 1

3-349-887-03

1/1.17

SECUTEST CLIP and PROFITEST CLIP

Leakage Current Clamp Meters for SECUTEST PRO and PROFITEST PRIME

Page 2

GMC-I Messtechnik GmbH

Notes Regarding these Operating Instructions

Texts, illustrations and technical specifications have been prepared with great

care. Errors can nevertheless not be entirely ruled out. The manufacturer of the

leakage current clamp meter cannot accept any legal responsibility or liability for

incorrect entries and their consequences!

Read these operating instructions carefully and co m pletely before using the

leakage current clamp meter!

Warnings and warning symbols in the operating instructions and on the leakage

current clamp meter are intended to alert the user to risks and hazards!

2

Page 3

GMC-I Messtechnik GmbH

Warnings and Safety Precautions

Read these operating instructions carefully and co m pletely before using the

necessary for safe operation and use of the leakage current clamp meter.

The SECUTEST CLIP / PROFITEST CLIP leakage current clamp meter has been

directives.

Safety of the operator, as well as that of the leakage current clamp meter, is only

assured when the device is used for its intended purpose.

The SECUTEST CLIP / PROFITEST CLIP leakage current clamp meter may only be

intended purpose (see also section 2, “Terminology” )!

leakage current clamp meter! They contain information and instructions which are

manufactured and tested in accordance with safety regulations

IEC 61557-13/-16, IEC 61010-1 and IEC 61010-2-032.

The CE conformity marking confirms com pliance with the EMC and low-voltage

used by electricians, other qualified persons or accordingly trained persons for its

3

Page 4

GMC-I Messtechnik GmbH

The following symbols draw the operator’s atte ntion to importa nt information and

instructions which are necessary for safe operation and use of the leakage current

clamp meter.

This symbol is used in the operating instructions in particular to

injury!

This symbol is used in the operating instructions and on the

uninsulated conductors.

This symbol is used in the operating instructions and on the

leakage current clamp meter in order to warn against incorrect

operation!

warn against risks and hazards associated with incorrect

operation!

Disregarding this warning symbol may result in severe or fatal

leakage current clamp meter in particular to warn against risks

and hazards associated with incorrect operation! Disregarding

this warning symbol may result in severe or fatal injury. During

use for its intended purpose, in consideration of the measuring

category, the leakage current clamp meter must not enclose any

4

Page 5

GMC-I Messtechnik GmbH

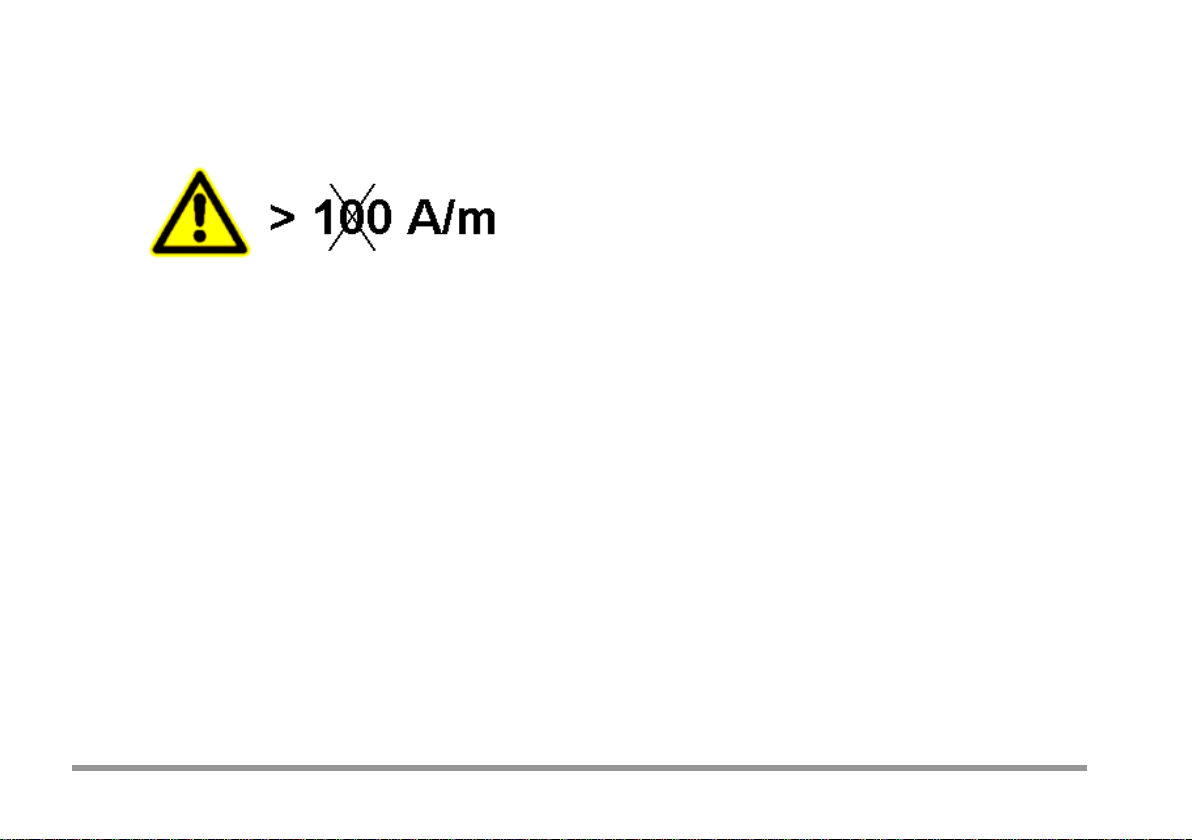

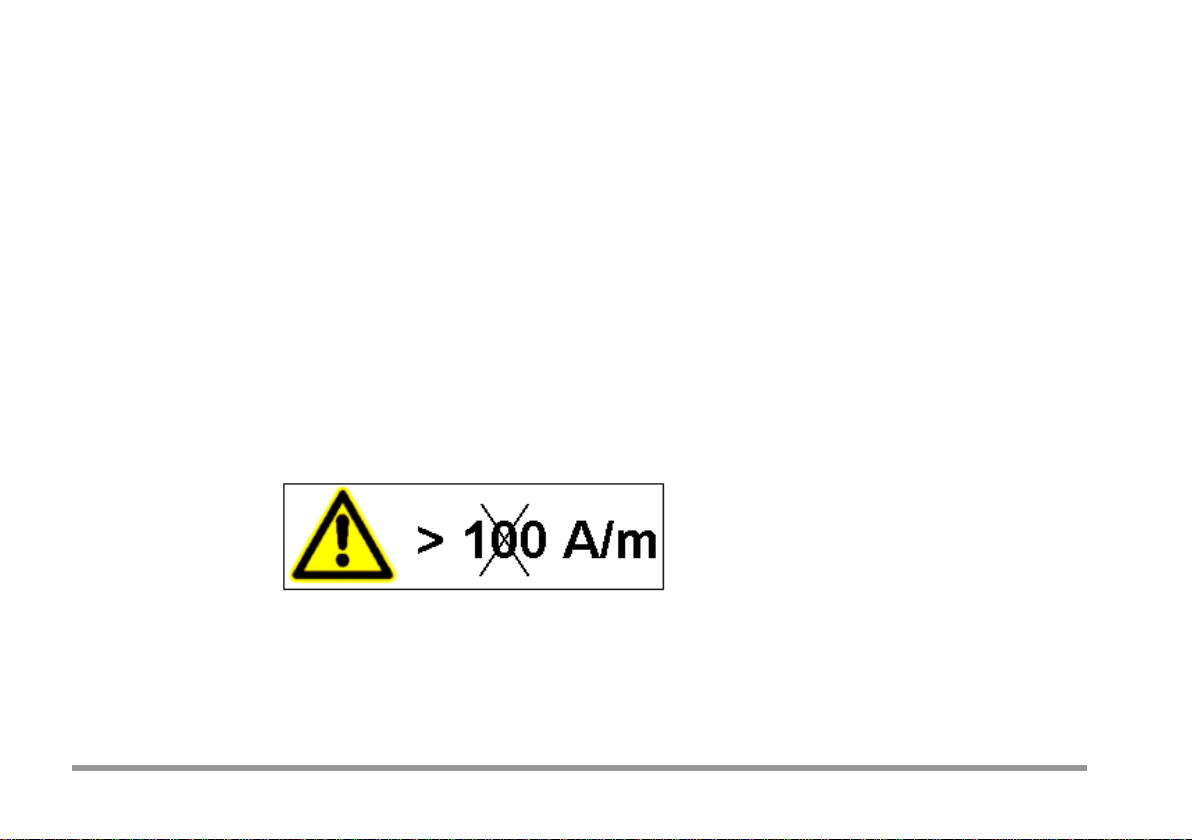

This warning symbol on the leakage

current clamp meter makes reference to

class 1.

sensitivity to external magnetic fields.

The field strength of the interfering

magnetic field may not exceed a value

of 100 A/m, which corresponds to use

5

Page 6

GMC-I Messtechnik GmbH

Opening the Instrument / Repairs

The instrument may only be opened by authorized, trained personnel in order to ensure

flawless operation and to assure that the guarantee is not rendered null and void.

Even original replacement parts may only be installed by authorized, trained personnel.

If it can be ascertaine d that t he instrument has bee n opened by unauthorized personnel, no

guarantee claims can be honored by the manufacturer with regard to personal safety,

measuring accuracy, compliance with applicable safety measures or any consequential

damages.

6

Page 7

GMC-I Messtechnik GmbH

Table of Contents

1

Applications ...................................................................................................................................... 8

2

Terminology ...................................................................................................................................... 8

3

Operation ......................................................................................................................................... 25

4

Connection Example s .................................................................................................................... 33

5

Calibration ....................................................................................................................................... 36

6

Care and M aintenance .................................................................................................................... 36

7

Guarantee ........................................................................................................................................ 37

8

Return and Environment al ly Sound Di spos al .............................................................................. 38

9

Technical Data ................................................................................................................................ 39

10 Product Support ............................................................................................................................. 44

11 Repair and Replacement Parts Service, Calibration Center and Rental Instrument Service .. 45

7

Page 8

GMC-I Messtechnik GmbH

1 Applications

When used for its intended purpose, the leakage current clamp

up to 600 V, e.g. at operating equipment.

Leakage Current Clamp Meter

A leakage current clamp meter is a current probe for the

1):2011, appendix A.

meter makes it possible to measure alternating current from 0.1 to

25 mA without interrupting any lines by closing the clamp around

one or more conductors in measuring category III electrical circuits

with up to 300 V between the phase conductor and gro und, e.g. in

build ing inst allations, or measuring category II electrical circuits with

2 Terminology

measurement of leakage current without interrupting the current

path of the measuring circuit. The meter must make it possible to

measure leakage current by means of the direct measuring method

or the differential current method.

The measurement results read out by the leakage current clamp

8

meter must take frequency response of test circuit A1 into

consideration in accordance with DIN EN 61010-1 (VDE 0411-

Page 9

GMC-I Messtechnik GmbH

Evaluation of frequency response is alrea d y taken into account by

the leakage current clamp meter.

Jaws

The components of the leakage current clamp meter which

enclose the conductor (see figure 3, item 1).

Yoke

The part of the leakage current clamp meter which is placed

field (see figure 3, item 2).

Use for Intended Purpose

The use for which the device is suitable in accordance with the

against operating the device under othe r than normal conditions.

around the conductor to be measured and detects the magnetic

manufacturer’s specifications (i.e. operating instructions).

Use for intended purpose also includes compliance with the

stipulated operating and maintenance conditions, as well as

consideration of foreseeable operating errors.

As a rule, normal conditions are a prerequisite for use for

intended purpose because the operating instructions warn

9

Page 10

GMC-I Messtechnik GmbH

Measuring Uncertainty

Measuring uncertainty is the specified difference between the

value displayed by the measuring instrument (measured va lue)

measured quantity in the operating range.

Intrinsic Uncertainty

Measuring error of a measuring instrument during operation

Electromagnetic Compatibility

All electrical currents generate electromagnetic fields which can

which also includes other equipment.

or the magnitude of the output signal and the actual value of the

under reference conditions.

cause current to f lo w in other electrical conductors, thus

resulting in interference. The European EMC directive for

electromagnetic compatibility (EN 61326-1) has been

implemented in order to avoid this interference or reduce it to an

absolute minimum.

Electromagnetic compatibility is the ability of a piece of electrical

equipment to function satisfactorily in its electromagnetic

environment without impermissibly influencing this environment,

10

Page 11

GMC-I Messtechnik GmbH

Stray Field Sensitivity

Influence error caused by a stray magnetic field which

determines the use class (DIN EN 60051-9).

Use Classes

Current probes are subdivided into 3 use classes based on

magnetic fields.

Strength of up to 100 A/m per Use Class 1

sensitivity to low-frequency magnetic fields with frequencies

ranging from 15 to 400 Hz. Current probes of all classes must be

furnished with a framed pictograph (see figure 1) which is plainly

visible to the operator, includes the corresponding symbol in

accordance with DIN EN 61010-1 (VDE 0411-1):2011 and warms

against exceeding the permissible limit value for external

Figure 1: Warning Symbol for Maximum Permissible Field

11

Page 12

GMC-I Messtechnik GmbH

Use Class 1

Use class 1 current probes must be suitable for use in external

low-frequency magnetic fields, in particular within a frequency

Use Class 2

Use class 2 current probes must be suitable for use in external

Use Class 3

Use class 3 current probes must be suitable for use in external

curren t cla m p meter by me a ns o f a pla inly vis ib l e warning s y m bo l.

range of 15 to 400 Hz, up to a field strength of 100 A/m. The

limit value for the magnetic field must be indicated on the

leakage current clamp meter by means of a plainly visible

warning symbol.

low-frequency magnetic fields, in particular within a frequency

range of 15 to 400 Hz, up to a field strength of 30 A/m. The limit

value for the magnetic field must be indicated on the leakage

current clamp meter by means of a plainly visible warning

symbol.

low-frequenc y ma g ne t ic f ie ld s , in par t ic ula r within a frequency

range of 15 to 400 Hz, up to a field strength of 10 A/m. The lim it

value for the magnetic field must be indicated on the leakage

12

Page 13

GMC-I Messtechnik GmbH

Electrician / Qualified Person / Trained Person

Only competent persons may use and conduct measurements

with leakage current clamp meters. In this sense, qualified

Electricians

An electrician is a person with suitable technical t raining,

01,

Qualified Persons

A qualified person is someone who posses the technical knowledge

Electrically Trained Persons

An electrically trained person is someone who has been

826-09-02, modified].

persons include:

knowledge and experience which makes it possible to recognize

and avoid the hazards associated with electricity [IEV 826-09modified].

required for testing equipment as a result of vocational training,

work experience and recent vocational activity [German

Occupational Safety Law (BetrSichV)]. Qualified persons are not

subject to any technical directives during the course of their

testing work and may not be disadvantaged by them.

adequately trained by a electric ian, thu s making it possible to

recognize and avoid the hazards associated with electricity [IEV

13

Page 14

GMC-I Messtechnik GmbH

Field Strength

Field strength designates the strength of and electrical,

Electrical Field Strength

The symbol for electrical field strength is E and its unit of

magnetic or other spatially distributed field at a specified point

in space. Field strength is frequently a vector and is calculated

on the basis of direction and magnitude. Well-known fields

include the

electrical field and the magnetic field.

measure is volts per meter (V/m). It increases along with

voltage U (V) between the charged bodies, and as distance L

(m) between the charged bodies is reduced.

E = U/L [V/m]

14

Page 15

GMC-I Messtechnik GmbH

Frequency Characteristics of the Human Body

Measuring setup for direct current and sinusoidal alternating

frequency range (below 1000 Hz).

current in accordance with IEC 61010-1, appendix A. This

measuring circuit (low-pass) prevents the measurement of

leakage current in the high-frequency range (as of roughly

1000 Hz). People react especia lly sensitively to the low-

15

Page 16

GMC-I Messtechnik GmbH

Calibration/Adjustment

What is calibration?

Calibration involves the determination of deviation of the

measuring instrument’s measured value / measurement signal

from the correct value of the measured quantity. An object with

known values (a so-called

standard) is measured by the device to

this end and deviation of the measured value / measurement

signal f r o m the known value is ascertained. The results and the

associated measuring uncertainty are documented in a ca libration

certificate.

No changes (adjustments) are made to the measuring equipment

during calibra t io n .

And thus calibration is simply the determination of the measured

value’s / measurement signal’s deviation from the true value.

What’s the purpose of calibration at regular intervals?

- It’s a requirement per DIN EN ISO 9000 ff.

- It prevents hazards due to incorrect measurement results.

- It assures reproducible measurement.

- It facilitates the acceptance of test reports and

measurement results.

16

Page 17

GMC-I Messtechnik GmbH

What is adjustment?

correc t v a lue . As a rule, ad ju s t ment is fo llowed by ca lib r a t ion.

Magnetic Field Strength

Every electrical current generates a magnetic field.

Measuring Categories

Measuring current circuits are subject to loading due to the

operating voltages and transient loads (overvoltage) in the circuits

In the field of measuring technology, adjustment involves

configuring or balancing a piece of measuring equipment

(measuring instrument, measuring adapter e tc.) such that the

measured or displayed value deviates as little as po ssible fr om the

The greater the amperage, the larger the magnetic field.

The symbol for magnetic field strength is H and its

measure is amperes per meter (A/m). Where magnetomotive

force (θ) remains unchanged, field strength increases as field line

length L (m) is reduced.

H = θ/L [A/m]

unit of

17

Page 18

GMC-I Messtechnik GmbH

to which they are connected. If the measuring curre nt circuit is

used to conduct a measurement at the mains, the transient loads

Figure 2: Measuring Categories

can be assessed via the location within the installation at w hich

the measurement is conducted. If the measuring current circuit is

used to measure any other signal, the transient loads must be

taken into consideration by the user such that they don’t exceed

the cap a b il ities and limitatio n s o f t h e me as u ring instr u m ent.

Electr ical circuits are s u bd iv id e d in t o t h e fo llo w ing measuring

categories: CAT I, CAT II, CAT III and CAT IV. The measuring

instrument may only be used in the category for which it has been

approved, or any lower categories.

18

Page 19

GMC-I Messtechnik GmbH

Examples:

CAT I:

- Battery powered devices

- Overhead power lines, underground cables

- Devices with electrical circuits which are internally

protected against overvoltage

- Circuits which are isolated from the mains

- Electronic circuits with corresponding power supply

CAT II:

- Household appliances

- Operating equipment

- Switches, lamps, electrical outlets e tc. in buildings

CAT III:

- Meters, control panels, test panels

- Machines

- High power operating equipment

CAT IV:

- Power lines used to feed buildings

19

Page 20

GMC-I Messtechnik GmbH

Measuring Category I (CAT I)

Measuring category I is intended for measurements in electrical

circuits which are not directly connected to the mains. Only

measurements at circuits which do not originate from the mains.

Measuring Category II (CAT II)

Measuring category II is intended for measurements in electrical

portable tools and similar devices.

Measuring Category III (CAT III)

Measuring category III is intended for measurements in building

installa tions. Conside r a ble overv o lt a ge can occur in these circuits.

Measuring Category IV (CAT IV)

Measuring category IV is intended for measurements at power

occur in these circuits.

minimal o vervoltage can occur in these circuits. Examples include

circuits which are directly connected to the low-voltage mains.

Overvoltage can occur in these circuits.

Examples include measurements at household appliances,

sources for low-voltage installations. Very high overvoltage can

20

Page 21

GMC-I Messtechnik GmbH

Reference Conditions

Influencing quantities for whose prese nce the measuring

instrument’s smallest specified or ascertained measuring

uncertainties (measuring error) apply.

Protection

In accordance with IEC 364-5-51 (VDE 0100, part510), the

assured.

Protection against foreign matter and dust

None IP0X

No dust ingress = IP6X

characteristic features of the respective operating equipment

must be determined by means of a protection class or a

conformity test.

Electrical operating equipment must be selected and set up in

consideration of external influences such that its intended

operation and the reliability of the protective measures are

Foreign matter > 50 mm = IP1X

Foreign matter > 12 mm = IP2X

Foreign matter > 2.5 mm = IP3X

Foreign matter > 1 mm = IP4X

No dust deposits = IP5X

21

Page 22

GMC-I Messtechnik GmbH

Protection against moisture

None IPX0

Vertically dripping = IPX1

Continuous submersion ( water pressure-tight) = IPX8

Protection Categories

Options for classifying electrical devices according to type of

connected to an electrical system.

Protection Category I

Devices with a protective conductor. The protective measure

conductor to the protective conductor of the electrical power

Dripping (15° angle) = IPX2

Spraying water = IPX3

Splashing water = IPX4

Water jets = IPX5

Powerful water jets = IPX6

Occasional submersion (water-proof) = IPX7

protective measure against electric shock, which becomes active

for them with priority or can become active after they are

against electric shock is based on connection of the protective

22

Page 23

GMC-I Messtechnik GmbH

supply system. All exposed, conductive par ts are connected to

the protective conductor as a rule. However, if any exposed,

implemented as protective measures against electric shock.

Protection Category II

Devices whose active parts are f u lly enclose d by an in s u la t in g

device ’ s in te rior, in c lud i n g t erminals, solder po st s an d t h e like.

Protection Category III

Devices for which exclusively protective extra-low voltag e is u se d.

conductive parts are not connected to the protective conductor,

doubled/reinforced insulation (protective insulation) or reliable

current limiting between such parts and the active parts must be

sleeve ( insulating b o d y wit h d o u ble or reinforced insulation). This

sleeve (body) ensures protection against electric shock for

persons who touch it.

The body also includes any exposed, conductive parts.

Protection category II devices can also have a connector plug with

earthing contact and a protective conductor in the connector

cable, which nevertheless may not be connected to any part in the

23

Page 24

GMC-I Messtechnik GmbH

Pollution Degree

Pollution involves the accumulation of solid, liquid or gaseous

(ionized gases) foreign matter, which can result in reduced

Pollution Degree 1

No pollution, or strictly dry, non-conductive pollution occurs. This

Pollution Degree 2

Usually only non-conductive pollution occurs. Occasional,

Pollution Degree 3

Conductive pollution accumulates or dry, no n -conductive

sites , in hea vy industry, in maritime applications etc.

dielectric strength or surface resistance. Pollution degrees have

been established for the ascertainment of clearances:

pollution has no impact.

temporary conductivity must nevertheless be reckoned with

which is caused by dew. This pollution degree is applicable in

laboratories, industrial environments etc.

pollution occurs, which becomes conductive due to expected

condensation. Under these conditions dev ices are usually

protected against direct exposure to sunlight, precipitation and

wind pressure, although neither temperature nor humidity are

regulated. This pollution degree is applicable at construction

24

Page 25

GMC-I Messtechnik GmbH

3 Operation

Figure 3

25

Page 26

GMC-I Messtechnik GmbH

1 Jaws (current probe)

2 Yoke

sockets)

3 Safety collar

4 Recessed grip

5 Power LED: lights up when supplied with power from

the interconnected test instrument

6 Handle

7 Serial plate

8 Jaw release button

9 PROFITEST CLIP (Z506H):

Connector plug for connection to supply power from

the PROFITEST PRIME test instrument

10 SECUTEST CLIP (Z745H):

Jack plug for supply power from the SECUTEST PRO or

SECULIFE ST BASE test instrument (service plug

socket)

11 SECUTEST CLIP (Z745H):

Connector plugs (signal output) for connection to the

voltage measurement input at the SECUTEST PRO or

SECULIFE ST BASE test instrument (COM and V

26

Page 27

GMC-I Messtechnik GmbH

Safety Precautions

Warnings and warning symbols on the leakage current clamp meter and in

these operating instructions are intended in particular to alert the user to risks

and hazards! See also section entitled “Warnings and Safety Precautions”!

General Preparation for Meas urement

- The corresponding safety measures for the prevention of electric

- Be aware of any influences caused by stray fields!

shock must be observed!

- The leakage current clamp meter must be intact, clean and dry.

- If the leakage current clamp meter has been subjected to severe

temperature fluctuation which has caused the precipitation of a layer

of moisture , it must be allowed to become sufficiently acclim atized

prior to use!

- It must be possible to close the jaws of the leakage current clamp

meter (see figure 4, item 1) without exerting force. The metal

lamellae (see figure 4, item 2) must not be bent or damaged!

27

Page 28

GMC-I Messtechnik GmbH

- Neither the clamp housing in its entirety nor the connector cables with

plugs may be damaged.

1

Closed jaws of the leakage current clamp meter

2 High-quality, sensitive metal lamellae

Figure 4

28

Page 29

GMC-I Messtechnik GmbH

Connecting the Leakage Current Clamp Meter to a Test Instrument

The leakage current clamp meter must always be connected to the (voltage)

measurement input of a measuring instrument first, before it’s closed around

Checking for Influence from Stray Fields

Before conducting a measurement, possible external influences must first be

checked with connected leakage current c lamp meter, but without enclosing a

a current-carrying conductor!

conductor. The measured value displayed by the measuring instrument must

be less than specified intrinsic uncertainty. If this is not the case , the

measurement must be performed at another location with less powerful

magnetic fields.

Example: Close the leakage current clamp meter around the conductor or

conductors to be measured. Attention: The jaws of the leakage current

clamp meter must be fully closed! Make sure that current is not yet flowing

through the conductor. Normally, no current should be displayed in this state.

29

Page 30

GMC-I Messtechnik GmbH

Enclosing the Conductor(s)

Before leakage current is measured, the conductor(s) must first be enclosed

measuremen ts re su lt.

by the leakage current clamp meter. It’s permissible to enclose the followin g:

PE or L+N (single-phase), or L1+L2+L3+N (3-phase)

The jaw release button (see figure 3, item 7), must be pressed to this end.

Caution!

- The fingers must not extend beyond the recessed grip (see figure 3,

item 4)! Safety clearance to the current-conducting cable is otherwise

not maintained!

- When enclosing the conductor, it must be ensured that conductor is as

close as possible to the middle of the yoke (see figure 3, item 2), and

that the jaws do not pinch any conductors!

- When closing the clamp, the jaws (see figure 4, item 1) must close

without exerting force, because the metal lamellae (see figure 4,

item 2) might otherwise be damaged.

- If the leakage current clamp meter is not fully closed, erroneous

30

Page 31

GMC-I Messtechnik GmbH

- External influences may have an impact on measurement results, thus

also causing erroneous measurements!

- The enclosed conductors should not lie loose ly w ithin the yoke, and

should instead be tightly bound together and/or twisted. Erroneous

measurements may otherwise result.

31

Page 32

GMC-I Messtechnik GmbH

Performing Measurements

If all of the preparations for measurement with the leakage

current clamp meter described in this section have been

properly conducted.

Removing the Leakage Current Clamp Meter

In order to rule out possible hazards, the leakage current clamp

observed and complied with, current measurement can be

meter must always be removed from the current-carrying

conductor(s) first! Only then is it permissible to remove the

leakage current clamp meter’s plug from the measuring

instrument!

32

Page 33

GMC-I Messtechnik GmbH

4 Connection Examples

The operating instructions for the test instruments include

connection examples for the respective leakage current clamp

meters.

Transformation Ratio

When using the SECUTEST CLIP / PROFITEST CLIP, the

transformation ratio parameter at the test instrument must be

set to 100:1 or 100 mV:1 mA, or to AT3 adapter.

General connection examples for differential current

measurement and for direct measure me n t are shown on the

following pages.

33

Page 34

GMC-I Messtechnik GmbH

Figure 5: Differential Current Measuring Method

Parallel ground connections have no effect

on the measurement results.

34

Page 35

GMC-I Messtechnik GmbH

Figure 6: Direct Measuring Method

The device under test is insulated and must not

have any parallel ground connections!

35

Page 36

GMC-I Messtechnik GmbH

5 Calibration

The leakage current clamp meter must be calibrated at regular

The leakage current clamp meter does not require any special

metal lamellae with h ard tools!

intervals by the manufacturer or a service center authorized by

the manufacturer. Annual calibration is recommended. If the

device is handled carefully, is used only infrequently and is

subjected to periodic testing at regular intervals, a qualified

electrician can stipulate a calibration interval of up to three years

on his or her own author ity .

6 Care and Maintenance

36

maintenance.

It may only be cleaned when disconnected!

Caution!

- In exceptional cases, the sensitive metal lamellae in the

jaws of the leakage current clamp meter can be carefully

cleaned with a fine, soft, dry brush. Never touch the

Page 37

GMC-I Messtechnik GmbH

- Do not use harsh cleansers or solvents for cleaning!

operation!

The manufacturer guarantees error-free materials and

operating and storage conditions.

- The leakage current clamp meter may only be used and

stored in dry condition!

- The leakage current clamp meter must be carefully

checked before each use in order to assure safe

7 Guarantee

workmanship of the SECUTEST CLIP / PROFITEST CLIP leakage

current clamp meter for a period of 12 months assuming is has

been used for its intended purpose only, under the specified

37

Page 38

GMC-I Messtechnik GmbH

8 Return and Environmentally Sound

The instrument is a category 9 product (monitoring and control

old devices (see address on back cover).

Disposal

instrument) in accordance with ElektroG (German electrical and

electronic device law). This device is subject to the RoHS

directive. Furthermore, we make reference to the fact that the

current status in this regard can be accessed on the Internet at

www.gossenmetrawatt.com by entering the search term

WEEE.

We identify our electrical and electronic devices in

accordance with WEEE 2012/19/EU and ElektroG using

the symbol shown at the right per DIN EN 50419.

These devices may not be disposed of with the trash.

38

Please contact our service department regarding the return of

Page 39

GMC-I Messtechnik GmbH

Measuring Conditions

9 Technical Data

Measuring range

SECUTEST CLIP: 0.1 mA … 25 mA AC

PROFITEST CL IP : 0.1 mA … 10 mA AC

Voltage output 100 mV/mA

Frequency / intrinsic uncertainty 50 Hz … 5 kHz: 5% rdg.

5 kHz … 1 MHz: 10% rdg.

(cut-off frequency: 1 kHz)

Measuring error 20%

Reference Conditions

Temperature 21 °C … 25 °C

Humidity 45% … 55%

Waveform Sinusoidal

Overload Capacity

Max. input current 30 A AC

39

continuous

TRMS

Page 40

GMC-I Messtechnik GmbH

Influencing Quantities and Influence Error

Influencing quantity /

sphere of influence

Influence error

Change of position ± 30°

1%

Change to supply voltage

of ± 0.25 V

DUT current: 0 … 30 A

± 2.5%

Low-frequency magnetic fields: 30 A/m

± 15%

± …% rdg.

± 2.5%

Temperature fluctuation: 0 °C … +35 °C

Frequency response of the output signal Per curve, see below

40

Max. ± 0.3%

Page 41

GMC-I Messtechnik GmbH

Relative Magnitude (dB)= 20 log U(f)/U(f=50 Hz)

41

Page 42

GMC-I Messtechnik GmbH

Electrical Safety

Protection category II (protective insulation by means of continuous

double or reinforced insulation)

Pollution degree 2

Measuring category

per EN 61010 CAT III 300 V, CAT II 600 V

Electromagnetic

compatibility EN 61326-1

Protection IP 40

Mechanical Data

Outside dimensions 62 x 28 x 172 mm

Clamp yoke 40 mm

Jaw opening 25 mm

Connector cable 1.8 m

Measurement connections SECUTEST CLIP: two 4 mm contact-protected

plugs, black/red

PROFITEST CLIP: via M12 plug to

PROFITEST PR IME

42

Page 43

GMC-I Messtechnik GmbH

Supply power 5 V DC

SECUTEST CLIP: via 3.5 mm jack plug

for connection to SECUTEST PRO / SECULIFE ST

BASE

PROFITEST CLIP: via vM12 plug to

PROFITEST PR IME

Weight Approx. 200 g

Ambient Conditions

Operating temperature -10 °C to +45 °C

Storage temperature -25 to +60 °C

Relat ive humidity Max. 80%, condensation is ruled out

Applicable Regulations and Standards

IEC61010-1/EN61010-1/VDE0411-1

Safety requirements for electrical equipment for measurement, control and

laboratory use – general requirements

EN61010-2-032

Particular requirements for hand-held and hand-manipulated

current sensors for electrical test and measurement

43

Page 44

GMC-I Messtechnik GmbH

DIN EN 61326-1/VDE 0843-20-1

Electrical equipment for measurement, control and laboratory use

Degrees of protection provided by enclosure s (IP code)

If required please contact:

e-mail: support@gossenmetrawatt.com

– EMC requirements – Part 1: General requirements

EN 60529/VDE 0470-1

Test instruments and test procedures

10 Product Support

GMC-I Messtechnik GmbH

Product Support Hotline

Phone +49-911-8602-0

Fax: +49 911 8602-709

44

Page 45

GMC-I Messtechnik GmbH

If required please contact:

D–K–15080, accredite d per DIN EN ISO/IEC 17025

11 Repair and Replacement Parts Service,

Calibration Center* and Rental

Instrument Service

GMC-I Service GmbH

Service Center

Thomas-Mann-Str. 20

90471 Nürnberg, Germany

Phone: +49 911 817718-0

Fax: +49 911 817718-253

e-mail: service@gossenmetrawatt.com

www.gmci-service.com

This address is only valid in Germany. Please contact our representatives or

subsidiaries for service in other countries.

* Calibration Laboratory for Electrical Qua ntities

45

Page 46

GMC-I Messtechnik GmbH

other manufacture rs as well.

Accredited quantities: direct voltage, direct current value, direct current

resistance, alternating voltage, alter nating current value, AC active power,

AC apparent power, DC power, capacitance, frequency and temperature

Competent Partner

GMC-I Messtechnik GmbH is certified per DIN EN ISO 9001.

Our DAKKS calibration laboratory is accredited by the Deutsche

Akkreditierungsstelle GmbH (national accre ditation body for the Federal

Republic of Germany) under registration number D–K–15080 in accordance

with DIN EN ISO/IEC 17025. We offer a complete range of expertise in the

field of metrology: from test reports and proprietary calibration certificates

right on up to DAKKS calibration certificates. Our spectrum of offerings is

rounded out with free test equipment management.

Our DAKKS calibration laboratory is part of our service department. If errors

are discovered during calibration, our specialized personnel are capable of

completing repairs using original replacement parts.

As a full service calibration laboratory, we can calibrate instruments from

46

Page 47

GMC-I Messtechnik GmbH

47

Page 48

GMC-I Messtechnik GmbH

Edited in Germany • Subject to change without notice • PDF versio n avail ab le o n the Internet

GMC-I Messtechnik GmbH Fax: +49 911 8602-777

Südwestpark 15 e-mail: info@gossenmetrawatt.com

48

90449 Nürnberg ● Germany www.gossenmetrawatt.com

Phone: +49 911 8602-111

Loading...

Loading...