Page 1

Condensed Operating Instructions

SECULIFE STPRO

Tester for Testing the Electrical Safety of Medical Devices

Important

Read carefully before use.

Recommendation: Keep on file for future reference!

3-447-033-03

1/7.19

Please read the full operating instructions as well,

which are available as a PDF file at

www.gossenmetrawatt.com.

The condensed operating instructions do not

replace the full operating instructions!

Download Center

Page 2

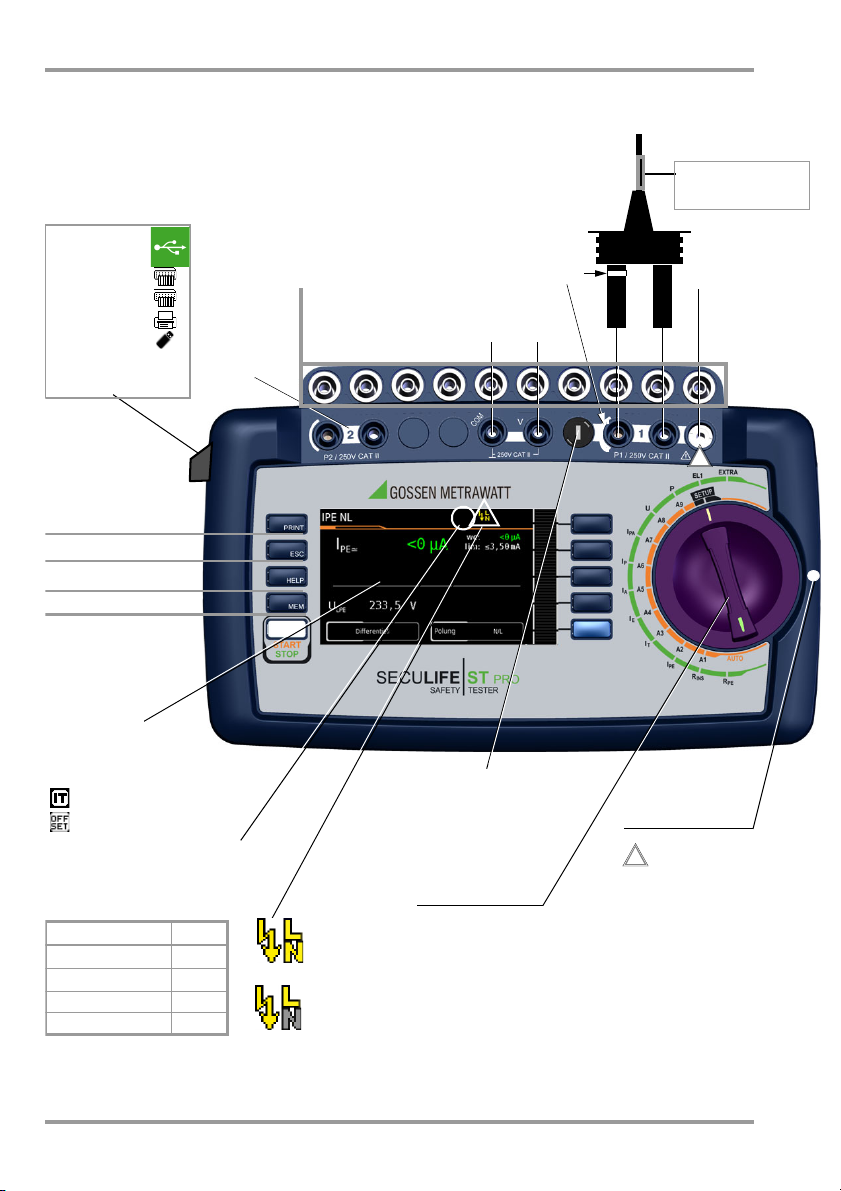

MEM: Database

ESC

: Return

HELP: Help images

START

: Start/Stopp

– Single meas.

– Test seq.

Finger contact

PRINT

: Print via USB

Softkeys

Fixed Function Keys

2 USB-Master

– For keyboard

– For scanner

– For printer

– For USB stick

1 USB-Slave

– For PC

!

Test socket for

connecting DUTs

Caution!

Depending on the measuring task, the test probe may

be charged with line voltage.

!

Rotary-

Selector Switch

Test sequences A1 ... A9

(test sequences per standard)

Rotary switch level: orange

Single measurements

Rotary switch level: green

LCD panel

Connection for

voltage supply

SECUTEST CLIP

(Z745H)

test probe

Fuse compartment

Voltage measurement

Sockets

2

nd

test probe

Special Symbol Displays:

– Measurement at IT line active

– OFFSET for RPE active

– for devices connected to the USB

master interface see above

AP A ... K

Applied parts sockets

Provided test sequences

Provided individual

measurements

See Page 7

Test sequence per

VDE 0701-0702

✔

IEC 62353

✔

IEC 60601 KA01

IEC 60974-4

✔

White/silver

identified and

fused high

current path

Kink protection grommet:

black: max. 16 A

green: max. 25 A

mains to test socket

SFC: normal condition

mains to test socket

SFC: N interrupted

SECULIFE ST PRO Operating and Connection Overview

Operating and Connection Overview

2 GMC-I Messtechnik GmbH

Page 3

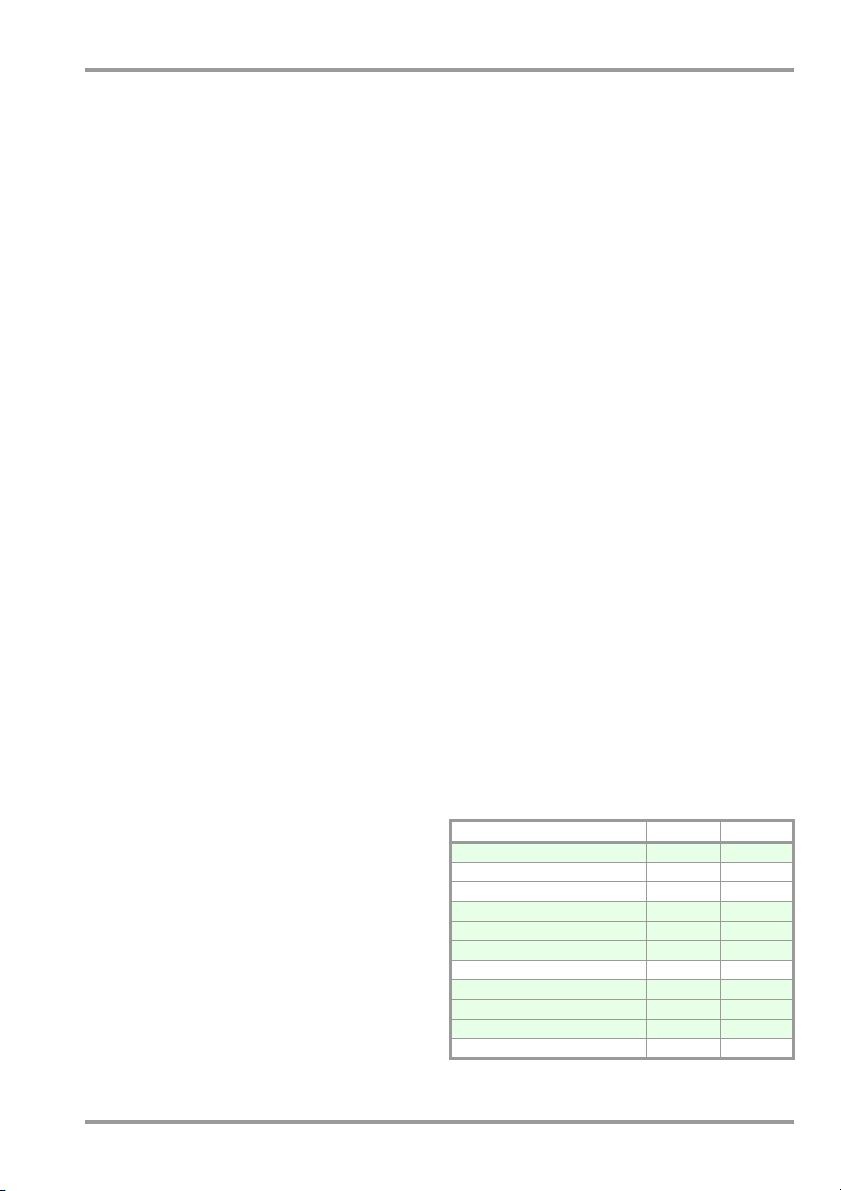

SECULIFE ST PRO Contents / Scope of Delivery

Table of Contents Page

1 Safety Precautions .....................................4

2 Initial Start-Up ...........................................6

2.1 Mains Connection ........................................ 6

2.2 Detection of Mains Connection Errors ............ 6

Functions Overview of Instrument ................ 7

3

4 User Interface Symbols – Parameter and

Softkey Symbols ........................................8

5 Internal Database ......................................9

5.1 Creation of Test Structures ...........................9

Export – Transmission and Storage of Test

5.2

Structures and Measurement Data ................... 9

5.3

Import ............................................................. 9

6 Data Input ..................................................9

6.1 Entry via Touch Screen .................................9

7 Notes on Saving Single Measurements

and Test Sequences ................................10

8 Single Measurements ..............................11

8.1 RPE – Protective Conductor Resistance for

Protection Class I Devices ...........................12

8.2 RINS – Insulation Resistance Measurement

for Protection Class I Devices ......................13

8.3 RINS – Insulation Resistance Measurement

for Protection Class II Devices .....................14

8.4 IPE – Protective Conductor Current .............15

8.5 IT – Touch Current .....................................16

8.6 IE – Device Leakage Current .......................17

8.7 IA –

8.8 IP – Patient Leakage Current ......................19

8.9 IPA – Patient Auxiliary Current ....................20

8.10 U – Probe Voltage ......................................21

8.11 U – Measuring Voltage ...............................22

8.12 FT – Functions Test ...................................23

8.13 EL1 – Function Testing of Extension Cords ..24

8.14 EXTRA – Special functions ..........................25

8.15 2-Pole Measurements with P1 &

8.16 Measurement with Current Clamp Sensor at

8.17 Measurements with Test Adapter ............... 28

Leakage Current from the Appl. Part ...........18

P2 Test Probes .......................................... 27

Permanently Installed DUTs of Safety Class I

9 Test Sequences in AccordanSce with

Standards ................................................ 29

9.1 General Procedure .................................... 29

9.2 Evaluation Procedure ................................. 29

9.3 Sample Test Sequence .............................. 30

10 Parameters for Individual Measurements

and Test Sequences ................................ 34

11 Repair and Replacement Parts Service

Calibration Center and Rental Instrument

Service .................................................... 34

12 Product Support ...................................... 34

13 Declaration of Conformity ....................... 35

14 Database Software ................................. 36

Scope of Delivery

Standard Version (country-specific)

1 Test instrument SECULIFE ST PRO

1 Mains connection cable

1 Test probe, 2 m, not coiled

1 USB cable, USB A to USB B, length: 1.0 m

1 Plug-on alligator clip

1 Cable set KS17-ONE

1 Calibration certificate

1 Condensed operating instructions

– Complete operating instructions avail-

able for download from our website

1 Card with registration key for

IZYTRONIQ BUSINESS Starter software

(software available for web download)

Order Options

M7050- without with

Touch screen — E01

10 A RPE test current — G01

5 A RPE test current — G02

2

2nd test probe — H01

Voltage measuring input * — I01

Applied parts sockets — J01

Test sequence per IEC 60601 KA00 KA01

Z853R – SECUTEST DB+ — KB01

IZYTRONIQ compatible — KC01

27

Z853S – SECUTEST DB COMFORT

®

Bluetooth

* for voltage measurement, for connecting current clamp

sensors or AT3 adapters as well as for temperature

measurement via RTD

— KD01

M00 M01

GMC-I Messtechnik GmbH 3

Page 4

Note!

Attention!

!

Attention!

!

SECULIFE ST PRO Safety Precautions

1 Safety Precautions

SECUTEST BASE(10), SECUTEST PRO and

SECULIFE ST BASE(25) test instruments are

manufactured and tested in accordance with

the following safety regulations:

IEC/EN 61010-1 / VDE 0411-1, DIN VDE

0404, IEC/EN 61577 / VDE 0413-2,-4 / DIN

EN 61557-16 / VDE 0413-16

The safety of the user, the test instrument

and the device under test (electrical equipment or electrical medical device) is only

assured when the instrument is used for its

intended purpose.

Read these condensed operating instructions and

the full operating instructions carefully and completely before placing your test instrument into

service (available at our homepage www.gossenmetrawatt.com for download). Follow all instructions contained therein. Make sure that the operating instructions are available to all users of the

instrument.

Tests may only be performed by a qualified

electrician, or under the supervision and

direction of a qualified electrician. The user

must be instructed by a qualified electrician

concerning performance and evaluation of

the test.

Suitable personal safety equipment is

required.

If you use any active or passive implanted

medical devices, please consult your doctor

or the manufacturer of these devices.

Manufacturers and importers of electrical

medical devices must provide documentation for the performance of maintenance by trained personnel.

Observe the following safety precautions:

• The instrument may only be connected

to electrical systems (TN, TT or IT) with a

maximum of 240 V which complies with

applicable safety regulations (e.g. IEC

60346, VDE 0100) and is protected with

a fuse or circuit breaker with a maximum

rating of 16 A.

• Measurements within electrical systems

are prohibited.

• Be prepared for the occurrence of unexpected voltages at devices under test (for

example, capacitors can be dangerously

charged).

• Make certain that the measurement

cables are in flawless condition, e.g. no

damage to insulation, no cracks in

cables or plugs etc.

• When using a test probe with coil cord

(SK2W):

Grip the tip of the test probe firmly, for

example during insertion into a jack

socket. Tensioning at the coil cord may

otherwise cause the test probe to snap

back resulting in possible injury.

• Measurement of insulation resistance and

equivalent leakage current (leakage current

alternative measuring methods)

Testing is conducted with up to 500 V.

Current limiting is utilized (I < 3.5 mA),

but if terminals L or N at the test socket

are touched, electrical shock may occur

which could result in consequential accidents.

• Leakage current measurement during opera-

tion with line voltage: Please note that the

device under test is operated with line

voltage during measurement. Exposed

conductive parts may conduct dangerous touch voltage during testing. Do not

touch under any circumstances! (Mains

power is disconnected if leakage current

exceeds approx. 10 mA.)

The function test may only be performed after the DUT has successfully

passed the safety test!

• Probe check for probe connector P1: Please

perform a probe check after each test.

If there is a fuse defect in test probe

P1 after having started the test, all

subsequent measurements which

are performed with this measurement path might be erroneously

rated as good!

4 GMC-I Messtechnik GmbH

Page 5

!

SECULIFE ST PRO Safety Precautions

Fuse replacement

The fuses may only be replaced when the

instrument is voltage-free, i.e. the instrument

must be disconnected from mains supply

power and may not be connected to a measuring circuit. The fuse type must comply

with the specifications in the technical data

or the labeling on the instrument.

Opening the instrument / repairs

The instrument may only be opened by

authorized, trained personnel in order to

ensure flawless operation and to assure that

the guarantee is not rendered null and void.

Even original replacement parts may only be

installed by authorized, trained personnel.

If it can be ascertained that the instrument

has been opened by unauthorized personnel, no guarantee claims can be honored by

the manufacturer with regard to personal

safety, measuring accuracy, compliance

with applicable safety measures or any consequential damages.

Any warranty claims will be forfeited when

the warranty seal has been damaged or

removed.

Switching power consumers (max. 16 A*)

Be absolutely sure to adhere to the

sequence specified below when switching

the live device under test. This prevents

excessive wear of the mains relays at the

test instrument.

The test instrument may not be used:

• If external damage is apparent, for example

if parts which conduct dangerous touch

voltage are freely accessible, if the display

is broken or defective (in which case dangerous voltage or mains connection errors

might no longer be indicated)

• If the seal or sealing lacquer has been

removed as the result of repairs or manipulation carried out by a non-authorized/noncertified service provider.

• With damaged connection and/or measurement cables and patient ports, e.g.

interrupted insulation or kinked cable

• If the instrument no longer functions flawlessly

• After serious damage due to transport

In such cases, the instrument must be

removed from operation and secured

against unintentional use.

Meanings of Symbols on the Instrument

The symbols on the instrument have the following meanings:

Warning regarding dangerous

electrical voltage

Warning concerning a point of

danger (attention: observe documentation!)

Before measurement:

1) DUT: Turn the DUT off via its own switch.

2) Tes te r :

3) DUT: Turn the DUT on via its own switch.

After measurement:

4) DUT: Turn the DUT off via its own switch.

5) Tes te r :

* for currents > 16 A AC please use adapter

AT3-II S32 (Z745X)

GMC-I Messtechnik GmbH 5

Switch line voltage to the test

socket.

Deactivate line voltage to the test

socket.

QR CODE QR CODE is a registered

Indicates European Conformity

This device may not be disposed of

with the trash. Further information

regarding the WEEE mark can be

accessed on the Internet at

www.gossenmetrawatt.com by

entering the search term „WEEE“.

If the guarantee seal is damaged

or removed, all guarantee claims

are rendered null and void.

trademark of

DENSO WAVE INCORPORATED

Page 6

Attention!

!

Attention!

!

Note!

SECULIFE ST PRO Initial Start-Up

2 Initial Start-Up

2.1 Mains Connection

Nominal mains values: 100 to 240 V, 50 Hz to 400 Hz

➭ Connect the test instrument to the mains

cable via its inlet plug and insert the

mains plug into an electrical outlet. The

function selector switch can be set to

any position. If a mains outlet (earthing

contact outlet) is not available, or if only a

3-phase outlet is available, the adapter

socket can be used to connect the

phase conductor, the neutral conductor

and the protective conductor. The

adapter socket has three permanently

attached cables and is included with the

KS13 cable set (see wiring diagram in

the operating instructions).

If connection is not possible via an

earthing contact outlet: Shut down

mains power first. Then connect the

cables from the coupling socket to

the mains using pick-off clips in accordance with the diagram. Disconnection from mains power is only

possible with the mains plug.

Measurements in IT Systems (as from FW 1.5.0)

The setting IT system can be activated in

selector switch position SETUP (Setup 1/3)

under sub-menu All Measurement:

Parameter „Meas. at IT-mains“ = Yes: active

leakage current measurements (and/or all

measurements which include the PE at the

mains connection end) are blocked. Test

sequences which contain such kind of measurements are disabled as well.

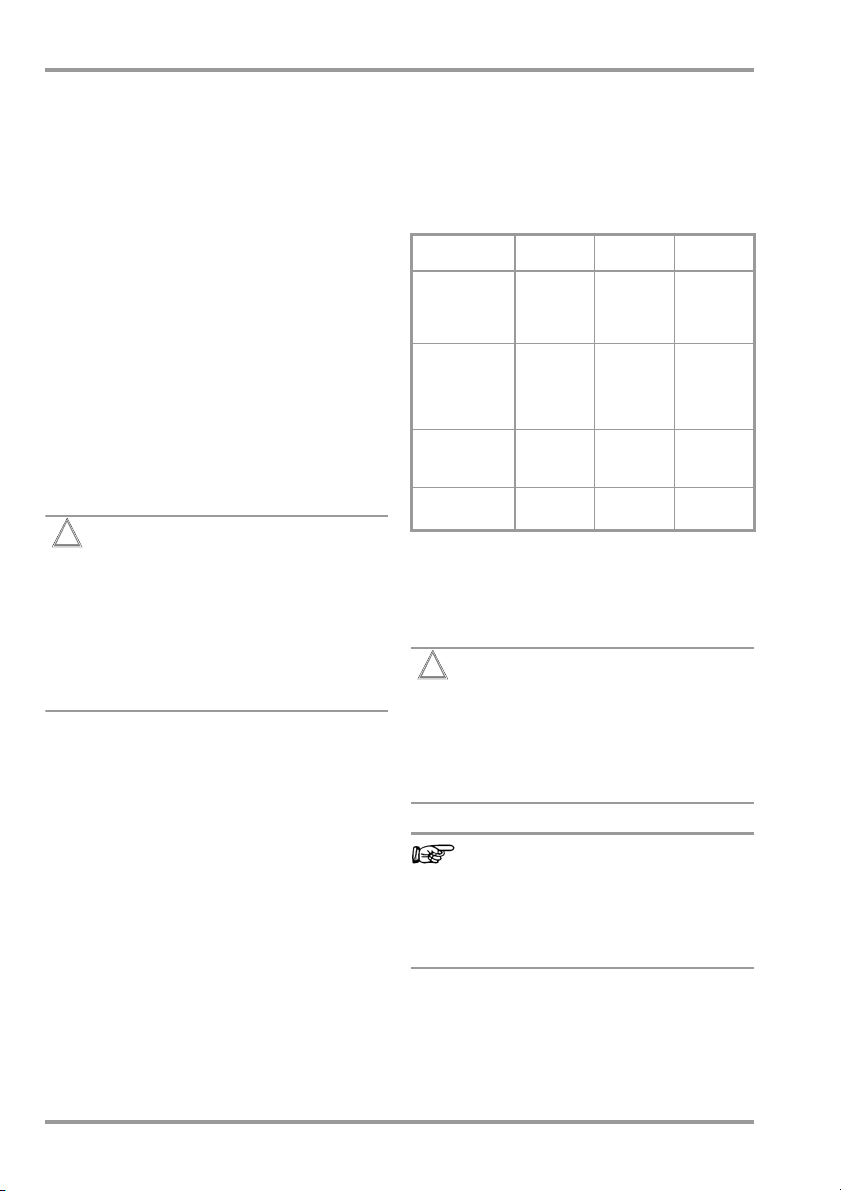

2.2 Detection of Mains Connection Errors

The device automatically recognizes mains

connection errors if the conditions in the following table have been fulfilled. The user is

informed of the type of error, and all measuring

functions are disabled in the event of danger.

Typ e o f

Connection Error

Voltage at protective conductor PE

to finger contact

(START/STOP key)

Protective conduc-

tor PE & phase

conductor L

reversed and/or

neutral conductor

N interrupted

Line voltage

< 180 V / < 90 V

(depending on mains)

Tes t o n IT/TN

system

1

10 A/25 A

voltages of 115/230 V and line frequencies of 50/60 Hz.

2

if the test person is highly insulated, the following error

message may appear: „Interference voltage at PE of

mains connection“

Message Condition

Press START/

Display at the

instrument

Display at the

instrument

RPE measurements are only possible with line

STOP button

U 25 V

Button PE:

< 1 M

Voltage at PE

>100V

U

L-N

U

L-N

Connection

N PE

> 20 k

In the event of mains connection errors as described in either of the first

two cases in the table above, immediately disconnect the test instrument

from the mains and arrange to have

the error eliminated!

Voltage at the

tive conductor PE

electrical system’s

may result in distorted

measurement values during testing for

the absence of voltage, or during leakage voltage measurements.

< 180 V

<90V

Measure-

All measure-

2

under certain

under certain

circumstances

ments

ments

disabled

Impossible

(no supply

power)

Possible

circum-

stances

Possible

protec-

1

6 GMC-I Messtechnik GmbH

Page 7

Note!

SECULIFE ST PRO Scope of Features

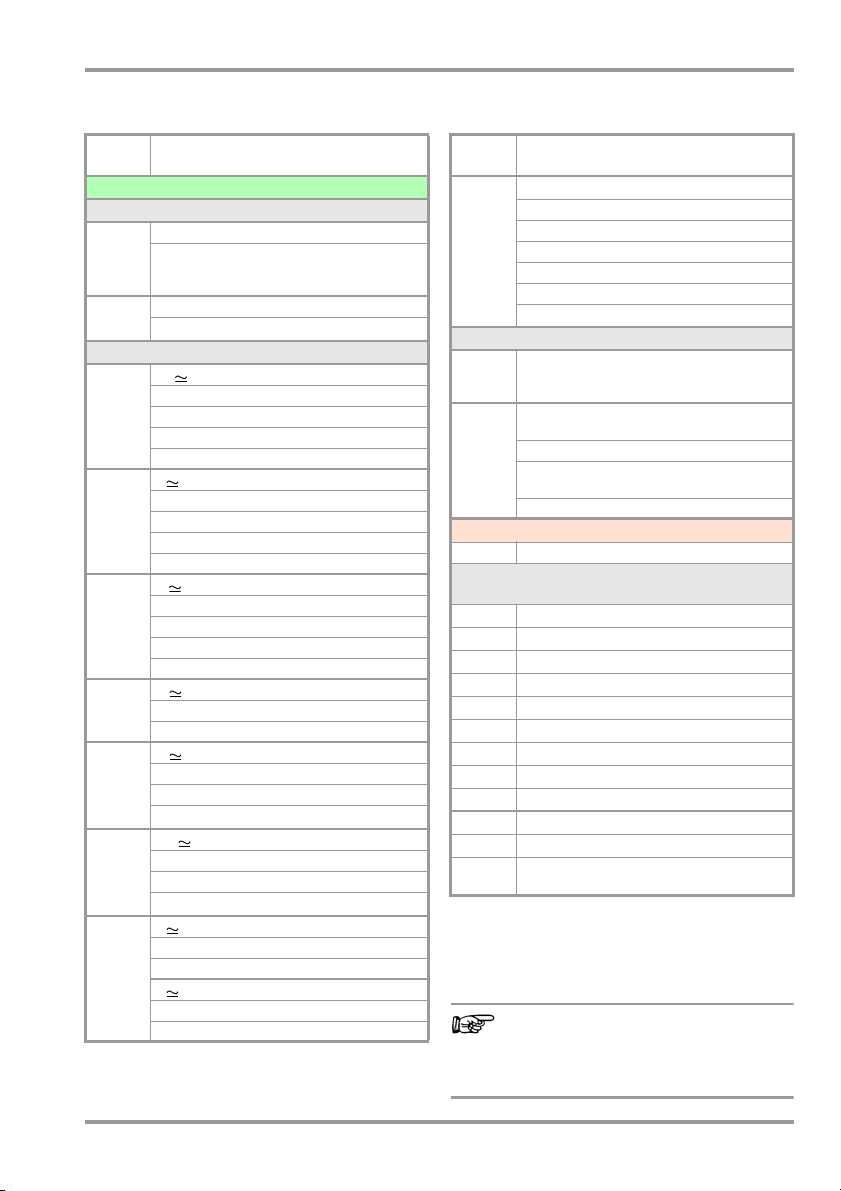

3 Functions Overview of Instrument

Switch

setting

Single measurements,

Measurements at voltage-free objects

R

Page 12

R

Page 13

Measurements at DUTs with line voltage

I

PE

Page 15

I

T

Page 16

I

E

Page 17

I

A

Page 18

I

P

Page 19

I

PA

Page 21

U

Page 21

Measuring functions,

test current/voltage

R

PE

Ip test current 200 mA

R

INS

U

I

PE

I

PE~

I

PE=

U

U

I

T

I

T~)

I

T=

U

U

I

E

I

E~

I

E=

U

U

I

A

U

U

I

P

I

P~

I

P=

U

I

PA

I

PA~

I

PA=

U

U probe voltage, TRMS

U

U

U RMS Voltage

U

U

protect. conductor resistance

PE

test current 10 A

test current 25 A

insulation resistance

INS

test voltage

INS

prot. conductor current, TRMS

AC component

DC component

test voltage

LPE

reference voltage (alternative)

Gen

touch voltage, TRMS

AC component

DC component

test voltage

LPE

reference voltage (alternative)

Gen

device leakage current, TRMS

AC component

DC component

test voltage

LPE

reference voltage (alternative)

Gen

leakage current from app. part

test voltage

LPE

voltage at applied part

Gen

patient leakage current, TRMS

AC component

DC component

test voltage

LPE

Patientenhilfsstrom effektiv

AC component

DC component

test voltage

LPE

AC voltage component

~

DC voltage component

=

AC voltage component

~

DC voltage component

=

rotary switch level: green

1

(Feature G01)

1)

(Feature G02)

2

2

2

Switch

setting

P (FT)

Measuring functions,

test current/voltage

Function test at the test socket

I current between L and N

U voltage between L and N

f frequency

P active power

S apparent power

Page 23

PF power factor

Probe measuring functions

EL1

Page 24

EXTRA

Page 25

Test sequences per standard

Page 29

Function test of extension cord with EL1/VL2E/

AT3-IIIE adapter: continuity, short-circuit,

reversed wires

Reserved for expansions in connection with

software updates

4

°C Temperature measurement 2 with Pt100/Pt1000

IZ Measurement of current at clamp with

current clamp sensor

3)

A

time to trip for 10/30 mA PRCD

t

rotary switch level: orange

Preconfigured (freely selectable) test sequences

Features * KA00 / ** KA01 (IEC 60601 3rd edition)

A1

A2

A3

A4

A5

A6

A7 *

A8 *

A9 *

A7 **

A8 **

A9 **

1

2

3

4

IEC 62353 passive TS BF APs A-K SK I

IEC 62353 passive TS BF APs A-K SK II

IEC 62353 passive TS BF APs A-K SK I+II

IEC 62353 active auto.

IEC 62353 active auto.

IEC 62353 active

VDE 0701-0702 passive

VDE 0701-0702 active

VDE 0701-0702 EDV

IEC 60601 active auto.

IEC 60601 active auto.

IEC 60601

IEC 60601

10 A/25 A-RPE measurements are only possible with line

voltages of 115 V/230 V and line frequencies of 50 Hz/60 Hz.

Voltage measuring inputs

Measurement of time to trip not possible in IT systems.

No checking for reversed polarity takes place when the

EL1 adapter is used.

active

active

det

. BF APs A-K SK I

det

. BF APs A-K SK II

auto. det. BF

APs

A-K SK I+II

auto. DUT det. SK I+II

auto. DUT det. SK I+II

active auto. DUT det. SK I+II

det

. BF APs A-K SK I

det

. BF APs A-K SK II

auto. det. BF

auto. det. CF

APs

A-E SK I+II

APs

F-K SK I+II

Changes in test sequences A1 ... A9

are preserved even after switching off

the test instrument.

GMC-I Messtechnik GmbH 7

Page 8

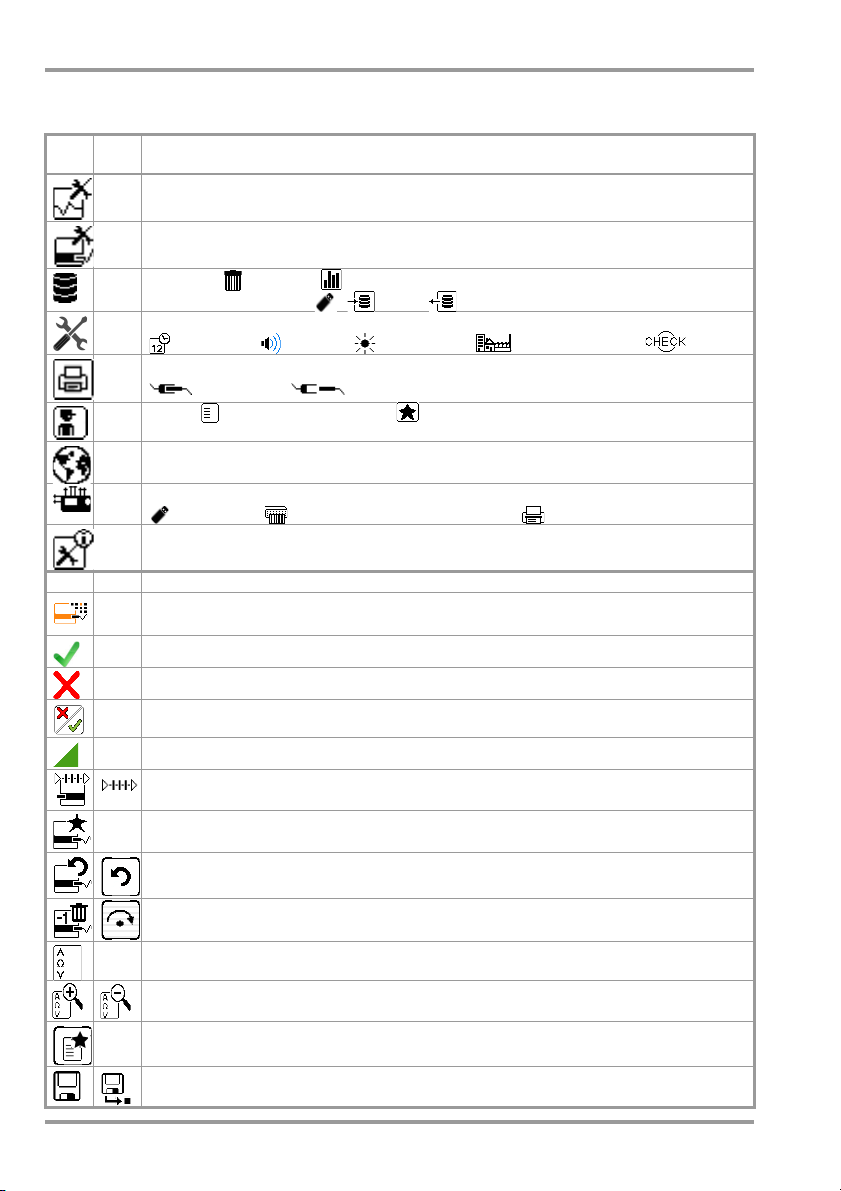

SECULIFE ST PRO Symbols

4 User Interface Symbols – Parameter and Softkey Symbols

Sym-

Setup

bols

Parameters and their significance

Page

Complete overviews of all symbols are included in the full operating instructions.

All measurements

1/3

have been standardized; Gnd fault sens.: continuous residual current monitoring (10/30 mA)

: Ref.voltage L-PE: voltage to which the measured values for leakage current

Automatic measurements: set parameters for test sequences: start and end view,

inclusive operation uncertainty (yes/no), auto measurement point (yes/no)

Database: deletion, statistics,

1/3

with inserted USB stick : save, restore database

System: set general device parameters;

1/3

2/3

2/3

2/3

2/3

3/3

date/time, volume, brightness,

Printer: printer selection for USB master interface

connected, disconnected

Te st er : select tester from list, add new tester

Culture: select language for operating instructions, keyboard and measuring

sequences by acknowledging the respective national flag; Reboot necessary!

Optionally connected external devices

USB stick, keyboard / barcode scanner, printer

System information: query software and hardware version, serial number, build

number, calibration data and storage occupancy

default settings, self-test

— Functions and their significance

Set classification parameters for the respective test sequence

(test sequences: switch settings A1 ... A9)

Accept parameters, acknowledge message

Abort single measurement or test sequence

Evaluate measurement of visual inspection with OK or not OK (toggle key)

Continue test, next test step in the test sequence

Symbol left: Direct selection key measurement type (connection type...) or measuring method (direct ...) / Symbol right: Selection between two states (no submenu)

Start evaluation – record measured value. Each time this softkey is pressed, an

additional measured value is saved and the number is increased by one.

Symbol left: Repeat measured value recording

Symbol right: Repeat test step in the test sequence

Symbol left: Delete measured value

Symbol right: Skip individual tests in the test sequence

Display measured values from performed measurements and test sequences

Magnifying glass symbol: show (+) or hide (–) details regarding database objects

or selected measurements

Enter a new ID for a test object either before or after a test, and in case the ID

has not yet been entered to the structure

Save measurement data / save measurement data as (with display of directory

path / ID or new entry of an ID other than the preselected one)

8 GMC-I Messtechnik GmbH

Page 9

Note!

Delete characters

Accept entry *

Display Field

Key Field

from right *

Switching between

uppercase and lowercase

* also possible via the associated softkey

SECULIFE ST PRO Database – Keyboard

5 Internal Database

5.1 Creation of Test Structures

A complete test structure with data regarding customers and devices under test be

created in the test instrument. This structure

makes it possible to store the results of single measurements or test sequences of test

objects belonging to various customers.

Manual single measurements can be

grouped together into a so-called „manual

sequence“.

base creation is included in the full operating

instructions for your test instrument.

5.2 Export – Transmission and Storage of

Structures set up in, and measurement data

saved to the test instrument can be imported

to the IZYTRONIQ report generating software

via a plugged-in USB stick (PRO and/or Feature KB01 only) or via the USB slave port.

Data can then be saved to the PC and

reports can be generated.

Furthermore, you can save the database to

a plugged-in USB stick for subsequent

restoring to the device memory.

5.3 Import

The test structures created at the PC with

the help of the report generating software

can be loaded into the test instrument via an

USB stick or via the USB slave port.

A complete description of data-

Test Structures and Measurement Data

Data transfer to IZYTRONIQ should not

be started during single measurements or test sequences.

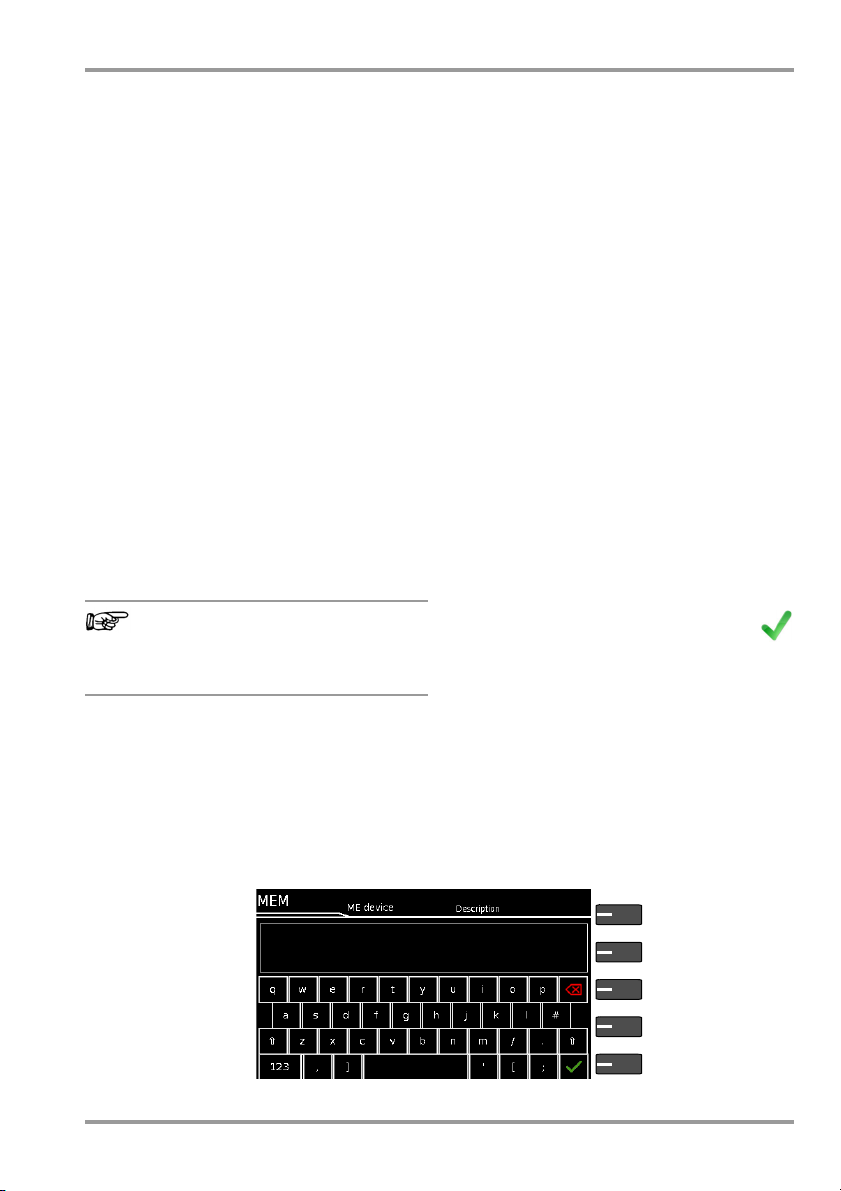

6 Data Input

6.1 Entry via Touch Screen

After selecting ID or any other object parameter, a keyboard is displayed which allows

for the entry of alphanumeric characters via

touch screen. Alternatively, entries can also

be made with the help of a USB keyboard or

barcode scanner which is connected to the

instrument.

Procedure

(example: entering a DUT designation)

1 Switch the keyboard between upper-

case and lowercase via the field.

2 Switch the keyboard from numeric to

special character or alphabetic character

entry mode via the „123“, „sym“ or „abc“

field.

3 After pressing on the respective charac-

ter, it appears in the display field.

4 Repeat steps 1 through 3 until the com-

plete designation is shown in the display

field.

5 After pressing the green check-

mark, the selected character string

is saved.

The touch screen allows for the convenient

entry of data and comments, parameters

and direct parameter selection.

GMC-I Messtechnik GmbH 9

Page 10

SECULIFE ST PRO Saving

7 Notes on Saving Single Measurements and Test Sequences

At the end of each test, test results can be

saved under an ID number which is unequivocally assigned to the respective test object.

Depending on the initial situation, i.e.

whether or not a test structure or database

is already available or an ID has already been

entered, the following different procedures

are used for saving:

Variant 1 – pre-selection of an existing ID

You’ve already set up a test structure in the

test instrument

IZYTRONIQ

Open the database view before starting the

measurement by pressing the MEM key.

Then select the test object or its ID within the

test structure by pressing the respective

scroll key. Exit the database view (MEM navigation) by pressing ESC and start the measurement. Press the Save as key at the

end of the measurement. The display is

switched to the SAVE view. The ID appears

with a green or orange background. Press

the Save key in order to complete the procedure.

Variant 2 – entry of an existing ID at the end of the

test

You’ve already set up a test structure in the

test instrument

IZYTRONIQ (

measurement without first opening the database. No test object was previously selected

in the database. Press the Save as key at

the end of the measurement. The following

message appears: „No DUT selected!“

Press the ID key. The softkey keyboard

appears.

If you enter an ID here which is already in the

database, the database view appears automatically (MEM navigation) and the test

object’s ID is displayed inversely. Acknowledge the entry by pressing the key. The

display is switched to the SAVE view. The ID

appears with a green or orange background.

Press the Save key once again in order to

complete the procedure.

or loaded one from the

.

or loaded one from the

SECUTEST PRO

only)

. You perform the

Variant 3 – entry of a new ID at the end of the test

You haven’t yet set up a test structure in the

test instrument, or the ID is not included in

the existing structure.

Press the Save as key at the end of the

measurement. The following message

appears: „No DUT selected!“ Press the ID

key in order to enter the test object’s ID. The

softkey keyboard appears.

If you enter an ID here which is not yet

included in the database, a prompt appears

asking you if you want to enter a new object.

– : If you press , the display is switched

to the SAYVE view. The ID appears with a

green background. Press the key once

again in order to complete the procedure.

– : If you press , the database view

appears (MEM navigation). Go to the next

page (Process objects 2/3) by pressing ,

and then enter a new test object. Press

to this end. All possible object types

are displayed. Press „DUT“. The newly

entered ID appears in red to the right of

the ID parameter. Acknowledge the entry

by pressing the key. The display is

switched to the database view (MEM navigation). The newly entered test object is

displayed inversely in the structure. Press

ESC in order to return to the SAVE view. The

ID appears with a green or orange background. Press the key once again in

order to complete the procedure.

– ESC: If you don’t want to save any mea-

sured values, press ESC twice in order to

go to the measuring view. If you press ESC

again, a prompt appears asking whether

or not you want to delete the measuring

points in order to continue with the measurement without saving.

10 GMC-I Messtechnik GmbH

Page 11

MEM

ESC

3

3

3

Select DUT

Start stop initiate saving

1 2 3 4

Check end saving

SECULIFE ST PRO Single Measurements

8 Single Measurements

Any measuring duration is possible. The

respective measurement is ended by pressing START/STOP. No limit values have been

entered for single measurements. As a

result, no evaluation of the measurement

results takes place.

Procedure for measuring with save function and

pre-selection of the (ME) device

If you’d like to save your single measurements to selected (ME) devices in a database (see section 5), the following procedure

is advisable.

1 Activate the database view (MEM

navigation) by pressing the MEM

key.

2 Select the (ME) device or its ID num-

ber for the following measurements

with the scroll keys.

3 Return to the measuring view by

pressing the ESC key or the START/

STOP key.

4 Start the test with the START/STOP

key before switching the DUT on.

The measured value recording

symbol shown at the right

appears. Each time this key is

pressed, the currently displayed

value is saved to the clipboard

and the number shown in the symbol is

increased by one.

5 Switch off the DUT before finish-

ing the test with the START/STOP

key. The Save as symbol appears

(floppy disk icon with the number

of measured values saved to the

clipboard).

6 If you press the save symbol now,

the display is switched to the SAVE

view, where the pre-selected (ME)

device is highlighted.

7 After pressing the Save symbol

once again, acknowledgement of

successful storage appears. At the

same time, the display returns to the

measuring view.

Procedure for measuring with save function and

subsequent entry of the (ME) device

As an alternative to the procedure described

above, you can start with step 4 and, after

measurement has been completed, assign

the results to a (ME) device or its ID number

which is included in the database: manually

by selecting ID and entering the ID via the

alphanumeric keyboard, or by scanning a

barcode.

GMC-I Messtechnik GmbH 11

Page 12

Select measuring function

1

R

PE

Select parameters

2

Set parameters

3

Connect DUT

4

PE(TS) – P1

P1

PE(mains) – P1

PE(mains)

P1

Start test

5

Acknowledge line voltage warning

6

!

With active: PE(TS)-P1 only

Save measured values to clipboard

6

Stop test

7

Save measurements under ID no.

8

SECULIFE ST PRO Single Measurements

8.1 RPE – Protective Conductor Resistance for Protection Class I Devices

1

The selected offset value is permanently stored to memory and

adapted for measurements in selector switch position

2

Connection also via EL1, VL2E, AT3 adapter, AT16DI/AT32DI

➭ Connect the DUT to the test socket.

➭ Contact all conductive parts which are

connected to the protective conductor

with test probe P1.

Special case: permanently installed DUT

Meas. Parameter Meaning

Mode (Measurement type)

admissible test current IP

PE(TS) – P1

@ IP =

200 mA/10 A/25 A

active: PE(TS)-P1

@ IP = 200 mA

PE(mains) – P1

Perm. conn. devices

@ IP = 200 mA

PE(Mains) – P1 clip @ IP = 10 A, see section 8.16

P1 – P2

@ IP =

200 mA/25 A

Testing between the 2 protective

conductor terminals: at test sock-

2

et

and test probe P1

same as PE(TS) – P1

mains voltage to socket and with

continuously increasing DC current

(PRCDs)

Testing between ground terminal

at mains and test probe P1

Only test devices with feature H01:

2-pole measurement between test

probe 1 and 2, see section 8.15

but with

➭ Contact all conductive housing parts

with test probe P1.

IP(set) Ip

200 mA

10 A Test current: 10 A

25 A Test current: 10 A

Test cur.: 200 mA AC (+/–/± DC)

(Feature G01)

(Feature G02)

f – only at 200 mA ~ (AC)

50 to 200 Hz

Offset

> 0 to < 5

1

Test sequence (adjustable in increments)

Zero balancing for selected ref. point.

AUTO

.

12 GMC-I Messtechnik GmbH

Page 13

Select measuring function

1

RINS

Select parameters

2

Set parameters

3

Connect DUT, Connect APs

4

LN(TS) – AP

P2 – AP

P1

Start test

5

Save measured values to clipboard

6

Stop test

7

Save measurements under ID no.

8

SECULIFE ST PRO Single Measurements

8.2 RINS – Insulation Resistance Measurement for Protection Class I Devices

Meas. Parameter Meaning

AP on / off

Selection: A / B / C / D / E / F / G / H / I / K

UINS(set)

> 50 to < 500 V Variable test voltage can be en-

1

Connection also via EL1, VL2E, AT3-II I E, AT3-I IS, AT3-II S32,

AT16DI/AT32DI or CEE adapter

tered with the numeric keypad

U+/U– = increase/decrease UINS(set)

Meas. Parameter Meaning

Mode (Measurement type)

LN(TS) – PE(TS)

LN(TS) – P1 See section 8.3

P1 – P2

PE(Mains) – P1

Permanently

connected devices

PE(TS) – P1

LN(TS) – P1//PE(TS)

LN(TS) – AP Testing is performed between the

PE(Mains) – AP

PE(TS) – AP

P1//PE(TS) – AP

P2 – AP

PC I: Testing between short-circuited LN mains terminals at test

socket and the DUT’s PE terminal

Only test devices with feature H01:

2-pole measurement between test

probe 1 and 2 instead of test socket

connection

Cable test: Testing between ground

terminal at mains and test probe P1

Testing between PE terminal at test

socket and test probe P1

Testing between short-circuited LN

mains terminals at test socket and test

probe P1, including PE at test socket

indicated measuring point (see

above) and the sockets of the selected applied parts

Special case P2 – AP

1

➭

Connect the DUT with the test socket (TS)

and the applied parts with the applied

parts sockets.

➭

P2-AP:

ductive, exposed parts which are not connected with the protective conductor.

➭ Switch DUT on

➭ Switch DUT off

Contact with test socket P2 the con-

GMC-I Messtechnik GmbH 13

Page 14

Select measuring function

1

RINS

Select parameters

2

Set parameters

3

Connect DUT

4

P1//PE(TS) – AP

P1

Start test

5

Save measured values to clipboard

6

Stop test

7

Save measurements under ID no.

8

SECULIFE ST PRO Single Measurements

8.3 RINS – Insulation Resistance Measurement for Protection Class II Devices

➭ Connect the DUT with the test socket

and the applied parts with the applied

parts sockets.

➭ Contact all conductive, exposed parts

with test probe P1.

➭ Switch DUT on

Measuring

Meaning

➭ Switch DUT off

Parameters

Mode (Measurement type)

LN(PD) – P1 ... between short-circuited LN TS* & P1

LN(PD)

– AP ... between short-circuited LN TS & AP

P2

– AP ... between test probe P2 & AP

AP on / off

Selection: A / B / C / D / E / F / G / H / I / K

UINS(set)

> 50 to < 500 V Variable test voltage can be entered with

* Connection via test socket, via adapter VL2E, AT3-

IIIE,

AT3-II S, AT3-II S32 or AT16DI/AT32DI

the numeric keypad

)

Legende

AP = Applied part; TS = test socket

P1//PE(TS) = test probe P1 parallel with PE test

socket

14 GMC-I Messtechnik GmbH

Page 15

Select Measuring Function

1

IPE

Select parameters

2

Set parameters

3

Connect DUT

4

Direct / Diff / Alt

Start test

5

Acknowledge line voltage warning

6

!

Direct & differential & AT3 Adapter:

Save measured values to clipboard

7

Stop test

8

Save measurements under ID no.

9

SECULIFE ST PRO Single Measurements

8.4 IPE – Protective Conductor Current

Prior to all leakage current measurements, please

make sure that the measurement parameters „Ref.

voltage L-PE“ and „Testingfreq. Alt“ have been cor-

rectly set in the SETUP, see section 10.

➭ Connect the DUT with the test socket

and the applied parts with the applied

parts sockets.

Meas. Parameter Meaning

Mode (Measurement type)

Direct

Differential Differential current measurement

Alternative Equivalent leakage current mea-

AT3-adapter

Clip

Test conditions – for direct mode only

None / AP > PE

Clip factor – for clip mode only

1mV : 1mA / 10mV : 1mA / 100mV : 1mA / 1V : 1mA

Single Fault Cond. – for direct mode only SFC

Normal condition / N interrupted

Polarity – for direct & differential mode only

L/N or N/L Selection of polarity for line volt-

1

Connection also via VL2E, AT3 adapter, AT16DI/AT32DI

GMC-I Messtechnik GmbH 15

Direct measuring method (via test

socket, AT16DI/AT32DI)

(via test socket)

suring method (via test socket

Measurement with adapter AT3-

IIIE,

AT3-II S or AT3-II S32

See section 8.17

See section 8.16

age at test socket

➭ Switch DUT on

1

)

➭ Switch DUT off

Page 16

Select measuring function

1

IT

Select parameters

2

Set parameters

3

Connect DUT

4

Direct P1/ Diff P1/ Alt P1

P1

Start test

5

Acknowledge line voltage warning

6

!

Direct & differential:

Save measured values to clipboard

7

Stop test

8

Save measurements under ID no.

9

SECULIFE ST PRO Single Measurements

8.5 IT – Touch Current

Prior to all leakage current measurements, please

make sure that the measurement parameters „Ref.

voltage L-PE“ and „Testingfreq. Alt“ have been correctly set in the SETUP, see section 10.

➭ Connect the DUT with the test socket

and the applied parts with the applied

parts sockets.

➭ Contact additional, accessible, conduc-

tive parts which are not connected to the

protective conductor with test probe P1.

Meas. Parameter Meaning

Mode (Measurement type)

Direct P1 Direct measuring method

Differential P1 Differential current measurement

Alternative P1

Permanent connection P1Permanently connected DUT

Alternative P1–P2

(via test socket

(via test socket)

Equivalent leakage current measuring

method (via test socket

Only test devices with feature H01:

Equivalent leakage current measurement method:

2-pole measurement between test

probe 1 and 2, see section 8.15

1

)

1

or VL2E)

➭ Switch DUT on

➭ Switch DUT off

Test cond. – for direct and perman. mode only

None / AP > PE (all APs)

Single Fault Cond. – for direct mode only SFC

Normal condition / N interrupted / PE interrupted

Polarity – for direct and differential mode

only

L/N or N/L Selection of polarity for line volt-

1

16 GMC-I Messtechnik GmbH

Connection also via

age at test socket

AT3-II I E, AT3-II S, AT3-II S32, AT16DI/AT32DI

Page 17

Select measuring function

1

IE

Select parameters

2

Set parameters

3

Connect DUT

4

Direct / Diff / Alt

P1

Start test

5

Acknowledge line voltage warning

6

!

Direct & differential & AT3 Adapter:

Save measured values to clipboard

7

Stop test

8

Save measurements under ID no.

9

SECULIFE ST PRO Single Measurements

8.6 IE – Device Leakage Current

➭ Connect the DUT with the test socket

and the applied parts with the applied

parts sockets.

➭ Contact accessible, conductive parts

which are not connected to the protective conductor with test probe P1.

Meas. Parameter Meaning

Mode (Measurement type)

Direct Direct measuring method (via test

Differential Differential current measurement

Alternative Equivalent leakage current mea-

AT3-adapter

Clip

Polarity – for direct, differential mode

and AT3-adapter only

L/N or N/L Selection of polarity for line

Factor V:A – for clip mode only

1mV : 1mA / 10mV : 1mA / 100mV : 1mA / 1V : 1mA

1

Connection also via AT16DI/AT32DI (only useful for differential current method)

Prior to all leakage current measurements, please

make sure that the measurement parameters „Ref.

voltage L-PE“ and „Testingfreq. Alt“ have been correctly set in the SETUP, see section 10.

GMC-I Messtechnik GmbH 17

socket1), optional probe contact

(via test socket)

suring method with probe contact

(via test socket, AT16DI/AT32DI)

Measurement with adapter AT3IIIE,

AT3-II S or AT3-II S32

See section 8.17

See section 8.16

voltage at test socket

➭ Switch DUT on

➭ Switch DUT off

Page 18

Select measuring function

1

IA

Select parameters

2

Set parameters

3

Connect DUT

4

Direct AP

AP – P2

P2

Start test

5

Acknowledge line voltage warning

6

!

Direct:

Save measured values to clipboard

7

Stop test

8

Save measurements under ID no.

9

SECULIFE ST PRO Single Measurements

8.7 IA –

Leakage Current from the Appl. Part

Meas. Parameter Meaning

Mode (Measurement type)

Direct P1 Direct measuring method (via test

Direct AP as above, here via AP socket

Alternative P1 Equivalent leakage current mea-

Alternative AP as above, here via AP socket

Permanent connection P1

Perman. conn. AP as above, here via AP socket

1)

AP – P2

socket) with test probe P1

suring method (via test socket)

with test probe P1

Permanently connected DUT

Test probe P2 at cond. parts without PE

AP on / off

Selection: A / B / C / D / E / F / G / H / I / K

Phase Angle – for Direct... and Perm. c. only

0 ° or 180 ° Selectable phase angle of the in-

ternal generator in relation to

mains phase angle

Polarity – for direct mode only

Prior to all leakage current measurements, please

make sure that the measurement parameters „Ref.

voltage L-PE“ and „Testingfreq. Alt“ have been correctly set in the SETUP, see section 10.

➭ Connect the DUT with the the test

socket and the applied parts with the applied parts sockets.

Special case AP – P2

➭

Contact with test probe P2 the conductive, exposed parts which are not connected with the protective conductor.

➭ Switch DUT on

➭ Switch DUT off

L/N or N/L Selection of polarity for line volt-

1)

for ME devices with proprietary power supply

18 GMC-I Messtechnik GmbH

age at test socket

Page 19

Select measuring function

1

IP

Select parameters

2

Set parameters

3

Connect DUT

4

P1

Direct AP

Perman. connection AP

P1

Start test

5

Acknowledge line voltage warning

6

!

Direct:

Save measured values to clipboard

7

Stop test

8

Save measurements under ID no.

9

SECULIFE ST PRO Single Measurements

8.8 IP – Patient Leakage Current

Meas. Parameter Meaning

Measurement mode

Prior to all leakage current measurements, please

make sure that the measurement parameters „Ref.

voltage L-PE“ and „Testingfreq. Alt.“ have been cor-

rectly set in the SETUP, see section 10.

➭

Connect the DUT with the test socket and

the applied parts with the AP sockets.

➭ Contact with test

probe

P1 the conductive, exposed parts with are not connected with the protective conductor.

Special case permanent connection

Direct P1 Direct measuring method (via test

Direct AP Measurement via selected applied

Permanent connection P1

Perman. connect. AP Measurement via selected applied

Test conditions – for AP mode only

AP to PE / housing to PE / AP & housing to PE / none

AP on / off

Selection: A / B / C / D / E / F / G / H / I / K

Single Fault Condition – depending on mode

Normal condition / N interrupted / PE interrupted /

Mains at applied parts

Polarity – for direct mode only

L/N or N/L Selection of polarity for line

GMC-I Messtechnik GmbH 19

socket) with test probe P1

parts sockets

Permanently connected DUT

parts sockets

➭ Switch DUT on

➭ Switch DUT off

voltage at test socket

Page 20

Select measuring function

1

IPA

Select parameters

2

Set parameters

3

Connect DUT

4

Direct AP

Perman. connection AP

Start test

5

Acknowledge line voltage warning

6

!

Direct:

Save measured values to clipboard

7

Stop test

8

Save measurements under ID no.

9

SECULIFE ST PRO Single Measurements

8.9 IPA – Patient Auxiliary Current

➭

Connect the DUT with the test socket and

the applied parts with the AP sockets.

Special case permanent connection

Meas. Parameter Meaning

Mode (Measurement type)

Direct AP Direct measurement from the

Perman. connect. AP Direct measurement from the

selected AP socket to all other

sockets

selected AP socket to all other

sockets (no individual errors or

polarity selectable)

AP on / off

Selection: A / B / C / D / E / F / G / H / I / K

towards remaining applied parts each

➭ Connect the applied parts with the AP

sockets.

➭ Switch DUT on

Single Fault Condition – direct mode only

Normal condition / N interrupted / PE interrupted

Polarity – direct mode only

L/N or N/L Selection of polarity for line volt-

age at test socket

➭ Switch DUT off

Prior to all leakage current measurements, please

make sure that the measurement parameters „Ref.

voltage L-PE“ and „Testing freq. Alt.“ have been correctly set in the SETUP, see section 10.

20 GMC-I Messtechnik GmbH

Page 21

Select measuring function

1

U

Select parameters

2

Set parameters

3

Connect DUT

4

PE – P1 (with mains)

Probe Voltage

P1

PE – P1

Probe Voltage

P1

Start test

5

Acknowledge line voltage warning

6

!

Only for measurement

type:

(with mains)

Save measured values to clipboard

7

Stop test

8

Save measurements under ID no.

9

SECULIFE ST PRO Single Measurements

8.10 U – Probe Voltage

➭ Connect the DUT to the test socket.

➭ Contact the ungrounded output for pro-

tective extra-low voltage with test probe

P1.

➭ Select line voltage polarity.

Special case: permanently installed DUT

➭ Contact all voltage conducting parts with

test probe P1.

Meas. Parameter Meaning

Mode (Measurement type)

PE – P1 Measurement of voltages with

PE – P1 (with Mains) Measurement of voltages with

L/N or N/L Selection of polarity for line volt-

GMC-I Messtechnik GmbH 21

reference to PE, test socket remains voltage-free, e.g. for permanently connected DUTs

reference to PE, line voltage is applied to the test socket

age at test socket

(with mains)“ only)

(with „PE – P1

➭ Switch DUT on

➭ Switch DUT off

Page 22

Select measuring function

1

U

Select parameters

2

Set parameters

3

Connect DUT

4

V – COM (with mains)

Measuring Voltage

VCOM

!

V – COM (RMS/AC/DC)

Meas. Volt.

VCOM

Start test

5

Acknowledge line voltage warning

6

!

Only for measurement

type:

(with mains)

Save measured values to clipboard

7

Stop test

8

Save measurements under ID no.

9

SECULIFE ST PRO Single Measurements

8.11 U – Measuring Voltage

Attention!

Only use the enclosed contact pro-

tected KS17-ONE measurement

cables for the measurement of dangerous

voltages please.

Special case: permanently installed DUT

➭ For testing mains power packs and charging

units: Connect the DUT mains terminal

with the test socket.

➭ Connect the DUT output, e.g. for mea-

suring safety extra low voltage (SELV),

with sockets V and COM.

Meas. Parameter Meaning

Mode (Measurement type)

V – COM (RMS) Effective value

V – COM (AC) AC value for perm. conn. DUTS

V – COM (DC) DC value for perm. conn. DUTS

V – COM Effective value + AC + DC for

V – COM (with mains) Effective value + AC + DC;

for permanently connected DUTs

perm. conn. DUTS

for line voltage at test socket

➭ Switch DUT on

➭ Switch DUT off

22 GMC-I Messtechnik GmbH

Page 23

Note!

Select measuring function

1

P

Select parameters

2

Set parameters

3

Connect DUT

4

Starting test

5

Acknowledge line voltage warning

6

!

Save measured values to clipboard

7

Stop test

8

Save measurements under ID no.

9

SECULIFE ST PRO Single Measurements

8.12 FT – Functions Test

➭ Connect the DUT to the test socket.

Meas. Parameter Meaning

Polarity

LN Phase L – neutral conductor N

NL Neutral conductor N – phase L

The following connection types are possible:

• Test socket

• CEE adapter (only for connection via

single-phase CEE or „caravan socket“)

• AT3 adapter (AT3-I I IE, AT3-IIS, AT3-IIS32)

• AT16DI/AT32DI

It is possible to use the adapters

listed above for function testing (initial

start-up of DUT). Apparent/active

power, power factor and current consumption can only be measured,

however, if the DUT is directly connected with the test socket or via the

CEE adapter (single-phase CEE

socket only).

GMC-I Messtechnik GmbH 23

➭ Switch DUT on

➭ Switch DUT off

Page 24

Note!

Select measuring function

1

EL1

Select parameters

2

Set parameters

3

Connect DUT

4

Test Socket – P1

EL1-Adapter

P1

VL2E-adapter

Start test

5

Save measured values to clipboard

6

Stop test

7

Save measurements under ID no.

9

SECULIFE ST PRO Single Measurements

8.13 EL1 – Function Testing of Extension Cords

Connection of EL1 Adapter

Meas. Parameter Testing for

Measurement type

Continuity

L(1/2/3), N

Short-circuit

between

L(1/2/3), N

Reversed

polarity /

Clockwise

EL1 adapter

VL2E adapter

AT3-IIIE adapter

XX —

XX X

XX X

This function allows for the evaluation of the

function of the active conductors L (1, 2, 3)

and N of an extension cable. The PE conductor

is not being tested in this process!

For the testing of R

tive single measurements.

and R

PE

see respec-

INS

➭ Connect the EL1 adapter to the P1

probe sockets at the test instrument.

➭ Connect the plug at the end of the ex-

tension cord to the test socket.

➭ Connect the coupling socket at the end

phase

of the extension cord to the plug at the

sequence

EL1 adapter.

Connection of Test Adapters VL2E and AT3-IIIE

➭ Connection examples are shown in sec-

tion 8.17.

Continuity test for L and N

See section 9, „Test Sequences in

Accordance with Standards“ (switch

setting A8) with regard to testing extension cords per DIN VDE 0701-0702, for

24 GMC-I Messtechnik GmbH

which RPE and R

are measured.

INS

Page 25

Select measuring function

1

EXTRA

Temp., Current (clip) or PRCD break time

2

3Connect DUT

4

V – COM PT100(0)

Start test

4

Save measured values to clipboard

5

Stop test

6

SECULIFE ST PRO Single Measurements

8.14 EXTRA – Special functions

Temp. – Temperature measurement

Additional measurement

functions are assigned to

rotary switch position

EXTRA.

➭ Select the desired measuring function.

GMC-I Messtechnik GmbH 25

Temperature measurement works both with

a Pt100 and a Pt1000 temperature sensor

and automatically recognizes the utilized

sensor type.

Page 26

3Connect DUT

4

VCOM

V – COM (AC) (w. Mains)

Set parameters

5

Start test

6

Save measured values to clipboard

7

Stop test

8

3

Connect DUT

4

P1

Start test (test current 30 mA)

5

Acknowledge line voltage warning

6

!

Execute test

7

Testing is stopped automatically.

8

Save measurements under ID no.

9

SECULIFE ST PRO Single Measurements

IZ – Current clamp measurement

tA – PRCD Time to Trip

(portable residual current device)

➭ Connect the PRCD to the test socket.

Meas. Parameter Meaning

Measurement type

V – COM (AC) A AC for permanently connected

V – COM (AC) (with

Mains)

Polarity – Mode with mains at TS only

L/N or N/L Selection of polarity for line

➭

Adjust the clamp factor (cl. factor):

– at the current clamp sensor

DUTs

A AC; for line voltage at test

socket

voltage at test socket

➭ Activate the PRCD.

➭ Contact neutral conductor L at the

PRCD with test probe P1 (if required, ascertain by trial and error).

The PRCD is tripped.

– at the test instument

Ascertained time to trip is displayed.

26 GMC-I Messtechnik GmbH

Page 27

P1P2

Switch position: R

PE

Measurement type: P1-P2

P1P2

Switch position: R

INS

Switch position: IT

Measurement type: P1-P2

V

COM

P1

Switch position: R

PE

Measurement type: Clamp

V

COM

Switch position: I

PE

Measurement type: Clamp

Switch position: IE

Measurement type: Clamp

COM-V

SECULIFE ST PRO Single Measurements

8.15 2-Pole Measurements with P1 & P2 Test Probes

In case your DUT is not equipped with a

country-specific mains plug that fits into the

tester test socket or if it is a permanently

installed DUT, the 2

nation with the 1

pole measurement (dual-lead measurement) of RPE, RINS and equivalent leakage

current.

Measurements with test probe 1 against test

probe 2 (P1 – P2) are electrically isolated

from the mains. There is no voltage present

at the test probe.

Connection Example of RPE Measurement

Measuring of protective conductor resistance RPE at permanently installed safety

class I devices

nd

test probe, in combi-

st

test probe, allows for 2-

8.16 Measurement with Current Clamp Sensor at Permanently Installed DUTs of Safety Class I

SECUTEST PRO and

SECUTEST PRO

Parameter

Tra n sf. Ra t i o

1 mV :1 mA

Connection Example for RPE Measurement (WZ12C only)

Measurement of test current by enclosing

PE in the electric circuit. This type of measurement can only be selected if the test

current has been set at 10 A AC.

Connection Example for IPE Measurement

(Direct measuring method)

SECULIFE ST BASE(25)

Clamp SECUTEST PRO

Tra ns-

former Ratio

1 mV : 1 mA

Measuring

WZ12C

1 mA ...

Range

15 A

only

Display Range

with Clamp

0 mA ... 300 A

Connection Example of RINS or IT

Measurements

Measuring of insulation resistance RINS or

touch current IT for safety class I devices

Measurement of protective conductor current by enclosing PE in the feeder.

Connection Example of IE Measurement

(Differential current measurement)

GMC-I Messtechnik GmbH 27

Measurement of device leakage current by

L and N

in the

enclosing conductors

feeder

.

Page 28

Attention!

!

EL1 adapter

P1

P1

COM-V

P1

SECULIFE ST PRO Single Measurements

8.17 Measurements with Test Adapter

Test with Adapter

EL1 VL2E AT3-

DUT terminals

Inlet plug 1P+N+PE 16 A

Schuko 1P+N+PE 16 A

CEE 1P+N+PE 16 A

CEE 3P+N+PE 16 A

CEE 3P+N+PE 32 A

5 x 4 mm sockets

— ✔✔ — —

— ✔ — — —

— ✔✔ — ✔

— ✔✔✔ / — ✔

— ✔✔— / ✔✔

——— — ✔

Test instrument terminals

Schuko 1P+N+PE 16 A

Socket for test probe

Plug for V–COM

—— ✔✔ —

— ✔✔ ——

1

—— ✔ ——

Active Testing

Protective conductor current IPE

– Direct method

– Differential current

—— ✔✔ —

——✔1✔ —

Device leakage current IE

– Direct method

– Differential current

Touch current IT

—— ✔✔ —

——✔1✔ —

—— ✔✔ —

Passive Testing

Protective conductor

resistance RPE

Insulation resistance

RINS

Protective conductor

current IPE (equiv. leakage current method)

Extension cables:

apart from RPE & RINS are conducted in switch position

single phase (3-pole)

3-phase (5-pole)

wire short circuit

wire interruption

wire reversal

1

Differential current method with

2

for IPE and IE: AT3-IIS or, alternatively, AT3-I I S32

✔✔ ✔ ✔ ✔

✔✔ ✔ ✔ ✔

— ✔✔ ✔ ✔

the following additional measurements

✔✔ ✔ ——

— ✔✔ ——

✔✔ ✔ ——

✔✔ ✔ ——

— ✔✔ ——

AT16DI

2

IIIE

AT32DI

SECUTEST PRO

CEEAdapter

EL1

only

Connection Example with EL1

Connection Example with VL2E

Connection Example for Protective Conductor

Current Measurement IPE (Direct Method) with

AT3-IIIE

Connection Example for Device Leakage Current

Measurement IE

(Differential Current Method)

with AT3-IIIE

For information on the correct connection of test adapter and DUT as we

particular aspects during the test sequence please refer to the operating instructions of the test adapters.

28 GMC-I Messtechnik GmbH

ll as

Page 29

MEM

ESC

0

SECULIFE ST PRO Test Sequences in Accordance with Standards

9 Test Sequences in Accordance

with Standards

If the same sequence of single tests will be

run frequently (one after the other with subsequent report generation), for example as

specified in the standards, it’s advisable to

make use of test sequences. Limit values

have been entered for test sequences in

accordance with standards. And thus a go/

no-go evaluation takes place during measurement based on worst-case assessment.

If the momentary measured value is displayed in green, it lies within the limit values

specified in the standard. If the measured

value is red, is does not fulfill the requirements set forth in the standard. If the measured value is shown in amber, further entries

are required. Even if the DUT fails just a single test step, the test sequence is aborted

and testing in accordance with the selected

standard is failed.

9.1 General Procedure

1 Select the desired test sequence with

the rotary switch (AUTO, A1 ... A9).

2 If no test object has been selected, enter

the ID number of the test object, for

example by means of a barcode scanner, after selecting ID.

3 As an alternative to step 2, activate

the database view with the MEM key:

4 Select the test object with the scroll

keys.

5 Return to the measuring view by

pressing the ESC key.

6 Start the test sequence with the

START/STOP key.

7 The measured value recording

symbol shown at the right appears.

Each time this key is pressed, the measuring or evaluation procedure is

restarted (see case B in section 9.2).

8 Proceed to the next measurement by

pressing the key shown to the right.

9 At the end of the test sequence,

you can generate a list of the

results of the individual test steps.

10 If you want to view details such as

the settings for the individual test

steps, select the desired measurement

with the cursor and press the + magnify-

ing glass key.

11 The display is returned to the list of

test steps by pressing the – magnify-

ing glass key.

12 Save the results of a successful test

sequence by pressing the Save key.

9.2 Evaluation Procedure

The evaluation procedure can be started manually for some test steps within a given test

sequence, but all others are run automatically.

• Case A – automatic triggering of evaluation:

Evaluation (with a duration of, for example,

5 seconds) is started automatically as

soon as the measured value has stabilized. The worst value which occurs during

this duration is saved, and automatic

switching to the next test step ensues.

•

Case B – manual triggering of evaluation:

Evaluation is started after pressing

the measurement value recording symbol (display: 0). After a specified period

of time has elapsed, the worst value is

saved to the right of wc: (worst case),

and the number 1 is displayed in the

measurement value recording symbol

indicating that the first measured value

has been saved. Pressing the measured

value recording icon again restarts the

evaluation procedure. If the worst value

is worse that the value obtained for the

previous measurement, the new value is

used. However, if this value is better than

the previous worst value, the original

value remains in the display. Depending

on whether you want to delete the last

value saved to the clipboard or all values,

press the symbol shown below an

appropriate number of times.

Proceed to the next test by pressing the symbol shown to the right.

GMC-I Messtechnik GmbH 29

Page 30

Select test sequence

1

A2

Open database

2

MEM

Select Device

3

Switch to start view

4

ESC

ab

c

Sequence parameters

5

Set classification parameters

6

a

b

c

bac

SECULIFE ST PRO Test Sequences in Accordance with Standards

9.3 Sample Test Sequence

As-delivered Condition (KA00):

A1 IEC 62353

A2 IEC 62353

A3 IEC 62353 passive, TS, BF APs A-K, SKI + I I

A4 IEC 62353 active, autom. E., BF APs A-K, SKI

A5 IEC 62353 active, autom. E., BF APs A-K, SKI I

A6 IEC 62353 active

A7

VDE 0701-0702

A8

VDE 0701-0702

A9

VDE0701-0702EDV

passive, test socket, BF APs A-K, SK I

passive, test socket, BF APs A-K, SK I I

, autom. E., BF

passive, autom. DUT conn. det. SK I+II

active,

autom. DUT conn. det. SKI+I I

active,

autom. DUT conn. det. SKI+I I

APs

A-K, SKI+II

Individual test steps can be configured with the sequence

parameters

, see detailed operating instructions.

Switch setting: A1 ... A9

Meas. Parameter Meaning

Standard Test standard / extension cord

Protection class * PC1/PC2/PC3

Connection type * Test socket / permanent / adapter

Measurement type

(MT) *

APs

(for IEC 62353)

PRCD Type

(for VDE 0701-0702PRCD)

Auto detection of Any desired combinations for au-

* If the configurations of the classification param-

eters are recognized automatically, they are

marked with an amber frame. They must be entered manually if they’re not automatically detected, or if they’re detected incorrectly.

Active or passive DUT

(on test: on = passive, off = active)

Applied parts: none, B, BF, CF or

combinations

Type B (Body): devices of this

type are suitable both for external

and internal applications on the

patient, except for direct application on the heart. The following

safety classes are permissible:

I, II, III or those with an internal

electric power source.

Type BF (Body Float): devices of

type B, however, with insulated

applied part of type F.

Type CF (Cardiac Float): devices

of this type are suitable for direct

application on the heart. The insulated applied part must be ungrounded. The following safety

classes are permissible: I, II or

those with an internal electric

power source.

PRCD (standard)

PRCD (SPE)

PRCD-S (SPE)

PRCD-K (SPE)

tomatic detection of:

– Connection

– Protection class (SK)

– Measurement type (MT)

30 GMC-I Messtechnik GmbH

Page 31

Note!

Connect DUT

7

Check connection &start test sequence

8

SECULIFE ST PRO Test Sequences in Accordance with Standards

Selection of Applied Parts (APs)

Connect the DUT to the test instrument in ac-

➭

cordance with the selected test sequence.

– Test socket

– Permanent connection

– Adapter

➭ Connect the applied parts with the AP

sockets.

➭ Press the key „Classification Param-

eter“.

➭ Change to page 2/2.

➭ Press the key „Applied parts“. The above

picture is shown.

➭ Select the desired applied parts

sockets via the key „Increase group“.

A red frame marks the sockets currenly

selected, always starting with socket A.

A new socket is added every time a key

is pressed. The number currently selected is indicated in the field at the bottom right.

➭ By pressing the key „Decrease

group“ you reduce the number of

sockets again.

➭ After selecting the sockets, you as-

sign the respective type via the key

„Typ e o f AP“. The corresponding symbols

are assigned to the selected sockets and

the type is displayed in the field at the

bottom left.

➭ After selecting the applied parts

and assigning the type, further

groups can be created by pressing the

key „next group“. You can subsequently

change a group that has already been

created by activating it by means of the

entry frame.

Additional groups can only be created via the key „+“ if a type has

been assigned to a group already

selected.

Switch position: A1 ... A9

Connection depends on the type of DUT.

Switch position A2

For testing extension cords in accordance

with standards: connection to the test

socket via the following adapter:

– EL1:

–

for single-phase extension cords

VL2E/AT3-IIIE: for single- or three-phase

extension cords

The following checks are run automatically before the test sequence

is started:

• Probe test P1 (whether or not the probe

is connected and if fuse P1 is OK)

• Insulation test (whether or not the DUT is

set up in a well-insulated fashion)

• On test and short-circuit test.

In order to be able to detect a short-circuit at the DUT, testing is conducted

between L and N, as well as LN and PE.

If you’ve set the „

Detected classification

“

parameter for the respective test

sequence to „Always accept“ and the

„

Auto-detection of

nection and SK“ (before triggering

“ parameter to „Con-

Start

), the

following additional checks will be run before

the test sequence is started:

• Protection class detection for DUTs with

protective conductor

• Connection check: whether or not the

DUT is connected to the test socket. In

the case of protection class I: whether or

not the two protective conductor terminals are short-circuited.

GMC-I Messtechnik GmbH 31

Page 32

Note!

Manual evaluation of visual inspection

9

Test step – start evaluation

10

Test step – automatic evaluation

11

Manual evaluation of functions test

12

SECULIFE ST PRO Test Sequences in Accordance with Standards

Visual inspection passed

Visual inspection not passed

(sequence is aborted, test failed)

Resume test sequence

If the plug is disconnected from the test

socket during the test sequence, the

sequence is immediately disconnected.

Green measured value:

complies with standard

Record measuring point.

Delete last measuring point.

The measured value is ascertained automatically within a specified period of time. The

test sequence is then automatically

resumed.

Green measured value:

complies with standard

Functions test passed

Functions test not passed

(sequence is aborted, test failed)

Resume test sequence

➭ Remove DUT from service

Resume test sequence.

32 GMC-I Messtechnik GmbH

Page 33

End of sequence – display results

13

13

Display detailed results

14

Hide details

15

Confirm results

16

Save results under ID no.

17

SECULIFE ST PRO Test Sequences in Accordance with Standards

Optional test step

(display of the memory screen depends on the

parameter pre-selection in the SETUP switch position:

Setup 1/3 > Auto. measurements > At end of

sequence > Memory screen. If set to events list,

is omitted.)

Optional test step

Optional test step

Switch to memory screen

(consideration of measuring error depends on

the parameter pre-selection for the SETUP switch

setting: Setup 1/3 > Auto. measurements > Error considered. > Yes)

Optional test step

GMC-I Messtechnik GmbH 33

Save results

or with feature KD01 „Z853S – SECUTEST DB

COMFORT“:

Send measurement data to the PC,

via USB or Bluetooth® (Feature M01),

e. g. for saving to the IZYTRONIQ

report generating software (pushprint function), description see online

help for IZYTRONIQ

Page 34

SECULIFE ST PRO SETUP Measurement Parameters

10 Parameters for Individual Mea-

surements and Test Sequences

Measurement parameters which apply for

both individual measurements and test

sequences, have to be entered in selector

switch position SETUP.

Setup 1/3 > All measurements

Meas. Parameter Meaning

Meas. at IT-mains

(Yes / No)

Ref.voltage L-PE

( 90 V, 110 V, 115 V,

220 V, 230 V, 240 V,

264 V)

Testingfreq Alt

(48 Hz ... 400 Hz)

Residual current

protection

10 mA / 30 mA

Yes : active leakage current mea-

surements (and/or all measurements which include the PE at the

mains connection end) are

blocked. Test sequences which

contain such kind of measurements are disabled as well.

The reference (line) voltage is the

voltage to which the measured

values for leakage current have

been standardized.

It is used in the case of leakage

current for mathematical adjustment of the current measuring

values to the predefined voltage.

Measurements with line voltage at the test socket:

The setting value has no influence

on the voltage with which the DUT

is supplied via the test instrument‘s test socket.

Leakage current measurements

with measurement type „Alternative“:

The setpoint value of the

synthetical test voltage is derived

from the value specified here.

Variable frequency setpoint value

for synthetical test voltage for all

leakage current measurements of

measurement type „Alternative“,

affecting the following measurements and/or rotary switch positions:

– Individual measurements

(green rotary switch level)

– Measurements in test se-

quences predefined ex factory

– Measurements in user-defined

test sequences

The test instrument is equipped

with a permanent residual current

monitoring for your safety. If the

differential current exceeds a defined limit value, all measuring

processes are stopped and

line voltage that might be fed

through is disconnected from the