Page 1

Operating Instructions

SECULIFEST and SECULIFEST HV

Test Instruments for Portable Appliance Testing according to Health and Safety Policy

and in Accordance with the Medical Product Law as well as for Routine Testing

3-349-448-03

16/11.11

Page 2

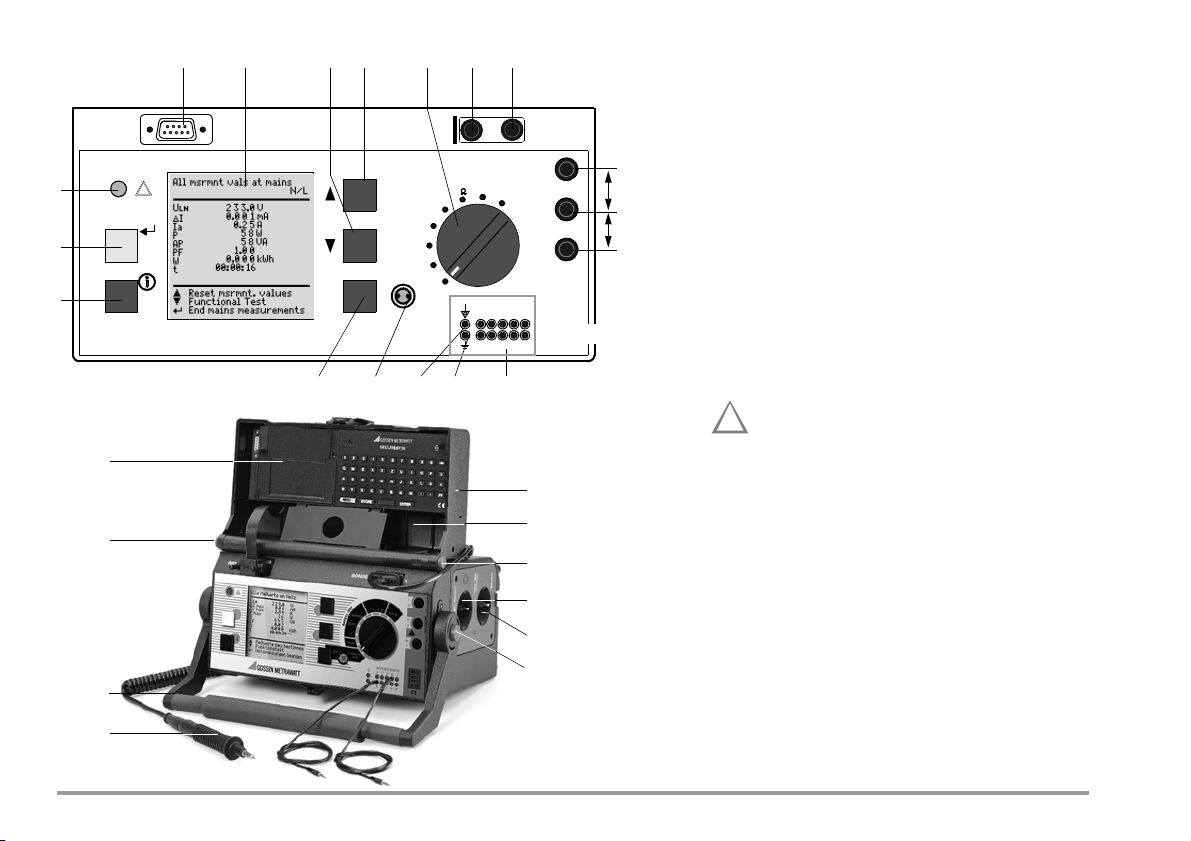

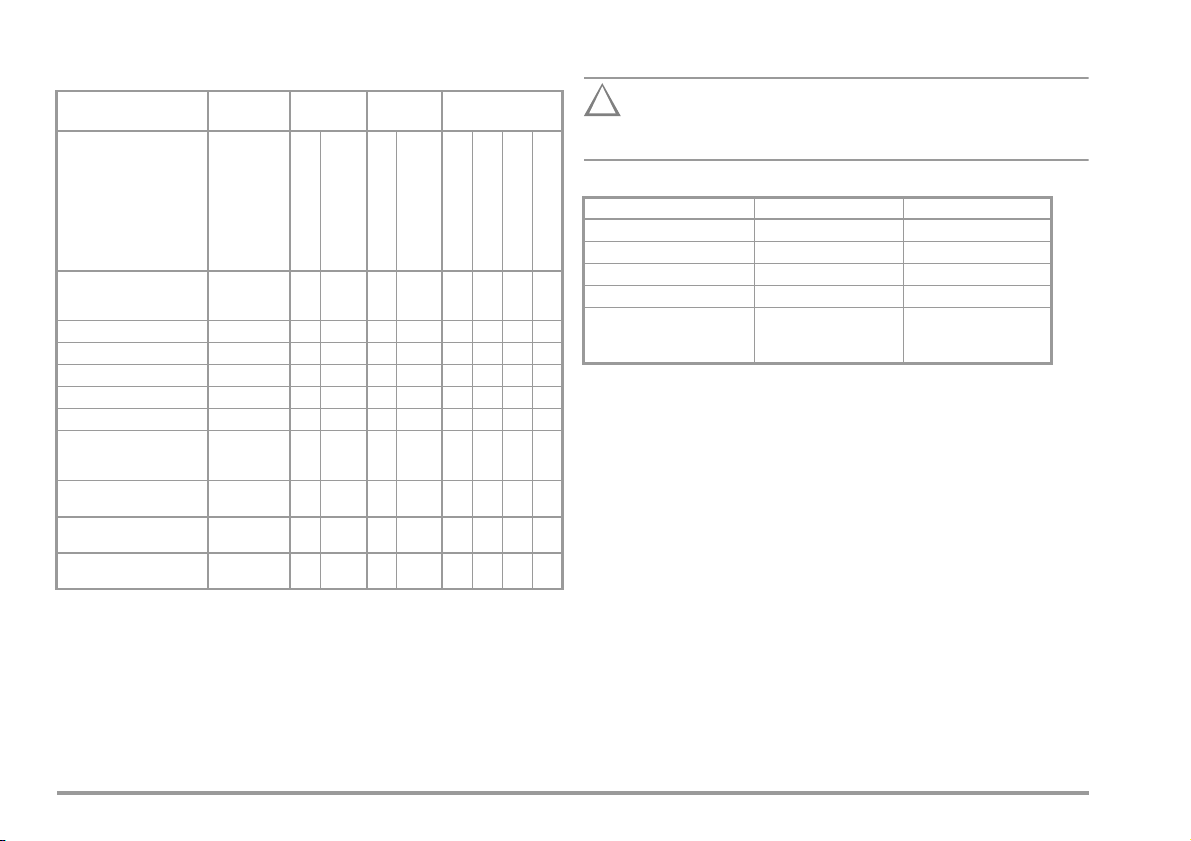

45678910

!

24

23

22

21

25

22

26

27

20

19

Probe connection

Insert the double plug of the probe into sockets 4 and

5 such that the plug with the white ring contacts

socket 5 (vertical bar).

Note: Contact problems with exposed conductive parts

when using the standard probe with test tip

In order to assure good contact, surface coatings must be

removed from devices under test with special tools at a suitable location so that the surface has a metallic shine. The tip

of the test probe is not suitable for scratching away paint, because this may impair its coating and/or mechanical

strength. The brush probe (Z745G) may be more suitable

than the test probe in certain individual cases.

Measurements at jacks 1 – 2 – 3

Always start with the measurement before contacting

the measuring point. Between jacks 1 and 2, a maxi-

11

12

13

RS232

IOIOI

PROBE

54

SONDE

Setup

3

2

1

HV

Function

Test

V

Aux

Applied Parts

AC E G I

BDFHK

!

Iso

I leakage

/

PE

Auto

L

3

max. 253 V

N

2

max. 10 V

SL

1

mum of 10 V may be applied. Between jacks 2 and 3,

14 15 1816 17

up to 253 V may be applied.

Attention: Jacks (2) and (3) are short-circuited

during all measurements at the test socket!

(Exception: see chapter 12.2)

Standard equipment

1

Test instrument with 10 + 2 connectors for application parts

1 Probe cable with test probe

1 Clip-on alligator clip for test probes

3 Clip-on quick-clamp terminals

10 conductor patient connection cable 2 mm

10 Clip-on alligator clip 2 mm

1 Calibration certificate per DKD

1 Operating instructions

1Carrying strap

Up-to-date PC software (free start-up programs or

demo software for data management, report and list

generation) is available on our website for download.

These operating instructions describe an

instrument with firmware version 7.24.

2 GMC-I Messtechnik GmbH

Page 3

1 Jack for protective conductor at device under test

Note

i

!

2 Jack for neutral conductor at device under test

3 Jack for phase conductor at device under test

4 Jack for connecting the probe

5 Jack for connecting the probe

6 Function selector switch

– Function Test: Function test

– Auto: Automatic test sequence according to selected standard

– PE: Protective conductor test

– Iso/HV: Insulation test / high-voltage test

– I leakage: Leakage current measurement

– V : Multimeter functions

– Aux: Auxiliary multimeter functions

– Setup: Device configuration

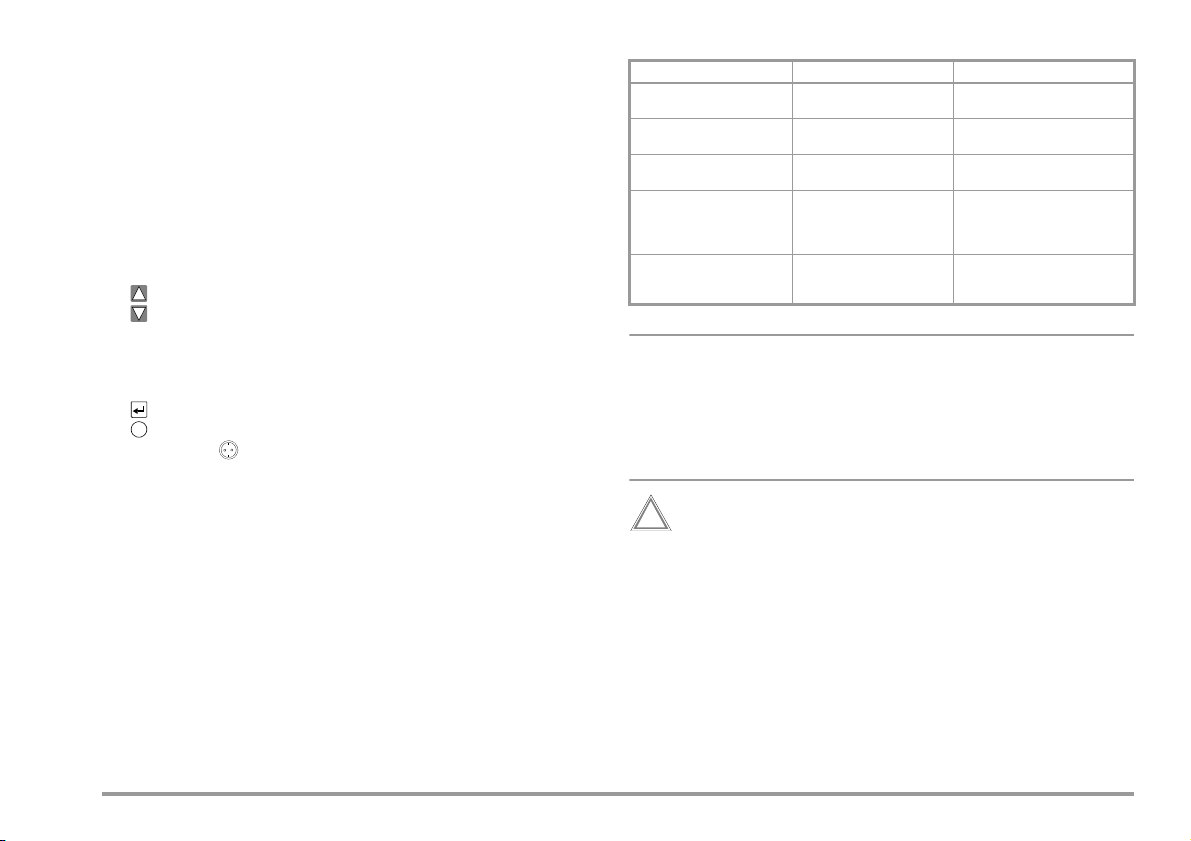

7 scroll key for menu and parameter selection

8 scroll key for menu and parameter selection

9 LCD window

10 Socket connector interface RS232 for (P)SI module SECUTEST PSI/SI+, storage

adapter

SECUSTORE

, barcode or RFID scanner

11 Signal lamp for mains connection error

12 key for entry and for starting test sequences and finger contact

13 help key (context sensitive)

14 Key next to the symbol for switching test voltage to

the test socket (only possible if symbol LED is blinking)

15 Signal lamp for the functions test

16 Functional earth (equipotential bonding)

17 Operational earth

18 Connector jacks for application parts

19 Push-buttons (left and right) for releasing the handle from its snap-in position

20 Earthing contact socket for service purposes (Feature B01),

e.g. for connecting a notebook or an A4 format printer, Terminal Data see page 63

21 Standard outlet socket (test socket) for connecting the device under test

22 Push-buttons (left and right) for releasing the lid

23 Lid

24 Compartment for probe and accessories

25 Cover or (P)SI module (accessory

SECUTEST PS I or SECUTEST SI+)

26 Carrying handle and tilt stand

27 Test probe (accessory probe with coil-cable SK2W (Z745N))

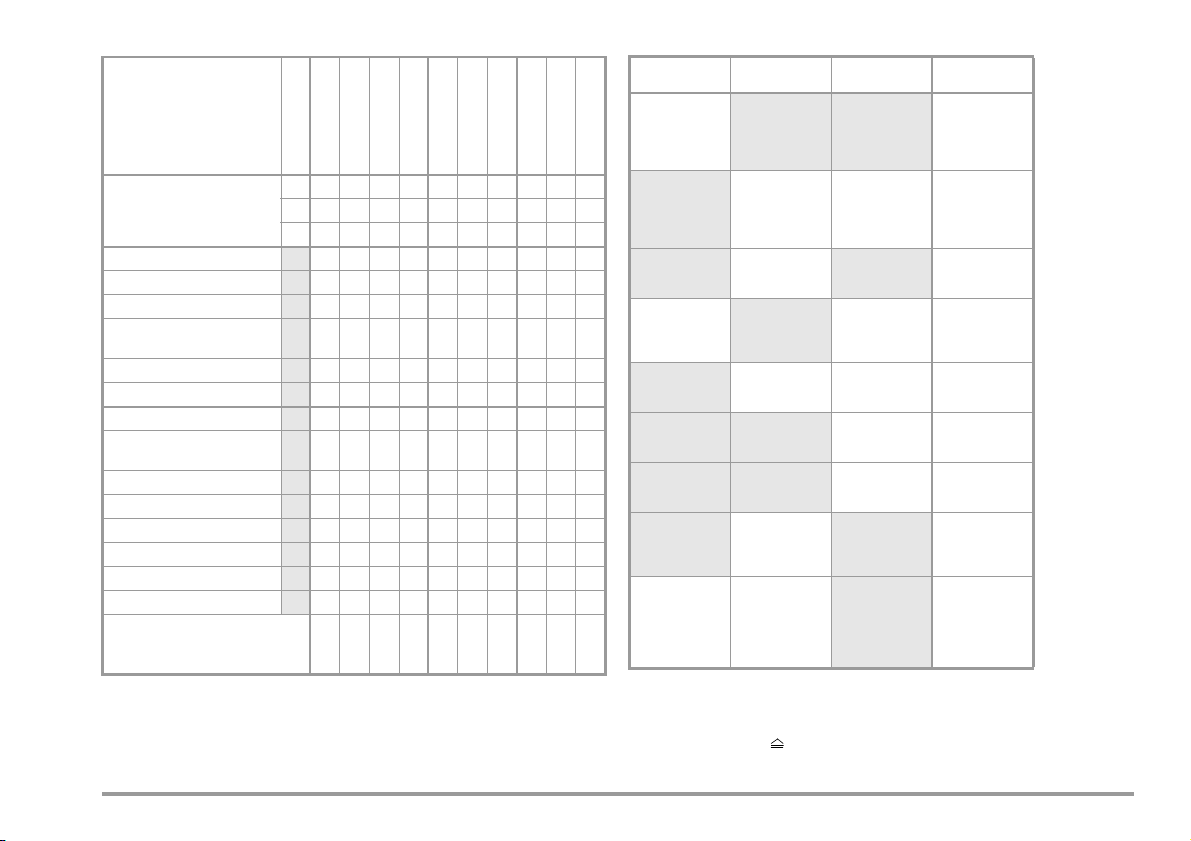

Overview of Available Probe Types

Probe Type Application Special Features

Standard probe (test probe with

coil-cable and alligator clip)

1)

SK2

1)

SK2W

Feature KD01 with probe SK5 Restriction with

Brush probe

Can be plugged onto all above

listed probes and test probes

1)

1)

Accessory

Max. test current: 25 A Probe with cable

Max. test current: 25 A Probe with cable (no coil-cable),

Max. test current: 25 A Probe with cable (coil-cable),

Feature G01 (I

short-circuit current < 25 A

Leakage current,

protective conductor resistance

>25A):

K

(no coil-cable)

2 meters long

2 meters long

Special probe in combination with

“automatic recognition of measuring point change” function (see

chapter 17)

For contacting devices under test

with rotating, vibrating, exposed

conductive parts

when using other probes than those specified above

The cables plugged into the sockets (4 and 5) must be short

circuited for testing with the probe, i.e. by plugging the ends of

the cable together, or via a conductive surface at the device

under test (4-wire measurement).

Remove any corrosion from the device under test.

Data Security

Measurement data, report data and user entries are stored to RAM at the

(P)SI module (accessory), as long as the respective battery supplies the

required amount of voltage.

Save your data to a PC on a regular basis in order to prevent any loss of data

at the (P)SI module. We assume no liability for data loss. We recommend the

following PC programs for data processing and data management:

• PS3 (transmission of measurement data to a PC, documentation,

management, report generating and deadline follow-up)

• PC.doc-WORD/EXCEL (report and list generation

• PC.doc-ACCESS (test data management)

• ELEKTROmanager/PROTOKOLLmanager for SECUTEST...

• patManager (Report and list generation)

GMC-I Messtechnik GmbH 3

Page 4

Contents Page Contents Page

1 Applications ...................................................................................6

8 Configuring Device Parameters ...................................................18

1.1 Table: Types of DUTs – Tests – Regulations .............................................. 6

1.2 Table: Individual Measurements and Regulations .....................................7

1.3 Table: Leakage Current Types ...................................................................7

1.4 List of Possible Options and Standard Types .............................................. 8

9 Measuring Protective Conductor Resistance ...............................19

9.1 Maximum Allowable Limit Values for Protective Conductor Resistance

for Connector Cables with a Length of up to 5 m ..................................... 20

2 Safety Features and Precautions ...................................................9

2.1 Notes Regarding the High-Voltage Test

(only Feature F02 or SECULIFE ST

HV) .......................................................10

3 Initial Start-Up ..............................................................................11

3.1 Connection to the Mains (115 V / 230 V, 50 Hz / 60 Hz) ............................11

3.2 Automatic Recognition of Mains Connection Errors ..................................12

4 General Notes ..............................................................................12

4.1 Online Instructions ....................................................................................12

4.1.1 Changing the User Interface Language .........................................................12

4.1.2 Automatic Safety Class Selection ..................................................................13

4.1.3 Manual or Automatic Operating Sequences ...................................................13

4.2 Online Help ................................................................................................13

4.3 Adjusting Contrast .....................................................................................13

4.4 Configuring Device Parameters, Setting Date and Time ...........................14

4.5 Configuring Measurement and Sequence Parameters .............................14

4.6 Setting Limit Values ..................................................................................14

4.7 Saving the Settings ...................................................................................14

5 Classification of Devices Under Test ............................................15

5.1 Safety Classes ...........................................................................................15

5.2 Application Parts (electrical medical devices) ..........................................15

6 Abbreviations ...............................................................................16

7 Connecting the Device Under Test ...............................................17

10 Insulation Measurement .............................................................. 20

10.1 Insulation Resistance R

10.2 Equivalent Leakage Current ..................................................................... 22

10.3 High-Voltage Test (Feature F02 or SECULIFE ST

. ....................................................................... 20

INS

HV) ................................. 24

11 Leakage Current Measurement ...................................................26

11.1 Earth Leakage Current IPE (Feature KA01) ................................................ 26

11.2 Housing Leakage Current I

11.3 Patient Leakage Current I

11.4 Patient Auxiliary Current IPA (Feature KA01) ............................................. 27

11.5 Residual Current I

RC .......................................................................................................27

(probe current, contact current) ................. 26

HL

PL ......................................................................................... 27

11.6 Device Leakage Current ILC per IEC 62353 (VDE 0751-1) ......................... 27

12 Multimeter Functions ...................................................................30

12.1 Probe Voltage U

12.2 Alternating / Direct Voltage U

12.3 Resistance R ............................................................................................. 31

– Max. 300 V ........................................................... 30

probe

– Max. 253 V .....................................30

AC/DC

13 Measurements with Accessories .................................................32

13.1 Alternating Current IC with Clip-On Converter ..........................................32

13.2 Protective Conductor Resistance R

13.3 Temperature T with Pt100/1000 Sensor ................................................... 33

via Clip-On Meter ..........................32

PE

14 Function Test ...............................................................................34

4 GMC-I Messtechnik GmbH

Page 5

Contents Page Contents Page

15 Measurements in Accordance with National and

International Standards with Selector Switch in Auto Position ... 36

15.1 Test Sequences .........................................................................................36

15.2 Setting Up Test Sequences .......................................................................37

15.3 Configuring Measuring Parameters ..........................................................39

15.4 Testing Devices in Accordance with DIN VDE 0701, Part 1 .......................40

15.5 Testing Devices in Accordance with DIN VDE 0701, part 240 ...................42

15.6 Testing Devices in Accordance with DIN VDE 0701-0702:2008 ................44

15.7 Testing Extension Cables for VDE 0701-0702 (VDE 0701 Part 1)

(optional EL1 adapter) ...............................................................................46

15.8 Testing Multiple Outlets for VDE 0701-0702 (optional EL1 adapter) .........47

15.9 Testing in Accordance with DIN EN 60 950 ...............................................48

15.10 Testing Devices in Accordance with EN 61010 ........................................50

15.11 Testing Devices in Accordance with EN 60335 ........................................52

15.12 Testing in Accordance with IEC 62353/VDE 0751 .....................................54

15.13 Testing in Accordance with EN 60601 (Feature KA01) .............................56

16 Storing in (P)SI Module (Accessory) and Database Operations

(Feature KB01) ............................................................................. 58

16.1 Storing Measurement Data in the (P)SI Module ........................................58

16.2 Database Operations .................................................................................58

16.2.1 Storing Test Results to the Test Instrument ...................................................58

16.2.2 Uploading Report Templates into Test Instrument, Reading Out From the Test

Instrument, Editing at the PC and Re-Saving to the Test Instrument ................58

16.2.3 Reading Out and Saving Test Results / Test Data from the (P)SI Module ..........58

20 RS 232 Interface .......................................................................... 64

20.1 Transmission of Measurement Results to the (P)SI module .....................64

20.2 PC Connection ...........................................................................................64

20.2.1 Software Evaluation of Measurement Results ................................................64

20.2.2 Instrument Control via Interface Commands ..................................................64

20.3 Interface Definition and Protocol ..............................................................64

21 Appendix ..................................................................................... 65

21.1 Evaluation of Measured Values for Individual Measurements

as well as for Calculated Quantities .........................................................65

21.2 Evaluation of Measured Values during Equivalent Leakage Current

Measurement (Automatic Test Sequence According to Standard) ........... 65

21.3 Index ......................................................................................................... 66

22 Maintenance - Recalibration ....................................................... 68

22.1 Housing Maintenance ...............................................................................68

22.2 Recalibration ............................................................................................. 68

22.3 Safety Checks ...........................................................................................68

22.4 Device Return and Environmentally Compatible Disposal ........................69

23 Repair and Replacement Parts Service

Calibration Center and Rental Instrument Service ...................... 69

24 Product Support .......................................................................... 70

17 Recognition of Probe to Protective Conductor

(Feature KD01) ............................................................................. 58

18 Storing Test Results and Printing in Report Form ....................... 59

19 Characteristic Values ...................................................................60

GMC-I Messtechnik GmbH 5

Page 6

1 Applications

Attention!

!

1.1 Table: Types of DUTs – Tests – Regulations

Start-up and

Modifications

Devices under test

to be tested in

accordance with the

following regulations

EC 62353 :2007

I

Laboratory instruments

Measuring and control instruments

Voltage generation devices

Electric tools

Electric heating devices

Electric motor devices

Lamps

Devices for entertainment

electronics, information and

communications technology

Cable reel, extension and

connection leads

Data processing and office

equipment

Electrical medical devices,

application parts

Testing after

Repairs

-0702:2008

DIN VDE 0701

DIN EN 62353:2008

(VDE 0751-1)

Periodic

Tes t in g

-0702:2008

1

EC 62353 :2007

I

DIN VDE 070

DIN EN 62353:2008

Routine Testing

EC 62353 :2007

I

DIN EN 62353:2008

DIN EN 60950/50 116

DINEN61010

DIN EN 60335/50 106

IEC 60601/DIN EN 60601

The test instrument may not be used for measurements

within electrical systems!

Applicable Standards

German National European International

DIN EN 61010 EN 61010 IEC 61010

DIN EN 60601 EN 60601 IEC 60601

DIN EN 60335-1 EN 60335-1 IEC 60335-1

DIN EN 60950 EN 60950 IEC 60950

IEC 62353 :2007

DIN EN 62353:2008

EN 62353 IEC 62353

(VDE 0751-1)

6 GMC-I Messtechnik GmbH

Page 7

1.2 Table: Individual Measurements and Regulations

Individual Measurements

per Regulation

Tes t Cur re nt [ A]

DIN VDE 0701-0702

DIN VDE 0701

DIN VDE 0701

DIN VDE 0701

DINEN60950

DINEN61010

DINEN60335

IEC 62353

0.2

Protective Conductor

Resistance

Insulation Resistance

Equivalent Leakage Current

High-Voltage Test

Equivalent (Device) Leakage

Current

Equivalent Patient Leakage Current

Residual Current

Contact Current

Absence of Voltage

(exposed conductive parts)

Housing Leakage Current

Earth Leakage Current

Patient Leakage Current

Total Patient Leakage Current

Patient Auxiliary Current

Device Leakage Current

Single Fault Conditions N

PE

Mains at Application Part

10

25

AC AC

Key

Standards printed in grey half-tone will be superseded by the new

DIN VDE 0701-0702:2008 standard.

Required test

IEC 601/EN 60 601 2nd

IEC 601/EN 60 601 3rd

1.3 Table: Leakage Current Types

DIN VDE

0701-0702

Equivalent

Leakage Current

Contact Current/

Measurement for

Absence of

Volta ge

Protective

Conductor

Current with

Residual

Current

Measurement

IEC 62353

(VDE 0751-1)

Equivalent

Device Leakage

Current

Equivalent

Patient Leakage

Current

Housing Leakage

Patient Leakage

Current

NC

Device Leakage

Current during

Operation, Direct

Measurement

Device Leakage

Current during

Operation,

with residual

Current

Measurement

DIN EN 60601-1 The following is

IEL interrupted

from N

Current

NC

Patient Leakage

Current

NC

Patient Auxiliary

Current

NC

Earth Leakage

Current

NC

Key

NC = normal condition

PAP = patient application part

PE = Potential earthing

PC = Protective conductor of the DUT

, system protective conductor

measured:

PROBE

(connected to

protective

conductor)

to L & N

PROBE

(connected to

protective

conductor)

to L & N

L & N & PE to

Patient Jacks

Probe to PE

Patient Jack to PE

Patient Jack to

Patient Jack

Protective

Conductor to PE

Protective

Conductor

Interrupted, Probe

+ PAP to PE

See chapter 11.5

GMC-I Messtechnik GmbH 7

Page 8

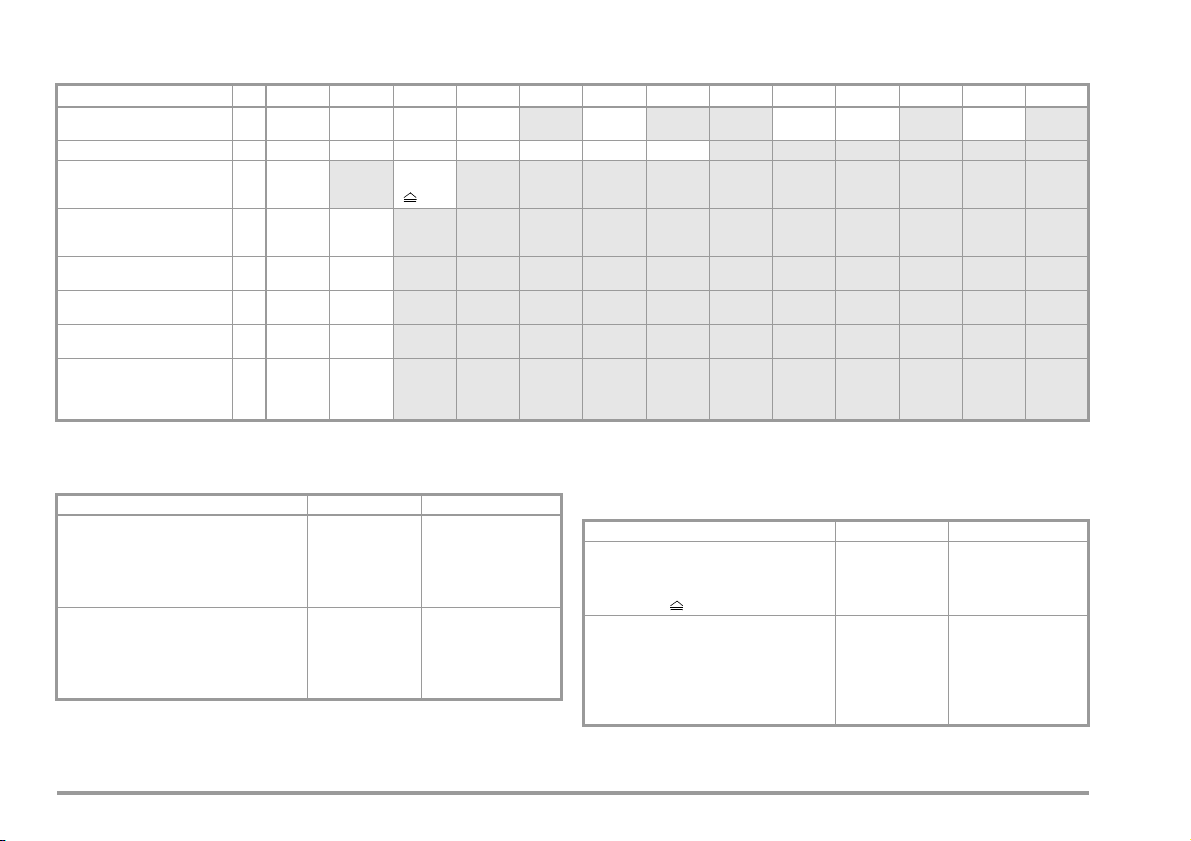

1.4 List of Possible Options and Standard Types

Features 00 01 02 03 04 05 06 07 08 09 10 11 XX

Mains Connection for

Respective Country

User Interface Language C DUKF I ECZENL

High Voltage Testing

HV-DC F without

AC Test Current 50/60 Hz

for Protective Conductor

Measurement

Test Sequence

for IEC 60601

Data Memory

for up to 125 Tests

Recognition of

Probe to Protective Conductor

Direct Printing after each

Measurement for Automatic

Test Sequences

Read-Out via RS232

1)

Each measured value is documented in this case, as opposed to the results of a

test sequence for which only the poorest value for each given test is displayed.

(via the PSI module, the SECUSTORE storage adapter or a PC)

5)

1)

B D

G 10 A 25 A

KA without with

KB without with

KD without with

KE without with

D + ser-

vice socket

4)

UK

max.

6.126 kV DC

( 4KVAC)

F/CZE DK

2)

Adapter set for international use (comes with Feature B01)

4)

if adapter (feature B11) is applied: HV-DC max. 1.5 kV DC

5)

without function test values and without comments on DUT

4)

China/AUS

4)

CH

adapter

set 2)

4)

Designation Type

Test instrument with test current

200 mA DC and 10 A AC

Sequences for IEC 61010, IEC 60 335,

IEC 60950 and IEC 60601,

data memory for up to 125 tests

SECULIFE ST M693A

Same instrument as M693A, however,

suited to international use with adapter

set for mains connection in the respective

user country and English user interface

language SECULIFE ST M693B

8 GMC-I Messtechnik GmbH

Article Number

Designation Type

Same instrument as M693A, however, with

test current 200 mA DC and 25 A AC,

additionally with high-voltage test max.

6.126 kV DC ( 4 KV AC) SECULIFE ST

Same instrument as M693C, however,

suited to international use with adapter

set (application of adapter: high-voltage

test max. 1.5 kV DC) for mains connection

in the respective user country and English

user interface language SECULIFE ST

Article Number

HV M693C

HV M693D

Page 9

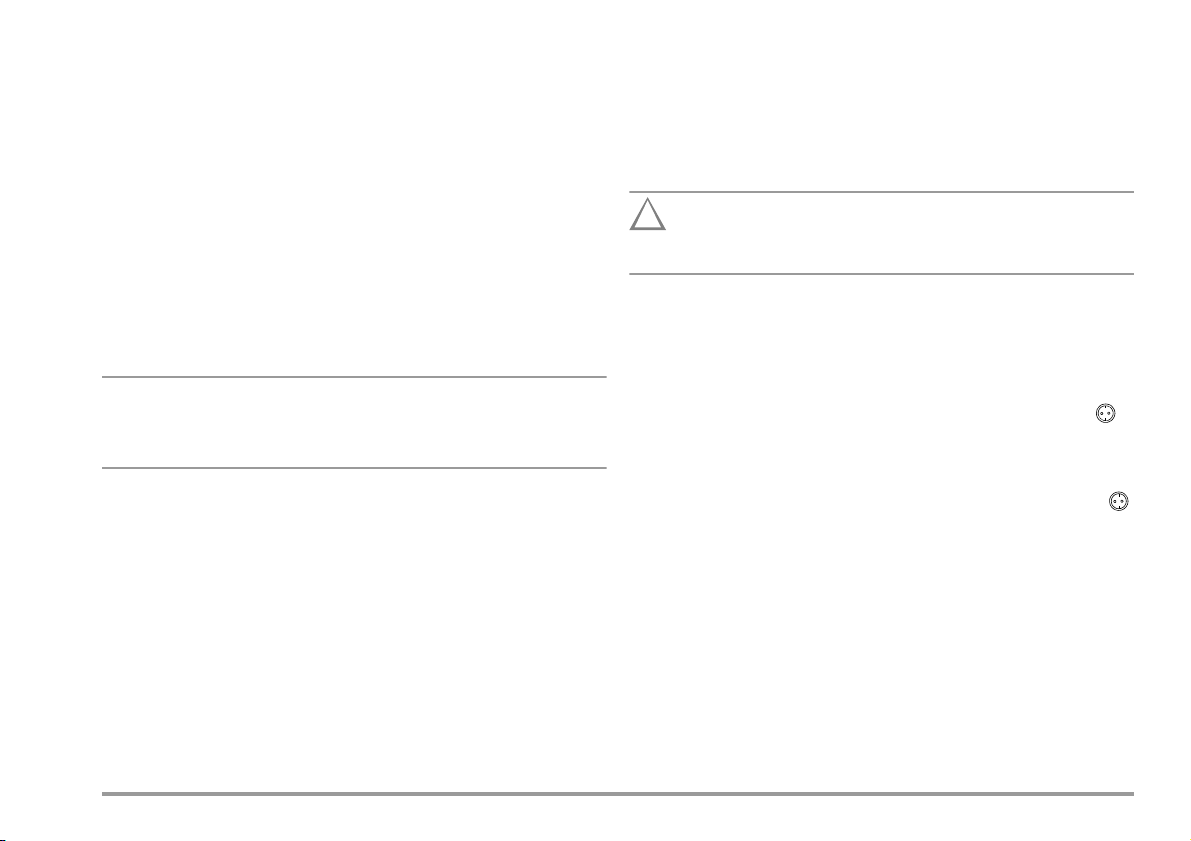

2 Safety Features and Precautions

Note

Attention!

!

This instrument fulfills the requirements of the applicable European and national EC guidelines. We confirm this with the CE marking. The relevant declaration of conformity can be obtained from GMC-I Messtechnik GmbH.

The test instrument has been manufactured and tested in accordance

with the following safety regulations:

IEC 61010-1 / DIN EN 61010-1 / VDE 0411-1, DIN VDE 0404, DIN VDE

0413 Part 2 and 4 and DIN VDE 0104 (Feature F02 or

Only when used for its intended purpose, the safety of the user, the test

instrument and the device under test (electrical equipment or electrical

medical devices) is assured.

Read the operating instructions carefully and completely before placing your test

instrument into service, and follow all instructions contained therein. Make sure

that the operating instructions are available to all users of the instrument.

Tests may only be performed by a qualified electrician or under the supervision of

a qualified electrician. The user must be instructed by a qualified electrician

concerning performance and evaluation of the test.

Manufacturers and importers of electrical medical devices must

provide documentation for the performance of maintenance by

trained personnel.

Observe the following safety precautions:

• The instrument may only be connected to electrical systems with a

maximum of 230 V +10% which are protected with a fuse or circuit

breaker with a maximum rating of 16 A.

• Measurements within electrical systems are prohibited.

• Be prepared for the occurrence of unexpected voltages at devices

under test (for example, capacitors can be dangerously charged).

• Make certain that the measurement cables are in flawless condition,

e.g. no damage to insulation, no interruptions in cables or plugs etc.

• When using a probe with coil cable (SK2W): Grip the test probe firmly,

for example after insertion into a jack socket. Tensioning at the coil

cord may otherwise cause the test probe to snap back resulting in

possible injury.

• Measurement of Insulation Resistance and Equivalent Leakage Current

This test is performed with a maximum voltage of 500 V, with a current

SECULIFE STHV)

limit having been set (I < 3.5 mA). However, contacting the terminals

(3 or 2) causes an electric shock which, in turn, may result in accidents.

• Leakage Current Measurement

During leakage current measurement it is imperative to ensure that the device under test is operated at line voltage. Exposed conductive parts may

be charged with hazardous contact voltage during the test and may consequently not be touched under any circumstances. (There is a power

shutdown as soon as the leakage current is higher than approx. 10 mA).

The function test may only be performed after the DUT has

successfully passed the safety test!

Switching loads on and off

When switching the DUT on or off under load it is imperative that you adhere to the order indicated below. This helps to prevent excessive wear

and tear of the mains relays at the test instrument.

Before the measurement:

1) DUT: Switch the DUT off at the proprietary switch.

2) SECULIFE ST or SECULIFE ST

3) DUT: Switch on the DUT at the proprietary switch.

After the measurement:

4) DUT: Switch the DUT off at the proprietary switch.

5) SECULIFE ST or SECULIFE ST

The measuring and test instrument may not be used:

• If it demonstrates visible damage

• With damaged connector cables, measuring cables or patient ports

• If it no longer functions properly

• After extraordinary stresses due to transport

In such cases, the instrument must be removed from operation and

secured against unintentional use.

HV:

Apply line voltage to the test socket .

HV:

Disconnect the test socket from the line .

GMC-I Messtechnik GmbH 9

Page 10

Meanings of Symbols on the Instrument

Attention!

!

!

The symbols on the instrument have the following meanings:

Warning regarding dangerous electrical voltage

Warning concerning a point of danger

(Attention: observe documentation!)

Test socket

Mark of approval from VDE test authority

Indicates EC conformity

This device may not be disposed of with the trash. For further

details on the WEEE marking, please refer to our website

www.gossenmetrawatt.com and enter search term ’WEEE’.

2.1 Notes Regarding the High-Voltage Test

(only Feature F02 or SECULIFE ST

The KS13 cable set, or similar cable sets, may not be used for the high-voltage

test. The high-voltage test may only be performed directly via the test socket!

Do not hold the device under test in your hand during testing,

especially when testing safety class II devices.

Make sure that the device under test does not make contact

with any equipment or persons during testing.

Liability Exclusion

In the event of sparkover, PCs operated in proximity to the test instrument may

“crash” resulting in data loss. All data and programs should be suitably backed up

before high-voltage testing is performed, and computers should be shut down if

necessary. A crash may occur even if no RS 232 connection has been established.

The manufacturer of the test instrument assumes no liability for direct or

consequential damage to computers, peripherals or data which occurs

during high-voltage testing.

The manufacturer assumes no liability for defects at the device under test

which result from high-voltage testing. As a rule, defects can only occur at

devices under test which are not in compliance with applicable standards,

which were previously damaged or which have been improperly repaired,

because high-voltage testing is required for type and routine testing by

IEC 61010-1/EN 61010-1 / VDE 0411, part 1, as well as EN 60 335,

EN 60601 and EN 60950.

HV)

10 GMC-I Messtechnik GmbH

Page 11

3 Initial Start-Up

Attention!

!

L1

N

green-yellow

green-yellow

PE

L1

L2

L3

N

PE

L1

L2

L3

N

green-yellow

U

L–N

= 115 V / 230 V

Connection to the Mains

3.1 Connection to the Mains (115 V / 230 V, 50 Hz / 60 Hz)

õ Connect the mains plug at the test instrument to the mains power out-

let. The function selector switch can be set to any position.

If a mains outlet (earthing contact outlet) is not available, or if only a

3-phase outlet is available, the adapter socket can be used to connect

the phase conductor, the neutral conductor and the protective conductor. The adapter socket has three permanently attached cables

and is included with the KS13 cable set.

If connection is not possible via an earthing contact outlet: Shut

down mains power first.

Then connect the cables from the coupling socket to the mains

using pick-off clips in accordance with the diagram.

Disconnection from mains power is only possible with the mains

plug.

GMC-I Messtechnik GmbH 11

Page 12

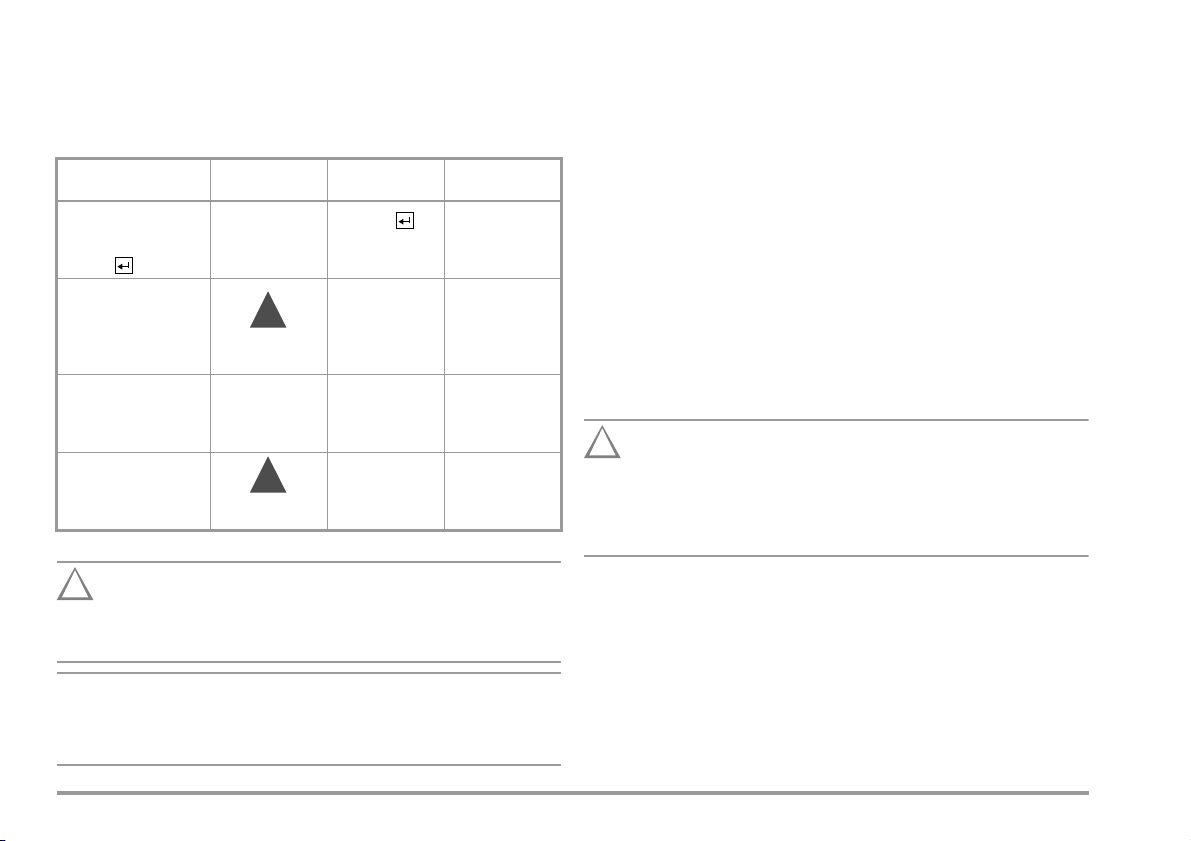

3.2 Automatic Recognition of Mains Connection Errors

Attention!

!

Note

Attention!

!

!

!

The test instrument automatically recognizes mains connection errors,

if the conditions in the following table have been fulfilled. The user is

informed of the type of error, and all measuring functions are disabled

in the event of danger.

Typ e of Ma ins

Connection Error

Voltage at protective

conductor PE to finger

contact

(key)

Protective conductor PE

and phase conductor L

reversed and/or

neutral conductor N

interrupted

Contact voltage at

protective conductor PE

to neutral conductor N

or phase conductor L

Mains voltage

too low lamp

1)

In SETUP – test sequence – IT system

In either of the first two cases listed in the table above,

immediately disconnect the test instrument from the mains

and eliminate the error!

Message Condition Measurements

Text appears at

LCD

lamp

lights up

Text appears at

LCD

lights up

Press

key

U 40 V

Voltage at PE

>65V

U 25 V

U

< 90/180 V

L-N

disabled

impossible

(no supply power)

disabled, although

disabling can be

deactivated

possible

under certain

circumstances

4 General Notes

4.1 Online Instructions

Integrated online instructions inform the operator regarding all required

connections, necessary work steps, operator errors, measurement results

and more in all measuring modes.

Information and test results appear at the dot matrix LCD in clear text.

4.1.1 Changing the User Interface Language

If you require a different language for the user interface of the test instrument, you can load it into your test instrument by means of the update

and options installation program „SECU-Up“. The program is available for

download from our website www.gossenmetrawatt.com (Products >

Software > Software for Testers > SECU-Up).

Upon installation on your PC and starting the program, you proceed by

selecting the „Update“ menu and choosing a language from the following

list:

Deutsch, English, Français, Italiano, .

Only one language at a time can be installed on the test instrument, the

one previously installed is overwritten in the process.

1)

During data transmission, the test instrument and PC may not

be disconnected from the mains power supply under any circumstances.

No other programs under WINDOWS may be activated during

the update.

Voltage at the electrical system’s protective conductor PE may

result in distorted measurement values during testing for the

absence of voltage, or during leakage voltage measurements.

12 GMC-I Messtechnik GmbH

Page 13

4.1.2 Automatic Safety Class Selection

Note

Auto

Depending upon the type of mains plug or the connection configuration

for the device under test, the test instrument recognizes the respective

safety class and recommends its use for the measurement to be performed.

4.1.3 Manual or Automatic Operating Sequences

Depending upon selections made in the setup menu (selector switch in

the Auto position), the next measurement is started automatically after the

current measurement has been completed, or can only be started after

manual acknowledgement. The integrated online instructions are adequate for most tests and measurements. However, the contents of these

operating instructions should nevertheless be read and observed.

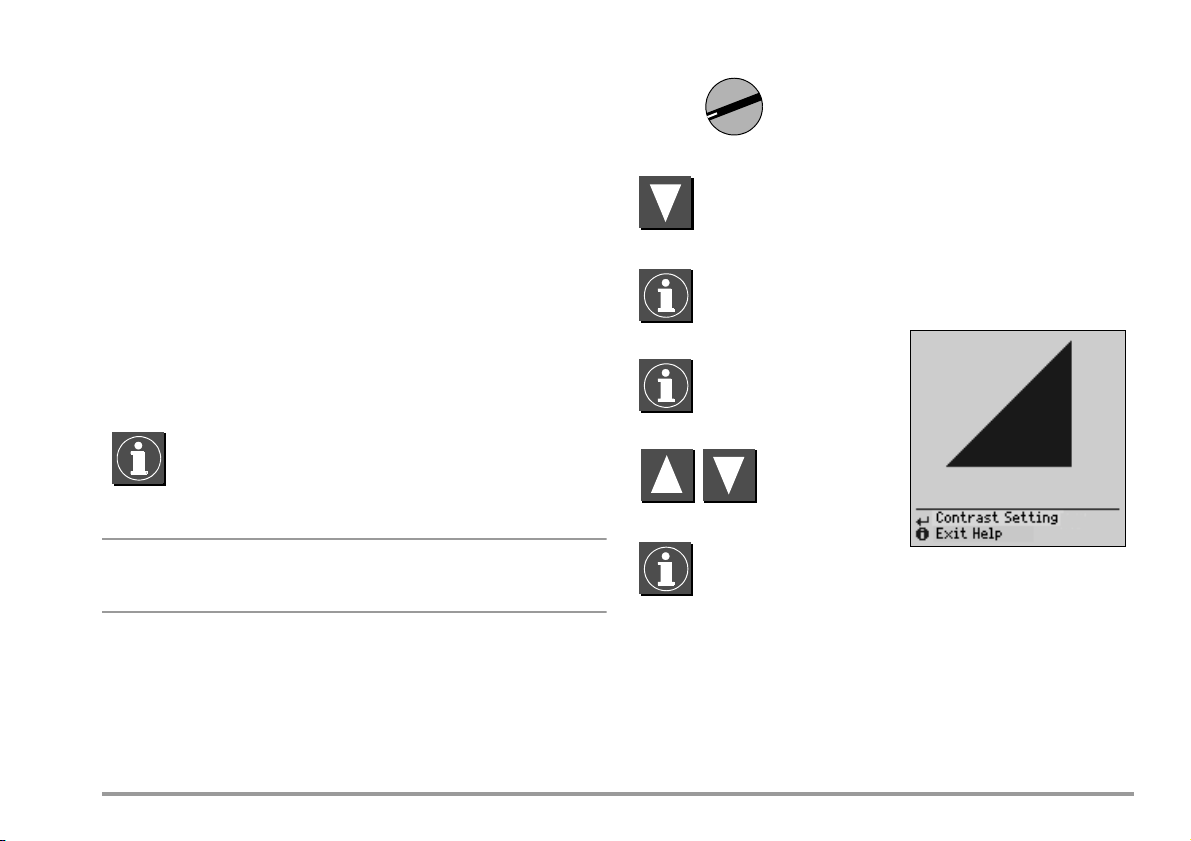

4.2 Online Help

Online help can be queried and displayed at the LCD for all measuring

and test functions, and for almost all settings. Schematic diagrams which

illustrate proper connection of devices under test to the test instrument

can be displayed as well.

õ Press the following key in order to query online help:

4.3 Adjusting Contrast

Set the selector switch to Auto.

Select the “Setup” menu, “return” is highlighted.

Activate contrast adjustment.

Press and hold the ENTER key.

õ Press the same key again in order to exit online help.

Adjust contrast.

Online help can be queried during measurement by pressing

and holding the help key.

Return to the menu.

Store the contrast setting to permanent memory with the save function in

the setup menu.

GMC-I Messtechnik GmbH 13

Page 14

4.4 Configuring Device Parameters, Setting Date and Time

Device parameters and functions which are valid for all selector switch

positions can be activated or deactivated with the selector switch in the

Setup position (see chapter 8 on page 18).

4.5 Configuring Measurement and Sequence Parameters

Measurement and sequence parameters, as well as functions, can be

activated or deactivated in the setup menu (selector switch in the Auto

position) for the respective test regulation. Refer to chapter 15.3 on page

39 for the significance of the various parameters.

4.6 Setting Limit Values

Upon delivery, the limit values set forth (at the point in time of issue) in applicable national and international standards are stored to the test instrument. Limit values for each of the respective standards can be queried

and changed if required with the setup menu (selector switch in the Auto

position), but changes can only be made which result in even stricter testing than is required by the respective standard.

Newly entered limit values become effective immediately. However, these

are only stored to memory permanently after activating the store function

in the setup menu.

If the limit values set forth in the standards for certain safety classes need

to be restored despite individualized settings, the menu function all values

per standard in the limit values sub-menu must be selected and acknowledged with the key.

If the limit values set forth in the standards are changed, the instrument’s

device software can be updated via the RS 232 interface.

4.7 Saving the Settings

All of the settings and changes which have been entered to the configure,

limit values (selector switch in the Auto position) and zero point (temperature

measurement) (selector switch in the Aux position) menus, as well as the se-

lected contrast setting are retained until the selector switch is turned, or

the test instrument is disconnected from mains power. If settings and

changes should be retained even after mains power has been interrupted,

they must be saved in the setup menu for the respective test regulation or

selector switch position.

14 GMC-I Messtechnik GmbH

Page 15

5 Classification of Devices Under Test

5.1 Safety Classes

Devices assigned to all of the following safety classes are equipped with

basic insulation, and provide for protection against electrical shock by

means of various additional precautions as well.

Safety Class I Devices

Exposed, conductive parts are connected to the protective conductor so

that they are not charged with voltage if the basic insulation should fail.

5.2 Application Parts (electrical medical devices)

Type B Application Parts (body)

Devices of this type are suitable for both internal and external patient

applications, except for use in direct proximity to the heart.

These devices provide for adequate protection against shock especially

as regards:

• Reliable leakage current

• Reliable protective conductor connection if utilized

Devices of the following safety classes are allowable:

I, II, III or devices with internal electrical power supply.

Safety Class II Devices

These devices are equipped with double insulation or reinforced insulation.

Safety Class III Devices

and Devices with Internal Power Supply

These devices are powered with Safety Extra Low Voltage (SELV). Beyond

this, no voltages are generated which exceed SELV. These devices may

not be connected to the mains. They may only be connected to the test

instrument at jacks 1 through 3.

Type BF Application Parts (body float)

Same as type B, but with type F insulated application parts.

Type CF Application Parts (cardiac float)

Devices of this type are suitable for use directly at the heart. The application part may not be grounded.

Devices of the following safety classes are allowable:

I, II or devices with internal electrical power supply.

Note: The DUT may only be connected to jacks 1 to 3 at the test instrument. It is only possible to perform a visual inspection, a measurement of

the insulation resistance or the supply voltage, see parameter “SC II I U

on page 39.

”

V

Classification Parameter (in the Sequence ... menu)

The test instrument always performs testing in accordance with the strictest limit values of the respectively selected safety class. The test is failed if

this limit value is exceeded.

However, higher limit values are allowed for certain devices under test.

If the classification parameter has been activated (= x), the user is asked if

higher limit values are allowable for these devices. If the user responds

with “Yes”, the DUT is reevaluated and the test may be passed.

Devices with Internal Power Supply

Devices with internal power supply are tested like permanently connected

Safety Class II or II I devices.

GMC-I Messtechnik GmbH 15

Page 16

6 Abbreviations

AE Error condition: application part grounded

AP Apparent power (during function test)

B, BF, CF Classifications for application parts

DEFI Defibrillator

I Residual current, fault current (during function test)

I

max

RC

wc

HE Error condition: housing grounded

I

CLIP

I-EHC

SCII

I-EHL

A1/A2

I-EHL

FRPE

IEL, I-EL Equivalent leakage current

, I-EDL

I

EDL

I

, I-EPL Equivalent patient leakage current

EPL

, IHL, I-HL Leakage current (differential, probe or contact current)

I

L

(Ia) (Maximum) load current (during function test)

I

L(max)

I

LC

I

PA

I

PE

I

PL

I

PMAP

IRC, (IRe) Residual current (current at protective conductor during

, I-HL Contact current (housing leakage current)

I

C, IHL

IT-system The IT system makes no direct contact between active

L Phase conductor connection of DUT

MedGV German medical device ordinance

Maximum residual current (during function test)

Residual current worst case

Current at clip-on meter

Equivalent device leakage current for devices with

additional safety class II components

Equivalent device leakage current with note A1/A2

(cross-reference within the standard)

Equivalent device leakage current for portable x-ray devices

+PE: with additional protective conductor

–PE: without additional protective conductor

Equivalent device leakage current (current at protective conductor)

Device leakage current

Patient auxiliary current

Earth leakage current (current at protective conductor)

Patient leakage current

Mains to application part (patient leakage current measurement)

automatic test sequence)

conductors and grounded parts: bodies within the electrical system are grounded.

MSELV Medical safety extra-low voltage

N Neutral conductor connection of DUT

NC Normal condition

OE Operational earth

P Active power (during function test)

PA Functional earth (equipotential bonding)

PE Protective conductor connection of DUT

PF Power factor (during function test)

RResistance

, R-INS Insulation resistance

R

INS

R-INS AP-PE Insulation resistance: application part to PE

R-INS

INT. KARD.

Insulation resistance: intercardiac

(application in proximity to the heart)

R-INS NL-PE Insulation resistance: neutral/phase conductor to PE

, R-PE Protective conductor resistance

R

PE

R-PEmains Protective conductor resistance limit value for

+mains: device under test with mains cable

–mains: device under test without mains cable

(protective conductor resistance limit value for mains

cable only = 0.1

SELV Safety extra-low voltage

SFC Single-fault condition

t On-time (during function test)

T, Temp Te mper a tur e

U

AC/DC

U

REF

, U-HV High-voltage

U

HV

, U-INS Test voltage for insulation measurement

U

INS

, U-LN Line voltage

U

LN

U

MEAS

U

Probe

AC/DC voltage

Reference voltage: voltage to which leakage current is

related (as a rule nominal line voltage)

Voltage at which testing was executed.

Displayed for all leakage current measurements.

Probe voltage

W Electrical energy (during function test)

ZVEH General Association of German Electricians

MLV manufacturer’s limit value

MPG German medical product law

16 GMC-I Messtechnik GmbH

Page 17

7 Connecting the Device Under Test

Note

Note

Attention!

!

Attention!

!

Attention!

!

õ Connect the DUT in accordance with the schematic diagrams included

in the online help function.

Connection of the DUT to the test instrument depends upon:

• The type of device under test:

electrical equipment or not, with or without application parts

• The type of connector included with the DUT:

– With plug (“to test socket” parameter), applies to EL1 adapter as well

– Without plug, single or multi-phase connection (“to jacks” parameter)

– No connection to tester (“permanent connection” parameter),

see also chapter 3.1

Whether or not an adapter is used:

– Adapter to socket (customer specific adapter)

– AT3-II S to socket, adapter for devices which are equipped with

5-pole, 16 A CEE plugs

– AT3-III E to socket, adapter for devices which are equipped with

5-pole, 32 A CEE plugs, see AT3-III operating instructions for test

sequence.

• The DUT’s safety class (I, II or III)

The DUT must be switched on for all tests. Switches, relays,

temperature regulators etc. must all be taken into consideration.

The test instrument automatically recognizes whether or not the DUT is

connected to jacks 1 through 3. The instrument also recognizes whether

or not the DUT has been connected to the test socket. As a default setting, the program sequence assumes that the plug from the DUT has

been connected to the test socket.

õ Position the cursor at the third line in the start menu for the test se-

quence.

õ A selection of possible connection setups can be displayed by

activating the key.

õ Select the desired connection setup with the cursor and

acknowledge with the key.

For omitting the protective conducter test in the case of fully insulated devices see

page 65.

Protective Conductor and Insulation Resistance Measurements for Permanently

Installed Devices Under Test

Deactivate the electrical system which supplies power to the

device under test before connecting the test instrument!

õ Remove the mains fuses from the device under test and disconnect

the neutral conductor N inside the device under test.

Measuring Contact Current (absence of voltage)

Make sure that the contacted parts are not grounded.

High-Voltage Test (Feature F02 or SECULIFE ST

The KS13 cable set, or similar cable sets, may not be used

for the high-voltage test. The high-voltage test may only be

performed directly via the test socket!

HV)

Safety Class II Devices with Safety Class I Mains Plugs

If the device under test is equipped with a safety class I plug

although it complies with safety class II, safety class I is recognized by the test instrument. If this is the case, switch from safety

class I to safety class II in the initial menu.

If the test instrument is unable to automatically recognize how the DUT

has been connected, the recommended connection setup should be

double checked and determined manually if necessary.

GMC-I Messtechnik GmbH 17

õ Connect the device under test to the test socket.

õ Safety class II only: Connect the probe to jacks 4 and 5.

Make sure that the application parts are not connected during

the high-voltage test!

Page 18

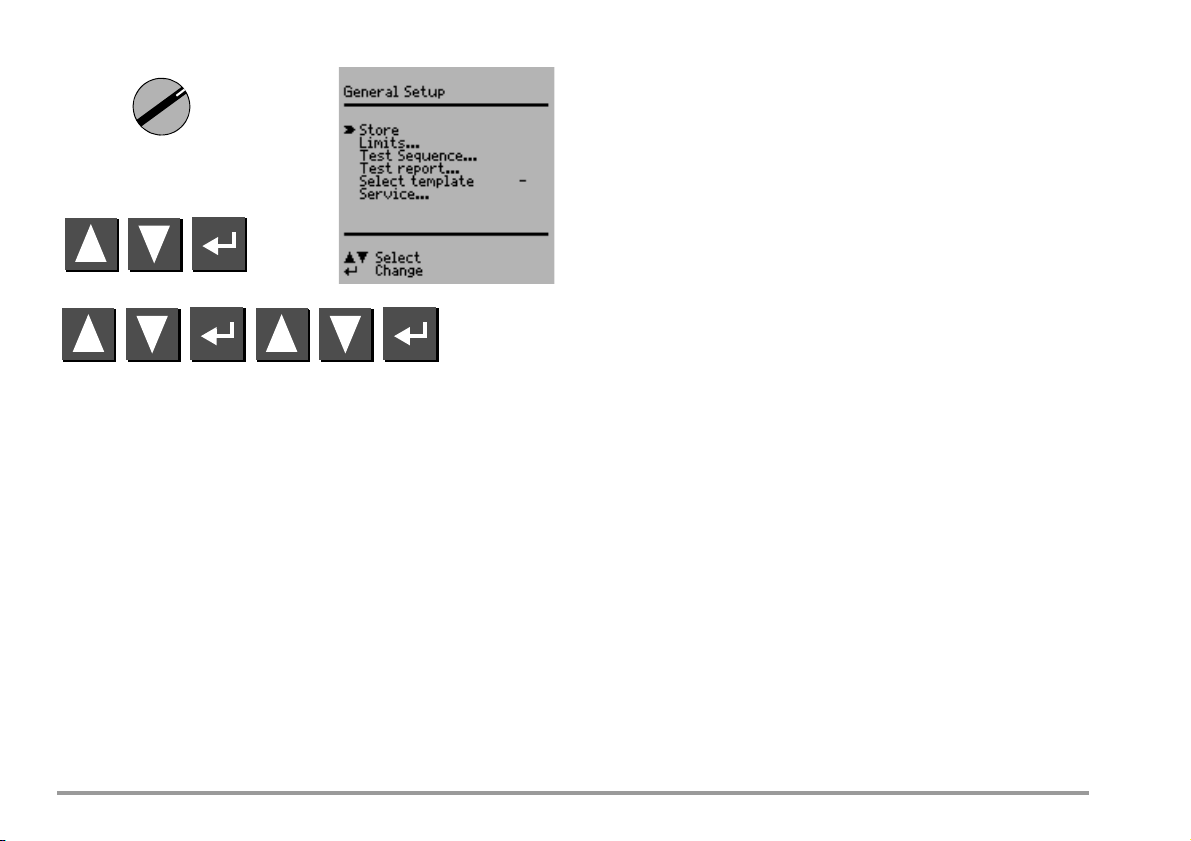

8 Configuring Device Parameters

Setup

duration selected in seconds under “Mains pause”

has elapsed.

Automode x: for fully automatic test sequences the messeges

are mainly suppressed

Test Sequence ...

General device parameters can be

configured and saved with the selector

switch in the Setup position.

Settings x / – = function activated / deactivated

Single-fault

If the single-fault condition has been activated, the test

is interrupted as a failure as soon as an error occurs.

Auto Class PSI Test results (passed or failed) for the various selector

switch positions are automatically assigned to the 8

statistics channels.

inc. Service Error Measurement results are compensated by taking

Select a menu and acknowledge.

IT Network Testing in IT systems can be performed by suppress-

service error into consideration (measuring error).

ing tests for U

whether or not voltage is present at PE.

PE-N

. The U

test determines

PE-N

(Leakage current measurement results may other-

Select parameter and acknowledge, change setting and acknowledge.

Limit values ...

Settings x / – = function activated / deactivated

Illumination Background illumination for the LCD. One of three

different conditions can be selected with the up and

down scroll keys: x: continuously on, –: off

Acst Sig, Seq

Acst Sig, Meas Acoustic signal is generated for: Measured value

Auto meas. point Prerequisite: Feature KD01. An acoustic signal indi-

numbers 1 through 9: duration in minutes after which

illumination is automatically deactivated.

Test time Duration of a single test (0 255 s)

Reference voltage: Voltage to which leakage current makes reference

(as a rule nominal line voltage)

Earth fault: During the short-circuit test, testing is also performed

to determine whether or not a connection exists

Direct Print-Out

Reports Reports which have been saved to memory can be

between L/N and PE (short-circuit to exposed conductive part). We assume that a short-circuit to an

exposed conductive part exists in the event of leakage current greater than 15 mA from L/N to PE. This

value should be increased for some DUTs (in particu-

Select template a report template can be selected for print-out from

Service – Time and date settings

lar high-current consumers), because greater leakage currents are present.

Mains wait Line voltage is first applied to the test socket.

18 GMC-I Messtechnik GmbH

However, testing does not begin until after the

wise be distorted.)

Acoustic signal is generated for: Incorrect connection of the

DUT, error in the electrical supply system, next test step.

fluctuations, test current polarity reversal

cates whether or not the probe is connected to the

protective conductor. The test sequence is run automatically.

Rapid signal frequency: probe connected to PE

Slow signal frequency: next measuring point

Prerequisite: Feature KE01, see chapter 18 on page 59.

selected from a list with an ID number and displayed

(see chapter 18 on page 59).

of 5 different templates.

(if a (P)SI module is used, the same time and date

must also be entered to the (P)SI menu)

– Service functions (password required)

Page 19

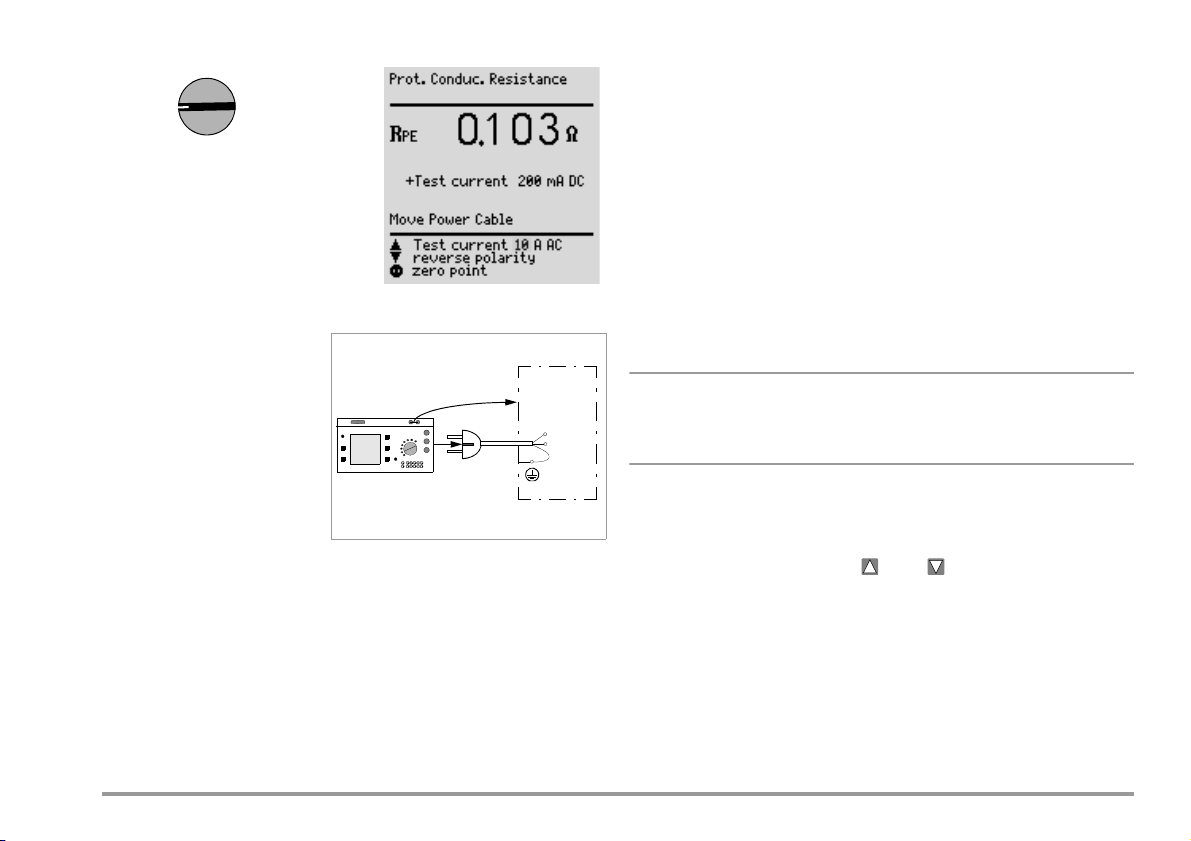

9 Measuring Protective Conductor Resistance

Note

PE

Connecting Safety Class I Devices to the Test Socket

When the DUT is connected, resistance is measured between the protective conductor terminal at the test socket or at the PE jack and the probe

connection at the DUT (contact with conductive parts of the housing).

õ In order to measure protective conductor resistance, contact a

conductive part of the housing with the probe, which is connected to

the protective conductor.

During measurement, the connector cable must only be moved in as far as

it is accessible during repair, modification or testing.

If a change in resistance occurs during the manual test step of the continuity test, it must be assumed that the protective conductor is damaged,

or that one of the connector contacts is no longer in flawless condition.

Definition

Protective conductor resistance

Testing Extension Cables

See test sequence in chapter 15.7 on page 46.

is the sum of the following

resistances:

• Connector cable or device

connector cable resistance

• Contact resistance at plug

and terminal connections

“Connection of the DUT: SC I/II” is not displayed when the test is

performed individually, but rather only during the automatic test

sequence.

• Extension cable resistance if

utilized

Resistance is measured:

• Between each conductive

part of the housing and the earthing contacts at the mains and the de-

vice plug (if a removable mains connector cable is used), or the protec-

Selecting Test Current and Polarity

Test current amperage (200 mA DC or 10 A AC (Feature G00 or SECULIFE ST) or

200 mA DC, 25 A AC (Feature G01 or SECULIFE ST

HV)) as well as polarity can

both be changed by pressing the or the key.

tive conductor terminal for permanently installed devices.

• as 4-pole measurement

• Between the earthing contacts at the mains plug and the earthing

contacts at the device plug for device connector cables

• Between the earthing contacts at the mains plug and the earthing

contacts at the coupling socket for extension cables

Testing with 10 A Test Current (Feature G00 or SECULIFE ST)

or 25 A (Feature G01 or SECULIFE ST

HV)

The test has a maximum duration of 30 s (fixed value) if 10 A or 25 A test

current is used. After this time period has elapsed, the last measured

value is frozen and “data hold, measurement stopped” appears at the display. If the test instrument becomes excessively warm, testing cannot be

repeated until after a waiting period of 1 minute. When testing with 10 A or

GMC-I Messtechnik GmbH 19

25 A, the last measurement can be repeated if the test results in failure.

Page 20

Combined Testing – Differential Protective Conductor Resistance

Iso / HV

f

o

r

S

C

I

I

Zero balancing is also possible for protective conductor measurement. With

zero balancing, all subsequent measurements are adjusted with an offset

such that 0 is displayed for a selected reference point which is connected to the protective conductor. When test points are contacted with

the probe which are electrically connected to this reference point, differential resistance R

point is displayed. The mains release key must be activated during

measurement in order to perform zero balancing. Press key

between the reference point and the contacted test

PE

„Store

value“ in order to save the reference and/or correction value. The meassage „Zero point corrected“ concerning the reference value is displayed

during all future measurements.

Attention: It is absolutely essential to delete the reference value after the

reference value has been stored and the test has been performed as it is

taken into account in all future tests. To delete the value, the procedure is

the same as for storage, press key

„Delete value“.

9.1 Maximum Allowable Limit Values for Protective Conductor Resistance for Connector Cables with a Length of up to 5 m

R

PE

Housing –

Device Plug

0.2 0.3

0.2 0.2

3)

Open-Circuit

Voltage

< 24 V

4 V < U

L

Tes t Sta nd ard Te st C urre nt

VDE 07010702:2008

IEC 62353

(VDE 0751-1)

EN 61010

EN 60335

EN 60950

EN 60601 0.1 0.2

1)

This value may not exceed 1 for permanently connected data processing

systems (DIN VDE 0701-702, DIN VDE 0701, part 240).

2)

Permanently connected cable

3)

Feature G00 = 10 A (SECULIFE ST) / G01 = 25 A (SECULIFE ST HV)

> 200 mA

10 A

~/25 A

to test socket

only

R

PE

Housing –

Mains Plug

1)

0.3

2)

+ 0.1

additional 7.5 m

2)

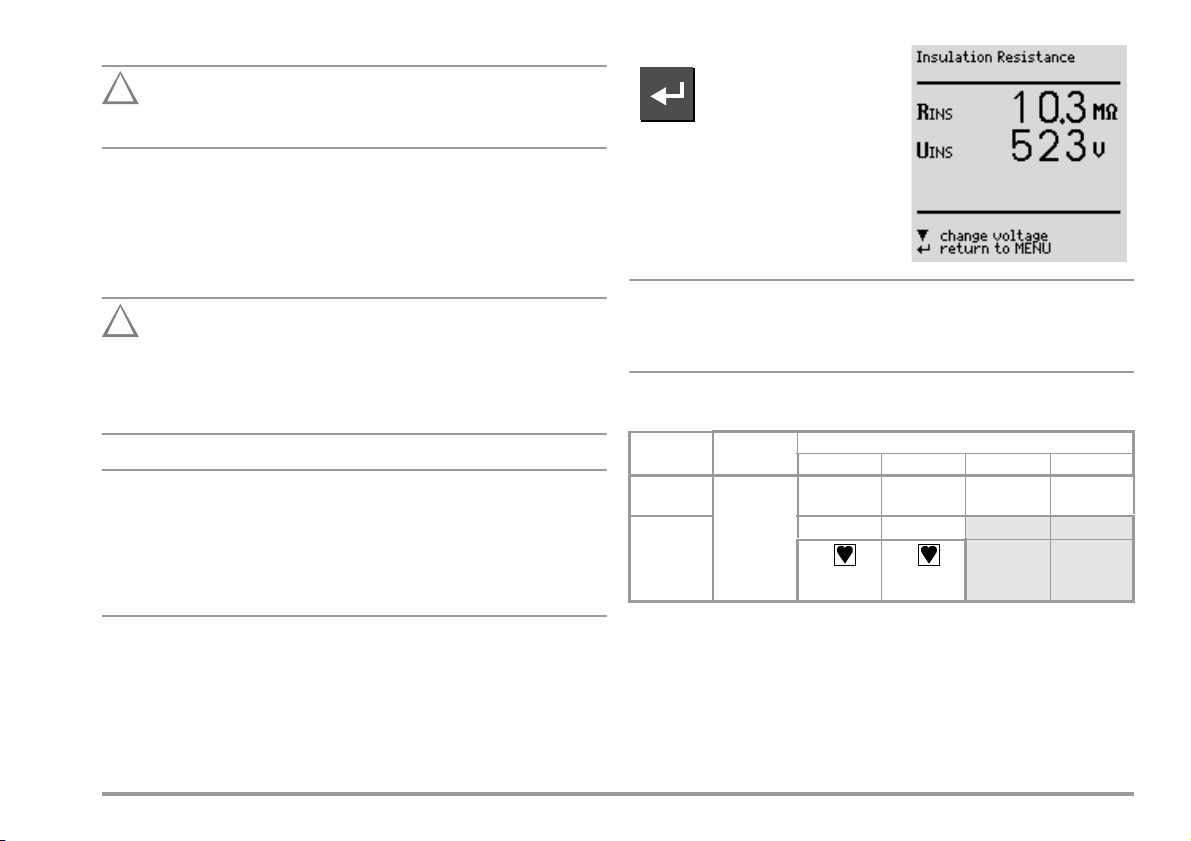

10 Insulation Measurement

10.1 Insulation Resistance R

Definition

Safety Class I

Insulation resistance is

measured between shortcircuited mains terminals and

the protective conductor.

Safety Classes II and I II

Insulation resistance is

measured between shortcircuited mains terminals and

external conductive parts

which can be contacted with

the probe.

INS

.

20 GMC-I Messtechnik GmbH

Page 21

Exception for Permanently Installed Safety Class I Devices

Attention!

!

Attention!

!

Note

Note

Deactivate the electrical system which supplies power to the

device under test before connecting the test instrument!

õ Remove the mains fuses from the device under test and disconnect

the neutral conductor N inside the device under test.

õ Connect the probe to phase conductor L at the device under test in

order to measure insulation resistance.

Sequence

Measurement of Insulation Resistance (equivalent leakage current)

This test is performed with a maximum voltage of 500 V, with a

current limit having been set (I < 3.5 mA). However, contacting

the terminals (3 or 2) causes an electric shock which, in turn,

may result in accidents.

All switches at the device under test must be set to the ON

position during measurement of insulation resistance. This also

applies to temperature controlled switches and temperature

regulators.

Measurement must be performed in all program stages for

devices equipped with program controllers.

R-INS

Start measurement.

Nominal voltage is 500 V DC in this

case.

Nominal voltage can be adjusted within

a range of 50 V to 550 V DC.

When insulation is first started from the menu, nominal voltage is

always set to 500 V. Open-circuit voltage is always greater than

nominal voltage.

Minimum Allowable Limit Values for Insulation Resistance

R

Tes t St anda rd Tes t Vo lta ge

VDE 07010702:2008

IEC 62353

(VDE 0751-1)

500 V

SCI SCII SCIII Heat

1M 2M 0,25 M 0.3 M

2M 7M

INS

70 M 70 M

* for Safety Class I devices with activated heating elements

Notes

All exposed, conductive parts of safety class II and III devices, as well as

of battery-powered devices must be scanned with the probe and insulation resistance and/or leakage current must be measured.

Batteries must be disconnected from their terminals during testing of battery powered devices.

*

GMC-I Messtechnik GmbH 21

Page 22

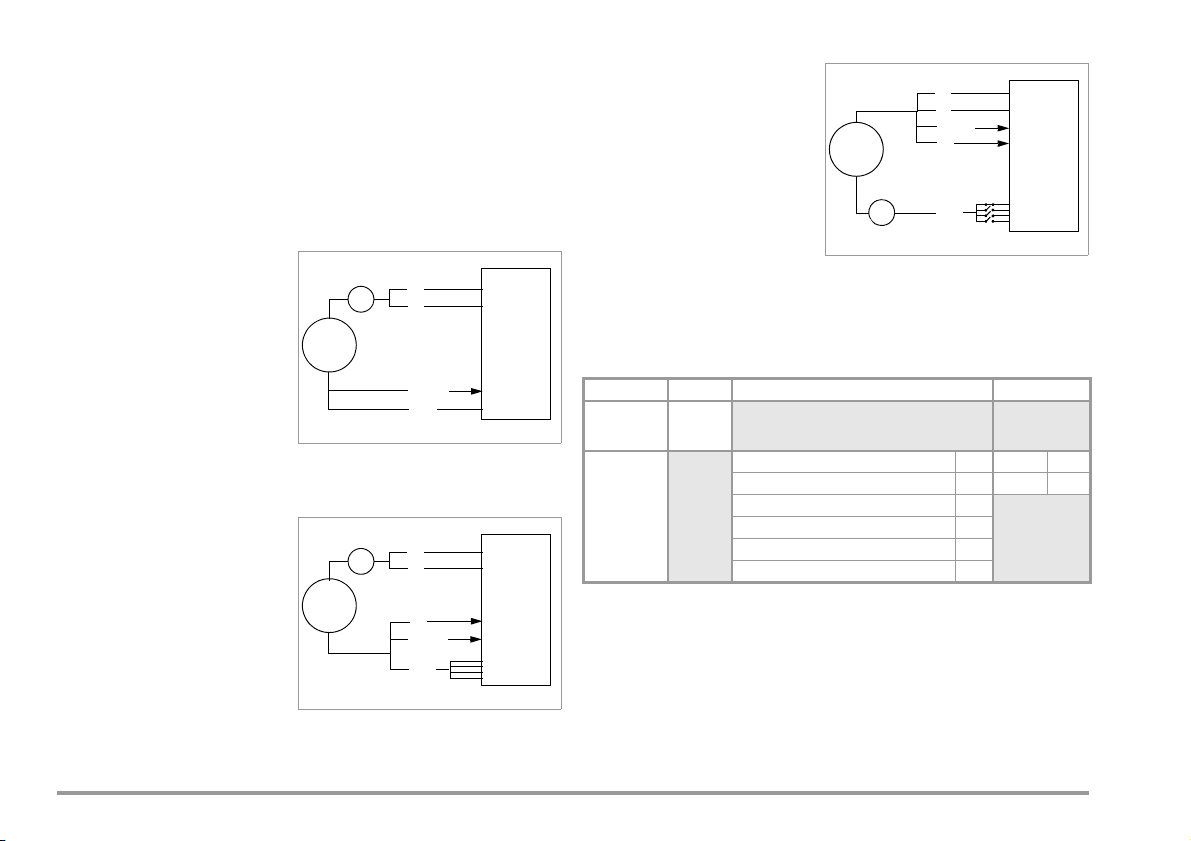

10.2 Equivalent Leakage Current

~

DUT

Probe

mA

PE

L

N

Probe

PAT

DUT

~

mA

L

N

PE

mA

Probe

PAT

DUT

L

N

~

PE

Equivalent Patient Leakage Current I

(IEC 62353 (VDE 0751-1))

EPL

Test S etu p

General

The equivalent leakage current measurement is a method for measuring

protective conductor current (DIN VDE 0701-0702) and/or device leakage

current (IEC 62353 (VDE 0751)).

A high-impedance power supply is connected between the short-circuited mains terminals and all exposed metal parts of the housing (which

are connected to one another).

Measurement of Equivalent Leakage Current I

per DIN VDE 0701-0702

EL

A high-impedance power supply

is connected between each patient port and all exposed metal

parts of the housing (which are

connected to one another). The

mains terminals are short-circuited, and connected to the

same point on the housing.

Measurement

The current which flows over the

insulation at the device under test is measured separately for each application part.

Measurement is always performed with an AC power supply with current

limiting. Varying line voltages are taken into account.

Maximum Allowable Limit Values for Equivalent Leakage Current in mA

Test Standard I

VDE 07010702:2008

Measurement of Equivalent Device Leakage Current I

(VDE 0751-1))

(per IEC 62353

EDL

IEC 62353

(VDE 0751-1)

The patient ports are linked with

each other and are connected to

the same point on the housing.

22 GMC-I Messtechnik GmbH

IELEquivalent leakage current

I

Equivalent device leakage current

EDL

I

Equivalent patient leakage current

EPL

PE Protective conductor

1)

for devices with heating power of 3.5 kW

2)

with and without line voltage applied to the application part

EL

SC I: 3.5

1 mA/kW

SC II: 0.5

1)

SC I (parts within or connected to PE)

Permanently connected devices with PE 10

Portable x-ray devices with additional PE 5

Portable x-ray devices without additional PE 2

I

EDL

SC II 0.2 Type BF 5

Devices with mineral insulation 5

1 Type CF 0.05

I

EPL

2)

2)

Page 23

Connection

Attention!

!

Refer to the schematic diagrams included with the online help for

connection instructions.

Equivalent Leakage Current I

DIN VDE 0701-0702 / 2 K

EL

Connection Exception for Permanently Installed Safety Class I Devices

Current is measured between the probe, with which the L and N conductors must be contacted, and the protective conductor terminal PE at the

device under test for permanently installed safety class I devices under

test.

Disconnect mains power before connecting the test instrument!

õ Remove the mains fuses from the device under test and disconnect

the neutral conductor N inside the device under test.

õ Connect the probe to phase conductor L and neutral conductor N at

the device under test in order to measure equivalent leakage current.

Sequence

Current is displayed during this type of equivalent leakage current

measurement which would flow during leakage current measurement

conducted in accordance with device regulations with nominal voltage.

Leakage current measurement in accordance with the respective device

regulations is usually not possible, because the device would have to be

set up in an electrically isolated fashion, or connected to an earth isolated

power supply to this end.

For the evaluation of measured values during equivalent leakage current

measurement please refer to chapter 21.2.

Select the I-EL measurement and start.

Equivalent leakage current is measured between short-circuited N and L,

and the protective conductor PE.

Measuring circuit resistance is equal to 2 k for VDE 0701-0702 for the

simulation of the mean body resistance of a human being.

Equivalent Device Leakage Current I

for IEC 62353 (VDE 0751-1) / 1 K

EDL

Select the I-EDL measurement and start

Equivalent device leakage current is measured between short-circuited N

and L, and the probe.

Measuring circuit resistance is equal to 1 k for IEC 62353/VDE 0751 for

the

simulation of mean patient resistance.

Equivalent Patient Leakage Current I

(IEC 62353 (VDE 0751-1))

EPL

Select the I-EPL measurement and start

Equivalent patient leakage current is measured between short-circuited N

and L and the respective application part. Jacks A through K (application

parts) are connected separately for each application part.

Groups of cables or sensors can be assigned to application parts in the

test sequence start menu in accordance with IEC 62353 (VDE 0751-1) or

EN 60601.

GMC-I Messtechnik GmbH 23

Page 24

10.3 High-Voltage Test (Feature F02 or SECULIFE ST HV)

Caution: High-Voltage!

Attention!

!

Only safety class I and II devices can be tested, which can be connected

to the test socket.

The high-voltage test is performed with direct voltage. In order to comply

with requirements for alternating voltage, testing is performed with 1.5fold direct voltage. This multiplier is applied automatically during testing. A

selected nominal voltage of 3.5 kV thus results in a DC output voltage of

5.25 kV.

Output voltage is measured for the entire duration of the test, and its minimum value is determined. The minimum voltage value is indicated as the

test result. If this value is less than the pre-selected test voltage, the test is

failed.

The conversion factor must be taken into consideration for testing and

calibration of the SECULIFE ST

HV.

The device is designed such that special measures in accordance with

DIN VDE 0104 (high-voltage test) need not be observed.

This is accomplished by means of the following characteristics:

1. Continuous short-circuit current is less than 3 mA (DC).

2. Discharge energy (at 5.25 kV) is less than 350 mJ.

In order to comply with high-voltage test regulations despite the minimal

continuous short-circuit current, the charging capacitors are connected to

the test socket (L, N) with relatively low-value protective resistors. This

results in a peak short-circuit current value of approximately 5 A (at 5 kV),

which causes plainly audible and visible sparking.

High-voltage testing can only be performed via the test socket. The protective conductor at the socket is grounded during the high-voltage test.

To uc h neither the test socket nor the device under test during

voltage testing!

A high-voltage of up to 5.5 kV is present at the test socket output!

A current may flow over your body, and although it does not

reach life endangering levels, the resulting shock is plainly

discernible.

Previous testing of the protective conductor is absolutely essential

for safety class I devices because if the protective conductor is in-

terrupted, the high-voltage test does not charge all dielectric material and the scope of testing is thus insufficient.

Connection

õ Insert the mains plug from the device under test into the test socket.

õ Safety class II: Connect the probe to jacks 4 and 5.

Make sure that the application parts (18) are not connected during high-voltage testing!

Individual Test

õ Set the rotary selector switch to the Iso/HV position.

õ Select the U-HV menu with the key and acknowledge with the

key.

õ If the device under test has not yet been switched on, a message to

this effect appears at the display. Nominal voltage is then selected.

õ Select the desired nominal voltage

from the display with the key.

The instrument multiplies this nominal voltage by a factor of 1.5, which

represents the actual test voltage

(see chapter 10.3).

Note: For SC I, the test voltage can

be set to maximum 1.5 kV.

õ Test voltage is applied to the test

socket, and in turn the device under

test, for as long as the

key is

held depressed. Activation of highvoltage is indicated with an acoustic

signal.

Currently measured minimum output voltage U

divided by 1.5), test voltage U

, and remaining test time are displayed.

DC

(measured value

HV AC

24 GMC-I Messtechnik GmbH

Page 25

õ Safety class II: Contact all exposed, conductive parts, simultaneously

Attention!

!

Note

if possible, in order to avoid unnecessarily long test durations or

repeats. Avoid contacting individual parts sequentially.

õ After the key is released, the equivalent AC voltage is displayed which

occurred during testing. This voltage is indicated as the test result. If

this value is less than the pre-selected nominal voltage, the test is

failed.

õ If you want to repeat the test, press the key. The test sequence is

started over again with selection of nominal voltage.

If sparkover should occur, the test is immediately interrupted

and the voltage measured at the moment sparkover occurred is

display as U

If the device is disconnected from the test socket during testing,

HV AC

.

even though this is prohibited, the test is immediately interrupted. The following message is displayed: “Caution, device

under test is still charged!”

Testing as Part of a Test Sequence

õ Select the high-voltage menu under the setup function for the respec-

tive test regulation in order to set parameters for the high-voltage test.

õ Enter the desired AC nominal voltages for safety classes I and II. The

instrument multiplies the respective AC nominal voltage by a factor of

1.5, which represents the actual DC test voltage (see chapter 10.3).

Test voltage is determined based upon the selected, or the automatically recognized safety class.

õ Save the setup values to memory.

õ Start the high-voltage test by pressing the key, if “manual

sequence” has been selected in the setup menu.

õ Safety class II only: Contact the device under test with the probe.

Activation of high-voltage is indicated with an acoustic signal.

The selected nominal voltage of 3.5 kV results in a DC output voltage of

maximum 5.25 kV.

The high-voltage test is ended auto-

matically after the test duration has

elapsed.

: Equivalent test voltage in DC

U

HV DC

U

: Measured DC value divided

HV AC

by 1.5

If the value U

lected nominal voltage U

failed.

is less than pre-se-

HV AC

AC

, the test is

In the event of sparkover, the

voltage measured at the moment sparkover occurred is displayed in the test results as minimum value U

reason the test was failed.

, along with the

HV AC

GMC-I Messtechnik GmbH 25

Page 26

11 Leakage Current Measurement

Attention!

!

I leakage

10 10210310410510

6

+20

0

–20

–40

–60

Frequency (f) in Hz

Relative Magnitude (dB): 20 log

U(f)

U(f=10)

2

3

L

N

1 Test socket (w/o protective conductor contact)

2 Patient connector cable

(insulated application part)

3 Device housing

1

11.1 Earth Leakage Current I

(Feature KA01)

PE

Current which flows from the power pack over the insulation to the

protective conductor, and thus to earth.

The protective conductor is disabled during this measurement.

Select the Ixx measurement and start.

Each time line voltage is applied to the

test socket, L and N are reversed, if this

function has been selected in the leakage current menu (see chapter 11 on page 26).

Attention:

Leakage Current Measurement

During leakage current measurement it is imperative to ensure that the device under test is operated at line voltage. Exposed conductive parts may

be charged with hazardous contact voltage during the test and may consequently not be touched under any circumstances. (There is a power

shutdown as soon as the leakage current is higher than approx. 10 mA).

Frequency response is

taken into consideration

in accordance with the

digram to the right when

leakage current is measured.

11.2 Housing Leakage Current I

Current which flows from housing

parts which are not connected to

the protective conductor via an

external conductive connection

to earth or another part of the

housing. Flow of current via the

protective conductor is excluded

in this case.

The AC component is measured. The DC component can

also be measured if individual

measurement is performed (instead of a test sequence).

EN 60601/VDE 0751: The following sequence is programmed for measuring

and documenting several exposed conductive parts:

If the acoustic signal chain changes from long to short intervals, it means

that measurement is completed and the next measuring point can be selected and scanned (key ).

(probe current, contact current)

HL

If each measured value is to be recorded (printed), it can be done by

pressing the key after each measurement (on condition that „Direct

print-out“ is activated, see chapter 18).

26 GMC-I Messtechnik GmbH

Page 27

11.3 Patient Leakage Current IPL

Note

Note

Attention!

!

2

3

(N) L

(L) N

1 Test socket w/o

protective conduc-

tor contact

2 Application part

3 Device housing

4 Measuring circuit

4

IEC 62353/

I

LC

1

VDE 0751

Current which flows from an application part via the patient to

earth. This current may be caused

by an unintentional interference

voltage at the patient, and may

flow via the patient and an insulated, floating type F application

part to earth. Useful patient current is excluded in both cases.

AC and DC components are measured.

Patient leakage current must also be measured if application

parts are available.

The displayed test voltage must be documented.

11.5 Residual Current I

RC

Sum of instantaneous current values which flow via the L and N conductors at the device mains connection (also known as differential current).

Residual current is practically identical to fault current in the event of an error. Fault current: Current which is caused by an insulation defect, and

which flows via the defective point.

11.6 Device Leakage Current I

per IEC 62353 (VDE 0751-1)

LC

Device leakage current is the

sum of all leakage currents from

the housing, all accessible

conductive parts and all application parts to PE. Measurement

must be performed for both

mains polarities and the largest

value is documented.

11.4 Patient Auxiliary Current I

Current which flows within the

patient between the electrodes of

the application part. Use for intended purpose is assumed. Furthermore, the current should not

cause any physiological effects.

For example, this is the case for

input current from amplifiers, or

current used for impedance

plethysmography.

AC and DC components are measured.

GMC-I Messtechnik GmbH 27

(Feature KA01)

PA

The highest device leakage current value and line voltage must

be documented.

The protective conductor is interrupted during this

measurement.

Page 28

Key for Tables

IPEEarth leakage current in the operating state (alternative: measurement of IEL)

I

Housing leakage current (probe or contact current)

HL

I

Residual current

RC

I

Device leakage current

LC

I

Patient leakage current

PL

I

Patient auxiliary current

PA

Maximum Allowable Limit Values for Leakage Current in mA

I

Test Standard

VDE 07010702:2008

SC I: 3.5

1 mA/kW

I

PE

NC SFC NC SFC

*

0.5

I

HL

RC

SC I: 3.5

1 mA/kW

*

SC II:

0.5

IEC 62353

(VDE 0751-1)

General 0.5 1

EN 60601

Notes 1 & 3 2.5 5

0.1 0.5

Note 2 5.0 10

* for devices with a heating power > 3.5 kW

Note 1: Devices without any accessible conductive parts which are connected to

the protective conductor, and which comply with I

e.g. electronic data processing devices with shielded power pack

and conceivably IPL,

HL

Note 2: Permanently connected devices with protective conductor

Note 3: Portable x-ray devices and devices with mineral insulation

I

LC

General 0.5

Notes 1 & 3 2.5

Note 2 5.0

SC II 0.1

I

Tes t

Standard

IEC 62353/

VDE 0751

EN 60601

Type B Type BF Type CF Type B Type BF Type CF

NCSFCNCSFCNCSFCNCSFCNCSFCNCSFC

Direct

0.01

Current

Alt.

0.1 0.1 5 * 0.01

Current

Direct

0.01 0.05 0.01 0.05 0.01 0.05 0.01 0.5 0.01 0.05 0.01 0.05

Current

Alt.

0.1 0.5 0.1

Current

PL

0.01 0.01

0.5

0.01

5 *

* Only with line voltage at the application part

I

PA

0.05

*

0.05

0.1 0.5 0.1 0.5 0.01 0.05

0.05

*

28 GMC-I Messtechnik GmbH

Page 29

This page has been deliberately left blank.

GMC-I Messtechnik GmbH 29

Page 30

12 Multimeter Functions

Attention!

!

V

12.2 Alternating / Direct Voltage U

– Max. 253 V

AC/DC

Direct, alternating and pulsating voltages of up to 253 V can be measured

between the 2 and 3 connector jacks.

Furthermore, it is possible to switch between minimum, maximum and momentary measured value via key .

This is particularly useful in combination

with the SECULOAD test adapter for weld-

ing equipment (article number Z745V).

Two procedures are to be distinguished as from firmware version 7.24:

12.1 Probe Voltage U

Voltage is measured between the mains PE terminal at the test instrument

and the probe. In this case the probe can also be used as a phase finder.

For IEC 61010: A selection can be made with the up scroll key as to