Gossen MetraWatt SECUTEST PRO, SECULIFE ST BASE 25, SECUTEST BASE 10 Operating Instructions Manual

Page 1

Operating Instructions

SECUTEST BASE(10) / PRO and SECULIFE ST BASE(25)

Test Instrument for Measuring the Electrical Safety of Devices

per VDE 0701-0702, IEC 62353 und IEC 60974-4

3-349-752-03

17/8.19

Page 2

Controls

Rotary selector switch

LCD panel

Single measurements

Sequences A1 ... A8, AUTO

(automatic test sequences)

MEM:

database functions

ESC: back

Fixed Function Keys

HELP: help images

START: start/stop

– Single measurement

– Test sequence

Finger Contact

PRINT: print via USB

Rotary switch level:

Rotary switch level:

Softkeys

Test Probe

!

Supply power connection SECUTEST CLIP (Z745H)

White identified

and fused high

current path

– For keyboard *

– For Barcode/RFID scanner *

– For printer

– For USB flash drive

Display of symbols for devices

connected to the USB master

interface (see below)

Display of special symbols:

– Measurement at IT system active

– Offset for RPE active

* The receiver must be plugged in here for wireless entry devices.

** Only displayed in case of active connection to another Bluetooth device

Bluetooth®** (feature M01)

Parameters: see page 86

®

Probe Type Applications

Strain relief sleeve,

black

Test current: 200 mA / 10 A

max. 16 A

SK2-25A (Z746C)

Strain relief sleeve,

green

Test current: 200 mA / 25 A

max. 25 A

Mains to test socket

Mains to test socket

N interrupted

orange

green

1

SECUTEST BASE10/PRO (feature G01)

2

A list of suitable devices is included in the appendix (see section 14)

No. Meaning

1

2nd test probe P2 for 2-pole measurement

(only with SECUTEST PRO or instrument with

feature H01)

2

Voltage measuring inputs

(only with

SECUTEST PRO or instrument with

feature I01)

3

Fuse link for probe input P1

4

Test probe connection (P1)

5

Connection (jack socket) for supplying power to

the SECUTEST CLIP (Z745H), see also operating

instructions for leakage current clamp meter

6

Country-specific standard socket (test socket)

for connecting devices under test

7

Carrying handle and tilt stand

8

Country-specific socket for mains power via inlet

plug

9

Fuse link 1 for the mains connection

10

Fuse link 2 for the mains connection

11

Additional fuse link

for 10 A

1

protective conductor test

12

USB master for connecting keyboard, barcode/

RFID scanner

2

, printer 2 and USB flash drive2

(must be FAT32 formatted – not NTFS)

13

USB slave for connection to a PC

3 454

6

7

9

10

8

11

12 13

2211

Connections

These operating instructions describe an instrument with software version FW3.0.0.

2 GMC-I Messtechnik GmbH

Page 3

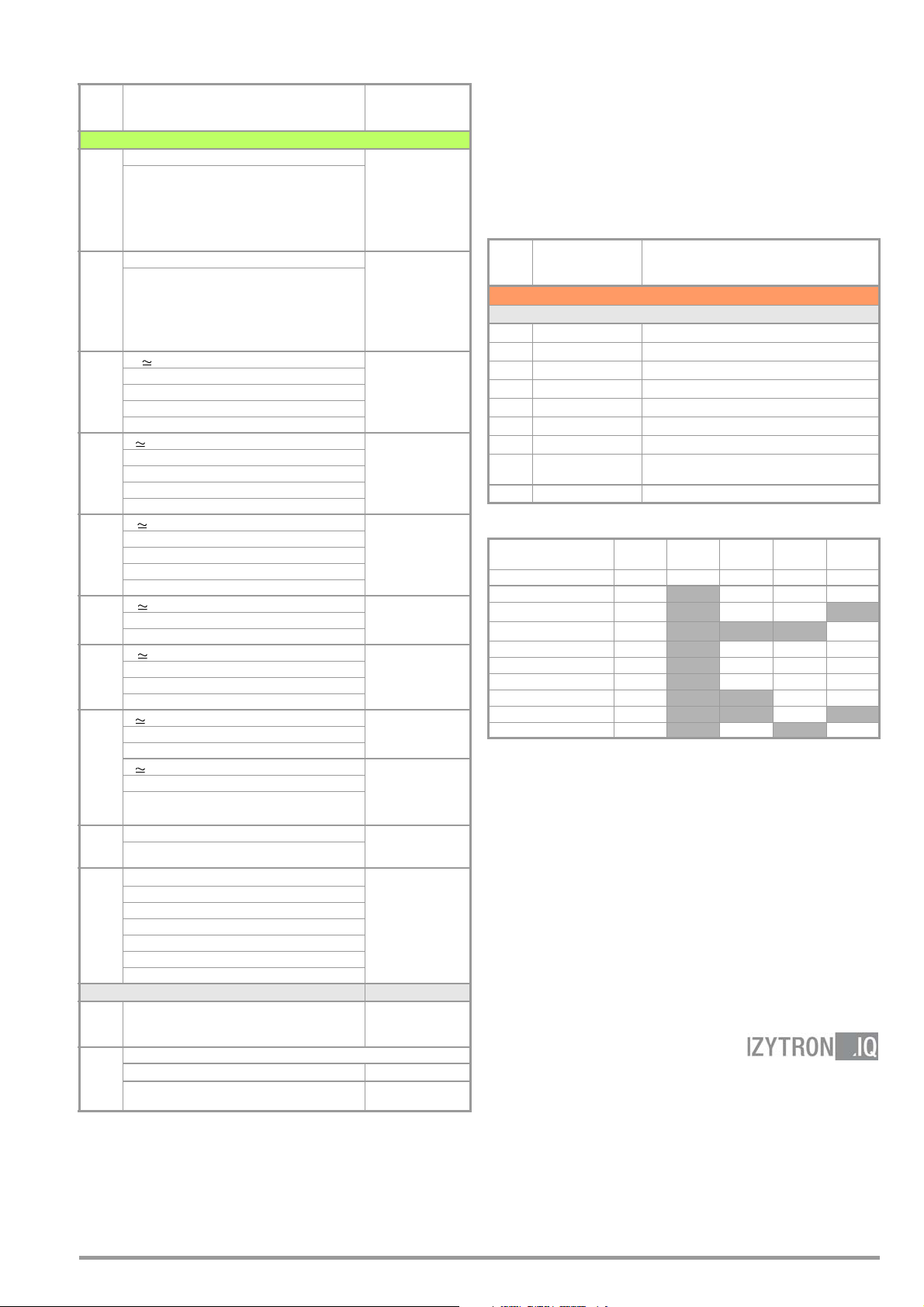

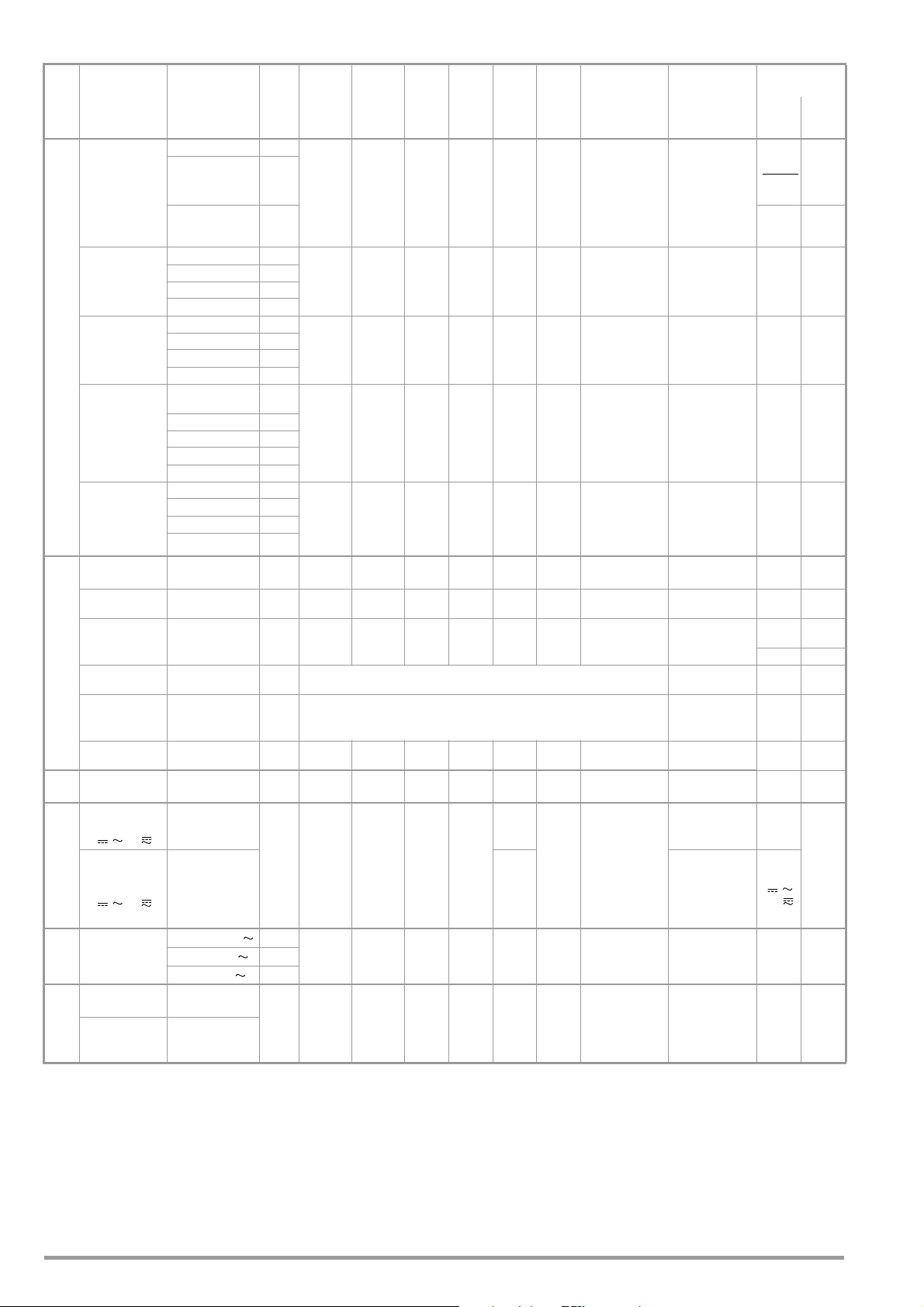

Overview of the Scope of Functions of the SECUTEST

BASE(10), PRO and SECULIFE ST BASE(25) Test Instruments

Measuring Functions

Test Current/Voltage

Switch

Position

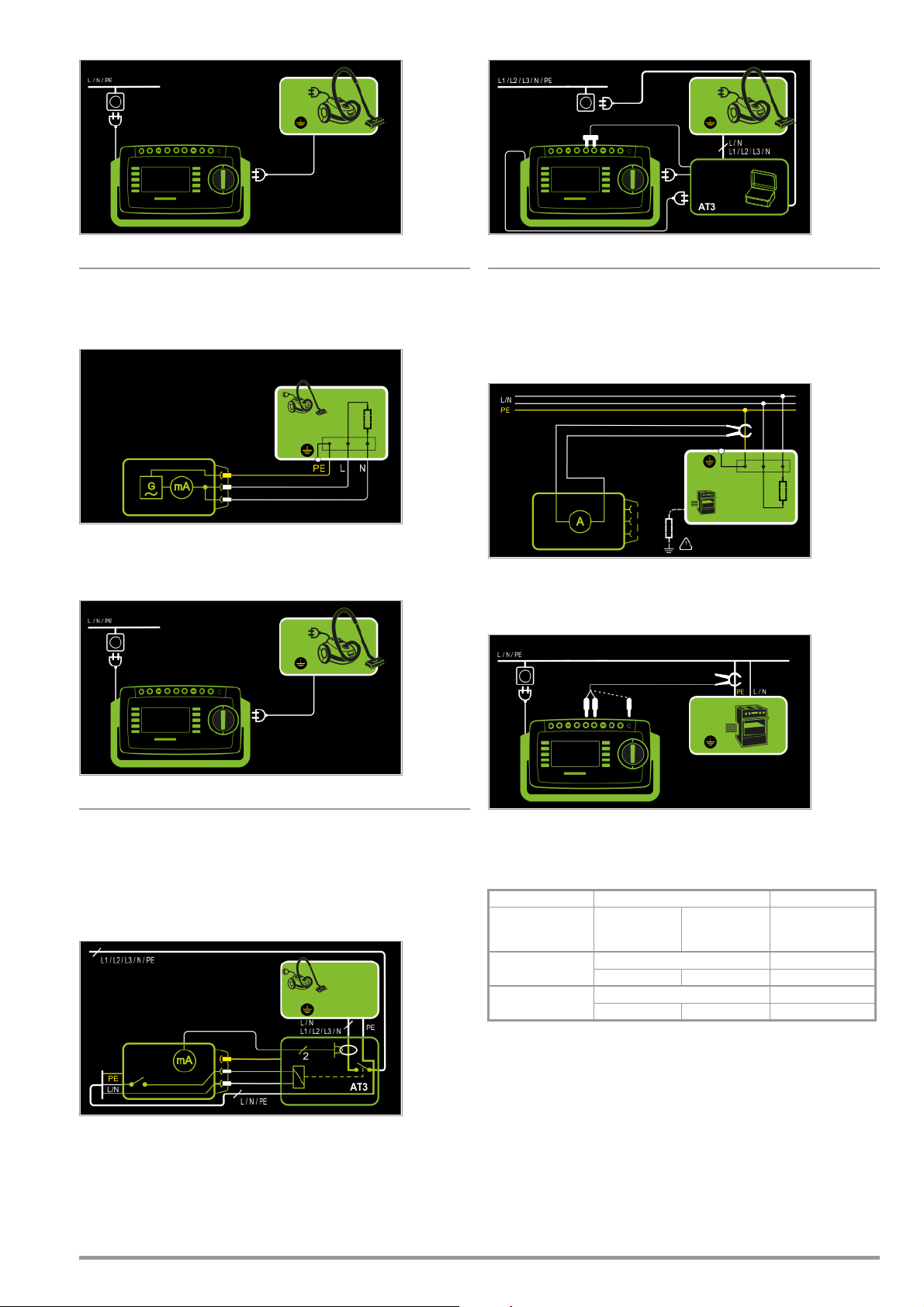

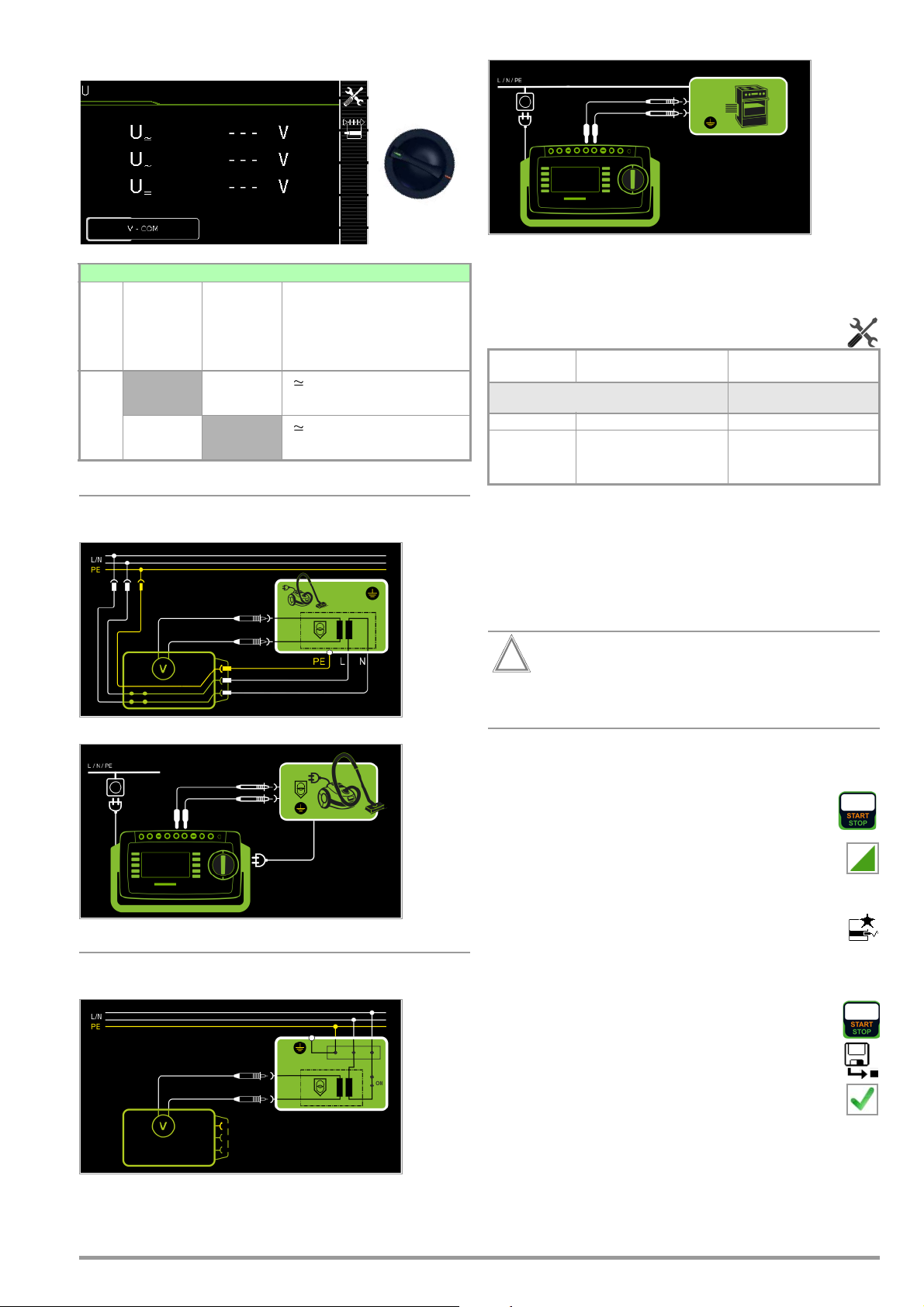

Single measurements, rotary switch level: green

R

R

PE

Section

8.5

Protective conductor resistance

PE

I

Test current (200 mA)

P

SECUTEST BASE10/PRO

and SECULIFE ST BASE 10 A

(feature G01)

and SECULIFE ST BASE25 25 A

1

1

(feature G02)

R

RISO

Insulation resistance (PC I/PC II)

INS

U

Test vo l t a g e

INS

Section

8.6

I

IPE

Section

8.7.1

IB

Section

8.7.2

IG

Section

8.7.3

IA

Section

8.7.4

IP

Section

8.7.5

U

Section

Protective conductor current, RMS

PE

AC component

I

PE~

DC component

I

PE=

Test vo l t a g e

U

LPE

A reference voltage (alternative)

U

Gen

I

Touch current, RMS

T

I

AC component

T~

DC component

I

T=

Test vo l t a g e

U

LPE

Reference voltage (alternative)

U

Gen

I

Device leakage current, RMS

E

AC component

I

E~

DC component

I

E=

Test vo l t a g e

U

LPE

Reference voltage (alternative)

U

Gen

Leakage current from the applied part, RMS

I

A

U

Test vo l t a g e

LPE

Reference voltage (alternative)

U

Gen

I

Patient leakage current, RMS

P

I

AC component

P~

DC component

I

P=

Test vo l t a g e

U

LPE

U

Probe voltage, RMS

Alternating voltage component

U

~

Direct voltage component

U

=

U Measuring voltage, RMS

Alternating voltage component

U

~

U

Direct voltage component

=

2

2

2

8.9

4

ta PRCD time to trip

ta

Section

U

Line voltage at the test socket

8.10

P

LN

Function test at the test socket

for 10/30 mA PRCDs

I Current between L and N

U Voltage between L and N

f Frequency

P Active power

S Apparent power

Section

8.11

PF Power factor

Probe measuring functions

Extension cord with adapter:

EL1

continuity, short-circuit, polarity (wire reversal

Section

8.12

Reserved for expansion within the framework of software updates

EXTRA

Section 9

1

10/25 A-RPE measurements are only possible with line voltages of 115/230 V and

line frequencies of 50/60 Hz.

2

Voltage measuring inputs with SECUTEST PRO or instrument with feature I01) and

SECULIFE ST BASE(25) only

3

Connection of 2nd test probe for two-pole measurement with SECUTEST PRO (or instrument with feature H01) and SECULIFE ST BASE(25) only

4

Measurement of time to trip is not possible in IT systems.

5

No checking for reversed polarity takes place when the EL1 adapter is used.

6

Type of connection not available with

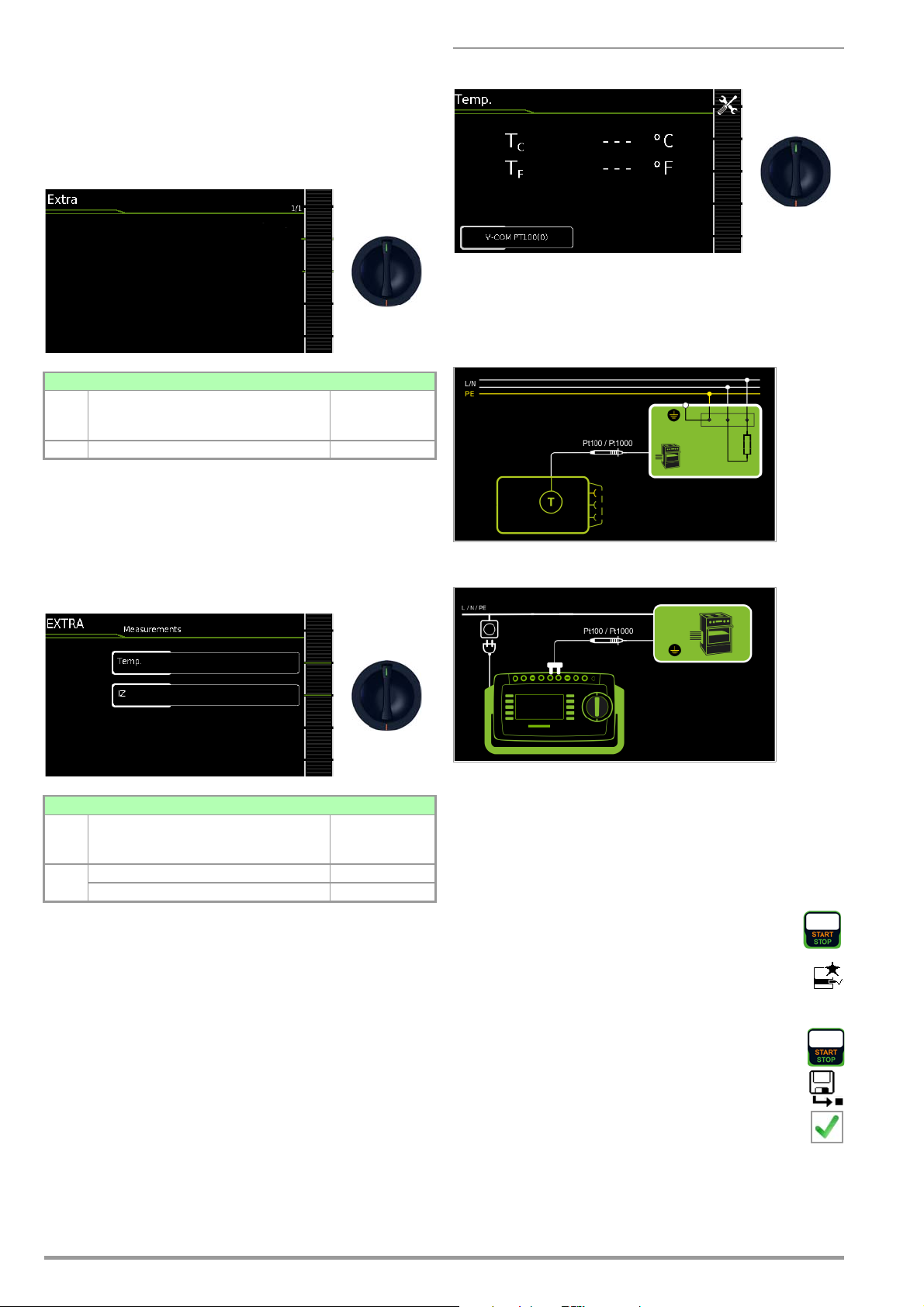

Temperature measurement 2

°C

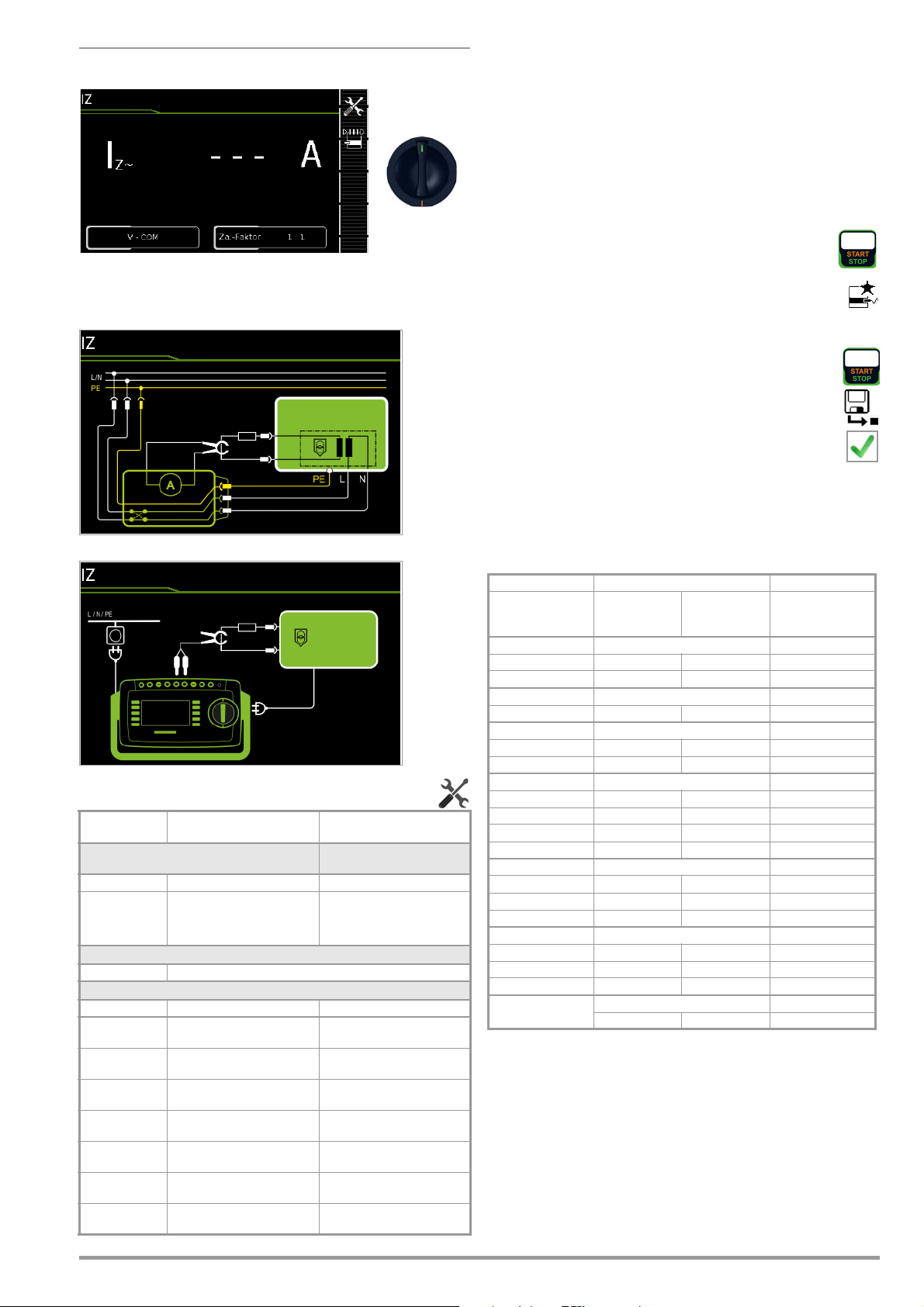

IZ Current clamp measurement

with the current clamp sensor

SECULIFE ST BASE25

with Pt100 / Pt1000

2

Measurement

Typ e,

Connection Type

PE(TS) - P1 passive

PE(TS) - P1 active

PE(mains) - P1

PE(mains) - P1 clamp

6

P1–P2 3

LN(TS) - PE(TS)

LN(TS) - P1

P1–P2

PE(mains) - P1

PE(TS) - P1

LN(TS) - P1//PE(TS)

Direct

Differential

Alternative

AT3-Adapter

Clamp

Direct

Differential

Alternative (P1)

Permanent connection

Alternative (P1–P2)

Direct

Differential

Alternative

AT3-Adapter

Clamp

Direct (P1)

Alternative (P1)

Perm. con. (P1)

Direct (P1)

Perm. con. (P1)

P1–P2

P1–P2 (with mains *)

* Polarity parameter

V – COM

V – COM (with mains)

Polarity parameter

EL1 adapter

5

)

AT3-IIIE adapter

VL2E adapter

V – COM

V – COM

(feature G02)

6

3

2

2

2

2

Key

Alternative = alternative measurement (equivalent leakage

Differential = differential current measurement

Direct = direct measurement

LN(TS) = short-circuited L and N conductors at test socket

P1 = measurement with test probe P1

P1-P2 = 2-pole measurement with test probes P1 and P2

PE-P1 = measurement between PE and test probe P1

PE(TS) = protective conductor at the test socket

2,

PE(mains) = protective conductor at the mains connection

Switch

Position

Automated test sequences, rotary switch level: orange

Preconfigured (freely adjustable) test sequences – default settings

A1

A2

A3

A4

A5

A6

A7

A8

AUTO

current measurement)

Standard Measurement Type, Connection Type

VDE 0701-0702 Passive measurement type, test socket

VDE 0701-0702 Active measurement type, test socket

VDE 0701-0702-EDV

IEC 62353 (VDE 0751) Passive measurement type

IEC 62353 (VDE 0751) Active measurement type

IEC 60974-4 Connection type: test socket

IEC 60974-4 Connection type: AT16-DI/AT32-DI

VDE 0701-0702

VDE 0701-0702 Active measurement type, test socket

Parameters configuration for EDP (active)

Extension cord measurement type (RPE, RINS), adapter:

EL1

/VL2E/

AT3-IIIE

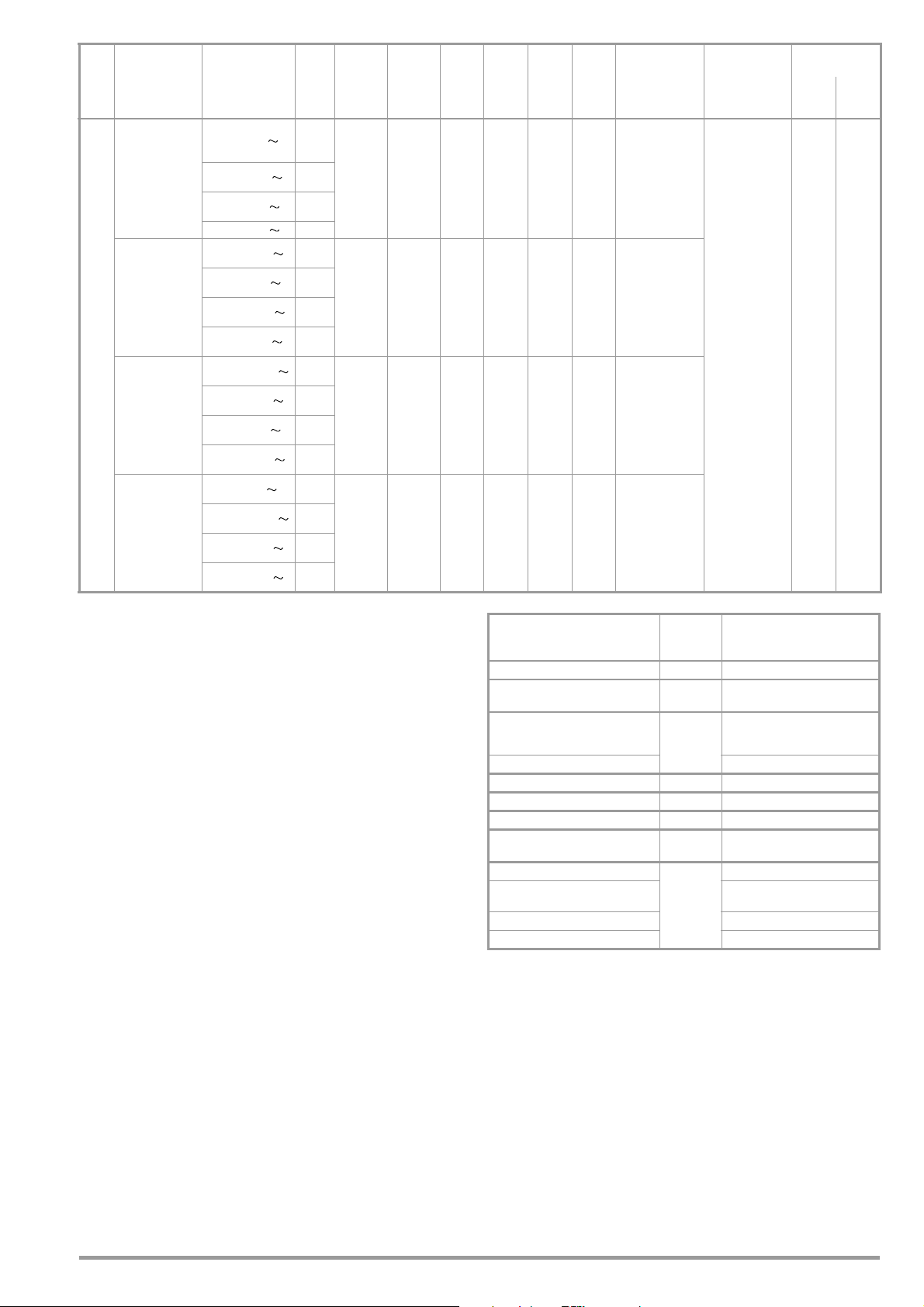

Differences with Regard to Included Features

SECUTEST...

SECULIFE... — ST BASE —

Touchscreen / keyboard E01 •••

10 A RPE test current

25 A RPE test current

2nd test probe H01 •••

Voltage measuring input *

SECUTEST DB+

SECUTEST DB COMFORT

®

Bluetooth

Antimicrobial housing

* For voltage measurement, or for connecting a current clamp sensor for current

measurement or an AT3 adapter, and for temperature measurement via RTD

Features

BASE PRO PRO BT

comfort

G01

••

G02

I01 •••

KB01 •••

KD01 ••

M01 •

— ST BASE •

Scope of Delivery

Standard Version (country-specific)

1 SECUTEST BASE(10)/PRO or SECULIFE ST BASE(25) test instrument

1 Mains power cable

1 Test probe, 2 m, not coiled

1 USB cable, USB A to USB B, 1.0 m long

1 Plug-on alligator clip

1 KS17-ONE cable set for voltage measuring input (only with

SECUTEST PRO and

1 Calibration certificate

1 Condensed operating instructions

Comprehensive operating instructions available on the Internet

1

1Card with

registration key

SECULIFE ST BASE(25)

for software

or device with feature I01)

—

ST BASE 25

•

GMC-I Messtechnik GmbH 3

Page 4

Contents Page Page

1 Applications ..................................................................... 5

1.1 Table: Types of DUTs – Tests – Standards .....................................5

1.2 Table: Single Measurements – Regulations ....................................5

2 Safety Features and Precautions ..................................... 5

3 General Operation ............................................................ 7

3.1 Measured Value Display .................................................................7

3.2 Language, Keyboard Layout (culture parameter) ..............................7

3.3 Help Functions (HELP key and QR code) ..........................................7

3.4 Entering Alphanumeric Characters ..................................................7

3.5 Print-Outs – Reports ......................................................................7

3.5.1 Multi-Print .....................................................................................7

3.5.2 Report Template for Reading Out Reports to a Thermal Printer or an

HTML File .....................................................................................7

3.5.3 Report Tapes from Thermal Printers ................................................8

3.5.4 Printing via IZYTRONIQ ..................................................................8

3.5.5 Saving Reports to a USB Flash Drive ...............................................8

3.6 Print-Out of ID Labels (as of firmware V1.3.0) ..................................8

3.7 Writing RFID Tags (as of firmware V1.5.0) .......................................8

4 Initial Startup ................................................................... 9

4.1 Connecting the Test Instrument to the Mains ...................................9

4.1.1

Measurements in IT Systems (new parameter as of firmware 1.5.0) .......9

4.1.2 Automatic Recognition of Mains Connection Errors ........................10

4.2 Connecting Test Probe P1 or P2 ...................................................10

4.3 Device Settings ............................................................................11

5 Internal Database ........................................................... 15

5.1 Creating Test Structures, General .................................................15

5.2 Transmitting and Saving Test Structures and Measurement Data ....15

5.2.1 Export – Transmitting Test Structures and Measurement Data from

the Test Instrument to the PC .......................................................15

Import – Uploading Test Structures Created in the Report Generating Pro-

5.2.2

gram to the Test Instrument (only with database extension

“Z853R – SECUTEST DB+”) .........................................................15

5.2.3 Backing Up and Restoring Test Structures and Measurement Data .15

Switching Between 2 Tree Structure Views

5.2.4

SECUTEST PRO

(for

feature KB01, “Z853R – SECUTEST DB+”) ...................................17

5.3 Data Entry ...................................................................................18

5.3.1 Keyboard Entries via Softkeys or External Keyboard ........................18

5.3.2 Data Entry via Touchscreen Keyboard

(only with

5.4 Creating a Test Structure in the Test Instrument, Navigating within

the Structure and Displaying Measured Values ..............................19

5.4.1 General Procedure for Creating Test Structures .............................20

5.4.2 Searching for Structure Elements ..................................................21

5.4.3 Display Measured Values from Saved Tests ...................................21

5.4.4 Clearing the Database ..................................................................21

SECUTEST PRO

and

SECULIFE ST BASE(25)

or test instrument with feature E01) ..........18

or feature KB01,

or for devices with

6 Connecting the Device Under Test ................................. 22

6.1 Residual Current Monitoring .........................................................22

6.2 Reference Voltage L-PE and Alternative Test Sequence ..................22

6.3 Manually Specifying the Connection Type for Single Measurements 22

6.4 Manually Selecting a Connection Type / Protection Category

for Automatic Test Sequences ......................................................22

6.5 Special Conditions .......................................................................23

6.6 2nd Test Probe (only SECUTEST PRO or feature H01) ...................23

6.7 Connection Prompts ....................................................................23

6.8 Connection Tests Conducted by the Test Instrument ......................23

7 Notes on Saving Single Measurements and

Test Sequences ............................................................. 24

7.1 QuickEdit Function – QEDIT

(feature KD01, “Z853S – SECUTEST DB COMFORT”) .....................24

8 Single Measurements .................................................... 25

8.1 General .......................................................................................25

8.2 Meaning of Symbols in the User Interface ....................................26

8.3 Displaying the Last Measured Values ............................................26

8.4 Measurement Series and Storage .................................................26

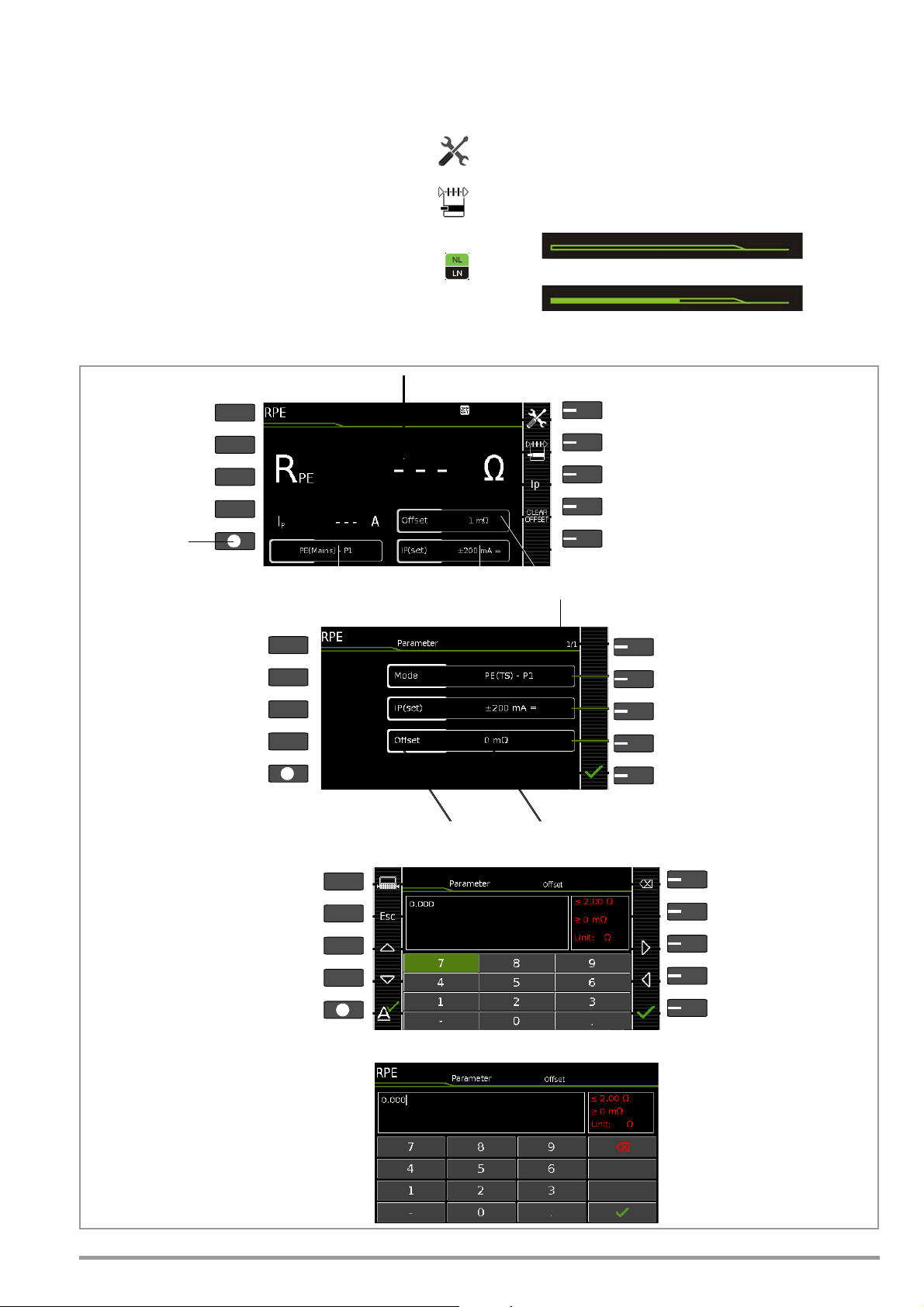

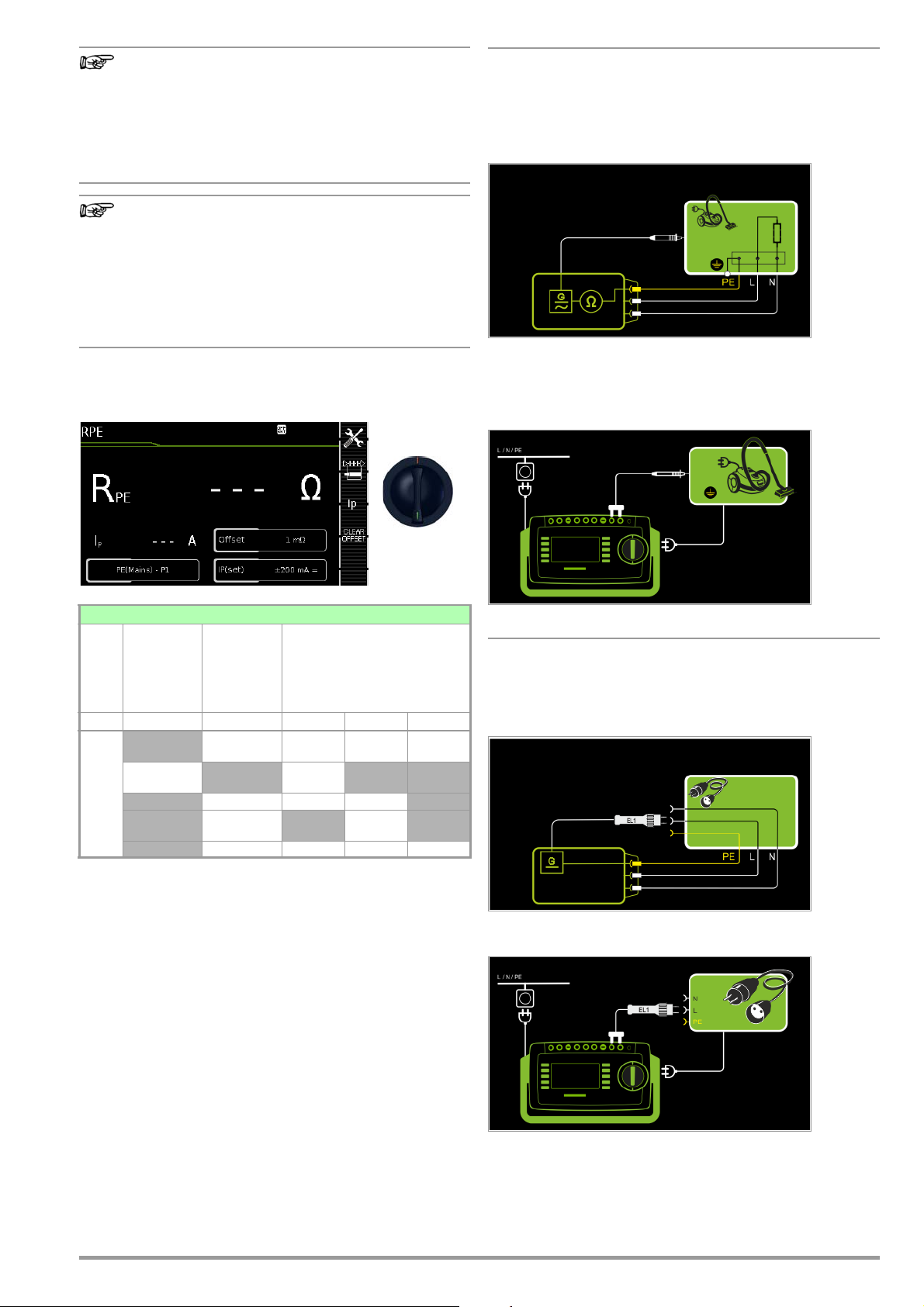

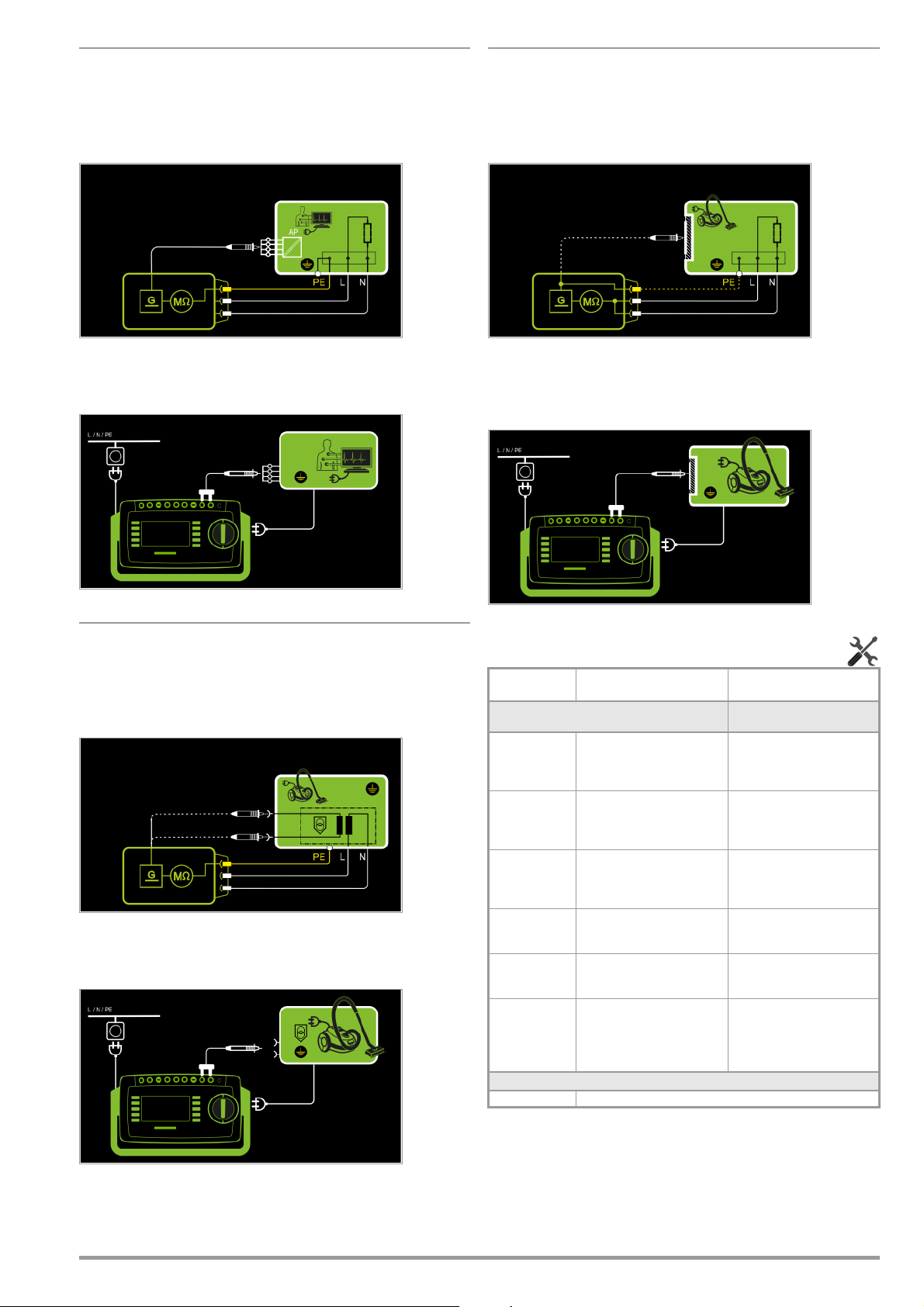

8.5 Measuring Protective Conductor Resistance – RPE ........................ 27

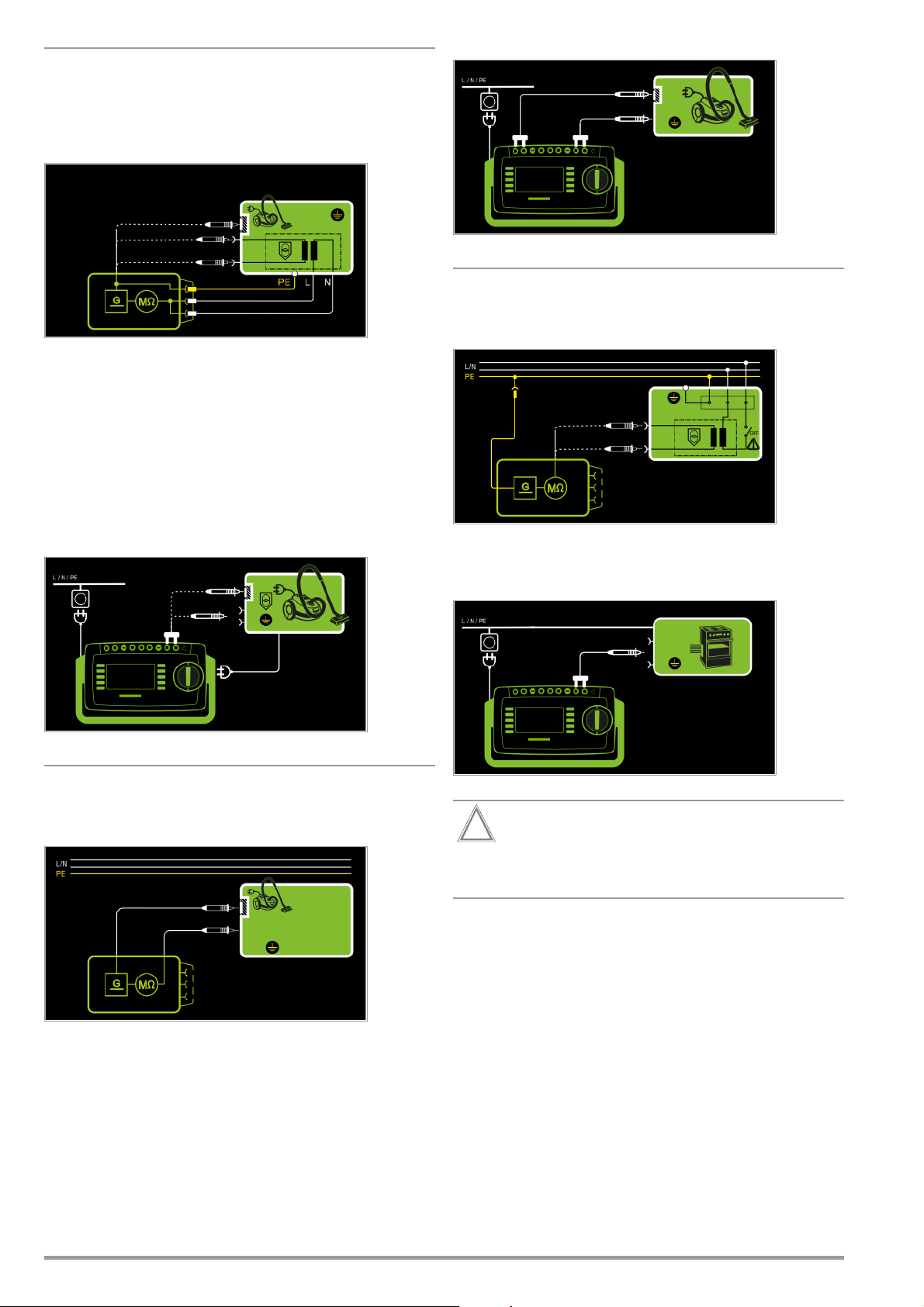

8.6 Insulation Resistance Measurement – RINS ...................................31

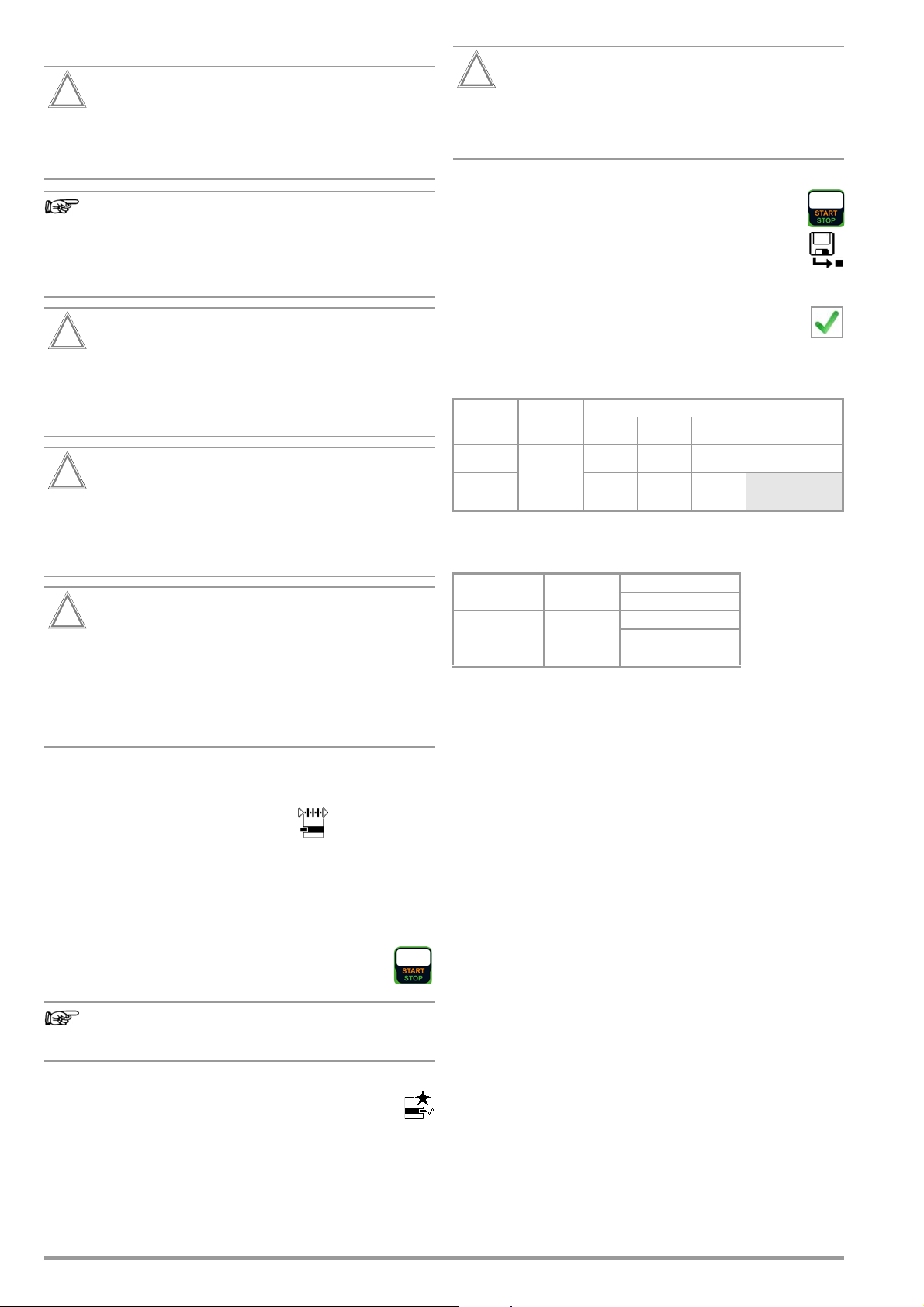

8.7 Measuring Leakage Current .........................................................35

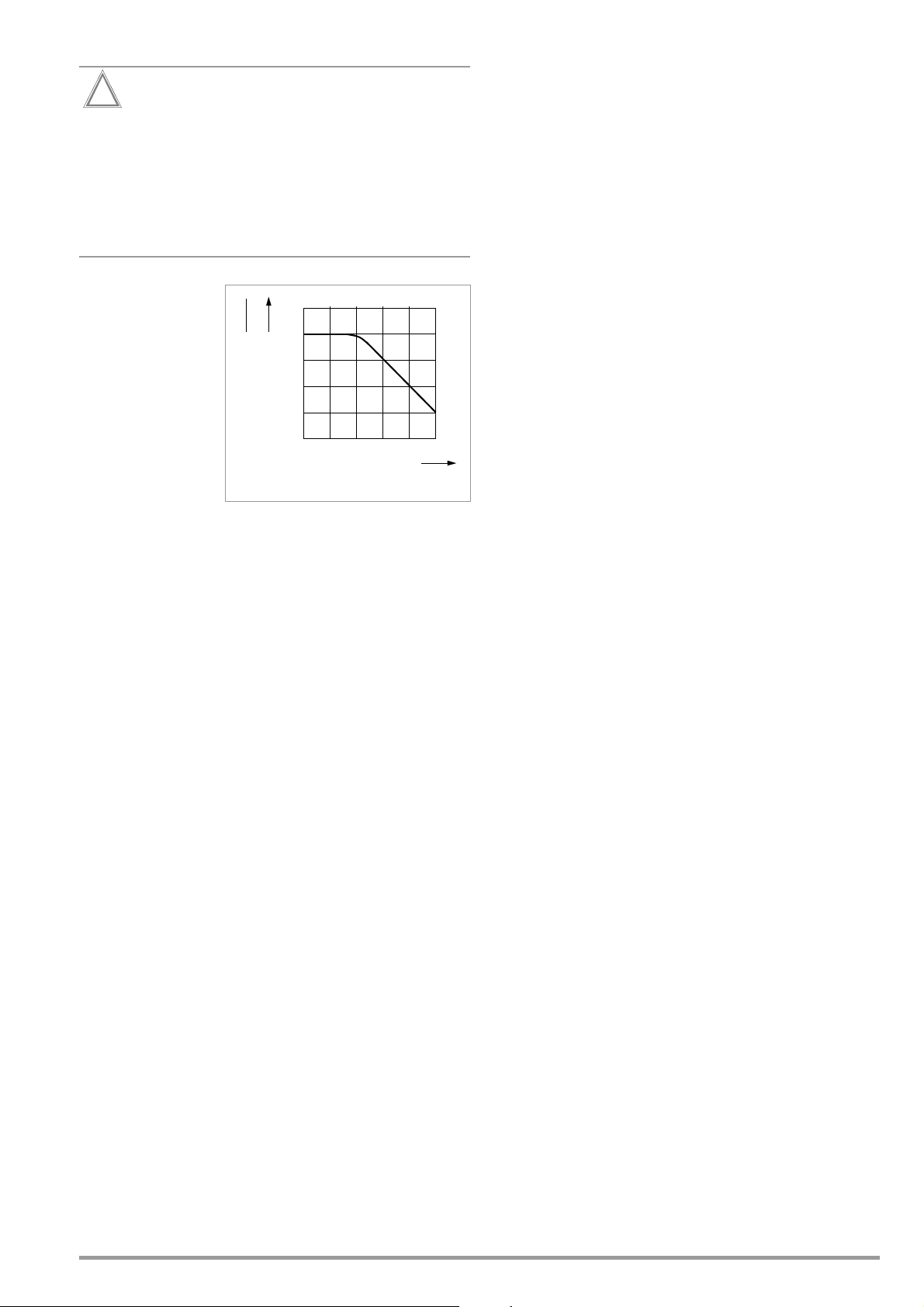

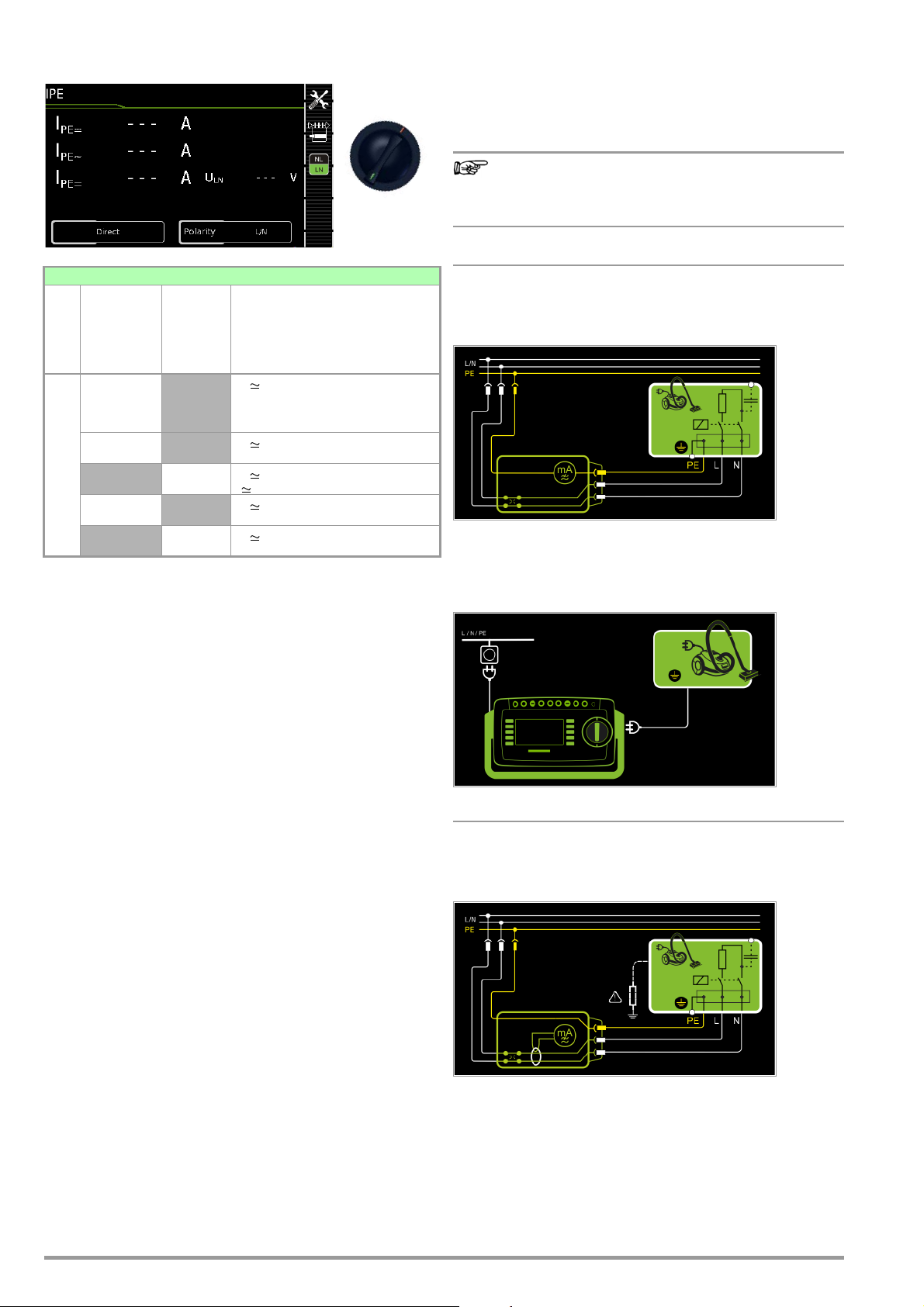

8.7.1 Protective Conductor Current – IPE ...............................................36

8.7.2 Touch Current – IB ...................................................................... 40

8.7.3 Device Leakage Current – IG ........................................................43

8.7.4 Leakage Current from the Applied Part – IA ..................................46

8.7.5 Patient Leakage Current – IP ........................................................47

8.8 Probe Voltage – U .......................................................................50

8.9 Measuring Voltage – U (SECUTEST PRO or feature I01 only) ......... 51

8.10 Measuring Time to Trip for RCDs of the Type PRCD – tA ................52

8.11 Function Test – P ........................................................................ 53

8.12 Testing Extension Cords for Correct Function – EL1 ....................... 54

9 Special Functions – EXTRA ............................................ 56

10 Test Sequences .............................................................. 58

10.1 General .......................................................................................58

10.2 User-Defined Test Sequences / Remote Control

(only with feature KB01, “Z853R – SECUTEST DB+”) ....................59

10.2.1 General .......................................................................................59

10.2.2 Testing of Probe Connection P1 and Probe Fuse P1 ......................59

10.3 General Settings (Setup: auto measurements parameter) ...............59

10.4 Selecting and Configuring a Test Sequence ...................................61

10.5 Connecting the DUT .....................................................................67

10.6 Selecting a Test Object ................................................................67

10.7 Checking Connection and Starting the Test Sequence ....................67

10.8 Executing and Evaluating Test Steps ............................................. 67

10.9 Setting Limit Values Manually .......................................................68

10.10 Ending the Test Sequence ............................................................68

10.11 Saving Test Results ..................................................................... 69

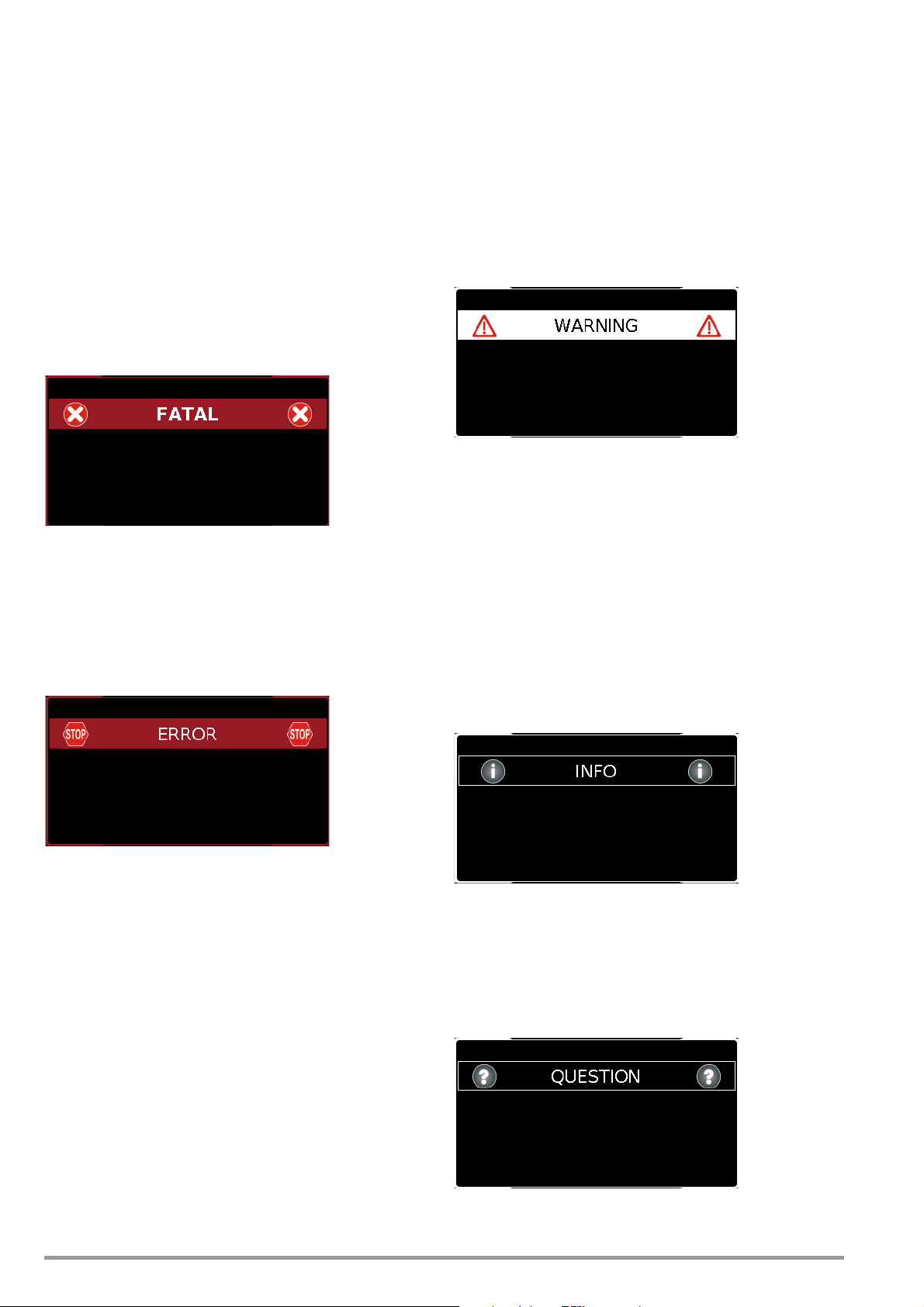

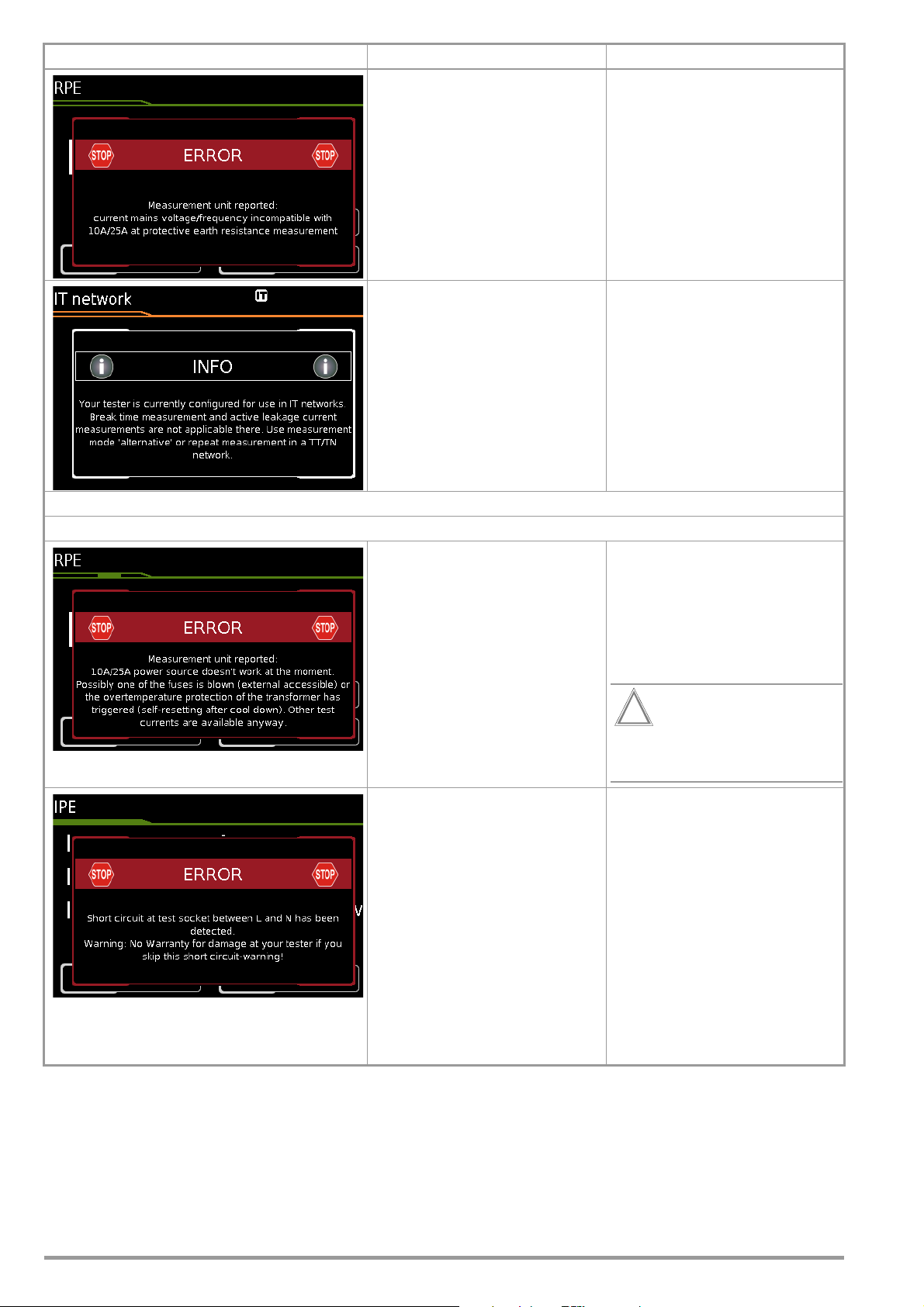

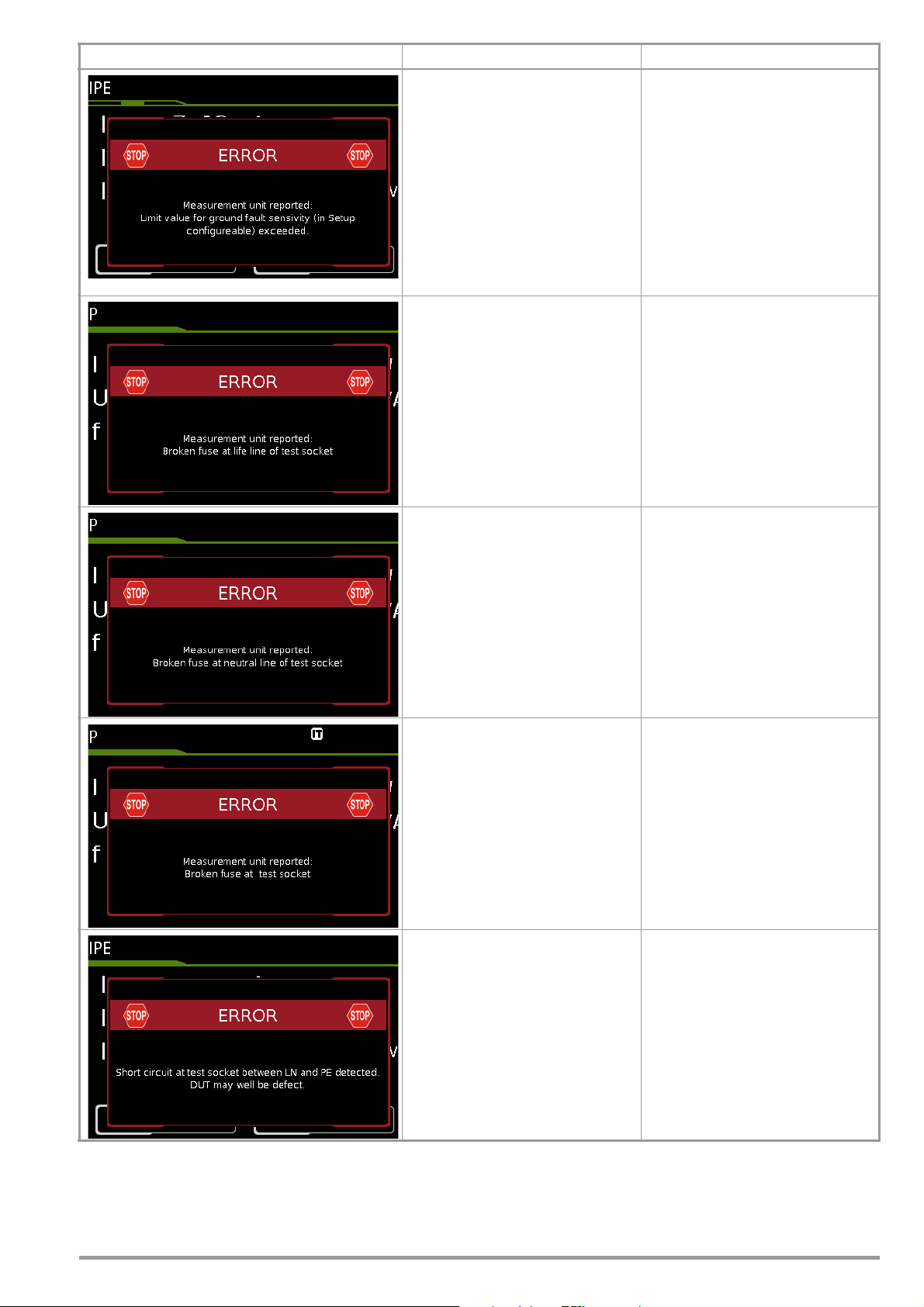

11 Warnings, Error Messages and Notes ............................ 70

11.1 List of error messages ................................................................. 71

11.2 List of Possible DUT Connections

Depending on Measurement Type ...............................................79

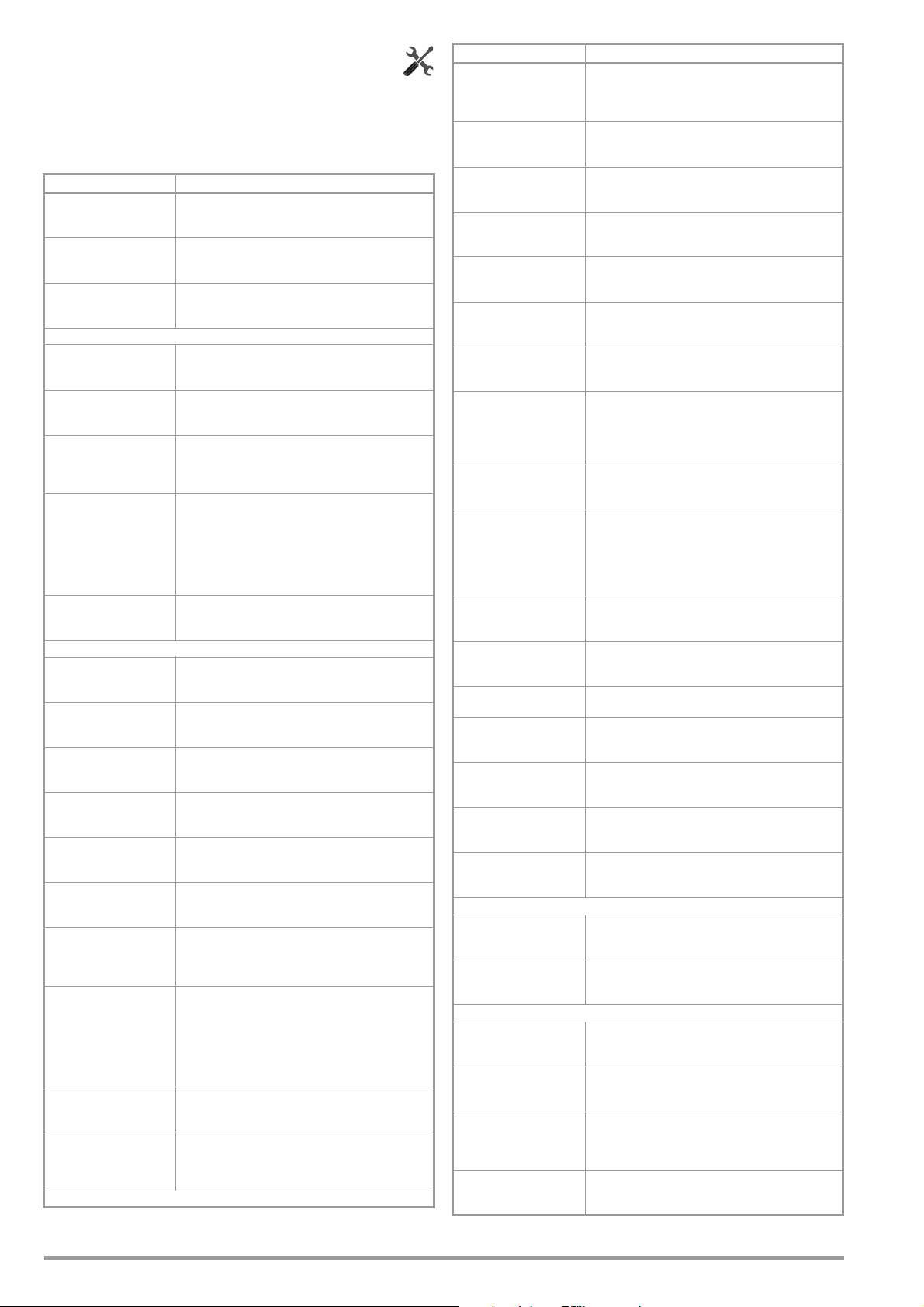

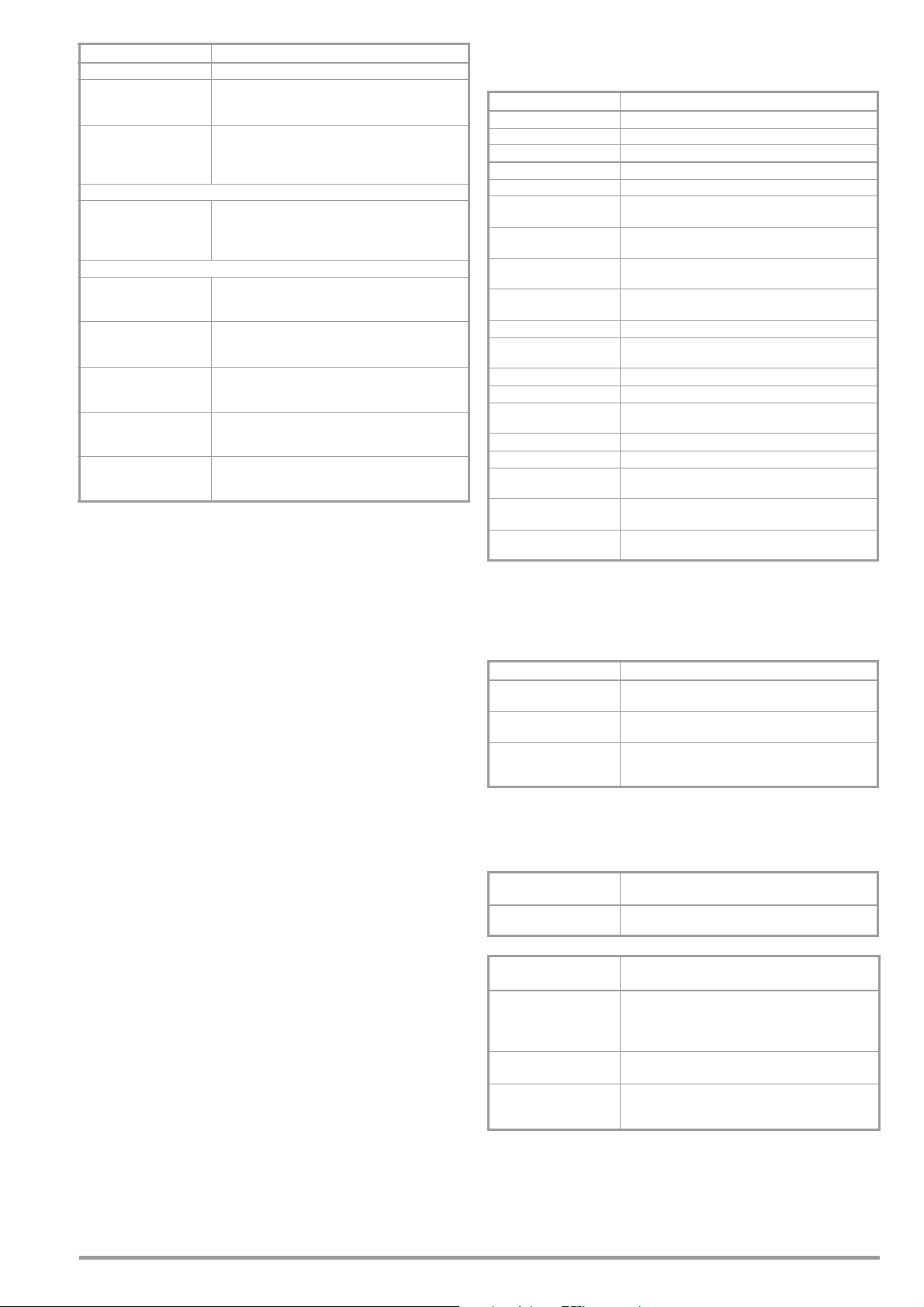

12 Characteristic Values .................................................... 80

13 Maintenance .................................................................. 83

13.1 Housing Maintenance .................................................................. 83

13.2 Testing the Color Display and the Buzzer (self-test parameter) ........83

13.3 Software Update (system info parameter) ......................................83

13.4 Backup Battery for Real-Time Clock ..............................................83

13.5 Fuse Replacement ....................................................................83

13.6 Recalibration ...............................................................................83

13.7 Technical Safety Inspections ........................................................83

13.8 Returns and Environmentally Sound Disposal ................................84

14 Appendix ........................................................................ 84

14.1 List of Suitable Printers with USB Port ........................................... 84

14.2 List of Suitable Barcode Scanners and RFID Scanners with

USB Port .....................................................................................85

14.3 Use of USB Storage Devices ......................................................... 85

14.4 Bluetooth Interface (SECUTEST PRO BT (comfort) or feature M01) 86

14.5 Remote Control Interface .............................................................86

14.6 Entry Via an External USB Keyboard .............................................. 87

14.6.1 Additional Key Functions, DB Comfort Option

(feature KD01, “Z853S – SECUTEST DB COMFORT”) ....................87

14.7 Index ..........................................................................................88

4 GMC-I Messtechnik GmbH

Page 5

15 Repair and Replacement Parts Service

Attention!

!

Note

Note

Attention!

!

Calibration Center and Rental Instrument

Service ............................................................................90

16 Product Support ............................................................. 90

1 Applications

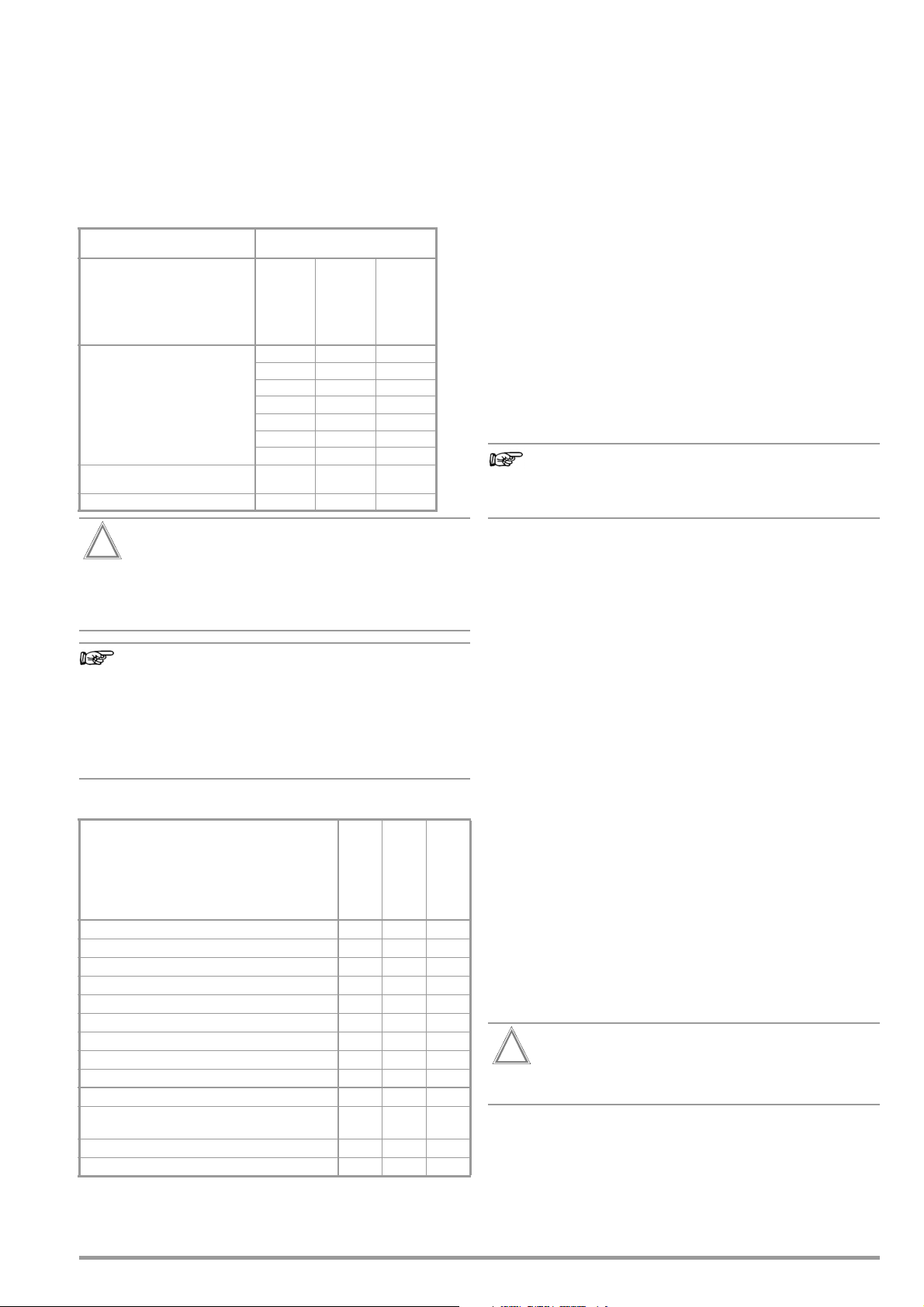

1.1 Table: Types of DUTs – Tests – Standards

Testing after Repairs /

Periodic Testing

Test DUTs

in accordance with

the following standards

EN 50678, draft

DIN VDE 0701-0702

IEC 62353

DIN EN 62353

(VDE 0751-1)

IEC 60974-4

DIN EN 60974-4

VDE 0544-4

Electric devices •

Work devices •

Mains operated electronic devices

Hand-held electric tools •

Extension cords •

Household appliances •

Data processing devices •

Medical electric

devices, applied parts

Welding units •

•

•

2 Safety Features and Precautions

SECUTEST BASE(10), SECUTEST PRO and SECULIFE ST BASE(25) test

instruments fulfill all requirements of applicable EU directives and

national regulations. We confirm this with the CE mark.

The relevant declaration of conformity can be obtained from

GMC-I Messtechnik GmbH.

The test instruments are manufactured and tested in accordance

with the following safety regulations: IEC 61010-1 / DIN EN

61010-1 / VDE 0411-1,

Safety of the operator, as well as that of the test instrument and

the device under test, is only assured when it’s used for its

intended purpose.

Read the operating instructions carefully and completely before placing your

test instrument into service. Follow all instructions contained therein. Make

sure that the operating instructions are available to all users of the instrument.

Tests may only be performed by a qualified electrician, or under the

supervision and direction of a qualified electrician.The user must be

instructed by a qualified electrician concerning performance and evaluation of the test.

Suitable personal safety equipment is required.

If you use active or passive body assistance, please consult your

physician or the manufacturer of the body assistance device.

Manufacturers and importers of medical electric devices must

provide documentation for the performance of maintenance by

trained personnel.

DIN EN 61557-16/VDE 0413-16

The test instrument may not be used for measurements

within electrical systems! The test instrument must be

operated within the same electrical system as the test

object!

Test sequences for VDE 0701-0702, ÖVE 8701 and

SNR 462638 are identical. In the interest of improved readability, only VDE 0701-0702 is described below. The explanations apply to ÖVE 8701 and SNR 462638 as well. The

instrument can be switched to the country-specific standard designation in SETUP (page 1/3) under “Auto Measurements”, “Measuring Sequence Parameters”.

1.2 Table: Single Measurements – Regulations

Single measurements

per Regulation

EN 50678, draft

Protective conductor resistance •

Insulation resistance

Protective conductor current

Primary leakage current

Device leakage current

Touch current

Current from welding circuits

Patient leakage current

Leakage current from the applied part

Test methods

Alternative measuring method (equivalent

(device) leakage current)

Differential current measuring method

Direct measuring method

•••

•

••

••

•••

•••

Key

• Specified test

DIN VDE 0701-0702

IEC 62353

DIN EN 62353

••

•

•

•

Observe the following safety precautions:

•

The instrument may only be connected to TN, TT or IT electrical

systems with a maximum of 240 V which comply with applicable

safety regulations (e.g. IEC 60346, VDE 0100) and are protected

with a fuse or circuit breaker with a maximum rating of 16 A.

• Measurements within electrical systems are prohibited.

Be prepared for the occurrence of unexpected voltages at

•

under test

(for example, capacitors can be dangerously charged).

• Make certain that the measurement cables are in flawless condition, e.g. no damage to insulation, no cracks in cables or plugs

etc.

• When using a test probe with coil cord (SK2W):

Grip the tip of the test probe firmly, for example if it has been

inserted into a jack socket. Tensioning at the coil cord may

otherwise cause the test probe to snap back resulting in possible injury.

• Measurement of insulation resistance and equivalent leakage current

(alternative leakage current measuring method)

Testing is conducted with up to 500 V. Current limiting is utilized (I < 3.5 mA), but if terminals L or N at the test socket or

the test probe are touched, electrical shock may occur which

could result in consequential accidents.

(VDE 0751-1)

IEC 60974-4

DIN EN 60974-4

VDE 0544-4

• Leakage current measurement while connected to line voltage

It’s absolutely essential to assure that the device under test is

operated with line voltage during performance of the leakage

current measurement. Exposed conductive parts may con-

•

duct dangerous touch voltage during testing, and may not

under any circumstances be touched.

(Mains power is discon-

nected if leakage current exceeds approx. 10 mA.)

•

The function test may only be performed after the DUT has

successfully passed the safety test!

devices

GMC-I Messtechnik GmbH 5

Page 6

• Probe Test

Attention!

!

Attention!

!

Attention!

!

!

®

Test the probe after completing each test (see also section 10.2.2).

If the fuse at test probe P1 is defective after testing has

been started, all subsequent measurements conducted

using this measuring path will be incorrectly evaluated as

good!

• Fuse Replacement

The fuses may only be replaced when the instrument is voltage-free, i.e. the instrument must be disconnected from

mains supply power and may not be connected to a measuring circuit. The fuse type must comply with the specifications

in the technical data or the labeling on the instrument.

Opening the Instrument / Repairs

The instrument may only be opened by authorized, trained personnel in order to ensure flawless operation and to assure that the

guarantee is not rendered null and void.

Even original replacement parts may only be installed by authorized, trained personnel.

If it can be ascertained that the instrument has been opened by

unauthorized personnel, no guarantee claims can be honored by

the manufacturer with regard to personal safety, measuring accuracy, compliance with applicable safety measures or any consequential damages.

If the guarantee seal is damaged or removed, all guarantee claims

are rendered null and void.

Safer Testing with Test Adapter

In the case of test objects for which a starting current of greater

than 30 A can be expected, we urgently recommend the use of a

test adapter for larger starting currents:

for example test adapters from the AT3 series

(AT3-IIIE, AT3-IIS, AT3-IIS32, AT16DI or AT32DI).

Alternative: Passive Test

If necessary on the basis of the hazard assessment, testing can

be conducted as a passive test (equivalent leakage current

method), i.e. without switching line voltage to the test socket.

The test instrument may not be used:

• If external damage is apparent, for example if parts which

conduct dangerous touch voltage are freely accessible, if the

display is broken or defective (in which case dangerous voltage or mains connection errors might no longer be indicated)

• If the seal or sealing lacquer has been removed as the result

of repairs or manipulation carried out by an unauthorized/noncertified service provider

With damaged connection and/or measurement cables and patient

•

ports, e.g. interrupted insulation or kinked cable

•If the instrument no longer functions flawlessly

• After extraordinary stressing due to transport

In such cases, the instrument must be removed from operation

and secured against unintentional use.

Meanings of Symbols on the Instrument

The symbols on the instrument have the following meanings:

Before opening the housing, pull the mains plug out of

the outlet and wait for at least 5 minutes.

Switching Power Consumers – Procedure

Be absolutely sure to adhere to the sequence specified below

when switching the live device under test. This prevents excessive

wear of the mains relays at the test instrument.

Before measurement:

1

Device under test: Turn the DUT off via its own switch.

2 Test instrument:

3

Device under test: Turn the DUT on via its own switch.

After measurement:

4

Device under test: Turn the DUT off via its own switch.

5 Test instrument:

Switch line voltage to the test socket.

Deactivate line voltage to the test socket.

Switching Loads – Maximum Starting Current

Our SECUTEST BASE(10), PRO and SECULIFE ST BASE(25) test instruments permit active testing of devices with a nominal current (load

current) of up to 16 A.

The test socket on the respective test instrument is equipped with

16 A fuses to this end and the switching capacity of the internal

relays is also 16 A. Starting current of up to 30 A is permissible.

Warning regarding dangerous electrical voltage

Warning concerning a point of danger

(attention: observe documentation!)

CE conformity marking

This device may not be disposed of with household

trash.

Further information regarding the WEEE mark can be

accessed on the Internet at www.gossenmetrawatt.com by entering the search term “WEEE”.

If the guarantee seal is damaged or removed, all guarantee claims are rendered null and void.

Utilized Trademarks

QR Code QR Code is a registered trademark of

DENSO WAVE INCORPORATED

®

The Bluetooth

trademarks of Bluetooth SIG, Inc

word mark and logo are registered

Despite extensive protective measures targeted at preventing overloading, the relay contacts may be welded

together if starting current exceeds 30 A. The following error

message appears in this case.

“L(N) test socket fuse defective”.

➭ Check both of the mains connection’s fuse links. If they’re de-

fective replace them with new ones.

If the error message described above still appears, it must be

assumed that the relay is defective. If this is the case, the test

instrument must be sent to our service department for repair (see

section 15 for address.

6 GMC-I Messtechnik GmbH

Page 7

3 General Operation

Note

Note

Note

Note

Note

3.1 Measured Value Display

The following items appear at the display panel:

• The selected measuring function or standard

• Measured values with abbreviations and units of measure

• Setting parameters such as type of connection and measurement type

• Symbols for softkey operation

• Wiring diagrams, notes regarding the test sequence

and error messages

Green progress bars appear in the header for single measurements, and orange progress bars appear for test sequences.

If the upper range limit is exceeded, the upper limit value is displayed and is preceded by the “>” symbol (greater than), which

indicates measurement value overrun. Falling short of the lower

range limit is indicated by the “<” symbol (less than), for example

with RINS.

The depiction of LEDs in these operating instructions

may vary from the LEDs on the actual instrument due to

product improvements.

Measured Value Storage

See section 8.4

3.2 Language, Keyboard Layout (culture parameter)

The desired user interface language, a country-specific keyboard

layout and a language for the test sequences (measuring

sequence parameter) can be selected in the SETUP switch setting

(see Section 4.3).

If you change the keyboard layout setting, you’ll be

prompted to scan in certain barcodes. This is necessary

in order to assure that the barcode reader still works correctly after changing the language. If the barcode reader

isn’t currently available, you can subsequently set it to the

new keyboard layout via Setup (2/3) > External Devices >

Barcode Reader > Type Z751A.

3.3 Help Functions (HELP key and QR code)

Depending on the rotary selector switch position and the selected

measurement type, appropriate wiring diagrams are displayed.

➭ Press the HELP key in order to query online help.

➭ Press the ESC key in order to exit online help.

3.4 Entering Alphanumeric Characters

Entry via the Keyboard

In addition to the softkey keyboard which can be accessed at the display, USB keyboards (with USB boot keyboard profile) can also be

used to enter texts such as offsets, ID numbers, type designations

and comments (see also section 5.3).

Reading in Barcodes

➭ Correct recognition of the barcode scanner by the test instru-

ment after connection to the USB port is indicated by the

icon in the header.

➭ Select the following parameter in order to configure the bar-

code scanner for initial start-up:

Setup (2/3) > External Device > Barcode Scanner > Type

Z751A.

➭ Scan the barcode which then appears.

When the menu for alphanumeric entry via the softkey keyboard

is open at the display, any value read in by means of a barcode

scanner is directly accepted.

See the appendix in section 14.2 concerning available accessory

devices.

We’re unable to offer any guarantees regarding the use of

scanning devices other than those listed in the appendix.

Reading In an RFID Code

➭ Correct recognition of the RFID scanner by the test instrument

after connection to the USB port is indicated by the icon in

the header.

When held at a distance of about 3 cm directly in front of the middle of the RFID tag, the tag’s current content is read (e.g. the ID

code) and the SCAN LED on the reader blinks.

If the database view (MEM) is active (before or after a measurement), the cursor automatically jumps to the DUT with the corresponding ID code.

If the object is not found, a prompt appears asking if you would

like to create a new object.

3.5 Print-Outs – Reports

If you’ve connected a suitable printer (see list in appendix in section 14.1) or USB flash drive via the USB master port, you can

read out a test report for each completed single measurement or

test sequence by pressing the PRINT key.

The respective single measurement or test sequence must be

previously selected in the memory menu with the help of the scroll

keys.

We’re unable to offer any guarantees regarding the use of

printers other than those listed in the appendix.

3.5.1 Multi-Print

If, in the memory menu, you move the cursor to a test object for

which several tests have been conducted (individual measurements or test sequences) and press the PRINT key, a combined

test report with all test results for the respective test object is read

out.

3.5.2 Report Template for Reading Out Reports to a Thermal Printer or an HTML File

A report can be read out concerning the results of individual measurements or test sequences stored to the internal database. A

report template is permanently stored to the test instrument for

this purpose. The designation of the standard in the report may

vary depending on which test sequence has been conducted.

The report template includes the following items:

•ID number

• Designation

• Customer name

• Location

•Date

•Time

• Comment with 64 characters

• Standard designation / sequence name / manual test

• Measured values

• Limit values

•Evaluations

• Test equipment (serial number)

The display which appears is not a print preview and

does not reflect the actual appearance of the printout.

GMC-I Messtechnik GmbH 7

Page 8

3.5.3 Report Tapes from Thermal Printers

Note

Note

Note

Note

Note

Note

Note

Report tapes can be printed out with the Z721S thermal printer

(accessory: Z722S thermal paper).

As of firmware V2.1.1: The test report can now be edited and a

company logo can be added to it directly in SETUP at the test

instrument (see page 14). A company logo can be loaded from a

USB flash drive for which the following image file formats are supported:

BMP, JPG, PNG or GIF, resolution: max. 800 x 800 pixels. Color

depth: max. 24-bit.

Report Designer PC software is no longer supported as a

firmware version 2.1.1.

3.5.4 Printing via IZYTRONIQ

Alternatively, stored measurement data can be read into IZYTRONIQ report generating software at a PC and printed out as a

report.

Code Recognition

Please make sure that the printed codes are recognized

by your scanner. Some code types have to be activated

on your scanner prior to being used (this is frequently the

case with Aztec/DataMatrix).

Minimum Width of Labels

Tape cartridges with a minimum width of 12 mm are recommended for print-out of 2D code labels (QR code,

MicroQR code, DataMatrix, Aztec).

If a blank label is discharged upon printing an ID number

as a 2D code with a 9 mm ribbon cartridge, replace it

with a 12 mm cartridge (or wider) and restart the printing

process.

3.5.5 Saving Reports to a USB Flash Drive

Select a measurement from the database view (MEM key) with the

scroll keys, for which a report will be saved to a USB flash drive.

Then press the PRINT key. “Print job finished” appears. The report

is written to an HTML file. The filename consists of the timestamp

and the ID of the test object.

Alternatively, reports can be save or printed out immediately after

conducting a test, or when the test list view is open.

A list of suitable USB flash drives is included in the appendix

(see section 14).

3.6 Print-Out of ID Labels (as of firmware V1.3.0)

A barcode printer permits for the following applications:

• Print-out of ID numbers encrypted as barcodes for devices

under test – for quick and convenient acquisition during periodic testing

• Print-out of repeatedly occurring designations such as test

object types encrypted as barcodes in a list, allowing them to

be read in as required for comments

We’re unable to offer any guarantees regarding the use of

printers other than those listed in the appendix.

3.7 Writing RFID Tags (as of firmware V1.5.0)

The following function is made possible by an RFID scanner (programmer):

• Read-out of encrypted ID numbers for devices under test to

an RFID tag for quick and convenient read-in during periodic

testing

If you’ve connected a suitable RFID scanner (see list in appendix

in section 14.1) via the USB master port, you can write an RFID

tag for each

➭ Correct recognition of the RFID scanner by the test instrument

after connection to the USB port is indicated by the icon in

the header.

➭ Switch to the database view (MEM key).

➭ Select the desired

new test object by means of its ID.

➭

Briefly press the

➭ You’re prompted to hold the scanner at a distance of about

3 cm directly in front of the middle of the RFID tag.

The “Successful write” message appears to indicate that the procedure has been completed.

test object

An error message appears if the ID cannot be converted to

an

RFID tag

by pressing the PRINT key:

test object

PRINT

key on the test instrument.

.

with the scroll keys or enter a

If you’ve connected a suitable barcode printer (see list in appendix

in section 14.1) via the USB master port, you can print out a barcode for each

➭ By viewing the printer information, you can first of all deter-

mine whether or not the connected barcode printer is correctly recognized by the test instrument:

Setup (2/3) > Printer > Z721D > Printer Information

or

Setup (2/3) > Printer > Z721E > Printer Information

➭ Select encryption in Setup (paper size is set automatically as

of FW 2.0):

Setup (2/3) > Printer > Z721D > Printer Settings

or

Setup (2/3) > Printer > Z721E > Printer Settings

➭ Switch to the database view (MEM key).

➭

Select the desired test object with the scroll keys.

➭ Press the PRINT key.

➭

Depending on your selection, the ID is printed onto the label as a

barcode. An error message appears if the ID cannot be read out

as a barcode or a 2D code.

8 GMC-I Messtechnik GmbH

test object

by pressing the PRINT key.

We’re unable to offer any guarantees regarding the use of

readers or writers other than those listed in the appendix.

Page 9

4 Initial Startup

Attention!

!

L1

N

Green-yellow

Green-yellow

PE

L1

L2

L3

N

PE

L1

L2

L3

N

Green-yellow

KS13

When selecting

between two

states: direct

change without

submenu

Icon Toggle

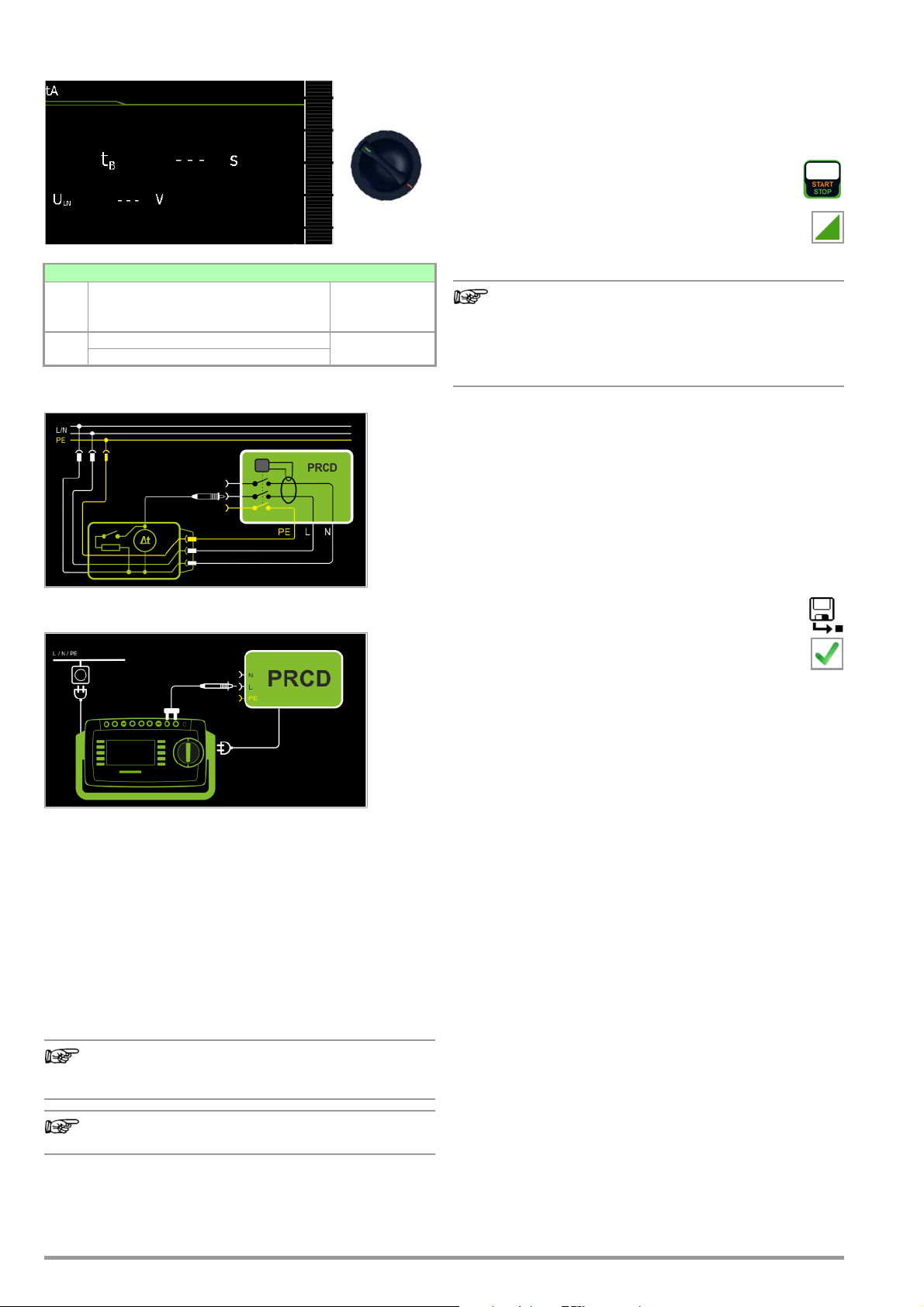

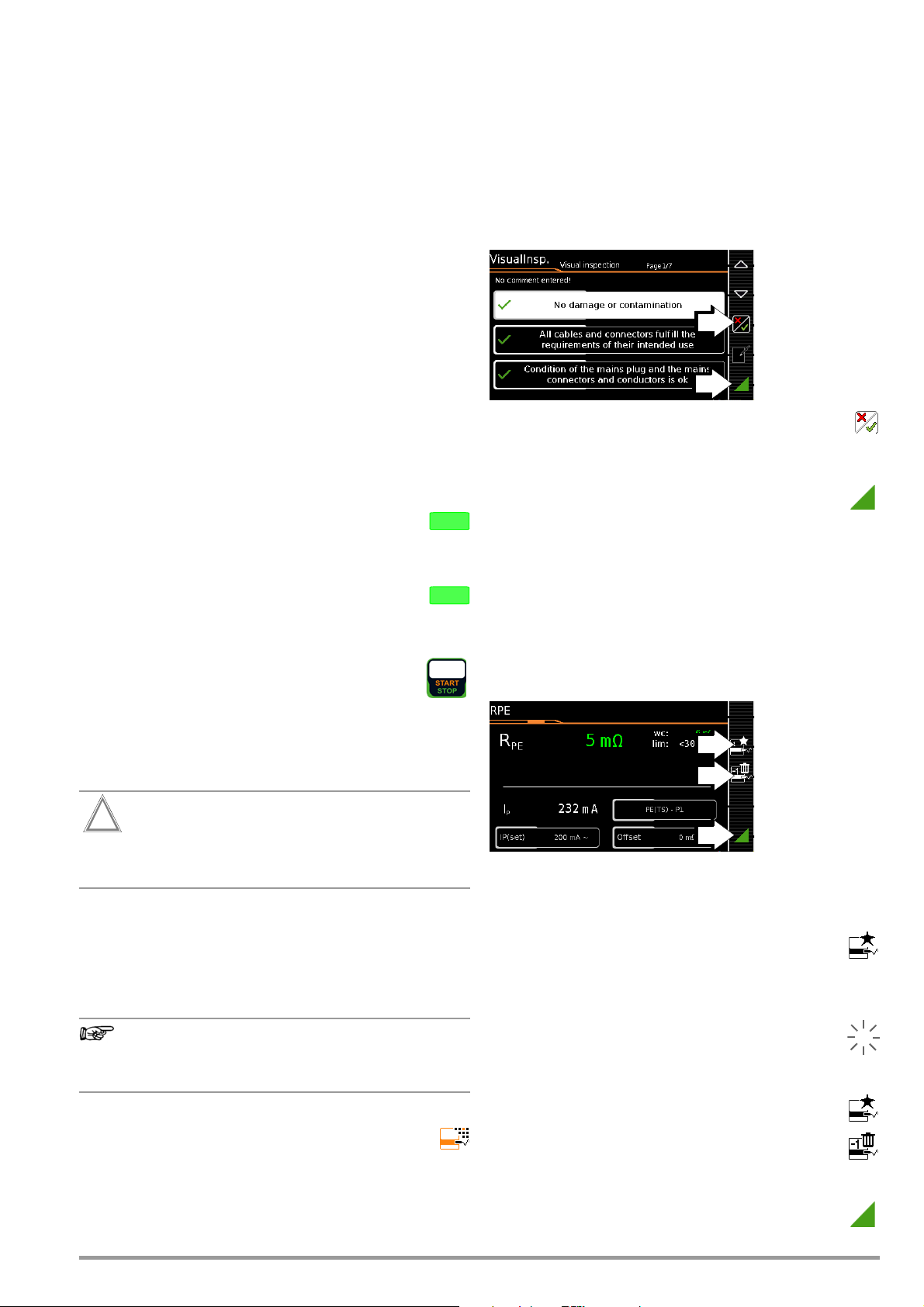

4.1 Connecting the Test Instrument to the Mains

➭ See section 12 for nominal mains values (nominal ranges of

use).

➭ Connect the test instrument to the mains cable via its inlet

plug and insert the mains plug into an electrical outlet. The

function selector switch can be set to any position.

If a mains outlet (earthing contact outlet) is not available, or if

only a 3-phase outlet is available, the adapter socket can be

used to connect the phase conductor, the neutral conductor

and the protective conductor. The adapter socket has three

permanently attached cables and is included with the KS13

cable set.

If connection is not possible via an earthing contact outlet: Shut down mains power first.

Then connect the cables from the coupling socket to the

mains using pick-off clips in accordance with the diagram.

Disconnection from mains power is only possible via the

mains plug.

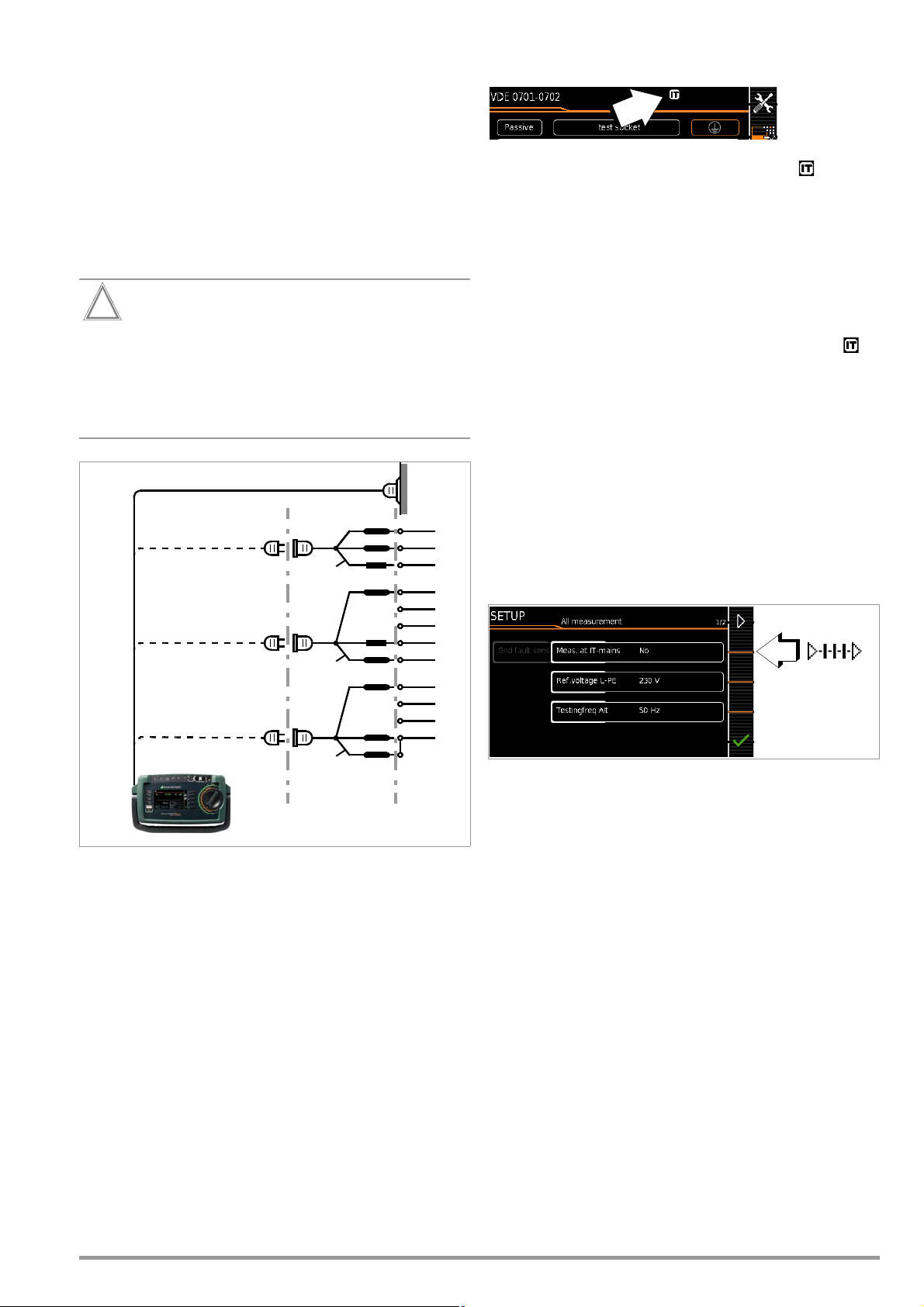

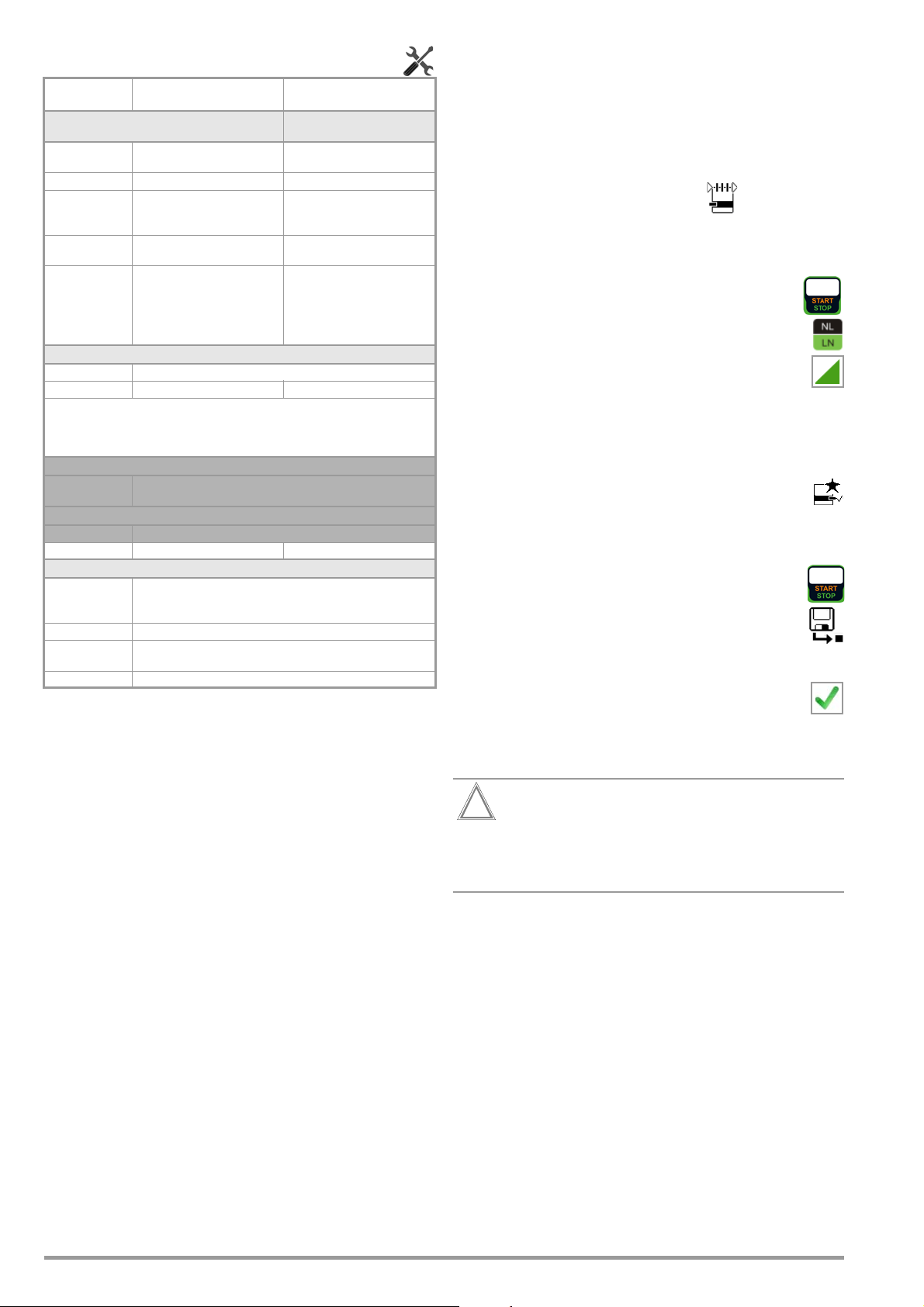

4.1.1 Measurements in IT Systems (new parameter as of firmware

1.5.0)

The IT system

setting can be

activated for all

single measure-

ments and test sequences in the SETUP switch position (Setup 1/

3) in the All measurements submenu (in this case the icon

appears in the header of each display page):

with “Measurement at IT system” set to Yes: active leakage current

measurements (or all measurements with reference to PE at the

mains connection side) are disabled. Test sequences which

include measurements of this sort are also disabled.

If, when being connected to line voltage, the SECUTEST detects

a change at PE as compared with the previously used mains connection, the inspector is asked directly after initial start-up if the

currently used outlet belongs to an IT system. The IT system

option in SETUP is activated based on the user’s answer. If “Measurement at IT system” is activated, this is indicated by the

icon in the header.

Regardless of this, it’s always possible to accordingly change the

option manually in SETUP.

The setting for the “Measurement at IT system” option is retained

even after disconnection from the mains.

In IT systems, active leakage current measurements (or any measurements with reference to PE at the mains connection side) do

not deliver reliable measured values, for which reason all single

measurements of this sort, as well as test sequences which

include this type of measurement, are disabled when the “Measurement at IT mains” option has been activated in SETUP.

Figure 1 Connecting the Test Instrument to the Mains

The Meas. at IT mains parameter can be set in Setup:

Setup 1/3 > All Measurements > Meas. at IT Mains

GMC-I Messtechnik GmbH 9

Page 10

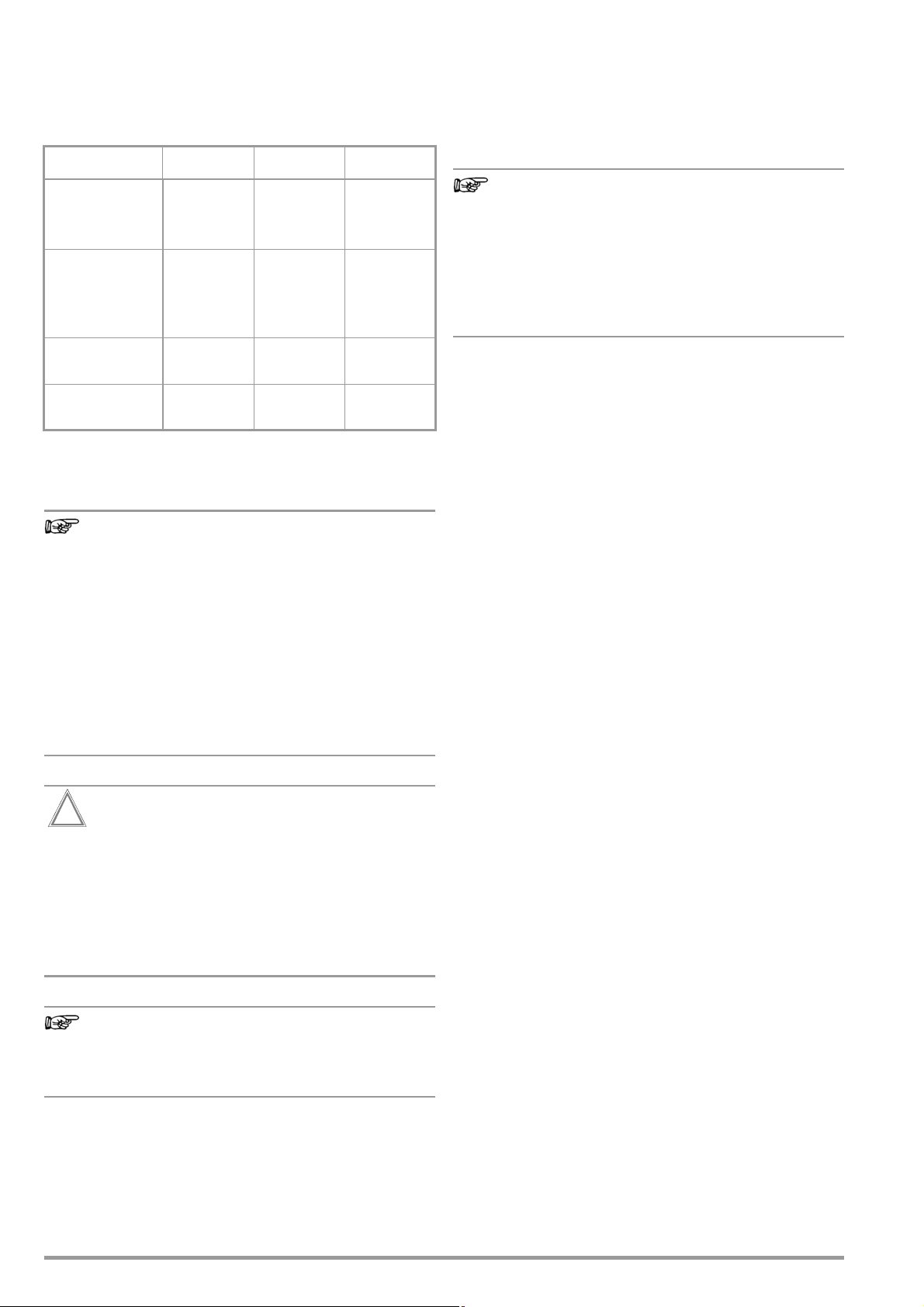

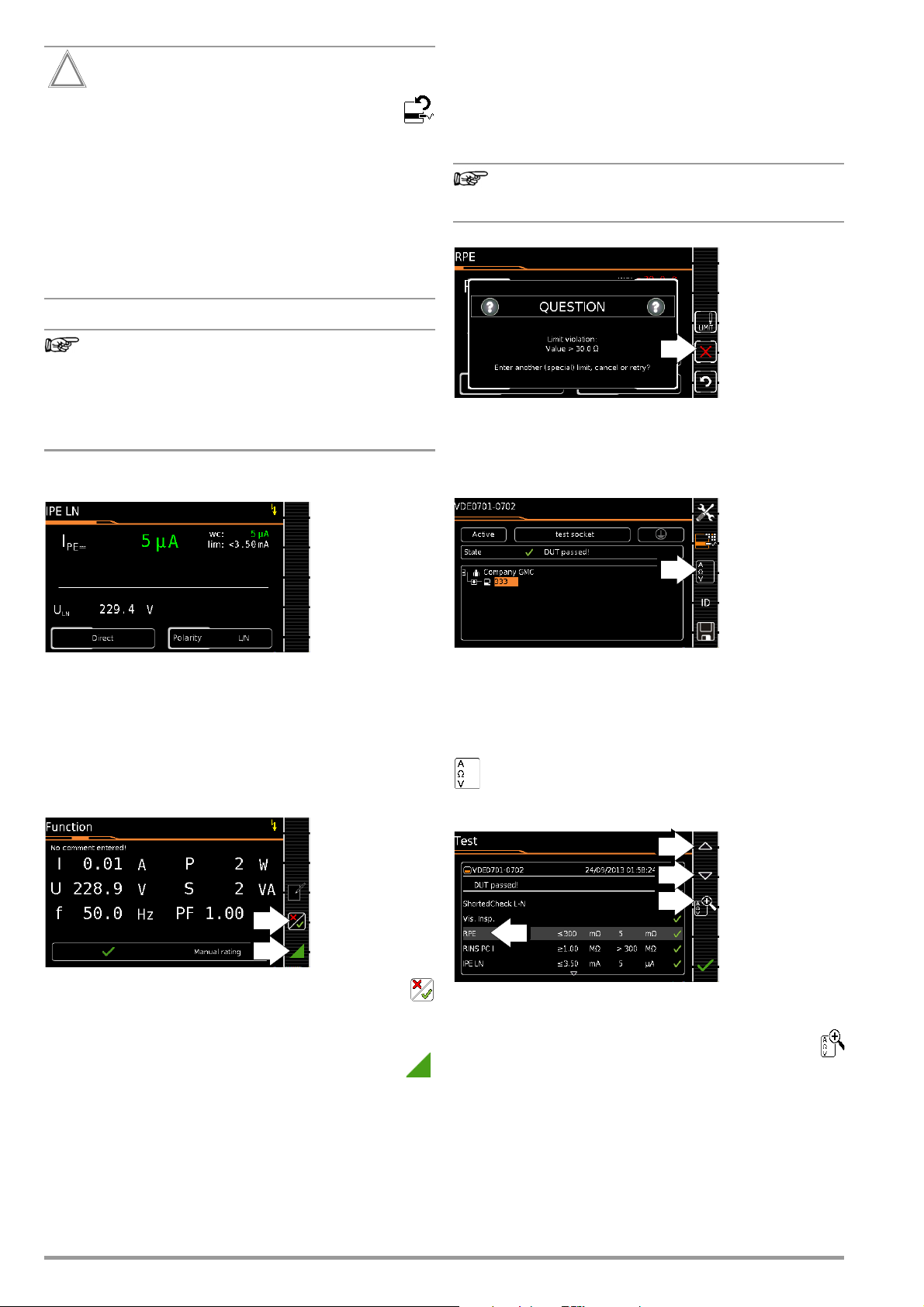

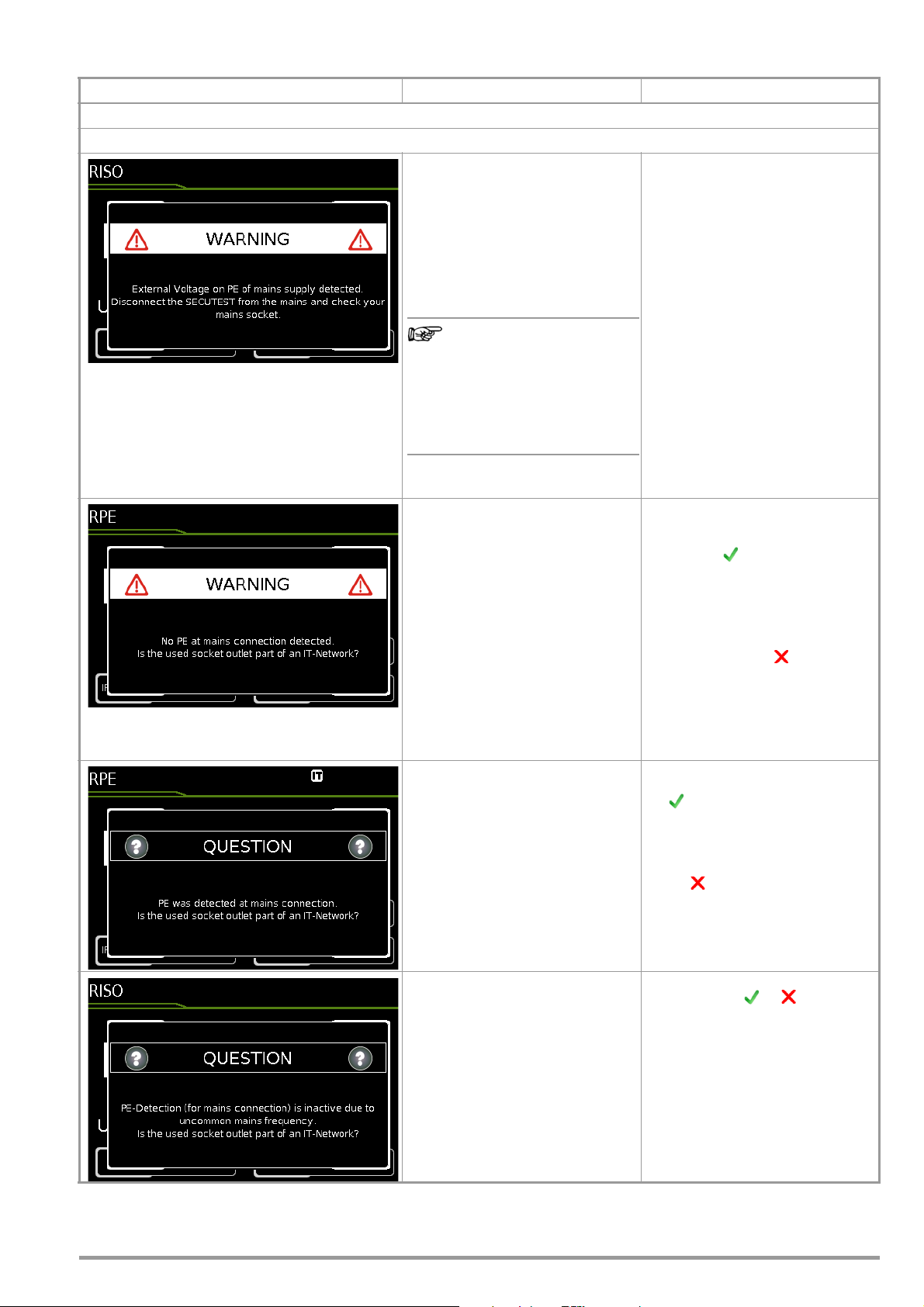

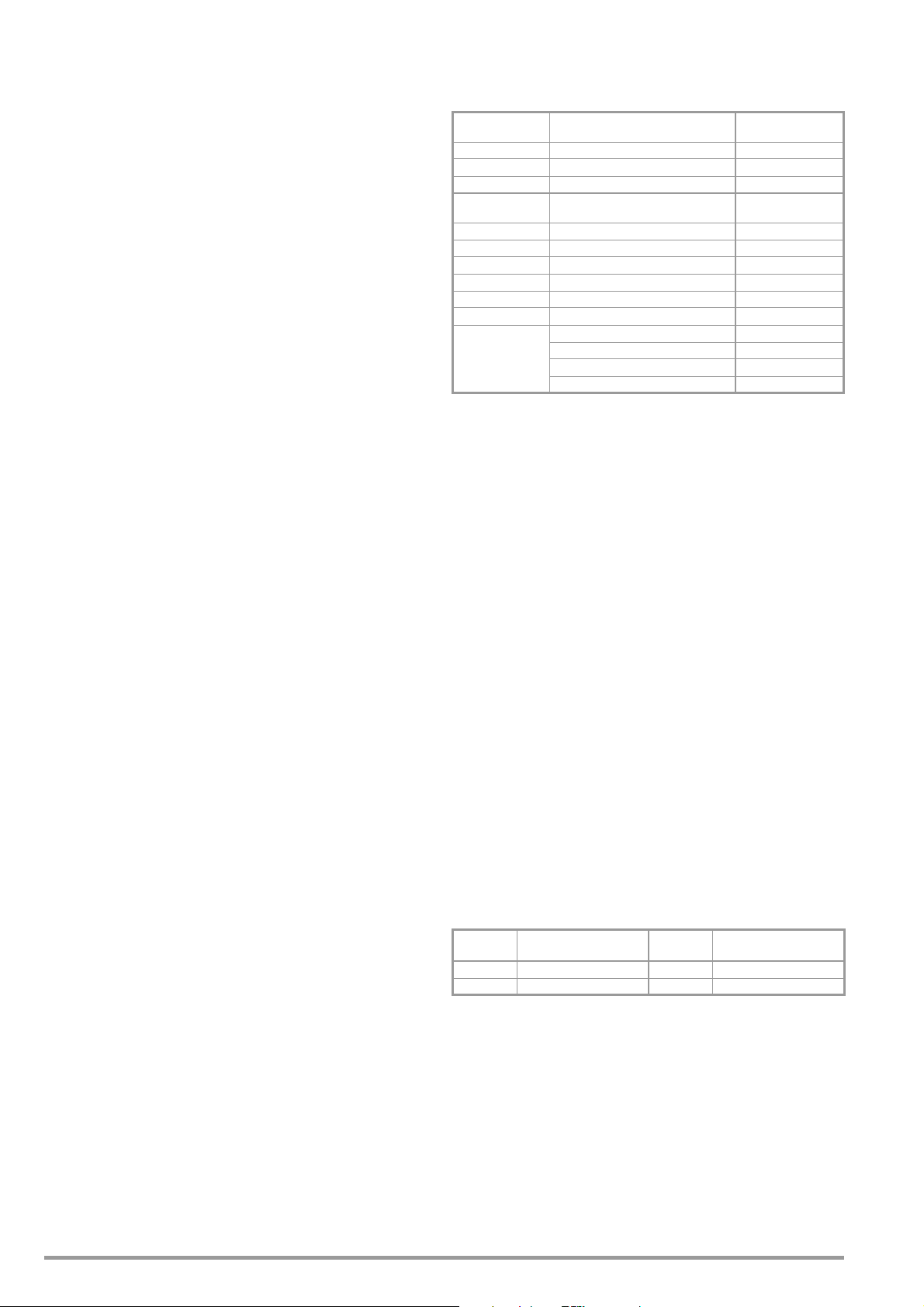

4.1.2 Automatic Recognition of Mains Connection Errors

Note

Attention!

!

Note

Note

The device automatically recognizes mains connection errors if

the conditions in the following table have been fulfilled. The user is

informed of the type of error, and all measuring functions are disabled in the event of danger.

Typ e o f Mai n s

Connection Error

Voltage at

protective conductor PE

to finger contact

(START/STOP key)

Protective conductor PE

and

phase conductor L

reversed and/or

neutral conductor N

interrupted

Line voltage

< 180 V / < 90 V

(depending on mains)

Test for IT/TN system

1

10/25 A-RPE measurements are only possible with line voltages of 115/230 V and

line frequencies of 50/60 Hz.

2

If the user of the test instrument is too well insulated, the following error message may

appear: “Interference voltage at mains connection PE”

Message Condition Measurements

Pres s START/STOP

Display at the

instrument

Display at the

instrument

button

U > 25 V

Key → PE:

2

< 1 MΩ

Voltage at PE

> 100 V

U

< 180 V

L-N

U

<90V

L-N

Connection

N → PE

> 20 kΩ

All measurements

disabled

Not possible

(no supply power)

Possible under

certain circum-

stances

Possible under cer-

tain circumstances

1

4.2 Connecting Test Probe P1 or P2

Insert the double plug from test probe P1 or P2 into socket 1 or 2

respectively such that the plug with the white ring makes contact

with the socket with the vertical bar.

The white ring identifies the terminal for the high current conductor which is safeguarded by the neighboring fuse link.

Difficultly in contacting exposed conductive parts

when using the standard probe with test tip

In order to assure good contact, surface coatings must

be removed from devices under test with special tools at

a suitable location.

The tip of test probe P1 is not suitable for scratching away

paint, because this may impair its coating and/or mechanical strength. Brush probe Z745G may be more suitable than

the test probe in certain individual cases.

Finger Contact

During this test for correct mains connection, a voltage

measurement is performed between the finger contact

and PE at the test instrument’s mains connection, and its

reference potential is acquired via the user’s body resistance to the conductive start key. In order to obtain reliable measurement results, this resistance value must be

less than 1 MΩ. If the user is wearing insulating shoes or

gloves, or is standing on an insulating floor covering,

erroneous measurements and display of the “Interference

voltage at mains connection PE” message may result. Try

to reduce resistance in this case, for example by touching

ground potential with the other hand (e.g. a radiator, but

not an insulating wall etc.).

If, while testing protective conductor potential, you determine that the mains protective conductor is carrying voltage

(in accordance with the first two mentioned cases), no

further measurements may be performed with the test instrument. If this is the case, potentially dangerous voltage is

also present at the accessible earthing contacts of the

standard socket (test socket). Immediately disconnect

the test instrument from the mains and arrange to have

the fault eliminated at the mains connection.

Voltage at the electrical system’s protective conductor PE may

result in distorted measurement values during testing for

the absence of voltage, or during leakage voltage measurements.

10 GMC-I Messtechnik GmbH

Page 11

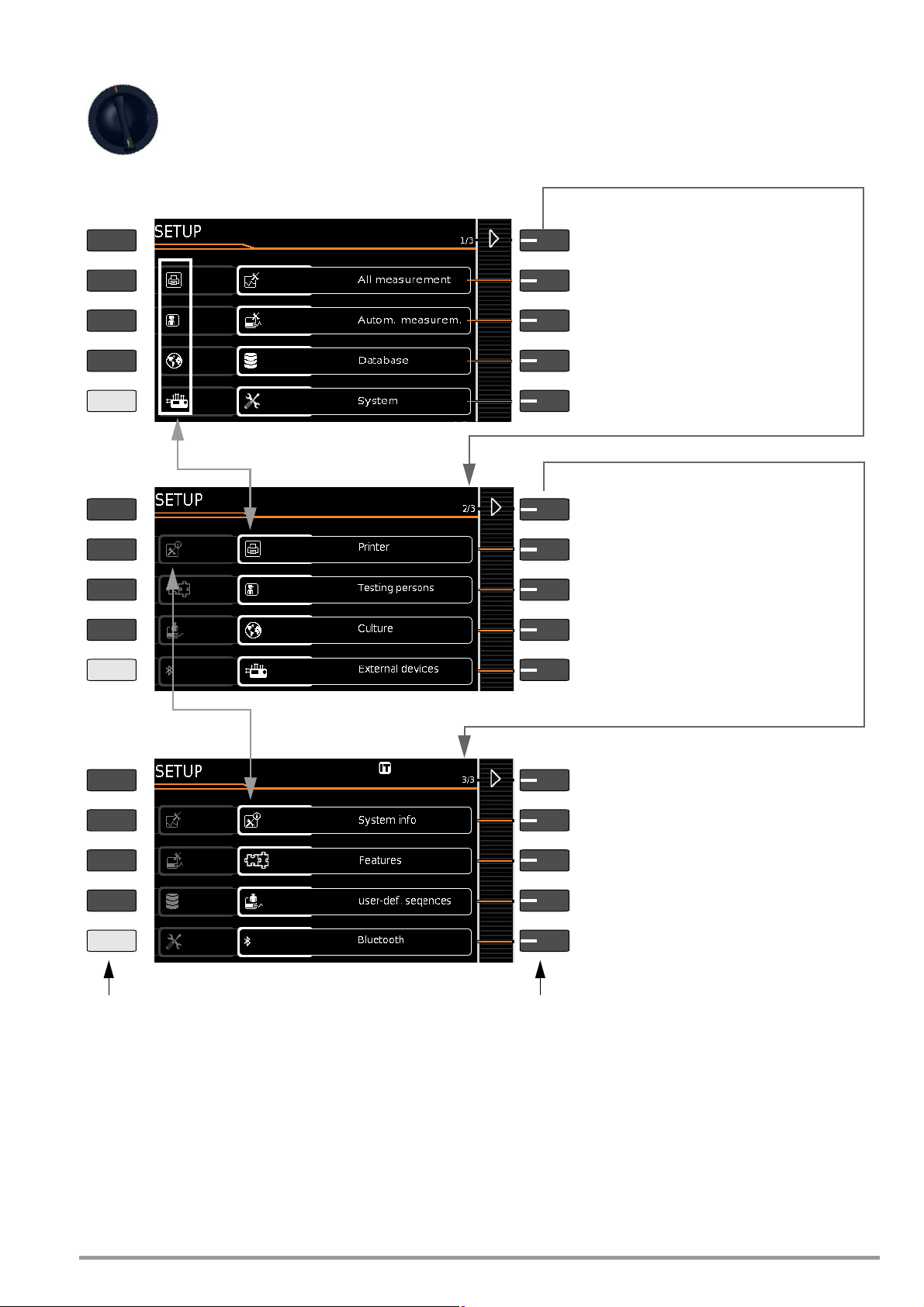

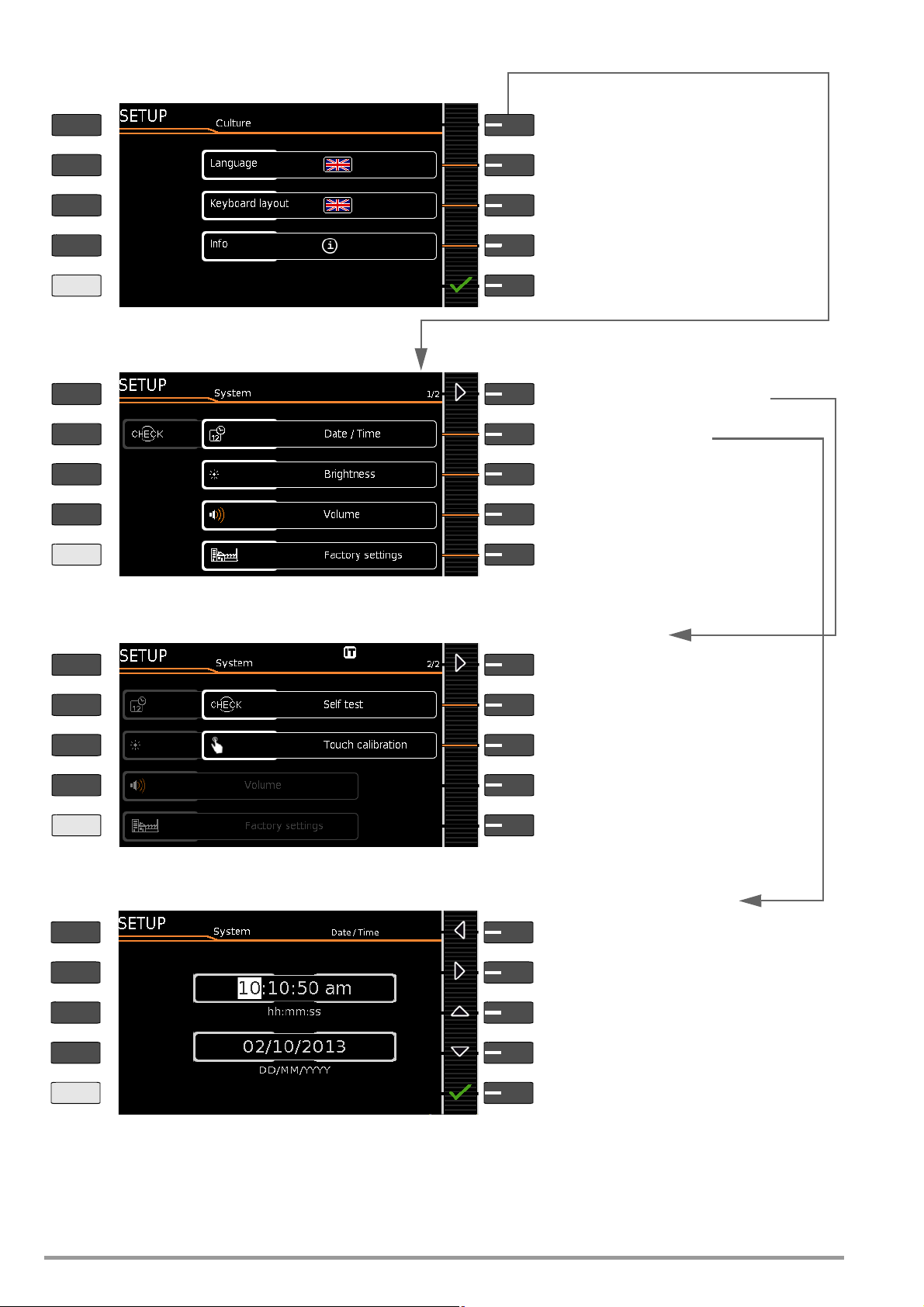

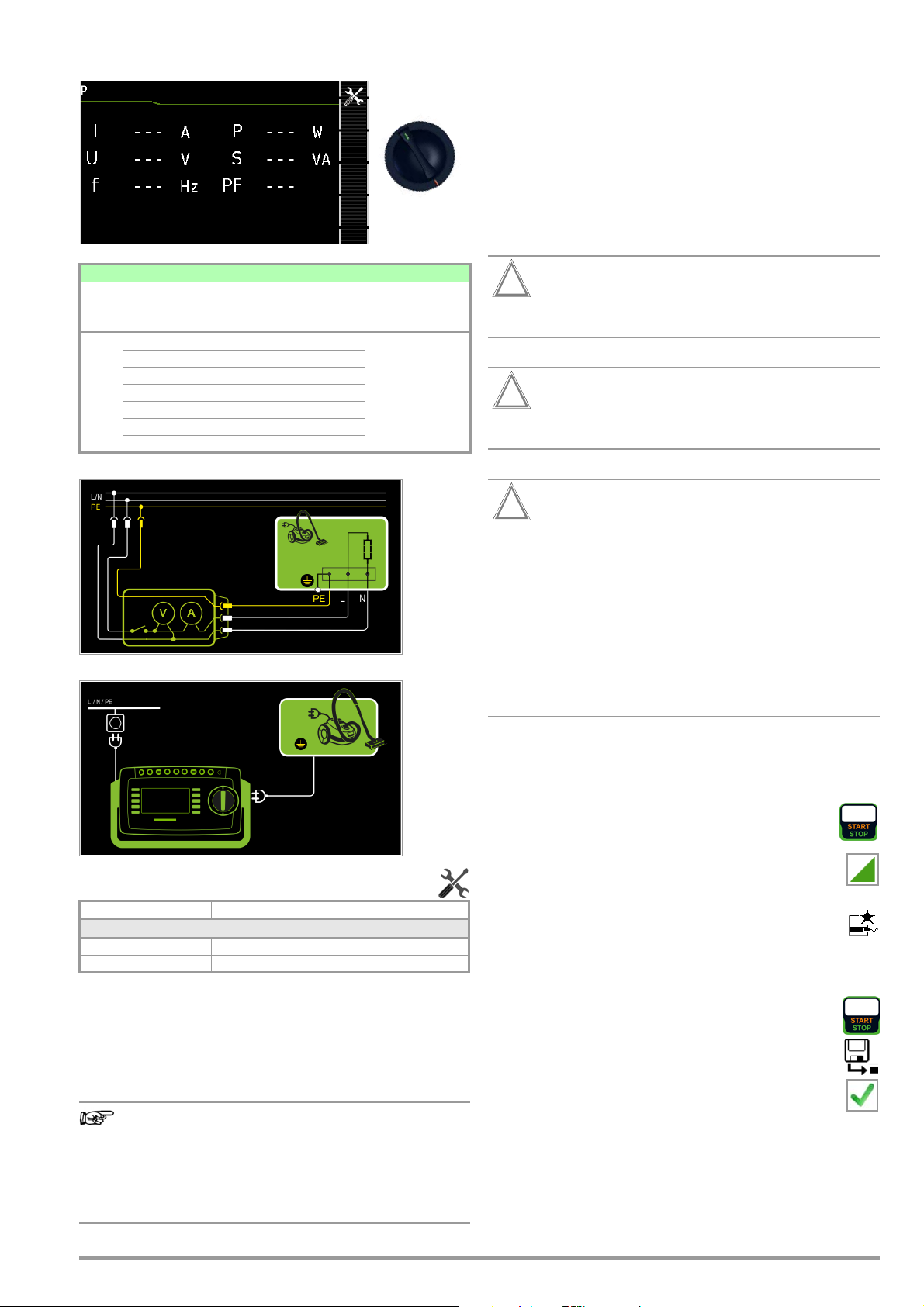

4.3 Device Settings

SETUP

Display additional menu pages

Menu selection for operating parameters, page 1 of 3

Clear database or display statistics,

Set date/time, volume, and brightness

Display additional menu pages

Menu selection for operating parameters, page 2 of 3

Add, select, delete or protect inspector

Select language for user interface and keyboard

For example, select and configure barcode scanner

Display additional menu pages

Menu selection for operating parameters, page 3 of 3

(see submenu on following page)

Keys with fixed functions

Softkeys = keys with functions that vary

depending on the operating level

PRINT

ESC

HELP

MEM

PRINT

ESC

HELP

MEM

PRINT

ESC

HELP

MEM

Setup 1/3

Setup 2/3

Setup 3/3

(see following page).

Save only appears if a USB flash drive is plugged in

by scanning the displayed barcode

Enable functions, display extras

Only with database extension or feature KB01:

Manage and import own sequences

with password (see note in this regard below)

Set test sequence parameters: amongst others measuring sequences (standard) (see section 10.3)

Parameters for single measurements and test

sequences (see section 4.1.1 and section 6.2)

Menus for using the Bluetooth interface

(see section 14.4) (only with feature M01)

To submenu for selecting and setting up a printer

(see page 14)

Query software/hardware version, serial no.,

Calibration data, memory occupancy, user’s manual *

* QR code with link to current operating instructions on the web

For the purpose of initial start-up, we recommend

setting the following basic parameters in the order

shown at the right:

Setup 2/3 > Culture > Language (for user interface)

Setup 2/3 > Culture > Keyboard Layout (for alphanumeric entries)

Setup 1/3 > System > Date / Time (for report generation)

Setup 1/3 > System > Brightness (display brightness as %)

Setup 1/3 > Auto Measurements

> 2/2 > Initial Window Style: Tree or Detail View

Figure 2 Device Settings, Main Menu Level – SETUP Switch Setting

The following parameters are advisable for maintenance purposes:

SETUP 3/3 > Test > Display / Buzzer (for checking info and warning

displays/signals)

SETUP 3/3 > System Info > Software Version for updates (see sec-

tion 13.3) and Calibration Data for adjustment, last and next calibration (see notes on bottom of page 12).

See section 13.3 regarding downloading the latest software version.

Notes Concerning the Inspector Parameter

– The inspector who has just been “selected” appears in tests

to be conducted as “Inspector”. None of the SECUTEST settings are stored specifically for the inspector – all settings in

GMC-I Messtechnik GmbH 11

the SECUTEST are stored for the respective device and are

available to all inspectors.

–

If an inspector is password-protected

know the password from “selecting” this inspector. There’s

word prompt when the test instrument is started up.

remains selected even in the event of a power failure – a

(password-protected) inspector can only be unselected by

selecting another inspector.

As of firmware 1.6.0: In order to delete an inspector whose

password you don’t know, it’s sufficient to enter an incorrect

password five times in a row and to confirm the entry each

time – a query then appears as to whether or not the inspector should be deleted. The inspector to be deleted may not be

the same as the currently selected inspector.

, this only prevents users who don’t

no

pass-

The inspector

Page 12

Manual selection for language and keyboard layout

PRINT

ESC

HELP

MEM

PRINT

ESC

HELP

MEM

PRINT

ESC

HELP

MEM

Select language for user interface

Country-specific keyboard layout

Jump back to next higher menu level

To parameter for default values

Menu selection for date, volume and brightness

Date and time setting menu

Volume setting menu

Brightness setting menu for LCD

To parameters

Default settings

Self-test for display and buzzer

PRINT

ESC

HELP

MEM

Move cursor left

Set time and date menu

Move cursor right

Increase number

Decrease number

Accept changes and jump back

See settings menu below

Setup 2/3 > Culture

Setup 1/3 > System 1/2

Setup 1/3 > System 2/2 > Default Settings

Setup 1/3 > System 1/2 > Date / Time

Page 2/2: Information on date format,

Messages, user interface, measurements

for USB or touchscreen keyboard

With SECUTEST PRO only (feature E01):

Calibrate touchscreen keyboard

Select language for user interface

Info: Date format, decimal separator *

Reset to default values

Caution: The setup configurations

are deleted! (also deletes list of inspectors,

database content and company logo

)

decimal separator

Figure 3 Device Settings, Submenu Level – SETUP Switch Setting

Notes on Calibration Data (adjustment, calibration)

SETUP 3/4 > System Info 2/6 > Calibration Data:

Whereas data for the last adjustment and calibration were set at

the calibration center, date and time of the next calibration (recalibration date) can be changed by the user, if necessary, by select-

12 GMC-I Messtechnik GmbH

ing the EDIT button as shown in the example above for setting

system time.

* As of firmware version 1.7.0, the “Measuring Sequences” parameter for the selec-

tion of country-specific standards (VDE, OVE and NEN) can be found

in SETUP 1/3 under “Auto measurements 2/2”.

Page 13

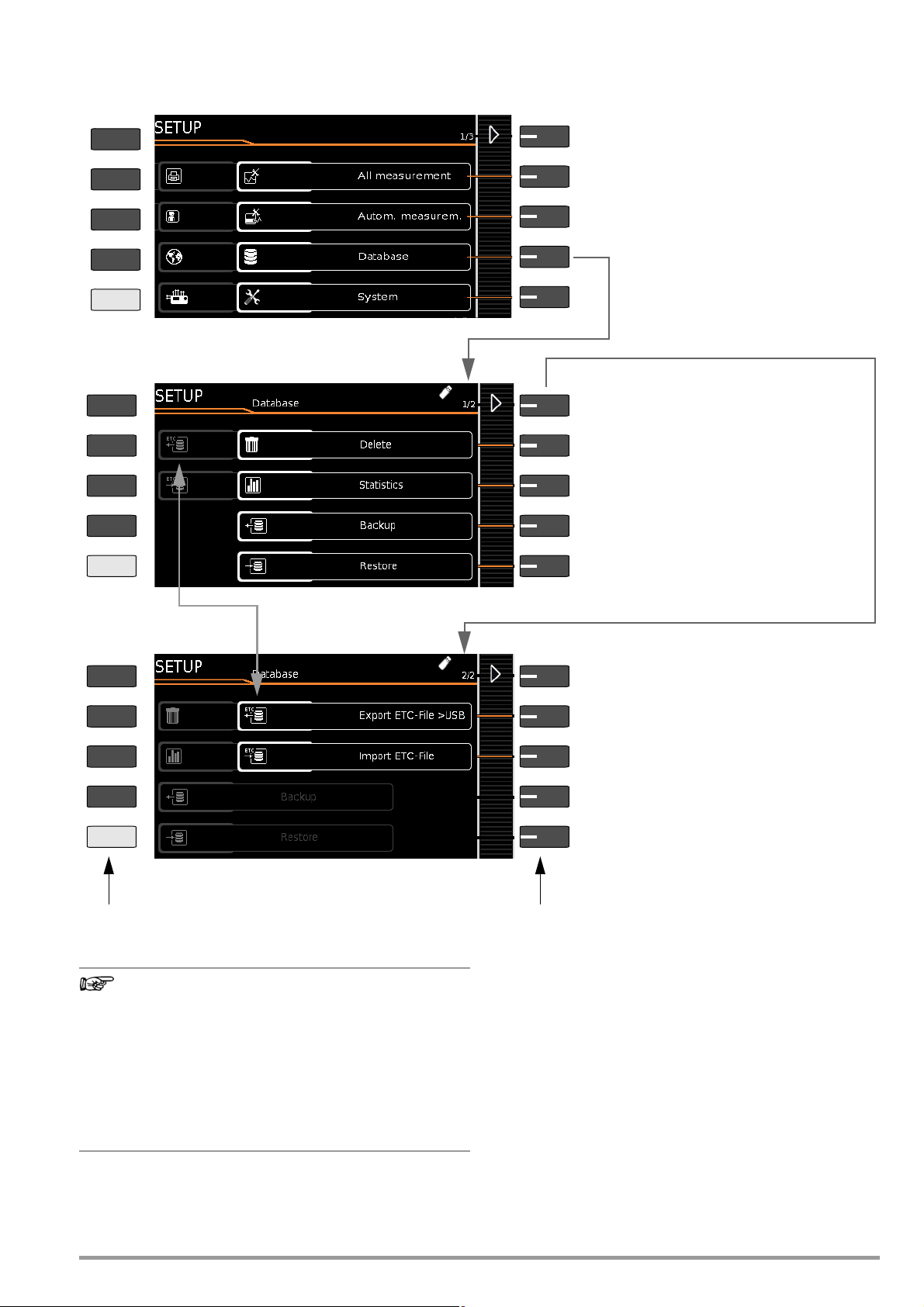

Database Functions

Note

Display additional menu pages

Menu selection for database functions, page 1 of 2

Display database statistics

Only with inserted USB drive:

Only with inserted USB drive:

Display additional menu pages

Menu selection for database functions, page 2 of 2

Keys with fixed functions

Softkeys = keys with functions that vary

depending on the operating level

PRINT

ESC

HELP

MEM

PRINT

ESC

HELP

MEM

Setup 1/3

Database 1/2

Database 2/2

Backup database to USB flash drive (

FAT32

formatted)

Restore database from USB flash drive

Delete database content (but not its structure)

Note: Data are irretrievably deleted!

* Z853R or feature KB01

Only with database extension * and inserted USB

drive: Import a database from a “.secu” file which has

been created specifically for the SECUTEST/

SECULIFE ST with

IZYTRONIQ

.

Only with database extension * and inserted USB drive:

Export database (“.secu” file **)

**

Compatible with IZYTRONIQ

PRINT

ESC

HELP

MEM

GMC-I Messtechnik GmbH 13

Modification of the file format

Direct import of data in the old file format (“.etc” file extension) is no longer possible as of firmware version

02.01.00.

Import the data into IZYTRONIQ report generating software

first and then convert them to the new “.secu” file format.

These data can then be imported to your test instrument

with the help of a USB flash drive.

Backup files (.etcbak) from previous firmware versions

are still compatible.

Page 14

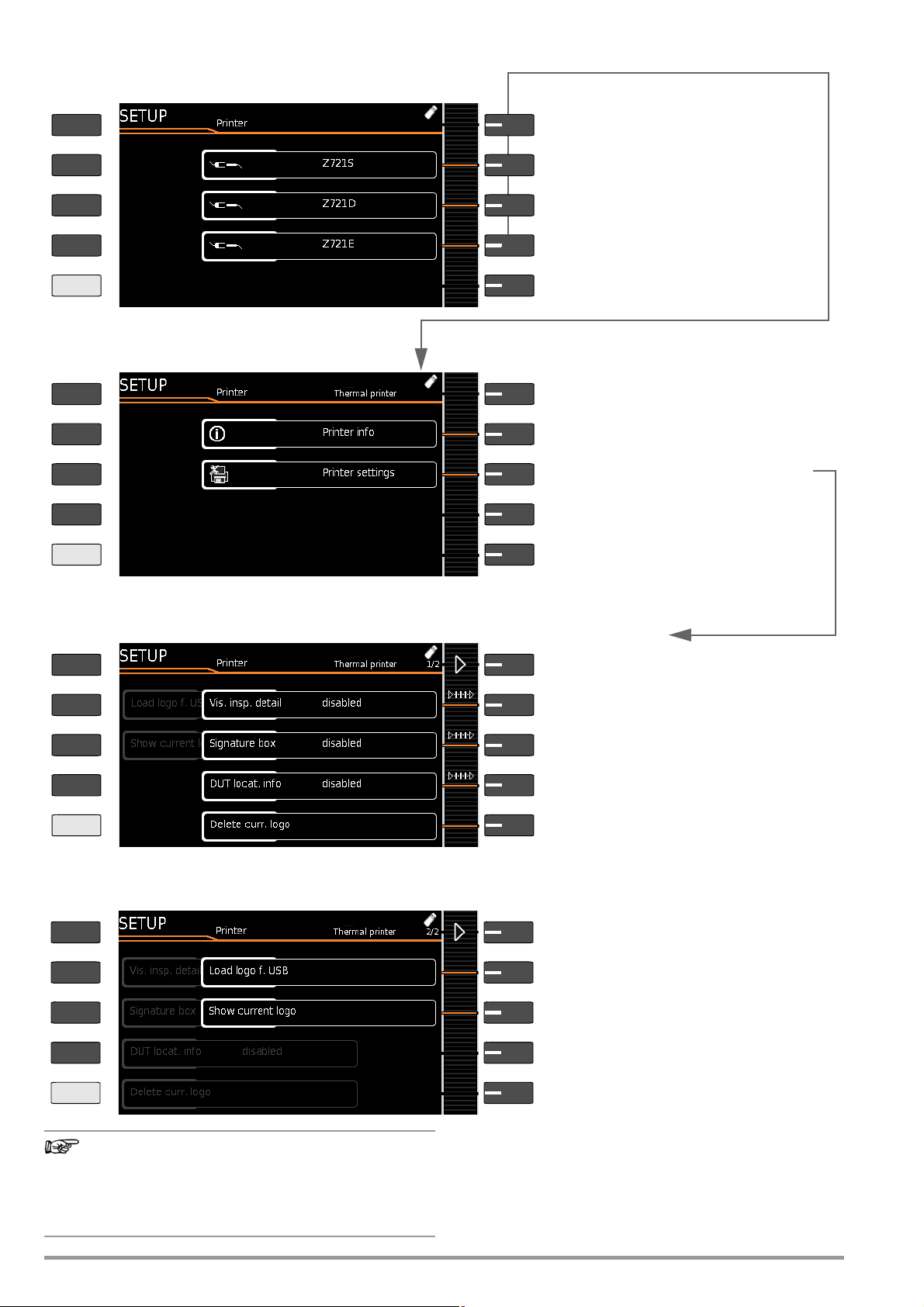

Printer Functions – Selection and Settings Using the Thermal Printer as an Example

Note

Select the connected printer

PRINT

ESC

HELP

MEM

PRINT

ESC

HELP

MEM

PRINT

ESC

HELP

MEM

Retrieval of information or settings

Setting parameters

PRINT

ESC

HELP

MEM

Setup 2/3 > Printer

Setup 2/3 > Printer > Z721S

Thermal Printer > Settings1/2

Thermal Printer > Settings 2/2

Z721E * printer: Barcode label printer

Printer info / printer settings

* For testing instrument firmware as of 1.8.3

Z721D * printer:

Printer info / printer settings

*Phase-out model

Z721S printer: Printer info / printer settings

Printer settings:

Parameters depend on printer type

Printer info: Name, status, type

Switch to page 2/2

Visual inspection details: show/hide

Signature field: show/hide

Location information: show/hide

Delete a (company) logo previously loaded from a

USB flash drive (see Settings 2/2).

Load and display a logo from a USB flash drive

Switch to page 1/2

Load a (company) logo from an inserted USB flash

drive: Selection list is displayed

Display the currently loaded logo.

Prerequisites for loading a logo:

Format: BMP, JPG, PNG or GIF, resolution: max.

800 x 800 pixels. Color depth: max. 24-bit.

Report Designer PC software is no longer supported as of

firmware version 2.1.1. The test report can now be edited

and a company logo can be added to it (only with thermal

printer Z721S) directly in SETUP at the test instrument

(see above).

14 GMC-I Messtechnik GmbH

Page 15

5 Internal Database

Attention!

!

Attention!

!

Note

Note

Attention!

!

Attention!

!

5.1 Creating Test Structures, General

A complete test structure with data regarding customer properties, buildings, floors, rooms and test objects can be created in

the test instrument. This structure makes it possible to save the

results of single measurements or test sequences to test objects

belonging to various customers. Manual single measurements

can be grouped together into a so-called “manual sequence”.

Objects can be identified with the following parameters (boldface

parameters are mandatory entry fields):

•

Device (ID, designation, location, test interval *, type, manufacturer,

comment, serial number, protection category, cost center

*

)

ment

ME device ** (ID

•

turer, comment, serial number, protection category, number of type

B application parts **,

number of type BF application parts **, number of type CF ** application parts, cost center, department, UDI **, mains connection **)

• Room * (ID and designation)

• Floor * (ID and designation)

• Building * (ID, designation, street, ZIP code and city)

• Property * (ID and designation)

• Customer (ID, designation, street, ZIP code and city)

* Only with database extension, feature KB01, “Z853R – SECUTEST DB+”

** Only with feature KD01, “Z853S – SECUTEST DB COMFORT”

, designation,

customer

, test interval *, type, manufac-

Key

ID = identification number

5.2 Transmitting and Saving Test Structures and Measurement

Data

The following functions are possible (as far as the test instrument

is concerned):

• Export: Transfer a structure including measured values from

the test instrument to the PC (ETC *** or IZYTRONIQ) (see sec-

tion 5.2.1).

• Import *: Transfer a test structure from the PC (ETC *** or

IZYTRONIQ) to the test instrument (see section 5.2.2).

• Backup *: Back up a database to a USB flash drive plugged

into the test instrument (must be FAT32 formatted – not NTFS)

(see section 5.2.3).

• Restore *: Restore a database to the test instrument from a

USB flash drive plugged into the test instrument (must be

FAT32 formatted – not NTFS) (see section 5.2.3).

• Reports: Save reports to a USB flash drive (see section 3.5.5).

* Only with database extension, feature KB01, “Z853R – SECUTEST DB+”

*** Communication with ETC is no longer supported as of firmware version 2.0.0.

If no USB flash drive has been plugged in, the above listed functions are grayed out and disabled.

In order to transfer structures and data, the test instrument and

the PC must be connected with a USB cable or a USB flash drive

must be available.

Please observe the following safety precautions:

During data transmission via the USB port (USB connection to the PC or connection of a USB flash drive), neither

the interface cable nor the USB drive may be disconnected.

*

, depart-

Data transfer to the PC should not be started during single measurements or test sequences.

5.2.1 Export – Transmitting Test Structures and Measurement Data from the Test Instrument to the PC

Structures set up in, and measurement data saved to the test

instrument can be exported to IZYTRONIQ report generating software via a connected USB flash drive (only with data base extension or feature KB01, “Z853R – SECUTEST DB+”), or via the USB

slave port. Select Export IZY file under Setup > Database 2/2 to

this end. The data are converted to an IZYTRONIQ-compatible format with the “.secu” file extension.

The report generating program is started at the PC by double

clicking the exported file and the data are read in. Data can then

be saved to the PC and reports can be generated.

5.2.2 Import – Uploading Test Structures Created in the Report Generating Program to the Test Instrument (only with database

extension or feature KB01, “Z853R – SECUTEST DB+”)

As an alternative, a test structure can be created at the PC with

the help of the respective report generating program and then

transferred to the test instrument via a connected USB flash drive,

or via the USB slave port. Select the Import IZY file function to this

end under Setup > Database 2/2. The data are converted to a

format which is compatible with the test instrument.

A complete description of database creation can be found in the

online help included with the respective report generating program.

The same backup files apply here as is also the case in the section covering export.

5.2.3 Backing Up and Restoring Test Structures and Measurement Data

Structures created and measurement data saved at the test

instrument can be backed up via an inserted USB flash drive

(must be FAT32 formatted – not NTFS). Select the Backup function

to this end under Setup > Database 2/2.

The test instrument creates a backup file on the USB flash drive

directly in the root directory.

The backup files on the USB flash drive are named by means of a

time stamp (file extension: .etcbak).

In order to restore structures and data from an inserted USB flash

drive, select the Restore function under Setup > Database 2/2.

When restoring, the files from the root directory are displayed as

well as those from the backup folder (which used to be created in

previous firmware versions). The files from the backup folder are

displayed with the “>” prefix.

Backup/Restore to/from USB Flash Drive

It’s also possible to restore backup files created with previous firmware versions

During data backup via the USB port (USB connection to

the PC or inserted USB drive), neither the interface cable

nor the USB drive may be disconnected. If the USB drive

is removed during the backup it may be rendered defective.

(as of firmware version 1.8.2)

.

The test instrument may not be disconnected from supply power during data backup via the USB port.

The test instrument may not be disconnected from supply power during transmission via the USB port. The

memory structure in the test instrument might otherwise

be destroyed.

GMC-I Messtechnik GmbH 15

Page 16

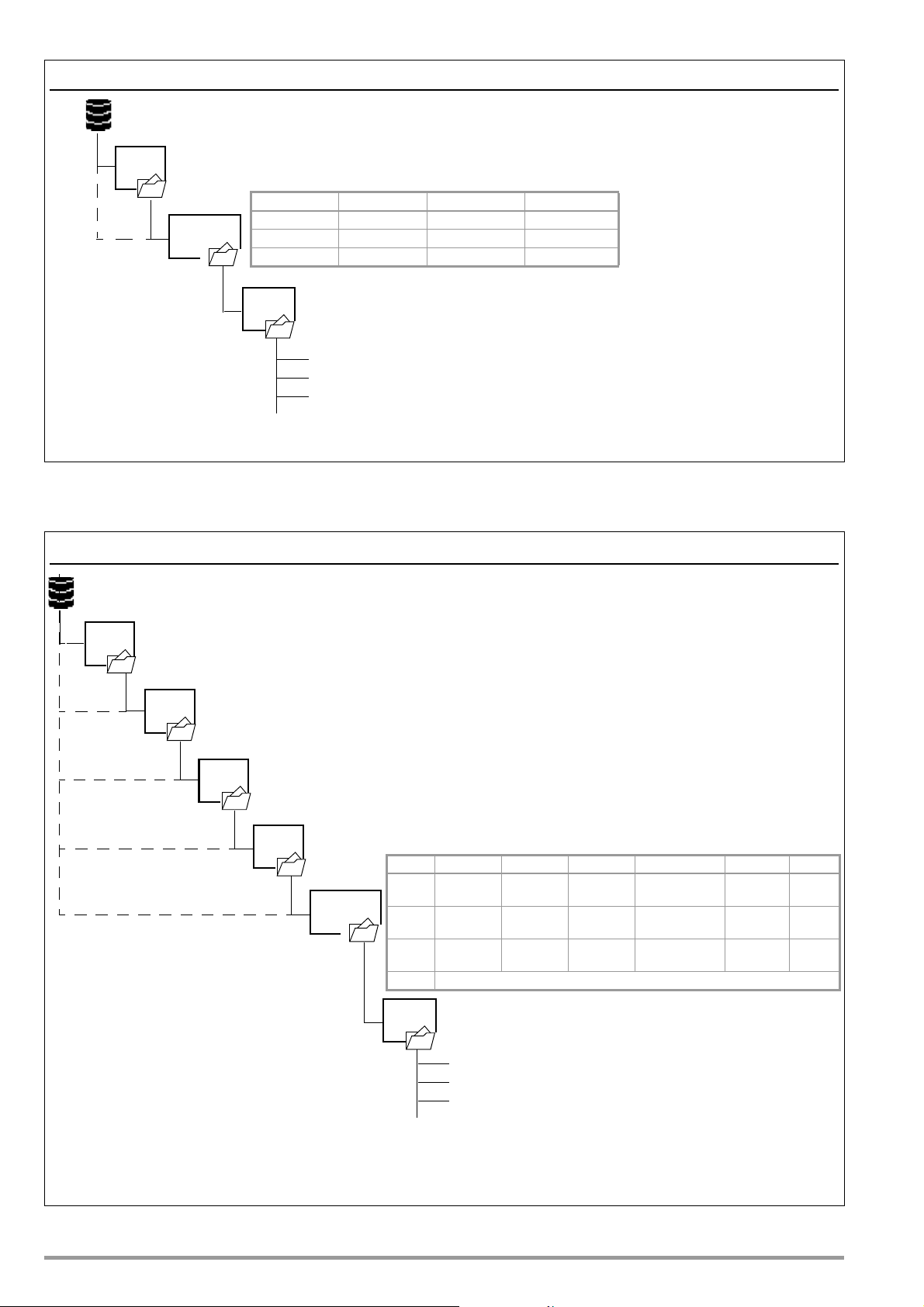

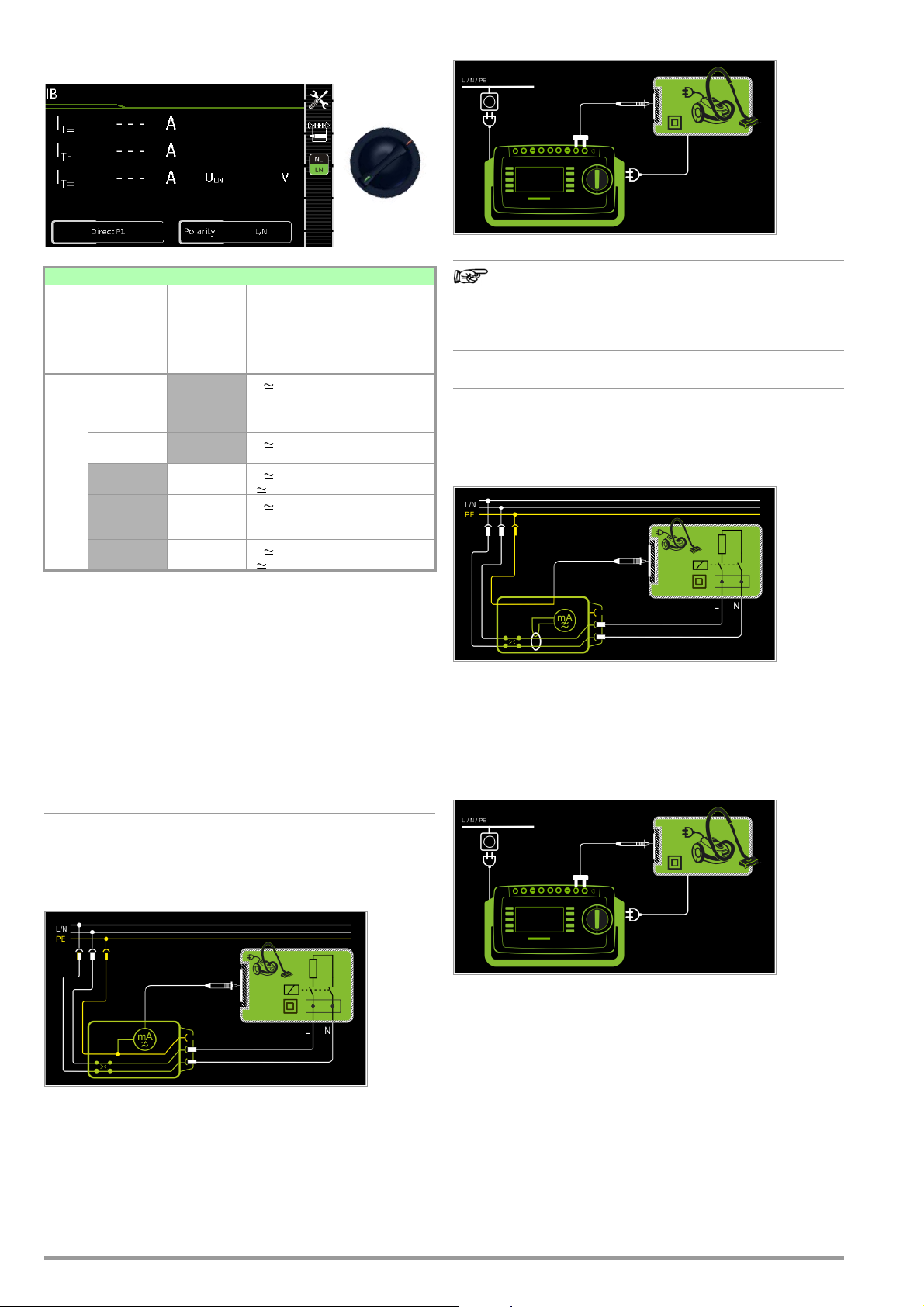

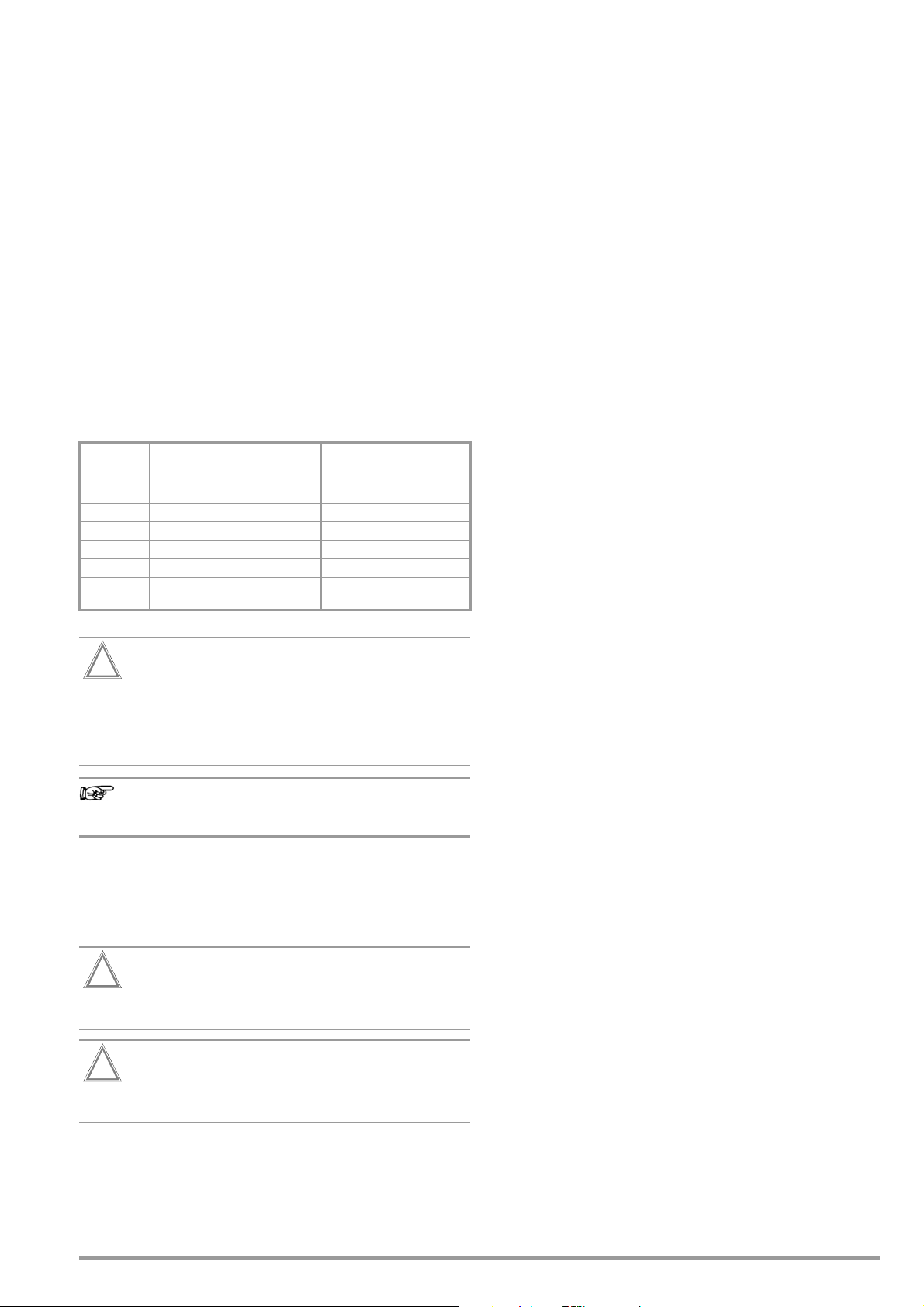

Test Structure – Hierarchy of Object Levels in the SECUTEST BASE(10)

Customer

ID

Designation

Street

Device

ZIP code

City

Database

ID

Designation

Measurement 1

Measurement 2

Measurement 3

Manual

sequence

* Test interval: additionally available for test instruments with database extension, feature KB01, “Z853R – SECUTEST DB+” or feature KD01, “Z853S – SECUTEST DB

COMFORT”

Customer MEM

1/4 2/4 3/4 4/4

ID Test interval * Comment Cost center *

Designation Type Serial number Department *

Location Manufacturer Protection category

Building

Floor

Room

ID

Designation

Street

ID

Designation

ID

Designation

Device

ZIP code

City

Database

Manual

ID

Designation

Measurement 1

Measurement 2

Measurement 3

Proper-

ID

Designation

ty

sequence

* Test interval: additionally available for test instruments with database extension, feature KB01, “Z853R – SECUTEST DB+” or feature KD01, “Z853S –

SECUTEST DB COMFORT”

** Only with SECUTEST PRO BT comfort or with database extension, feature KD01, “Z853S –

SECUTEST DB COMFORT”:

additional entry option for medical electric device (ME Device) and further parameters such as UDI and application parts

ME device **

UDI = unique device identification

1/6 2/6 3/6 4/6 5/6 6/6

ID Test interval * Comment No. of type B appl.

parts **

Cost center

Mains

conn. **

Designation Type Serial no. No. of type BF

appl. parts **

Department

Customer Manufacturer Protection

category

No. of type CF

appl. parts **

UDI **

Location Property

Building Floor Room

Location MEM

Figure 4 Database Structure

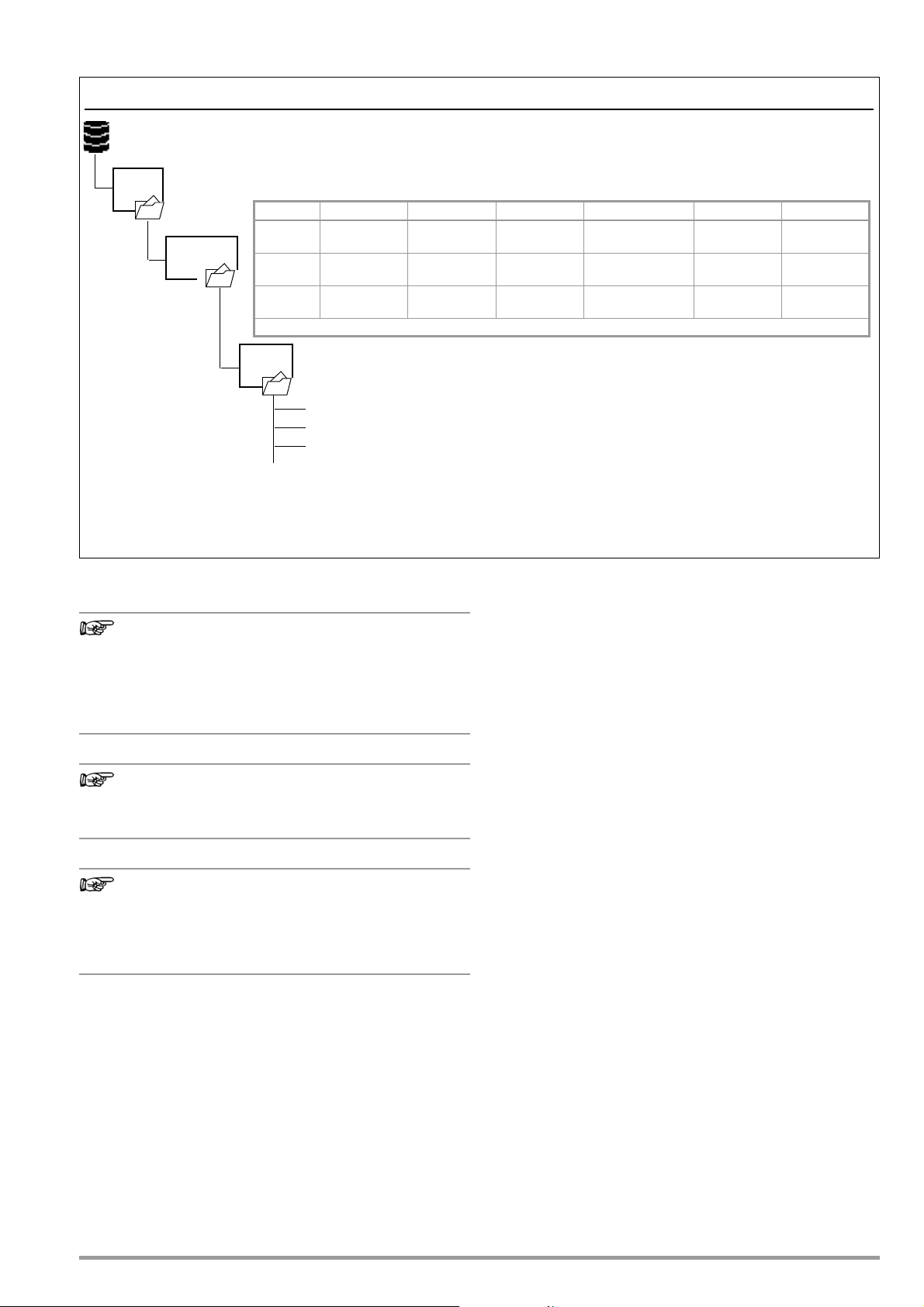

Test Structure – Hierarchy of Object Levels in the SECUTEST PRO and the SECULIFE ST BASE(25)

or in Devices with Database Extension, Feature KB01, “Z853R – SECUTEST DB+”

Figure 5 Database Structure as Location View in Test Instruments with Feature KB01, “Z853R – SECUTEST DB+”

16 GMC-I Messtechnik GmbH

Page 17

Test Structure, Customer View – Hierarchy of Object Levels in the SECUTEST PRO and the SECULIFE ST BASE(25)

Note

Note

Note

Customer

ID

Designation

Street

Device

ZIP code

City

Database

Manual

ID

Designation

Measurement 1

Measurement 2

Measurement 3

sequence

* Test interval: additionally available for test instruments with database extension, feature KB01, “Z853R – SECUTEST DB+” or feature KD01, “Z853S – SECUTEST DB

COMFORT”

** Only with SECUTEST PRO BT comfort or with database extension, feature KD01, “Z853S –

SECUTEST DB COMFORT”:

additional entry option for medical device (ME Device) and further parameters such as UDI and application parts

ME device **

UDI = unique device identification

1/6 2/6 3/6 4/6 5/6 6/6

ID Test interval * Comment No. of type B appl.

parts **

Cost center

Mains connection **

Designation Type Serial no. No. of type BF appl.

parts **

Department

Location Manufacturer Protection cate-

gory

No. of type CF appl.

parts **

UDI **

Customer

Customer

Customer MEM

or in Devices with Database Extension, Feature KB01, “Z853R – SECUTEST DB+”

Figure 6 Database Structure as Customer View in Test Instruments with Feature KB01, “Z853R – SECUTEST DB+”

Hierarchies and Data Migration

Database objects “Device” and “ME Device” must always be subordinate to a Customer. If so-called “legacy data” have been

imported into the test instrument which do not comply with this

rule (e.g. as a result of a firmware update or via the “Restore database” function), Customer objects are generated automatically.

The same applies to database objects “Room” and “Floor”, which

must always be subordinate to a Building. In this case, Building

objects are generated automatically if necessary.

Grayed Out Database Elements

The corresponding elements are grayed out in devices

without enabling for the following options: “Extended

database structure” Z835R (feature KB01 = property,

building, floor, room) and SECUTEST DB comfort Z853S

or feature KD01 (medical electric devices).

Mandatory Fields

Mandatory fields are marked in red in the entry fields at

the test instrument, as well as in Figure 5 and Figure 6.

Hierarchies

It’s imperative to adhere to the following hierarchies:

Room or Floor must always be subordinate to a Building.

Devices or ME Devices (medical electric devices) always be

allocated to a Customer.

5.2.4 Switching Between 2 Tree Structure Views (for SECUTEST PRO and SECULIFE ST BASE(25) or for devices with feature KB01, “Z853R – SECUTEST DB+”)

➭ The display can be switched back and forth between the lo-

cation and customer views by repeatedly pressing the MEM

key.

➭ The database view can be exited by pressing the ESC key.

GMC-I Messtechnik GmbH 17

Page 18

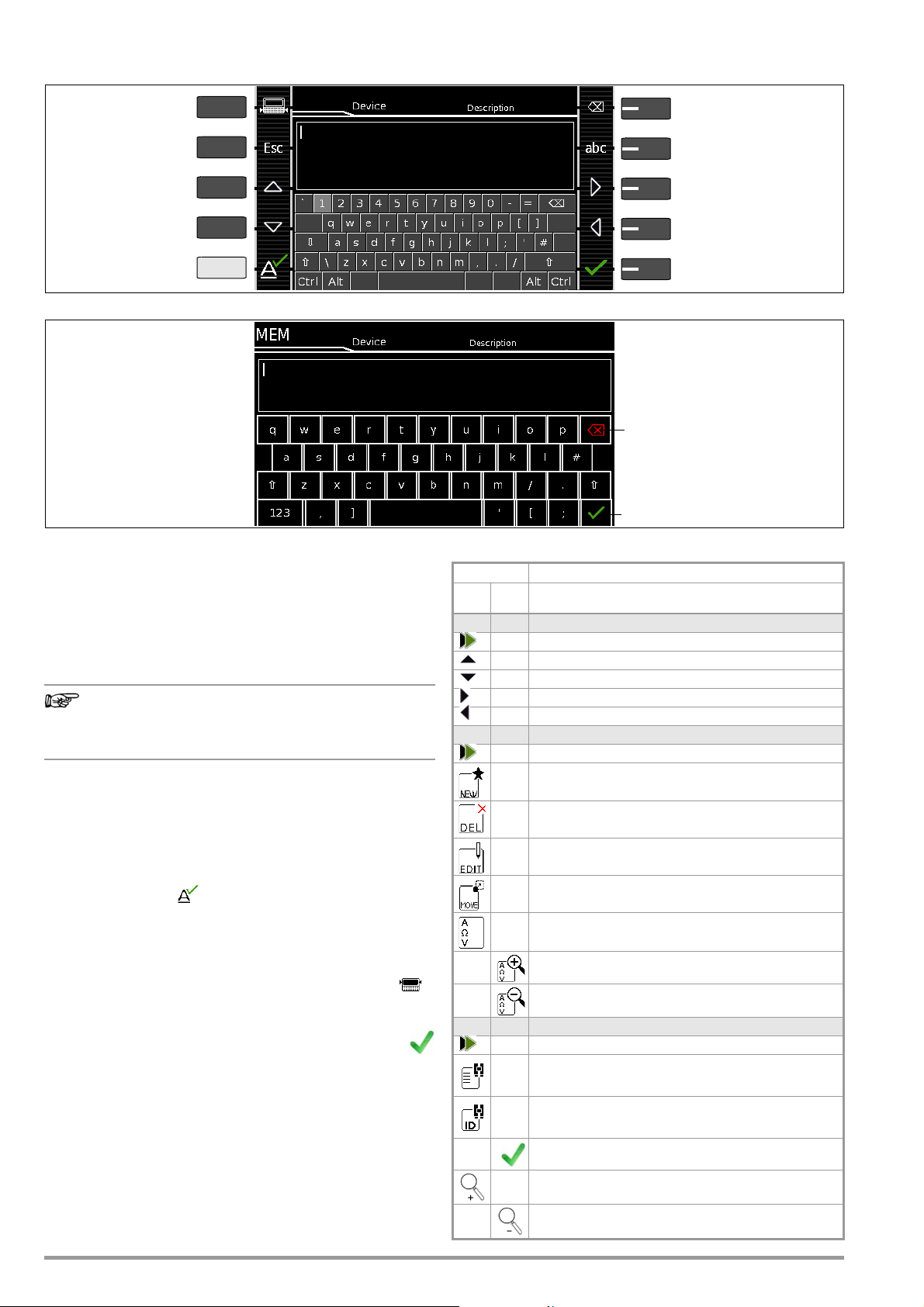

5.3 Data Entry

Note

Delete characters from right

Switch between upper/

Scroll left

Accept entry

lowercase, and symbols

Switch between

Scroll down

Transfer character at

Exit entry function

Scroll right

Display panel

Keypad

cursor position to display field

without saving

Scroll up

keys and display panel

PRINT

ESC

HELP

MEM

Accept entry *

Display Panel

Keypad

Delete characters from right *

* Also via assigned softkey

➭

Briefly pressing the shift key

once causes the next character to appear in uppercase.

➭

Pressing the shift key for a

longer period of time causes

all following characters to appear in uppercase.

➭

The cursor can be positioned

as desired by pressing the

display panel at the respective point in the existing text.

Overview of Keyboard Entries Via the Softkeys with the SECUTEST BASE(10)

Overview of Keyboard Entries via the Touchscreen Keyboard with the SECUTEST PRO (feature E01)

5.3.1 Keyboard Entries via Softkeys or External Keyboard

After selecting ID or any other object parameter, a keyboard is displayed which allows for the entry of alphanumeric characters via

the fixed function keys and the softkeys. Alternatively, entries can

also be made with the help of a USB keyboard or barcode scanner which is connected to the instrument.

The keyboard layout can be matched to the language in SETUP.

SETUP 2/3 > Culture > Keyboard Layout (for alphanumeric entries)

In order to use a USB keyboard at the SECUTEST..., the

“Keyboard Layout Settings” in Setup must coincide with

the connected keyboard.

Procedure (example: entering a designation):

1 Switch the keyboard to uppercase, lowercase or special char-

acters with the abc key (Abc, ABC, Symb).

2 Select the desired alphanumeric character or a line break with

the scroll keys (left, right, up and down). The selection cursor

can be accelerated by pressing and holding the respective

scroll key.

3 After pressing the key, the respective character appears

at the display panel.

4 Repeat steps 1 through 3 until the complete designation is

shown at the display panel.

5 The designation at the display panel can be changed subse-

quently by hiding the bottom keyboard by pressing the

key. The cursor position can then be changed in order to

delete individual characters.

6 The value appears at the display after pressing the

green checkmark.

5.3.2 Data Entry via Touchscreen Keyboard (only with SECUTEST PRO or test instrument with feature E01)

The touchscreen keyboard permits convenient entry of data and

comments, selection of parameters and direct parameter selection, and menu-driven operation is still possible via the softkeys as

an alternative.

18 GMC-I Messtechnik GmbH

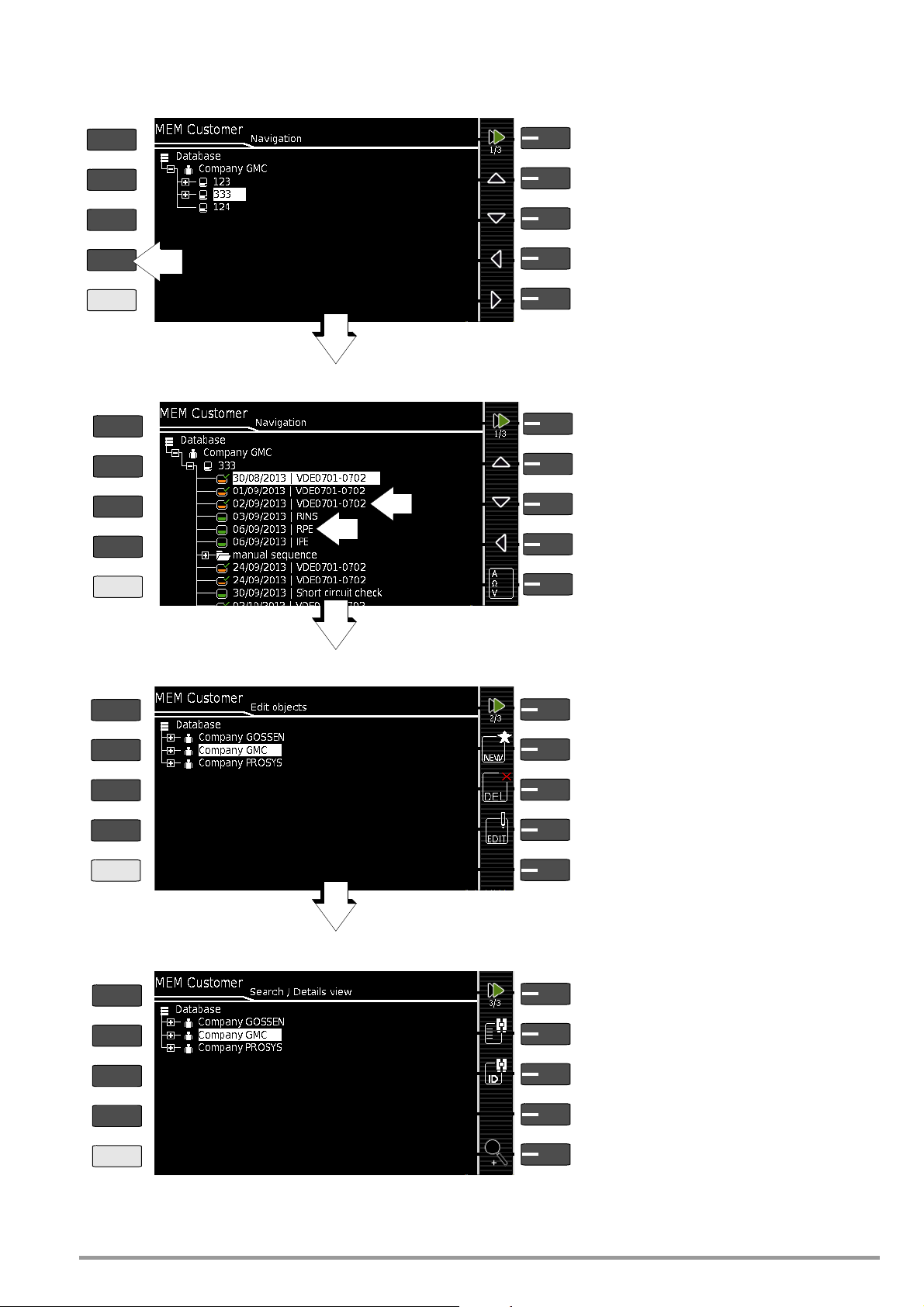

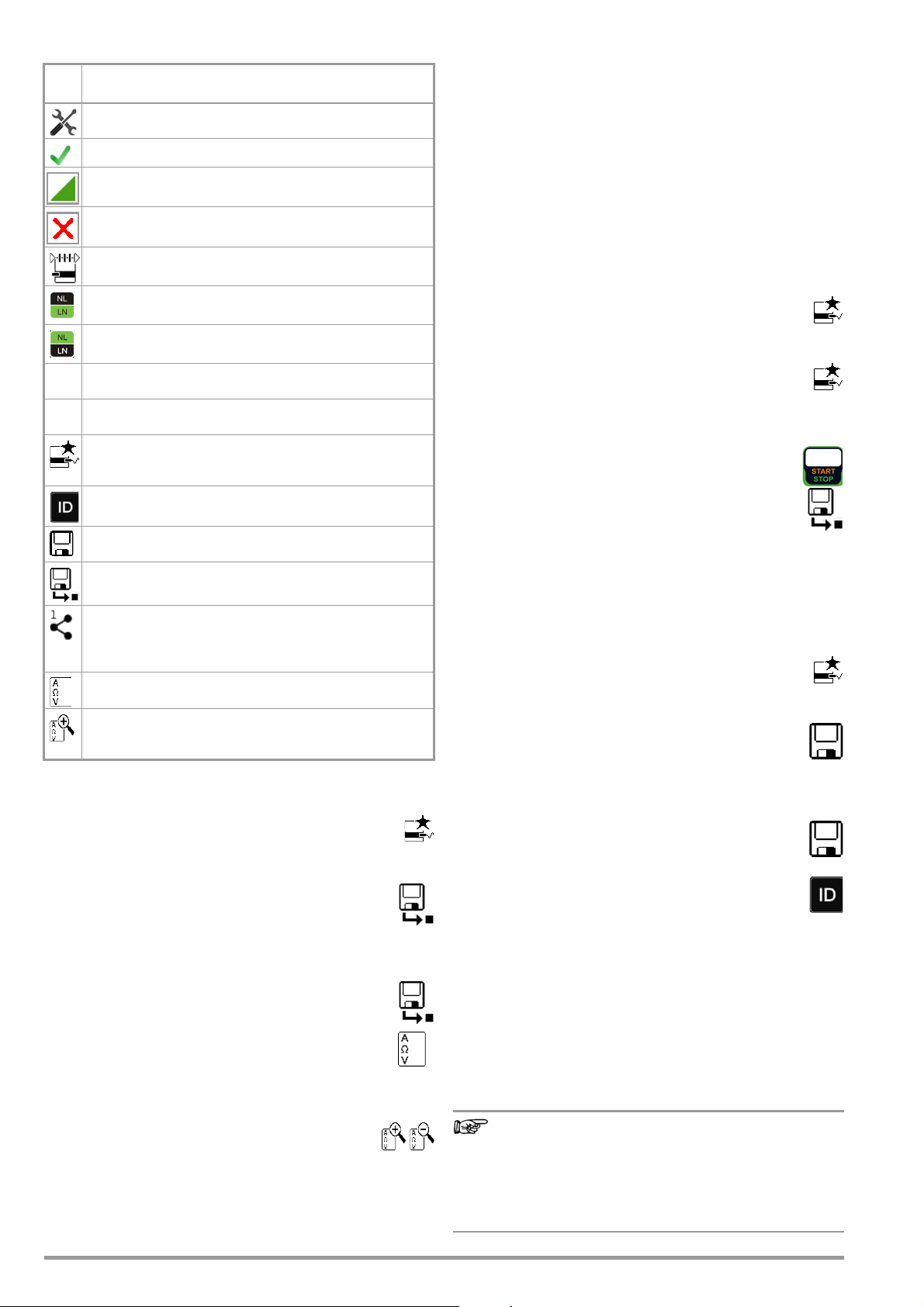

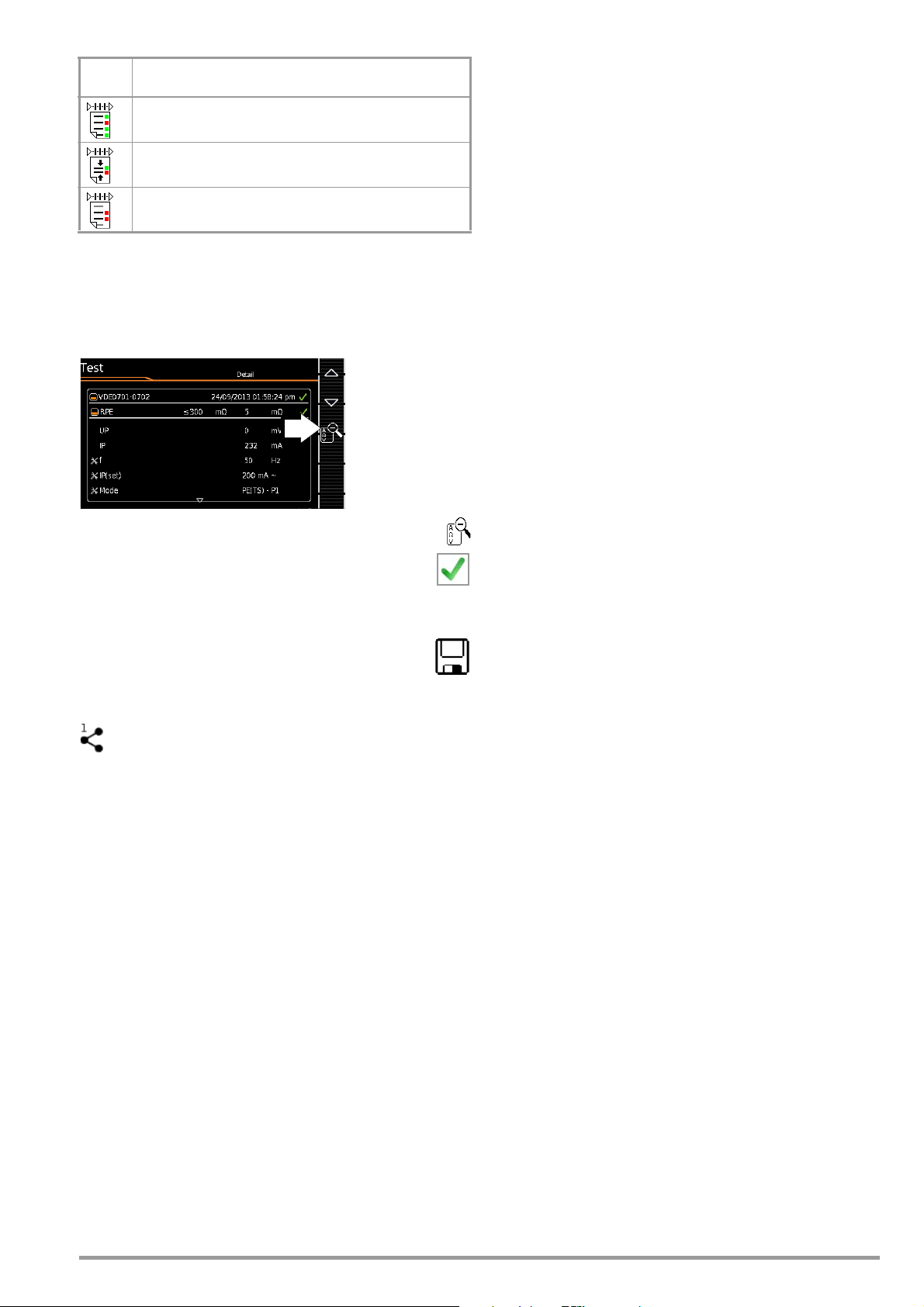

Meaning of Symbols in the User Interface – Database Management

Symbol Meaning

Main

Sub-

Level

level

Memory menu, page 1 of 3

Change display to menu selection

Cursor UP: scroll up

Cursor DOWN: scroll down

Cursor RIGHT: open tree

Cursor LEFT: close tree

Memory menu, page 2 of 3

Change display to menu selection

Add a structure element

Delete selected structure element or measurement

Edit structure elements

(ID, designation, comment ...)

Move structure element

(feature KD01, “Z853S – SECUTEST DB COMFORT”)

When a measurement is selected: Display mea-

sured values

Display details from the measurement results list

Hide details from the measurement results list

Memory menu, page 3 of 3

Change display to menu selection

Search for ID, text or UDI > enter complete ID num-

ber (ID) or text (complete word)

Search for ID number: > Enter complete ID number

of a test object

Confirm search results

Display the structure designation

Hide the structure designation

Page 19

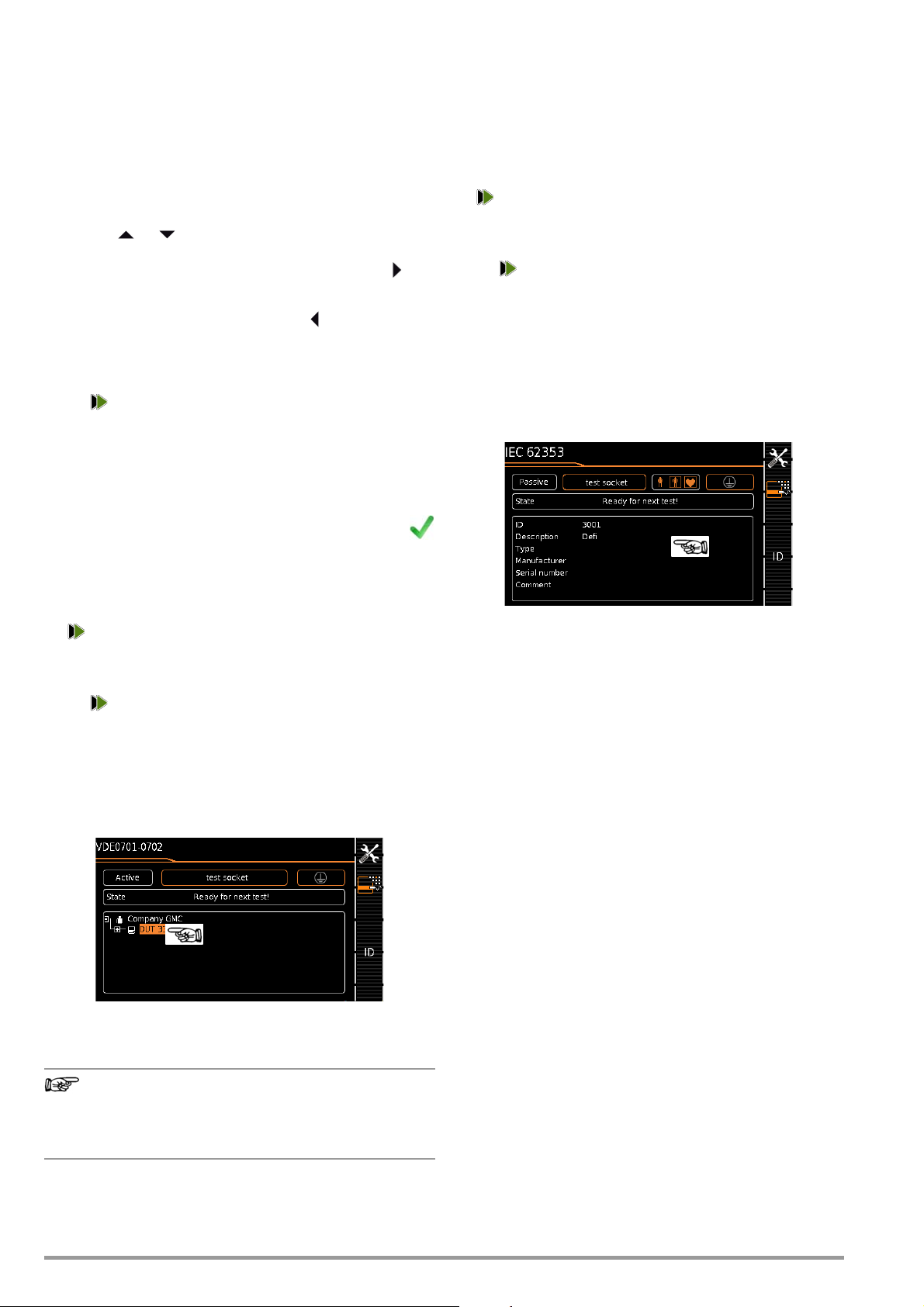

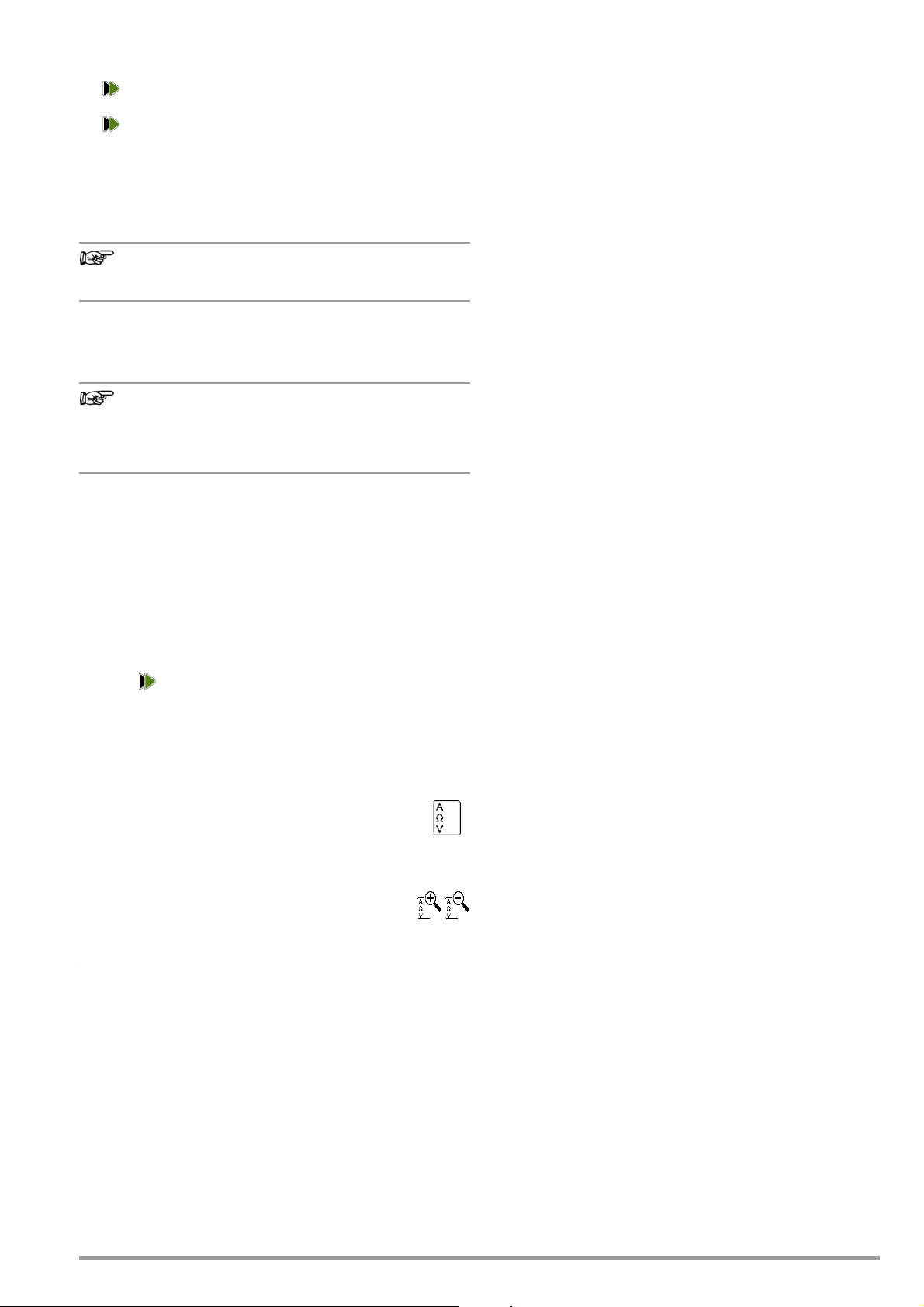

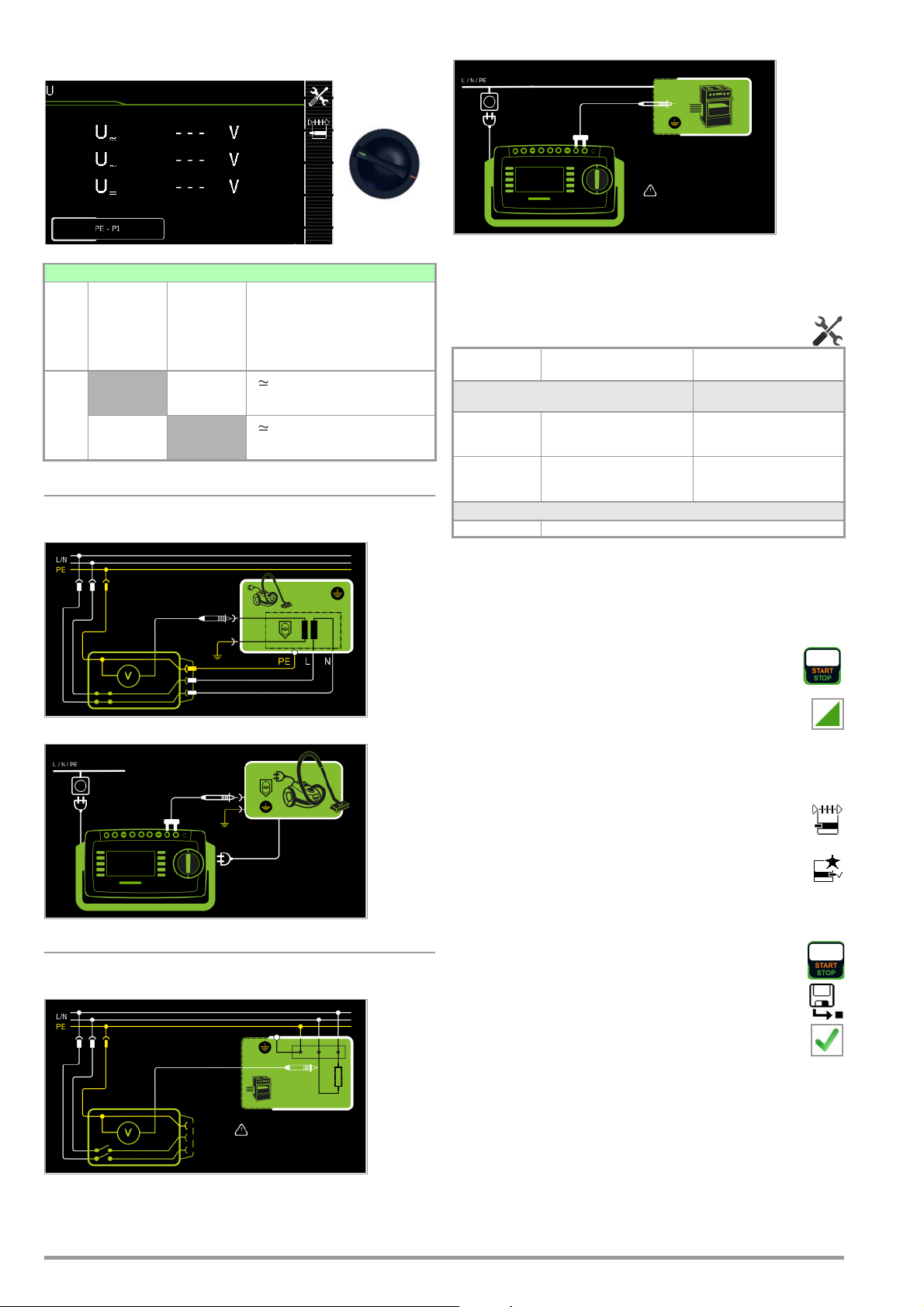

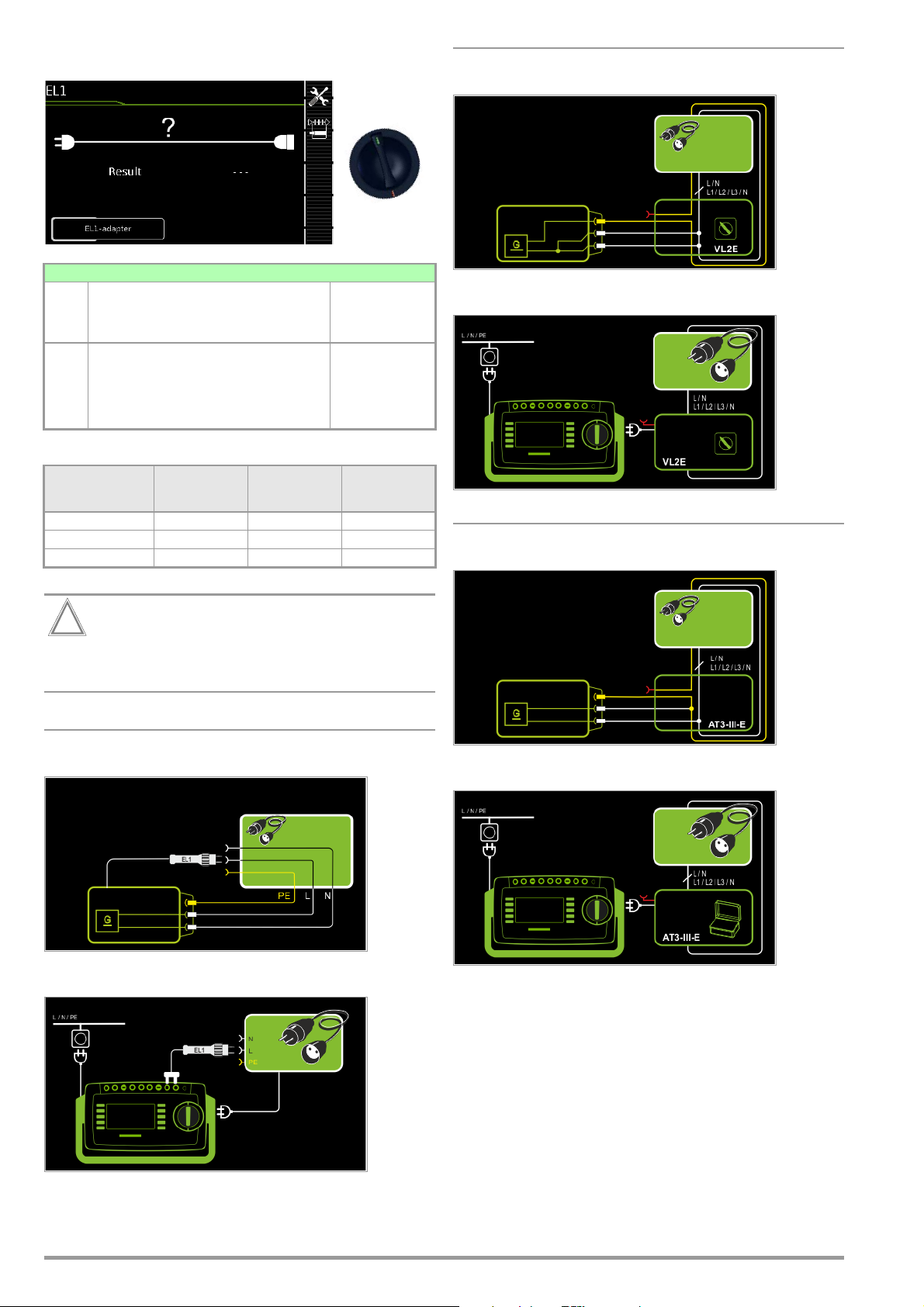

5.4 Creating a Test Structure in the Test Instrument, Navigating within the Structure and Displaying Measured Values

Scroll to next menu (page 2/3)

Object selection menu – page 1/3

PRINT

ESC

HELP

MEM

Select customers or devices

Select customers or devices

Select customers or devices

Scroll to next menu (page 3/3)

Object editing menu – page 2/3

Edit device/customer

Move object

Scroll to next menu (page 1/3)

Object search menu – page 3/3

Search by entering text

Search by entering IDs

Display designation and ID

of the selected device

MEM 1/3

MEM 2/3

MEM 3/3

Scroll to next menu (page 2/3)

Measurement selection menu – page 1/3

Selection of measurements

Selection of measurements

Jump back (one hierarchical level higher)

MEM 1/3

or close open branches

Jump back (one hierarchical level higher)

or close open branches

1

2

Display measured values for a selected test

1: Test sequence per standard (symbol: orange)

2: Single measurement (symbol: green)

Note: See page 17 concerning grayed out database elements.

Either “Delete selected customer, (ME) device or measurement” or “Delete selected object with all subordinate

objects/measurements”

Add new (ME) device to the selected customer or

clone current element (as of firmware 3.0)

PRINT

ESC

HELP

MEM

PRINT

ESC

HELP

MEM

PRINT

ESC

HELP

MEM

Overview of the Meanings of the Symbols for Creating Objects – Navigation within Test Structures

Figure 7 Overview of Navigation, Object Editing and Object Search in the Database

GMC-I Messtechnik GmbH 19

Page 20

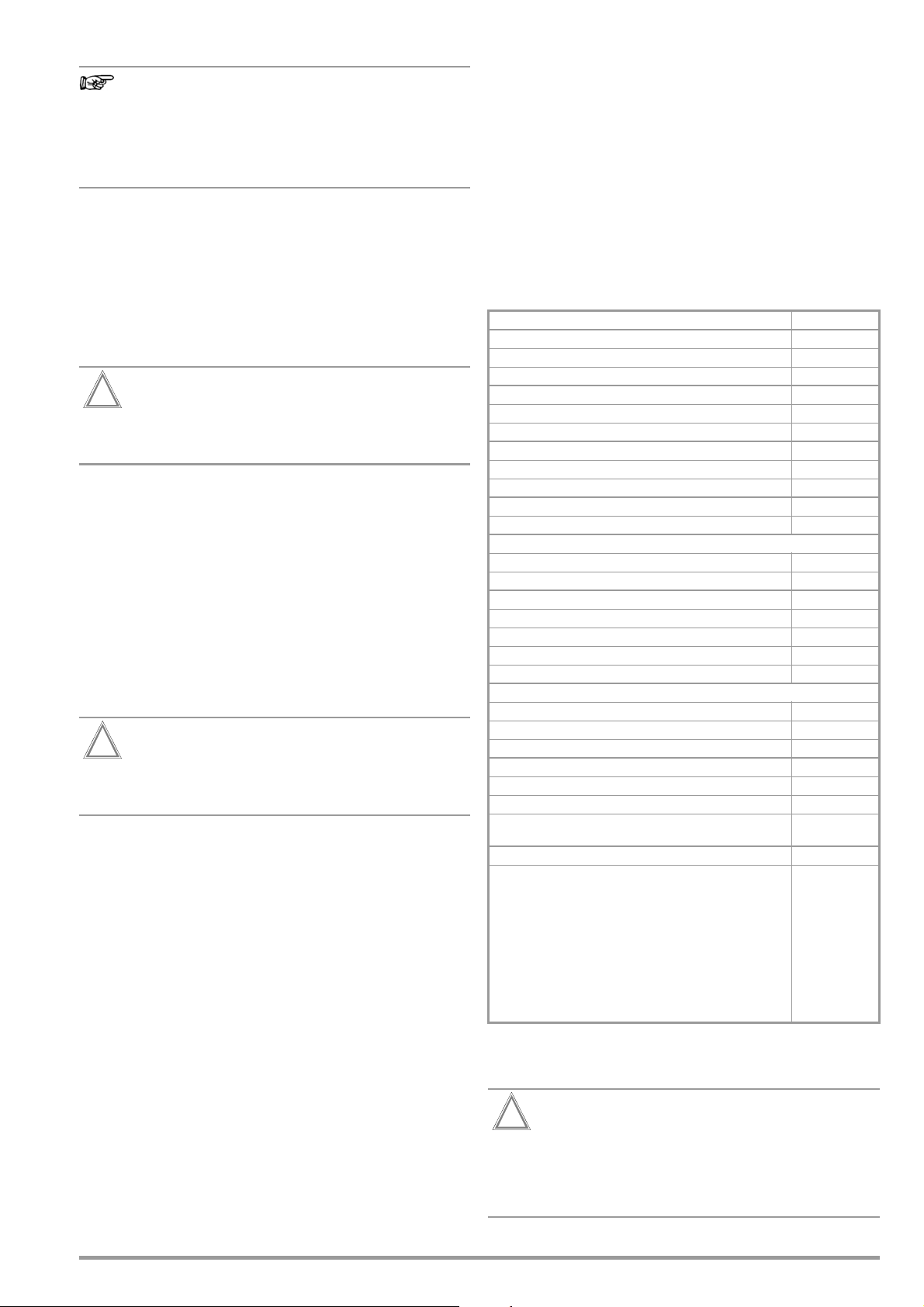

5.4.1 General Procedure for Creating Test Structures

Note

After selection with the MEM key, all setting options for the creation of a tree structure are made available on three menu pages

(1/3, 2/3 and 3/3). The tree structure consists of structure elements, referred to below as objects.

Results of measurements/tests can only be saved under structure

elements types “Device” or “ME device” (medical electric device),

which are also referred to as “test objects” in the following.