Page 1

Operating Instructions

SECU-cal 10

Calibration Adapter for Testers

per DIN VDE 0701-0702/

EN 62353 (VDE 751-1)

3-349-169-15

7/2.13

Page 2

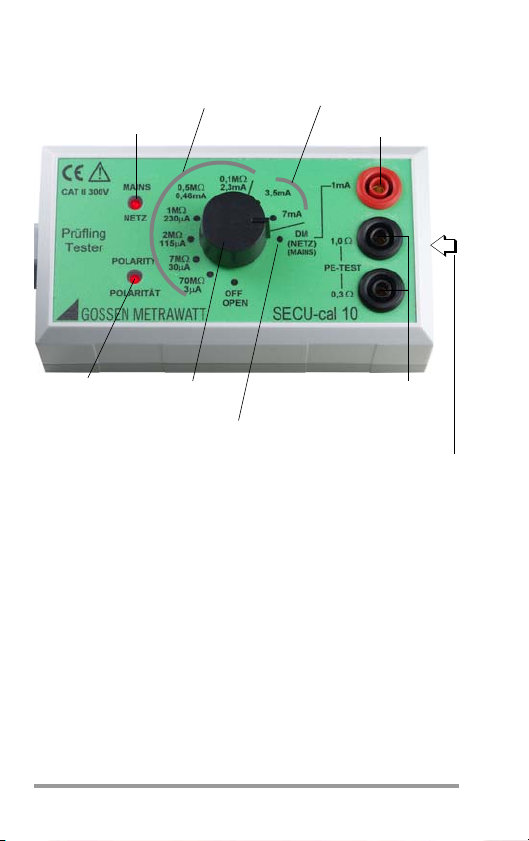

Function selector

1mA terminal

Reference terminals

Mains indicator lamp

Polarity display

for test instrument probe

for measurement of R

PE

may not light up

Reference values for equivalent

leakage current measurement I

EA

during

Tests with line voltage!

– Leakage current measurement

– Residual current measurement

with the help of an ammeter, see

chapter 5 regarding connection

with max. 1 A test current

measurement!

Lateral imprint

showing the reference values

of test resistances R

PE

switch

Reference values for

measurement of R

ISO

and equivalent leakage current I

EA

Note

The indicated current values of 30 mA and 3 mA for switch

positions 7 M and 70 M are merely guidance values.

Usually, the capacitance of the connector cables is sufficiniently high to ensure that the current values actually measured exceed considerably that level and can therefore not be

used as reference values.

This applies particularly for the test instruments of the SECUTEST

2 GMC-I Messtechnik GmbH

®

... series.

Page 3

Contents Page

1 Applications ..................................................................4

2 Safety Features and Precautions ..................................4

3 Connecting the Calibration Adapter to the Test

Instrument ....................................................................7

3.1 Tests without Line Voltage .......................................................... 7

3.2 Tests with Line Voltage ..............................................................7

4 Performing Tests without Line Voltage .........................8

4.1 Checking Display Values for Protective Conductor Resistance

Measurement ............................................................................ 8

4.2 Checking Display Values for Insulation Resistance Measurement ..8

4.3 Checking Display Values for Equivalent Leakage Current

Measurement ............................................................................ 9

4.4 Checking Display Values for Equivalent Device Leakage Current

Measurement per DIN EN 62353 (VDE 0751-1) ......................... 10

4.5 Checking Display Values for Equivalent Patient Leakage

Current Measurement per DIN EN 62353 (VDE 0751-1) ............. 10

5 Performing Tests with Line Voltage ............................11

5.1 Checking Display Values for Leakage Current Measurement ....... 11

5.2 Checking Display Values for Patient Leakage Current

Measurement .......................................................................... 12

6 Characteristic Values .................................................. 13

6.1 Nominal Range of Use .............................................................. 13

6.2 Ambient Conditions .................................................................. 13

6.3 Electrical Safety ....................................................................... 13

6.4 Mechanical Design ................................................................... 13

7 Maintenance ...............................................................14

7.1 Housing Maintenance ............................................................... 14

7.2 Device Return and Environmentally Compatible Disposal ............14

8 Repair and Replacement Parts Service

Calibration Center and Rental Instrument Service .....15

9 Product Support ..........................................................15

GMC-I Messtechnik GmbH 3

Page 4

1 Applications

Attention!

!

The adapter is used for testing measuring accuracy of test

instruments in accordance with DIN VDE 0701-0702 and

DIN EN 62353 (VDE 0751-1). As a rule, these instruments

must be tested once each year as set forth by accident prevention regulation BGV A3 (formerly BGV A2 and/or VBG4), as

well as for certification in accordance with the ISO 9000 quality standard.

All measuring ranges for tests required in accordance with

DIN VDE 0701-0702 such as protective conductor resistance,

insulation resistance, equivalent leakage current and residual

and/or contact current must be tested.

2 Safety Features and Precautions

This instrument fulfills the requirements of the applicable European and national EC guidelines. We confirm this with the CE

marking. The relevant declaration of conformity can be

obtained from GMC-I Messtechnik GmbH.

The SECU-cal 10 calibration adapter is manufactured and

tested in accordance with safety regulations IEC 61010-1 /

EN 61010-1 / VDE 0411-1.

If used for its intended purpose, safety of the user and of the

device is assured.

Read the operating instructions completely and carefully

before using the adapter, and follow all instructions included

therein. Observe the operating instructions included with the

test instrument to be tested as well.

The calibration adapter may only be used for testing

test instruments in accordance with DIN VDE 0404!

Under no circumstances may the adapter be used

in electrical systems!

4 GMC-I Messtechnik GmbH

Page 5

Attention!

Before plugging the calibration adapter into a live

Attention!

Attention!

!!!

outlet (test socket or mains outlet) for the performance of tests with line voltage, set the rotary

switch at the calibration adapter to the DI/I position.

Non-observance may result in:

• Destruction of the adapter

• Charging of the protective conductor with impermissible

fault currents of up to 8.25 mA

• Tripping of 10 mA RCCBs

If the “NETZ/MAINS” and “POLARITÄT/POLARITY” lamps light

up simultaneously during the test with mains voltage in rotary

switch position DI/I, the polarity of the calibration adapter must

be reversed before measurement is performed. Only the

“NETZ/MAINS” lamp may remain illuminated. Non-observance may result in erroneous measurements.

Only test instruments with a protective conductor test

current of no greater than 1 A may be connected to the

calibration adapter. Greater current values result in

destruction of the adapter.

The device is not equipped with overcurrent or

excessive temperature protection.

Under no circumstances may the device’s load

capacities be exceeded, because this may damage

the device or reduce its level of accuracy.

GMC-I Messtechnik GmbH 5

Page 6

Visual Inspection of Test Instruments

!

Perform a visual inspection of test instruments and their connector cables before connecting them to the calibration

adapter. Damaged test instruments must first be repaired.

The calibration adapter may not be used:

• with open housing

• if visible damage is apparent

• if the connection cable is damaged

• if it no longer functions flawlessly

• if the safety sockets are damaged

• after excessive stress, i.e. if the load capacities specified

in the technical data have been exceeded

• after lengthy periods of storage under unfavorable conditions (e.g. humidity, dust, temperature)

The calibration adapter may only be repaired by the manufacturer. Observance of technical measuring and safety requirements cannot otherwise be assured.

Meanings of symbols on the device

The symbols on the device have the following meanings:

Indicates EC conformity

Warning concerning a source of danger

(Attention, observe documentation!)

This device may not be disposed of with the trash.

Further information regarding the WEEE mark can be

accessed on the Internet at

www.gossenmetrawatt.com by entering the search

term ’WEEE’.

6 GMC-I Messtechnik GmbH

Page 7

3 Connecting the Calibration Adapter to the Test

Instrument

3.1 Tests without Line Voltage

➭ Make sure that the test socket is voltage-free

(e.g. set Mains VDE (Netz-VDE) switch to VDE position for

SECUTEST

➭ The earthing contact outlet of the calibration adapter may

only be plugged into the earthing contact outlet of the test

instrument, identified as test socket.

Reversal of L and N at the outlet has no effect on measurement results.

3.2 Tests with Line Voltage

➭ Before connecting the calibration adapter to the test

socket: Set the rotary switch to the DI/I position.

The rotary switch must also be set to the DI/I position for auto-

matic test instruments, and for test panels with VDE MAINS

selector switches before activating the test function (i.e. before

starting the function test).

If the “NETZ/MAINS” and “POLARITÄT/POLARITY” lamps light

up simultaneously, mains plug polarity must be reversed for

the test instrument or the calibration adapter before measurement is performed.

Only the “NETZ/MAINS” lamp may be illuminated during measurement.

®

11P, 15P or 21F workshop test panels).

GMC-I Messtechnik GmbH 7

Page 8

4 Performing Tests without Line Voltage

Attention!

!

➭ Connect the test instrument to mains power.

➭ Make sure that the test socket at the test instrument is

voltage-free.

➭ Plug the earthing contact plug of the calibration adapter

into the test socket at the test instrument.

4.1 Checking Display Values for Protective Conductor Resistance Measurement

Use test instruments with test current of less than

1 A only. The reference resistors are destroyed at

values of greater than 1 A.

➭ Connect the probe from the test instrument to the “0.3 ”

or “1.0 ”socket at the calibration adapter.

➭ Start “protective conductor measurement” at the test in-

strument.

The value displayed at the test instrument must lie within the

test instrument’s specified operating error tolerance for the

selected test type, plus calibration adapter error.

The reference values of the test resistances R

on the front side of the calibration adapter and in the test

report. Please use these values for assessing your DUT.

Calibration adapter intrinsic error for protective conductor

resistance measurement: 1%

4.2 Checking Display Values for Insulation Resistance Measurement

➭ Start “insulation measurement” at the test instrument.

➭ Set the selector switch at the calibration adapter to either

70 or 0.1 M.

The value displayed at the test instrument must lie within the

test instrument’s specified operating error tolerance for the

selected test type, plus calibration adapter error.

Calibration adapter intrinsic error for various insulation resistance values

Value in M 70 0.1 7

Intrinsic error as % 10.5

are indicated

PE

8 GMC-I Messtechnik GmbH

Page 9

4.3 Checking Display Values for Equivalent Leakage Current Mea-

Note

surement

➭ Start “equivalent leakage current measurement” at the

test instrument.

➭ Set the selector switch at the calibration adapter to either

3.5 or 7 mA.

The value displayed at the test instrument must lie within the

test instrument’s specified operating error tolerance for the

selected test type, plus calibration adapter error.

I

[mA] = 230 V

Display

Rxrepresents the resistors integrated into the SECU-cal 10. Any possi-

ble phase error is avoided through the use of ohmic resistors.

represents the internal resistance of the test instrument during equiv-

R

i

alent leakage current measurement. It amounts to typ. 2 k, according to standard.

Rx + R

i

Calibration adapter intrinsic error for equivalent leakage current measurement: 1 %

Before introduction of the DIN VDE 0701:2000-09

standard, the display value was calculated according

to the following formula:

I

[mA] = 230 x 1.06

Display

Rx + 2 k,

i.e. the display value included an allowance of 6%.

Veteran instruments therefore show an equivalent

leakage current increased by 6 %. We recommend

upgrading such instruments to the current version as

soon as possible.

GMC-I Messtechnik GmbH 9

Page 10

4.4 Checking Display Values for Equivalent Device Leakage Current Measurement per DIN EN 62353 (VDE 0751-1)

➭ Start “equivalent leakage current measurement

(Ri = 1 k)” at the test instrument.

➭ Connect the probe to the 0.3 socket.

In accordance with DIN EN 62353 (VDE 0751-1), the protective conductor at the test socket is not connected. The

probe functions as a return conductor.

The value displayed at the test instrument must lie within the

test instrument’s specified operating error tolerance for the

selected test type, plus calibration adapter error.

I

[mA] = 230 V

Display

Rxrepresents the resistors integrated into the SECU-cal 10. Any possi-

ble phase error is avoided through the use of ohmic resistors.

R

represents the internal resistance of the test instrument during equiv-

i

alent device leakage current measurement. It amounts to typ. 1 k,

according to standard.

Rx + R

i

Nominal Values

Switch Positions

70 M 3.29 A 3.29 A

7 M 32.8 A 32.8 A

2 M 115 A 115 A

1 M 0.23 mA 0.23 mA

0.5 M 0.46 mA 0.46 mA

0.1 M 2.25 mA 2.28 mA

3.5 mA 3.5 mA 3.55 mA

7 mA 7.0 mA 7.22 mA

Equivalent Leakage

Current

Equivalent Device

Leakage Current

4.5 Checking Display Values for Equivalent Patient Leakage Current Measurement per DIN EN 62353 (VDE 0751-1)

Plug the calibration adapter into the test socket at the test

instrument. Plug the probe into sockets 4 and 5 at the test

instrument. The probe handle is left open and may not be

touched (hum). Connect one of the applied parts sockets (A

through K) to the 1 mA socket at the SECU-cal 10. The

included quick clip and a 2 mm cable can be used to this end.

Start “equivalent patient leakage current measurement” at the

10 GMC-I Messtechnik GmbH

Page 11

test instrument. The display value must lie within a range of

Attention!

Note

!

0.98 mA and 1.01 mA plus the measuring uncertainty of the

test instrument. Other values cannot be tested with the SECUcal 10. In order to test all of the sockets (A through K) for correct functioning, connect each of these sockets with the 1 mA

socket at the SECU-cal 10, one after the other. The display

value must lie within the above specified range for each of the

sockets.

5 Performing Tests with Line Voltage

Set the rotary switch at the calibration adapter to

the DI/I position before plugging the calibration

adapter into the test socket.

The following test with line voltage must be performed with an

additional ammeter (calibrated multimeter, 1 mA respectively

10 mA AC range, e.g. METRAHIT X-TRA).

5.1 Checking Display Values for Leakage Current Measurement

The “POLARITÄT/POLARITY” lamp may not light up

during measurement.

➭ Start the requested leakage current measurement with

mains voltage at the test instrument.

➭ Connect the “contact and probe current measurement”

socket at the test instrument to the “1 mA” safety socket

at the calibration adapter via a series connected multime-

ter with the help of measurement cables.

The values displayed at the multimeter and the test instrument

must be in compliance by taking device tolerances into

account.

Line voltage tolerances influence measurement results.

GMC-I Messtechnik GmbH 11

Page 12

5.2 Checking Display Values for Patient Leakage Current Measurement

This test can be performed with all test instruments of the

SECUTEST/SECULIFE series with sockets A through K for

applied parts.

Please proceed as follows to calibrate the patient leakage current with SECU-cal 10:

➭ Connect SECU-cal 10 with the test socket.

➭ Select function „I-leakage“ at the SECUTEST (via switch po-

sition or menu), and then patient leakage current.

➭ Start measurement.

➭ Connect the applied part A to the 0.3 Ohm socket of

SECU-cal 10 via a series connected multimeter with the

help of measurement cables.

➭ Select „SFC Prot. Cond. interrupted“.

➭ Set the requested leakage current at the SECU-cal 10 test

instrument (e. g. 115 μA).

The values displayed at the multimeter and the test instrument

must be in compliance by taking device tolerances into

account.

12 GMC-I Messtechnik GmbH

Page 13

6 Characteristic Values

6.1 Nominal Range of Use

Maximum Voltage For the measurement of

Maximum Current For the measurement of protective

AC frequency: 50 Hz 60 Hz, sinusoidal

6.2 Ambient Conditions

Operating Temperature 0 C +40 C

Storage Temperature –20 C +60C

6.3 Electrical Safety

Safety Class I per IEC 61010-1

Operating Voltage 300 V

Measuring Category I for insulation resistance

Pollution degree 2

EMC IEC/EN 61326

6.4 Mechanical Design

Protection housing: IP 40, terminals: IP 20

Extract from table on the meaning of IP codes

IP XY

(1

Protection against

st

digit X)

foreign object entry

0 not protected 0 not protected

2 12.5 mm dia. 2

4 1.0 mm dia. 4 splashing water

Dimensions

Weight approx. 0.26 kg

Insulation resistance: 600 V DC

Equivalent leakage/equivalent

device leakage current: 250 V AC

Equivalent patient leakage current:

250 V AC

Leakage current: 250 V AC

conductor resistance:

1ADC/AC

Insulation resistance: 2 mA

Equivalent leakage current:

3.5 mA AC

II for all other measurements

IP XY

(2nd digit Y)

Protection against the

penetration of water

vertically falling drops

with enclosure tilted 15

125 mm x 66 mm x 41 mm (L x W x H)

eff

eff

GMC-I Messtechnik GmbH 13

Page 14

7 Maintenance

Annual calibration, performed by the manufacturer, is recommended.

7.1 Housing Maintenance

No special maintenance is required for the housing. Keep outside surfaces clean. Use a slightly dampened cloth for cleaning. Avoid the use of solvents, cleansers and abrasives.

7.2 Device Return and Environmentally Compatible Disposal

The instrument is a category 9 product (monitoring and control

instrument) in accordance with ElektroG (German Electrical

and Electronic Device Law). This device is not subject to the

RoHS directive.

We identify our electrical and electronic devices (as of

August 2005) in accordance with WEEE 2002/96/EG

and ElektroG with the symbol shown to the right per

DIN EN 50419.

These devices may not be disposed of with the trash. Please

contact our service department regarding the return of old

devices.

14 GMC-I Messtechnik GmbH

Page 15

8 Repair and Replacement Parts Service

Calibration Center* and Rental Instrument Service

When you need service, please contact:

GMC-I Service GmbH

Service Center

Thomas-Mann-Strasse 20

90471 Nürnberg • Germany

Phone +49 911 817718-0

Fax +49 911 817718-253

E-mail service@gossenmetrawatt.com

www.gmci-service.com

This address is only valid in Germany.

Please contact our representatives or subsidiaries for service

in other countries.

* DAkkS Calibration Laboratory

for Electrical Quantities D-K-15080-01-01

accredited per DIN EN ISO/IEC 17025:2005

Accredited measured quantities: direct voltage, direct current values,

DC resistance, alternating voltage, alternating current values, AC

active power, AC apparent power, DC power, capacitance, frequency

and temperature

9 Product Support

When you need support, please contact:

GMC-I Messtechnik GmbH

Product Support Hotline

Phone +49 911 8602-0

Fax +49 911 8602-709

E-Mail support@gossenmetrawatt.com

GMC-I Messtechnik GmbH 15

Page 16

Edited in Germany • Subject to change without notice • A pdf version is available on the internet

GMC-I Messtechnik GmbH

Südwestpark 15

90449 Nürnberg •

Germany

Phone +49 911 8602-111

Fax +49 911 8602-777

E-Mail

info@gossenmetrawatt.com

www.gossenmetrawatt.com

Loading...

Loading...