Page 1

Installation Instructions

R6000

8-Channel Controller

3-349-163-29

8/3.14

Alternative

Page 2

Contents Page

1 Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.1 Meanings of symbols on the instrument . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2 Identification by Means of Serial Plate . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.1 Identification According to Article Number and Device Feature Code. . . . . . . 4

2.2 Identification of Features at the Housing Front Panel . . . . . . . . . . . . . . . . . . 5

3 Mounting, Setup and Installation Instructions . . . . . . . . . . . . . . . . . . . . 5

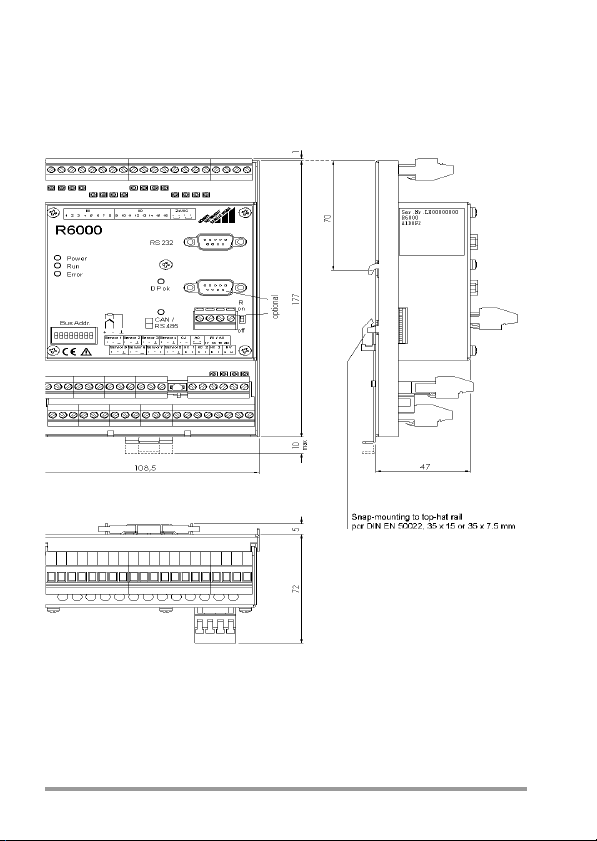

3.1 Dimensional Drawing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

4 Electrical Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

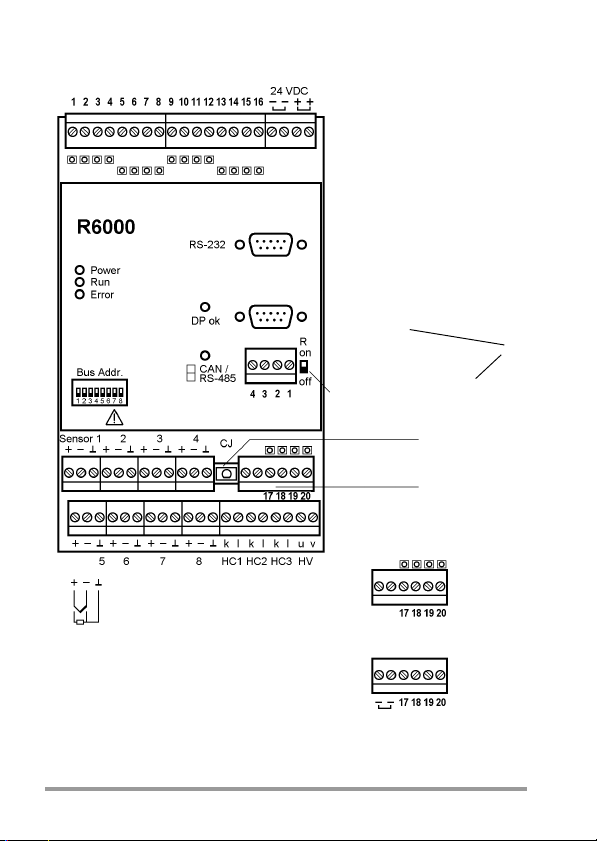

4.1 Terminal Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4.2 Auxiliary Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4.3 Binary Inputs / Outputs (I/O) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4.4 Thermocouple and Pt100 Measurement Inputs, 20 mA

(sensors 1 through 8) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4.5 Remote Cold Junction (CJ). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.6 Additional Binary Inputs / Outputs (I/O) . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.7 Additional Continuous Outputs (AO) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.8 Heating Current Monitoring (HC 1 ... 3, HV). . . . . . . . . . . . . . . . . . . . . . . . 13

4.9 Data Interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5 LED Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

6 Initial Start-Up. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

6.1 Device Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

6.2 Device Performance after Connecting Auxiliary Voltage . . . . . . . . . . . . . . . 18

6.3 Possible Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

7 Parameters Configuration and Operation . . . . . . . . . . . . . . . . . . . . . . . 19

8 Maintenance and Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

9 Characteristic Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

10 Repair and Replacement Parts Service,

and Rental Instrument Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

11 Product Support Industrial Division . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

2 GMC-I Messtechnik GmbH

Page 3

1 Safety Precautions

Attention!

!

!

The R6000 controller is manufactured and tested in accordance with

safety regulations IEC 61010-1 / EN 61010-1 / VDE 0411 part 1.

If used for its intended purpose, safety of the user and of the device is

assured.

Check the specified nominal voltage at the front housing panel

before placing the instrument into service.

Make sure the connector cables are not damaged, and that

they are voltage-free while wiring the instrument.

If it can be assumed that safe operation is no longer possible,

the device must be immediately removed from service (disconnect auxiliary voltage!). Safe operation can no longer be relied upon if the device demonstrates visible damage.

The device may not be placed back into operation until troubleshooting, repair and subsequent testing have been performed at our factory, or by one of our authorized service

centers.

Work on live open instruments may only be carried out by

trained personnel who are familiar with the dangers involved.

Capacitors inside the device may be dangerously charged,

even if it has been disconnected from all power sources.

Requirements set forth in VDE 0100 must be observed during the

performance of all work.

Safety clearances to neighboring electrical circuits with dangerous

voltages must be maintained during installation.

1.1 Meanings of symbols on the instrument

Warning concerning a point of danger

(Attention: observe documentation!)

Indicates CE conformity

This device may not be disposed with the trash. For further

details on the WEEE marking, please refer to our website

www.gossenmetrawatt.com and enter search key ’WEEE’.

GMC-I Messtechnik GmbH 3

Page 4

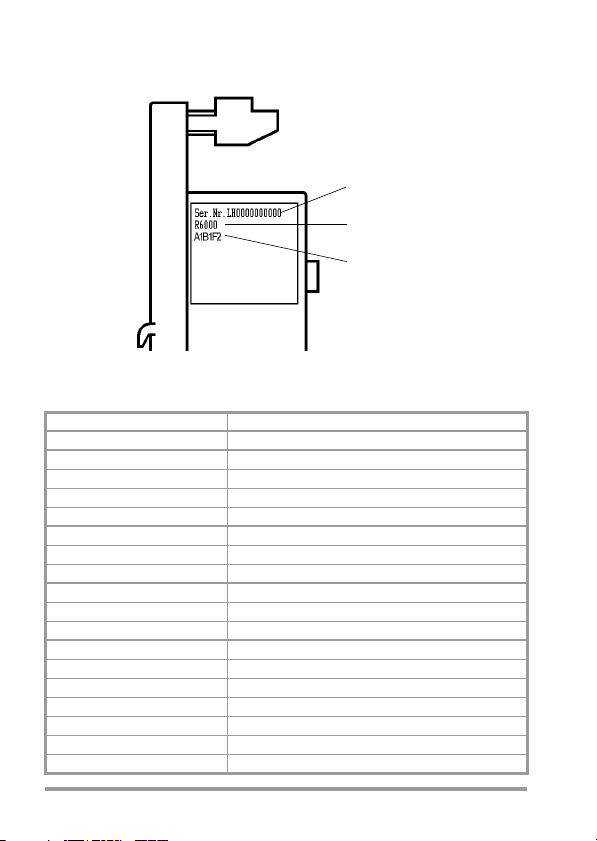

2 Identification by Means of Serial Plate

Serial Number

Article Number

Device Feature

Code

The controller is identified by means of a serial plate. The serial plate is

located on the left-hand side of the housing.

Figure 1 Serial Plate Labeling

2.1 Identification According to Article Number and Device Feature Code

Article Number / Feature Description

R6000 8-Channel Controller

A0 16 binary inputs / outputs

A1 20 binary inputs / outputs

A2 16 binary inputs / outputs, 4 continuous outputs

B1 Thermocouple, Pt100

B2 0 / 4 ... 20 mA, without Heating current monitoring

D0 Screw terminal blocks

D1 Clamp-type terminal blocks

F1 CAN / CANOpen

F2 Profibus DP

F3 RS 485 / Modbus protocol

F4 RS 485 / EN 60870 protocol

F7 RS 485 / HB-Therm protocol

F8 RS 485 / DIN 19244 protocoll as R7000

4 GMC-I Messtechnik GmbH

Inputs / Outputs

Measurement Input

Connectors

Bus Interface

Page 5

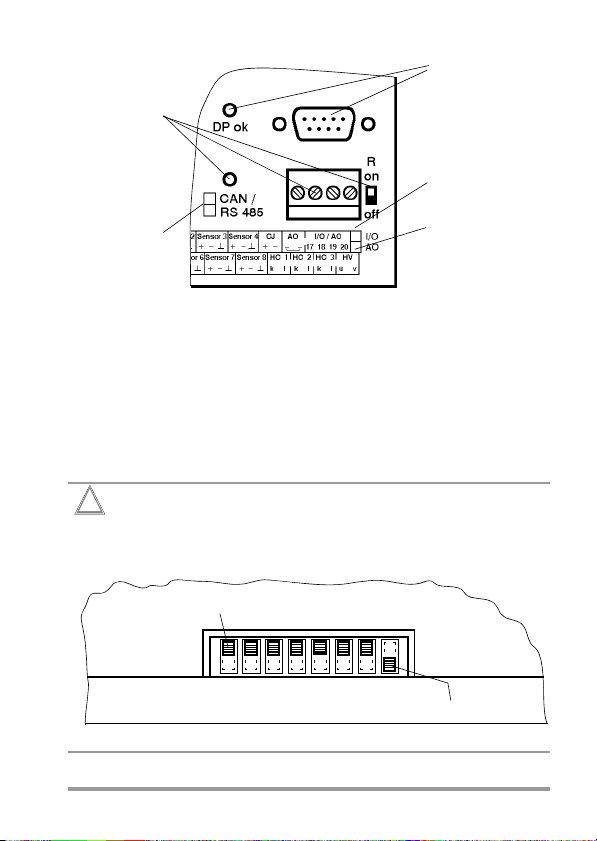

2.2 Identification of Features at the Housing Front Panel

Attention!

!

Subminiature

plug and

“DP OK” LED

provided with

feature F2

(Profibus DP)

4-pole connection, LED

and bus terminating switch

provided with

feature F1, F3,

F4, F7 or F8

(CAN or RS

485),

ID field is

marked

accordingly

I/O field is

marked for

feature A1.

AO field is

marked for feature A2.

No marking for

feature A0

1234 5678

Switch at Upper Position = Thermocouple

Switch at Bottom Position = Pt100

Figure 2 Device Variant According to Included Features

3 Mounting, Setup and Installation Instructions

The R6000 is a compact 8-channel temperature controller in a top-hat

rail mount housing. The controller is mounted by snapping it onto a

top-hat rail in accordance with DIN EN 50022.

During installation make sure to keep safe distances to adjoining electrical circuits involving hazardous voltages.

A sensor type must be selected for each channel with the DIP

switch at the left-hand side of the housing before mounting.

Unused inputs must be set to thermocouple.

The factory default setting is always thermocouple.

Figure 3 Selecting a Sensor Type

GMC-I Messtechnik GmbH 5

Page 6

Unobstructed air circulation must always be assured when one or sev-

All dimensions in millimeters

eral devices are installed. The ambient temperature underneath the

devices may not exceed 50° C.

Aggressive vapors shorten the service life of the controller.

3.1 Dimensional Drawing

Figure 4 Dimensional Drawing for Top-Hat Rail Mounting

6 GMC-I Messtechnik GmbH

Page 7

4 Electrical Connection

Attention!

!

Observe terminal assignments at the housing front panel!

The instrument is not equipped with an integrated circuit breaker. Therefore, during installation, care should be taken to ensure that

– the building where the instrument is installed includes a

circuit breaker,

– the circuit breaker is positioned in close proximity to the

instrument and is easily accessible to the operator

– it is clearly marked as a circuit breaking device for the

instrument.

Tighten screws with a manual screwdriver only!

Maximum tightening torque for all screw connections is

0.6 Nm.

Connectors: Terminal blocks for wires with cross-sections of up to

2.5 square mm, or two-core wire-end ferrules for cross-sections of up

to 2 x 1.0 square mm

EN 55022 requires the following warning as regards

electromagnetic compatibility:

Warning

This is a class A device. It may cause radio interference in residential environments.

If this is the case, the operator may be required to implement appropriate corrective measures.

Reliable wiring is accomplished with the help of screw and clamp-type

terminals which are separated according to function. Only terminal

blocks of like polarity or identical color may be plugged onto the

appropriate bases.

Mismatching of the terminal blocks may result in damage to the R6000

controller or interconnected components.

GMC-I Messtechnik GmbH 7

Page 8

4.1 Terminal Assignments

Connection

Binary inputs / outputs (I / O)

Service

interface

Profibus-DP

(Version F2)

CAN / RS-485

(Version F1/F3/F4/F7/F8)

Bus connection resistance

on / off

Auxiliary voltage

Heating circuit monitoring

Binary inputs/outputs refer to

minus (–) of auxiliary voltage

Vers ion A 2

Contiuous outputs (AO)

Binary inputs/outputs (I/O)

Vers ion A 1

Reference junction connection

Optional additional outputs

Vers ion A 0

not assigned

alternative

Sensor

Figure 5 Positioning and Significance of the Terminals

8 GMC-I Messtechnik GmbH

Page 9

4.2 Auxiliary Voltage

+24 V

0 V

SPC

Output

Input

R6000

Output

SSR or Similar Device

Input

Input

Output

Mechanical or

Electronic Switch

Auxiliary voltage is 24 V DC.

The two connector terminals for the negative poles are connected with

one another inside the device, as is also the case for the two positive

poles.

In this way, supply power can be looped through to several R6000

controllers. The terminals have a maximum current carrying capacity of

10 A (also in the event of malfunction) which may not be exceeded!

The terminal block for auxiliary voltage is black.

A completely separate safety power supply system is to be used for

operation of the instrument.

4.3 Binary Inputs / Outputs (I/O)

Figure 6 Schematic Diagram, Binary Inputs / Outputs

Binary I/Os which are configured as outputs connect the auxiliary voltage positive pole by means of a semiconductor switch. The load (SSR,

controller input etc.) is connected to the auxiliary voltage negative pole.

Three SSRs can be connected in series for controlling 3-phase heaters.

Maximum load for each individual output is 500 mA, with a limit of 3 A

per controller. All outputs are safeguarded by means of integrated,

self-restoring overload protection.

GMC-I Messtechnik GmbH 9

Page 10

Attention!

!

After overload protection has been triggered, not only does

Attention!

!

+–

Sensor

+–

Sensor

+–

Sensor

Pt100

2-wire

Pt100

3 or 4-wire

Thermocouple

+–

Sensor

0 / 4 ...

20 mA

the overload have to be eliminated, all other outputs must be

de-energized as well in order to allow for self-restoration of the

circuit breaker. Self-restoration may take several minutes.

If the I/Os are used as inputs, control is accomplished either by means

of an active positive signal at the auxiliary voltage negative pole, or with

a floating contact which switches the auxiliary voltage positive pole to

the input.

The assignment of I/Os to channels and functions can be freely configured via the interface.

Before I/Os used as inputs are configured as such, an active

output signal can be read out depending upon configuration.

The output of the connected device may thus be damaged as

a result.

4.4 Thermocouple and Pt100 Measurement Inputs, 20 mA

(sensors 1 through 8)

Figure 7 Sensor Terminal Assignments

10 GMC-I Messtechnik GmbH

Page 11

Thermocouples are connected to the positive and negative terminals.

Te rm in al s

Remote Cold

Junction

R6000

Sensor 8

Copper

CJ

+

+

+

–

–

–

Thermocouple

Sensor 1

No connections may be made to the terminal.

If impermissible measured values should occur when using insulated

thermocouples, all negative legs at the insulated thermocouples

should be connected to each other. If necessary, they can be connected to the switch cabinet ground terminal.

3-wire connection is used for Pt100 sensors.

In the event of 2-wire connection, the negative terminal must be connected to the terminal at the controller.

The terminals are connected with each other internally.

If Pt100 sensors with 4-wire connection are used, the fourth wire may

not be connected at all.

The reference junction (CJ) remains attached also for PT100 sensors.

4.5 Remote Cold Junction (CJ)

Figure 8 Schematic Diagram, Remote Cold Junction

If the thermocouple equalizing leads are not connected to the controller, the Z306A accessory (remote cold junction) is required. The remote

cold junction includes a temperature sensor and a 2-pole terminal

block.

The plug-on reference junction (CJ) at the R6000 is removed and is

replaced with the 2-pole terminal block. The temperature sensor is

attached at the transition from the thermocouple or the equalizing lead

GMC-I Messtechnik GmbH 11

Page 12

to the copper conductor, and is connected to the 2-pole terminal

R6000

AO 17

AO 20

AO –

+

–

24 V

0 V

block at the R6000.

The original reference junction which has now been removed from the

R6000 is not used.

4.6 Additional Binary Inputs / Outputs (I/O)

Device variants including feature A1 have four additional I/Os.

All of the specifications included in chapter 4.3 on page 9 apply to

these I/Os as well.

No connections may be made at the AO negative terminals at the

same terminal block.

4.7 Additional Continuous Outputs (AO)

Figure 9 Schematic Diagram, Continuous Outputs

Device variants with feature A2 are equipped with 4 additional continuous outputs for controlling proportional actuators.

The negative terminals at the actuators are all connected to the negative AO terminals. The auxiliary voltage negative pole may not be used

for this purpose.

12 GMC-I Messtechnik GmbH

Page 13

4.8 Heating Current Monitoring (HC 1 ... 3, HV)

Attention!

!

R6000

HC1 HC2 HC3 HV

kl kl kl uv

L1

L2

L3

N

Figure 10 Schematic Diagram, Current Transformer Connection

Commercially available current transformers with max. 1 A secondary

current are connected to terminals HC k and l. Compliance voltage is

max. 2 V.

Three inputs are provided for monitoring 3-phase current.

Several control loops are monitored via summation current principle.

If the terminal block is removed during operation, excessive

voltage occurs at the secondary side of the current transformer.

In order to enable more accurate current monitoring, current fluctuations which result from line voltage fluctuations can be compensated.

A voltage transformer with a secondary open-circuit voltage of 12 to

40 V is connected to terminals HV u and v to this end. A representative

phase voltage from the heater power supply is used at the primary

side.

All interconnected transformers must assure safe electrical separation,

and may not be connected to each other at the secondary side.

GMC-I Messtechnik GmbH 13

Page 14

4.9 Data Interfaces

9876

54321

9-pin sub-miniature plug connector at the controller

Typ e Se rv ic e

Interface

Feature F2 F1 F3/F4/F7/F8

Interface RS 232 Profibus DP CAN /

Maximum number of

devices

13210032

Range of addresses – 0 ... 126 0 ... 127 0 ... 254

Transmission speed 9.6 or 19.2

kBaud

9.6 kBaud ...

12 MBaud

Protocol per EN 60870 DIN 19245

Connection 9-pin sub-

miniature plug

9-pin sub-

miniature plug

part 3

Fieldbus Interface

CANOpen

10 kBaud ...

1 MBaud

IEC 1131

CANOpen

4-pole screw terminal

RS 485

9.6 or 19.2

kBaud

Modbus /

EN 60870/

HB-Therm/

DIN 19244

4.9.1 RS 232 Service Interface

Figure 11 Diagram of Sub-miniature Plug for RS 232 Interface

Connector Pin Assignments for

Sub-miniature Plug Connector for

RS 232 Service Interface

Connector Pin

Assignments at the PC

COM1 or COM2

Pin Number Designation Description Pin Number Designation

2 TxD Data output 2 RxD

3 RxD Data input 3 TxD

5 GND Signal ground 5 GND

1, 4, 6 ... 9 Not assigned

Socket

housing

14 GMC-I Messtechnik GmbH

Shield, connected to controller housing

Establish

connection to

Page 15

A non-crossed serial extension cable (modem cable) is required for

Attention!

!

43 21

connection to a laptop or a notebook. This can be ordered as an

accessory (article no. GTZ 3241000R0001).

With the CAN bus and Profibus variants (features F1 and F2), the service interface can be used independent of bus operation.

With RS 485 variants (features F3, F4 and F7), communication

is only possible via the service interface after the 4-pole bus

plug has been removed, or when the bus is not in use.

4.9.2 Bus Interfaces

The following points must be observed when wiring the bus interfaces:

– Corresponding terminals must all be connected in parallel.

– Wiring must be executed from device to device, devices may not

be star-connected.

– The two bus ends should be terminated with characteristic wave

impedance.

This is accomplished by setting the “R” switch at the R6000 to

“on”.

CAN (variant with feature F1)

4-pole terminal block

Figure 12 Diagram of Terminal Block for CAN Interface

Terminal Assignments for CAN Interface Terminal Block

Terminal Number Designation Description

1 CAN-GND Ground

2 CAN-L Low dominant bus signal

3 CAN-SHLD Optional shield, connected to controller housing

4 CAN-H High dominant bus signal

GMC-I Messtechnik GmbH 15

Page 16

Profibus DP (variant with feature F2)

9876

54321

43 21

9-pin sub-miniature plug connector at the controller

Figure 13 Diagram of Sub-miniature Plug for Profibus DP Interface

Pin Assignments for Sub-miniature Plug Connector for Profibus DP Interface

Pin Number Designation Assignment / Description

1 SHIELD Shield, connected to controller housing

3 RxD / TxD-P Bus signal (positive open-circuit level to RxD / TxD-N)

5 DGND Signal ground

6 VP +5 V supply power for terminating resistor

8 RxD / TxD-N Bus signal (negative open-circuit level to RxD / TxD-P)

2, 4, 7, 9 No connection

Socket housing Shield, connected to controller housing

A commercially available Profibus plug can be used for connection (not

included).

RS 485 (variant with feature F3 / F4 / F7)

4-pole terminal block

Figure 14 Diagram of Terminal Block for RS 485 Interface

Terminal Assignments for RS 485 Terminal Block

Terminal No. Designation Description

1 C = DGND Ground

2 A = RxD / TxD-P Bus signal (positive open-circuit level to RxD / TxD-N)

3 SHIELD Optional shield, connected to controller housing

4 B = RxD / TxD-N Bus signal (negative open-circuit level to RxD / TxD-P)

16 GMC-I Messtechnik GmbH

Page 17

Note!

Designations A and B are not defined uniformly in various stan-

LEDs on sheet

metal housing

1234 5678

Bus Addr.

Upper Position =

High

Bottom Position =

Low

Least Significant Bit Most Significant Bit

dards or for various devices. If the bus does not function, A

and B may be reversed.

5 LED Functions

LEDs provide information regarding the status of the device, as well as

the switching outputs and switching inputs of the controller and the

fieldbus.

Status Displays

Power on green

Run green

Active bus communication yellow

Error red

Binary input / output

is active yellow SMD LEDs

at terminal blocks

6 Initial Start-Up

6.1 Device Configuration

• Selecting the sensor type: see “Mounting, Setup and Installation

Instructions” on page 5.

• Selecting the bus address:

The bus address is selected with the DIP switch at the front panel.

Figure 15 Example: Bus Address = 3

• All other settings are executed via the bus interface or the service

interface.

GMC-I Messtechnik GmbH 17

Page 18

6.2 Device Performance after Connecting Auxiliary Voltage

• As soon as auxiliary voltage is connected, the green “Power” LED

lights up.

• Shortly thereafter, the green “Run” LED lights up, and the red

“Error” LED blinks once briefly.

• The binary output LEDs then light up in accordance with control

loop settings. The binary output LEDs may light up even if auxiliary

voltage has not been connected, if the inputs are driven actively.

• The yellow LED for the respective bus terminal indicates active bus

communication.

6.3 Possible Errors

Error Possible Cause

Power LED does not light up. No auxiliary voltage or reversed polarity

Run LED does not light up or blinks. Defective processor or data error

Error LED lights up. Defective hardware

Binary output LEDs do not light up. Short-circuit at output or

Binary I/O LEDs continuously illuminated No connection between negative pole at the

Profibus LED does not light up. No data exchange

RS 485 / CAN LED does not light up. No transmission from R6000

overload protection has been triggered

actuators and auxiliary voltage

e.g. due to incorrect address,

bus terminator switch set incorrectly

18 GMC-I Messtechnik GmbH

Page 19

7 Parameters Configuration and Operation

Information regarding parameters configuration and operation of the

R6000 is included in the comprehensive operating instructions.

These are available from the internet at www.gossenmetrawatt.de.

Read the operating instructions completely and carefully before using the

device, and follow all instructions included therein.

The operating instructions should be made available to all users.

8 Maintenance and Service

The R6000 controller does not require maintenance at regular intervals.

If the controller should nevertheless require replacement, it can be

removed from the rail by pulling on the tab at the bottom of the device.

This disengages the top-hat rail mount and the controller can be

removed by lifting it up and forward.

Before replacement, the DIP switches at the replacement device must

be configured to match those at the original device (bus address and

selection of Pt100 or thermocouple).

The replacement device is attached to the top-hat rail with the mounting hooks at the rear, and is snapped into place by gently pushing

down and back.

Screw or clamp-type terminal blocks can plugged from one device to

the next for quick device replacement if service is required.

GMC-I Messtechnik GmbH 19

Page 20

9 Characteristic Values

Inputs / Outputs

Sampling rates 100 ms for each controlled variable

Thermocouple Measurement Input

Thermocouples per IEC 60584 / EN 60584 / DIN 43710

Measuring range 0 ... 50 mV

Accuracy / Error 0,3 mV

Resolution 0.1 K

Continous overload AC sinusoidal 50 / 60 Hz / 50 V AC

Input impedance > 50 k

Error meassages for sensor breakage or polarity reversal

Reference Junction Measurement Input

Nominal input range 0 ... 70 °C

Accuracy 2 K

Reference junction KTY 10

P1 100 Resistance Thermometer Measurement Input

2 or 3-wire Connection

Pt100 per IEC 60751 / DIN EN 60751

Measuring range 18 ... 320

Nominal input range –200 ... 600 °C

Sensor current

Accuracy / Error < 0.5 % of measuring range span

Resolution 0.1 K

Continuous overload AC sinusoidal 50 / 60 Hz / 50 V AC

Input impedance 13 k

Cable resistance

(both directions) 2-wire connection: 0 ... 30 adjustable

Error message for sensor breakage or short circuit

Measuring Input 20 mA

Input range 0 / 4 ... 20 mA configurable

Load approx. 45

Accuracy < 0.7 % of measuring range span

Continuous overload 60 mA

Error message if measured quantity is more than 10% outside

Heating Current Monitoring Input

Measuring range 1 A AC (direct connection of a commercially

Resolution < 0.1 % of upper range value

Accuracy < 5 % of upper range value

DC 1 V DC

DC 1 V DC

3-wire connection: 0 ... 30 compensated

measuring range

available measuring transducer)

20 GMC-I Messtechnik GmbH

Page 21

Heating Voltage Input

3 mm dia. LEDs,

at sheet metal housing

Measuring range 10 ... 50 V AC (direct connection of a

Resolution < 0.1 % of upper range value

Accuracy < 5 % of upper range value

Binary Inputs / Outputs

Output function active switching outputs

Function controlled variable output / alarm output

Read-out cycle adjustable within a range of 0.1 ... 300 s

Nominal range of use H signal: U auxiliary voltage –0.5 V

Input function Read back output status, external control of PLC or

Nominal range of use H signal: > 14 V

Overload limit

H, L signal continuous short-circuit, interruption

Continuous Outputs

Output function actuator output for proportional actuators

Output quantity 0 ...10 V at > 1 k load,

Resolution 0.1 % of upper range value

Accuracy 2 % of upper range value

commercially available measuring transducer)

supplied directly from auxiliary voltage

I 500 mA

L signal: < 0.1 mA

e.g. for driving up to 3 commercially available

semiconductor relays (SSR) in series

similar

L signal: < 7 V / < 0.2 mA

0 ... 20 mA at < 300 load

total current 3 A per device

8 ... 16 mA at 24 V

Status Displays

Power on green

Run green

Bus communication active yellow

Error red

Binary input / output

active yellow SMD-LEDs,

at clamp-type terminal blocks

Auxiliary Voltage

A completely separate safety power supply unit is to be used for operating the

controller.

Nominal value 24 V DC

Nominal range of use 18 V ... 30 V DC

Power consumption max. 10 VA, typically 6 W (without load)

GMC-I Messtechnik GmbH 21

Page 22

Data Interfaces

Service Interface

RS 232

Max. number of devices 1

Range of addresses –

Transmission speed 9.6 / 19.2 kBaud

Protocol per EN 60870

Connection

Field Bus Interfaces

Profibus-DP

Max. number of devices 32

Range of addresses 0 ... 126

Transmission speed 9.6 kBaud ... 12 MBaud

Protocol per EN 50170

Connection

CAN / CANOpen

Max. number of devices 100

Range of addresses 0 ... 127

Transmission speed 10 kBaud ... 1 MBaud

Protocol per IEC 1131 CANOpen

Connection

RS 485

Max. number of devices 32

Range of addresses 0 ... 254

Transmission speed 9.6 / 19.2 kBaud

Protocol per Modbus / EN 60870 / HB-Therm

Connection

Bus Address Selection

The bus address is selected in binary mode with the DIP switch at the front

panel.

Service Interface

A laptop or notebook can be connected to the RS 232 interface for service

purposes.

9-pin sub-miniature plug

9-pin sub-miniature plug

4-pole screw terminal

4-pole screw terminal

Electrical Safety

Attention: The device is not equipped with an integrated circuit breaker

Design IEC 61010-1 / EN 61010-1 / VDE 0411, part 1

Safety class II

Measurement category CAT II

Contamination degree 2

Protection IEC 60529 / EN 60529 / VDE 0470, part 1

Housing IP 20

PCB IP 10

Term in al s IP 20

22 GMC-I Messtechnik GmbH

Page 23

Electromagnetic Compatibility

Interference emission IEC 61326-1 / EN 61326-1 class A

Interference immunity IEC 61326 / A1 / EN 61326 / A1 criterion A, B

Ambient Conditions

Annual mean relative humidity,

no condensation 75 %

Ambient temperature

– Nominal range of use 0 °C ... + 50 °C

– Operating range 0 °C ... + 50 °C

– Storage range – 25 °C ... + 70 °C

Mechanical Design

Housing Sheet metal / plastic per UL-V0

Dimensions incl.

terminal blocks

(H x W x D) max. 182 x 109 x 78 mm

Weight approx. 0.6 kg incl. terminal blocks

Connectors terminal blocks

Mounting integrated,

for wire cross sections to 2.5 mm

double wire-end ferrules for 2 x 1.0 mm

for top-hat rails per DIN EN 50022

35 x 7.5 mm or 35 x 15 mm

2

or

2

GMC-I Messtechnik GmbH 23

Page 24

10 Repair and Replacement Parts Service,

and Rental Instrument Service

When you need service, please contact:

GMC-I Service GmbH

Service Center

Thomas-Mann-Str. 20

90471 Nürnberg • Germany

Phone +49 911 817718-0

Fax +49 911 817718-253

E-Mail service@gossenmetrawatt.com

www.gmci-service.com

This address is only valid in Germany.

Please contact our representatives or subsidiaries for service in other

countries.

11 Product Support Industrial Division

When you need support, please contact:

GMC-I Messtechnik GmbH

Product Support Hotline – Industrial Division

Phone +49 911 8602-500

Fax +49 911 8602-340

E-Mail support.industrie@gossenmetrawatt.com

Edited in Germany • Subject to change without notice • A pdf version can be found on the internet

GMC-I Messtechnik GmbH

Südwestpark 15

90449 Nürnberg •

Germany

Phone +49 911 8602-111

Fax +49 911 8602-777

E-Mail

info@gossenmetrawatt.com

www.gossenmetrawatt.com

Loading...

Loading...