Page 1

Operating Instructions

PROFiTEST DC-II

Test Instrument for the Suppression of RCCB Tripping

and for Tripping Tests of DC Components

in AC-DC Sensitive RCCBs

3-348-973-37

7/5.14

Page 2

2 GMC-I Messtechnik GmbH

Contents Page

1 Safety Precautions .....................................2

2 Description .................................................3

2.1 Loop Resistance Measuring Mode with the

PROFiTEST... with Suppression of RCCB Tripping ...3

2.2 Tripping Test Operating Mode

for AC-DC Sensitive RCCBs ...................................3

2.2.1 With Rising DC Residual Current and Measurement of

Tripping Current for Undelayed RCCBs ...................3

2.2.2 With Rising DC Residual Current and

Measurement of Tripping Current for

Selective or Short-Time-Delay RCCBs ....................3

2.2.3 With Constant DC Residual Current and Measurement

of Time to Trip ......................................................4

3 Connecting the PROFiTEST DC-II Test

Instrument to the System Under Test ........4

3.1 Testing in Systems with Neutral Conductor .............4

3.2 Testing in Systems without Neutral Conductor ........4

4 Operation ...................................................5

4.1 Loop Resistance Measurement Mode

with the PROFiTEST... with

Suppression of RCCB Triggering ............................5

4.2 Tripping Test Operating Mode

for DC Components in AC-DC Sensitive RCCBs .......5

4.2.1 With Rising DC Residual Current

and Measurement of Tripping Current

for Undelayed RCCBs ............................................5

4.2.2 With Rising DC Residual Current

and Measurement of Tripping Current

for Delayed RCCBs ................................................6

4.2.3 With Constant DC Residual Current

and Measurement of Time to Trip

for Undelayed RCCBs ............................................6

5 Characteristic Values .................................6

6 Maintenance ..............................................7

6.1 Internal Fuse ........................................................7

6.2 External Fuse ........................................................7

6.3 Housing ...............................................................7

6.4 Recalibration ........................................................7

6.5 Return and Environmentally Sound Disposal ...........8

7 Repair and Replacement Parts Service

Calibration Center

and Rental Instrument Service ..................8

8 Product Support .........................................8

1 Safety Precautions

The PROFiTEST DC-II test instrument has been

manufactured in accordance with safety regulations EN 61010-1,

VDE 0411-1 and IEC 61010-1.

If used for its intended purpose, the safety of both

the operator and the instrument is assured. Their

safety is however not assured,

if the test instrument

is operated inco

rrectly or handled improperly.

The test instrument should only be connected to

the mains as long as is necessary to perform the

desired measurement, in order to avoid unnecessarily high temperatures within the instrument.

Attention!

!

Always be certain to select the correct

line voltage when operating the test instrument (voltage selector switch at the

right hand side of the housing labelled:

230/400 V).

Opening the instrument / repairs

The instrument may only be opened by authorized, trained personnel in order to ensure flawless

operation and to assure that the guarantee is not

rendered null and void.

Even original replacement parts may only be

installed by authorized, trained personnel.

If it can be ascertained that the instrument has

been opened by unauthorized personnel, no guarantee claims can be honored by the manufacturer

with regard to personal safety, measuring accuracy, compliance with applicable safety measures

or any consequential damages.

Any warranty claims will be forfeited when the

warranty seal has been damaged or removed.

Meanings of symbols on the instrument

Warning concerning a point of danger

(Attention: observe documentation!)

Protection class II device

EU seal of approval

This device may not be disposed of with

the trash. Further information regarding

the WEEE mark can be accessed on the

Internet at www.gossenmetrawatt.com

by entering the search term “WEEE”.

Meaning of symbols in the operating instructions

Selective RCCB

Pulse-controlled RCCB

AC-DC sensitive RCCB

I

F

Rising DC residual current

!

S

Page 3

GMC-I Messtechnik GmbH 3

2Description

2.1 Loop Resistance Measuring Mode

with the PROFiTEST...

with Suppression of RCCB Tripping

The PROFiTEST DC-II test instrument allows for

the measurement of loop resistance in TN

systems with RCCBs (10/30/100/300/500 mA

nominal residual current) without DC sensitive

components.

The test instrument generates a DC residual current which saturates the magnetic circuit of the

RCCB.

The PROFiTEST 0100S/S-I I,PROFi TEST 2 or

PROFiTEST

C superimposes a measuring current

which demonstrates only half-waves of like polarity. The RCCB cannot detect this measuring current and can thus no longer be tripped during

measurement.

2.2 Tripping Test Operating Mode

for AC-DC Sensitive RCCBs

2.2.1 With Rising DC Residual Current and

Measurement of Tripping Current

for Undelayed RCCBs

A slowly rising direct current is applied to N and

PE with the selector switch in the I

F

position.

The measured current value is displayed continuously. When the RCCB is tripped, the last measured current value is stored for several seconds

and can be read from the display.

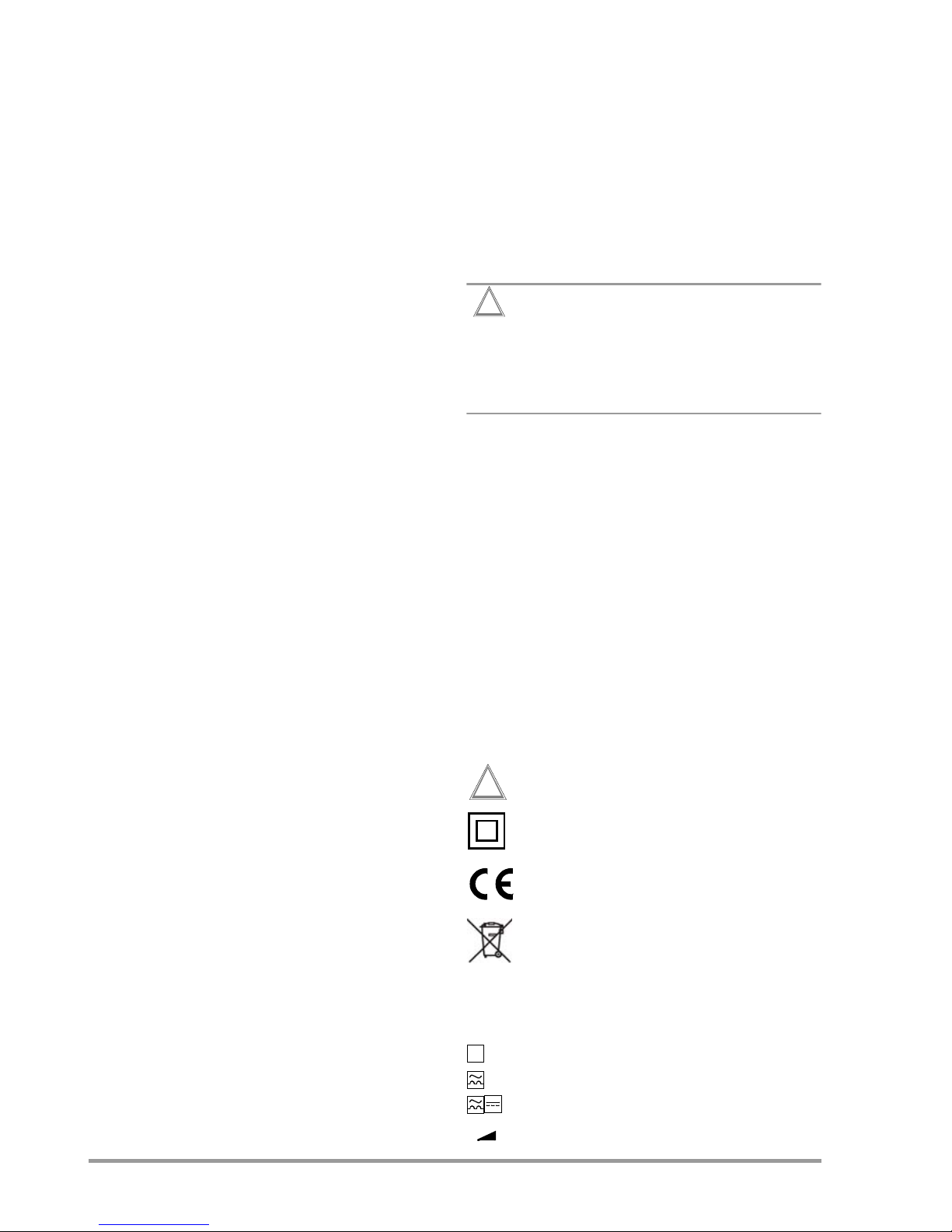

2.2.2 With Rising DC Residual Current and

Measurement of Tripping Current for

Selective or Short-Time-Delay RCCBs

The current ramp demonstrates a gradual overall

rise with the selector switch in the position.

Test duration is considerably longer. Use this

selector switch position for testing tripping current

for selective or short-time-delay AC-DC sensitive

RCCBs.

Start

t1 t3

Measure

t2

Active

RCCB inoperable!

t

I

F

/mA

Suppression of RCCB Tripping

with Pulse-Controlled RCCB

S

0.4 0.8 1.0 1.6 2.0 2.4 2.8 3.2 3.6 4.0 4.4 4.8

100

200

300

400

500

600

I

F

/mA

t/s

A residual current curve with a lesser slope

between 0 and 100 mA provides for

enhanced resolution.

Start

Tripping Occurs

A residual current curve with

a steeper slope as of

100 mA allows for more

rapid testing.

Measurement of Tripping Current for AC-DC Sensitive RCCBs

Page 4

4 GMC-I Messtechnik GmbH

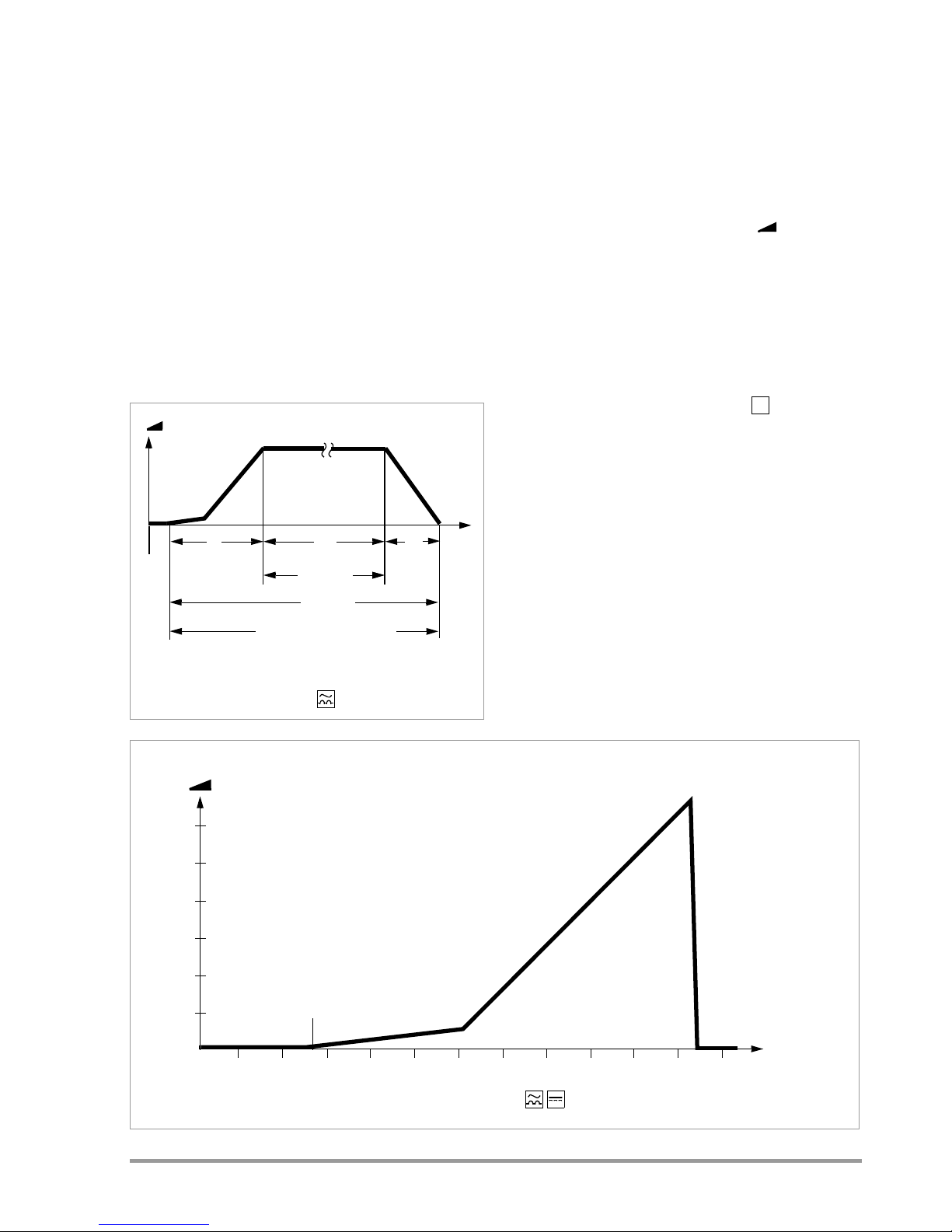

2.2.3 With Constant DC Residual Current and Measurement of Time to Trip

With the selector switch set to the respective

nominal residual current, twice the nominal current is applied to N and PE. Time to trip is measured and displayed for the RCCB.

3 Connecting the PROFiTEST DC-II Test Instrument to the System Under Test

3.1 Testing in Systems with Neutral Conductor

Perform testing at an earthing contact outlet with

the provided earthing contact device connector

cable in systems which have both a neutral and a

protective conductor.

➭ Set the voltage selector switch to 230 V (at

the right hand side of the housing labelled:

230/400 V).

Note!

If the voltage selector switch has been set

to 400 V, the test instrument is inoperable

and only random values appear at the

display.

➭ Perform testing as described in chapter 4.2.1.

3.2 Testing in Systems without Neutral Conductor

Proceed as follows in order to test RCCBs in systems without a neutral conductor:

➭ Set the voltage selector switch to 400 V.

➭ Use the Z523A test adapter with three test

probes.

➭ Connect the test probes as follows:

➭ Connect the black test probe to a phase

conductor downstream from the RCCB.

➭ Connect the blue test probe to a different

phase conductor downstream from the

RCCB.

➭ Connect the red test probe to the same

phase conductor as the blue test probe has

been connected to, but upstream from the

RCCB.

➭ We recommend performing the test on all

three phases.

Attention!

!

When a connection is made between two

phases, the voltage selector switch must

be set to 400 V. Otherwise the internal

device fuse will blow!

10 20 40 50

100

200

300

400

500

600

I

Test

/mA

t/ms

Start

Tripping Occurs

30 60 70

Measurement of Time to Trip

for AC-DC Sensitive RCCBs

L1

L2

L3

N

PE

red

blue

black

!

400 V

230 V

L1

L2

L3

red

blue

black

!

400 V

230 V

Page 5

GMC-I Messtechnik GmbH 5

4Operation

Overview

4.1 Loop Resistance Measurement Mode

with the PROFiTEST... with

Suppression of RCCB Triggering

➭ Connect the PROFiTEST DC-II to the system

under test:

The “Mains” lamp lights up green. The display

value is equal to or close to 0.

➭ If the polarity lamp lights up, reverse the poles

at the mains connection.

➭ Connect the PROFiTEST... via the earthing

contact outlet at the PROFiTEST DC-II mains

plug. Select positive half-wave for the R

Loop

/

Z

Loop

range (loop resistance).

➭ Set the selector switch to the I

F

position

and the slide switch to “undelayed”.

➭ Press the “START” key at the

PROFiTEST DC-II.

The “Active” lamp lights up.

➭ The “Measuring” lamp lights up after approxi-

mately 4 to 5 s.

The RCCB is disabled (disabling of the RCCB

lasts for approximately 30 s).

Magnetizing current is displayed in mA.

➭ Measure loop resistance with the

PROFiTEST... with the switch in the “R

Loop

/

Z

Loop

“ position after “positive half-wave to

earth” has been selected in the menu.

➭ After the measurement has been completed,

wait until the “Measuring” lamp has gone out,

followed by the “Active” lamp about 6 s later.

Disconnect the instrument from the system.

Attention!

!

The RCCB is disabled during operation and

measurement.

The RCCB must be tripped after measure-

ment with the PROFiTEST DC-II in order

to test for proper functioning.

Either activate the test button at the

RCCB, or perform a tripping test with the

PROFiTEST....

Important Notes

If the “R

Loop/ZLoop

> max.” lamp lights up, loop

resistance is greater than approximately 8 . Cor-

rect measurement is impossible in this case. The

fact that the lamp may flicker during measurement

is of no consequence.

If the “Temperature” lamp lights up, disconnect

the PROFiTEST DC-II from the mains and allow it

to cool.

4.2 Tripping Test Operating Mode

for DC Components in AC-DC Sensitive RCCBs

4.2.1 With Rising DC Residual Current

and Measurement of Tripping Current

for Undelayed RCCBs

➭ Connect the PROFiTEST DC-II to the system

under test:

The “Mains” lamp lights up green. The display

value is equal to or close to 0.

➭ If the polarity lamp lights up, reverse the poles

at the mains connection.

➭ Set the function selector switch to the I

F

position and the slide swItch to “undelayed”.

➭ Press the “START” key at the

PROFiTEST DC-II.

The “Active” lamp lights up.

Measurement Results:

a) Current rises until the RCD is tripped. Tripping

current is subsequently displayed for approximately 5 s.

or

b) If the RCD fails, current rises until saturation

current has been reached.

Saturation current is displayed in mA for

approximately 30 s, after which the displayed

current value again approaches 0.

Measurement RCCB Type Selector Switch Position Display

Loop Resistance Standard

I

F

undelayed PROFiTEST...

Triggering Current AC-DC Sensitive

I

F

undelayed PROFiTEST DC-II

Triggering Current AC-DC Sensitive, Delayed

I

F

PROFiTEST DC-II

Time to Trip AC-DC Sensitive 10/30/100/300/500 mA PROFiTEST DC-II

S

Page 6

6 GMC-I Messtechnik GmbH

4.2.2 With Rising DC Residual Current

and Measurement of Tripping Current

for Delayed RCCBs

Set the slide switch to the position in order to

determine tripping current for selective or shorttime-delay AC-DC sensitive RCCBs.

➭ Connect the PROFiTEST DC-II to the system

under test:

The “Mains” lamp lights up green. The displayed value is equal to or close to 0.

➭ If the polarity lamp lights up, reverse the poles

at the mains connection.

➭ Set the function selector switch to the I

F

position and the slide switch to .

➭ Press the “START” key at the

PROFiTEST DC-II.

The “Active” lamp lights up.

Measurement Results

Current rises continuously, but gradually, until the

RCD is tripped. Tripping current is then displayed

in mA for about 5 s.

This test may last as long as 1 minute.

4.2.3 With Constant DC Residual Current

and Measurement of Time to Trip

for Undelayed RCCBs

➭ Connect the PROFiTEST DC-II to the system

under test:

The “Mains” lamp lights up green. The displayed value is equal to or close to 0.

➭ If the polarity lamp lights up, reverse the poles

at the mains connection.

➭ Set the function selector switch to the 10, 30,

100, 300 or 500 mA position, depending

upon the rated current for the RCCB.

➭ Set the slide switch to the “undelayed” posi-

tion.

➭ Press the “START” key at the

PROFiTEST DC-II.

The “Active” lamp lights up and remains lit

until testing has been completed.

Time to trip is continuously displayed.

Measurement Results

a) Time to trip is displayed in ms for about 5 s

after tripping occurs or

b) If the RCD fails, or if the selected nominal

residual current value is too small, measurement is performed for a period of up to

2000 ms. Time overflow is indicated thereafter

by means of a flush left 1 at the display.

Note!

Test current is two times nominal residual

current in accordance with

DIN VDE 0664.

The AC components of AC-DC sensitive RCCBs

are to be tested with the PROFiTEST....

5 Characteristic Values

Line Voltage 230/400 V

(–10%, +25 %), 50 Hz

DC Residual Current

for Suppression of

RCCB Tripping DC 1.25 A +30%

* limited by means of maximum DC residual current (see above)

Temperature Ranges / Climatic Category

Operating Temperatures –10 C ... +50 C

Storage Temperatures –20 C ... +60 C

Electrical Safety

Protection Class II per IEC 61010-1/

EN 61010-1/

VDE 0411-1

Operating Voltage 300 V

Test Voltage 3.7 kV 50 Hz

Measurement Category II

Pollution degree 2

Internal Fuse electronic (PTC)

External Fuse cartridge fuse link

in plug:

5 mm x 20 mm:

FF 1.6/250

S

S

Measure-

ment

Measuring

Range

Measuring

Accuracy

Measurement

uncertainty

Tripping

Current

1 ... 1999 mA* (4 % rdg. + 5 d) (8% rdg. + 5 d)

Time to

Trip

2 ... 1999 ms (3 % rdg. + 5 d) (6 % rdg. + 5 d)

Selector Switch Position

for Measurement of Time to Trip

(nominal residual current)

Test Cur re n t

10 mA 20 mA +10%

30 mA 60 mA +10%

100 mA 200 mA +10%

300 mA 600 mA +10%

500 mA 1000 mA +10%

Page 7

GMC-I Messtechnik GmbH 7

Electromagnetic Compatibility (EMC)

Product standard DIN EN 61326:2006

Inputs and Outputs

The mains connection provides for power supply

and simultaneously functions as an output for test

and magnetizing current.

Mechanical Design

Protection housing: IP 40 per

DIN VDE 0470

Extract from table on the meaning of IP codes

Dimensions L x W x D:

205 mm x 120 mm x

100 mm (without power

cable)

Weight 1.5 kg (without power

cable)

6 Maintenance

6.1 Internal Fuse

An internal fuse protects the test instrument

against operator error.

If the instrument is overloaded with 400 V instead

of 250 V mains power, the electronic fuse is

tripped. LEDs may still be illuminated and characters may still appear at the display, but the instrument will not function if a test is started.

In such a case, wait for approximately 2 minutes

until the protective circuit has been deactivated

and the test instrument is once again ready for

operation.

6.2 External Fuse

The device connector cable is equipped with a

fuse.

Attention!

!

Be absolutely certain that only the specified fuses are used! If fuses are used

which demonstrate other blowing characteristics, rated current or breaking capacity, danger exists for the user, as well as

for damping diodes, resistors and other

components.

The use of repaired fuses or short-circuiting the

fuse holder is prohibited.

6.3 Housing

The test instrument may only be cleaned with a

soft cloth or brush. If the housing should become

statically charged, discharging may be performed

with an antistatic agent or a damp cloth.

6.4 Recalibration

The measuring tasks performed with your instrument, and the stressing it’s subjected to, influence

aging of its components and may result in deviation from the specified levels of accuracy.

In the case of strict measuring accuracy requirements, as well as in the event of use at construction sites with frequent stress due to transport and

considerable temperature fluctuation, we recommend a relatively short calibration interval of once

per year. If your instrument is used primarily in the

laboratory and indoors without considerable climatic or mechanical stressing, a calibration interval of once every 2 to 3 years is sufficient as a rule.

During recalibration* at an accredited calibration

laboratory (DIN EN ISO/IEC 17025), deviations

from traceable standards demonstrated by your

measuring instrument are documented. Ascertained deviations are used to correct displayed

values during later use of the instrument.

We would be happy to perform DAkkS or factory

calibration for you at our calibration laboratory.

Further information is available at our website:

www.gossenmetrawatt.com ( Company

DAkkS Calibration Center or FAQs Questions and Answers Regarding Calibration).

Recalibration of your instrument at regular intervals is essential for the fulfillment of requirements

according to quality management systems per

DIN EN ISO 9001.

* Examination of the specification, as well as adjustment,

are not included in calibration. However, in the case of

our own products, any required adjustment is performed and adherence to the specification is confirmed.

Interference

Emission

EN 55022 class B

Interference

Immunity

Test Valu e

EN 61000-4-2 Contact/Atmosphere - 4 kV/8 kV

EN 61000-4-3 10 V/m

EN 61000-4-4 Mains connection - 2 kV

EN 61000-4-5 Mains connection - 1 kV

EN 61000-4-6 Mains connection - 3 V

EN 61000-4-11 0.5 period / 100%

IP XY

(1st digit X)

Protection against

foreign object entry

IP XY

(2nd digit Y)

Protection against

the penetration of

water

4 1,0 mm

0 not protected

Page 8

Edited in Germany • Subject to change without notice • A pdf version is available on the internet

GMC-I Messtechnik GmbH

Südwestpark 15

90449 Nürnberg •

Germany

Phone +49 911 8602-111

Fax +49 911 8602-777

E-Mail info@gossenmetrawatt.com

www.gossenmetrawatt.com

6.5 Return and Environmentally Sound Disposal

The instrument is a category 9 product (monitoring and control instrument) in accordance with

ElektroG (German electrical and electronic device

law). This device is RoHS-compliant. Furthermore,

we make reference to the fact that the current status in this regard can be accessed on the Internet

at www.gossenmetrawatt.com by entering the

search term WEEE.

We identify our electrical and electronic

devices (as of August 2005) in accordance with WEEE 2002/96/EC and

ElektroG using the symbol shown at

the right per DIN EN 50419.

These devices may not be disposed of with the

trash.

Please contact our service department regarding

the return of old devices (see address in

section 7).

7 Repair and Replacement Parts Service

Calibration Center*

and Rental Instrument Service

When you need service, please contact:

GMC-I Service GmbH

Service Center

Thomas-Mann-Str. 20

90471 Nuremberg, Germany

Phone +49 911 817718-0

Fax +49 911 817718-253

E-mail service@gossenmetrawatt.com

www.gmci-service.com

This address is only valid in Germany.

Please contact our representatives or subsidiaries

for service in other countries.

* DAkkS Calibration Laboratory

for Electrical Quantities D-K-15080-01-01

accredited per DIN EN ISO/IEC 17025

Accredited measured quantities: direct voltage, direct

current values, DC resistance, alternating voltage,

alternating current values, AC active power, AC apparent power, DC power, capacitance, frequency and

temperature

Competent Partner

GMC-I Messtechnik GmbH is certified in accordance with DIN EN ISO 9001:2008.

Our DAkkS calibration laboratory is accredited by

the Deutsche Akkreditierungsstelle GmbH

(National accreditation body for the Federal

Republic of Germany) in accordance with DIN EN

ISO/IEC 17025:2005 under registration number

D-K-15080-01-01.

We offer a complete range of expertise in the field

of metrology: from test reports and proprietary cali-

bration certificates right on up to DAkkS calibration

certificates.

Our spectrum of offerings is rounded out with free

test equipment management.

An on-site DAkkS calibration station is an integral part

of our service department. If errors are discovered

during calibration, our specialized personnel are

capable of completing repairs using original

replacement parts. As a full service calibration laboratory, we can calibrate instruments from other

manufacturers as well.

8 Product Support

When you need support, please contact:

GMC-I Messtechnik GmbH

Product Support Hotline

Phone +49 911 8602-0

Fax +49 911 8602-709

E-mail support@gossenmetrawatt.com

Loading...

Loading...