Page 1

Operating Instructions

PROFITEST2

Tester DIN VDE 0100

3-349-491-03

8/12.14

Page 2

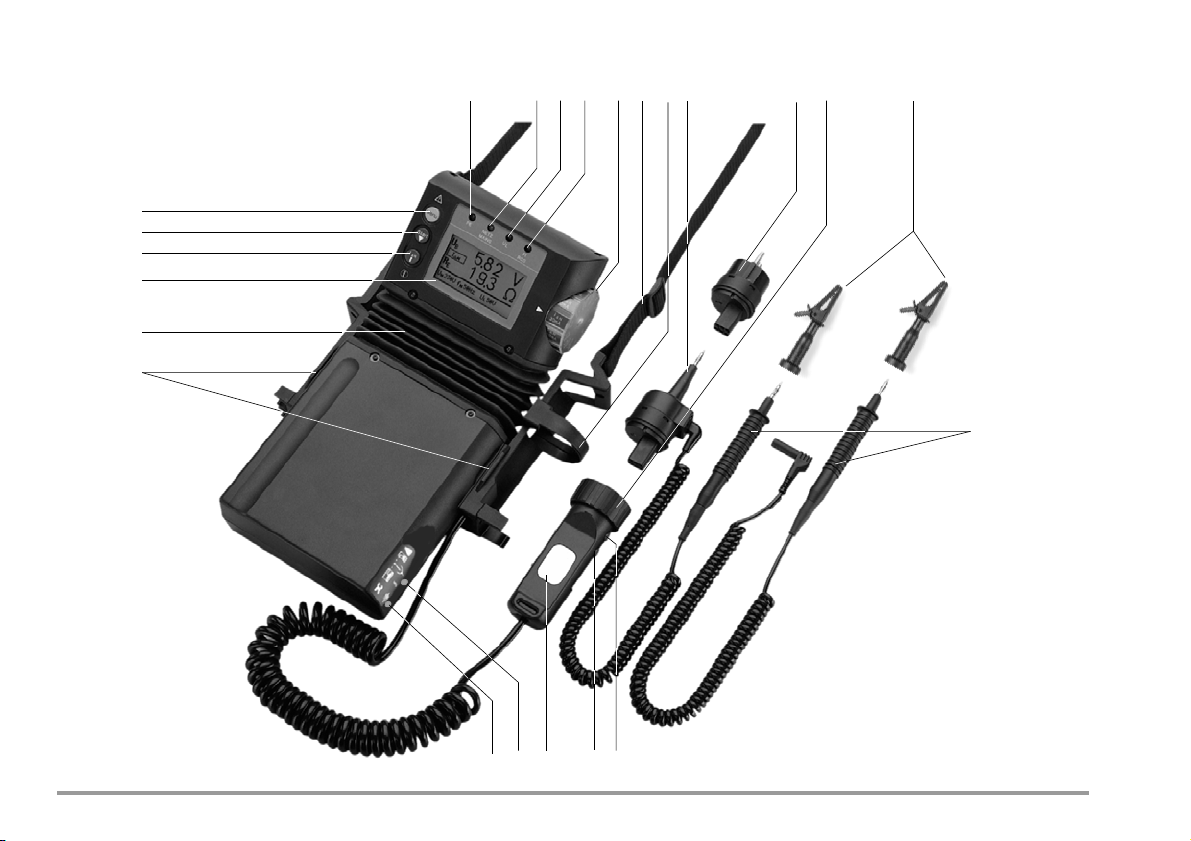

1

2

3

4

22

21

56789101112 1314

16

17181920

15

35

2 GMC-I Messtechnik GmbH

Page 3

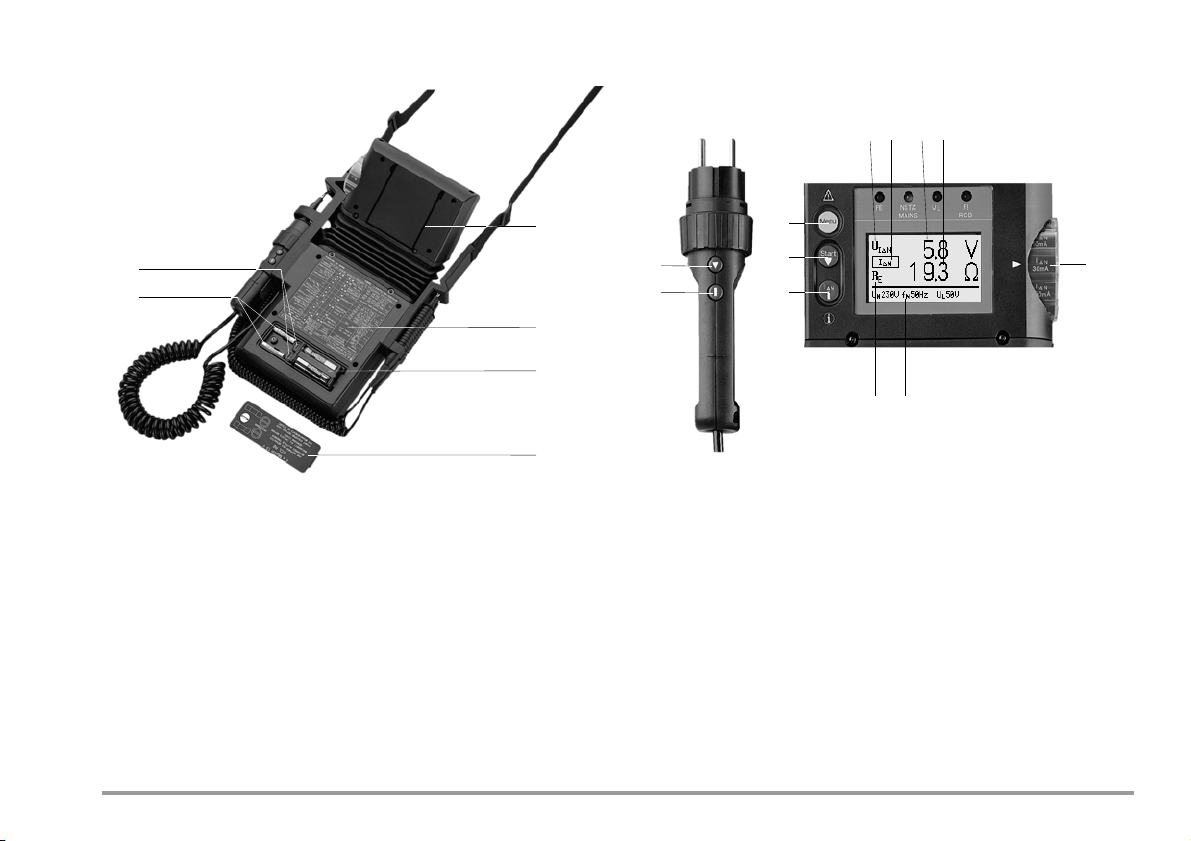

17

18

2

3

4

34 33

29 30 31 32

9

24

23

25

26

27

28

1 LC Display Field

/ i Key

2I

N

3Start Key

4Menu Key

5 PE Lamp

6 NETZ/MAINS Lamp

L/RL

Lamp

7U

8 FI/RCD Lamp

9 Function Selector Switch

10 Shoulder Strap

11 Test Plug Holder

GMC-I Messtechnik GmbH 3

12 Measuring Adapter (2-pole)

13 Plug Insert

(country specific)

14 Test Plug

(with retainer ring)

15 Alligator Clip

(plug-on)

16 Test Probes

17 Start Key

18 Key I

19 Contact Surfaces

20 Probe Connector Socket

21 Strap Eyelets

22 Swivel Hinge

23 Replacement Fuses

24 Fuses

25 Fold-Out Stand

26 Serial Plate

27 Battery Holder

28 Battery Compartment Lid

29 Measurement Value 1,

Abbreviated

30 Abbreviation for Selected

Sub-Function

31 Three Place Numeric Display: Measure-

32 Three Place Numeric Display: Measure-

33 Abbreviation for Selected Sub-Function,

34 Measurement Value 2, Abbreviated

35 Charging Socket / Current Transformer

ment Value 1 with Unit of Measure

ment Value 2 with Unit of Measure

Messages and Help

Connector Jack

Page 4

Contents Page Contents Page

1 Applications ..................................................................................6

7.3 Testing for Special RCDs ...............................................................25

7.3.1 Systems with Selective RCDs ......................................................... 25

2 Safety Features and Precautions ..................................................7

7.3.2 Type G RCCBs ..............................................................................27

7.4 Testing with Adjustable Residual Current ........................................28

3 Initial Start-Up ..............................................................................8

3.1 Installing or Replacing Batteries .......................................................8

7.5 Testing RCDs in IT Systems ...........................................................28

7.6 Testing Residual Current Circuit Breakers in TN-S Systems .............30

3.2 Selecting a Language, Basic Function and Sub-Function Settings ......8

3.3 Battery Test ....................................................................................9

3.4 Recharging the rechargeable Batteries ...........................................10

4 Abbreviated Instructions for Quick Initial Start-Up .....................12

5 General Instructions ...................................................................14

5.1 Connecting the Instrument .............................................................14

5.2 Automatic Settings, Monitoring and Shut-Off ..................................14

5.3 Measurement Value Display ...........................................................15

5.4 Testing Earthing Contact Sockets for Correct Connection .................15

5.5 Help Function ...............................................................................16

Testing of Breaking Requirements for Overcurrent Protective Devices,

8

Measurement of Loop Impedance and Determination of ShortCircuit Current (functions Z

and IK) ......................................31

Loop

8.1 Measurement with Positive or Negative Half-Waves ........................32

8.2 Evaluation of Measurement Values .................................................33

8.3 Loop Impedance Measurement

– Measurement via and without tripping the RCCB .........................33

8.4 Testing Meter Start-Up with the Adapter ......................................... 34

9 Measuring Supply Impedance (function Z

) ................................35

I

9.1 Testing Meter Start-Up with Earthing Contact Adapter .....................36

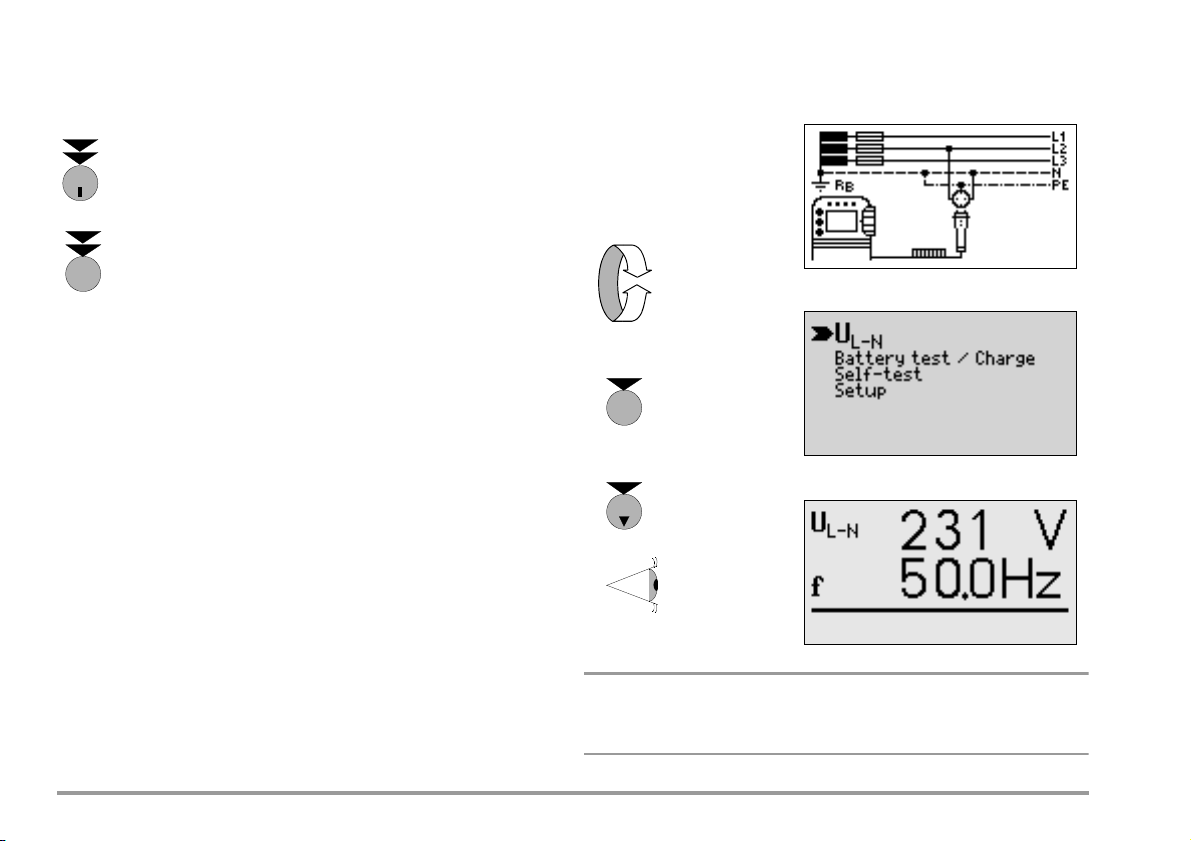

6 Measuring Alternating Voltage and Frequency ...........................16

6.1 Voltage between L and N (U

) .....................................................16

L-N

6.2 Voltage between L and PE, N and PE, as well as L and N ................17

6.3 Voltage between the Probe and PE (U

) ......................................18

S-PE

10 Earthing Resistance Measurement (function R

) .......................37

E

10.1 Measuring with Probe ...................................................................38

10.2 Measuring without Probe ...............................................................38

10.3 Evaluation of Measurement Values .................................................39

6.4 Measuring Current with a Clip-On Current Transformer ...................18

11 Measuring Insulation Resistance

7 Testing RCDs ..............................................................................20

7.1 Measuring Contact Voltage (with reference to nominal residual current)

with 1/3 Nominal Residual Current and Tripping Test with Nominal Re-

sidual Current ...............................................................................20

(Function R

11.1 Insulation Measurement with Rising Test Voltage ............................ 41

11.2 Evaluation of Measurement Values .................................................42

11.3 Setting the Limit Value ..................................................................42

) ............................................................................40

ISO

7.2 Special Testing for Systems and RCCBs .........................................23

7.2.1 Testing for Systems and RCCBs with Rising Residual Current ..........23

7.2.2 Testing of RCCBs which are Suited for

Pulsating DC Residual Current .......................................................24

4 GMC-I Messtechnik GmbH

Page 5

Contents Page Contents Page

12 Measuring Low-Value Resistance of up to 100

(protective conductor and bonding conductor) .......................... 42

12.1 Measuring Low-Value Resistance (function RLO) ............................. 42

12.2 Compensation for Extension Cables of up to 10

(function R

) ............................................................................ 44

LO

12.3 Calculation of Cable Lengths for Common

Copper Conductors ....................................................................... 45

17 Appendix .................................................................................... 61

17.1 Table 1 ........................................................................................ 61

17.2 Table 2 ........................................................................................ 61

17.3 Table 3 ....................................................................................... 62

17.4 Table 4 ....................................................................................... 62

17.5 Table 5 ........................................................................................ 63

17.6 List of Abbreviations and their Meanings ........................................ 64

12.4 Setting the Limit Value ..................................................................45

18 Repair and Replacement Parts Service

13 Phase Sequence Testing ............................................................ 46

Calibration Center and Rental Instrument Service .......................... 65

14 Operating and Display Elements ................................................47

15 Characteristic Values ................................................................ 52

19 Recalibration .............................................................................. 65

20 Product Support ......................................................................... 66

15.1 Lamp Functions ............................................................................ 56

16 Maintenance ..............................................................................57

16.1 Self-Test ...................................................................................... 57

16.2 Battery and Rechargeable Battery Operation, and Charging ............. 59

16.3 Fuses .......................................................................................... 60

16.4 Housing ....................................................................................... 60

16.5 Device Return and Environmentally Compatible Disposal .................60

GMC-I Messtechnik GmbH 5

Page 6

1 Applications

!

–

+

The PROFITEST 2 test instrument allows for quick and effective

testing of protective measures in accordance with DIN VDE 0100

part 610:2004, ÖVE-EN 1 (Austria), NIV/NIN SEV 1000 (Switzerland), as well as regulations specific to additional countries.

The device is equipped with a microprocessor and complies with

IEC 61557/EN 61557/VDE 0413 regulations:

Part 1: General requirements

Part 2: Insulation resistance testers

Part 3: Loop resistance testers

Part 4: Instruments for the measurement of resistance at earth-

ing conductors, protective conductors and bonding con-

ductors

Part 5: Earthing resistance testers

Part 6: Instruments for the testing of proper functioning of resid-

ual current devices (RCDs) and the effectiveness of pro-

tective measures in TT and TN systems

Part 7: Phase sequence testers

Part 10: Electrical safety in low-voltage systems

It is especially suited for:

•Systems set-up

• Initial start-up

• Periodic testing

• Troubleshooting for electrical systems

All measurement values required for approval reports (e.g. ZVEH)

can be acquired with the instrument.

The applications range of the PROFITEST 2 covers all alternating

and three-phase current systems with nominal voltages of 230 V

(240 V if “English/UK-parameter” has been selected in setup) /

400 V (300 V / 500 V) and nominal frequencies of 162/3/ 50 /

60 / 200 / 400 Hz.

The following measurements and tests can be performed with the

PROFITEST 2:

• Voltage / frequency / phase sequence

• Loop impedance / line impedance

• RCD protection

• Earthing resistance

• Insulation resistance

• Low-value resistance (potential equalization)

• Leakage currents with clip-on current transformer

• Meter start-up

•Cable length

Meaning of Symbols on the Instrument

Warning concerning a point of danger

(Attention, observe documentation!)

Safety class II device

9 V DC charging socket

for battery charger

This device and the inserted (rechargeable) batteries

may not be disposed of with the trash.e trash.

Further information regarding the WEEE mark can be

accessed on the Internet at www.gossenmetrawatt.com by entering the search term ’WEEE’.

EC label of conformity

6 GMC-I Messtechnik GmbH

Page 7

2 Safety Features and Precautions

Note

This instrument fulfills the requirements of the applicable European and national EC guidelines. We confirm this with the CE

marking. The relevant declaration of conformity can be obtained

from GMC-I Messtechnik GmbH.

The PROFITEST 2 electronic measuring and test instrument is manufactured and tested in accordance with safety regulations

IEC 61010-1/EN 61010-1/VDE 0411-1.

When used for its intended purpose, safety of the operator, as

well as that of the instrument, is assured.

Read the operating instructions thoroughly and carefully before placing

your instrument into service, and follow all instructions contained

therein. Make sure that the operating instructions are available to all

users of the instrument.

Tests may only be performed under the supervision of a qualified electrician. The user must be instructed by a qualified electrician concerning

performance and evaluation of the test.

Manufacturers and importers of electrical medical devices must

provide documentation for the performance of maintenance by

trained personnel.

The measuring and test instrument may not be placed into service:

• if the battery compartment lid has been removed

• if external damage is apparent

• if connector cable or measuring adapters are damaged

• if the instrument no longer functions flawlessly

• after a long period of storage under unfavorable conditions

(e.g. moisture, dust, extreme temperatures).

Exclusion of Liability

When testing systems with RCCBs, the latter may switch off. This

may occur even though the test does not normally provide for it.

Leakage currents may be present which, in combination with the

test current of the test instrument, exceed the shutdown threshold value of the RCCB. PCs which are operated in proximity to

such RCCB systems may switch off as a consequence. This may

result in inadvertent loss of data. Before conducting the test, precautions should therefore be taken to ensure that all data and

programs are adequately saved and the computer should be

switched off, if necessary. The manufacturer of the test instrument assumes no liability for any direct or indirect damage to

equipment, computers, peripheral equipment or data bases when

performing the tests.

Grip and hold the test plug and test probes securely when they

have been inserted, for example, into a socket. Danger of injury

exists if tugging at the coil cord occurs, which may cause the test

plug or test probes to snap back.

GMC-I Messtechnik GmbH 7

Opening of Equipment / Repair

The equipment may be opened only by authorized service personnel to ensure the safe and correct operation of the equipment

and to keep the warranty valid.

Even original spare parts may be installed only by authorized service personnel.

In case the equipment was opened by unauthorized personnel,

no warranty regarding personal safety, measurement accuracy,

conformity with applicable safety measures or any consequential

damage is granted by the manufacturer.

Page 8

3 Initial Start-Up

Attention!

Note

Attention!

MENU

START

MENU

START

MENU

!

!

U

L-N

3.1 Installing or Replacing Batteries

Before opening the battery compartment, disconnect the

instrument from the measuring circuit (mains) at all poles!

Six commercially available 1.5 V mignon cells in accordance with

IEC LR 6 are required for operation of the PROFITEST 2.

Only alkaline manganese cells may be used which comply with

IEC LR 6. The use of zinc-carbon batteries is to be avoided due

their short service life.

3.2 Selecting a Language, Basic Function and Sub-Function Settings

Rechargeable NiCd or NiMH cells may also be used. See

also chapter 16.2 on page 59 concerning charging and

the battery charger.

Always replace batteries in complete sets.

Dispose of batteries in an environmentally sound fashion.

Ð Loosen the slotted screw at the Battery Compartment Lid (28)

and remove the lid.

Ð Pull the Battery Holder (27) out with the strap and insert six

1.5 V mignon cells with plus and minus poles in accordance

with the symbols on the holder.

Ð Insert the Battery Holder (27) with batteries into the battery

compartment (strap must be positioned beneath the holder).

The holder can only be inserted in its proper position.

Ð Replace the lid and retighten the screw.

The instrument may only be placed into service if the

battery compartment lid is securely fastened!

8 GMC-I Messtechnik GmbH

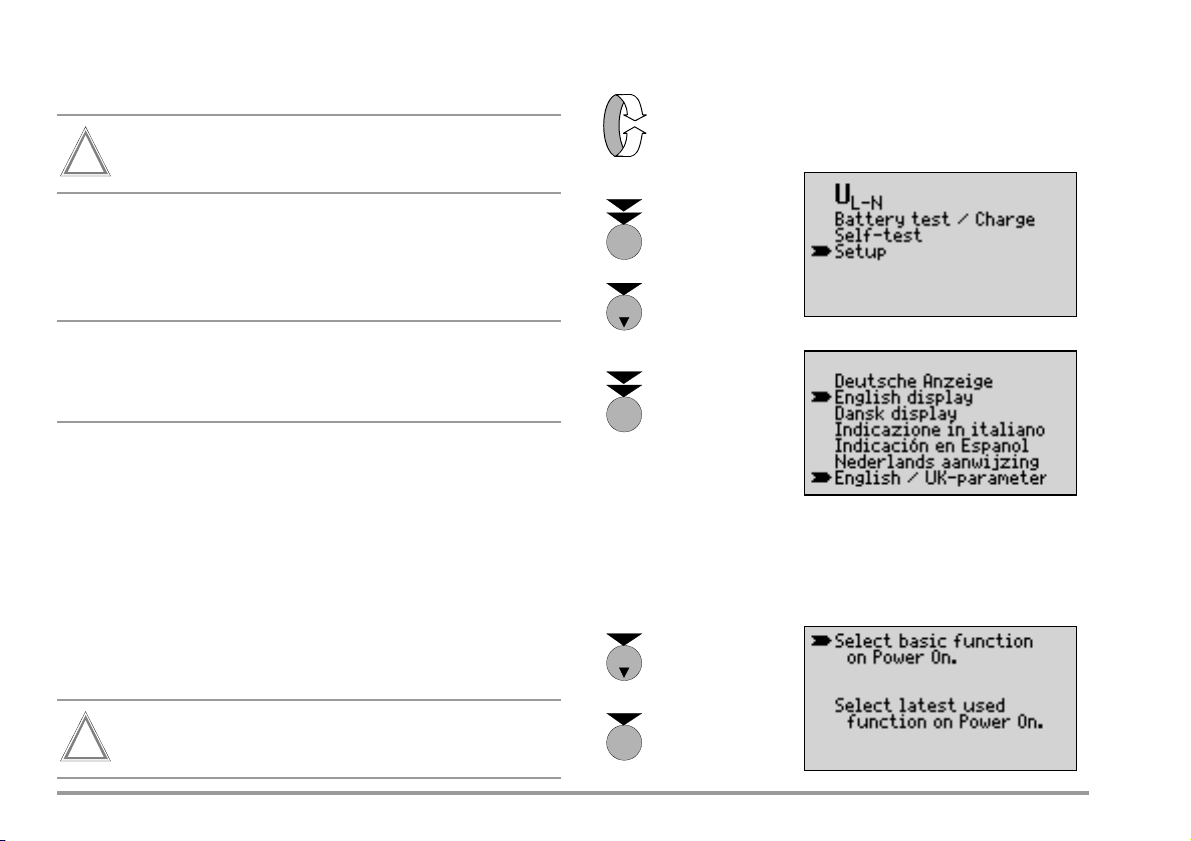

Any of the available languages can be selected by

pressing the Menu Key (4).

If the “English/UK-parameter” has been selected, the following

differences apply to the other menu items:

• Nominal voltage of 240 V instead of 230 V

• RCD trip test includes 2 sec. at 50% (nominal fault)

current before RCD is tripped

• No autom. change Phase to Neutral for socket outlets wired incorrectly

Page 9

By pressing the Menu Key (4), you can determine whether the

Note

START

MENU

START

MENU

MENU

START

Note

U

L-N

basic instrument functions are made available when the instrument is switched on, or if the last selected sub-function is made

available for immediate measurement.

The basic functions are selected automatically if the Function Selector Switch (9) has been activated. If the device is

in self-test mode, self-testing must first be completed!

Display Illumination

Display illumination can be deactivated by pressing the Menu Key

(4) in order to extend the service life of the batteries.

On-Time

The period of time after which the test instrument is automatically

shut off can be selected here with the Menu Key (4).

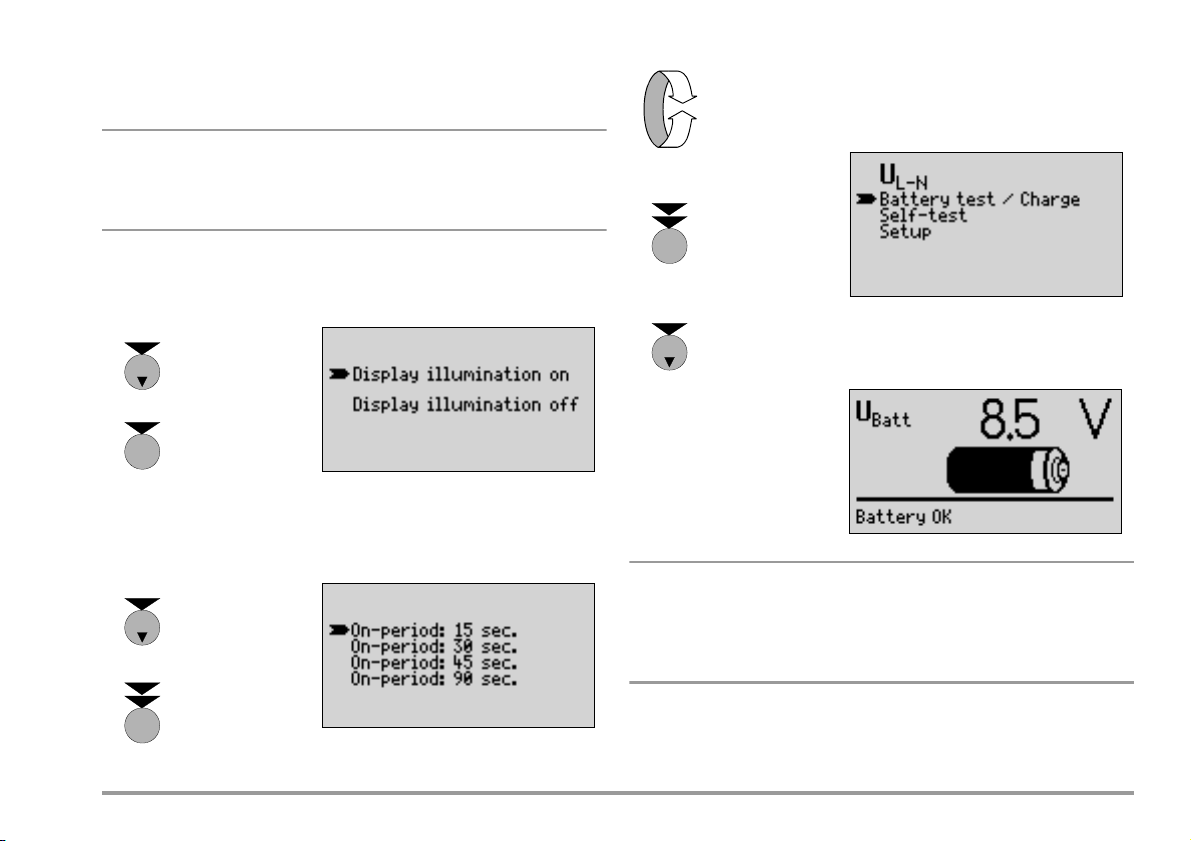

3.3 Battery Test

Batteries or rechargeable batteries are tested under load

conditions. When the Start Key (3 or 17) is activated,

the NETZ/MAINS, UL/RL and FI/RCD lamps light up

briefly for this reason.

The selected on-time has as substantial influence on battery service life.

GMC-I Messtechnik GmbH 9

Page 10

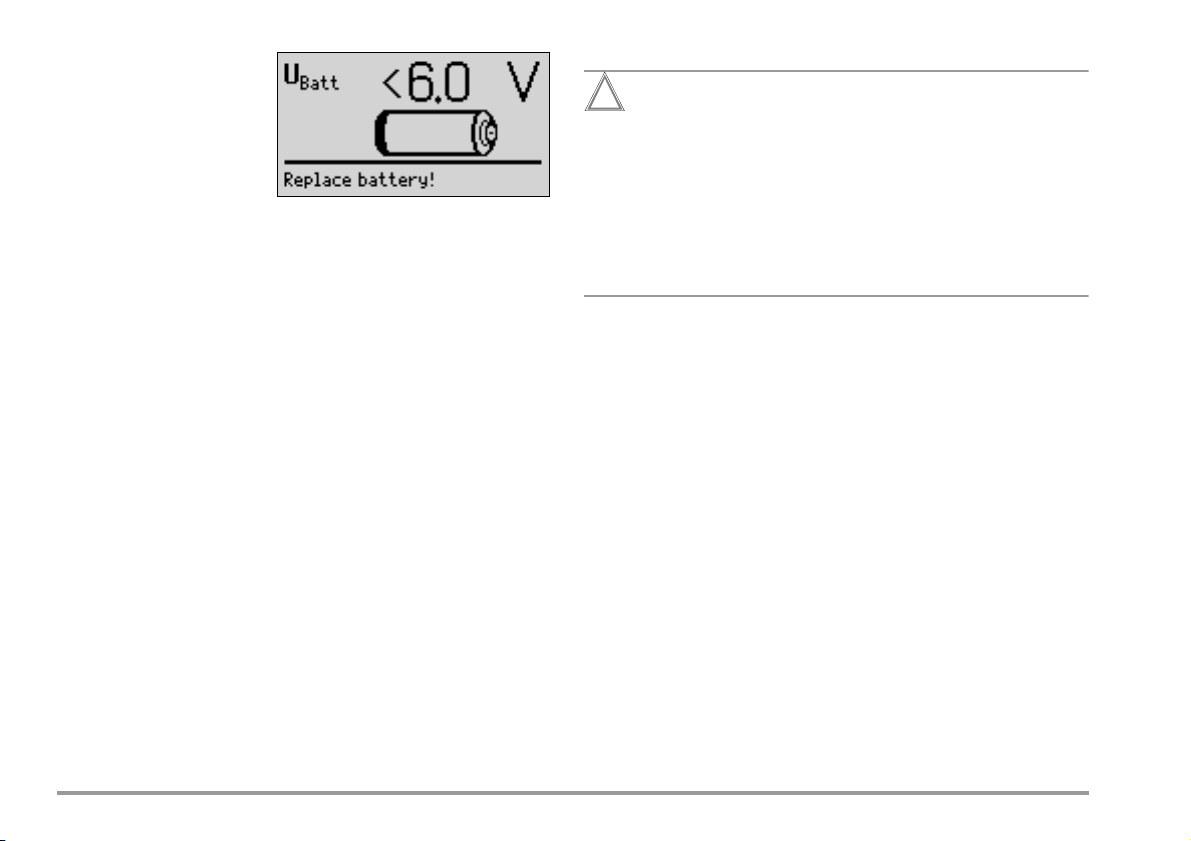

If battery voltage has fallen

Attention!

!

below the allowable lower

limit, the symbol to the

right appears:

The instrument does not

function if the batteries

have been depleted excessively, and no display

appears.

3.4 Recharging the rechargeable Batteries

Use only the NA101 (article no. Z501M) battery charger

with reliable electrical insolation for the recharging of batteries.

Before connecting the charger to the charging socket

make certain that:

– Rechargeable batteries have been installed

(not standard batteries)

– The instrument has been disconnected from the

measuring circuit at all poles

Connect the NA101 battery charger to the charging socket at the

side of the housing bottom with the 3.5 mm jack plug.

Charging is started with the same procedure as used for the battery test. The instrument detects the presence of the charger and

initiates the charging process.

Depleted batteries (display < 6 V) require approximately 4 hours

for complete charging. The test instrument cannot be switched

on if the batteries are severely depleted. In such a case, leave the

instrument switched on with battery charger connected for about

30 minutes, and then proceed as described above.

10 GMC-I Messtechnik GmbH

Page 11

This page was intentionally left free.

GMC-I Messtechnik GmbH 11

Page 12

4 Abbreviated Instructions for Quick Initial Start-Up

U

L-NUL-PE

I

N

10 mA

I

N

30 mA

The performance of measurements and testing with the

PROFITEST 2 is quick and easy.

The integrated on-line help and the abbreviated instructions are

sufficient for most measurements. Nevertheless, you should read

and observe the instructions which follow these abbreviated

instructions as well.

Term in ol og y

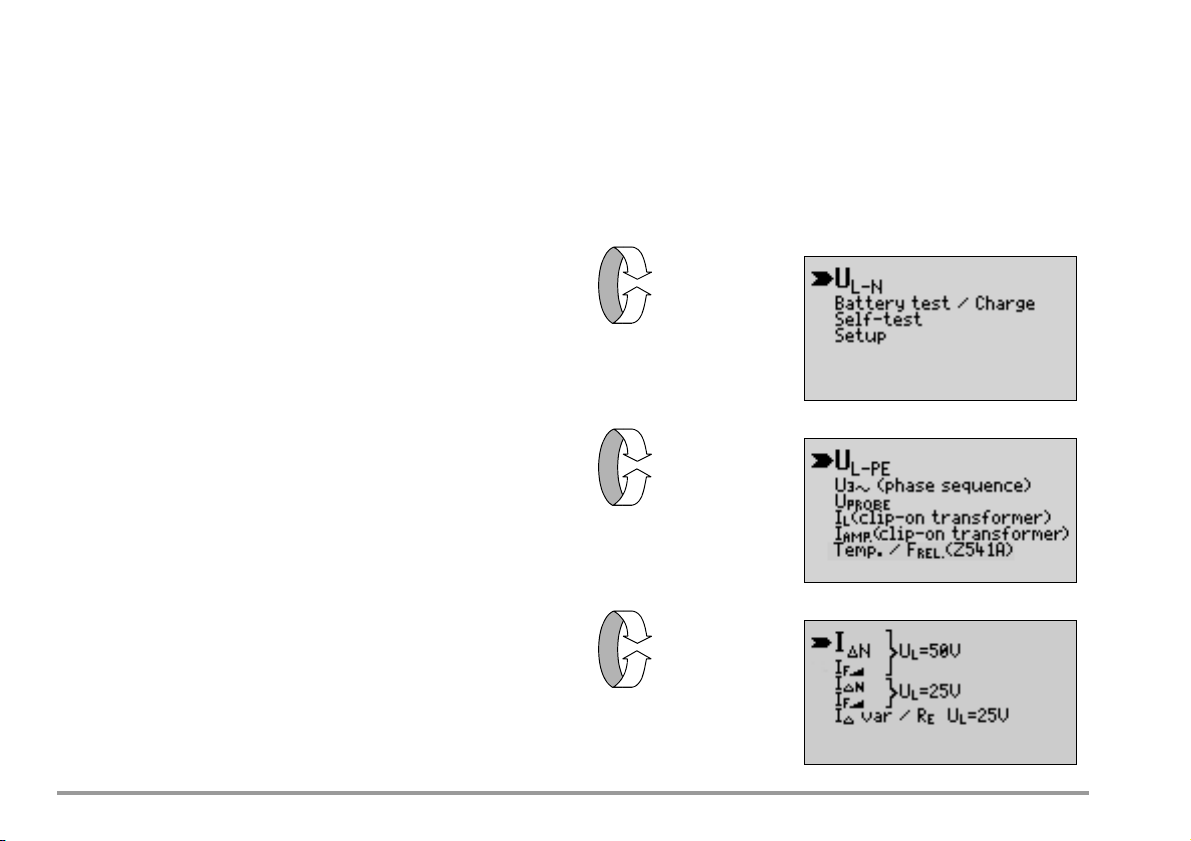

Basic Function The basic functions are selected with the Func-

tion Selector Switch (9). The basic function is

the first entry in the menu window and is automatically selected when the function selector

switch is activated.

Sub-Function Functions which are subordinate to the basic

function in the menu window. Sub-functions

are selected with the yellow Menu Key (4), and

are subsequently highlighted with the arrow.

Measurements can be performed as follows for all measuring

functions:

ò Select the basic function with the Function Selector Switch (9)

Ð Turn the Function Selector Switch (9) to the desired basic func-

tion.

After a basic function or a sub-function has been selected as

described below, the corresponding circuit diagram can be queried at the LC Display Field (1) by pressing the IN / i key

(2 or 18).

ä Selecting a basic function or a sub-function with the Menu Key (4)

When the Menu Key (4) is first activated, the instrument is

switched on. The basic function and its corresponding

sub-functions are displayed in the menu:

ù Connect the test instrument

Ð Connect the Test Plug (14) with attached Plug Insert (13) to the

mains outlet, or connect the instrument directly in a 2-pole

mannerwith the plug-on Measuring Adapter (2-pole) (12).

12 GMC-I Messtechnik GmbH

Page 13

Ð Repeatedly press the Menu Key (4) until the arrow points to the

IN100 mA

I

N

300 mA

I

N

500 mA

Z

Loop

ZIRER

ISORLO

desired function.

On-line help can be queried for any selected function with the

I

/ i keys (2 or 18).

N

The selection of a function is not necessary if basic functions and

sub-functions have been pre-configured as described.

ë Start measurement with the Start Key (3 or 17) and

read measurement results

Ð Press the I

the instrument has shut itself off automatically) in order to perform the tripping test for RCCBs.

GMC-I Messtechnik GmbH 13

key (2 or 18) during the on-time period (before

N

Page 14

5 General Instructions

5.1 Connecting the Instrument

For systems with earthing contact sockets, connect the instrument with the Test Plug (14), on which the Plug Insert (13) is

attached, to the mains. Voltage between phase conductor L and

the PE protective conductor may not exceed 253 V!

Poling at the socket need not be taken into consideration. The

instrument detects the positions of phase conductor L and neutral conductor N, and automatically reverses poles if necessary.

This does not apply to the following measurements:

– Voltage measurement in selector switch position U

– Insulation resistance measurement

– Low-value resistance measurement

– Phase sequence testing

– Selection of “English/UK-parameter” in setup. In this case no

automatic pole reversal occurs.

The positions of phase conductor L and neutral conductor N are

identified at the Plug Insert (13).

If measurement is to be performed at three-phase outlets, at distribution cabinets or at permanent connections, the Measuring

Adapter (2-pole) (12) must be fastened to the Test Plug (14) (see

also chapter 15.1). Connection is established with the test

probes: one at PE or N and the other at L.

The 2-pole measuring adapter must be expanded to 3 poles with

the included measurement cable for the performance of phase

sequence testing. Measurements with the Measuring Adapter (2pole) (12) are not possible with the Function Selector Switch (9) in

the U

in selector switch positions U

or ZI positions. These measurements can be performed

L-N

L-PE

and Z

Loop

.

Contact voltage (during RCCB testing) and earthing resistance

can be, probe voltage and RCCB performance in IT systems must

be measured with a probe. The probe is connected to the Probe

Connector Socket (20) with a 4 mm contact protected plug.

L-PE

5.2 Automatic Settings, Monitoring and Shut-Off

The PROFITEST 2 automatically sets all operating conditions which

it is able to determine itself. It tests line voltage and frequency. If

these lie within their valid nominal ranges, they appear at the LC

Display Field (1). If they are not within nominal ranges, prevailing

voltage (U) and frequency (f) are displayed instead of U

Line voltage fluctuations have no effect on measurement results.

Contact voltage which is induced by test current is monitored for

each measuring sequence. If contact voltage exceeds the limit

value of > 25 V or > 50 V, measurement is immediately interrupted. The UL (7) lamp lights up red.

If battery voltage falls below the allowable limit value the instrument

cannot be switched on, or it is immediately switched off.

The measurement is interrupted automatically, or the measuring

sequence is blocked (except for voltage measuring ranges and

phase sequence testing) in the event of:

• non-allowable line voltages (< 60 V, > 253 V / > 330 V /

> 440 V or > 550 V) for measurements which require line voltage

• interference voltage during insulation resistance or low resis-

tance measurements

• overheating at the instrument.

As a rule, excessive temperatures only occur after approximately 500 measurement sequences at intervals of 5 s, when

the Function Selector Switch (9) is set to the Z

tion.

If an attempt is made to start a measuring sequence, an appropriate message appears at the LC Display Field (1).

or ZI posi-

Loop

and fN.

N

14 GMC-I Messtechnik GmbH

Page 15

The instrument only switches itself off automatically after comple-

Note

Attention!

!

tion of an automatic measuring sequence, and after the predetermined on-time has expired (see chapter 3.2). On-time is reset to

its original value as defined in the setup menu, as soon as any key

or the Function Selector Switch (9) is activated.

The instrument remains on for approximately 75 s in addition to

the preset on-time for measurements with rising residual current

in systems with selective RCDs.

The instrument always shuts itself off automatically!

5.3 Measurement Value Display

The following appear at the LC Display Field (1):

• Measurement values with abbreviations and units of measure

• Selected function

• Nominal voltage

• Nominal frequency

• Error messages

Measurement values for automatic measuring sequences are

stored and displayed as digital values until the next measurement

sequence is started, or until automatic shut-off occurs.

If the measuring range upper limit is exceeded, the upper limit

value is displayed and is preceded by the “>” symbol (greater

than), which indicates measurement value overrun.

5.4 Testing Earthing Contact Sockets for Correct Connection

The testing of earthing contact sockets for correct connection

prior to protective measures testing is simplified by means of the

instrument’s error detection system. The instrument indicates

improper connection as follows:

• Non-allowable line voltage (< 60 V or > 253 V):

The NETZ/MAINS Lamp (6) blinks red and the measuring sequence is blocked.

• Protective conductor not connected or potential to earth 100 V at f >

45 Hz: The PE Lamp (5) lights up red when contact is made

with the Contact Surfaces (19).

The measurement is not blocked when the lamp is lit. It does

not light up, i.e. is not functional, when the instrument is

switched on and the Function Selector Switch (9) is in the U

or the Z

position (see Lamp Functions on page 56).

I

L-N

If the instrument is off and the selector switch is in the

U

or the ZI position, the red PE lamp may light up if

L-N

contact is made with the Contact Surfaces (19), and if the

terminal designated N at the plug insert is connected to

the phase conductor at the socket.

• Neutral conductor N not connected:

The NETZ/MAINS Lamp (6) blinks green

(see Lamp Functions on page 56).

• One of the two protective contacts is not connected:

Testing for this condition is performed automatically for the FI,

Z

, Z

and RE functions. Poor contact resistance at one of

I

Loop

the contacts leads to one of the following displays depending

upon poling of the plug:

– A value of only approximately half the anticipated line voltage

is displayed.

– A “STOP-sign” with the following warning appears: “Earthing

resistance to high or defective fuse”.

Reversal of N and PE in a system without RCCBs cannot

be detected and is not indicated by the instrument. If an

RCCB is present in the system, it is tripped during Z

measurement if N and PE have been reversed.

I

GMC-I Messtechnik GmbH 15

Page 16

5.5 Help Function

MENU

START

Note

I

N

MENU

U

L-N

The appropriate circuit diagrams and on-line help can be queried

at the LC Display Field (1) for each of the basic functions and subfunctions, after these have been selected in the corresponding menu.

Press the I

diagram. Press the same key again to alternate between

the circuit diagram and on-line help.

Press the Menu Key (4) to exit the help function.

/ i key (2 or 17) once to display the circuit

N

6 Measuring Alternating Voltage and Frequency

6.1 Voltage between L and N (U

Set-Up

L-N

)

Measurements cannot be made with the Measuring

Adapter (2-pole) (12) in the U

16 GMC-I Messtechnik GmbH

function!

L-N

Page 17

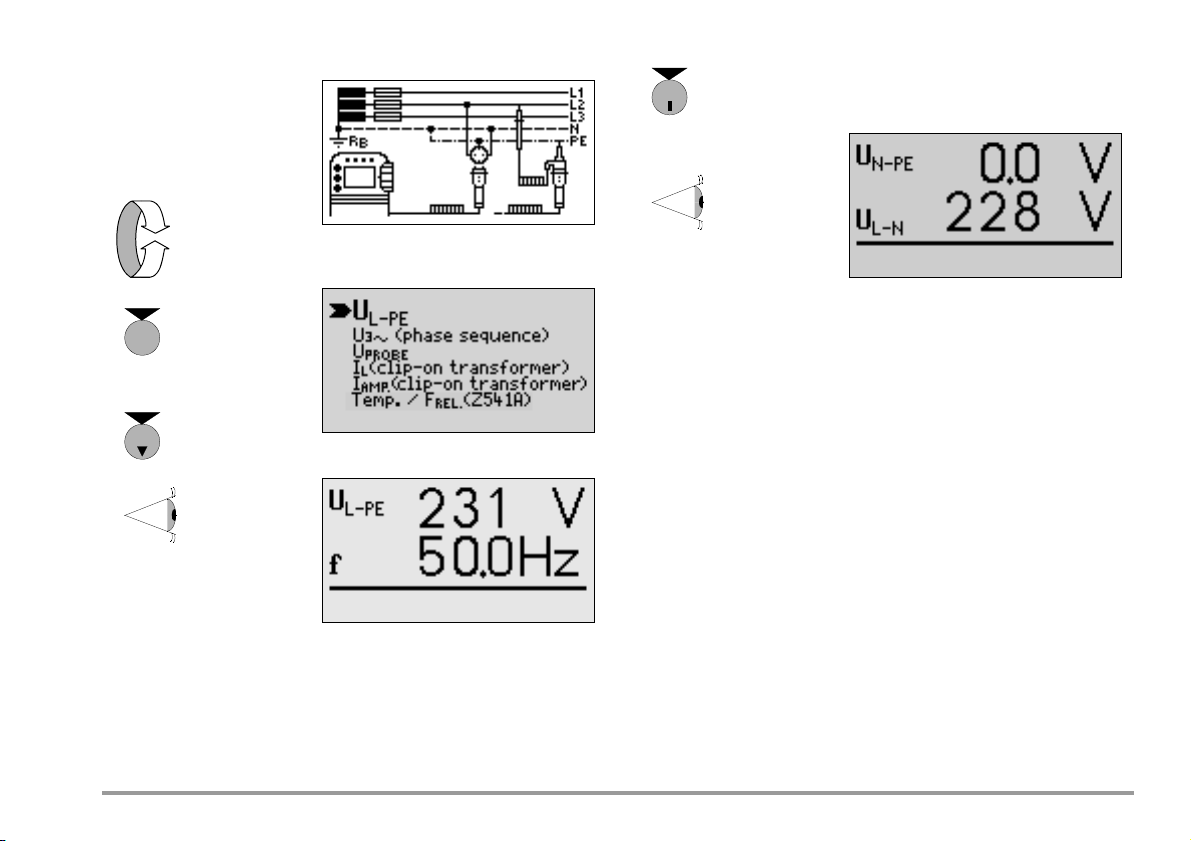

6.2 Voltage between L and PE, N and PE, as well as L and N

MENU

START

I

N

U

L-PE

Set-Up

The display is switched to the other two voltages measured at the

socket by pressing the I

be recalled by pressing the START key.

GMC-I Messtechnik GmbH 17

/ i key. The previous display can only

N

Page 18

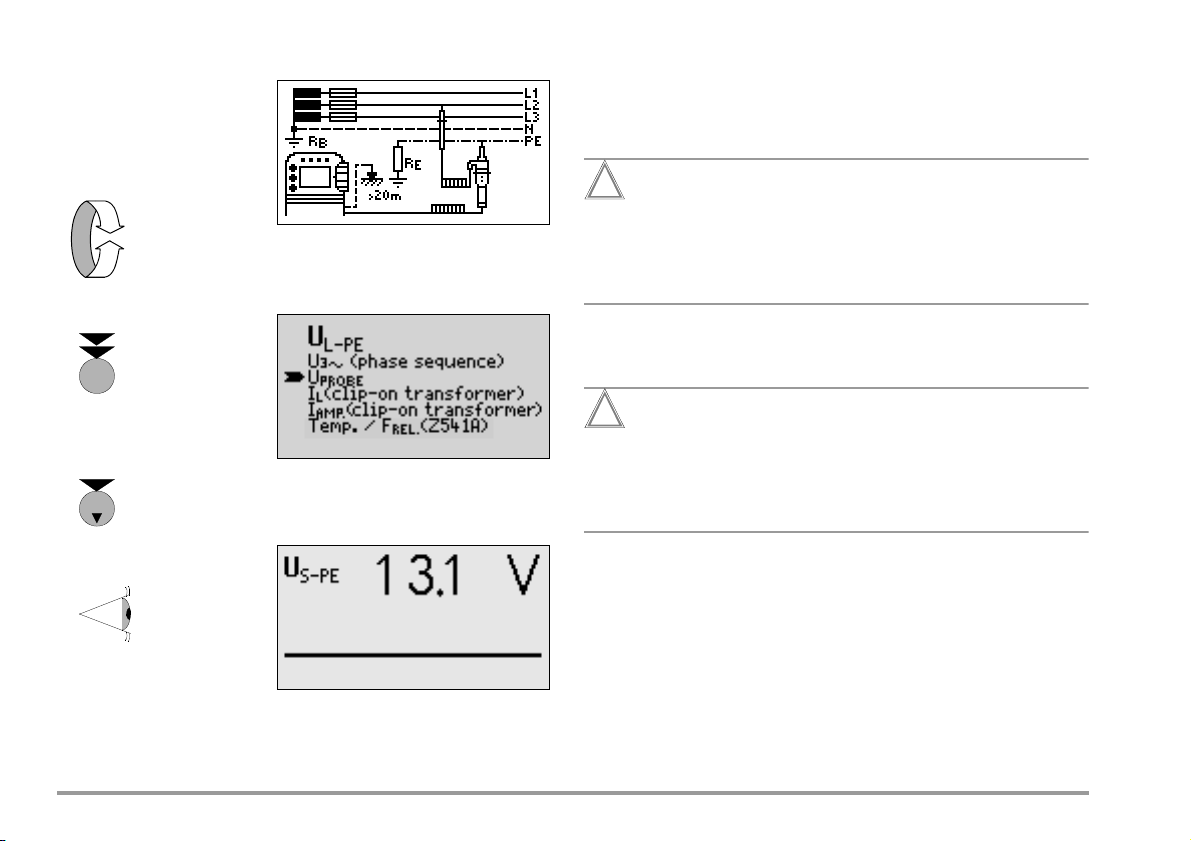

6.3 Voltage between the Probe and PE (U

MENU

START

Attention!

!

Attention!

!

U

L-PE

Set-Up

S-PE

)

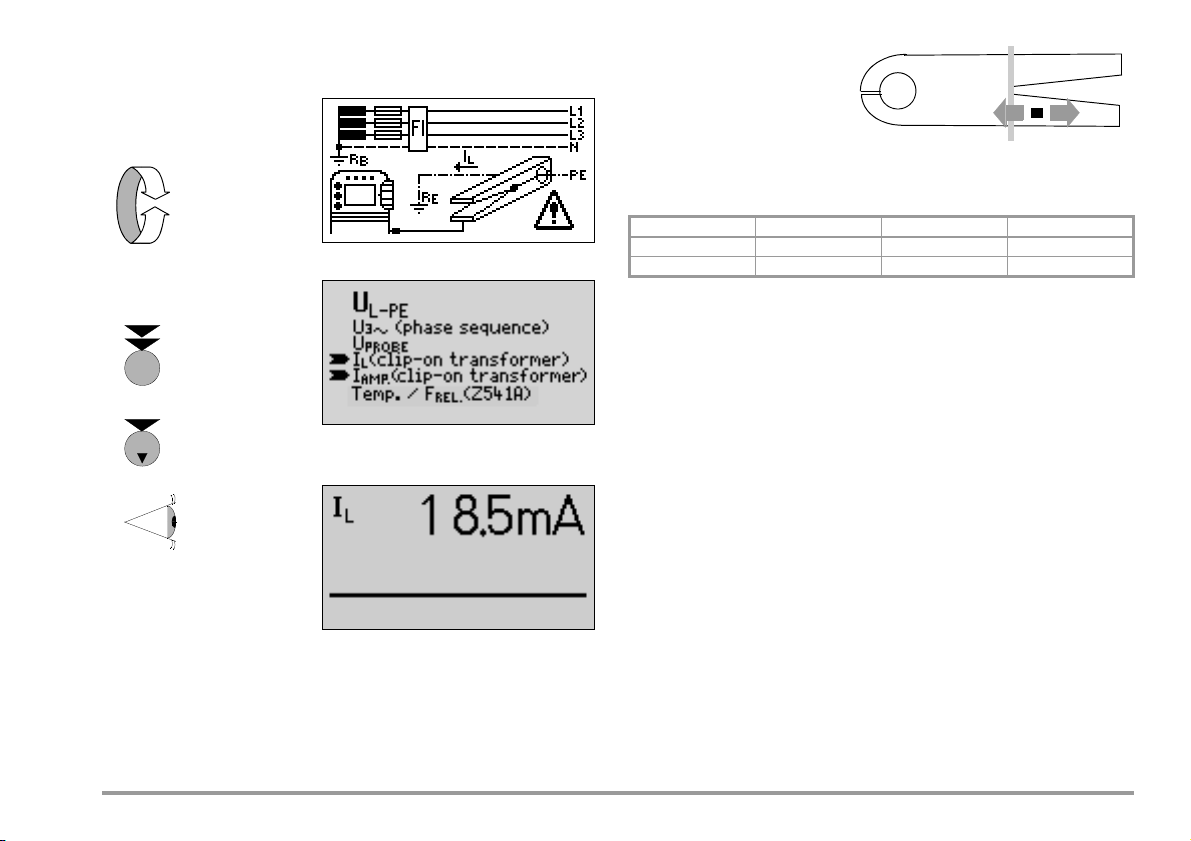

6.4 Measuring Current with a Clip-On Current Transformer

Bias, leakage and circulating current to 1 A, as well as leakage

current to 150 A can be measured with the help of the

0100S Clip, special clip-on current transformer, which is connected at the charging socket.

High-Voltage Danger!

Use only the above mentioned clip-on current transformer.

Other current clips may not be terminated with an output

load at the secondary side. Dangerously high voltage may

endanger the user and the device in such cases.

The maximum allowable operating voltage is equal to the nominal

voltage of the current transformer. Take additional display error

into consideration when reading the measurement value.

Do not, under any circumstances, connect any accessories to the charging socket which have not been recommended and approved by GMC-I Messtechnik GmbH!

The instrument and the user may otherwise be endangered and may suffer damage or injury.

All other instrument test functions are blocked if the clip-on current transformer or the battery charger is connected. If you nevertheless attempt to activate another function, the following message appears: “remove adapter”. No testing is performed. After

the clip-on current transformer or the battery charger has been

removed, this message disappears automatically for functions

involving long-term measurements (e.g. voltage measurement).

For other functions it disappears as soon as a new measurement

is started, or when a new function is selected.

18 GMC-I Messtechnik GmbH

Page 19

If no clip-on current transformer has been connected for the IL or I

MENU

START

U

L-PE

I

L

I

AMP.

CLIP0100s

function, the following message appears: “use current clip”.

Set-Up

AMP

The switch position at the

respective clip-on current transformer must be

matched to the ranges of

the selected measuring

parameter, I

Measuring Range Tester CLIP0100S Z3512A *

* Connection via CLIP-ON adapter cable (Z501G);

ranges b and c not possible in this case.

I

AMP.

or I

L

I

L

!

AMP.

5 mA ... 1.0 A 1 mA... 15 A d: 1 mA ... 1 A

10 ... 150 A 1 A ... 150 A a: 1 ... 1000 A

GMC-I Messtechnik GmbH 19

Page 20

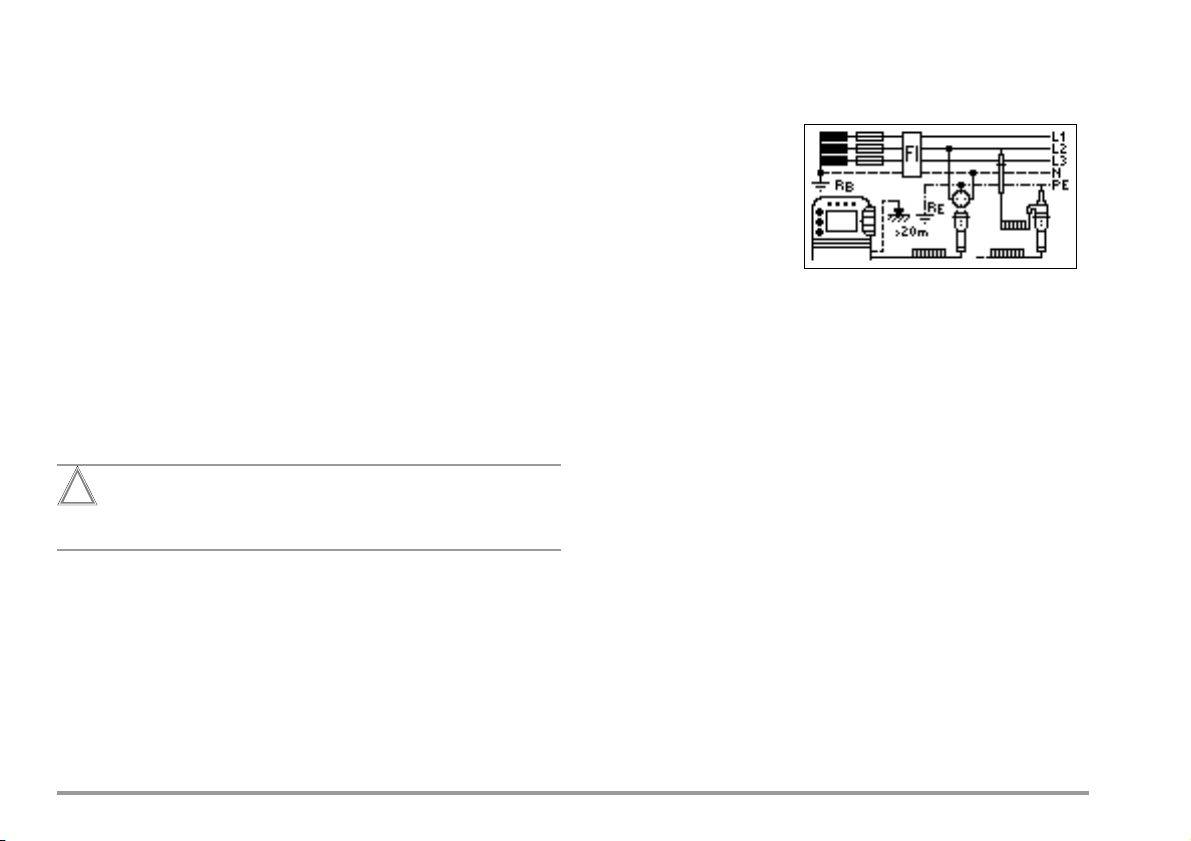

7 Testing RCDs

Attention!

!

The testing of residual current devices (RCDs) includes:

• Visual inspection

•Testing

•Measurement

The PROFITEST 2 is used for testing and measurement. Measure-

ments can be performed with or without a probe. However, a

probe is always required for measurements in IT systems.

Measurements with probe require that the probe and reference

earth are of like potential. This means that the probe must be

positioned outside of the resistance area of the earth electrode

(RE) at the RCD.

The distance between the earth electrode and the probe should

be at least 20 m.

The probe is connected with a 4 mm contact protected plug.

In most cases this measurement is performed without probe.

The probe is part of the measuring circuit and may carry

a current of up to 3.5 mA in accordance with VDE 0413.

Testing for the absence of voltage at the probe can be performed

with the U

function. See also chapter 6.3 on page 18.

PROBE

7.1 Measuring Contact Voltage (with reference to nominal

residual current) with

1

/3 Nominal Residual Current and

Tripping Test with Nominal Residual Current

Set-Up

Measuring Method

The following must be substantiated per DIN VDE 0100 part 600:

2008:

– Contact voltage occurring at nominal residual current may not

exceed the maximum allowable value for the system.

– Tripping of the RCCB must occur within 400 ms

(1000 ms for selective RCDs) at nominal residual current.

1) Measurement of Contact Voltage

The instrument uses a measuring current of only 1/3 nominal

residual current for the determination of contact voltage U

which occurs at nominal residual current. This prevents tripping of

the RCCB.

This measuring method is especially advantageous, because

contact voltage can be measured quickly and easily at any electrical outlet without tripping the RCCB.

The usual, complex measuring method involving testing for the

proper functioning of the RCD at a given point, and subsequent

substantiation that all other systems components requiring protection are reliably connected at low resistance values to the

selected measuring point via the PE conductor, is made unnecessary.

IN

20 GMC-I Messtechnik GmbH

Page 21

Contact voltage U

Note

Attention!

!

Note

MENU

I

N

10 mA

I

N

30 mA

appear at the LC Display Field (1).

and calculated earthing resistance RE

IN

Displayed earthing resistance RE is measured with

relatively little current and may thus be inaccurate where

small values are involved. Use the RE selector switch

position for accurate determination of earthing

resistance.

After contact voltage has been measured, testing can be performed to determine whether or not the RCCB is tripped within

400 ms, or 1000 ms, at nominal residual current.

If the RCCB is tripped at nominal residual current, time to trip and

earthing resistance are displayed.

If the RCCB is not tripped at nominal residual current, FI/RCD

Lamp (8) lights up red.

The tripping test need only be performed at one measuring point

for each RCCB.

The measurement of contact voltage with 30% nominal

residual current does not normally trip an RCCB. However, the trip limit may be exceeded as a result of leakage

current in the measuring circuit, e.g. due to interconnected consumers with EMC circuit, e.g. frequency converters, PCs.

In order to prevent the loss of data in data processing

systems, perform a data backup before starting the

measurement and switch off all consumers.

Interference voltages at protective conductor PE, at the

earth electrode or at the probe (if properly connected) have

no influence on measurement results. Interference voltages

can be measured with the Measuring Adapter (2-pole) (12)

by means of voltage measurement. If bias currents should

occur, these can be measured with the help of a clip-on current transformer as described in chapter 6.4 on page 18.

The RCCB may be tripped during the testing of contact voltage if extremely large bias currents are present within the

system, or if a test current was selected which is too great

for the RCCB. In such cases, the following message

appears: “check test set-up”.

If the “English/UK parameter” has been selected in setup, a 2 second test at 50% nominal residual current is performed before the

RCD is tripped. If the RCD trips within this test period, the FI/RCD

Lamp (8) also lights up red, and no trip delay is displayed.

GMC-I Messtechnik GmbH 21

Page 22

MENU

START

If contact voltage U

Note

Note

I

N

IN100 mA

I

N

300 mA

I

N

500 mA

nal residual current I

the U

(7) lamp lights up red.

L/RL

If contact voltage U

sequence, safety shut-down occurs. See also Note „Safety Shut-

, which has been measured with 1/3 nomi-

IN

and expounded to IN, is > 50 V (> 25 V),

N

exceeds 50 V (25 V) during the measuring

IN

down“ on page 22.

Contact voltages of up to 70 V are displayed. If contact voltage is

greater than 70 V, U

> 70 V is displayed.

IN

The measured earthing resistance value RE is acquired

with very little current. More accurate results can be

obtained with the selector switch in the R

Perform measurement upstream from the RCCB in order

position.

E

to prevent it from tripping in the case of the high measuring currents used in this context.

Limit Values for Allowable, Continuous Contact Voltage

The limit for allowable, continuous contact voltage is equal to

U

= 50 V for alternating voltages (international agreement).

L

Lower values have been established for special applications

(e.g. medical applications UL=25V).

Safety Shut-down: Up to 70 V, a safety shut-down is

tripped within 3 s in accordance with IEC 61010.

2) Tripping Test after the Measurement of Contact Voltage

Ð Press the I

(approximately 30 s).

key (2 or 18) before on-time has expired

N

If the RCCB is tripped at nominal residual current, the NETZ/

MAINS Lamp (6) blinks red (line voltage disconnected), and time

to trip t

Field (1).

and earthing resistance RE appear at the LC Display

A

22 GMC-I Messtechnik GmbH

Page 23

If the IN key (2 or 18) is pressed again, the previous display

Attention!

!

Note

MENU

I

N

10 mA

I

N

30 mA

appears at LC Display Field (1) for about 3 s.

If the RCCB is not tripped at nominal residual current, the FI/RCD

Lamp (8) lights up red.

If contact voltage is too high, or if the RCCB is not

tripped, the system must be repaired (e.g. earthing resistance is too high, defective RCCB etc.)!

For proper RCD testing at three-phase connections, the tripping

test must be conducted for each of the three phase conductors

(L1, L2 and L3).

Voltage peaks may occur within the measuring circuit if

inductive consumers are shut down during an RCCB trip

test. If this is the case, the test instrument may display the

following message: “Check test setup”. If this message

appears, switch all consumers off before performing the

trip test. In extreme cases one of the fuses in the test

instrument may blow.

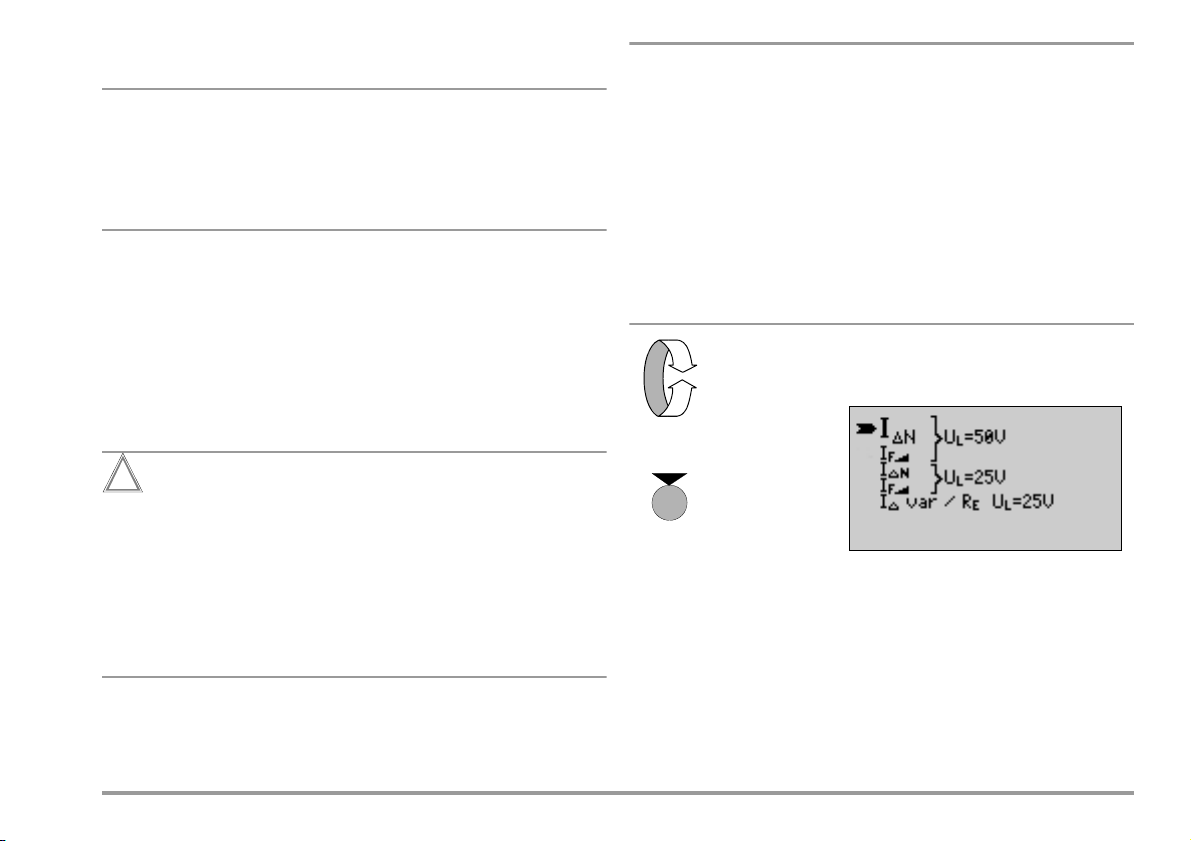

7.2 Special Testing for Systems and RCCBs

7.2.1 Testing for Systems and RCCBs with Rising Residual Current

Measuring Method

The instrument generates a continuously rising residual current of

(0.3 ... 1.3) I

The instrument stores the contact voltage and tripping current

values which were measured at the moment tripping of the RCCB

occurred, and displays them.

One of two contact voltage limit values, U

can be selected for measurement with rising residual current.

Set-Up

within the system for the testing of RCDs.

N

=25V or UL=50V,

L

GMC-I Messtechnik GmbH 23

Page 24

MENU

START

Measuring Sequence

Attention!

!

+

I

N

MENU

I

N

100 mA

I

N

300 mA

I

N

500 mA

After the measuring sequence has been started, the test current

generated by the instrument is continuously increased starting at

0.3 times nominal residual current, until the RCCB is tripped. This

rise can be observed at the horizontal bar display.

If contact voltage reaches the selected limit value (U

25 V) before the RCCB is tripped, safety shut-down occurs. The

=50V or

L

UL/RL (7) Lamp lights up red.

If the RCCB is not tripped before the rising current reaches nomi-

nal residual current I

, the FI/RCD Lamp (8) lights up red.

N

If bias current is present within the system during measurement, it is superimposed onto the residual current

which is generated by the instrument and influences

measured values for contact voltage and tripping current. See also note on page 21.

According to DIN VDE 0100, Part 610, rising residual current

must, however, be used for measurements in the evaluation of

RCDs, and contact voltage at nominal residual current I

be calculated from the measured values.

N

must

The faster, more simple measuring method should thus be taken

advantage of (see chapter 7.1).

7.2.2 Testing of RCCBs which are Suited for Pulsating DC Residual Current

In this case, RCCBs can be tested with either positive or negative

half-waves. The standard calls for tripping at 1.4 times nominal

current.

Press and *

hold the

key!

24 GMC-I Messtechnik GmbH

Page 25

+

I

N

MENU

Note

Note

7.3 Testing for Special RCDs

MENU

S

I

N

100 mA

I

N

300 mA

I

N

500 mA

Press and *

hold the

key!

According to DIN EN 50178 (VDE 160), RCCBs of type B

(AC-DC sensitive) are sufficient for devices > 4 kVA,

which are capable of generating smooth DC fault currents (e.g. frequency converters).

Tests with pulsating DC fault currents are not suitable for

these RCCBs. For this purpose we recommend the

PROFiTESTDC-II adapter.

Measurement is performed with positive and negative

half-waves for testing RCCBs during manufacturing. If a

circuit is charged with pulsating direct current, the function of the RCCB can be executed with this test in order

to assure that the RCCB is not saturated by the pulsating

direct current so that it no longer trips.

* Press the key repeatedly until the symbol for positive or negative

pulsating DC current appears.

7.3.1 Systems with Selective RCDs

Selective RCDs are used in systems which include two series

connected RCCBs which are not tripped simultaneously in the

event of a fault. These selective RCDs demonstrate delayed

response characteristics and are identified with the symbol .

Measuring Method

The same measuring method is used as for standard RCCBs (see

points 7.1 on page 20 and 7.2.1 on page 23).

If selective RCDs are used, earthing resistance may not exceed

half of this value for standard RCCBs.

For this reason, the instrument displays twice the measured value

for contact voltage.

GMC-I Messtechnik GmbH 25

Page 26

START

Tripping Test

Note

START

Ð Press the I

glass appears at the LC Display Field (1), which is followed by

key (2 or 18). The RCCB is tripped. The hour

N

the display of time to trip tA and earthing resistance RE.

Selective RCDs demonstrate delayed response characteristics. Tripping performance is briefly influenced (up to

30 s) due to pre-loading during measurement of contact

voltage. In order to eliminate pre-loading caused by the

measurement of contact voltage, a waiting period must

If the IN key (2 or 18) is activated again, the LC Display Field (1)

returns to the U

display.

IN

be observed prior to the tripping test. After the measuring

sequence has been started (tripping test), the hour glass

appears in the LC Display Field (1).

Times of up to 1000 ms are allowable.

26 GMC-I Messtechnik GmbH

Page 27

7.3.2 Type G RCCBs

MENU

Note

Note

I

N

10 mA

I

N

30 mA

In addition to standard RCCBs and selective RCDs, the special

characteristics of the type G RCCB can also be tested with the

PROFITEST 2 test instrument.

Menu item S for selective RCDs is not suitable for type G

RCCBs.

Ð Set the test instrument function selector switch to I

or 10 mA, and select the I

menu item with the cursor.

N

=30mA

N

Contact voltage and time to trip can be tested in the same way as

for standard RCCBs.

It must be observed that time to trip for type G RCCBs

may be as long as 1000 ms when measurement is made

at nominal residual current. In such cases disregard the

red FI/RCD Lamp.

GMC-I Messtechnik GmbH 27

Page 28

7.4 Testing with Adjustable Residual Current

I

N

The same tests as described in chapter 7.1 can be performed

under menu item I

ments are performed with a test current which can be adjusted

VAR/RE

within a range of 3 mA to 550 mA. This function (e. g. contact voltage at the tripping contact) is suitable for the examination of RCD

characteristics and contact voltage directly at the RCCB tripping

contact, as well as for the determination of earthing resistance in

systems with RCDs when no PROFiTEST

bridging the RCDs. This menu item can only be used for 10 mA

and 30 mA RCCBs.

Proceed as follows in order to select the desired residual current:

Ð Select menu item I

Ð Press the I

appears.

/ i key. A field for the entry of residual current

N

except that all tests and measure-

DC-II is available for

VAR/RE

.

If the Menu Key is pressed again, the main menu appears at the

display. If no entries are made within approximately 10 s, the

menu is exited.

The determination of contact voltage, as well as the tripping test,

are performed with the pre-selected residual current.

If a residual current value is selected which is very close to the

tripping current of the RCCB, the calculated contact voltage corresponds to the contact voltage which occurs at the moment the

RCCB is tripped.

7.5 Testing RCDs in IT Systems

All of the tests described in chapters 7.1 through 7.5 can also be

performed in IT systems with the PROFITEST 2. The only prerequisite is that the system is capable of applying the necessary test

and tripping currents to earth.

Set-Up

Each time the I

pressing and holding the I

ously. The speed at which the value rises is increased after a few

/ i is activated current is increased by 1 mA. By

N

/ i key, the value is increased continu-

N

Ð Connect the test instrument to the phase conductor which

demonstrates the greatest earth potential.

seconds. If the Menu Key is pressed and held at the same time, the

value is reduced at the same speed. After the desired value has be

set, testing can be started with the Start Key as described in chapter 7.1. Testing is started with the positive half-wave. If the test is to

be started with the negative half-wave, the menu item “Start with

negative half-wave (180

28 GMC-I Messtechnik GmbH

” must be selected prior to testing.

Page 29

Attention!

!

Testing of RCCBs in IT systems cannot be performed

+

I

N

MENU

MENU

START

Note

+

I

N

MENU

I

N

10 mA

I

N

30 mA

I

N

100 mA

I

N

300 mA

I

N

500 mA

without a probe; a probe is absolutely necessary! The

probe and reference earth must be of like potential.

Press and *

hold the key!

The MAINS Lamp (6) has no function for the testing of

RCDs in IT systems (in the IT mode).

Exit IT mode manually:

Press and hold the Menu Key and repeatedly press the IN/I key

until the IT symbol group and half-wave disappear.

The IT mode is exited automatically if:

– an attempt is made to perform the measurement without a

probe or if probe resistance is greater than 50 k

– a prohibited bias occurs between the probe and earth

– the function selector switch (9) is turned

– the instrument shuts itself off automatically

* Press the key repeatedly until the IT symbol group appears.

GMC-I Messtechnik GmbH 29

Page 30

7.6 Testing Residual Current Circuit Breakers in TN-S Systems

Note

UINREIN 1 30mA 30mV 0 03V,== ==

Connections

RCCBs can only be used in TN-S systems. An RCCB would not

work in a TN-C system because PE is directly connected to the

neutral conductor in the outlet (it does not bypass the RCCB).

This means that residual current would be returned via the RCCB

and would not generate any differential current, which is required

in order to trip the RCCB.

As a rule, the display for contact voltage is also 0.0 V, because

the nominal residual current of 30 mA together with minimal loop

resistance result in a very small voltage value:

In determining contact voltage and earth resistance, it must be

kept in mind that loop impedance Z

earth resistance R

Due to minimal measuring current with a value of, for example,

.

E

10 mA for a 30 mA RCCB, resolution is only 3 for R

Since loop resistance is generally less (e.g. 1 ), 0 is displayed

is determined rather than

Loop

E

(=Z

Loop

Measuring resolution is 100 mV, and the display value is thus

rounded down to 0.0 V.

).

in most cases.

Observe national regulations, e.g. the necessity of conducting measurements without regard for RCCBs in Austria, see also chapter 8.3.

30 GMC-I Messtechnik GmbH

Page 31

8 Testing of Breaking Requirements for Overcurrent Protective Devices,

Measurement of Loop Impedance and Determination of Short-Circuit Current (functions Z

Testing of overcurrent protective devices includes visual inspection and measurement. The PROFITEST 2 is used for the perfor-

mance of measurements.

Measuring Method

Loop impedance Z

ascertained in order to determine if the breaking requirements for

is measured and short-circuit current IK is

Loop

protective devices have been fulfilled.

Loop impedance is the resistance within the current loop (utility

company plant – phase conductor – protective conductor) when

a short-circuit to an exposed conductive part occurs (conductive

connection between phase conductor and protective conductor).

Short-circuit current magnitude is determined by the loop impedance value. Short-circuit current I

mined value set forth by DIN VDE 0100, so that reliable breaking

may not fall below a predeter-

K

of the protective device (fuse, automatic circuit breaker) is

assured.

Thus the measured loop impedance value must be less than the

maximum allowable value.

Tables containing allowable display values for loop impedance

and minimum short-circuit current display values for ampere ratings for various fuses and circuit breakers can be found in chapter

17 starting on page 61. Maximum device error in accordance with

VDE 0413 has been taken into consideration in these tables. See

also chapter 8.2.

In order to measure loop impedance Z

test current of 0.83 A to 4 A dependent upon line voltage and line

, the instrument uses a

Loop

frequency. The test has a duration of max. 600 ms.

If dangerous contact voltage occurs during measurement

(> 50 V), safety shut-down occurs.

The test instrument calculates short-circuit current I

measured loop impedance Z

current calculation is made with reference to nominal line voltage

for line voltages which lie within the nominal ranges for 120 V,

230 V (240 V for „English/UK-parameter“) and 400 V systems. If

line voltage does not lie within these nominal ranges, the instrument calculates short-circuit current I

voltage and measured loop resistance Z

Loop resistance can be measured with either the positive or the

negative half wave with the PROFITEST 2.

This measuring method, in combination with the

PROFiTEST

DC-II adapter, allows for the measurement of loop

impedance in systems which are equipped with RCCBs.

A four conductor measuring cable is used between the instru-

ment and the Test Plug (14). Cable and measuring adapter (12)

resistance is automatically compensated for during measurement

and does not effect measurement results.

and IK)

Loop

and line voltage. Short-circuit

Loop

based upon prevailing line

K

Loop

K

.

based on

GMC-I Messtechnik GmbH 31

Page 32

Set-Up

MENU

START

MENU

START

Z

Loop

Z

Loop

8.1 Measurement with Positive or Negative Half-Waves

Measurement by means of half-waves in combination with the

PROFiTEST

impedance in systems which are equipped with RCCBs.

Set-Up

Whether positive or negative half-waves are used for the measurement depends upon the poling of DC biasing at the ballast. If

the RCCB is tripped, testing is then performed with the other halfwave.

DC-II adapter allows for the measurement of loop

Measurement of loop impedance to earth must be performed at

all three phase conductors (L1, L2, and L3) for the testing of overcurrent protective devices at three phase outlets.

32 GMC-I Messtechnik GmbH

Page 33

8.2 Evaluation of Measurement Values

I

N

Attention!

!

Z

Loop

The maximum allowable loop impedance Z

played after allowance has been made for maximum operating

measurement error (under normal measuring conditions) can be

determined with the help of Table 5 on page 63. Intermediate values can be interpolated.

The maximum allowable nominal current for the protective device

(fuse or circuit breaker) for a line voltage of 230/240 V after allowance has been made for maximum measuring error can be determined with the help of Table 5 on page 63 based upon measured

short-circuit current (corresponds to DIN VDE 0100 Part 610).

After measurement has

been performed, allowable fuse types can be displayed by pressing the I

/ i key.

lI

breaking current, IK short-circuit current, IN nominal current

A

tA time to trip < 0.4: current standard 2004 issue 0.5: previous standard 1994 issue

N

The table shows maximum allowable nominal current dependent

upon fuse type and breaking requirements.

which may be dis-

Loop

99.9 . Calculated short-circuit current is also displayed. Recommended fuse types do not appear at the display. If RCCBs are utilized, fuse values are determined based upon internal system

resistance.

This measurement can be performed for system RCD protection

where RCCBs up to 500 mA are utilized as protective devices,

although, for example, loop resistance must be determined for

purposes of documentation.

The measurement is sufficiently accurate for testing earth-fault

loop impedances of less than 100 (at 500 mA).

Earth-fault loop impedances of less than 1 must be

reliably substantiated for testing trip conditions with

protective multiple earthing. Loop impedance

measurement must be performed with the help of the

PROFiTEST

DC-II for testing purposes

(see chapter 8.1).

8.3 Loop Impedance Measurement – Measurement via and without tripping the RCCB

Loop impedance L-PE can be determined with a nominal residual

current of at least 30 mA with this function, even downstream

from RCCBs. Measurement is performed for 2 seconds with a

nominal residual current of 15 mA, and results are displayed with

a typical accuracy of 1 . The display range runs from 0.1 to

GMC-I Messtechnik GmbH 33

Page 34

8.4 Testing Meter Start-Up with the Adapter

MENU

Attention!

!

START

Z

Loop

Start-up of energy consumption meters which are connected

between L and L or L and N can be tested with this function.

Set-Up

Use only the 2-pole adapter and contact L1 (L2, L3) and

N at the meter output.

Meters are tested with the help of an internal load resistor. After

pressing the Start Key t (3), the meter can be tested for proper

start-up within a period of 5 s. All phases must be tested against

N, one after the other.

After testing has been completed, testing power is displayed. The

instrument is now ready for further testing (“READY”).

34 GMC-I Messtechnik GmbH

Page 35

9 Measuring Supply Impedance (function ZI)

MENU

START

Note

Z

I

Measuring Method

Supply impedance Z

used for loop impedance Z

ever, the current loop is completed via neutral conductor N rather

than protective conductor PE as is the case with loop impedance

measurement.

Set-Up

is measured by means of the same method

I

(see chapter 8, page 31). How-

Loop

Measurement of supply impedance is only possible with

the Z

is attached!

function if the Measuring Adapter (2-pole) (12)

Loop

GMC-I Messtechnik GmbH 35

Page 36

9.1 Testing Meter Start-Up with Earthing Contact Adapter

MENU

START

Z

I

Start-up of energy consumption meters which are connected

between L and N can be tested with this function.

Set-Up

Meters are tested with the help of an internal load resistor. After

pressing the Start Key t (3), the meter can be tested for proper

start-up within a period of 5 s. All phases must be tested against

N, one after the other.

After testing has been completed, testing power is displayed. The

instrument is now ready for further testing (“READY”).

36 GMC-I Messtechnik GmbH

Page 37

10 Earthing Resistance Measurement (function RE)

Note

Attention!

!

Earthing resistance is the sum of earth electrode resistance (RA)

and earth conductor resistance. Earthing resistance is measured

by applying an alternating current via the earth conductor, the

earth electrode and earth electrode resistance. This current, as

well as voltage between the earth electrode and a probe, are

measured.

The probe is connected to the Probe Connector Socket (20) with

a 4 mm contact protected plug.

Direct measurement of earthing resistance R

within a measuring circuit which includes a probe. However, this

means that the probe and reference earth must be of like potential, i.e. that they are positioned outside of the earth electrode

resistance area. The distance between the earth electrode and

the probe should be at least 20 m.

In many cases, especially in extremely built-up areas, it is difficult,

or even impossible, to set a measuring probe. In such cases,

earthing resistance can be measured without a probe. In this

case, however, the resistance values for the operational earth

electrode RB and phase conductor L are also included in the

measurement results (see chapter 10.2 “Measuring without

Probe“ on page 38).

Measuring Method

The instrument measures earthing resistance R

ammeter-voltmeter test (earth electrode loop resistance). The test

current which is applied to earthing resistance is controlled by the

instrument and demonstrates the following values in the various

measuring ranges:

0 to 10 k- 4 mA, 0 to 1 k - 40 mA, 0 to 100 - 0.4 A and 0 to

10 > 0.8 A to approx. 4 A (independent of voltage).

A voltage drop is generated which is proportional to earthing

resistance.

Measuring range selection, and thus the selection of test current

as well, are carried out automatically.

is only possible

E

by means of the

E

Measurement cable and measuring adapter (12) resistance are compensated for automatically during measurement and have no effect on measurement results.

Interference voltages at protective conductor PE, at the

earth electrode or at the probe (if properly connected) do

not influence measurement results. They can be measured by means of voltage measurement (with the Measuring Adapter (2-pole) (12)).

If dangerous contact voltages occur during measurement

(> 50 V), the measurement is interrupted and safety shutdown occurs.

Probe resistance does not effect measurement results

and may be as high as 50 k. If probe resistance is too

high, measurement is automatically performed without

the probe (see chapter 10.2 “Measuring without Probe“

on page 38).

The probe is part of the measuring circuit and may carry

a current of up to 3.5 mA in accordance with VDE 0413.

GMC-I Messtechnik GmbH 37

Page 38

10.1 Measuring with Probe

MENU

START

START

R

E

Set-Up

Automatic Measuring Range Selection

10.2 Measuring without Probe

In the event that it is impossible to set a probe, earthing resistance can be estimated by means of an “earth loop resistance

measurement” without probe.

The measurement is performed exactly as described in chapter

10.1 “Measuring with Probe“ starting on page 38. However, no

probe is connected to the Probe Connector Socket (20).

The resistance value R

method also includes operational earth electrode resistance and

resistance at phase conductor L. These values must be deducted

from the measured value in order to determine earthing resistance.

If conductors of equal cross section are assumed (phase conductor L and neutral conductor N), phase conductor resistance is half

as great as supply impedance ZI (phase conductor + neutral conductor).

Supply impedance can be measured as described in chapter 9

starting on page 35.

In accordance with DIN VDE 0100, the operational earth electrode R

must lie within a range of “0 to 2 ”.

B

obtained with this measuring

ELoop

38 GMC-I Messtechnik GmbH

Page 39

Earthing resistance is determined with the following equation:

RER

E

Loop

=

1

2

---

– RI RB–

The value for operational earth conductor resistance R

ignored in the calculation of earthing resistance, because it is

should be

B

generally unknown.

The calculated earthing resistance thus includes operational earth

conductor resistance as a safety factor.

10.3 Evaluation of Measurement Values

The maximum allowable displayed resistance values which assure

that the required earthing resistance is not exceeded, and for

which maximum device operating error has already been taken

into consideration (at nominal conditions of use), can be determined with the help of Table 2 on page 61. Intermediate values

can be interpolated.

GMC-I Messtechnik GmbH 39

Page 40

11 Measuring Insulation Resistance

Note

Note

MENU

START

Note

R

ISO

(Function R

Set-Up

If you use the test plug together with a plug insert, insulation resistance is only measured between the phase conductor terminal designated “L” and the protective conductor terminal PE!

Checking the Measurement Cables

Before performing insulation measurement, the test

probes on the measurement cables should be shortcircuited in order to assure that the instrument displays a

value very close to 0 . In this way, incorrect connection

can be avoided and broken measurement cables can be

detected.

ISO

)

If measured insulation resistance is less than the selected limit

value (see chapter 11.3), the U

Lamp (7) lights up.

L/RL

Insulation resistance can only be measured at voltagefree objects.

If an interference voltage of 10 V is present within the system,

insulation resistance is not measured. The NETZ/MAINS Lamp (6)

lights up and a display appears at the LC Display Field (1), e.g.:

40 GMC-I Messtechnik GmbH

Page 41

START

All conductors (L1, L2, L3 and N) must be tested against PE!

Attention!

!

Attention!

!

Note

When an insulation resistance measurement has been performed

on a capacitive object it is automatically discharged by the instrument after the StartKey(3 or 17) has been released. Contact

between the object and the instrument may not be interrupted.

The voltage decline can be observed directly at the LC Display

Field (1).

Do not disconnect the object until voltage has fallen below 25 V!

The instrument’s batteries are exposed to excessive

stress during insulation resistance measurement. Only

hold the Start Key (3 or 17) depressed until the display

has stabilized.

Do not touch the instrument’s terminal contacts during

insulation resistance measurements!

If nothing has been connected to the terminal contacts, or if a

resistive load component has been connected for measurement,

your body would be exposed to a current of approx. 1 mA at a

voltage of 500 V.

The resulting electrical shock is not life endangering. However, the

noticeable shock may lead to injury (e.g. resulting from a startled

reaction etc.).

If measurement is performed at a capacitive object such

as a long cable, it becomes charged with up to approx.

500 V!

Touching such objects is life endangering!

GMC-I Messtechnik GmbH 41

11.1 Insulation Measurement with Rising Test Voltage

The “U

tion, as well as to determine response voltage for voltage limiting

components.

As long as the START key is held depressed, test voltage rises

continuously. Insulation measurement is started:

• As soon as the upper voltage limit of 500 V has been reached

or

• As soon as the START key has been released

(when the desired voltage appears at the display)

or

• As soon as a measurable test current has been detected (e.g.

after sparkover occurs at breakdown voltage).

Test voltage, any response and breakdown voltage which may be

present and insulation resistance are displayed.

” function is used to detect weak points in the insula-

ISO

Page 42

11.2 Evaluation of Measurement Values

START

I

N

MENU

Attention!

!

MENU

R

LO

Instrument measuring error must be taken into consideration in

order to assure that the limit values set forth in DIN VDE regulations are not fallen short of. The required minimum display values

for insulation resistance can be determined with the help of

Table 3 on page 62. These values take maximum device error into

consideration (under nominal conditions of use). Intermediate values can be interpolated.

11.3 Setting the Limit Value

The insulation resistance limit value can be set with the

“R

Limit” function. If measurement values occur which are

ISO

below this limit value, the red U

limit values ranging from 100 k to 10 M is available. Select the

limit value with the I

N

/i key.

The instrument can be returned to the menu display by pressing

the MENU key, or testing can be started with the basic function

by activating the START key.

LED lights up. A selection of

L/RL

12 Measuring Low-Value Resistance of up to 100

(protective conductor and bonding conductor)

12.1 Measuring Low-Value Resistance (function RLO)

According to the regulations, the measurement of low-value resistance at protective conductors, earth conductors or bonding conductors must be performed with (automatic) pole reversal of the

test voltage, or with current flow in one (+ pole to PE) and the

other direction (– pole an PE).

Low-value resistance can only be measured at voltagefree objects.

Set-Up

42 GMC-I Messtechnik GmbH

Page 43

Attention!

!

The test probes should always be in contact with the DUT

START

before the Start Key (3 or 17) is activated.

If the object is charged with voltage, the measurement is

blocked if the test probes are first placed into contact with the

DUT, and the instrument fuse is blown if the StartKey is activated first.

After the measuring sequence has been started, the instrument

performs measurement with automatic pole reversal, first with

current flow in one direction, and then in the other. The largest

measured resistance value is always displayed.

Differing results for measurements in both directions indicate voltage at the DUT (e.g. thermovoltages or unit voltages). In the case

of major deviations between the two measured values, both values are displayed:

GMC-I Messtechnik GmbH 43

Measurement results can be distorted by parallel connected

impedances at operating current circuits and by circulating current, especially in systems which make use of “overcurrent protection devices” (earlier neutralization) without an isolated protective conductor. Resistances which change during measurement

(e.g. inductance), or a defective contact, can also cause distorted

measurements (double display).

In order to assure unambiguous measurement results, causes of

error must be located and eliminated.

Display for interference voltage, for example:

In order to find the cause of the measuring error, measure resistance in both current flow directions.

Page 44

The instrument’s batteries are exposed to excessive stress during

Note

Note

insulation resistance measurement. For measurement with current flow in one direction, only press and hold the Start Key

(3 or 17) as long as is necessary for the measurement.

Measuring Low-Value Resistance

Measurement cable and Measuring Adapter (2-pole) (12)

resistance is compensated for automatically thanks to the

four conductor method and do not effect measurement

results. However, if an extension cable is used its resistance must be measured and deducted from the measurement results in accordance with chapter 12.2.

Resistances which do not demonstrate a stable value

until after a “settling in period” should not be measured

with automatic pole reversal. Measurement with automatic pole reversal may lead to varying and/or inflated

measurement values, and thus to an ambiguous reading.

Examples of resistances whose values may change during measurement include:

– Incandescent lamp resistance, whose values change

due to warming caused by test current

– Resistances with a great conductive component

– Contact resistance

12.2 Compensation for Extension Cables of up to 10

(function R

If extension cables are used, their resistance can be deducted

automatically from the measurement results. Proceed as follows:

Ð Short-circuit the end of the measurement extension cable with

the second test probe at the instrument.

Ð Select one of the items under R

Ð Initiate measurement with the Start Key.

Ð After measurement has been completed, press the I

The following message appears in the status line at the display: RLO Offset xxx , where xxx is equal to a value between

0.00 and 9.99 . This value will now be deducted from the

actual measurement value for all subsequent R

ments. Once the offset has been stored to memory, it remains

even after the instrument has been switched off.

Only use this function when taking measurements with

an extension cable. Whenever different extension cables

are used, the above described procedure must be

repeated.

)

LO

in the menu.

LO

/i key.

N

measure-

LO

44 GMC-I Messtechnik GmbH

Page 45

12.3 Calculation of Cable Lengths for Common

START

I

N

MENU

I

N

Copper Conductors

If the IN/ i key is activated after performance of resistance measurement in accordance with chapter 12.1, the

cable lengths corresponding to common conductor cross

sections are displayed.

If results vary for the two different current flow directions, cable

length is not displayed. In this case, capacitive or inductive components are apparently present which would distort the calculation.

This table only applies to cables made with commercially available

copper conductors and cannot be used for other materials (e.g.

aluminum)!

12.4 Setting the Limit Value

The resistance limit value can be set with the “RLOLimit” function.

If measurement values which exceed this limit occur, the red U

LED lights up. Limit values can be selected within a range of

R

L

0.10 to 10 . Select the desired limit value with the I

The display returns to the menu when the MENU key is activated.

N

The instrument can be returned to the menu display by pressing

the MENU key, or testing can be started with the basic function

by activating the START key.

L

/i key.

/

GMC-I Messtechnik GmbH 45

Page 46

13 Phase Sequence Testing

MENU

Note

START

U

L-PE

Set-Up

Clockwise rotation

The Measuring Adapter (2-pole) (12) is required for connection of

Counter-clockwise rotation

the instrument, and is expanded to a 3-pole measuring adapter

with the included measurement cable.

PE or N to phase

The following appear at the LC Display Field (1):

Phase missing

– Highest occurring voltage within the measuring circuit

– All three phases displayed in order of their sequence

represented by the numbers 1, 2, 3

(the numbers are separated by two periods)

– A circle with an arrow, which indicates

direction of rotation

46 GMC-I Messtechnik GmbH

Page 47

14 Operating and Display Elements

Note

(1) LC Display Field

The following are displayed at the LCD:

• One or two measurement values as three place numeric display with unit of measure and abbreviated measuring quantity

• Nominal values for voltage and frequency

•Circuit diagrams

• On-line help

• Messages and instructions

(2) I

The following sequences can be started with this key:

• Starts the tripping test after measurement of contact voltage

• Displays the appropriate circuit diagram and on-line help after

• Selects special RCCB tests (testing with positive or negative

• Displays information for Z

This key has the same function as the Ikey (18).

/ i Key

N

for RCCB testing (I

N

).

a function has been selected in the menu.

half-wave in IT systems).

, ZI and RLO measurements.

Loop

(4) Menu Key

The basic functions menu for the function selected with the Function Selector Switch (9) is called up with the yellow menu key, and

the instrument is switched on at the same time, if is was off. Each

additional activation of the key advances the arrow for the selection of one of the various functions.

(5) PE Lamp