Gossen MetraWatt PROFITEST 204, PROFITEST 204L+, PROFITEST 204HP, PROFITEST 204HV, PROFITEST 204 PLUS Operating Instructions Manual

...Page 1

PROFITEST 204+, 204L+, 204HP, 204HV

Test Instrument for EN 60204 / DIN VDE 0113

3-348-781-03

21/3.13

Operating Instructions

Test instrument

may only be

operated under

supervision of a

qualified electrician!

Page 2

2 GMC-I Messtechnik GmbH

1236

7

8

9

10 11

45

15

14

13

12

13

16

121812

17

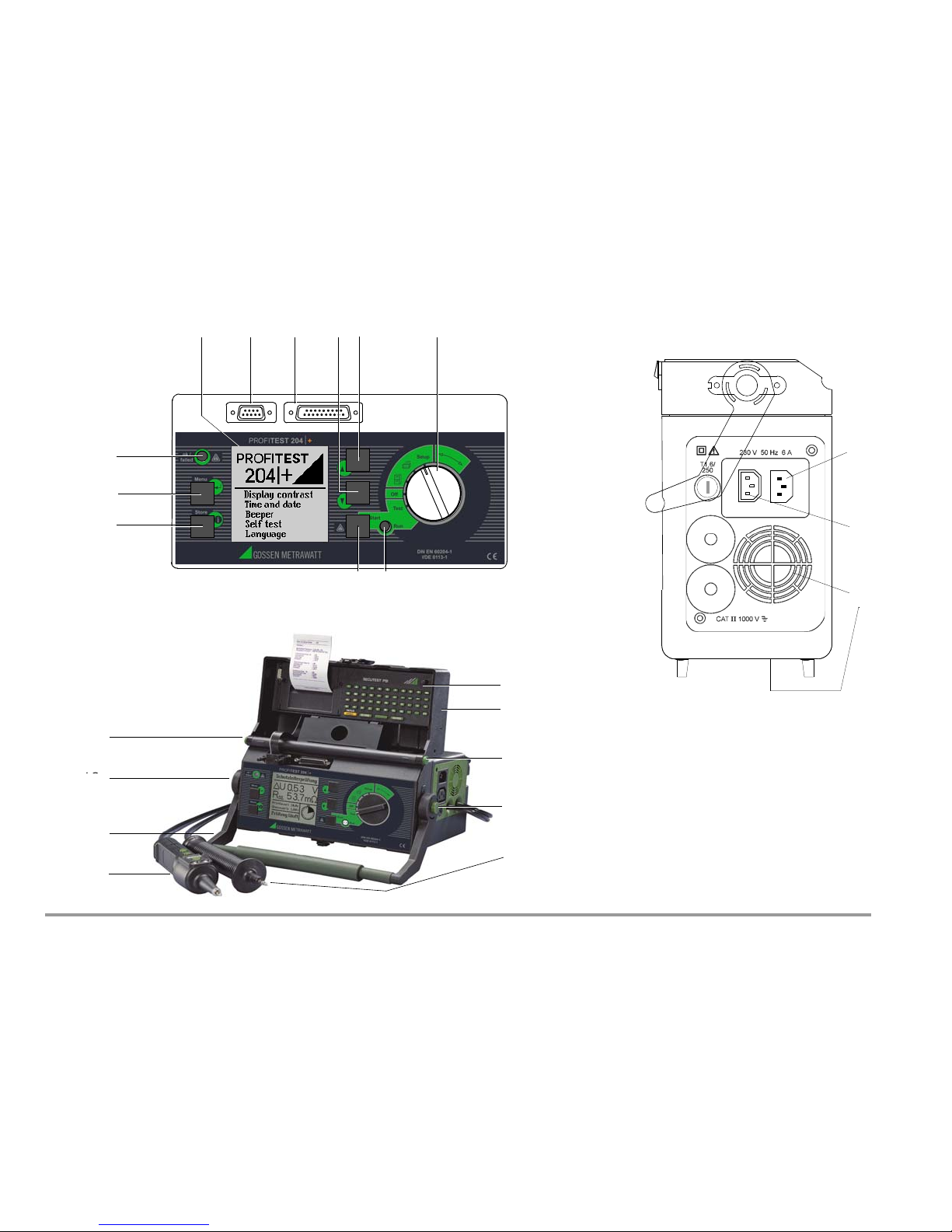

Connector Panel

PROFITEST 204+:BasicInstrument

22

23

24

Page 3

GMC-I Messtechnik GmbH 3

!

Attention!

The ventilation slots at the bottom of the housing (24)

and in the connector panel of the basic instrument must

remain unobstructed!

1 Function selector switch

2 key

3 key

4 Printer port

5 Connector socket for RS 232 interface

6LCD window

7 Signal lamp: test passed (green) / test failed (red)

8 MENU key

9 Help key / save key

10 Start key for selected test

11 Signal lamp “test in progress” (yellow)

12 Push-buttons (left and right) for releasing the handle from its snap-in

position

13 Push-buttons (left and right) for releasing the lid

14 Lid

15 Accessory input module SECUTEST (P)SI

(not included in standard equipment)

16 Carrying handle and tilt stand

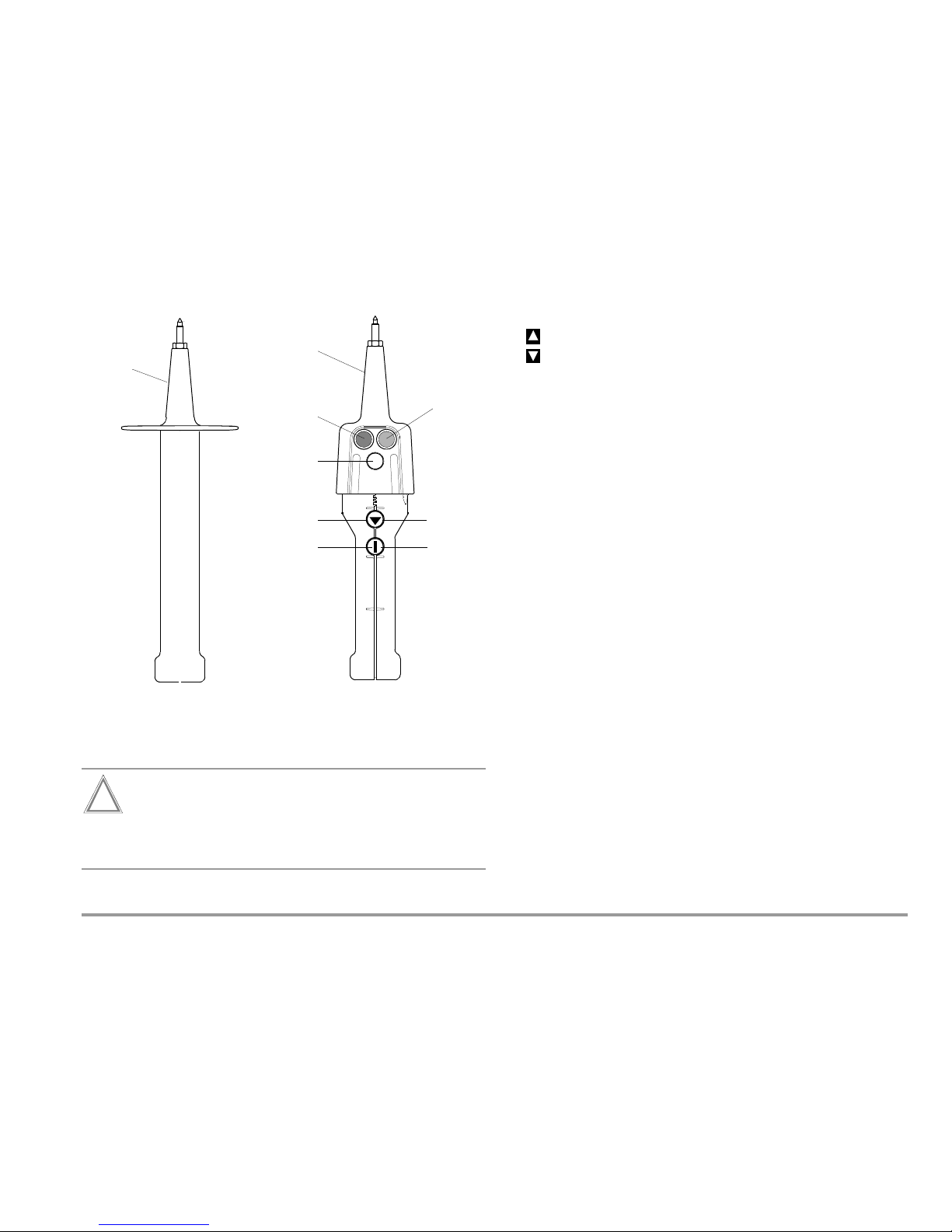

17 Test probe with integrated controls

18 Test probe with integrated fuse

19 Key for saving measurement value

20 Key for starting protective conductor measurement

21 Key for starting insulation measurement

22 Mains connector

23 Power supply connector for high-voltage module (max. 6 A)

24 Ventilation slots

11

18

START R

INS

START R

PC

STORE

7

21

20

19

17

Remote Control

PROFITEST 204+:TestProbes

Page 4

4 GMC-I Messtechnik GmbH

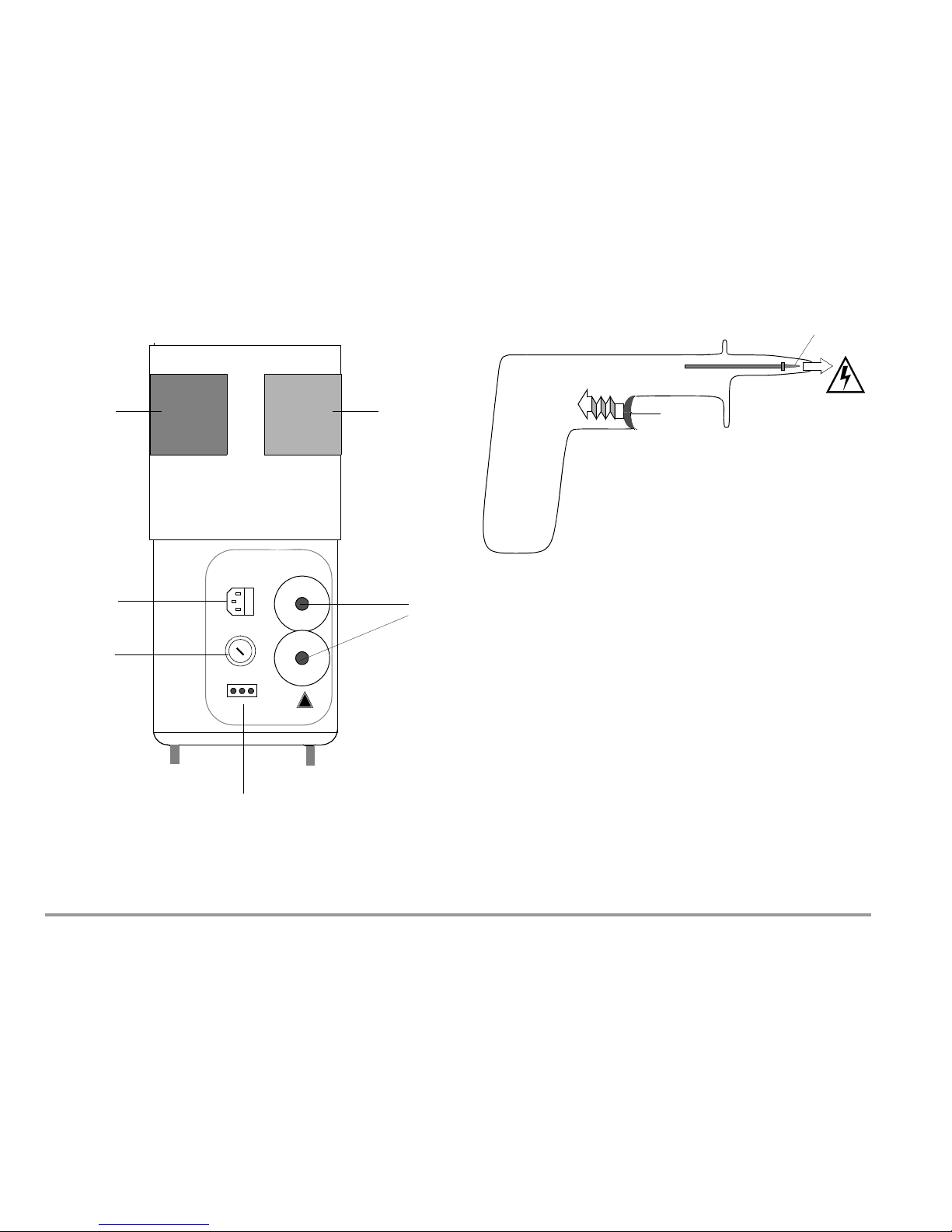

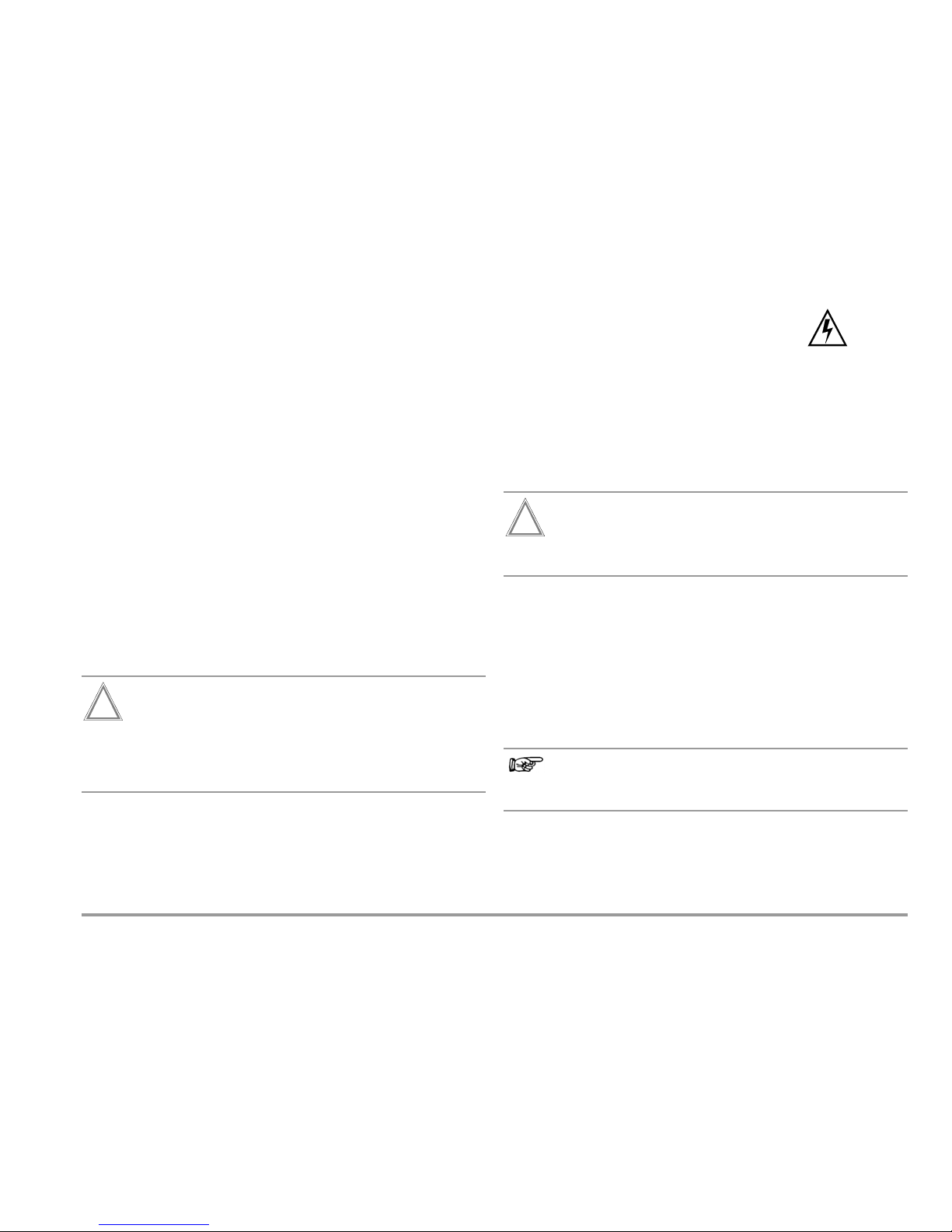

1 Inlet connector for power supply to high-voltage module with insert for fuse

2 Key switch for the prevention of unauthorized use

3 Terminals for external signal lamps (see chapter 3.1.3, page 15)

4 When green signal lamp is illuminated, high-voltage module is ready for

operation

5 When red signal lamp is illuminated, high-voltage module is ready to be

activated. Caution, danger!

6 Permanently attached measurement cable

7 Trigger (switch).

As opposed to high-voltage pistols without switch, the high-voltage switching pistol is identified with a red clamping ring on the connector cable underneath the handle.

8 Recessed safety test probe

0

I

!

5

4

1

2

3

PROFITEST 204 HP/HV High-Voltage Module

Connector Panel

6

8

7

High-Voltage Pistol with Switch

Page 5

GMC-I Messtechnik GmbH 5

Items Shipped with the Instrument

If you have two sets of operating instructions with different issue dates:

Use only the newest operating instructions.

The issue date appears on the title page underneath the order

number (3-348-781-xx), e.g. 17/9.10 means: 17

th

revision,

September 2010.

PC Program WinProfi for communication with PROFITEST 204+

The free PC starter software WinProfi* is used for communication

with your PROFITEST 204+ test instrument. WinProfi is available on

our homepage with the following content and functions:

• up-to-date test instrument software

– for loading a different language

for the user interface

– for loading an updated software version

• Transmission of measurement data from the test instrument to

the PC

• preparation and modification of templates for test reports at the

PC and transmission of the templates to the test instrument

• preparation, printout and filing of test reports at the PC

The following interface cables and/or converters are required for

communication between test instrument and PC:

– Z3241 RS232 (tester*) – RS232 (PC)

– RS232-USB Converter (Z501L) RS232 (tester*) – USB (PC)

* not possible via the RS232 terminal of a connected SECUTEST SI+

Up-to-date PC software (free of charge starter or demo software

for data management, report and list generation) is available from

our homepage for download.

* WinProfi is currently applicable up to Windows 7 (32 Bit)

Notes on SECUTEST SI+ Operating Instructions

The SECUTEST SI+ module is used together with the

PROFITEST 204+ exclusively for entering comments at the alphanu-

meric keypad.

The following chapters from the operating instructions included

with the SECUTEST SI+ (3-349-613-15) are relevant for operation

with the PROFITEST 204+:

• Chapter 2: Safety Features and Precautions

•

Chapters 3.1 and 3.2:

Inserting and activating the SI Module

• Chapter 10: Characteristic Values

• Chapter 11: Maintenance

• Chapter 12: Repair and Replacement Parts Service

• Chapter 13: Product Support

The following functions are not active, and are only sensible in

combination with the SECUTEST... test instrument:

• Display and save reports

• Statistics

• Utilization in combination with a barcode scanner

Page 6

Contents Page Contents Page

6 GMC-I Messtechnik GmbH

1 Applications ..................................................................................8

1.1 PROFITEST 204+ ...........................................................................8

1.2 PROFITEST 204L ...........................................................................8

2 Safety Features and Precautions ..................................................9

2.1 Meanings of Symbols ....................................................................10

2.1.1 Symbols on the Instrument ............................................................10

2.1.2 Symbols in the Operating Instructions .............................................10

2.1.3 Symbols which Appear at the PROFITEST 204+ Display .................10

2.1.4 Symbols which Appear at the Display of the

PROFITEST 204HP/HV High-Voltage Module ...................................11

2.2 Special Safety Precautions and Instructions for the

PROFITEST 204HP/HV High-Voltage Module ...................................12

3 Initial Start-Up ............................................................................14

3.1 Start-Up of the Optional High-Voltage Module .................................14

3.1.1 Mounting the High-Voltage Module to the Basic Instrument .............14

3.1.2 The Key Switch .............................................................................15

3.1.3 Indication of Operating States ........................................................15

3.2 Mounting the Instruments to the Optional Caddy .............................16

3.3 Connecting the PROFITEST204+ to 230 V Mains Power .................17

3.4 Connecting the High-Voltage Module to 230 V Mains Power ............17

3.5 Operating Software .......................................................................18

3.6 Online Help ...................................................................................18

3.7 Setup ...........................................................................................19

3.7.1 Adjusting Contrast and LCD Illumination .........................................19

3.7.2 Setting Time and Date ...................................................................20

3.7.3 Configuring the Signal Generator ....................................................20

3.7.4 Performing the Self-Test ................................................................21

3.7.5 Uploading the Desired Language or a Software Update ....................23

4 Testing Machines in Accordance with DIN VDE 0113 and EN 60 204 .... 26

4.1 Protective Conductor Test .............................................................26

4.1.1 Configuring Test Parameters .........................................................27

4.1.2 Start the Test ...............................................................................28

4.2 Insulation Resistance Test .............................................................29

4.2.1 Configuring Test Parameters .........................................................30

4.2.2 Start the Test ...............................................................................30

4.3 Leakage Current Test ....................................................................31

4.3.1 Configuring Test Parameters .........................................................31

4.3.2 Start the Test ...............................................................................31

4.4 Voltage Measurement (protection against residual voltage) .............. 33

4.4.1 Configuring Test Parameters .........................................................34

4.4.2 Start the Test ...............................................................................34

4.5 Voltage Test (option: PROFITEST 204HP/HV) ..................................35

4.5.1 Functions Test (test preparation) ....................................................35

4.5.2 Configuring Test Parameters .........................................................37

4.5.3 Test Sequence .............................................................................39

4.5.4 Pulse Control Mode ....................................................................... 41

4.5.5 Ending the Voltage Test .................................................................41

5 Processing, Transmitting and Deleting Data ..............................42

5.1 Selecting a System .......................................................................42

5.1.1 Entering a Description ...................................................................43

5.1.2 Copying Descriptions ....................................................................43

5.1.3 Deleting a Description ...................................................................43

5.2 Data Processing (viewing measured values) ....................................44

5.3 Data Reorganization ......................................................................44

5.3.1 Deleting Recorded Data .................................................................44

5.3.2 Memory Test ................................................................................45

5.4 Clearing Memory .......................................................................45

5.5 Data Transmission ........................................................................46

Page 7

GMC-I Messtechnik GmbH 7

Contents Page Contents Page

6 Printing, Uploading and Creating Reports .................................. 48

6.1 Print Values (PSI) / Print a Report ................................................... 48

6.2 Selecting a Form for Report Printing ..............................................49

6.3 Uploading a Report Form .............................................................. 50

6.4 Report Form Generating Program .................................................. 53

6.4.1 List of Code Words and their Meanings .......................................... 53

6.4.2 Report Layouts ............................................................................. 54

6.4.3 Uploading a Report Form to the Test Instrument .............................54

7 Characteristic Values ................................................................. 55

8 Setting Ranges for Parameters and Standard Values per DIN VDE ........57

9 Data Interfaces ........................................................................... 60

9.1 RS 232 Serial Interface .................................................................60

9.1.1 Software Analysis of Measurement Results ....................................60

9.1.2 Interface Definition and Protocol .................................................... 60

9.1.3 Connector Pin Assignments .......................................................... 60

9.2 Parallel Interface (printer port) ....................................................... 60

9.2.1 Connector Pin Assignments ......................................................... 60

10 Signals / Error Messages, Causes and Remedies ...................... 61

11 Maintenance .............................................................................. 66

11.1 Replacing Fuses ........................................................................... 66

11.1.1 Replacing the Mains Fuse .............................................................66

11.1.2 Replacing the Measuring Circuit Fuse in the

Test Probe at the PROFITEST 204+ .............................................. 66

11.2 Housing and Test Probes .............................................................. 66

11.3 PROFITEST 204+ Measurement Cables ........................................ 66

11.4 PROFITEST 204HP/HV Test Cables ................................................ 67

11.5 Repair, Parts Replacement and Instrument Balancing ..................... 67

11.5.1 Cleaning the Transmitter and Receiver Diodes ................................ 67

11.5.2 Replacing Signal Lamp Bulbs,

Disconnecting the High-Voltage Module .........................................67

11.5.3 Replacing Bulbs at the External Signal Lamps ................................ 68

11.6 Software ...................................................................................... 68

11.7 Recalibration ................................................................................ 69

11.8 Device Return and Environmentally Compatible Disposal ................. 69

12 Appendix .................................................................................... 70

12.1 Checklist for the High-Voltage Test ................................................ 70

12.2 Minimum Display Values

in Consideration of Operating Error ................................................ 71

12.3 List of Abbreviations ..................................................................... 71

12.4 Index ........................................................................................... 72

13 Repair and Replacement Parts Service

Calibration Center and Rental Instrument Service ..................... 74

14 Product Support ......................................................................... 74

Page 8

8 GMC-I Messtechnik GmbH

1 Applications

1.1 PROFITEST 204+

The PROFITEST 204+ test instrument is used for quick and safe

testing of electrical and electronic equipment and systems at

machinery in accordance with DIN VDE 0113/EN 60204-1.

The following initial and periodic tests must be performed in

accordance with these regulations:

• Testing for continuity of the protective conductor circuit with a

test current of at least 10 A

• Insulation resistance test

• Voltage test (optional PROFITEST 204HP/HV)

• Testing for residual voltage

Beyond this, other tests can be performed which are not required

for the safety of electrical equipment at machinery, but which

nevertheless supplement the instrument in a practical fashion:

• Measurement of electrostatic discharge capacity for floor

coverings in accordance with DIN 51953

• Leakage current test for the substantiation of the absence of

voltage

• Voltage and frequency measurements

All values required for approval reports can be measured with this

instrument.

The optional SECUTEST SI+ module (an input module which can be

set into the lid of the instrument and which is equipped with an

integrated interface and keypad) expands the applications range

of the PROFITEST 204+.

All measured data can be archived with the measuring and test

report which can be printed out directly or at a PC. This is

especially important where product liability is concerned.

1.2 PROFITEST 204L

The PROFITEST 204L test instrument has been furnished with

an extra-long measurement and control cable, allowing for

comfortable use at large machines and machine components.

Please note that use of the LEADEX 204 extension cable is

only possible to a restricted extent as a result of this extra-long

measurement cable.

Due to the additional, relatively high ohmic resistance of the

LEADEX 204 extension cable, the minimum test current of

10 A AC as specified by EN 60204 may be fallen short of under

certain circumstances, causing the instrument to abort the test

and display a corresponding message. As a rule, this does not

occur during use of the LEADEX 204 extension cable until

protective conductor resistance at the device under test has

reached a value of 200 m or greater. This effect may even occur

with relatively low line voltage values (less than 210 V).

If you require longer measurement cables than those supplied

with the PROFITEST 204L for your application, we recommend the

use of extension cables with a significantly larger

cross-section.

Our product support team (see address on page 74) would be

happy to assist you with any questions you may have.

Page 9

GMC-I Messtechnik GmbH 9

2 Safety Features and Precautions

This instrument fulfills the requirements of the applicable European and national EC guidelines. We confirm this with the CE

marking. The relevant declaration of conformity can be obtained

from GMC-I Messtechnik GmbH.

The PROFITEST 204+, 204 HP and 204 HV test instruments have

been manufactured and tested in accordance with the following

safety regulations:

IEC 61010-1 / DIN EN 61010-1 / VDE 0411-1,

DIN VDE 0413, part 1, and EN 60204 / DIN VDE 0113

If used for their intended purpose, the safety of the user, the

instrument and the device under test is assured.

Read the operating instructions thoroughly and carefully before using

your instrument, and follow all instructions included therein.

Make sure that the operating instructions are readily available to all operators.

Observe the following safety precautions:

• The instrument may only be connected to electrical supply

systems with 230 V/240 V which conform to the valid safety

regulations (e.g. IEC 60364, VDE 0100) and are protected with

a fuse or circuit breaker with a maximum rating of 16 A.

• Be prepared for the occurrence of unexpected voltages at

devices under test (for example, capacitors may be

dangerously charged).

• Make certain that connector cables, measurement cables and

test cables are in flawless condition, e.g. no damage to

insulation, no interruptions in cables or plugs, no kinks etc

.

• Impulse withstand voltages of up to 2.5 kV may occur in

overvoltage category II systems with 230/400 V.

The PROFITEST 204+ basic instrument and the PROFITEST 204HP and HV

high-voltage modules may not be operated:

• If visible damage is apparent

• If connector, measuring or test cables are damaged

• If they no longer function correctly

• If the signal lamps are defective

• If the functions test is not passed (see chapter 4.5.1, page 35)

In such cases, the instrument must be removed from service and

secured against unintentional use.

Send the instrument to the

Repair and Replacement Parts Service Department (see chapter 13).

Opening of Equipment / Repair

The equipment may be opened only by authorized service personnel to ensure the safe and correct operation of the equipment

and to keep the warranty valid. Even original spare parts may be

installed only by authorized service personnel.

In case the equipment was opened by unauthorized personnel,

no warranty regarding personal safety, measurement accuracy,

conformity with applicable safety measures or any consequential

damage is granted by the manufacturer.

Data Backup

The measurement, report and input data are stored and secured

in the test instrument RAM as long as the associated battery supplies the required voltage. Please note that the data will be lost

during a software update. We therefore advise you to regularly

transmit your stored data to a PC in order to prevent potential loss

of data in the test instrument. We assume no responsibility for any

data loss. For data processing and management we recommend

the following PC software programs:

•ETC

• PS3 (documentation, management, report generation and

monitoring of deadlines)

• PC.doc-WORD™/EXCEL™ (report and list generation)

• PC.doc-ACCESS™ (test data management)

• ELEKTROmanager for PROFITEST 204+

Page 10

10 GMC-I Messtechnik GmbH

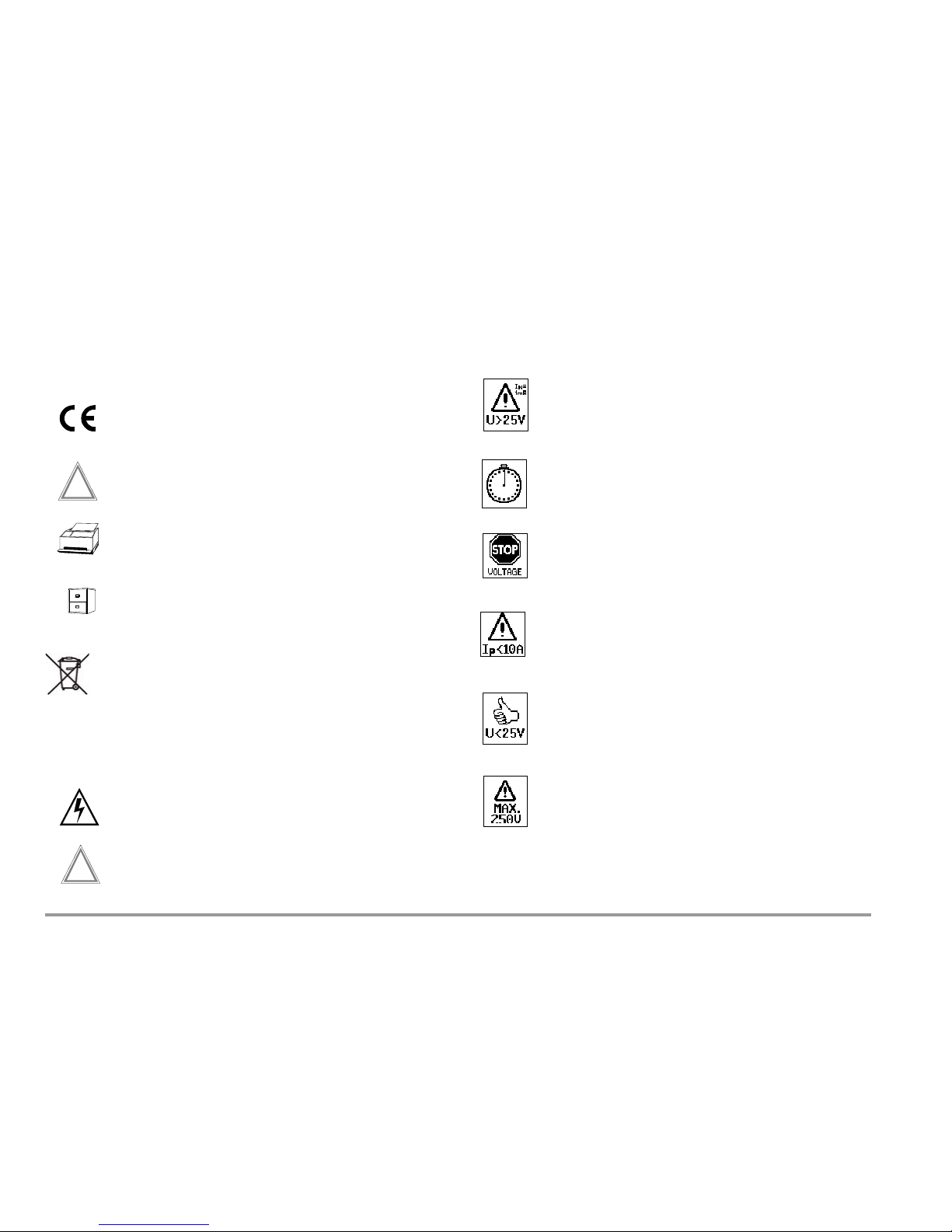

2.1 Meanings of Symbols

2.1.1 Symbols on the Instrument

The symbols on the instrument have the following meanings:

Indicates CE conformity

Warning concerning a point of danger,

(Attention, observe documentation!)

Report functions

Data management

This device may not be disposed of with the trash.

Further information regarding the WEEE mark can

be accessed on the Internet at www.gossenmetrawatt.com by entering the search term

’WEEE’.

2.1.2 Symbols in the Operating Instructions

Life endangering for the operator if instructions

identified with this symbol are not observed

Danger for the operator and the instrument if

instructions identified with this symbol are not

observed

2.1.3 Symbols which Appear at the PROFITEST 204+ Display

Warning concerning a point of danger,

e.g. voltage at the test probe is greater than 25 V

Timer function, indicates test duration

Protective conductor and insulation measurement:

interference voltage present at the test probes

Indication that test current is less than 10 A during

protective conductor measurement.

Indicates “all-clear” after insulation test:

voltage at the test probe is less than 25 V

Warning for leakage current test:

voltage may not exceed 250 V

!

!

Page 11

GMC-I Messtechnik GmbH 11

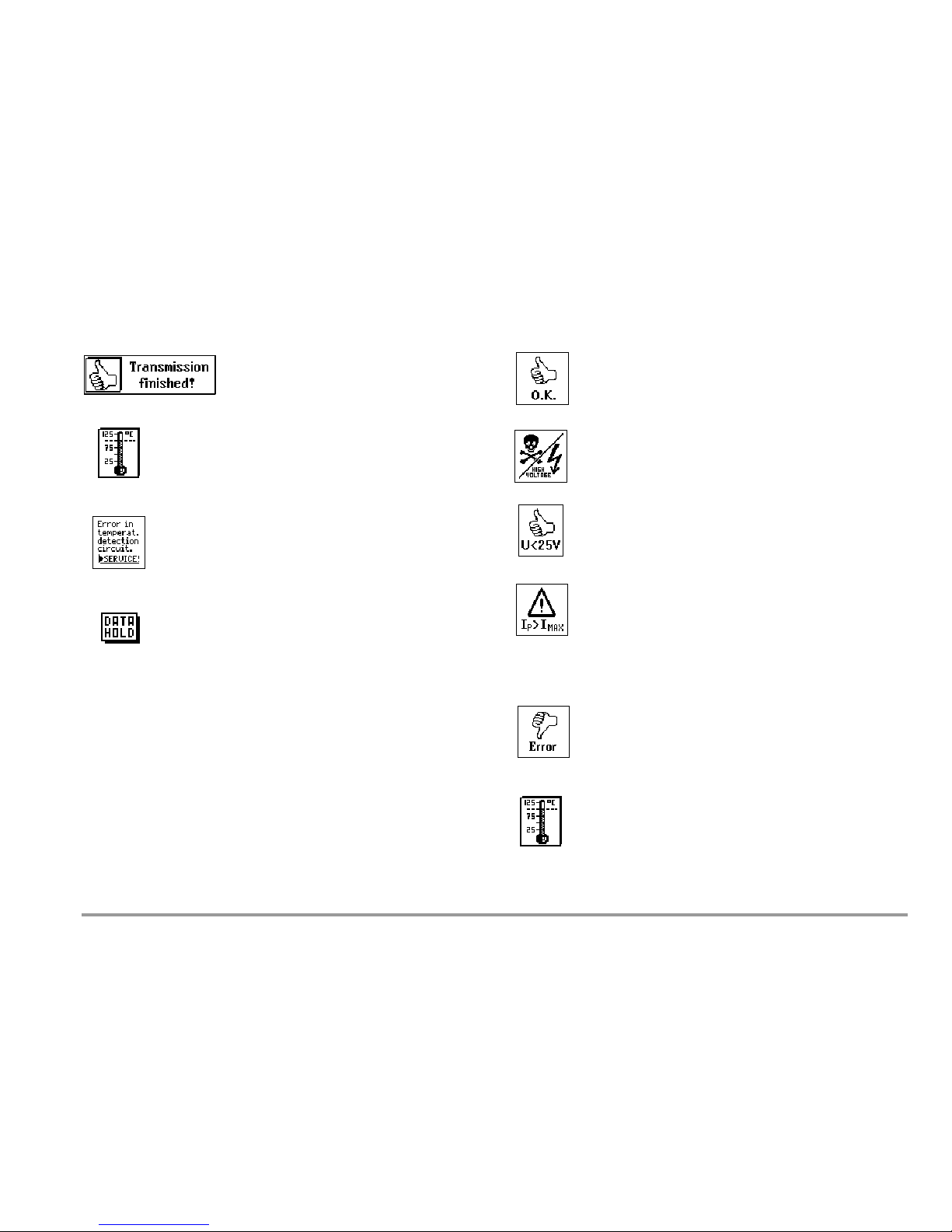

Data management message:

data transmission successfully completed

Excessive temperature inside the test instrument

(protective conductor test)

Allow instrument to cool down for approx. 10 minutes.

Internal temperature monitoring is defective.

Send the high-voltage module to the Repair Department

at GMC-I Service GmbH.

This symbol appears after the measured voltage

value has been frozen at the display (see chapter

4.4, page 33).

2.1.4 Symbols which Appear at the Display of the

PROFITEST 204HP/HV High-Voltage Module

High-voltage module ready for activation

A life endangering high-voltage of up to

5kV is present at the test probes of

the high-voltage module.

Test completed successfully:

residual voltage less than 25 V

The predefined limit value I

MAX

has been

exceeded. The current limiting function has

switched the instrument to the stand-by mode.

It is entirely possible that the displayed value for I

T

is less than I

MAX

, because the last measured value

is always displayed.

Instrument is defective! / Transmission

between PROFITEST 204+ and 204HP/HV

interrupted.

Excessive temperature inside the test instrument

(high-voltage test)

Allow instrument to cool down for approx. 10 minutes.

Page 12

12 GMC-I Messtechnik GmbH

2.2 Special Safety Precautions and Instructions for the

PROFITEST 204HP/HV High-Voltage Module

Precautions for the prevention of unauthorized activation:

•Key Switch

Precautions for the prevention of unintentional activation:

• Multiple Key Operation:

It is only possible to activate test voltage with the trigger at the

high-voltage pistol with switch, after pressing the start key at

the basic instrument.

• Two-Hand Operation:

Each of the high-voltage pistols is equipped with its own

trigger. The test probes are only made accessible when both

triggers are pulled and held simultaneously.

• High-Voltage Pistol with Switch (pistol with yellow marking)

Includes double safety feature:

The test probe is made accessible after the trigger at the

high-voltage pistol with switch has been pulled to its initial

mechanical limit stop. High-voltage is not switched to the test

probe until the trigger is pulled beyond this position, assuming

the instrument is in the “ready to activate” state.

General Safety Precautions

• Integrated signal lamps identify the operating status of the test instrument.

• Test voltage is electrically isolated from mains power. This

prevents heavy current from flowing to ground via the

high-voltage pistol with switch.

• Current Limiting in the Event of Sparkover:

If the current limiting value entered as a parameter is exceeded

in the event of sparkover, the instrument is automatically

switched to the stand-by mode.

• The instrument is automatically switched to the stand-by mode

when power is restored after a mains failure.

!

Attention!

The ventilation slots at the bottom of the high-voltage

module and at the connector panel of the basic

instrument must remain unobstructed!

Page 13

GMC-I Messtechnik GmbH 13

!

Attention!

Observe regulations set forth in EN 50191,

“Erection and operation of electrical test equipment”.

!

Attention!

If safety test probes are used, the operator must make

certain that the probe tips and the connector cables are

in flawless condition before beginning work.

All utilized equipment must be inspected for visibly

apparent external damage and defects before use (see

chapter 11.2, page 66, through chapter 11.4, page 67).

!

Attention!

Make sure that all points of access to the danger zone

have been secured before testing is started, and that no

persons remain within the danger zone when the system

is made ready for activation.

Danger: High-Voltage!

The test probe is made accessible after the trigger at

the high-voltage pistol with switch has been pulled to its

initial mechanical limit stop. High-voltage is not switched

to the test probe until the trigger is pulled beyond this

position, assuming the instrument is in the “ready to

activate” state.

Danger: High-Voltage!

Touch neither the test probes nor the device under test

during the voltage test!

A life endangering high-voltage of up to 5kV is present at

the high-voltage module test probes!

Exclusion of Liability

In the event of a sparkover, PCs which are operated in proximity

may crash, causing data loss in the process. Please therefore

ensure, prior to conducting the high-voltage test, that all data and

programs are saved appropriately and that the computer is

switched off, if necessary. This phenomenon may even occur

without an RS232 connection.

The manufacturer of the test instrument assumes no liability for

any direct or indirect damage to computers, peripheral equipment

or data stocks in connection with the execution of high-voltage

tests.

Furthermore, the manufacturer assumes no liability for defects in

DUTs caused by high-voltage tests. This applies especially for

electronic components within devices.

Please also observe the checklist for high-voltage tests given in chapter

12.1.

Page 14

14 GMC-I Messtechnik GmbH

3 Initial Start-Up

3.1 Start-Up of the Optional High-Voltage Module

3.1.1 Mounting the High-Voltage Module to the Basic Instrument

The HP or the HV high-voltage module must be mounted to the

PROFITEST 204+ test instrument before initial start-up.

When correctly mounted, reliable data exchange is assured

between the two devices by means of LED transmission (see

chapter 3.7.4, “Performing the Self-Test”).

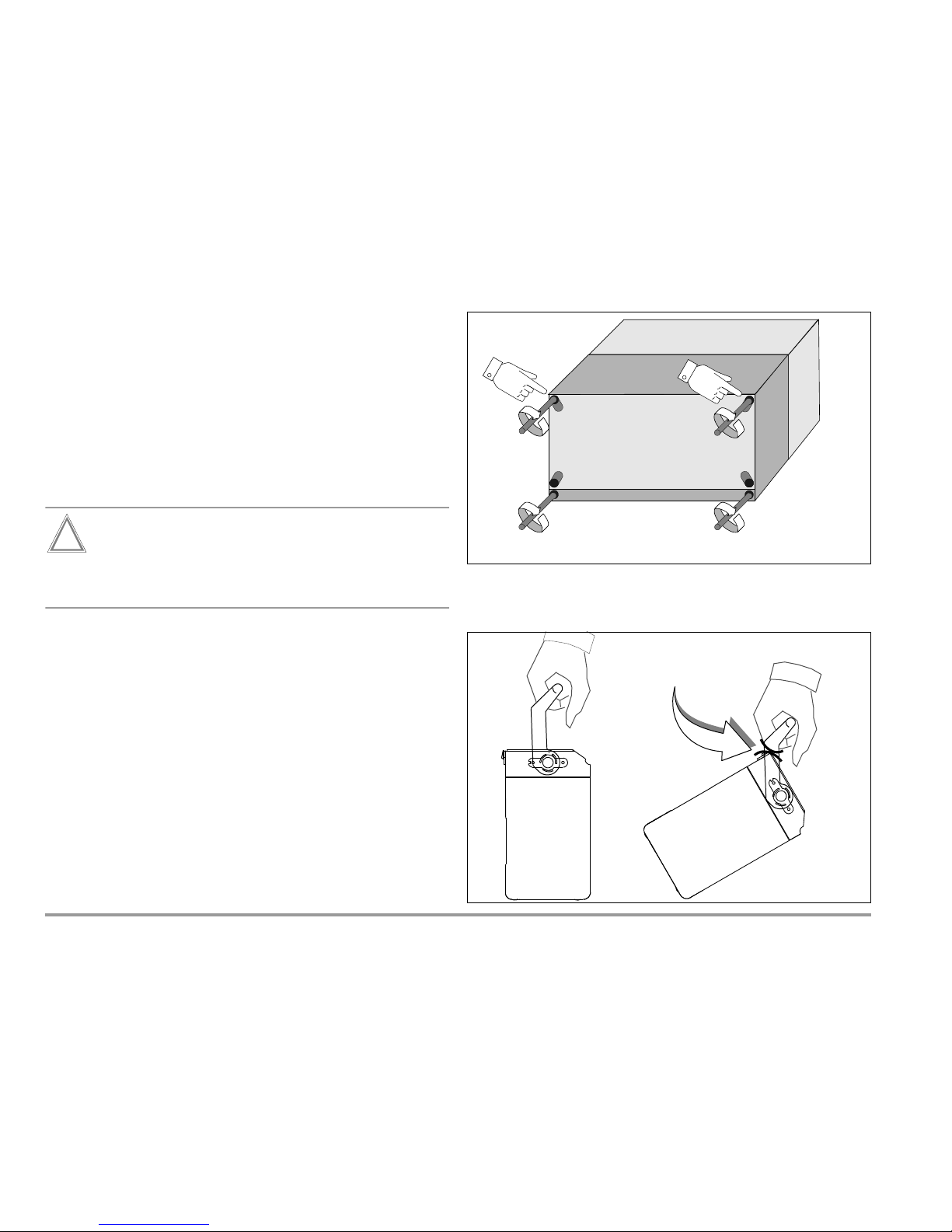

!

Attention!

The basic instrument and the high-voltage module must

both be disconnected from the mains and from the

measuring circuit prior to mounting.

➭ Close the lid of the basic instrument.

➭ Turn the basic instrument upside down. Place it onto a soft

surface in order to avoid scratching the lid.

➭ Pull the two rubber feet from the bottom of the basic

instrument behind which the through-holes are concealed.

➭ Position the high-voltage module such that the connector

terminals and cables from both devices are on the same side.

➭ Pull the two rubber feet from the bottom of the high-voltage

module behind which the through-holes are concealed.

➭ Set the four threaded rods into the through-holes (see sketch).

➭ Tighten the threaded rods with a screwdriver (4.5 mm).

➭ Insert the two previously removed rubber feet into the holes at

the high-voltage module.

Rear Panel, High-Voltage Module

Remove

rubber feet.

Caution, danger

of pinching!

Page 15

GMC-I Messtechnik GmbH 15

3.1.2 The Key Switch

The key switch protects the instrument against unauthorized use.

Keep the key in a safe place to which only authorized personnel

have access.

Each time testing is completed, turn the key to the “0” position

and remove it from the lock.

3.1.3 Indication of Operating States

Signal Lamps

The signal lamps integrated into the high-voltage module indicate

the two different operating states:

Green: Stand-By State

• Key switch is in the “I” position (on).

• Power supply to signal and control circuits at the

high-voltage module is switched on.

• All test voltage circuits are switched off and are secured

against inadvertent activation.

!

Attention!

All safety precautions which are required before entering

the danger zone should now already be implemented,

including posting of warning signs (WS1) and additional

signs (ZS2) in accordance with DIN 40008, part 3.

Red: Ready for Activation, Caution: Danger!

• The menu used to start the voltage test has been opened and

the start key has been activated.

• No voltage has yet been applied to the safety test probe,

assuming the trigger at the high-voltage pistol has not been

pulled.

• The test probes are secured against unintentional contact,

assuming the triggers at the high-voltage pistols have not been

pulled.

!

Attention!

When the instrument is “ready for activation”, all points of

access to the danger zone must be secured!

See chapter 11.5.2, page 67, regarding signal lamp replacement.

External Signal Lamps

The external signal lamps indicate the same operating states as

the signal lamps integrated into the high-voltage module. They are

used for additional security at the measuring site, and must be

plainly recognizable beyond the boundaries of the danger zone.

The external signal lamps can be directly connected to the

respective terminals at the high-voltage module.

Note

For reasons of safety, only Z504D signal lamps by

GMC-I Messtechnik GmbH may be used.

See chapter 11.5.3, page 68, regarding signal lamp replacement.

Page 16

16 GMC-I Messtechnik GmbH

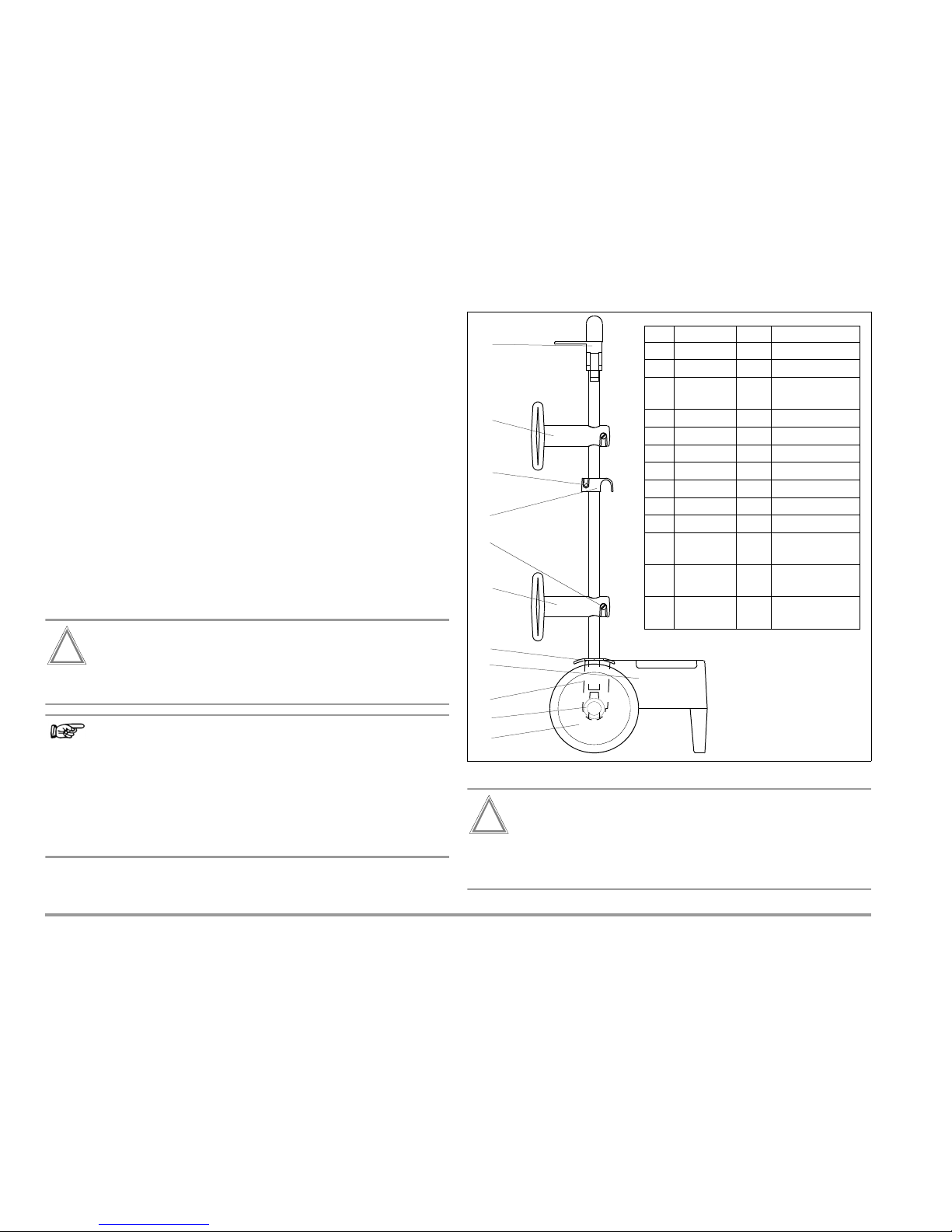

3.2 Mounting the Instruments to the Optional Caddy

➭ Place the unit (consisting of the basic unit and the high-voltage

module) onto the caddy platform (1) such that the lid of the

basic unit can still be opened.

➭ Secure the handle of the basic unit with the handle fixtures (3)

on the vertical posts as follows:

➭ First loosen the screws at handle fixtures (9) with a 4 mm hex

socket wrench.

➭ Push the handle fixtures (3) onto the handle and retighten the

screws (9).

➭ Wind the two cables from the safety test probes at the

high-voltage module onto the lower cable reel (2, bottom).

➭ Then wind the two cables from the test probes at the basic

instrument onto the upper cable reel (2, top).

➭ Secure the cables and test probes with the included rubber

bands (12).

!

Attention!

Observe regulations for portable testing systems as set

forth in DIN VDE 0104 (3.6).

Note

Wind the cables from the safety test probes onto the

reels included for this purpose at the back of the caddy

after each use. The test cables may not, under any

circumstances, be mechanically stressed or kinked,

because this may result in impaired insulation

characteristics. Remember that damage may

not always be externally recognizable.

!

Attention!

Always inspect the test cables for mechanical damage

before starting up the high-voltage module, each time it

is used.

10

11

8

2

3

2

5

6/7

1

4

9

Item Designation Qty. Order No.

1 Platform 1 3-117-193-01

2 Cable Reel 2 3-326-653-01

3

Handle

Fixture

2 3-326-652-01

4 Cover 2 3-164-609-01

5 Wheel 2 3-419-038-01

6 Disk 4 3-740-013-01

7 Circlip 2 3-743-024-59

8 Screw 6 3-712-007-10

9 Hex Nut 6 3-730-119-12

10 Screw 2 3-716-018-24

11

Caddy

Frame

1 3-121-111-01

12

Rubber

Band

2 3-326-627-01

13

Protective

Cover

1 3-171-302-01

Transport Caddy 204

Page 17

GMC-I Messtechnik GmbH 17

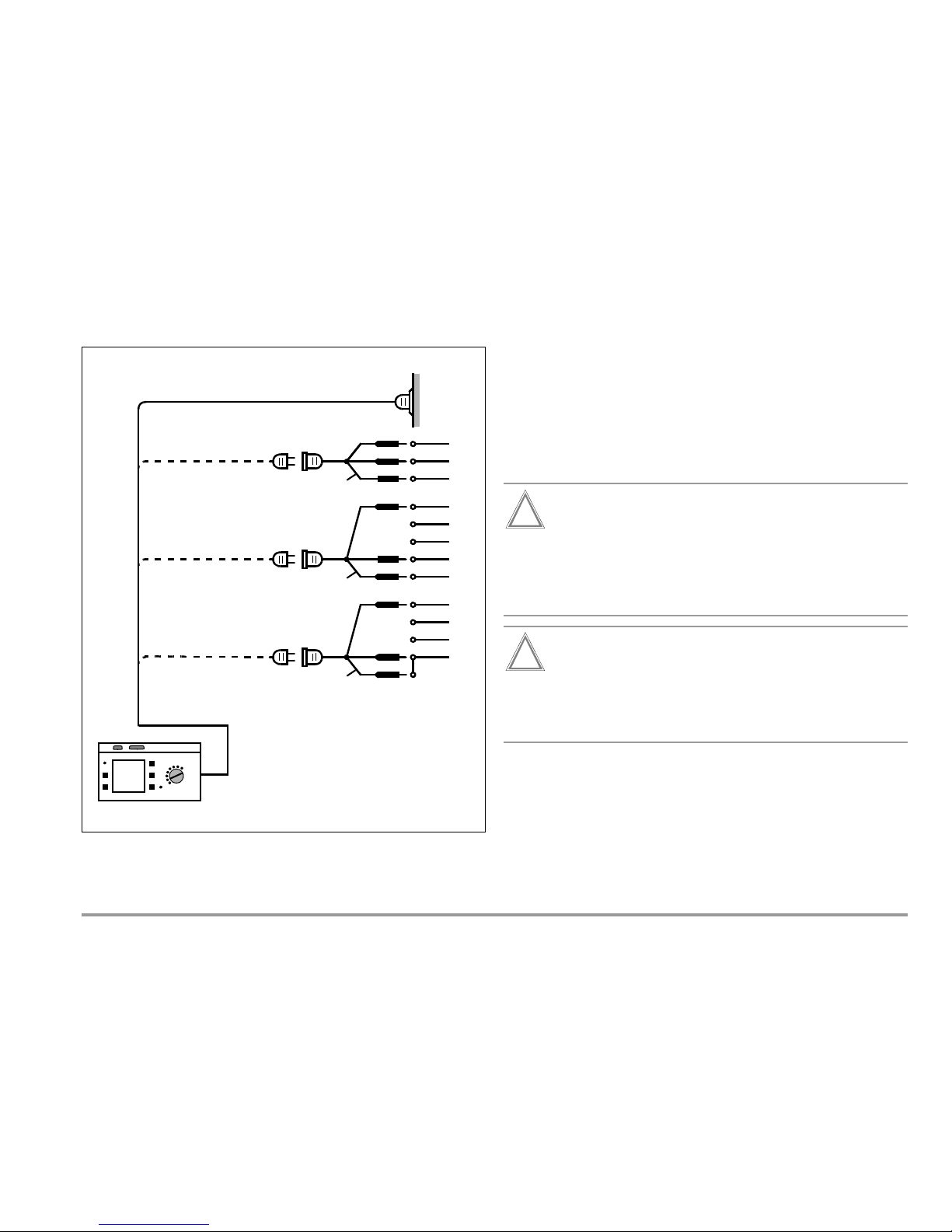

3.3 Connecting the PROFITEST 204+ to 230 V Mains Power

➭ Connect the test instrument to 230 V mains power with the

attached mains connection line (connection 22 at the instrument).

If an earthing contact outlet is unavailable, or if only a 3-phase

outlet is available, the phase conductor, the neutral conductor

and the protective conductor can be connected with the help

of the socket adapter. The socket adapter is equipped with

three permanently attached cables and is included as part of

the KS13 cable set, which is available as an accessory.

!

Attention!

If a connection via earthing contact outlet is not possible,

disconnect the mains from all sources of voltage before

connecting the cables of the coupling socket via pick-up

clips with the mains connections, as shown in the drawing.

!

Attention!

The recessed outlet at the basic instrument is used to

supply power to the HP/HV high-voltage module.

If this outlet is used for any other purpose, current

consumption may not exceed 6 A.

3.4 Connecting the High-Voltage Module to 230 V Mains Power

Connect the recessed outlet at the basic instrument to the inlet

plug at the high-voltage module with the included power cable.

The high-voltage module can also be connected directly to 230 V

mains power.

L1

N

green-yellow

green-yellow

PE

L1

L2

L3

N

PE

L1

L2

L3

N

green-yellow

U

L–N

= 230 V

Page 18

18 GMC-I Messtechnik GmbH

3.5 Operating Software

Measuring and testing is quick and easy with the PROFITEST 204+.

The integrated operating software informs the user concerning all

necessary operating procedures, errors and measuring results

etc., regardless of the selected measuring function. All information

and measurement results are displayed at the dot matrix LCD in

clear text.

The integrated operating software is sufficient for most tests and

measurements. However, the operator should nevertheless read

and observe the contents of these operating instructions.

3.6 Online Help

Online help can be queried and displayed at the LCD for all

measuring and test functions, and for practically all settings.

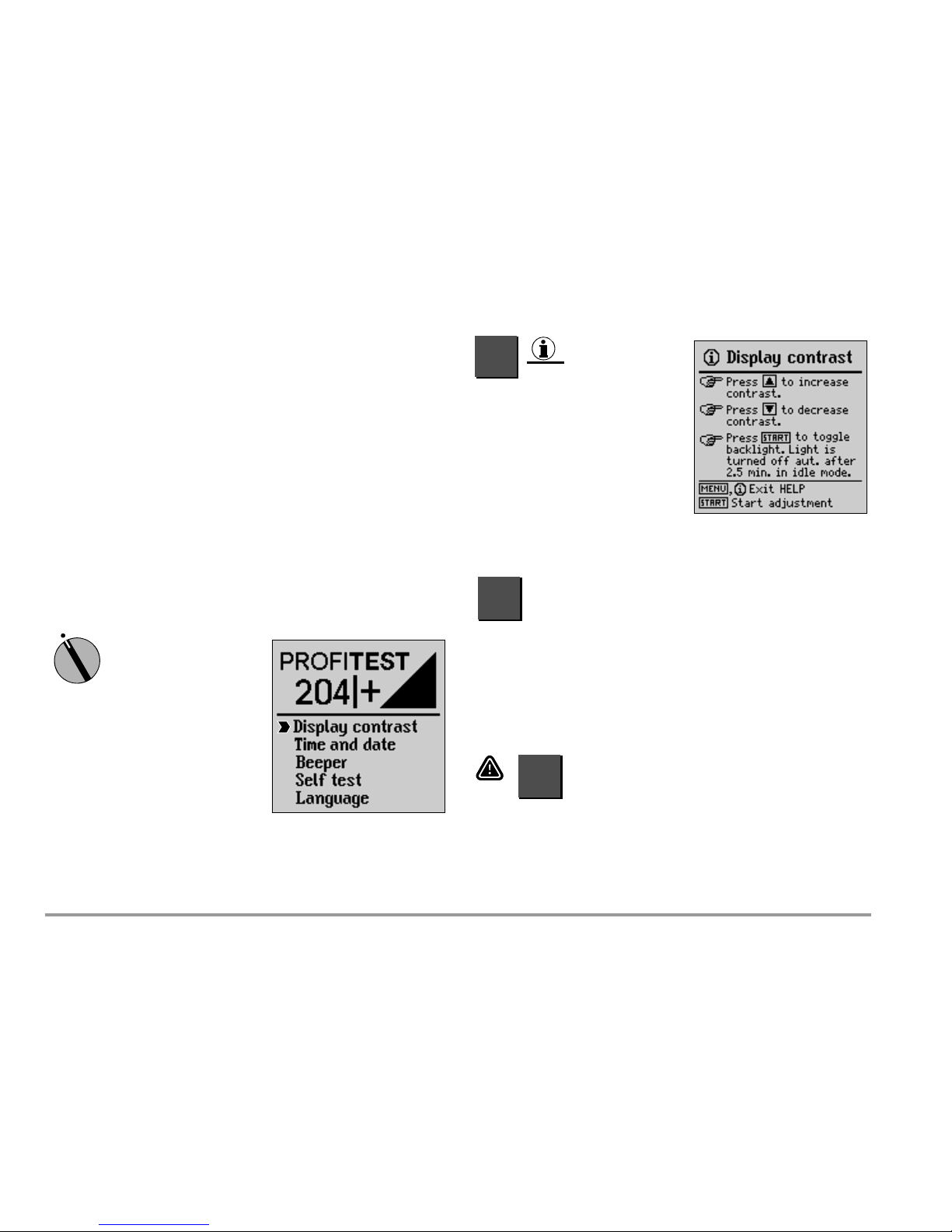

Example: Display Contrast Function

SETUP

Switch position

➭ Press the STORE key in order to query online help:

STORE

Query online help.

➭ Press the same key once again, or the MENU key, in order to

exit the online help function:

MENU

Exit online help.

or

➭ Start the selected function directly from the online help menu

with the START key:

START

Start the selected function.

Page 19

GMC-I Messtechnik GmbH 19

3.7 Setup

Various basic settings can be configured for the test instrument

with the selector switch in the SETUP position.

SETUP

Select the desired parameter.

MENU

Open parameters entry window.

All settings and changes entered via the menus which are made

available when the selector switch is in the SETUP position, are

saved automatically and are retained, even after the test

instrument has been disconnected from mains power.

MENU

Exit function.

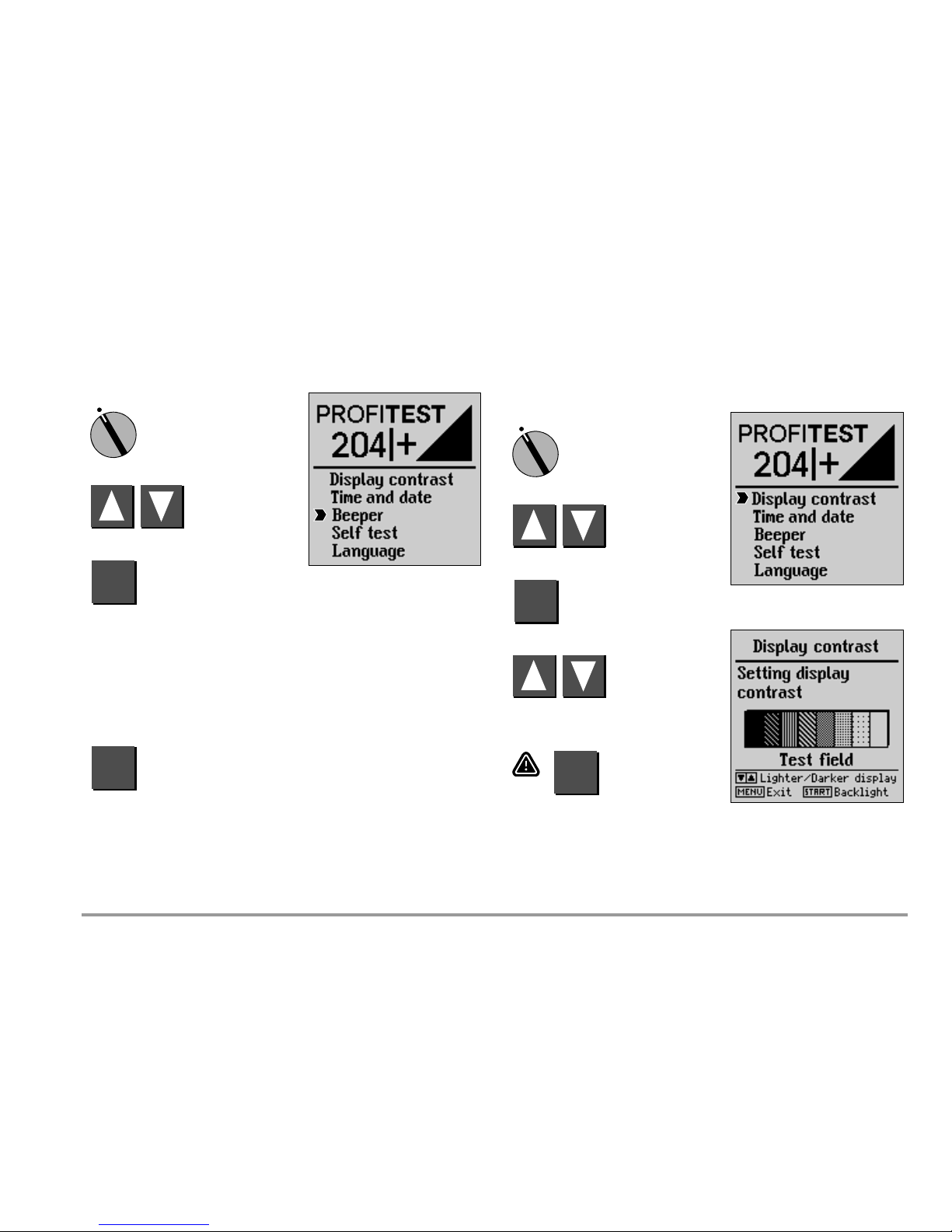

3.7.1 Adjusting Contrast and LCD Illumination

Contrast can be increased or reduced with this function.

Furthermore, illumination can be activated or deactivated.

(Only for devices with electroluminescence lighting)

SETUP

MENU

Adjust contrast.

START

Activate or deactivate illumination. *

* This function is only available for devices with electroluminescence lighting.

Background illumination is switched off automatically after 2.5 minutes, as long

as no keys are activated during this period of time. Background illumination is

reactivated for an additional 2.5 minutes each time a key is pressed.

Page 20

20 GMC-I Messtechnik GmbH

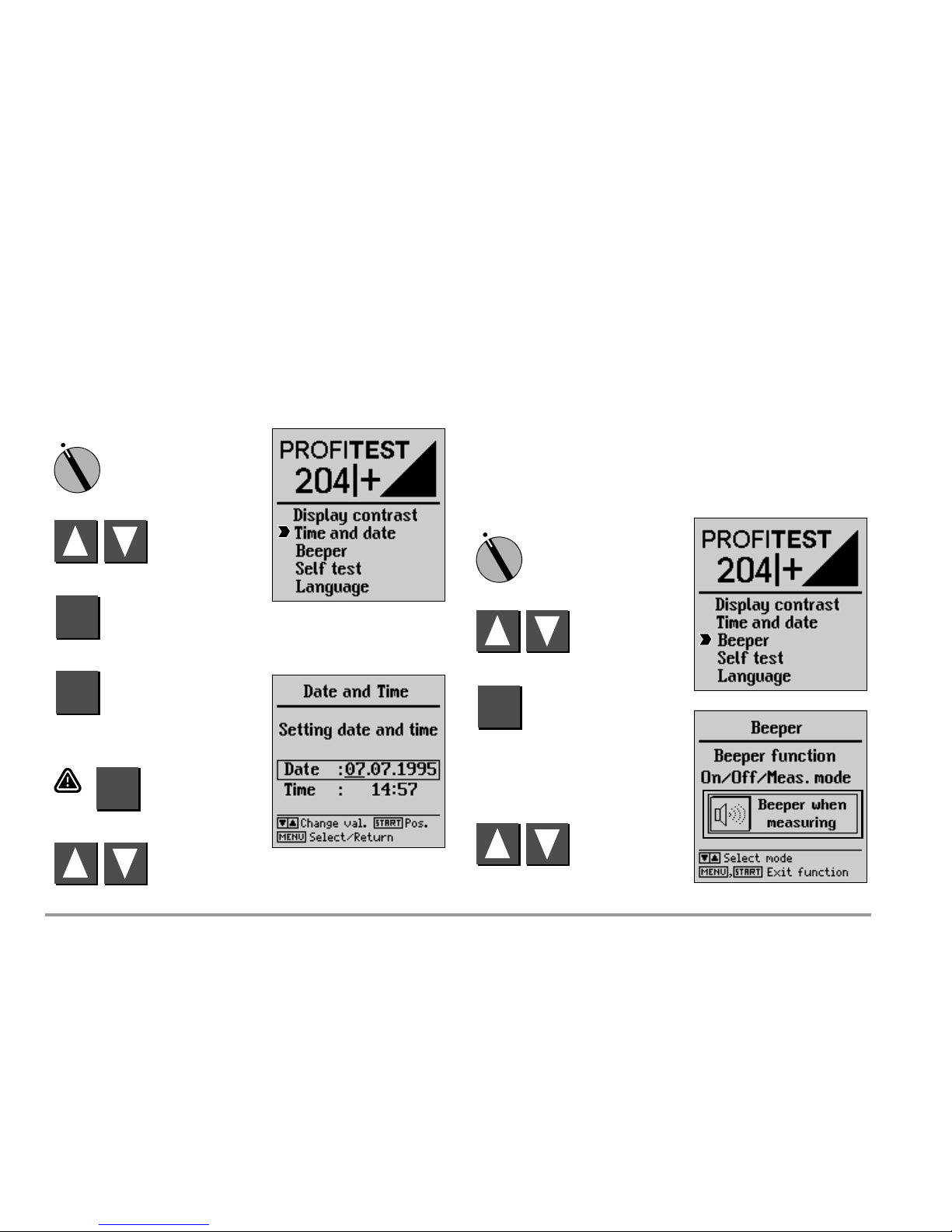

3.7.2 Setting Time and Date

The test instrument’s internal clock can be set with this function.

The clock continues to run, even after the instrument has been

disconnected from mains power. Time and date are included in

the printed test reports.

The date is entered as follows: DD.MM.YYYY (Day.Month.Year).

SETUP

MENU

MENU

Select time or date.

START

Select cursor position for data entry.

Change values.

3.7.3 Configuring the Signal Generator

If “Measuring mode” or “On” is selected, various acoustic

signal sequences are generated during operation of the

high-voltage module which identify its operating state.

Measuring Mode:

A “good” measurement is indicated with a single,

long acoustic signal, and a “bad” measurement

with three short acoustic signals.

On: Same as “Measuring mode”, plus each key

activation is acknowledged with an acoustic

signal as well.

Off: No acoustic signals are generated.

SETUP

MENU

Select On, Off or Measuring mode.

Page 21

GMC-I Messtechnik GmbH 21

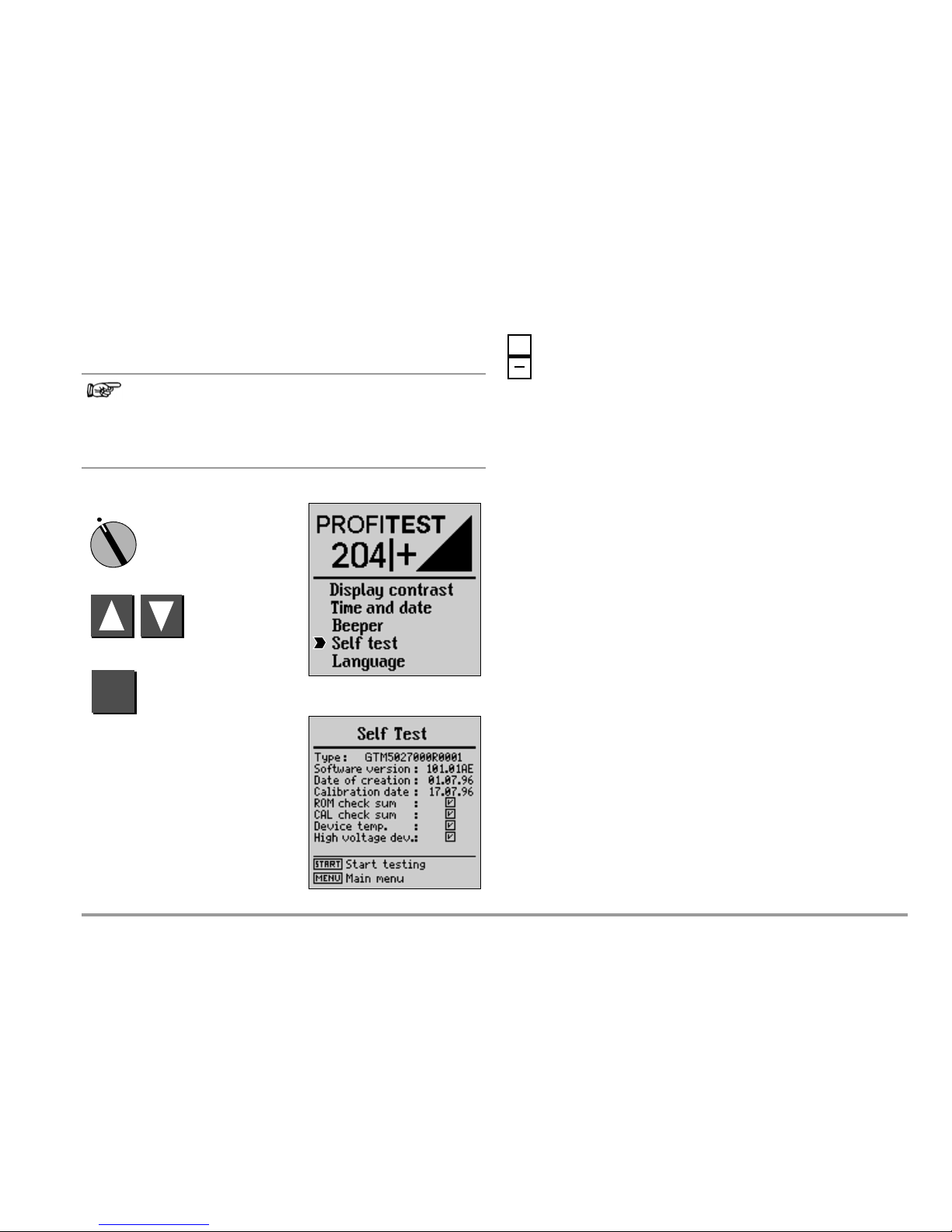

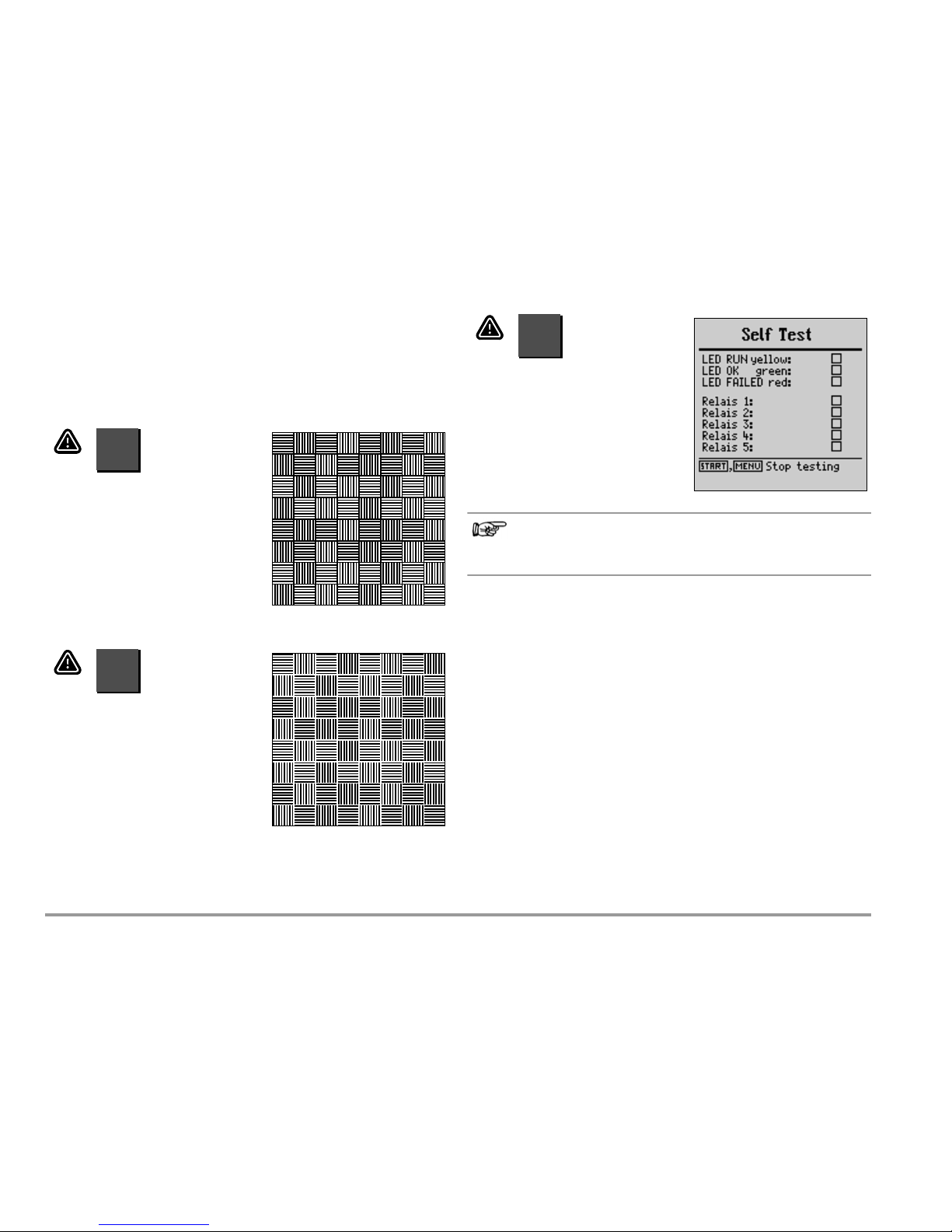

3.7.4 Performing the Self-Test

Display, lamp and relay functions, as well as options, are

automatically tested and results are displayed.

Note

Before starting the self-test, both test probes must be

disconnected from any devices under test, and must be

kept separate from one another. It is also essential to

assure that no voltage is present at the test probes.

SETUP

MENU

Error Messages and their Meanings

Test results OK or option installed (high-voltage module)

Error message: Test failed, device under test defective or

option not installed

ROM Checksum

A software error may have occurred. Install the included system

software to the test instrument again. If problems persist, we

recommend calling our product support hotline.

CAL Checksum

This portion of the self-test examines the calibration subassembly.

Even if the CAL checksum is OK, this does not mean that the

PROFITEST 204+ need not be calibrated in accordance with the

prescribed schedule.

If this portion of the self-test is failed, the instrument must be

returned to the manufacturer for re-calibration.

Temperature Inside the Test Instrument

The temperature limit has been intermittently exceeded inside the

instrument. The measuring mode is disabled until the temperature

drops back into the allowable range.

Do not start the next measurement until the temperature error has

been cleared.

High-Voltage Module

An installed high-voltage module is recognized automatically.

Proceed as follows if an error message is read out for this portion

of the self-test, even though a high-voltage module has been connected:

Check the connections at both instruments and, above all, make

sure that the signal tubes at the high-voltage module have not

been obstructed or covered.

✓

Page 22

22 GMC-I Messtechnik GmbH

LCD Test

In the following two tests, neighboring horizontal and vertical

elements at the LCD are activated separately. If individual cells do

not become active, send the instrument to an authorized service

center for repair.

START

Continue testing.

START

Continue testing.

START

Continue testing.

Note

The LEDs must first blink, and the relays must be

switched before they can be checked off as OK.

Page 23

GMC-I Messtechnik GmbH 23

3.7.5 Uploading the Desired Language or a Software Update

If a language other than the one included with the instrument is

desired, it can be uploaded with the help of the WinProfi* PC program. The file with the desired language is transmitted to the test

instrument via the serial interface. The previously installed

language is overwritten in the process.

Software updates can also be uploaded with the same program,

independent of the currently installed language.

Note

WinProfi software can be used to upload the desired language to the test instrument. The software encompasses

all of the functions required for establishing communications between the PROFITEST 204+ and a PC. A program

description is contained in the online instructions

included with the WinProfi software.

WinProfi software

* *WinProfi is currently applicable up to Windows 7 (32 Bit)

A Installing and Starting WinProfi Software at the PC

➭ Download the WinProfi software from our homepage:

http://www.gossenmetrawatt.com

(Products Software Software for Testers WinProfi)

➭ Unzip the zip file „winprofi.zip“.

➭ Install the software on your PC by executing file

Setup_WinProfi_Vx.xx.exe.

➭ Select the desired language for the WinProfi software and for

the user interface of the test instrument.

➭ Follow the instructions which appear at the monitor.

The program is added to your start menu after installation.

➭ Establish a connection between the PC and the

PROFITEST 204+. Use an appropriate interface cable to this end,

see page 5.

➭ Start WinProfi again.

➭ Switch the test instrument on.

Display or print out online user’s manual.

The online manual contains information concerning the software

which is not included in these operating instructions.

Page 24

24 GMC-I Messtechnik GmbH

B Prerequisites for Software-Update or Exchange of Data

➭ Find the interface to which the PROFITEST 204+ is connected.

Note

Always start this function first, before performing an update

or changing report templates.

After starting this function, WinProfi loads the report files

specifically necessary for the connected instrument.

Due to the fact that WinProfi has been created for use

with several types of test instruments, incorrect test

reports may otherwise be loaded, or erroneous options

may be made available.

➭ Query information regarding current software version.

C Transmitting a Software Update to the Test Instrument

!

Attention!

Previously saved data are lost during the updating procedure.

Save the measured values to your PC before.

➭ PC: Select Update all from the Update menu. Follow the instruc-

tions which appear at the monitor.

Depending upon the utilized PC, updating takes from 1 to 2 minutes.

The green LED indicates that the instrument is ready to receive data.

If the PC and the test instrument are correctly synchronized, the yellow LED lights up and the green LED goes out. The red LED lights up

during programming sequences. After transmission has been completed, the LED goes out and the instrument is restarted.

The message “Transmission done” appears at the PC.

!

Attention!

The instrument may not, under any circumstances, be

switched off during transmission, nor may the connection to the PC be interrupted!

• Subsequently select „Language“ (loading the respective language), if applicable.

Page 25

GMC-I Messtechnik GmbH 25

D Organizing Report Data

➭ Connect the test instrument directly with the PC via an appro-

prate interface cable.

Note

Do not connect the PC to the SI module.

• Send or receive a data file

•Print data

• Edit or transmit report templates

6

3

5

2

1

4

Page 26

26 GMC-I Messtechnik GmbH

4 Testing Machines in Accordance with DIN VDE 0113 and EN 60 204

Each of the following tests is automatically allocated to the

currently selected system number. If the respective test results are

saved with the STORE key, they are assigned to this number. The

system number can be entered in the “Select system” menu (see

chapter 5.1, page 42).

The following sequence applies to the measuring mode:

• Select the desired test.

• Enter test parameters (if required).

• Start measurement or return to the initial menu.

• Save measured values to memory and enter a description (if

desired)

The protective conductor test, the insulation test and saving measured values to memory can be triggered from the test probe (17).

Test Parameters and Limit Values per DIN VDE

Note

If test parameters and limit values have been changed,

we recommend resetting these to the default settings in

accordance with DIN VDE before testing a new system.

Switch the test instrument on to this end. Press the MENU key

and then turn the function selector switch to the TEST position.

This restores default values in accordance with DIN VDE.

Standard values in accordance with DIN VDE are included in the

table in chapter 8, page 57.

Setting Ranges for PROFITEST 204+ Parameters

The lower and upper limit values for all adjustable parameters are

included in the table in chapter 8, page 57.

4.1 Protective Conductor Test

Uninterrupted connection of a protective conductor system is

tested here by using an alternating current of approximately 10 A

with a line frequency of 50 Hz. Testing must be conducted

between the PE terminal and various points within the protective

conductor system.

If resistance values of less than 1.00 occur, voltage drop U for

respective protective conductor resistance is displayed. This is the

calculated voltage value based upon a 10 A test current in

accordance with DIN VDE 0113.

Voltage at the test probes is displayed for resistance values of

1.00 to 25.0 and for over-ranging (> 25.0 , because

calculated voltage drop U based upon 10 A would lead to

unrealistically high results in this case.

After expiration of the test duration, the highest measured

protective conductor resistance value and the corresponding

voltage drop value are displayed.

Always assure that adequately good contact has been established with the device under test before starting the test. The test

can be started with the key (20) on the test probe (17) if preferred.

If test current drops to a value of less than 10 A during the

selected test duration, a corresponding message appears at the

display. However, testing is continued normally. In the event of

poor contact or if the test probes are not connected, testing is

aborted.

If voltage is present at the test probes after measurement has

begun*, no measurement is performed. Interference voltage at test

probes appears at the display, and a STOP signal is displayed simultaneously.

* this message may be displayed in the case of interrupted protective conductor

connections as well, as external voltages have been included capacitively here.

Page 27

GMC-I Messtechnik GmbH 27

TEST

Select the desired test.

MENU

Open the parameters entry window.

4.1.1 Configuring Test Parameters

Test d ura t ion can be adapted to local circumstances.

Recommended test duration: 10 s.

The limit value for protective conductor resistance can be

changed depending upon conductor cross-section and the

characteristics of the overvoltage protection device which is used

with the machine.

MENU

Select the parameter.

Set the value.

The limit value setting for protective conductor resistance is

based upon the cross-section of phase conductor L and, if

applicable, neutral conductor N, and not the cross section of

protective conductor PE. This is necessary because cables with

phase conductor cross-sections of greater than 16 square mm

are equipped with protective conductors of reduced crosssection, and selection on the basis of protective conductor crosssection would not be unequivocal.

A rated current (nominal current) is assigned to the phase

conductor cross-section for the respectively utilized overcurrent

protection device, as shown in the following table. The table can

be displayed from the TEST menu in order to simplify selection as

an aide to the protective conductor test function.

STORE

Query help.

Due to the fact that according to EN60204-1:2006 overcurrent

protection devices with varying tripping characteristics are

permissible for each phase conductor cross-section, 5 different

types are offered for cross-sections of up to 16 square mm, and

two for cross-sections of greater than 16 mm when selecting the

limit value.

Page 28

28 GMC-I Messtechnik GmbH

MENU

Select the parameter.

Set the value.

Proceed as follows in order to select the limit value:

➭ Ascertain the phase conductor cross-section of your

connector cable.

➭ If applicable, check to see whether or not the nominal current

of the utilized overcurrent protection device is allocated to the

phase conductor cross-section. If an overcurrent protection

device with low nominal current is used, you can determine the

limit value on the basis of the phase conductor current

assigned to this nominal current.

➭ Select the limit value on the basis of the triggering

characteristics offered for the various overcurrent protection

devices.

If your machine/system includes components with different power

cable cross-sections (e.g. fans, pumps etc.), and if these are

equipped with their own overcurrent protection devices, the limit

value for the protective conductor test must be selected in

accordance with the power cable cross-section of these

components, or with the overcurrent protection devices which

have been installed for them.

4.1.2 Start the Test

START

or

Note

The test can only be started with the START key on the

test instrument from the test parameters window (see

picture on page 27).

STORE

Press briefly: Store an event.

Press and hold:

Store an event and activate the entry field.

Up to 15 characters can be entered to the entry

field, or to the info field at the bottom left as a

description for the measurement.

See chapter 5.1.1 regarding data entry.

or

STORE

Press briefly: Save results.

The green/red signal lamp is extinguished briefly as

acknowledgement.

Page 29

GMC-I Messtechnik GmbH 29

4.2 Insulation Resistance Test

In accordance with EN 60204/DIN VDE 0113, insulation resistance measured between the phases of all current circuits and

the protective conductor circuit with 500 V direct voltage may not

be less than 1 M.

Four nominal voltage ranges are included with the PROFITEST 204+

for this test: 100 V, 250 V, 500 V and 1000 V. These can be configured as test parameters, as is also the case with the allowable

limit value for insulation resistance.

The measurement can be started in an ideal fashion with the key

(21) on the test probe (17). For capacitive devices under test, or

for DUTs with relatively long cables, press and hold the key (21 or

10) until stabilized display values have been obtained. When the

START key is pressed and held, the instrument performs

continuous, instead of an individual measurement.

Voltage at the device under test appears at the LCD in addition to

measured insulation resistance.

Discharge

Upon completion of the measurement, the device under test is

automatically discharged in order to assure absence of voltage.

The falling voltage value can be observed at the display during

discharging. The measured insulation resistance value remains in

memory during this period of time.

Interference voltage

If voltage is present at the test probes after

measurement has begun, no measurement is

performed. Interference voltage at test probes

appears at the display, and a STOP signal is

displayed simultaneously.

!

Attention!

Do not touch the test probes during this measurement!

A direct voltage of up to 1000 V is present between the

test probes.

Note

Testing of measurement cables

The first test should be conducted on test probes with

short-circuited measurement cables. The instrument

must indicate a value of approximately zero . This

serves to establish whether the measurement cables are

disconnected at any point.

TEST

Select the desired test.

MENU

Open the sub-menu.

Page 30

30 GMC-I Messtechnik GmbH

4.2.1 Configuring Test Parameters

Select a test voltage of 500 V for the main circuit, or 1000 V if

required for extended testing. A lower test voltage can also be

selected for testing voltage sensitive components. The allowable

limit value for insulation resistance can also be changed.

MENU

Select the desired parameter.

Adjust to the desired value.

4.2.2 Start the Test

START

or

Note

The test can only be started with the START key on the

test instrument from the test parameters window.

STORE

Press briefly: Store an event.

Press and hold:

Store an event and activate the entry field.

Up to 15 characters can be entered to the entry

field, or to the info field at the bottom left as a

description for the measurement.

See chapter 5.1.1 regarding data entry.

or

STORE

Press briefly: Store an event.

The green/red signal lamp is extinguished briefly as

acknowledgement.

Page 31

GMC-I Messtechnik GmbH 31

4.3 Leakage Current Test

This test is required by DIN VDE 0701-0702. It can be used to

test devices, machines and systems for the observance of limit

values for leakage current (contact current).

Leakage current and voltage drop resulting from this current at a

2kload are measured and displayed.

Note

If a voltage of greater than 20 V occurs at the test probes,

leakage current measurement is stopped. The 2 k load

is also deactivated in this case.

Display of measured voltage U nevertheless continues.

!

Attention!

Interference voltage may not exceed 250 V.

TEST

Select the desired test.

MENU

Open the sub-menu.

4.3.1 Configuring Test Parameters

The limit value (maximum leakage current) can be changed.

MENU

Select the desired parameter.

Adjust to the desired value.

4.3.2 Start the Test

START

Note

The leakage current test can only be started with the

START key on the test instrument.

Page 32

32 GMC-I Messtechnik GmbH

STORE

Press briefly: Store an event.

Press and hold:

Store an event and activate the entry field.

Up to 15 characters can be entered to the entry

field, or to the info field at the bottom left as a

description for the measurement.

See chapter 5.1.1 regarding data entry.

or

STORE

Press briefly: Store an event.

The green/red signal lamp is extinguished briefly as

acknowledgement.

Page 33

GMC-I Messtechnik GmbH 33

4.4 Voltage Measurement (protection against residual voltage)

EN 60204 requires that voltages in excess of 60 V occurring at all

accessible machine components during operation must drop to a

residual voltage value of 60 V or less within a period of 5 seconds

after supply power has been switched off.

Testing for the absence of voltage is conducted with the

PROFITEST 204+ by means of a voltage measurement which measures discharge time as well. During discharge, elapsed time is

continuously displayed at the LCD after supply power has been

switched off, until the limit value of 60 V has been reached.

In addition to the type of voltage (AC, DC or AC+DC), the

respective frequency is measured and displayed as well. The

mean value is always read out.

In addition to voltage and frequency, type of voltage (AC, DC or

AC+DC) is displayed in the symbol field at the bottom right-hand

portion of the display.

If, during a voltage measurement with a measured value of more

than 60 V, the voltage value drops by more than 5% of the

measured value during one measuring period (approx. 0,7 s), time

measurement for the testing of protection against residual voltage

is started automatically. Elapsed time can be observed in the

symbol field at the display. Time measurement is stopped as soon

as the measured value drops to below the 60 V threshold.

Elapsed time required for discharge to 60 V now appears at the

display. Voltage measurement continues until maximum allowable

discharge time has elapsed (normally 5 s). The measured voltage

value is then frozen and the DATA HOLD symbol appears at the

display. If the 60 V limit is not reached within the allowable

discharge period, the voltage value measured at the end of this

period is frozen and time measurement continues until 10

seconds have elapsed. If the voltage value is still above 60 V, the

test is aborted and the instrument resumes voltage measurement.

If a value has been frozen at the display, voltage measurement is

not resumed by the instrument until:

• The START key is pressed

• The measurement is stored to memory with the i/STORE key

• Voltage measurement is restarted from the menu

• Voltage at the test probes climbs again to a value of greater

than 60 V, or, assuming the last measured voltage value was

greater than 60 V, the following measured value is even higher,

i.e. if rising voltage can be observed.

Elapsed time and the measured voltage value at the end of the

allowable discharge period are stored to memory by activating the

i/STORE key. If discharge does not occur, only the voltage value is

saved.

Note

If conductors are exposed when a machine is switched

off which are not protected against direct contact (e.g. if

plug connections are interrupted), the maximum

allowable discharge period is 1 second!

Page 34

34 GMC-I Messtechnik GmbH

TEST

Select the desired test.

MENU

Open the sub-menu.

4.4.1 Configuring Test Parameters

The discharge period (the time during which the voltage value must

be reduced to a safe level of less than 60 V) can be set within a

range of 0 to 9 seconds. “Residual voltage less than 60 V!” is displayed when this threshold has been reached.

Set discharge period duration.

4.4.2 Start the Test

START

Note

The voltage test can only be started with the START key

on the test instrument.

STORE

Press briefly: Store an event.

Press and hold:

Store an event and activate the entry field.

Up to 15 characters can be entered to the entry

field, or to the info field at the bottom left as a

description for the measurement.

See chapter 5.1.1 regarding data entry.

or

STORE

Press briefly: Save results.

The green/red signal lamp is extinguished briefly as

acknowledgement.

Page 35

GMC-I Messtechnik GmbH 35

4.5 Voltage Test (option: PROFITEST 204HP/HV)

Electrical equipment at machinery must withstand a test voltage

applied between the conductors of all electrical circuits and the

protective conductor circuit for a period of at least 1 second, with

a value of twice the rated voltage of the equipment or 1000 V~,

whichever is greater. The test voltage must have a frequency of

50 Hz and must be generated by a transformer with a minimum

power rating of 500 VA.

Note

The PROFITEST 204+ must be used in combination with

the PROFITEST 204HP/HP-2.5kV high-voltage module

for testing in accordance with DIN VDE 0113.

The PROFITEST 204HV/HV-5.4kV is required for testing

with up to 5 kV.

The PROFITEST 204+ automatically recognizes which type of

high-voltage module has been connected. Communication

between the basic instrument and the high-voltage module can

be tested as described in chapter 3.7.4.

!

Attention!

Inspect the test instrument, high voltage cables and

high-voltage pistols to assure flawless condition before

beginning work (see also chapter 11.4, page 67).

Note

Testing of measurement cables

The first test should be conducted on test probes with

short-circuited measurement cables. The instrument

must indicate a value of approximately zero . This

serves to establish whether the measurement cables are

disconnected at any point.

4.5.1 Functions Test (test preparation)

Perform the following functions test in the indicated order from a)

through e).

a) Key Switch

➭ Set the key switch to “0”.

• Neither the green nor the red signal lamps may light up.

b) Voltage Test

➭ Set the key switch to “I”.

• The green signal lamps must light up.

➭ Select the voltage test with the keys.

TEST

Select the desired test.

Initialisation of high-voltage module

as a prerequisite for correct parameter input

➭ Press the START key.

The corresponding high-voltage module is recognized and displayed in the bottom left corner of the LCD provided it has been

correctly connected and the key switch is in the „I“ position.

The initialisation ensures that the parameter values that are subsequently entered are within the limits applicable to the respective

high-voltage module.

Page 36

36 GMC-I Messtechnik GmbH

➭ Select the desired values for test duration, test voltage,

breaking current I

MAX

and rise time (chapter 4.5.2, page 37).

Note

Do not set I

MAX

to pulse control!

➭ Press the START key.

• The red signal lamps must light up.

• The following values are displayed at the LCD:

U

T

= –––V

I

T

=–––mA

The following symbol appears:

Danger: High-Voltage!

Touch neither the test probes nor the device under test

during the voltage test!

A life endangering high-voltage of up to 5kV is present at

the high-voltage module test probes!

➭ Pull the trigger at the marked high-voltage pistol with switch to

its limit stop and hold depressed.

• The following values are displayed at the LCD:

U

T

= selected value

I

T

= 00.0 mA or 0.00 mA

The following symbol appears:

➭ Release the trigger (switch).

• Voltage is switched off automatically after the selected test

duration has elapsed.

c) Shutdown Functions

➭ Short circuit the two high-voltage pistols.

➭ Pull the trigger at the marked high-voltage pistol with switch to

its limit stop and hold depressed.

• The instrument is shut down immediately.

• The green signal lamps must light up, and

the red signal lamps may not light up.

• The following values are displayed at the LCD:

U

T

= XXX V

I

T

= > XXX mA

The last measured voltage value before breaking current was

exceeded is displayed along with breaking current I

MAX

.

The following symbol appears:

Page 37

GMC-I Messtechnik GmbH 37

d) Signal Lamps

Two lamps are arranged diagonally at the test instrument and are

used to signal operating states. If both lamps go out when the

instrument is in the “ready to activate” operating state (RED), test

voltage is no longer generated.

Do not start the voltage test unless all signal lamps indicate

correct functioning.

Defective lamps must be replaced as described in chapter 11.5.2,

page 67.

Acoustic Signals (signals for “On” or “Measuring mode”)

See chapter 3.7.3, page 20 regarding activation of this function.

4.5.2 Configuring Test Parameters

The following parameters can be configured with the green signal

lamps illuminated in the stand-by state:

Test D ura t ion: Time period during which test voltage is applied.

Setting range: 1.00 to 120 s, the continuous

operation symbol >>>>>>> can

be selected with the key by

scrolling to below 1.00 s

Test Volt a ge: Test voltage level

Setting range: HP: 250 V .....2.00 kV

HP-2.5kV: 250 V ..... 2.50 kV

HV: 650 V .....5.00 kV

HV-5.4kV: 650 V ..... 5.35 kV

I

MAX

: Maximum allowable current before high-voltage is

switched off

Setting range: HP: 10.0....... 250 mA

HP-2.5kV: 10.0.......200 mA

HV: 0.50.... 10.0 mA

HV-5.4kV: 0.50.... 10.0 mA

Control symbol >>>>>>> can be selected with the

key by scrolling to below 10.0 or 0.5 mA

Rise Time: Period of time during which test voltage rises to

the selected value.

Setting range: 100 ms to 99.9 s

At table showing all setting ranges and standard values is

included in chapter 8, page 57.

0

t [s]

1

2

3

0

t [s]

1

2

3

0

t [s]

1

2

3

Ready to Activate

During Test

IT>I

MAX

Repetitive Sequence

Single Sequence

Repetitive Sequence

Page 38

38 GMC-I Messtechnik GmbH

MENU

Select the desired parameter.

Adjust to the desired value.

Te st

Voltage

Rise

Tes t D ec li n e*

Test Tim e

Time

*Constant=0.1s

U

T

Page 39

GMC-I Messtechnik GmbH 39

4.5.3 Test Sequence

!

Attention!

Make sure that all points of access to the danger zone

have been secured before testing is started, and that no

persons remain within the danger zone when the system

is made ready for activation.

➭ Turn the key switch to the “I” position.

The test instrument is switch to the stand-by mode.

The green signal lamps are illuminated.

➭ Check the test parameters.

➭ Press the START key.

The instrument is switched from stand-by to the “ready for

activation”. The red signal lamps are illuminated.

START

Danger: High-Voltage!

Touch neither the test probes nor the device under test

during the voltage test!

A life endangering high-voltage of up to 5kV is present at

the high-voltage module test probes!

➭ Position the high-voltage pistol in proximity to the device under

test.

➭ Pull both triggers, but only pull the trigger at the high-voltage

pistol with switch to its initial limit stop.

The test probes are exposed.

➭ Establish contact with the test circuit.

➭ Pull the trigger at the high-voltage pistol with switch to its final

limit stop.

High voltage is now switched to the test probes.

Testing continues until the selected rise time and the test duration

have elapsed.

An acoustic signal is generated by an internal buzzer for the

duration of the test (application of high voltage including rise and

decline).

➭ For subsequent testing of neighboring circuits, release the

trigger until it reaches its initial limit stop, establish contact with

the next test circuit and pull the trigger to its final limit stop.

Testing is started again.

Page 40

40 GMC-I Messtechnik GmbH

Storing Measured Values to Memory

After the test sequence has been completed, the last measured

values for U

T

and IT remain at the display. These results can be

saved with or without a comment, and a consecutive number is

assigned to the test automatically.

Up to 15 characters can be entered to the entry field, or to the info

field at the bottom left as a description for the measurement. See

chapter 5.1.1, page 43, regarding data entry.

The values at the display are overwritten when the next test is

executed.

STORE

Press briefly: Save results.

Press and hold:

Store an event and

activate the entry

field.

No values are saved to memory for U

T

and IT during continuous

operation (with test duration set to >>>>>>>).

Premature Interruption of the Test

The test can be interrupted prematurely at any time by releasing

the trigger at the high-voltage pistol with switch.

If testing is interrupted by releasing the trigger at the high-voltage

pistol before the pre-selected test duration has elapsed, the values displayed for U

T

and IT may deviate from the last measured

values.

Note

Regarding Breakdown Voltage:

If the selected breaking current I

MAX

is

exceeded before the selected test voltage

value has been reached, the test voltage

measured at this point in time is preceded

with the “>” symbol at the display, and is stored to

memory. The corresponding symbol appears as well.

Page 41

GMC-I Messtechnik GmbH 41

4.5.4 Pulse Control Mode

The pulse control mode is recommended for troubleshooting

(locating the point of flashover).

Breaking current I

MAX

is set to a fixed value of approximately

125 mA for the 204HP and 5 mA for the 204HV in the pulse

control mode. If this value is exceeded, test voltage is switched

off within 0.5 ms. After approximately 0.6 s, test voltage is

increased from 0 to the selected maximum value within a period

of 0.2 s, or is switched off again if breaking current is exceeded.

➭ Set I

MAX

to >>>>>>> for selection of the pulse control mode

(see chapter 4.5.2, page 37).

➭ If continuous operation is required, set test duration to >>>>>>>

as well (see chapter 4.5.2, page 37).

4.5.5 Ending the Voltage Test

➭ Release the triggers at the high-voltage pistols.

➭ Press the MENU key.

➭ The signal lamps switch from red to green.

➭ If the test system is left unattended, it must be switched to the

“out of service” mode (signal lamps off).

➭ Turn the key switch to the “0” positions and remove the key.

Secure the instrument against unauthorized use.

PauseRise

U

T

t

0.6 s

0.2 s

Page 42

42 GMC-I Messtechnik GmbH

5 Processing, Transmitting and Deleting Data

Previously stored data or data records can be processed with the

function selector switch in the data management position.

The following functions are available:

• Select a System

A system number can be selected with this function to which

measurement results can then be stored. A description of the

system can be entered as well.

• Data Processing

Individual data from a previous measurement (e.g. protective

conductor test) can be displayed for the selected system and

can be deleted if desired.

• Data Reorganization

Previously added systems can be deleted from memory, and a

memory test can be performed.

• Clear Memory

This command deletes data records which have been saved

for all existing systems. Full memory capacity is made available

in this way.

• Data Transmission

Measurement data (the entire contents of the memory at the

PROFITEST 204+) can be transmitted to a PC with this function,

where they can be subsequently analyzed, e.g. with the

programs WinProfi, PS3 or EXCEL. Data records which have

been saved to the PC can be transmitted back to the test instrument.

Memory Capacity

Current memory capacity is continuously displayed as a bar

graph in the first three functions listed above.

Depending upon how many systems have been entered (max.

254), up to 2800 measurements can be stored to memory.

5.1 Selecting a System

Select the desired command.

MENU

Sub-menu

System No.

Select a number.

Status: A filled in file cabinet indicates that measurement data

have already been stored for the selected system.

Page 43

GMC-I Messtechnik GmbH 43

5.1.1 Entering a Description

MENU

Description

Description:

Descriptions can be entered for the

various systems. The description is

displayed and subsequently printed out when the respective system is selected.

Note: An ID number should be entered for each system if PS3

software is used. Enter the number in parentheses. The system

description appears to the right of the ID number (see illustration

above). Parentheses are entered by pressing and holding the shift

key, and simultaneously pressing the number keys 8 and 9.

Descriptions can be entered in two different ways:

– Convenient Entry with the SI Module (optional)

Descriptions can be entered with the alphanumeric keypad at

the SI module (see operating instructions included with the

SECUTEST SI+).

– Entry with the Keys at the PROFITEST 204+

Select letters, numbers or characters.

STORE

Move the entry cursor left.

START

Move the entry cursor right.

MENU

Entered data must be acknowledged with the MENU key.

The previously entered data are then saved to memory.

Alternatively, data can be saved by pressing the STORE key at the

SI module.

Up to 250 characters can be entered. The entry field scrolls

automatically from one line of text to the next. Apart from the SI

module, data can also be entered via the PC keyboard (requires

adapter PROFI-MF-II, article number Z504H).

A comment can be entered for each test procedure in the same

way, immediately after completion of the test. However, the length

of these comments is limited to 15 characters.

5.1.2 Copying Descriptions

➭ Select the system with the description to be copied, and press

the MENU key three times.

➭ Select the new system and press the MENU key.

The copied text appears and can be edited as desired.

5.1.3 Deleting a Description

➭ Simultaneously press the i/STORE and the START keys.

The description is deleted and the cursor jumps to the first entry

position in the respective description entry field.

Page 44

44 GMC-I Messtechnik GmbH

5.2 Data Processing (viewing measured values)

Measured values can be viewed, and individual measurements

can be deleted if desired.

Select the desired command.

MENU

Select the desired measurement.

STORE

Delete the measurement.

“Data record deleted” appears at the display after deletion of the