Page 1

PROFITEST 204

Tester for DINEN60204 and VDE0113

• Clear-cut operating menus

• Illuminated display

• Two 4 m measurement cables

(4-wire connection)

• Remote control for efficient use

• Limit value adjustment

• Convenient memory and

report generating functions

• Data interfaces for PC and printer

• Can be expanded for quick, on-site alphanumeric

data entry and reports printing

• Can be retrofitted for high-voltage testing

3-348-802-03

12/6.07

QUALITY MANAGEMENT SYSTEM

DQS certified per

DIN EN ISO 9001:2000

Reg. No.1262

Applications

The PROFITEST 204 tester has been designed for quick, safe

testing of electrical and electronic equipment and systems at

machinery in accordance with DIN EN 60204-1 and VDE 0113

with nominal voltages of up to 1000 V.

The following periodic tests must be performed in accordance

with the standard:

– Testing for continuity at connections within the

protective conductor system with 10 A test current

– Insulation resistance test

– Voltage tests (optionally HP or HV)

– Testing for residual voltage

Beyond this, the following tests and measurements

may be performed as well:

– Leakage current test

– Voltage measurement

– Frequency measurement

All values required for approval reports can be measured with this

instrument.

Display

The LCD window consists of an illuminated dot matrix display at

which menus, device settings and measurement results, as well

as online help can be displayed.

Help Key

Information regarding the current menu item can be queried with

this key. Online help texts appears at the LCD window.

Function Selector Switch

Testing, report generating and data management functions are

selected with the rotary switch.

Limit Values

Limit values can be assigned for use with each measurement,

allowing for individualized adaptation of the various tests to

prevailing local conditions, as well as to the latest requirements

set forth in the standards.

Data Memory

Depending upon the number of systems for which data logging is

performed (max. 254), up to 2800 measurements can be saved

to memory.

Remote Control

The test probe with integrated control panel allows for remote

control of protective conductor and insulation resistance measurements, as well as storage of the respective values to memory.

Integrated lamps indicate measurement progress status.

All PROFITEST 204 operating functions can also be controlled via

the RS 232 interface. Signal and display values can be remote

queried as well.

RS 232 Interface for Input Module and PC

This port provides for data transmission and the supply of

electrical power to the optionally available SECUTEST⏐SI input

module.

Other devices (e.g. a PC) can also be connected to this port with

the help of an interface cable.

GMC-I Gossen-Metrawatt GmbH

Page 2

PROFITEST 204

Tester for DIN EN 60204 and VDE 0113

CENTRONICS Parallel Port

Any commercially available printer can be connected to this data

interface (except for PostScript printers). Detailed report forms

which have been uploaded to the instrument can be read out via

this port.

Characteristic Values

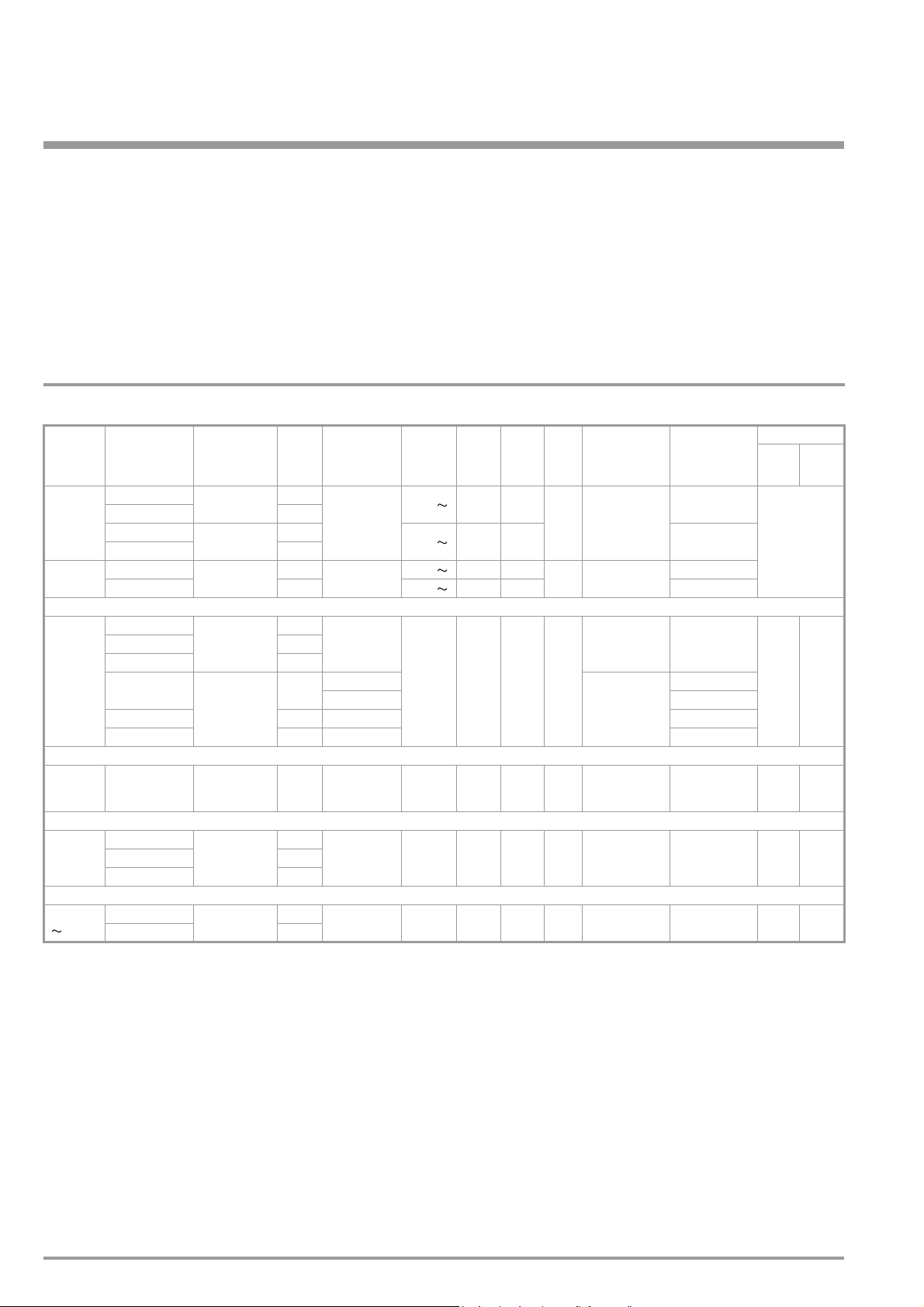

Meas.

Quantity

Protective

Conductor

Resistance

R

SL

Δ

U

Insulation

Resistance

R

ISO

Measuring

Range

0 … 85 mΩ

85 … 999 m

1.00 … 9.99 Ω

10.0 … 25.0

2)

0 … 9.99 V*

10.0 … 12.0 V 0.1 V 12 V — —

0 … 999 kΩ

1.00 … 9.99 MΩ 10 kΩ

10.0 … 99.9 MΩ 100 kΩ

100 … 499 MΩ

500 … 999 M

1 … 3G

Nominal Range

of Use

10 … 330 mΩ

Ω 1mΩ

Ω 100 mΩ

—

—

0.050 … 50 MΩ

Ω 1MΩ 500/1000 V ±(10% rdg. +2 d)

Ω 10 MΩ 1000 V ±(20% rdg. +2 d)

—

Resolution

100 μΩ

10 m

0.01 V

1kΩ

1MΩ

Nom. Voltage

U

N

Ω

100/250/500/

500/1000 V

—

—

1000 V

250 V

OpenCircuit

Voltage

U

0

12 V 10 A

12 V — — ±(3% rdg. + 10 d)

12 V 10 A 12 A

max.

1.3 • U

Report Generating Functions

The following report generating functions are available:

– Upload report forms to the test instrument with the help of a

PC and included PROTOCOL software

– Select one of three report forms stored to the instrument

– Read out measurement data via the CENTRONICS parallel

port to commercially available printers

– Transmit measurement data to a PC and process with EXCEL

Nom.

Short-

Int.

Meas. Error Intrinsic Error Overload

Resist.

R

I

±(3% rdg. + 5 d)

±(8.6% rdg.+6 d)

—

——

±(5.5% rdg.+4 d)

of

0.05M

Ω...50MΩ

—

—

±(2% rdg. + 3 d)

±(10% rdg. + 3 d)

±

(3% rdg. +2 d)

±(8% rdg. +2 d)

±(5% rdg. +2 d)

Capac-

Dura-

ity

tion

Fuse:

16 A/1000 V

Breaking

Capacity:

5kA

1200 V cont.

N

Current

I

N

1mA

1)

Circuit

Current

I

K

12 A

max.

1.6 mA

Leakage

Current

ΔI

Voltage

U DC/AC

Frequency

f

1)

up to 330 mΩ maximum

2)

related to 10 A nominal current

0.00 … 9.99 mA 0.2 … 9.9 mA 0.01 mA — — — — 2 k

0.0 … 99.9 V

1.00 … 1.2kV 0.01kV

8.0 …99.9 Hz

100 … 999 Hz 1 Hz

1.0 … 1000 V

10 … 1000 Hz

0.1 V

0.1 Hz

Ω±(8.6% rdg. +9 d) ±(5% rdg. + 5 d) 250 V cont.

————20M

————20M

Ω±(8.6% rdg. +9 d) ±(5 % rdg. + 5 d) 1200 V cont.100 … 999 V 1 V

Ω±(8.6% rdg. +2 d) ±(2 % rdg. + 1 d) 1200 V cont.

2 GMC-I Gossen-Metrawatt GmbH

Page 3

PROFITEST 204

Tester for DIN EN 60204 and VDE 0113

Applicable Regulations and Standards

IEC 204–1

DIN EN 60204–1

VDE 0113 Part 1

IEC 61010–1

DIN EN 61010–1

VDE 0411 Part 1

DINEN60529

DIN VDE 0470–1

VDI/VDE 3540 Reliability of measuring, control and regulating devices

DIN 43 751 Part 1, 2 Digital measuring instruments

DIN EN 61326

VDE 0843 Part 20

Regulations and Standards for Use of the Tester

IEC 204–1

DIN EN 60204–1

VDE 0113 Part 1

DIN EN 60439–1

VDE 0660 Part 500

DIN IEC 60–1, HD 588.1

VDE 0432 Part 1

DIN EN 60335–1

DIN VDE 0700–1

DIN VDE 0701–1/5.93 Repair, modification and testing of electrical devices

DIN VDE 0701–200/6.88 Mains powered electronic devices and accessories

DIN VDE 0701–240/4.86 Safety requirements for data processing systems and

DIN VDE 0701–260 Hand-held electric tools

DIN VDE 0472 Testing cables and insulated conductors

DIN VDE 0404–2/7.88 Devices for technical safety testing of electrical

Machine safety:

Electrical equipment at machinery

Part 1: General requirements

Safety requirements for electrical equipment

for measurement, control and laboratory use

– General requirements

Protection provided by enclosures (IP code)

– Climatic categories for devices and accessories

Electrical equipment for measurement, control and

laboratory use – EMC requirements

Machine safety:

Electrical equipment at machinery

– General requirements

Low-voltage switchgear assemblies

High-voltage test methods

Safety tests for household appliances

Part 1: Safety of electrical devices for

household use and similar purposes

– General requirements

for household use and similar, general applications

office machinery

equipment – Devices for periodic testing

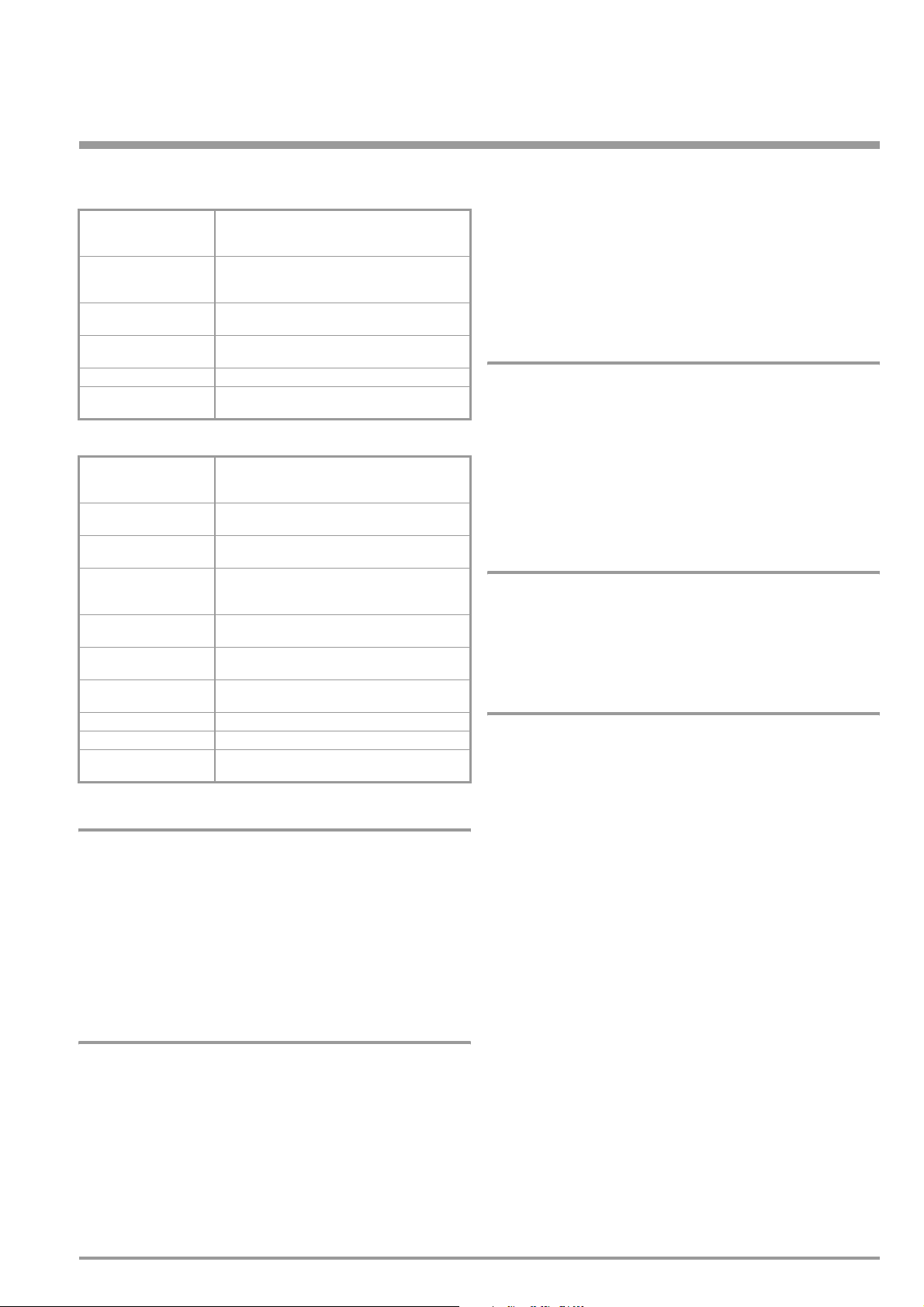

Reference Conditions

Line Voltage 230 V ± 1%

Line Frequency 50 Hz

± 0.1%

Waveshape Sine (deviation between effective

and rectified value < 1%)

Ambient Temperature + 23

Relative Humidity 40%

°C ± 2K

… 60%

Load Impedance Ohmic

Nominal Ranges of Use

Line Voltage 207 V … 253 V

Line Frequency 45 Hz

Line Voltage Waveshape Sine

Temperature Range

… 65 Hz

0°C … +40°C

Ambient Conditions

Storage Temperature – 20 °C … +60°C

Operating Temperature – 5

Accuracy 0

°C … +40°C

°C … +40°C

Relative Humidity Max. 75%,

no condensation allowed

Elevation to 2000 m

Power Supply

Line Voltage 207 V … 253 V

Line Frequency 45 Hz

Power Consumption

… 65 Hz

204:

approx. 180 VA

w/o accessories

204HP: max. 700 VA

204HV: max. 100 VA

Max. Leakage Current 0.5 mA basic device and 204HP or HV

Current Consumption Max. 6 A basic device and 204HP or HV

RS 232 Data Interface

Type RS 232C, serial, per DIN 19241

Data Format 9600, 8, N, 1

Connector

9-pin subminiature socket connector

Electrical Safety

Safety Class 204: II

Nominal Voltage 230 V

Test Voltage, 204 5.55 kV 50 Hz

Test Voltage, 204HP/HV Mains /PE / key switch /

Measuring Category II

Contamination Degree 2

Safety Shutdown if instrument overheats

Fuses 204:

204HP/HV: I

per IEC 61010-1/

EN 61010-1 and VDE 0411-1

external signal lamps to

high voltage measuring terminals:

204HP: 5kV AC 50Hz

204HV: 8kV AC 50Hz

Mains to PE:

1.5 kV AC

Mains to external signal lamps:

2.3 kV AC (type test)

Mains: T 1.6 / 250

Test probe: T16 / 1000

204HP/HV:

Mains: F 3.15 / 250

GMC-I Gossen-Metrawatt GmbH 3

Page 4

PROFITEST 204

Tester for DIN EN 60204 and VDE 0113

Electromagnetic Compatibility EMC PROFITEST 204

Product standard EN 61326-1: 1997

Interference Emission Class

EN 55022 A

Interference Immunity

EN 61000-4-2 Contact/Atmos. - 4 kV/8 kV A

EN 61000-4-3 10 V/m B

EN 61000-4-4 Mains Connection - 2 kV B

EN 61000-4-5 Mains Connection - 1 kV A

EN 61000-4-6 Mains Connection - 3 V A

EN 61000-4-11 0.5 Period / 100% A

Test Value Performance Feature

EN 61326: 1997/A1: 1998

Mechanical Design

Display Multiple dot matrix display

Protection IP 40 per DIN EN 60529 /

Extract from table on the meaning of IP codes

IP XY

(1st digit X)

4 ≥ 1.0 mm dia. 0 not protected

Dimensions 204: (WxDxH)

Weight 204: approx. 5.1 kg

Protection against

foreign object entry

128 x 128 pixels

VDE 0470 part 1

IP XY

(2nd digit Y)

255 mm x 133 mm x 240 mm

204HP/HV:

254 mm x 130 mm x 285 mm

overall height, mounted on caddy:

380 mm x 250 mm x 650 mm

204HP/HV: approx. 8 kg

Protection against the

penetration of water

Sample Displays, Menu-Driven Instrument Operation:

Standard Equipment

1 PROFITEST 204 test instrument with data interface (RS 232)

and CENTRONICS port for external printer

1 test probe with integrated control panel for remote control of

protective conductor and insulation measurement functions,

with permanently attached measurement cable

1 test probe with integrated fuse and permanently attached

measurement cable

1 cable lug

1 power cable with earthing contact plug

1 CD ROM with download program for report forms

1 maker’s calibration certificate

1 RS232 bus cable for connecting the COM interface

1 operating instructions

1 PC software WinProfi for communication with

PROFITEST 204. The PS3 CD-ROM includes the software

WinProfi with the following content and functions:

• up-to-date test instrument software

– for loading other user interface languages

– for loading firmware version updates

• Exchange of measured data between test instrument and PC

• Preparation and modification of templates for test reports

at the PC, transfer of templates from PC to test instrument

• Preparation, print-out and filing of test reports at the PC

4 GMC-I Gossen-Metrawatt GmbH

Page 5

PROFITEST 204

Tester for DIN EN 60204 and VDE 0113

PROFITEST 204 Accessories

Expanded Features for PROFITEST 204HP-2.5kV and 204HV-5.4kV

• Test voltage selectable in 50 V steps

• Rise time (ramp) adjustable from 0.1 to 99 s

• Test duration adjustable from 1 to 120 s

• Floating test voltage outputs

• Electronically controlled test sequence

• Test sequence can be started with test pistol

• Breakdown voltage display

• Pulse-arc operation

• Phase angle display

• Measured values can be saved to memory

• Acoustic and optical error messages

• Key switch for protection against unauthorized start-up

• Connector terminals for external signal lamps

Expanded Features for PROFITEST 204HP-2.5kV

• Voltage test per EN 60204 / VDE 0113

• Test power: 500 VA (intermittent)

• Breaking current adjustable in 1 mA steps

Expanded Features for PROFITEST 204HV-5.4kV

•Test power: 50VA

• Breaking current adjustable in 0.5 mA steps

Sample Displays, Menu-Driven Instrument Operation:

Extension PROFITEST 204HP...

Both of the high-voltage components, either of which can be

mounted to the bottom of the basic instrument, allow for highvoltage testing. Voltage, current and phase angle are measured

with permanently attached measurement cables.

The bidirectional infrared interface at the base of the

PROFITEST 204 is used for controlling the high-voltage

component, as well as for uploading measured values to the

basic instrument.

Technical Data, PROFITEST 204HP-2.5kV

Tes t V oltage

U AC

Meas.

Quantity

Current

I AC

Nominal Range

of Use

250 V … 2.5 kV

10.0 …200 mA

Resolu-

Measuring Error Intrinsic Error

tion

1V

±(5% rdg. + 5 d) ±(2.5% rdg. + 5 d)

10 V

0.1 mA

±(7% rdg. + 5 d) ±(5% rdg. + 5 d)

1mA

Technical Data, PROFITEST 204HV-5.4 kV)

Tes t Vo lt a ge

U AC

Meas.

Quantity

Current

I AC

Nominal Range

of Use

650 V…1.00 kV

1.00 kV…5.35 kV

1.0 … 10.0 mA

Resolu-

Measuring Error Intrinsic Error

tion

1V

+2 … –7% rdg.

10 V

+2 … –5% rdg.

0.01 mA

0.1 mA

±(7 % rdg. + 5 d) ±(5 % rdg. + 5 d)

0 … –5% rdg.

0 … –3% rdg.

Signal 204

Signal lamp set for

high-voltage testing in

accordance with

DIN VDE 0104.

GMC-I Gossen-Metrawatt GmbH 5

Page 6

PROFITEST 204

Tester for DIN EN 60204 and VDE 0113

SECUTEST PSI

RS232

OK / FAILED

MENU

STORE

PROFITEST 204

PRINTER

START

EN 60204

SETUP

OFF

TEST

RUN

DIN VDE 0113

230 V 50 Hz 3 A

F3,15 / 250

I

0

12 V 5 W

!

PROFITEST 204HP/HV

6 GMC-I Gossen-Metrawatt GmbH

Page 7

PROFITEST 204

Tester for DIN EN 60204 and VDE 0113

SECUTEST⏐SI

The alphanumeric keypad allows for the entry of descriptions for

each individual system. These descriptions are automatically

saved to memory along with the appropriate data record.

The SI module is screwed into the lid of the PROFITEST 204 for

space-saving storage.

Caddy 204

System requirements for PS3

• a Windows compatible PC with at least a Pentium IV CPU

> 2 GHz

• Windows 2000 SP4 / Windows XP

• working memory: 512 MB RAM

• a hard disc with approx. 800 MB free memory (without data)

• CD-ROM drive

• e-mail connection for loading control and/or clearing files

Remote 204 (Windows Software)

Control programming software for PROFITEST 204, 204L, 204HP, 204HV

tester

Instead of starting individual tests manually, you can perform automatic test sequences with the PROFITEST 204/MetraMachine 204

tester by means of the PC software Remote 204.

This includes the creation of control files, the execution of the

tests in accordance with the control files, the preparation of test

reports as well as the export of data. The format supported by the

software is easy to read in and process by all common spreadsheet programs.

In detail, Remote 204 includes the following functions:

• 3 different user interface languages are offered for choice,

• 2 serial ports are supported for activation of the

PROFITEST 204,

• read out information on the test instrument,

• select control file for the test,

• create new control files or modify existing ones,

• perform tests automatically by menu control mode,

• skip, interrupt and continue tests,

• prepare new report templates or modify existing ones,

• store test data either manually or automatically,

• print test data in test reports,

• convert data into a common spreadsheet format,

• display online user manual,

• control files of the DOS program PROFI SPS 204 can be

used.

PS3 Intelligent Modular Software for Test Instruments

Measurement data acquired with test instruments is transferred to

PS3 and are then automatically assigned to activities such as

testing, maintenance or inspection. Ready-to-sign test and work

reports can thus be prepared with a minimum of effort.

The basic module and the device module are sufficient for standard requirements such as reading in measurement data and

report printing.

Additional requirements such as following up on deadlines, test

data history, data selection and list generation, right on up to

complete object management (devices and buildings) with inventory management, errors indication, work orders and repairs are

handled with the expansion module and with add-on modules.

An overview of all of the features included with this software is

given on our website.

GMC-I Gossen-Metrawatt GmbH 7

Page 8

PROFITEST 204

Tester for DIN EN 60204 and VDE 0113

Order Information

Designation Type Article number

Device for tests in accordance with

VDE 0113 / EN 60204 with RS232

interface and CENTRONICS port for

external printer, 2 test probes firmly

connected via measuring cables with a

length of 4 m, 1 plug-on cable lug,

power cable with earthing contact plug,

test report, operating instructions,

PS3 CD-ROM containing the PC software Winprofi for loading another user

interface language into the test instrument, for updating the test instrument

firmware, for preparing test report templates at the PC and transferring them

to the test instrument as well as for

completing, storing and printing out test

reports from the PC PROFITEST 204 GTM 5027 000 R0001

Same test instrument as

PROFITEST 204, however, with firmly

connected measuring cable with a

length of 12 m with START/MEMORY

operation in the test plug PROFITEST 204L M505C

Sets

Complete system for tests in accordance with DIN EN 60204-1/VDE 0113

part 1, consisting of: PROFITEST 204,

PROFITEST 204HP, Signal 204,

Leadex 204, Caddy 204, test report

Complete system for tests in accordance with DIN EN 60204-1/VDE 0113

part 1, consisting of: PROFITEST 204,

PROFITEST 204HP, Caddy 204, test

report

Complete system for tests in accordance with DIN EN 60439-1/VDE 0660

part 500, consisting of:

PROFITEST 204, PROFITEST 204HV,

Signal 204, Leadex 204 and

Caddy 204, test report

Extensions

Special variant,

High-voltage component to 2.5 kV

Special variant,

High-voltage component to 5.4 kV

SI-Modul including batteries and

operating instructions SECUTEST⏐SI M702F

PC Software

Software for maintenance and

electronic equipment management PS3

Basic

module and device driver, allows

for read-out of the measured values from

the PROFITEST 204 ,

PRO

Fi

TEST®0100S-II

METRISO®C and

SECUTEST

®

, PROFiTEST®C

... test instruments PS3 GM Z530E

MetraMachine

204/2.5 M504D

MetraMachine

204-I/2.5 M504E

MetraMachine

439/5.4 M504F

PROFITEST 204HP-

2.5kV M505A

PROFITEST 204HV-

5.4kV M505B

,

Designation Type Article number

Device modules, basic module and add-on

module complemented by the following

modules

– electronic equipment management

– remote

– maintenance management

– barcode printing

Control programming software

in 3 languages for remote-control of

PROFITEST/ MACH 204 from the PC Remote 204 Z532A

PC software for the generation of reports and lists in addition to MS WORD;

user languages: German/English PC.doc-WORD™

PC program for the management of test

data in addition to MS Access;

user languages: German/English

Upgrade of PC.doc win/med... to

PC.doc-WORD™ PC.doc upgrade Z714C

Accessory equipment

RS232 interface cable, 2 m Z3241 GTZ 3241 000 R0001

Adapter for SL /ISO tests with

PROFiTEST 0100S-II and

PROFITEST 204 Adapter 701 Z501F

Signal lamp set for high-voltage testing

in accordance with DIN VDE 0104 Signal 204 Z504D

Plug-on cable lug for secure attachment of the test probe to the terminals Kabelschuh 204 Z504E

12 m extension cable for use with the

measuement cable and test probe with

integrated measuring circuit fuse Leadex 204 Z504C

Transport caddy

for PROFITEST 204 and 204HP/HV,

including rubber straps for securing test

cables and protective cover Caddy 204 Z504A

EMERGENCY STOP switch

for PROFITEST 204HP/HV STOP 204 Z504F

For securing sites against unauthorized

presence during high-voltage testing Claim 204 Z504G

Interface adapter for keyboards PROFI-MFII Z504H

Pack of 10 rolls recording chart for

PSI module (1 roll = approx. 6.7 m) PS-10P GTZ 3229 000 R0001

Pack of 10 ink ribbon cartridges for PSI

module Z3210 GTZ 3210 000 R0001

Universal carrying bag

(for PROFITEST 204 and SECUTEST...

without HV-module) F2000

D)

Data sheet available

PS3 AM Z531N

D)

Z714A

PC.doc-ACCESS™ D)Z714B

D)

Z700D

For additional information on accessories, please refer to

• our Measuring Instruments and Testers Catalog

• our website www.gossenmetrawatt.com

Edited in Germany • Subject to change without notice • A pdf version is available on the internet

GMC-I Gossen-Metrawatt GmbH

Thomas-Mann-Str. 16-20

90471 Nürnberg •

Germany

Phone +49 911 8602-111

Fax +49 911 8602-777

E-Mail info@gossenmetrawatt.com

www.gossenmetrawatt.com

Loading...

Loading...