Page 1

Operating Instructions

Attention!

!

B

A

PGS10

Test Probe with Pulse Current Generator

for SECUSTAR FM+ and SECULIFE SB/SR

Applications

The test probe is suitable for testing

protective conductor connections at

electrical consumers with contact resistance

caused by, for example, oxidation. With

contact resistance of this sort, protective

conductor resistance might not comply with

the specified values during testing with the

minimum test current of 200 mA in

accordance with the standard.

Measurement results with considerably

lower impedance values can be obtained for

a short time by exposing these connections

to a higher current with a value of approx.

10 A,

because resistance-increasing deposits,

layers of oxidation and other contamination

can thus be eliminated for a given period of

time.

Use of “cleaning” by means of a current

surge should be taken into consideration in

the hazard evaluation for the object under

test.

Determine whether or not the test probe

complies with electrical safety requirements

and ambient conditions for use with your

test instrument. The test probe may only be

used for applications which are specified in

the operating instructions for your test

instrument. Make certain that the connector

cable, the test probe and the switch are in

flawless condition, e.g. no damage to

insulation, no interruptions in cables or

plugs etc.

Only perform the test with voltage-free protective

conductor connections to prevent the internal

fuse from blowing.

3-349-573-15

2/12.12

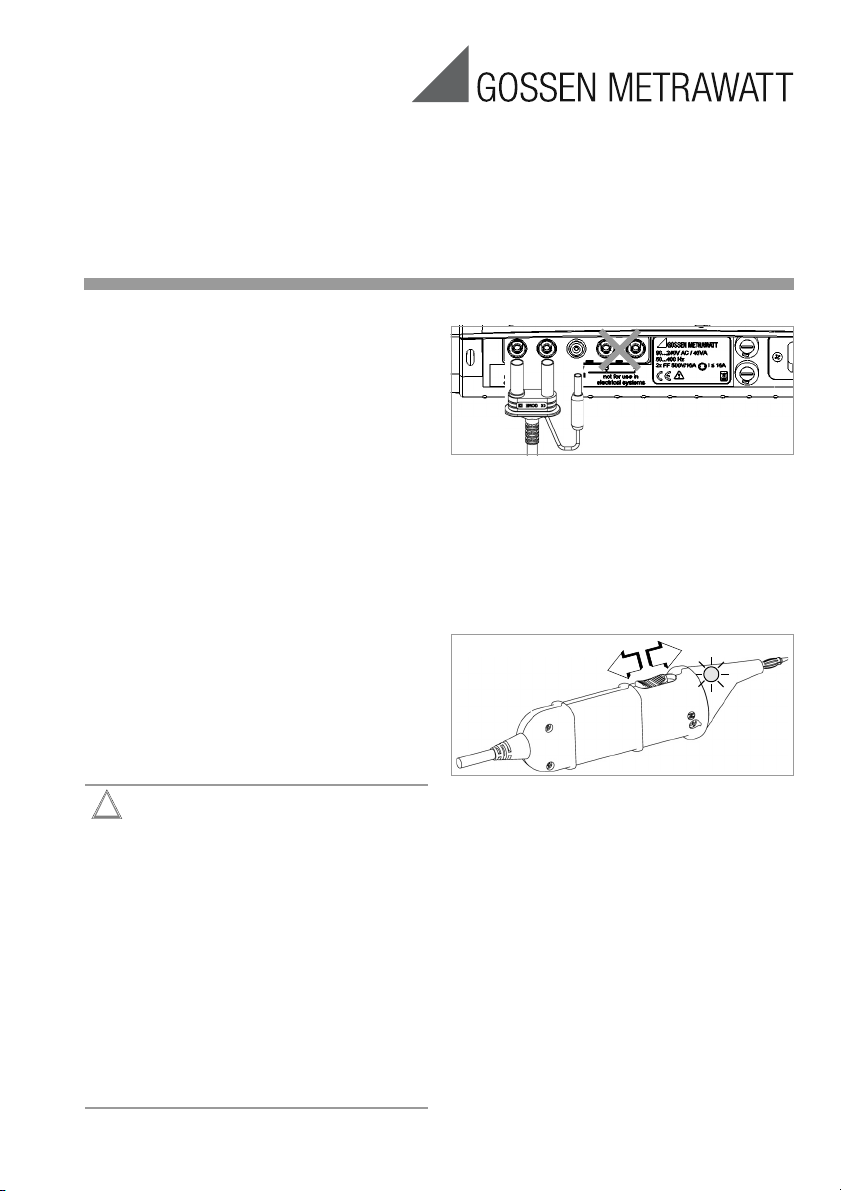

Connection

➭ Connect the test probe as follows:

Insert the test probe’s double plug into

sockets 1 and 2 such that the plug with

the white ring makes contact with socket

1, and insert the separate plug into the

test current output at the test instrument

(the socket between sockets 2 and 3).

Operation (single measurement)

➭

With the instrument in the “Manual Test”

mode, select resistance measurement R

➭ Press the start key at the test instrument

in order to initialize resistance measurement.

➭ Wait for at least 1 second.

➭ Contact the measuring point with the

test probe.

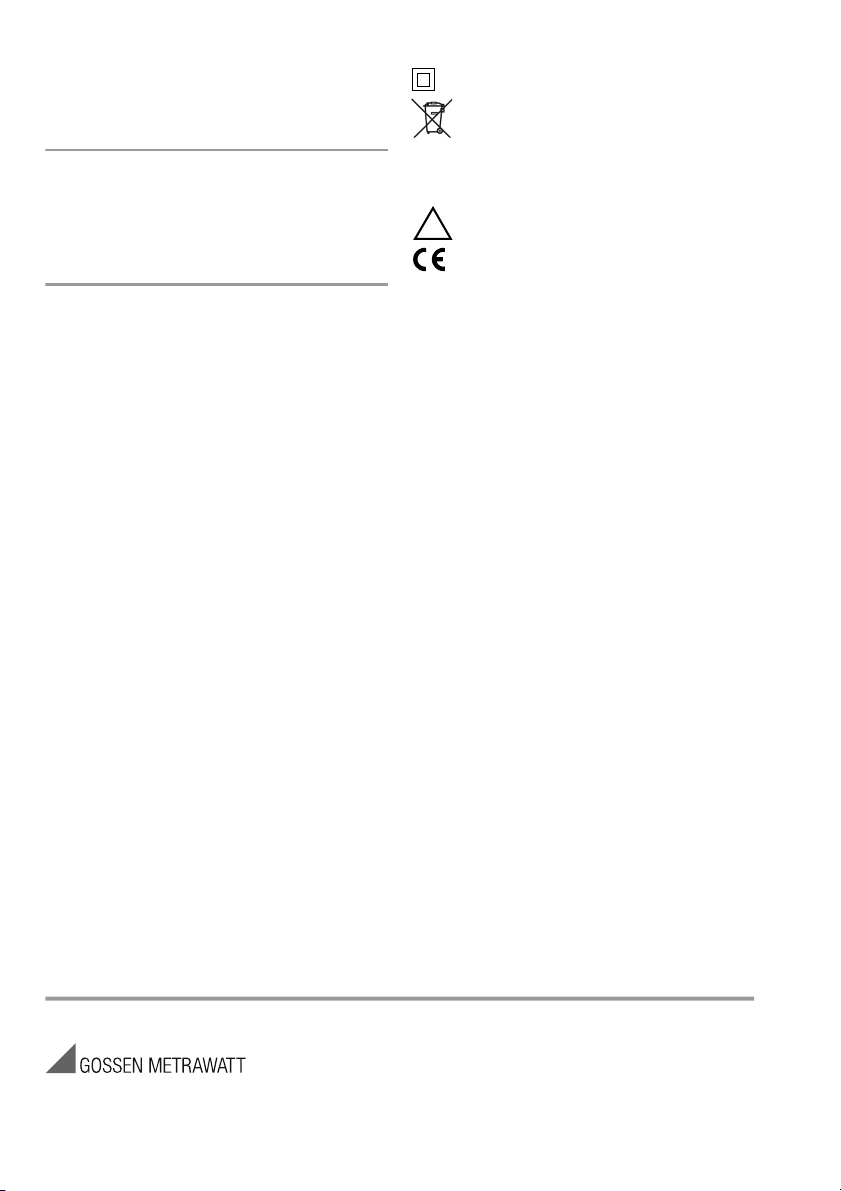

➭ Activate the current surge by briefly

pushing the slider switch on the test

probe into position B towards the tip of

the probe (spring force must be

overcome manually). The control LED

flashes up briefly. The short-term, high

current burns off any

resistance-increasing deposits.

PE

.

Page 2

➭

Note!

!

Return the slide switch to normal position

after which test current in accordance

A,

with the standard flows via the test

probe for the performance of resistance

measurement.

A waiting period with a duration of 1

second between measurements is

required in order to reactivate the

pulse current generator and charge

the capacitor.

Operation During Test Sequences

The following test step order must be

adhered to during test sequences:

➭ Start protective conductor resistance

measurement.

➭ Wait for at least 1 second.

➭ Contact the measuring point with the

test probe.

➭ Briefly push the slide switch into position

B (see single measurement).

➭ Record the desired measured value.

A test sequence for use of the test probe in

combination with a SECUSTAR FM+ or

SECULIFE SB/SR test instrument is

included in scope of delivery on the CF card,

or can be downloaded from out website.

Electricity Safety

Maximum

rated voltage

Maximum

rated current 1.5 A

Measuring category CAT II

Fuse Internal, 1.5 A

300 V

Ambient Conditions (EN 61010-031)

Temperature -20 to + 50 C

Relative humidity Max. 90%

Elevation to 2000 meters

Pollution degree 2

Significance of Symbols

Continuous, doubled insulation

This device may not be disposed of

with the trash. Further information

regarding the WEEE mark can be

accessed on the Internet at

www.gossenmetrawatt.com by

entering the search term ’WEEE’.

Warning concerning a point of danger

(attention, observe documentation!)

EC mark of conformity

Mechanical Design

Dimensions LxWxH: 190 x 40 x

Weight Approx. 270 g

Protection IP 40

40 mm

Housing Maintenance

No special maintenance is required for the

housing. Keep outside surfaces clean. Use a

slightly dampened cloth for cleaning. Avoid

the use of cleansers, abrasives or solvents.

Repair and Replacement Parts Service

Calibration Center and Rental

Instrument Service

If required please contact:

GMC-I Service GmbH

Service-Center

Thomas-Mann-Str. 20

90471 Nürnberg · Germany

Phone: +49 911 817718-0

Fax: +49 911 817718-253

e-mail: service@gossenmetrawatt.com

www.gmci-service.com

This address is only valid in Germany. Please

contact our representatives or subsidiaries

for service in other countries.

Product Support

If required please contact:

GMC-I Messtechnik GmbH

Product Support Hotline

Phone: +49-911-8602-0

Fax: +49 911 8602-709

e-mail:

support@gossenmetrawatt.com

Edited in Germany • Subject to change without notice • PDF version available from the Internet

GMC-I Messtechnik GmbH

Südwestpark 15

90449 Nürnberg •

Germany

Phone: +49 911 8602-111

Fax: +49 911 8602-777

e-mail: info@gossenmetrawatt.com

www.gossenmetrawatt.com

Loading...

Loading...