Operating Instructions

METRISO XTRA

High-Precision Insulation, Low Resistance and Voltage Measurement Instrument

3-349-818-03

2/12.17

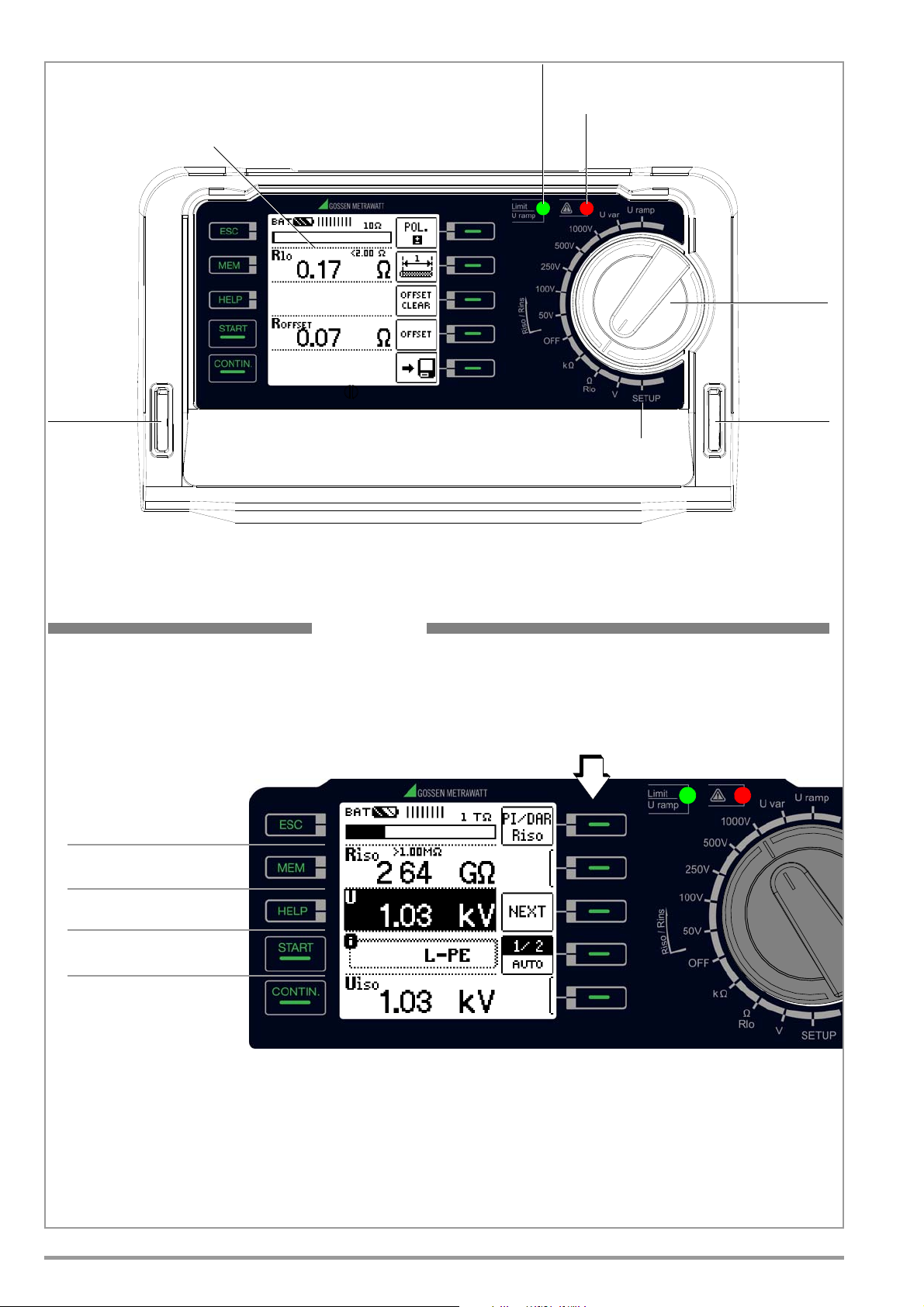

LCD Panel

Red LED: limit value exceeded

Red LED:

– Interference voltage with device off

Setup Menu

Function

Selector Switch

Slot for

Carrying Strap

Slot for

Carrying Strap

Green LED: limit value adhered to

– High test voltage at the measuring terminals

MEM: Key for memory

functions

ESC: Exit submenu /

activate instrument

standby state

Control panel

Fixed Function Keys

LEDs → section 4.3

CONTIN: Continuous

measurement of

Rins and R (kΩ)

HELP: Access context

sensitive help

START: Start measurement

Softkeys

• Parameter selection

• Limit value specification

• Entry functions

• Memory functions

METRISO XTRA

during Riso/Rins

2 GMC-I Messtechnik GmbH

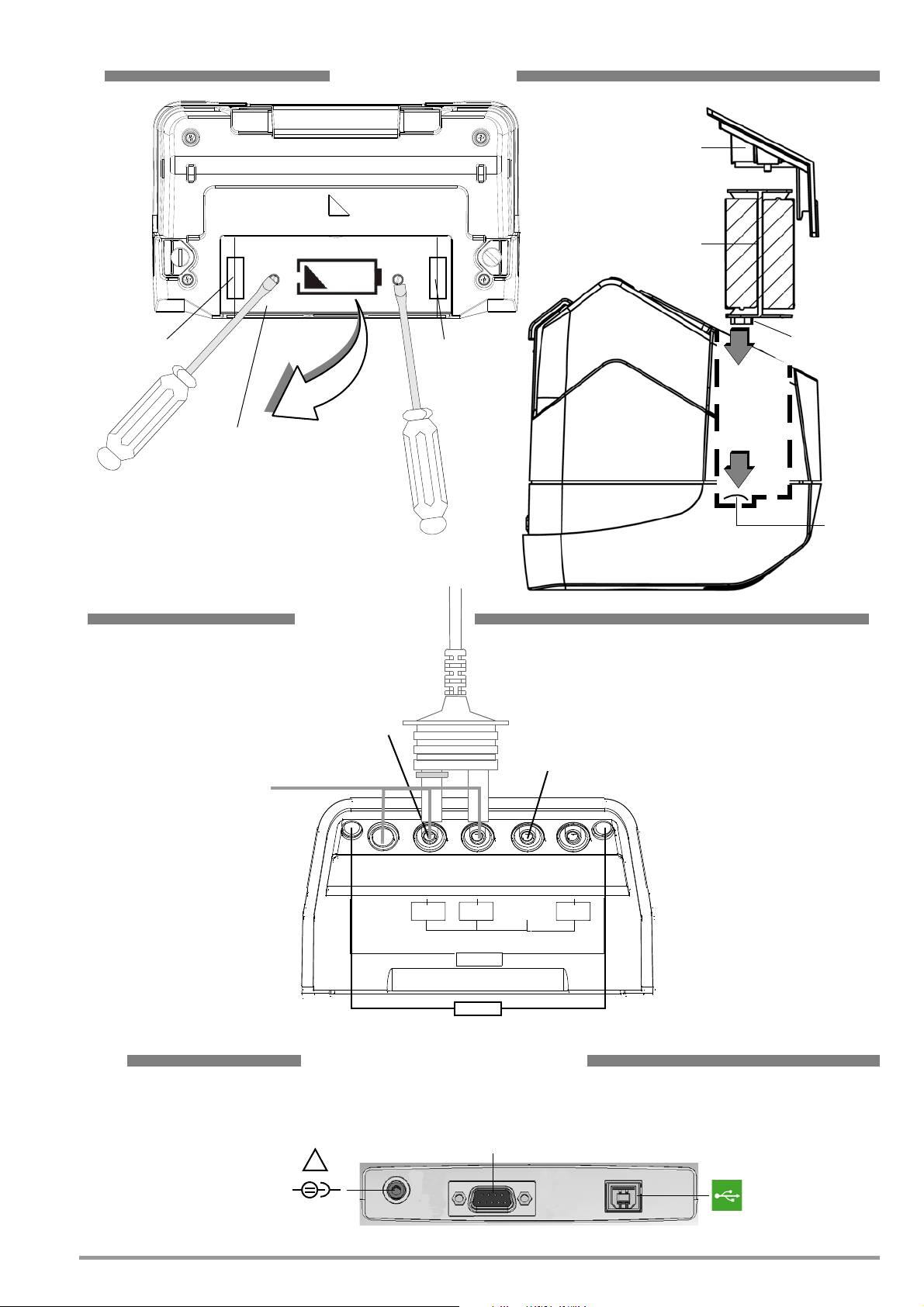

Battery Holder

Battery Compartment Lid

Battery Holder

Contacts

Battery

Contact

Spring

User Interface

Batteries, Fuses

Measuring

!

RS 232

+

COM

+

COM

SHIELD

SHIELD

Option KS-C (Z541F)

Option Z550A*

Charger Socket, Interfaces

These connections are located under a protective rubber flap.

a b

Replacement

Fuse

Socket for Z502R charger

Caution!

Make sure that no batteries are inserted

before connecting the charger.

The test instrument must remain off

during the charging process.

Fuse

Inserting the Battery Holder (side view)

USB slave for

PC connection

Port for connecting Barcode/RFID reader

GUARD

* Regarding Z550A:

Test Probe with measurement key

remote control and LED for

illuminating the measuring point:

Do not use when measuring PI and

DAR.

Compartment Lid

Battery

Compartment

Connections

Test Resistor 10 MΩ

GMC-I Messtechnik GmbH 3

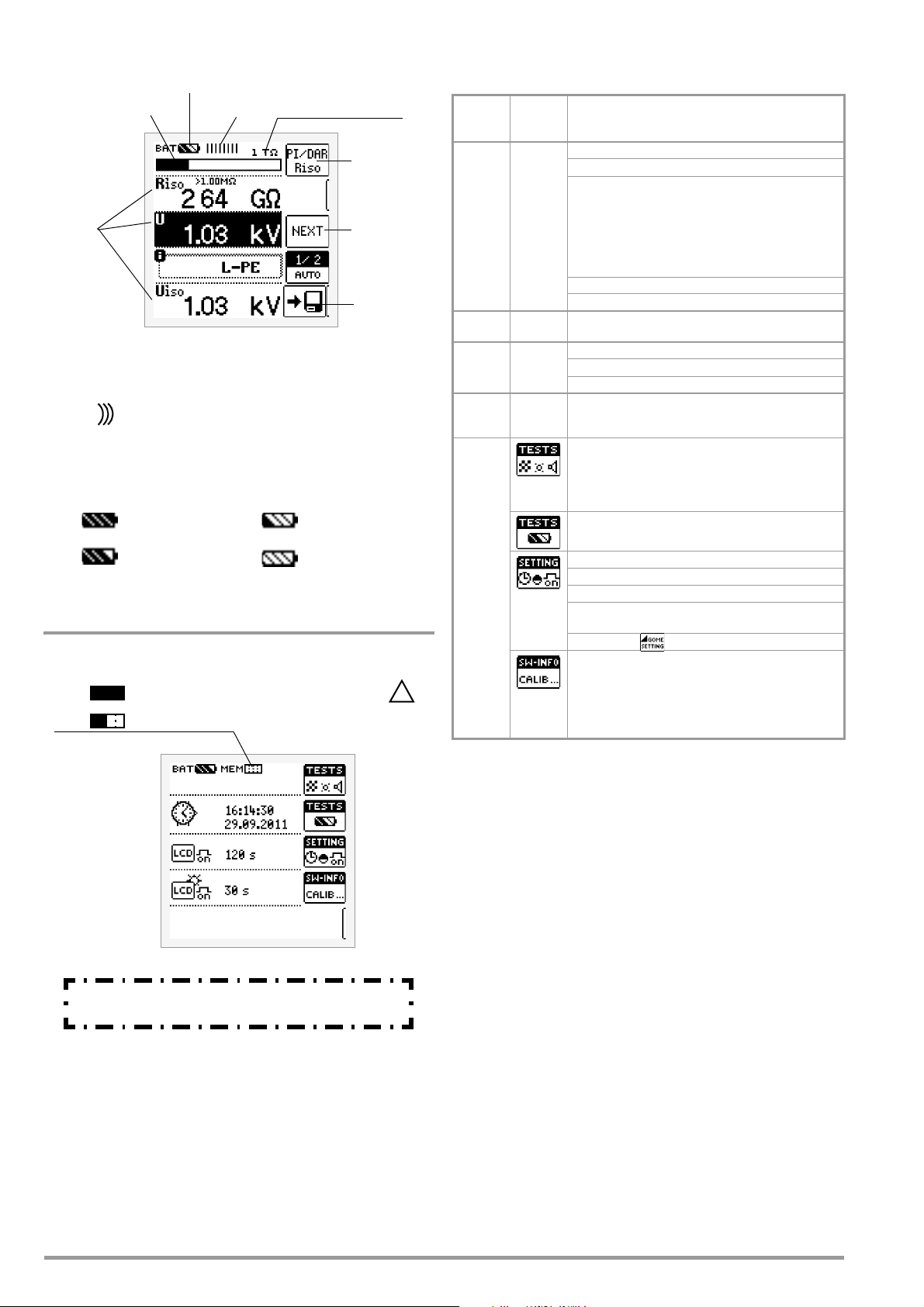

Overview of Device Settings and Measuring Functions

Battery level

Bar graph display

Measurement

Upper range limit

Measuring

Parameter

Display panel

Save

Battery full

Battery OK

Battery weak

Battery (nearly)

Battery Level Indicator

BAT

BAT

BAT

BAT

depleted U < 8.5 V

Measuring Status

Measurement in progress: Bars moves from left

Measurement on pause: Bars are static.

to right.

||||||||||

||||||||||

Polarity reversal‚

L-PE / N-PE for

documentation

setting

value

quantities

indicator

in progress

Memory Occupancy Display

MEM

Memory half full

MEM

Memory full > transfer data to PC!

These operating instructions describe a tester with

software version SW-VERSION (SW1) 01.02.00.

!

Relative to Rotary Switch Setting

Switch

setting,

see as of

RISO

RINS

page 15

kΩ

page 20

RLO

page 21

V

page 14

SETUP

Pictograph

Device settings,

measuring functions

RINS Insulation resistance

U Voltage at the test probes

U

fix Fixed test voltage,

N

Uvariable Variable test voltage, limit value:

Uramp Variable test voltage,

PI Polarization index

DAR Absorption index

R Resistance measurement

RLO Low-resistance with polarity reversal

RLO+, RLO–

R

OFFSET Offset resistance

U Voltage measurement

Tests: LCD pixel display

Battery test Ubat

limit values per VDE 0100

1 MOhm (for go/no-go display

while saving the measured value)

ramp: triggering/breakdown voltage

Low-resistance, single-pole

LCD pixel display

All pixels off

Green limit LED All pixels on

Red limit LED Acoustic signal

Date/time

CULT Language (D, GB)

Brightness

page 8

SET on: On-time for

Contrast Default settings

Device type

Serial number

Software version

Hardware version

Calibration date

Adjustment date

LCD and tester

Scope of delivery:

1 Insulation and resistance measuring instrument

1 DAkkS calibration certificate

1 Set batteries (8 pieces in battery holder)

1Carrying strap

1 Alligator clip

1 KS17-4 cable set

1USB cable

1 Condensed operating instructions

1 Supplement Safety Information

– Detailed operating instructions for download from our website

at www.gossenmetrawatt.com

4 GMC-I Messtechnik GmbH

Table of Contents Page Page

1 Applications ......................................................................6

1.1 Optional Z550A Remote Control .................................................. 6

1.2 Overview of Measuring Instrument Performance

Features ...................................................................................... 6

2 Safety Features and Precautions .....................................7

3 Initial Start-Up .................................................................. 7

3.1 Battery test ................................................................................. 7

3.2 Installing or Replacing Batteries ................................................. 7

3.3 Charging the Batteries in the Tester ........................................... 7

3.4 Device Settings – SETUP ........................................................... 8

4 General Operation ...........................................................11

4.1 Connecting the Instrument ....................................................... 11

4.2 Switching On, Monitoring and Switching Off ............................ 11

4.3 Optical Indicators ..................................................................... 11

4.4 Measurement Value Display and Memory ................................ 12

4.5 Help Function ............................................................................ 12

4.6 Setting Measuring Parameters

using Insulation Resistance Measurement as an Example ....... 12

4.7 Specifying Nominal Voltage for Uvar and Uramp ...................... 13

5 Measuring Direct Alternating Voltage ............................. 14

6 Measuring Insulation Resistance ...................................15

6.1 Measuring with Constant Test Voltage

and Nominal Value Selection via Rotary Switch Position ......... 16

6.2 Measurement with Constant Test Voltage

and Variably Adjustable Nominal Value .................................... 16

6.3 Measurement with Rising Test Voltage (ramp function)

and Variably Adjustable Final Value .......................................... 17

6.4 Insulation Resistance Measurement – Special Conditions ....... 17

6.4.1 Measurements with the Guard Cable ............................................ 17

6.5 Discharging the Device Under Test ........................................... 18

6.6 Evaluation of Measured Values ................................................. 18

6.7 Polarization Index Measurement .............................................. 18

6.7.1 Absorption Index (DAR) – DC Charging Test .................................. 19

11 Characteristic Values ...................................................... 29

12 Maintenance ...................................................................31

12.1 Firmware Revision and Calibration Information ....................... 31

12.2 Rechargeable Battery Operation and Charging ........................ 31

12.2.1 Charging Procedure with the Z502R Charger (accessory) .............. 31

12.3 Fuses ........................................................................................ 31

12.3.1 Melting Fuse ............................................................................... 31

12.3.2 Electronic Fuse ........................................................................... 31

12.4 Housing ..................................................................................... 32

12.5 Return and Environmentally Sound Disposal ............................ 32

13 Appendix .........................................................................32

13.1 Sample Connection Layouts for Insulation Resistance Measure-

ment ......................................................................................... 32

13.2 Error Messages ........................................................................ 34

13.3 Attaching the Test Probe Holder to the Carrying Strap ............. 36

13.4 Technical Data for Measurement Cables

(scope of delivery: KS17-4 safety cable set) ............................ 36

13.5 Optional Accessories (not included) ......................................... 37

14 Repair and Replacement Parts Service

Calibration Center and Rental Instrument

Service ............................................................................38

15 Recalibration ..................................................................38

16 Product Support .............................................................. 38

7 Test Resistor for Insulation Measurement for Checking the

Insulation Measuring Instrument .................................... 19

8 Measuring Resistance – kOhm Function ........................ 20

9 Measuring Low-Value Resistance of up to 10 Ohm

(protective conductor and equipotential bonding conductor) ... 21

10 Database ........................................................................24

10.1 Creating Distributor Structures, General ................................... 24

10.2 Transferring Distributor Structures ........................................... 24

10.3 Creating a Distributor Structure in the Test Instrument ........... 24

10.3.1 Creating Structures (example for electrical circuit) ......................... 25

10.3.2 Searching for Structural Elements ................................................26

10.4 Saving Data and Generating Reports ........................................ 27

10.4.1 Use of Barcode Scanners and RFID Readers ................................. 28

GMC-I Messtechnik GmbH 5

1 Applications

This instrument fulfills all requirements of applicable European and

national EC directives. We confirm this with the CE mark. The relevant declaration of conformity can be obtained from GMC-I

Messtechnik GmbH.

The METRISO XTRA insulation and resistance measuring instrument allows for quick and efficient testing of protective measures

in accordance with DIN VDE 0100, ÖVE-EN 1 (Austria), SEV 1000

(Switzerland), and regulations specific to other countries as well.

The device is equipped with a microprocessor and complies with

IEC/EN 61557 / VDE 0413 regulations:

Part 1: General requirements

Part 2: Insulation resistance

Part 4: Resistance of earth connection, protective conductors

and equipotential bonding

Part 10: Electrical safety in low-voltage systems up to 1000 V

AC and 1500 V DC – Equipment for testing, measuring

or monitoring of protective measures

As well as requirements per VDE 0701-0702:

Repair, modification and testing of electrical devices

The test instrument is especially well suited for:

•Systems setup

• Initial start-up

• Periodic testing

• Troubleshooting in electrical systems

The following measurements and tests can be performed with the

insulation measuring instrument:

• Insulation resistance

• Low-resistance

• Voltage

The following can also be tested by using a shielded measurement cable:

• Floor covering electrostatic discharge capability

1.2 Overview of Measuring Instrument Performance Features

METRISO XTRA

Article No. M550S

Measurement

U = 50, 100, 250, 500, 1000 V ✓

R

INS

Uvar = 50 ... 1000 V ✓

R

INS

Uramp (U) = 100 ... 1000 V ✓

R

INS

PI ✓

DAR ✓

R 10 ... 10 kΩ ✓

R

LO

U 0 ... 1000 V ✓

Display Functions

Backlit display ✓

Limit value LED (green/red) for:

limit values per VDE 0100

in addition to acoustic signal

URamp limit value LED for:

indicating ramp characteristics

LED for dangerous contact voltage

(when switched off)

Battery level display ✓

Special Functions

Discharge capacitive devices under test ✓

Safety shutdown (UBatt < 8 V) ✓

Data storage at the instrument ✓

ETC software for data acquisition, data management and reporting ✓

Features

Measuring categories: CAT II 1000 V / CAT II I 600 V / CAT IV 300 V ✓

Test resistance: 10 MΩ ✓

Connections: charging socket, USB port (slave), RS 232 port ✓

DAkkS calibration certificate ✓

0.01 ... 10 Ω ✓

R

INS RLO

R

INS

✓

1.1 Optional Z550A Remote Control

The optional remote control with triggering key on the test probe

and a key for illuminating the measuring point makes it possible to

use the measuring instrument at difficult to access places.

For safety reasons, a predefined voltage is only applied to the test

probes for as long as the triggering key is held depressed.

The start key on the test instrument should be used instead of

remote control for triggering polarization and absorption index

measurements, because these two measurements involve complete measuring cycles.

6 GMC-I Messtechnik GmbH

2 Safety Features and Precautions

Attention!

!

Attention!

!

Attention!

!

Attention!

!

!

XY123

2012-06

D-K

15080-01-01

Consecutive number

Registration number

Date of calibration (year – month)

Deutsche Akkreditierungsstelle GmbH – calibration lab

The electronic measuring and test instrument is manufactured

and tested in accordance with safety regulations IEC/EN 610101/VDE 0411-1 and EN 61 557.

safety of the operator, as well as that of the instrument, is assured.

Read the operating instructions thoroughly and carefully before

using your instrument. Follow all instructions contained therein.

The measuring and test instrument may not be placed into service:

• If the battery compartment lid has been removed

• If external damage is apparent

• If connector cable or measuring adapters are damaged

•If the instrument no longer functions flawlessly

• After extraordinary damage due to transport

• After a long period of storage under unfavorable conditions

(e.g. humidity, dust or extreme temperature).

Opening of Equipment / Repair

The equipment may be opened only by authorized service personnel to ensure the safe and correct operation of the equipment

and to keep the warranty valid.

Even original spare parts may be installed only by authorized service personnel.

In case the equipment was opened by unauthorized personnel,

no warranty regarding personal safety, measurement accuracy,

conformity with applicable safety measures or any consequential

damage is granted by the manufacturer.

Data Backup

We advise you to regularly transfer your stored data to a PC in

order to prevent potential loss of data in the test instrument.

We assume no responsibility for any data loss.

We recommend ETC software (Electric Testing Center) for back-

ing up, processing and managing data.

Meaning of Symbols on the Instrument

Warning concerning a point of danger

(Attention, observe documentation!)

Protection class II device

When used for its intended purpose,

If battery voltage has fallen below the allowable lower

limit, the pictograph shown at the right appears. The

instrument does not function if the batteries have been depleted

excessively, and no display appears.

3.2 Installing or Replacing Batteries

New batteries must be inserted for initial start-up, or if only one

filled segment remains in the battery symbol.

Before opening the battery compartment (see page 5 for

location), disconnect the instrument from the measuring

circuit (mains) at all poles.

Eight 1.5 V size AA batteries in accordance with IEC LR 6 are

required for operation of the insulation measuring instrument. Use

new alkaline manganese batteries only.

Rechargeable NiCd or NiMH batteries may also be used. These

can be charged externally or by connecting the Z502R charger to

the test instrument. We recommend rechargeable NiMH batteries.

Always replace batteries in complete sets.

Dispose of batteries in an environmentally sound fashion.

➭ Loosen both slotted screws for the battery compartment lid

on the back, and remove the lid.

➭ Remove the battery holder and insert eight 1.5 V size AA bat-

teries with correct polarity in accordance with the symbols.

Make sure that all of the batteries are inserted with correct

polarity. If just one battery is inserted with reversed polarity, it will not be recognized by the instrument and may

result in leakage from the batteries.

➭ Push the battery holder into the battery compartment such

that the battery holder’s contacts touch the contact springs at

the bottom of the battery compartment (see drawing on

page 3).

If the battery holder is not inserted as specified, the instrument

cannot be supplied with power.

➭ Replace the battery compartment lid and retighten the

screws.

Charging socket for extra-low direct voltage (Z502R

charger)

Attention!

Only rechargeable batteries may be inserted when the charger is connected.

EC mark of conformity

The device and included batteries may not be disposed of with the trash. Further information regarding

the WEEE mark can be accessed on the Internet at

www.gossenmetrawatt.com by entering the search

term “WEEE”.

Calibration Seal (blue seal):

See also “Recalibration” on page 38.

3 Initial Start-Up

3.1 Battery test

Four different battery symbols, ranging from fully depleted to fully

charged, continuously indicate the momentary charge level in the

upper left-hand corner of the display

GMC-I Messtechnik GmbH 7

The instrument may only be placed into service if the

battery compartment lid is securely fastened!

3.3 Charging the Batteries in the Tester

Use only the Z502R charger (available as an accessory)

to charge batteries which have already been inserted into

the test instrument.

Make sure that the following conditions have been fulfilled before connecting the charger to the charging socket:

– Rechargeable batteries have been installed with

correct

polarity (not standard batteries)

– The test instrument has been disconnected from the

measuring circuit at all poles

– The instrument must remain off during charging.

Refer to section 12.2.1 with regard to charging batteries which

have been inserted into the tester.

If the batteries or the battery pack have not been used or

recharged for a lengthy period of time (> 1 month), thus resulting

in excessive depletion:

Observe the charging sequence (indicated by the LED at the

charger) and initiate a second charging sequence if necessary

(disconnect the charger from the mains and from the test instrument to this end, and then reconnect it).

3.4 Device Settings – SETUP

SETUP

LED and LCD test menu

Battery test menu

Brightness/contrast menu

Software revision level

Calibration date

Display: date / time

Display: automatic shutdown

Display: automatic shutdown

of display illumination after 30 s.

of the tester after 120 s. Time, language, profiles

1

2

3

4

0b

0a

0

Return to main menu

Limit LED: test red

Limit LED: test green

Cell test

Inverse cell test

Hide all pixels

Show all pixels

Acoustic signal test

1

Return to main menu

Increase brightness

Decrease brightness

Increase contrast

Decrease contrast

Set time

→

Default settings →

User interface

language

→

3

3a

3b

3c

3d

Set date →

On-time for

display illumination / tester

0b

Return to submenu

0a

Display Illumination On-time

Brightness and Contrast Settings Time, On-Time and Default Settings

Menu Selections for Operating Parameters

LED Tests LCD and Acoustic Signal Tests

Test Instrument On-Time

Automatic shutdown,

deactivated = OFF

8 GMC-I Messtechnik GmbH

SETUP

LED and LCD test menu

Battery test menu

Brightness/contrast menu

Software revision level

Calibration date

Display: date / time

Display: automatic shutdown

Display: automatic shutdown

of display illumination after 15 s.

of the tester after 45 s.

Time, language, profiles

1

2

3

4

0b

0a

0

Return to main menu

Increase brightness

Decrease brightness

Increase contrast

Decrease contrast

Set time

→

Default settings →

User interface

language

→

3

3a

3b

3c

3d

Set date →

On-time

for display illumination / tester

Set time

Menu Selection for Operating Parameters

Adjusting Brightness and Contrast Set Time, Language, Profiles, Acoustic Signal

Set date

Select time/date

Increase

Increase

hours

Activate

settings

minutes

3a

Increase

seconds

Return to submenu

Decrease

Decrease

hours

minutes

Decrease

seconds

Select time/date

Increase

Increase

day

Activate

settings

month

3b

Increase

year

Return to submenu

Decrease

Decrease

day

month

Decrease

year

GMC-I Messtechnik GmbH 9

Significance of Individual Parameters

Note

Attention!

!

0a

0b23c

3d

4

Test Instrument On-Time

The period of time after which the test instrument is automatically

shut off can be selected here. This selection has a considerable

influence on the service life and the charging status of the batteries.

On-Time for LCD Illumination

The period of time after which LCD illumination is automatically

shut off can be selected here. This selection has a considerable

influence on the service life and the charging status of the batteries.

Submenu: Battery Level Query

Battery voltage U

the battery to a load.

(Uo) can be queried here without subjecting

BAT

Data are lost when the language

is changed, or if the instrument is

reset to its default settings!

Back up your measurement

data to a PC with the help of

ETC software before pressing the respective key.

The prompt window shown at

the right asks you to confirm

deletion.

User Interface Language (CULTURE)

➭ Select the desired language with the appropriate country

code and acknowledge your selection by pressing the ✓ key.

Measuring Sequence

If battery voltage drops to below 8.0 V

during the course of a measuring

sequence, this is only indicated by

means of a pop-up window. Measured

values are invalid. Measurement results cannot be saved

to memory.

➭ Press ESC in order to return to the main menu.

Default Settings (GOME SETTING)

The test instrument is returned to its original default settings when

this key is activated.

Firmware Revision and Calibration Information (example)

➭ Press any key in order to return to the main menu.

10 GMC-I Messtechnik GmbH

START/STOP SHIELD COM

Option Z550A

+

KS-C

(Z541F)

+

C

O

M

SH

I

E

L

D

Limit

Green

Limit

Red

Uramp

Green

Uramp

Red

Red

!

Limit

4 General Operation

4.1 Connecting the Instrument

The test leads are connected to the “+” and “COM” jacks.

Special Case:

When inserting

the 3-pole plug,

make sure that

the jack plug is

inserted in the

START/STOP

position. Press

and align the 3pole plug such

Test Probe for Remote Triggering (Option Z550A)

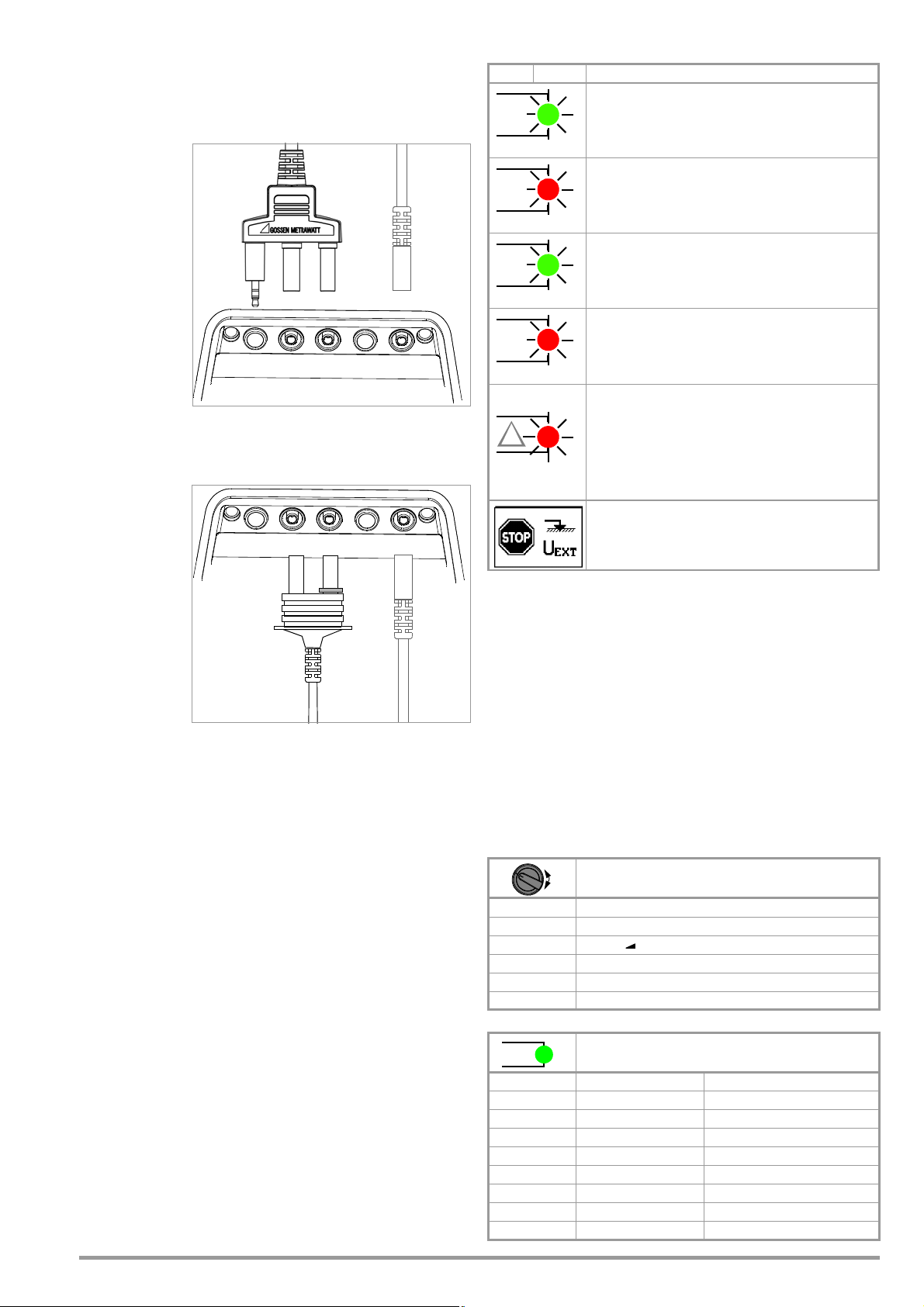

4.3 Optical Indicators

LED Status

Function – Cause

Limit Value Indication

– Measured insulation resistance does not violate the limit

value.

– Measured low-resistance Rlo does not violate the limit

value.

Limit Value Indication

– Measured insulation resistance has fallen short of the

selected limit value.

– Measured low-resistance Rlo does has exceeded the

permissible limit value.

Indication of ramp characteristics

– Maximum ramp voltage (upper voltage limit) has been

reached (without breakdown).

that it is placed

flush on the connection terminal.

This is the only

way to assure

that the three

contacts of the

jack plug are

properly connected with the command cables.

Special Case: Measuring High-Value Resistance with the KS-C Probe (Option)

When measuring

electrostatic discharge capacity

for floor coverings, the shielded

cable should be

connected to the

COM and SHIELD

jacks (KS-C

accessory set,

“cable set consisting of measurement cable

and high-resistance measurement cable for

measurements in the GΩ range”, see diagram). Be sure to

observe color coding.

1

Function testing should be executed at regular intervals (see following

section regarding testing the LEDs).

Testing the LED which Indicates Detection of Interference Voltage

when Switched Off – OFF Switch Position

➭ Apply a voltage of greater than 50 V (+ and COM jacks).

➭ Turn the rotary switch to the V position.

➭ Read the voltage value at the LCD.

➭ Turn the rotary switch to the OFF position.

Test results: If applied voltage is unchanged and the LED which

indicates the detection of interference voltage lights up red, the

Indication of ramp characteristics

– Maximum ramp voltage (upper voltage limit) has not been

reached (due to breakdown).

Breakdown voltage is displayed.

Interference voltage in switched-off condition

lings of test voltage during insulation measurement

Dangerous voltage of greater than 50 V is present at the measurement inputs:

– Initialization of insulation resistance and

low-resistance measurement is disabled.

– High test voltage is applied to the measuring terminals

(Riso/Rins, PI and DAR) during insulation measurement

Detection of interference voltage in the on-state

in the resistance measuring ranges after starting measurement

The value of interference voltage is displayed in addition to signalling

in the resistance measuring ranges for as long as it is present.

1

and signal-

LED is OK. In this case, the LED reliably indicates interference

voltage even when the instrument is switched off. We recom-

4.2 Switching On, Monitoring and Switching Off

If supply voltage drops to a value of less than 8.5 V, the

LOW BATT pop-up message appears: No more measurements

can be started.

If battery voltage falls below the allowable limit value of 8.0 V, the

mend executing this test at regular intervals.

METRISO XTRA Measuring Functions, Measuring Ranges and

Limit Values

Measuring Ranges

instrument cannot be switched on, or it is switched off.

Measurements cannot be started in the resistance measuring

ranges in the event of interference voltage.

The instrument only switches itself off automatically after comple-

tion of an (automatic) measuring sequence, and after the predetermined on-time has expired (see page 8). On-time is reset to its

original value as defined in the setup menu, as soon as any key or

the rotary function switch is activated.

/ R

R

ISO

INS

/ R

R

ISO

INS

/ R

R

ISO

INS

R 10 ... 10 kΩ

R

LO

U 0 ... 1000 V

U = 50, 100, 250, 500, 1000 V

Uvar = 50 ... 1000 V

Uramp (U ) = 100 ... 1000 V

0.01 ... 10 Ω

If the instrument is switched off automatically with the rotary

switch in any position other than OFF, it can be reactivated by

pressing the ESC key. The instrument is also reactivated if the

Limit Values

rotary switch is activated and turned through the OFF position.

/ R

Limit R

The instrument can be switched off manually by turning the rotary

switch to the OFF position.

GMC-I Messtechnik GmbH 11

ISO

PI limit Adjustable 1.0, 1.1, 1.5, 2.0, 3.0, 4.0

DAR limit Adjustable 1.25, 1.6

Limit R

LO

Fixed setting 50 kΩ @ U

INS

Fixed setting 100 kΩ @ U

Fixed setting 500 kΩ @ U

Fixed setting 1 MΩ @ U

Fixed setting 1 MΩ @ U

Fixed setting 1 MΩ @ U

Fixed setting 2 Ω

ISO/UINS

ISO/UINS

ISO/UINS

ISO/UINS

ISO/UINS

ISO/UINS

= 50 V

= 100 V

= 250 V

= 500 V

= 1000 V

= Uvar

4.4 Measurement Value Display and Memory

Note

HELP

1

2

3

2

The following appear at the display panel:

• Measurement values with abbreviations and units of measure

• Selected function

• Error messages

Measurement values for automatic measuring sequences are

stored and displayed as digital values until the next measurement

sequence is started, or until automatic shut-off occurs.

4.5 Help Function

A wiring diagram can be displayed for selected switch positions,

as well as basic functions after they have been selected with the

rotary selector switch:

➭ Press the HELP key in order to query online help.

➭ Press the ESC key in order to exit online help.

If the upper range limit is exceeded, the upper limit value is displayed and is preceded by the “>” symbol (greater than), which

indicates measurement value overrun.

The depiction of LEDs in these operating instructions

may vary from the LEDs on the actual instrument due to

product improvements.

4.6 Setting Measuring Parameters using Insulation Resistance Measurement as an Example

1 Access the submenu for setting the desired parameter.

2 Select a parameter using the ↑ or ↓ scroll key.

3 The setting value is not permanently accepted for the respective measure-

ment until the ✓ key is pressed, after which the display is returned to the

main menu. You can return to the main menu by pressing ESC instead of

✓, without accepting the newly selected value.

12 GMC-I Messtechnik GmbH

4.7 Specifying Nominal Voltage for Uvar and Uramp

Note

Select value.

Select value.

↵ Accept value.

Delete characters =

✓Save value (to list).

Select the EDIT menu.

change cursor position.

Nominal voltage can be freely selected within specified limits for

the Uvar and Uramp measuring functions:

1 Access submenu for selecting the desired voltage:

Press the key with the icon.

2 Select the desired value with the left or right scroll key. The value is

accepted by pressing the ↵ key. The entire value is acknowledged by

selecting ✓ and then pressing the ↵ key.

The new nominal voltage appears at the main display.

Observe the predefined limits for the new setting value.

New, freely selected limit values or nominal values

included in the parameters list can be deleted/edited at

the PC with the help of ETC software.

GMC-I Messtechnik GmbH 13

5 Measuring Direct Alternating Voltage

Note

V

L1

L2

N

PE

L3

R

B

R

E

Max.

1.2 kV

U

+

COM

+

COMSHIELD

1

2

2

3

Direct voltage

Alternating voltage

Pulsating voltage

(DC + AC TRMS)

You can measure direct voltage, as well as sinusoidal alternating

voltage with frequencies ranging from 45 to 65 Hz, with this test

instrument.

Select Measuring Function

➭ Select the V measuring function with the rotary switch.

Connection

➭ Connect the measurement cables to the + and COM jacks.

➭ Contact the measuring point with both test probes.

Measurement

The measured value is displayed directly (without pressing the

START key) – in analog format at the bar graph and in digital format

at the matrix display.

➭ After completing the measurement, switch the instrument off

by turning the rotary switch to the OFF position.

The ESC, START and CONTIN. keys have no function in this case.

Set the waveform parameter (voltage type).

Input impedance for the voltage measuring range is

10 MΩ.

14 GMC-I Messtechnik GmbH

6 Measuring Insulation Resistance

Note

Note

R

INS

U

var

U

ramp

HELP

1/2

2/2

L-PE

N-PE

1/4

2/4

3/4

4/4

L1-PE

L2-PE

L3-PE

N-PE

AUTO1 AUTO3

R

ISO/RINS

→ MEMORY

MEMORY → R

ISO/RINS

Switch

and save

Switch

without saving

NEXT

Select Measuring Function

➭ Select the R

depending on the measuring task, constant or variable test

voltage (Uvar), or a ramp function (Uramp).

Connection

measuring function with the rotary switch and,

INS

Semiautomatic Measurement in Multipole Systems

Fast, semiautomatic polarity reversal is possible in all rotary switch

positions for insulation resistance measurement. However, polarity selection is only relevant for documentation.

Fast Polarity Reversal

The polarity parameter is set to AUTO1 (single-phase mains voltage) or AUTO3 (3-phase mains voltage).

There are two ways to quickly and conveniently switch amongst

all polarity variants without switching to the parameter settings

submenu:

• Press the NEXT key.

• Press the save key at the instrument twice after each measurement.

➭ Connect the device under test to the + and COM jacks.

Sample connection layouts for insulation resistance measurement

are included in section 13.1.

Insulation resistance can only be measured at voltage-free

objects. If mains voltage or interference voltage is applied to the

measurement inputs, measurement cannot be started.

Checking Measurement Cables Before Measurements

Before performing insulation measurement, the test

probes on the measurement cables should be short-circuited in order to assure that the instrument displays a

value of less than 1 kΩ (see section 9). In this way, incorrect connection can be avoided and broken measurement cables can be detected.

Continuous Measurement via the CONTIN. Key

The instrument’s batteries are rapidly depleted during the

insulation resistance measurement. Stop continuous

measurement with “constant test voltage” as soon as the

display has settled in.

GMC-I Messtechnik GmbH 15

6.1 Measuring with Constant Test Voltage and Nominal Value

Note

Polarization index

Test voltage switch position:

50 V / 100 V / 250 V / 500 V / 1000 V

Absorption index

Insulation resistance

START

CONTIN

Variable test voltage

50 V ... 1000 V

(constant nominal value):

START

CONTIN

Selection via Rotary Switch Position

Set Parameters

6.2 Measurement with Constant Test Voltage and Variably Adjustable Nominal Value

A test voltage which deviates from nominal voltage, and is usually

lower, can be selected for measurements at sensitive components, as well as systems with voltage limiting devices.

Set Parameters

The constant test voltage function offers two options:

• After briefly pressing the START key, specified test voltage UN is

read out and insulation resistance RINS is measured. As soon

as the measured value is stable (settling time may be several

seconds in the case of high cable capacitance values), measurement is ended and the last measured values for RINS and

UINS are displayed. U is the voltage which is measured at the

test probes during and after testing. This voltage drops to a

value of less than 10 V (see section entitled “Discharging the

Device Under Test”.

or

• As soon as you press the CONTIN key, test voltage UN is applied

and insulation resistance RINS is measured. Do not press the

key again in order to stop measurement until the measured

value has settled in (settling time may be several seconds in

the case of high cable capacitance values). Voltage U, which

is measured during testing, corresponds to voltage UINS.

After once again pressing the CONTIN key, measurement is

ended and the last measured values for RINS and UINS are

displayed. U drops to a value of less than 10 V after measurement (see the section entitled “Discharging the Device Under

Test”.

Start Measurement

Refer to section 4.7 regarding how to enter the variable voltage.

The selected nominal voltage is displayed in the main menu.

❏ Pole Selection Report Entry

The poles between which testing takes place can only be entered

here for reporting purposes. The entry itself has no influence on

the actual polarity of the test probes or pole selection.

Start Measurement

After pressing the START key, nominal voltage UN (50 to 1000 V)

entered previously via the parameters menu is applied until the

measured values settles in.

After pressing the CONTIN. key, the previously selected test voltage

or nominal voltage U

key is pressed once again.

(50 to 1000 V) is applied until the CONTIN.

N

U is the voltage which is measured at the test probes during and

after testing. This voltage drops to a value of less than 10 V after

measurement (see section 6.5, “Discharging the Device Under

Test’ ’) .

Test voltage U

After pressing the START key, nominal voltage UN (50 ... 1000 V)

selected with the rotary switch is applied until the measured values settles in.

After pressing the CONTIN. key, the previously selected test voltage

or nominal voltage U

key is pressed once again.

U is the voltage which is measured at the test probes during and

after testing. This voltage drops to a value of less than 10 V after

measurement (see section 6.5, “Discharging the Device Under

Test’’).

Test voltage U

16 GMC-I Messtechnik GmbH

(50 to 1000 V) is applied until the CONTIN.

N

is displayed for U

INS

.

is displayed for U

The instrument’s batteries are rapidly depleted during the

insulation resistance measurement. Stop continuous

measurement with “constant test voltage” as soon as the

display has settled in.

INS

.

6.3 Measurement with Rising Test Voltage (ramp function)

Note

Attention!

!

Attention!

!

Note

Maximum test voltage

100 V ... 1000 V

(final ramp value)

Max. 1 mA (at 1 KΩ/V)

Current load:

START

+Measurement Cable

–Measurement Cable

Guard Cable

Conductor

Insulation

Material

Guard Rings

Contact Ring

(COM)

and Variably Adjustable Final Value

The “Uramp” rising test voltage function (ramp function) is used to

detect weak points in the insulation, as well as to determine

response voltage for voltage limiting components.

Set Parameters

6.4 Insulation Resistance Measurement – Special Conditions

Insulation resistance can only be measured at voltagefree objects.

If measured insulation resistance is less than the selected limit

value, the limit LED lights up red.

Refer to section 4.7 regarding how to set the final ramp value. The

selected nominal voltage value is displayed in the main menu.

❏ Pole Selection Report Entry

The poles between which testing takes place can only be entered

here for reporting purposes. The entry itself has no influence on

the actual polarity of the test probes or pole selection.

Start Measurement

After briefly pressing the START key, test voltage is continuously

increased until the specified nominal voltage U

reached.

Insulation measurement with rising test voltage is ended:

• As soon as specified maximum test voltage U

the measured value is stable

or

• After sparkover occurs at breakdown voltage

(100 ... 1000 V) is

N

is reached and

N

If an interference voltage of roughly

– Interference Voltage” appears in a pop-up window, insulation

resistance is not measured. In the case of interference voltage >

50 V, the “> 50 V” LED lights up.

In 3-phase systems, all conductors (L1, L2, L3 and N) must be

tested against PE!

Do not touch the instrument’s terminal contacts during

insulation resistance measurements!

If nothing has been connected to the terminal contacts, or if a

resistive load component has been connected for measurement,

your body would be exposed to a current of approximately 1 mA

at a voltage of 1000 V. The noticeable shock may lead to injury

(e.g. resulting from a startled reaction etc.).

≥ 15 V is present and “U

EXT

6.4.1 Measurements with the Guard Cable

The measurement of very high resistances necessitates extremely

minimal measuring current and may be rendered problematic as a

result of influences such as electromagnetic fields, humidity or

surface pollution. An accurate test set-up is thus absolutely

essential.

A guard cable must be used for measurements within a range of

100 GΩ (10 GΩ) … 1TΩ, in order to prevent surface current from

distorting measurement results. The guard rings prevent current

at the surface of the insulation material from flowing from the

+measurement cable to the –measurement cable, instead of

through the insulation material itself.

➭ Insert the plug from the guard cable into the appropriate jack

in the test instrument.

➭ Plug the alligator clip onto the guard cable test probe.

➭ Connect the alligator clip to the guard ring between the two

measuring points at the insulation material under test.

➭ Refer to section 6.1 to section 6.3 regarding the measuring

sequence.

As soon as the final ramp value is reached, the Uramp LED lights

up green. If the final ramp value is not reached due to sparkover,

the Uramp LED lights up red.

U is the voltage which is measured at the test probes during and

after testing. This voltage drops to a value of less than 10 V after

measurement (see section 6.5, “Discharging the Device Under

Test’’).

Highest achieved test voltage U or any triggering or breakdown volt-

age which occurs is displayed for U

GMC-I Messtechnik GmbH 17

.

INS

Measurement can be stopped at any time by pressing

the START key or the CONTIN. key.

The following materials can be used as guard rings: aluminum foil, copper foil or metallic hose clamps.

6.5 Discharging the Device Under Test

Attention!

!

Attention!

!

Note

PI

R

10min

R

1min

--------------=

Polarization Index

Test voltage switch position:

50 V / 100 V / 250 V / 500 V / 1000 V

Absorption index

Insulation resistance

START

If measurement is performed at a capacitive object such

as a long cable, it becomes charged with up to approx.

1000 V!

Touching such objects is life endangering!

When an insulation resistance measurement has been performed

on a capacitive object it is automatically discharged by the instrument after measurement has been completed. Contact with the

device under test must be maintained to this end. The falling voltage value can be observed at the U display.

Do not disconnect the DUT until less than 10 V is displayed for U!

6.6 Evaluation of Measured Values

Instrument measuring error must be taken into consideration in

order to assure that the limit values set forth in DIN VDE regulations are not fallen short of. The required minimum display values

for insulation resistance can be determined with the help of the

table, “

Display Values in Consideration of Measuring Uncertainty

page 30. These values take maximum device error into consideration (under nominal conditions of use). Intermediate values can

be interpolated.

”, o n

Z550A Option

Use of the measurement cable with remote start/stop is

not advisable for polarization index measurement PI or

absorption index measurement DAR, because measurement is only conducted as long as the START key is

pressed and held.

sequence is nevertheless executed, start each measurement

with the

Set Parameters

In order to assure that the entire measuring

START

key at the test instrument only.

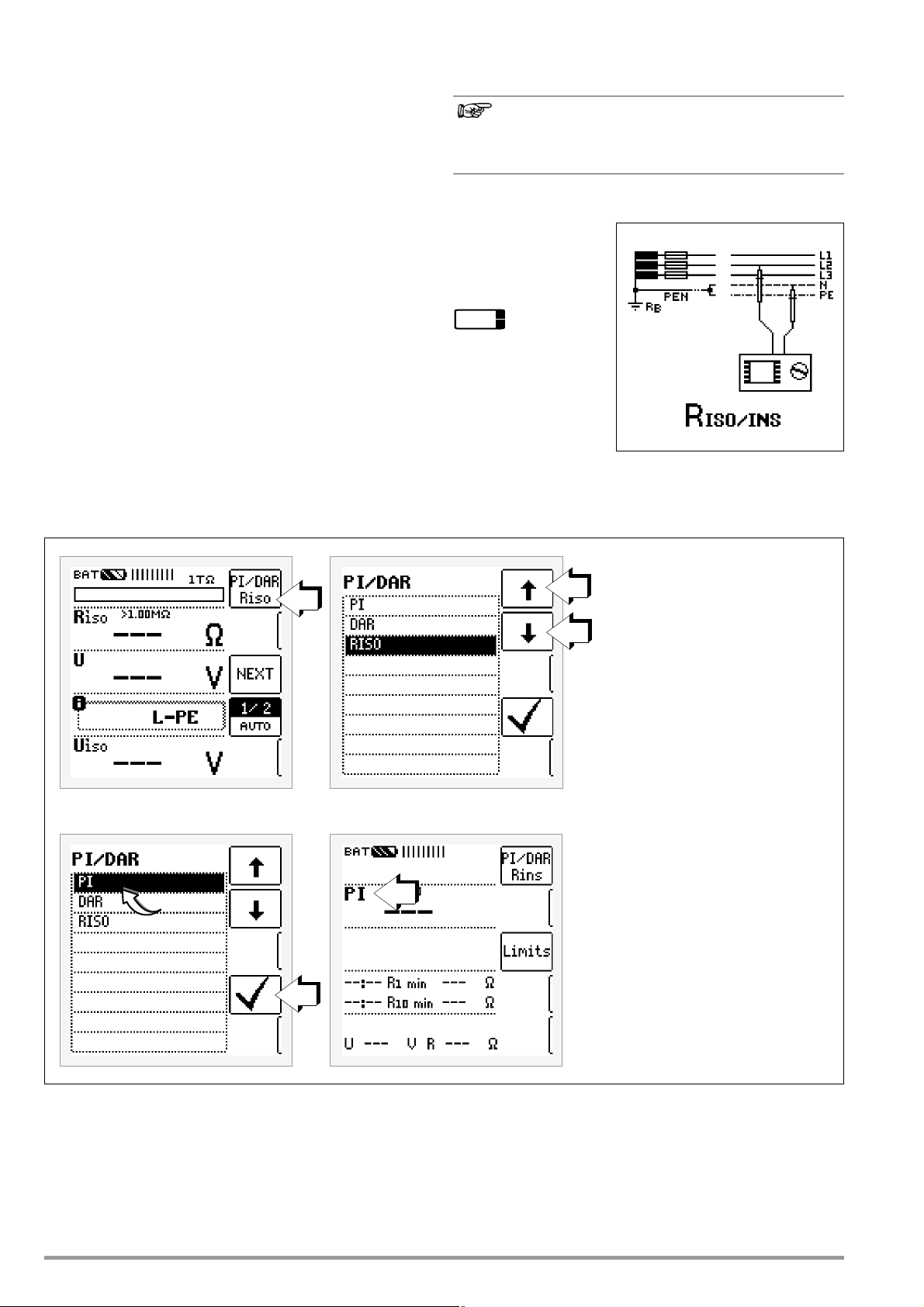

6.7 Polarization Index Measurement

In the case of electrical machines which include components with

windings (generator and motor windings), it’s advisable to conduct polarization index testing. This procedure involves expanded

testing of insulation resistance. The accumulation of moisture and

contamination on windings can be detected as reduced insulation

resistance.

DC measuring voltage from the METRISO XTRA is applied to the

insulation for a duration of 10 minutes to this end. Measured values are documented after one minute, and after ten minutes. If

the insulation is good, the value measured after ten minutes is

higher than the value measured after one minute. The relationship

between the two measurement values is the polarization index.

The molecules within the insulation are aligned due to the application of measuring voltage over a long period of time, resulting in

polarization. The polarization index indicates whether or not the

molecules contained in the insulation can still be moved, thus

allowing for polarization. This, in turn, is an indication of the condition of the insulation. The more freely the charge carriers can be

moved, the better is the condition of the insulation.

The following rules apply in general:

PI value < 1: Troubleshooting is required.

PI value = 1 to 2: Maintenance is advisable.

PI value = 2 to 3: DUT is OK!

PI values > 3: Error-free device under test

No immediate action is required.

Preventive maintenance can be planned

according to workload.

Start Measurement

Applications

Determination of moisture and contamination levels

The selected polarization index menu is only

displayed until the rotary

For PI measurement, test instrument on-time should be

set to OFF (see section 3.4, “Device Settings – SETUP’’).

18 GMC-I Messtechnik GmbH

switch is activated or the

parameter is changed.

6.7.1 Absorption Index (DAR) – DC Charging Test

DAR

R

60s

R

30s

---------=

Polarization Index

Test voltage switch position: 50 V / 100 V / 250 V / 500 V / 1000 V

Absorption index

Insulation resistance

START

+

COM

10M

Ω

+

COMSHIELD

R

ISO/RINS

10 MΩ

The absorption index test is part of the polarization index test.

Insulation resistance measurements are placed in relationship to

one another after 30 and 60 seconds.

Applications:

Set Parameters

Faster version of the polarization index test.

The selected polarization index menu is only displayed until the

rotary switch is activated or the parameter is changed.

7 Test Resistor for Insulation Measurement for

Checking the Insulation Measuring Instrument

According to section 5.3.1.2 of VDE 0105-100 (EN 50110-1), the

following applies: “These measuring instruments must be tested

before, and if applicable after use.”

The two outermost jacks on the connection panel must be connected to each other internally via a 10 MΩ test resistor to this

end.

The sum of test resistor and cable resistance (for both cables),

including test probes, amounts to 10 MΩ ±5%. This value allows

for quick self-testing.

Start Measurement

➭ Connect the measurement cables to the + and COM jacks.

➭ Insert the test probes into the above described jacks.

➭ Select the RiSO/iNS measuring function with the rotary

switch, as well as the desired test voltage, e.g. RiSO 100V.

➭ Press the start key and view the measurement results.

GMC-I Messtechnik GmbH 19

8 Measuring Resistance – kOhm Function

Attention!

!

kΩ

+

C

O

M

R

x

START

CONTIN

Connector with

Shielded Cable,

Option KS-C (Z541F)

+

C

O

M

Shielded

Cable

S

H

I

E

L

D

Resistances of greater than 10 Ω and less than 10 kΩ are measured in this switch position. Refer to section 9 regarding resistances of less than 10 Ω .

Select Measuring Function

➭ Select the kΩ measuring function with the rotary switch.

Connection

➭ Connect the device under test to the + and COM jacks.

Special Case: Measuring High-Value Resistance with the KS-C Probe

Connection

➭ Connect the device under test to the + and COM jacks with a

shielded cable via the optional KS-C probe.

Resistance can only be measured at voltage-free objects. If mains voltage or interference voltage is applied to

the measurement inputs, measurement cannot be

started.

Start Measurement

➭ Start an individual measurement by briefly pressing the START

key, or initiate continuous measurement by briefly pressing

the CONTIN key.

20 GMC-I Messtechnik GmbH

9 Measuring Low-Value Resistance of up to

Attention!

!

Attention!

!

Note

Note

R

LO

HELP

+

COM

R

LO

+

COMSHIELD

R < 10

Ω

R

LO

R

x

0V !

!

Polarity: ± to PE

10 Ohm

(protective conductor and equipotential

bonding conductor)

According to the regulations, the measurement of low-value resistance at protective conductors, earth conductors or bonding conductors must be performed with (automatic) polarity reversal of

the test voltage, or with current flow in one direction (+ pole to PE)

and then the other (– pole an PE).

In the measuring function RLO, measurements are performed with currents about 200 mA.

Please check before measuring whether your DUT or

your circuit is designed for these high current values.

Low-value resistance can only be measured at voltagefree objects.

Select Measuring Function

Set Polarity Parameter (direction of current flow)

➭ Select a polarity option or automatic polarity reversal.

Measuring ROFFSET

When using extension cables with resistance of up to 5.00 Ω,

their resistance can be deducted automatically from the measurement results. Proceed as follows:

➭ Select the Rlo measuring function with the rotary switch.

Connection

➭ Short-circuit the end of the measurement extension cable with

the second test probe at the instrument.

➭ Start measurement of offset resistance with OFFSET.

If the difference between RLO+ and RLO– is great than

10% with automatic polarity reversal, no offset is

accepted. A pop-up window appears which must be

acknowledged by any desired key. The respectively

smaller value is otherwise stored to memory as an offset

value.

The maximum offset value is 5.00 Ω. Negative resistances may result due to the offset value.

The permissible value for R

In the case of values of greater than 5.00 Ω, a pop-up window

appears and the value is not accepted. The error message must

be acknowledged and/or cleared by any desired key.

The measured R

measurement value for all subsequent R

R

OFFSET can be deleted at any time by pressing the OFFSET CLEAR

key.

OFFSET value will now be deducted from the actual

Only use this function when performing measurements

with extension cables.

When different extension cables are used, the above

described procedure must always be repeated.

OFFSET is between 0.00 and 5.00 Ω.

measurements.

LO

➭ Connect the device under test to the + and COM jacks.

GMC-I Messtechnik GmbH 21

Start Measurement

Attention!

!

Note

START

Measurement of + pole to

PE

Measurement of – pole to

PE

Automatic Polarity Reversal

After the measuring sequence has been started, the instrument

performs measurement with automatic polarity reversal, first with

current flow in one direction, and then in the other.

If the difference between RLO+ and RLO– is greater than 10%

with automatic polarity reversal, RLO+ and RLO– values are displayed instead of RLO. The respectively larger value, RLO+ or

RLO–, appears at the top and is saved to the database as the

RLO value.

Resistances which do not demonstrate a stable value until after a

“settling in period” should not be measured with automatic polarity reversal. Measurement with automatic polarity reversal may

lead to varying and/or inflated measurement values, and thus to

an ambiguous reading.

Limit Value Indication

If the measured value is less than or equal to 2 Ω, the limit LED

lights up green. If the measured value is greater than 2 Ω, the LED

lights up red.

Evaluating Measurement Results

Differing results for measurements in both directions indicate voltage at the DUT (e.g. thermovoltages or unit voltages).

Measurement results can be distorted by parallel connected

impedances at load current circuits and by equalizing current,

especially in systems which make use of “overcurrent protection

devices” (previous neutralization) without an isolated protective

conductor. Resistances which change during measurement (e.g.

inductance), or a defective contact, can also cause distorted

measurements (double display).

In order to assure unambiguous measurement results, causes of

error must be located and eliminated.

In order to find the cause of measuring error, measure resistance

in both current flow directions.

Final results

The measurement cannot be started until the test probes

are in contact with the device under test.

If a voltage of U > approx. 3 V is present at the device

under test, a pop-up window appears which warns

against interference voltage.

This error message must be acknowledged and/or

cleared by any desired key. Eliminate the interference

voltage.

If resistance is greater than 10 Ω, OL appears at the display.

In the case of single-pole measurement, the respective value is

saved to the database as RLO.

Measuring Low-Value Resistance

If an extension cable is used its resistance must be measured and deducted from the measurement results.

Resistances which do not demonstrate a stable value

until after a “settling in period” should not be measured

with automatic polarity reversal, but rather one after the

other with positive and negative polarity.

Examples of resistances whose values may change

during measurement include:

– Incandescent lamp resistance, whose values change

due to warming caused by test current

– Resistances with a large conductive component

– Contact resistance

Polarity Selection Display Condition

+ pole to PE RLO+ None

– pole to PE RLO– None

RLO If ΔRLO ≤ 10%

± pole to PE

22 GMC-I Messtechnik GmbH

RLO+

RLO–

If ΔRLO > 10%

Evaluating of Measured Values

See table, “

on page 30.

Display Values in Consideration of Measuring Uncertainty

”,

Calculation of Cable Lengths for Common Copper Conductors

If the key is activated after performance of resistance

measurement, the cable lengths corresponding to common conductor cross sections are displayed.

If results vary for the two different directions of current flow, cable

length is not displayed. In this case, capacitive or inductive components are apparently present which would distort the calculation.

This table only applies to cables made with commercially available

copper conductors and cannot be used for other materials (e.g.

aluminum)!

GMC-I Messtechnik GmbH 23

10 Database

10.1 Creating Distributor Structures, General

A complete distributor structure with customer, building and distributor data can be created in the METRISO XTRA test instrument.

This structure makes it possible to assign measurements to distributors in various buildings and customer facilities.

10.2 Transferring Distributor Structures

The following data transfer operations are possible:

• Transfer a distributor structure from the PC to the test instrument.

• Transfer a distributor structure including measured values

from the test instrument to the PC.

There are two possible procedures:

• On location or at the

construction site:

Create the distributor

structure in the test

instrument. A distributor structure with

up to 50,000 structural elements can

be created in the test

instrument, which is

saved to the instrument’s flash memory.

or

• Create and save a distributor structure at a PC with the help of

ETC report generating software (Electric Testing Center) (see condensed operating instructions for ETC report generating software). The distributor structure is then transferred to the test

instrument.

The test instrument and

the PC must be connected with a USB cable

in order to transfer distributor structures and

data.

The following image

appears at the display

during transfer of structures and data.

10.3 Creating a Distributor Structure in the Test Instrument

Overview of the Meanings of Icons used to Create Structures

Icon Meaning

Main

Sub-

Level

Level

Memory menu, page 1 of 3

Cursor UP: scroll up

Cursor DOWN: scroll down

Note regarding ETC Report Generating Software

The following steps must be completed before using the software:

• Install USB device drivers:

(required for operation of the METRISO XTRA at a PC):

GMC-I Driver Control software can be downloaded from

Gossen Metrawatt's website at:

http://www.gossenmetrawatt.com

→ Products → Software → Software for Testers

→ Utilities → Driver Control

• Install ETC report generating software:

You can download the current ETC version free of charge from

our homepage under section mygmc after registration or login:

http://www.gossenmetrawatt.com

→ Products → Software → Software for Testers

→

Protocol Software without Database →

ETC → myGMC → zum Login

ENTER: acknowledge selection

+ → – change to sub-level

(open directory) or

– → + change to main level

(close directory)

Display structure designation or ID number

Switch back and forth between structure designation and ID number

Hide structure designation or ID number

Change display to menu selection

Memory menu, page 2 of 3

Add a structural element

Meaning of icons from top to bottom:

Customer, building, distributor, RCD and electrical circuit (display of the icons depends on the selected

structural element).

Selection: up/down scroll keys and ↵

In order to add a designation to the selected

structural element, refer to the edit menu below.

EDIT

For additional icons see edit menu below.

Delete the selected structural element.

Show measurement data, if a measurement has

been performed for this structural element.

24 GMC-I Messtechnik GmbH

Icon Meaning

Distributor

A check mark to the right of a structural element means that all measurements

within the respective hierarchy have been passed.

x: At least one measurement has not been passed.

No symbol: Measurement has not yet been performed.

Building

Customer

Same type of element as in the Windows Explorer:

+: Sub-object available, display by pressing ↵.

–: Sub-objects are displayed, hide by pressing ↵.

Scroll up

Scroll down

Acknowledge selection /

Display object

Next page

change level

or ID number

Create object

Delete object

VΩA: show measurement data

Edit designation

Edit the selected structural element.

Memory menu, page 3 of 3

Search for ID number.

> Enter complete ID number.

Search for text.

> Enter full text (complete word).

Search for ID number or text.

Continue searching.

Edit menu

Cursor left:

Select an alphanumeric character.

Cursor right:

Select an alphanumeric character.

ENTER: Accept an individual character.

Acknowledge entry

←

Cursor left

→

Cursor right

Delete characters.

Distributor Structure Symbology / Tree Structure

10.3.1 Creating Structures (example for electrical circuit)

After selection with the MEM key, all setting options for the creation of a tree structure are made available on three menu pages

(1/3, 2/3 and 3/3). The tree structure consists of structural elements, referred to below as objects.

Select the position at which a new object will be added.

Switching amongst different types of alphanumeric characters:

A Upper case letters

a Lower case letters

0Numbers

@ Special characters

Use the ↑↓ keys in order to select structural elements.

Change to the sub-level with the ↵ key.

Go to the next page with the >> key.

Create a new object.

GMC-I Messtechnik GmbH 25

Press the key in order to create a new object.

Select a new object from a list.

Scroll up

Scroll down

Acknowledge selection

Select character

Select character

↵ Accept character

Delete characters

Character selection:

✓ Save object designation

A, a, 0, @

Scroll up

Scroll down

Acknowledge selection /

Display object

Menu selection → page 3/3

change level

or ID number

Search for ID number

Search for text

Search for ID number or text

Select character

Select character

↵ Accept character

Delete characters

Character selection:

✓ Save object designation

Continue searching

Search for ID number

Search for text

Search for ID number or text

Search for ID number

Search for text

End search

Search for ID number or text

After selecting text search ...

Select the desired object from the list with the ↑↓ keys and

acknowledge with the ↵ key.

Enter a designation (Example Distributor).

Enter a designation and then acknowledge it by entering a ✓.

10.3.2 Searching for Structural Elements

... and entering the desired text (only full matches are found – no

wild cards, case sensitive) ...

... the first match is displayed.

Further matches can be found by selecting the icon shown

at the right.

If no further matches are found, the message shown above is displayed.

Mark the structural element from which the search will be started.

Objects located underneath or next to this object will be included

in the search.

Go to page 3/3 in the database menu.

26 GMC-I Messtechnik GmbH

10.4 Saving Data and Generating Reports

Note

Note

Preparing and Executing a Measurement

Measurements can be performed and stored to memory for each

structural element. Proceed as follows, adhering to the prescribed

sequence:

➭ Select the desired measurement with the function selector

switch.

➭ Start the measurement by pressing the START key.

Upon completion of measurement, the “→ Floppy Disk” softkey is

displayed.

➭ Briefly press the “Save Value” key.

The display is switched to the memory menu or the

structural view.

➭ Navigate to the desired memory location, i.e. to the desired

structural element / object, for which the measurement data

will be saved.

➭ If you would like to save a comment along with the

measurement, press the key shown at the right and

enter a designation via the “EDIT” menu as described in

section 10.3.1.

➭ Complete data storage by pressing the “STORE” key.

Retrieving Saved Measured Values

➭ Switch the display to the distributor structure by pressing the

MEM key and select the desired electrical circuit with the scroll

keys.

➭ Switch to page 2

by pressing the key shown here:

➭ Display the measurement data

by pressing the key shown here:

One measurement with date

and time, as well as any comment you might have entered, is

displayed in each screen.

Example:

RCD Measurement

Alternative Storage Procedure

➭ The measured value can be saved to the last se-

lected object in the structural diagram by pressing

and holding the “Save Value” key, without switching

the display to the memory menu.

If you change the parameters in the measurement view,

they are not saved for the structural element. A measurement with changed parameters can nevertheless be

saved to the structural element, and any changed parameters are documented in the report for each measurement.

An inverse displayed check mark in the header means that

the respective measurement has been passed.

An inverse displayed X means that the measurement has

not been passed.

➭ Scrolling amongst measurements

is possible with the keys shown here:

➭ The measurement can be deleted with the key

shown here:

A prompt window asks you to confirm

deletion.

With the help of the key shown at the right (MW:

measured value / PA: parameter), the setting parameters can be displayed for this measurement.

➭ Scrolling amongst measurements is possible with

the keys shown here:

GMC-I Messtechnik GmbH 27

Data Evaluation and Report Generation with ETC Software

Note

Note

All data, including the distributor structure, can be transferred to

the PC and evaluated with the help of ETC software. Additional

information can be entered here subsequently for the individual

measurements. After pressing the appropriate key, a report

including all measurements within a given distributor structure is

generated, or the data are exported to an Excel spreadsheet.

The database is exited when the rotary selector switch is

turned. Previously selected parameters in the database

are not used for the measurement.

10.4.1 Use of Barcode Scanners and RFID Readers

Search for an Already Scanned Barcode

The search can be started from any switch setting and menu.

➭ Scan the object’s barcode.

The search is started based on the currently selected structural

element down though lower hierarchical levels. The found barcode is displayed inversely.

➭ This value is accepted after pressing the ENTER key.

An already selected object cannot be found.

Continued Searching in General

Regardless of whether or not an object has been found,

searching can be continued by pressing this key:

– Object found: Searching is continued underneath the previ-

ously selected object.

– No further object found: The entire database is searched at

all levels.

Reading In a Barcode for Editing

If the menu for alphanumeric entry is active, any value scanned by

means of a barcode or RFID reader is accepted directly.

Using a Barcode Printer (accessory)

A barcode printer allows for the following applications:

• Read-out of ID numbers as encrypted barcodes; for quick

and convenient acquisition for periodic testing

• Read-out of repeatedly occurring designations, such as test

object types, encrypted as barcodes in a list, allowing them to

be read in as required for comments.

28 GMC-I Messtechnik GmbH

11 Characteristic Values

METRISO XTRA

Meas.

Qty.

R

ISO

U

AC/DC

R

LO

R

1)

the indicated accuracy is only achieved with the optional accessory

„shielded high-resistance measuring cable KS-C (article number Z541F)“

4)

up to 5 Ω

U

iSO

50 V

100 V

250 V / 500 V

Display range as of

01.0 Ω

Range Measuring Range

100 k 10 kΩ ... 99.9 kΩ 0.1 k

1 M 100 kΩ ... 999 kΩ 1 k

10 M 1.00 MΩ ... 9.99 MΩ 10 k

100 M 10.0 MΩ ... 99,9 MΩ 100 k

1000 V

1 G 100 MΩ ... 999 MΩ 1 M

10 G 1.00 GΩ ... 9.99 GΩ 10 M

100 G 10,0 GΩ ... 99.9 GΩ 100 M ±(8% rdg. + 3 d)

1 T 100 GΩ ... 999 GΩ 1 G ±(25% rdg. + 5 d) 1)±

100 V 10.0 V ... 99.9 V 0.1 V

1000 V 100 V ... 999 V 1 V

10 Ω 0.17 ... 9.99 Ω

100 Ω 10.0 ... 99.9 Ω 0.1 Ω

1 kΩ 100 ... 999 Ω 1 Ω

10 kΩ 1.00 ... 9.99 kΩ 10 Ω

Reso-

lution

0.01

Ω

Open-Circuit

Voltage

U

50 V /100 V:

1.25 U

250 V /

500 V /

1000 V:

1.1 U

4 V < U0 < 6 V

U0 max. 15 V

Test Current Intrinsic Uncertainty Measuring Uncertainty Overload Capacity

0max

ISO

IN = 1 mA

I

≤ 5 mA

K

ISO

——±(2.5% rdg. + 3 d) ±(5% rdg. + 3 d)

200 mA ≤ I

I ≤ 260 mA

1 mA ≤ I

I ≤ 1.3 mA

2)

does not conform to DIN EN 61557-2

3)

Display range up to 1.2 kV

±(5% rdg. + 3 d) ±(7% rdg. + 3 d)

1)

±(10% rdg. + 3 d)

(50% rdg. + 20 d)

±(2.5% rdg. + 3 d) ±(5% rdg. + 3 d)

4)

±(2.5% rdg. + 3 d) ±(5% rdg. + 3 d)

1)

1) 2)

1000 V AC/DC

TRMS

1000 V AC/DC

3)

TRMS

1000 V AC/DC

TRMS

1000 V AC/DC

TRMS

Breakdown Voltage (Uramp)

Parameter Range Intrinsic

Voltage range 100 … 1000 V

Rise time 5 … 300 s — —

Measuring time 1 … 120 s /

uto / cont. measurement

a

Uncertainty

±(10% rdg. + 8 d)

——

Measuring

Uncertainty

±(15% rdg. + 10 d)

Polarization Index (PI), Absorption Ratio (DAR)

t1 [min.] t2 [min.] Limit [min.]

PI 01:00 10:00 > 4.0 / > 3.0 / > 2.0 / > 1.5 / > 1.1 / > 1.0

DAR

00:30 01:00 > 1.60 / > 1.25

PI and DAR are calculated values. Insulation measurement specifications apply.

Reference Conditions

Reference

temperature + 23 °C ± 3 K

Relative humidity 40 to 75%

Measured quantity

frequency 45 to 65 Hz

Measured quantity

waveshape Sine, deviation between TRMS and recti-

fied value < 1%

Battery voltage 9.5 V ±0.1 V

Test resistance 10 MΩ±1%

Electrical Safety

Protection class II per IEC/EN 61010-1/VDE 0411-1

Pollution degree 2

Measuring category

CAT II 1000 V / CAT III 600 V / CAT IV 300 V

Fuses

Fuse link FF315mA/1000V, effective in all resis-

tance measuring ranges, 1 additional

replacement fuse in the battery compart-

ment

Electronic fuse Protects low-resistance and resistance

measurements R

and R

LO

Electromagnetic Compatibility (EMC)

Interference emission EN 61326-1:2013, class B

Interference immunity EN 61 326-1:2013

Power Supply

Batteries 8 ea. 1.5 V mignon cell (8 ea. size AA)

(alkaline manganese per IEC LR14)

or 8 rechargeable NiMH batteries (must be

recharged externally)

Z502R charger Broad-range charger with barrel connec-

tor, input: 100 to 240 V AC,

output: 16.5 V DC, 1 A (Mascot)

Nominal range of use 8.5 to 12 V

Battery test Battery capacity display with battery sym-

Battery saver circuit Automatic shutdown of display illumination

Service life For R

Safety shutdown If supply voltage is too low (U < 8 V), the

Recharging socket Installed rechargeable batteries can be

Charging time Approx. 2 hours *

* Maximum charging time with fully depleted rechargeable batteries.

A timer in the charger limits charging time to no more than 4 hours.

bol in 4 segments: .

Querying of momentary battery voltage via

menu function.

after 10 to 30 seconds (after the last time

the rotary switch is actuated) can be

selected in the setup menu (see page 8).

The test instrument is automatically

switched to the standby mode if the mea-

sured value remains unchanged for

approximately 15 minutes, and if none of

the controls are activated during this time.

The instrument is switched off automatically

if the measured value remains unchanged

for a long period of time and if none of the

keys or the rotary switch have been acti-

vated during on-time (specified in sec-

onds).

(1000 V / 1 MΩ) and RLO with

INS

25 s on-time and 1 subsequent measure-

ment each for a duration of 5 s

– With batteries (alkaline manganese):

700 measurements

– With rechargeable batteries (2000 mAh):

650 measurements

instrument is switched off, or cannot be

switched on.

recharged directly by connecting a charger

to the recharging socket:

charger Z502R

GMC-I Messtechnik GmbH 29

Displays

!

100

Ux/V

R

x

/kΩ

U

N

= 100 V

0

20

40

60

80

100

250

Ux/V

R

x

/kΩ

U

N

= 250V

0

50

100

150

200

250

0

100

200

300

400

500

500

U

N

= 500V

Ux/V

R

x

/kΩ

0

200

400

600

800

1000

1

U

N

= 1000V

Ux/V

R

x

/MΩ

Digital display Multiple display with dot matrix

Limit LED LED lights up red to indicate an exceeded

LED LED lights up red to indicate the presence

Uramp LED LED lights up green to indicate ramp

128 x 128 pixels, backlit (transflective),

dimensions: 65 x 65 mm

limit value.

LED lights up green to indicate adherence

to the limit value.

of an external voltage (with the instrument

switched off)

or high test voltage during insulation measurement (Riso/Rins, PI and DAR) at the

measuring terminals

sequence in progress.

LED lights up red to indicate interrupted

ramp sequence (e.g. in case of breakdown).

Ambient Conditions

Accuracy temperature

range 0 ... +40 °C

Operating temperature

Storage temp. range –25 ... +70 °C (without batteries)

Relative humidity Up to 75% (max. 85% during storage/

Elevation Max. 2000 m

Calibration interval 1 year (recommended)

–10 ... +50 °C

transport), no condensation allowed

Table for determining maximum display values for low-value resistance in

consideration of the instrument’s measuring uncertainty.

Limit Value