Operating Instructions

METRISO PRO

Analog Insulation, Low Resistance and Voltage Measurement Instrument

3-349-815-03

1/9.14

Overview of Included Features Scope of Delivery

a b

Replacement Fuse

Fuse Link

Battery Compartment Lid

METRISO PRO

Article number M550R

Measurements:

U = 50, 100, 250, 500, 1000 V

R

INS

R

LO

U 10 ... 1000 V

Display Functions:

Scale illumination

Limit value LED (green/red) for:

additional acoustic signal,

limit values per VDE 0100

Caution LED

for dangerous contact voltage

– When switched off

– For active test voltage

FUSE LED

For blown fuse

Battery level display

Special Functions:

Discharge capacitive devices under test

Safety shutdown (UBatt < 8 V)

0.17 ... 4

R

INS RLO

3

3

3

3

3

3

3

3

3

1 Insulation and resistance measuring instrument

1 Factory calibration certificate

1 Set of batteries (8 pieces in battery holder)

1Carrying strap

1 Alligator clip

1 KS17-4 cable set

1 Condensed operating instructions

1 Supplement Safety Information

– Detailed operating instructions for download from our website

at www.gossenmetrawatt.com

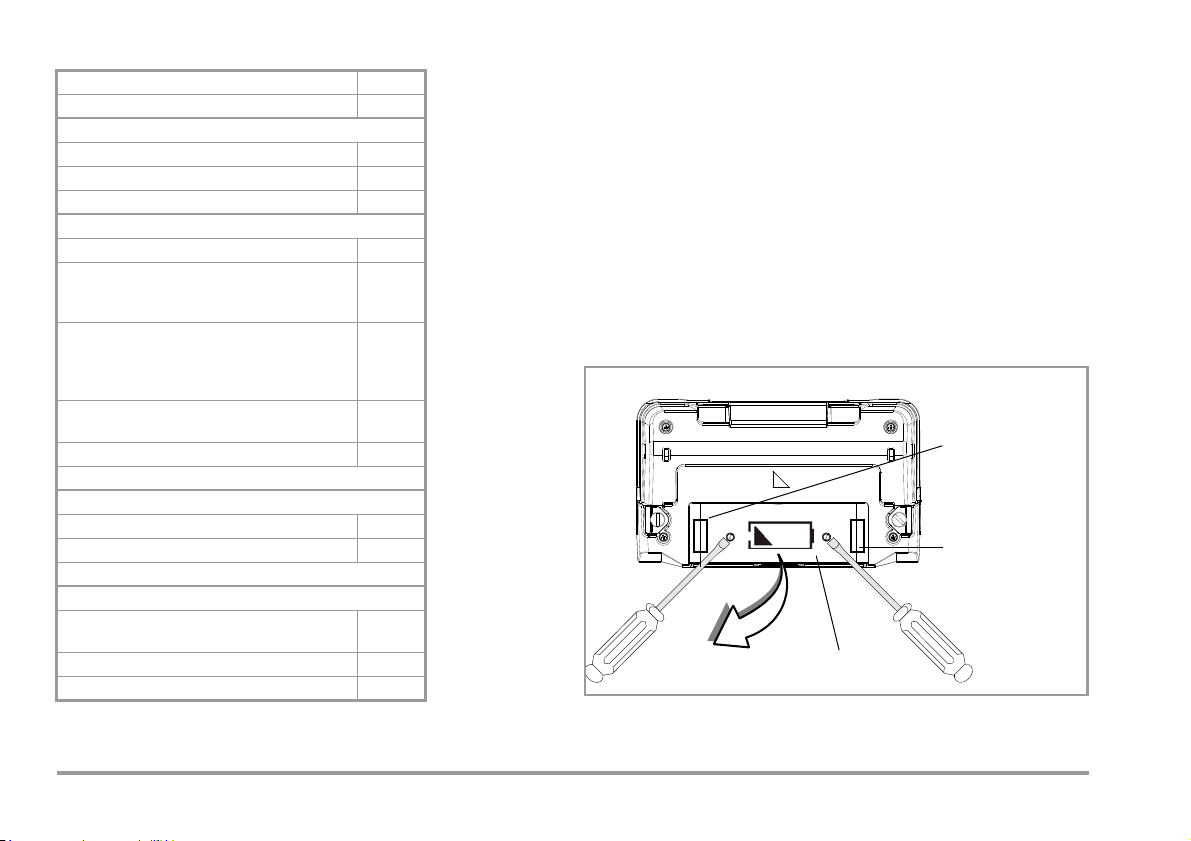

Battery Compartment Lid and Location of the Fuses

(housing bottom)

Features:

Measuring category

CAT II 1000 V / CAT III 600 V / CAT IV 300 V

Test resistor: 10 M

Factory calibration certificate

2 GMC-I Messtechnik GmbH

3

3

3

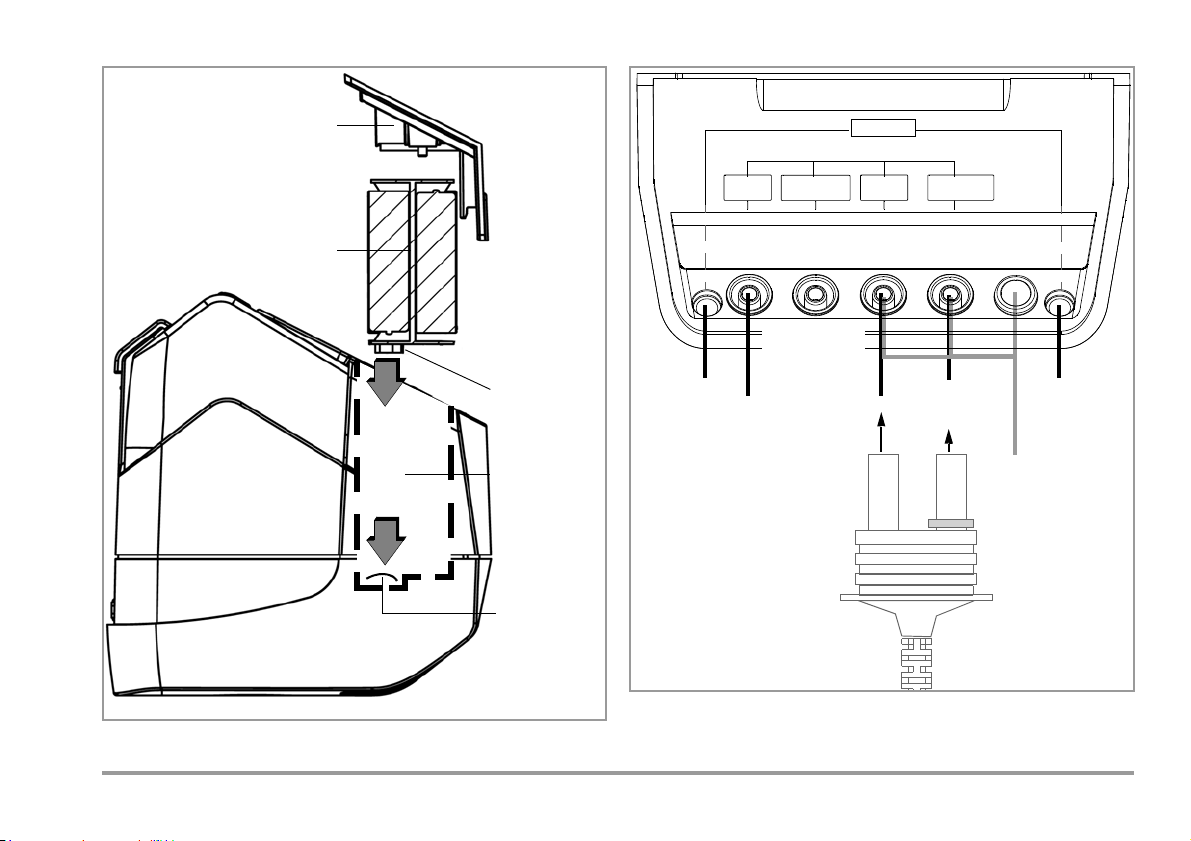

Inserting the Battery Holder (side view) Connections (housing top)

Battery Holder

Battery Compartment Lid

Battery Holder

Contacts

Battery

Contact

Spring

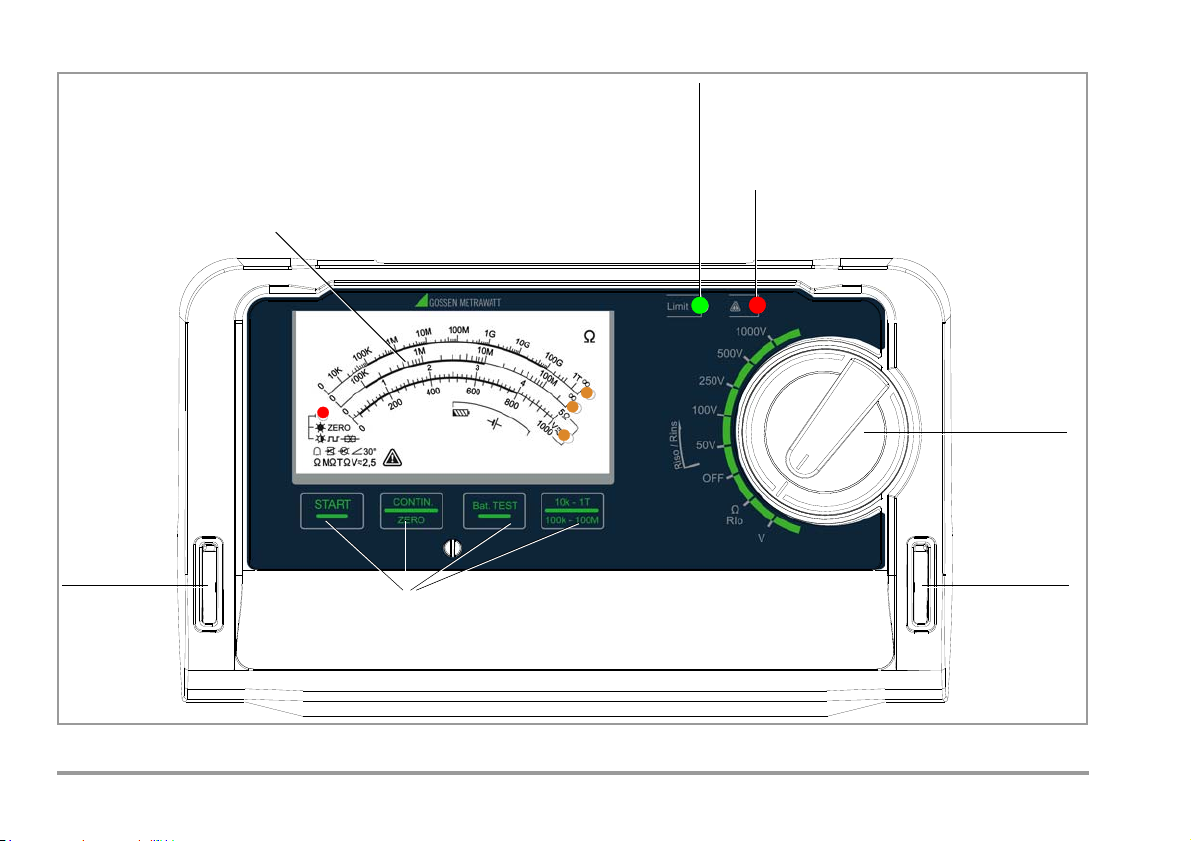

User Interface

Compartment

Shielded

Cable

Te st

Resistor

Tes t

Resistor

Test Pro b e w i th

Control Keys

1

Connector with

Shielded Cable,

Option KS-C (Z541F)

(G500/G10

G500/G1000)

Measuring Connections

+

COM

+

COM

10 M

GUARD

SHIELD

Guard connection

see section 5.4

GMC-I Messtechnik GmbH 3

1

Z550A accessory as option: test probe with measurement key and an additional

key for illuminating the measuring point, including shielded, plug-in connector

cable

User Interface

Red LED: limit value violated

Red LED:

– Interference voltage with device off

Function

Selector Switch

Guide for

Carrying Strap

Guide for

Carrying Strap

Green LED: limit value complied with

– Blinking indicates standby mode

Control Panel Keys

(see description on page 5)

Display Panel

(see description on page 5)

Refer to page 10 for a description of the LEDs.

– Test voltage active

4 GMC-I Messtechnik GmbH

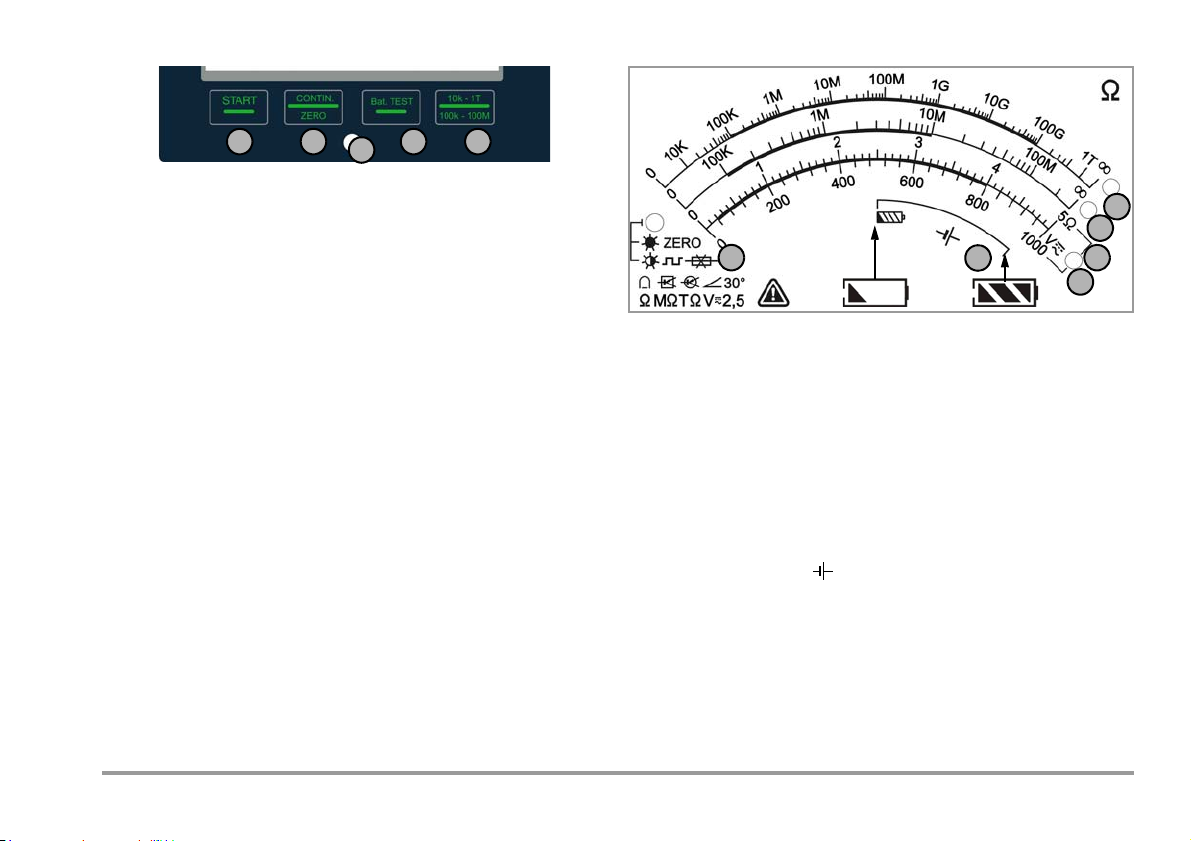

a b c d

e

1

2

4

5

6 3

➀

➁

➃

➅

Control Panel Keys – Adjusting Screw

a START: Starts insulation resistance measurement depending

on rotary selector switch setting (see measuring ranges

➀ and

Analog Display Symbols

➁), or low-resistance measurement with automatic polarity

reversal (see low-resistance measuring range

Reactivates the instrument from the standby mode.

b CONTIN./ZERO *

Starts long-term measurement for insulation and low resistance (low resistance: polarity in one direction only).

Each measurement takes up to 3 minutes; the instrument is

then switched to standby. Reactivates the instrument from the

standby mode.

c Bat. TEST: Starts the battery test (see battery level display

and section 3.1).

d 10k-1T/100k-100M

Switches between measuring ranges for insulation resistance

measurement (see measuring ranges

tion 5.2).

Reactivates the instrument from the standby mode.

➀

and ➁, as well as sec-

Mechanical Zero Point – Adjusting Screw (e)

If necessary, use the adjusting screw (e) to set the pointer to the

mechanical zero point (measuring range lower limit for all measuring ranges, except battery level indicator) with the switch in the

OFF position.

Electrical Zero Point – ZERO Function (Roffset)

ZERO function (Roffset): for subtracting cable resistance from the

measurement results with the help of the CONTIN. and 10k-1T/

100k-100M keys (see section 7.3).

* the supplementary labelling „ZERO“ depends on the product series

GMC-I Messtechnik GmbH 5

➂).

1 Insulation resistance measuring range: 10 k ... 1 T

LED

➀ lights up orange: this measuring range is active

➀ blinks orange: open cable ends (special case with

LED

50 V test voltage: full-scale pointer deflection of 1 G)

➄

2 Insulation resistance measuring range: 100 k ... 100 M

➁ lights up orange: this measuring range is active

LED

3 Low-resistance measuring range: 0 ... 5

LED ➃ blinks orange if the range is exceeded

4 Voltage measuring range: 0 ... 1000 V

LED ➃ lights up orange: low-resistance measurement is active

LED ➃ lights up orange: voltage measurement is active

5 Battery level indicator :

Left-hand range limit: batteries low or weakly charged

Right-hand range limit: batteries full or fully charged

6 Fuse link and electronic fuse:

FUSE ZERO/FUSE

Voltage measurement is still possible.

– Funktion ZERO (Roffset):

LED ZERO/FUSE

offset blancing, see section 7.3.

➅ blinks red: blown fuse

➅ lights up red permanently after

Contents Page Contents Page

1 Applications ...............................................................................7

2 Safety Features and Precautions ..............................................8

3 Initial Start-Up ...........................................................................9

3.1 Battery Test .....................................................................................9

3.2 Installing or Replacing Batteries .....................................................9

4 General Operation ....................................................................10

4.1 Switching On, Monitoring and Switching Off ................................10

4.2 Analog Display ...............................................................................11

5 Insulation Resistance Measurement

– Riso/Rins Function ...............................................................12

5.1 Connection ....................................................................................12

5.2 Executing the Measurement .........................................................12

5.3 Ending the Measurement – Safe Discharging ...............................14

5.4 Measurements with the Guard Cable ............................................14

6 Measuring Direct, Alternating and

Pulsating Voltage – V Function ................................................15

Measuring Low-Resistance of up to 5

7

– RLO Function ........................................................................16

7.1 Measurement with Automatic Polarity Reversal ...........................17

7.2 Measurement with Manual Polarity Reversal ................................17

7.3 Taking Measurement Cables and Extension Cables into Account (up

to 5 ) – ZERO Function (Roffset) .................................................18

List of Abbreviations and their Meanings ..................................... 23

10

11 Maintenance ........................................................................... 24

11.1 Battery and Rechargeable Battery Operation ................................24

11.2 Fuses .............................................................................................24

11.2.1Fuse Link – ZERO/FUSE LED ......................................................................24

11.2.2Electronic Fuse – ZERO/FUSE LED ............................................................. 25

11.3 Housing .........................................................................................25

12 Recalibration ........................................................................... 26

13 Appendix ................................................................................. 26

13.1 Sample Connection Layouts for Insulation Resistance Measurement 26

13.2 Attaching the Test Probe Holder to the Carrying Strap ................. 29

13.3 Technical Data for Measurement Cables

(scope of delivery: KS17-4 safety cable set) .................................30

13.4 Optional Accessories (not included) ..............................................31

14 Repair and Replacement Parts Service

Calibration Center* and Rental Instrument Service ...................... 31

15 Product Support ...................................................................... 32

8 Test Resistor for Insulation Measurement for Checking the

Insulation Measuring Instrument .............................................18

9 Technical Data ........................................................................19

6 GMC-I Messtechnik GmbH

1 Applications

These instruments fulfills all requirements of applicable European

and national EC directives. We confirm this with the CE mark. The

relevant declaration of conformity can be obtained from GMC-I

Messtechnik GmbH.

The METRISO PRO insulation and resistance measuring instrument allows for quick and efficient testing of protective measures

in accordance with DIN VDE 0100, ÖVE-EN 1 (Austria), SEV 1000

(Switzerland), and regulations specific to other countries as well.

The device is equipped with a microprocessor and complies with

IEC/EN 61557 / VDE 0413 regulations:

Part 1: General requirements

Part 2: Insulation resistance measuring instruments

Part 4: Instruments for measuring resistance at

ductors, protective conductors and equipotential bonding

Part 10: Combined measuring equipment for testing, measuring

or monitoring protective measures

as well as requirements per VDE 0701-0702:

Repair, modification and testing of electrical devices

earthing con-

The test instrument is especially well suited for:

•Systems setup

• Initial start-up

• Periodic testing

• Troubleshooting in electrical systems

The following measurements and tests can be performed with the

insulation measuring instruments:

• Insulation Resistance

• Low-resistance

• Voltage

The following can also be tested by using a shielded measurement cable:

• Floor covering electrostatic discharge capability

GMC-I Messtechnik GmbH 7

2 Safety Features and Precautions

!

The electronic measuring and test instrument is manufactured

and tested in accordance with safety regulations IEC/EN 610101/VDE 0411-1 and EN 61557. When used for its intended purpose, safety of the operator, as well as that of the instrument, is

assured.

Read the operating instructions thoroughly and carefully before

using your instrument. Follow all instructions contained therein.

The measuring and test instrument may not be placed into service:

• If the battery compartment lid has been removed

• If external damage is apparent

• If connector cable or measuring adapters are damaged

• If the instrument no longer functions flawlessly

• After extraordinary damage due to transport

• After a long period of storage under unfavorable conditions

(e.g. humidity, dust or extreme temperature)

Opening of Equipment / Repair

The equipment may be opened only by authorized service personnel to ensure the safe and correct operation of the equipment

and to keep the warranty valid.

Even original spare parts may be installed only by authorized service personnel.

In case the equipment was opened by unauthorized personnel,

no warranty regarding personal safety, measurement accuracy,

conformity with applicable safety measures or any consequential

damage is granted by the manufacturer.

Meanings of Symbols on the Instrument

Warning concerning a point of danger

(attention, observe documentation!)

Protection class II device

CAT II / III Device assigned to measuring category

CAT II 1000 V / CAT III 600 V / CAT IV 300 V

EC mark of conformity

The device and included batteries may not be disposed of with the trash. Further information regarding

the WEEE mark can be accessed on the Internet at

www.gossenmetrawatt.com by entering the search

term “WEEE”.

8 GMC-I Messtechnik GmbH

3 Initial Start-Up

Note

Attention!

!

Attention!

!

Attention!

!

3.1 Battery Test

A battery test should be conducted after inserting the batteries, or

if none of the measuring range LEDs lights up during insulation

resistance measurement. Press and hold the Bat. TEST key to this

end. Pointer deflection within the scale for the battery test indicates the condition of the batteries with an average load amounting to a test voltage of 1000 V. The rotary selector switch position

is not taken into consideration. The left-hand scale limit represents minimum required supply voltage, and the right-hand limit

represent maximum available supply power.

If the pointer is only deflected into the minimum supply

power range, several measurements can still be executed

with test voltages of less than 1000 V, because the battery test is conducted with a load which amounts to a test

voltage of 1000 V.

The instrument does not function if the batteries have been

depleted excessively, and alarm indication does not work either.

3.2 Installing or Replacing Batteries

New batteries must be inserted for initial start-up, or if only minimal supply power is indicated.

Eight 1.5 V size AA batteries in accordance with IEC LR 6 are

required for operation of the insulation measuring instrument. Use

new alkaline manganese batteries only.

Rechargeable NiCd or NiMH batteries may also be used. These

can only be recharged externally. We recommend rechargeable

NiMH batteries.

Always replace batteries in complete sets.

Dispose of batteries in an environmentally sound fashion.

Ð Loosen both slotted screws for the battery compartment lid

on the back, and remove the lid.

Ð Remove the battery holder and insert eight 1.5 V size AA bat-

teries with correct polarity in accordance with the symbols.

Make sure that all of the batteries are inserted with correct

polarity. If just one battery is inserted with reversed polarity, it will not be recognized by the instrument and may

result in leakage from the batteries.

Ð

Push the battery holder into the battery compartment such that

the battery holder’s contacts touch the contact springs at the

bottom of the battery compartment (see drawing on page 3).

If the battery holder is not inserted as specified, the instrument

cannot be supplied with power.

Ð Replace the battery compartment lid and retighten the

screws.

Before opening the battery compartment (see page 5 for

location), disconnect the instrument from the measuring

circuit (mains) at all poles.

GMC-I Messtechnik GmbH 9

The instrument may only be placed into service if the

battery compartment lid is securely fastened!

4 General Operation

KS-C

(Z541F)

+

C

O

M

S

H

I

E

L

D

G

U

A

R

D

Limit

Green

Limit

Red

!

Red

The test leads are connected to the “+” and “COM” jacks.

When measuring electrostatic

discharge capacity for floor

coverings, the shielded cable

should also be connected to

the COM and SHIELD jacks (KS-C

accessory set, “cable set consisting of measurement cable

and high-resistance measurement cable for measurements

in the G range” (see diagram). Be sure to observe color coding.

4.1 Switching On, Monitoring and Switching Off

The instrument is switched on as soon as the rotary switch is

turned to any position other than OFF.

If battery voltage falls below the allowable limit value (U < 8 V), the

instrument cannot be switched on, or it is immediately switched

off.

Measurement cannot be started in the resistance measuring

ranges in the event of interference voltage.

The instrument is switched to the standby mode after 3 minutes,

if neither the rotary switch nor any keys have been activated during this time.

A brief acoustic signal is generated before the instrument

switches itself off automatically with the rotary switch in a position

other than OFF. Moreover, 6 brief acoustic signals indicate every

10 minutes that the device is still on standby. The device should

be switched off by setting the rotary selector switch to OFF in

order to save (rechargeable) batteries.

The instrument can be activated once again by pressing the START

key.

The instrument can be switched off manually by turning the rotary

switch to the OFF position.

For purposes of transport and maintenance, we recommend turning the rotary selector switch to the OFF position in order to avoid

switching the test instrument on inadvertently.

Start-Up Test

When the instrument is switched on, i.e. as soon as the rotary

switch is turned to any position other than OFF, all LEDs light up

briefly: limit, caution, blown fuse, insulation resistance measuring

ranges, voltage measurement and scale illumination.

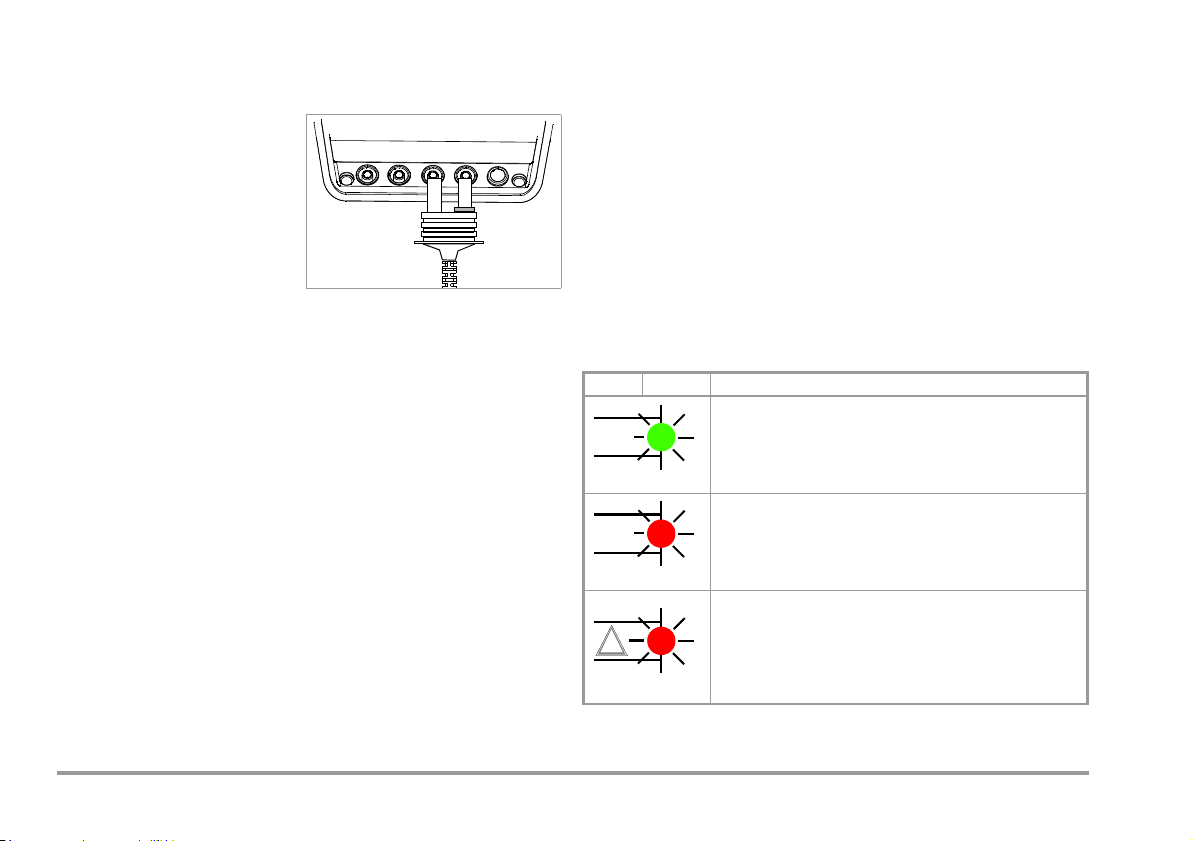

Optical Indicators

LED Status Function – Cause

Limit value indication

–Measured insulation resistance does not violate the limit

value.

– Measured low-resistance Rlo does not violate the limit

value.

Limit value indication

– Measured insulation resistance has fallen short of the limit

value.

– Measured low-resistance Rlo has exceeded the permissible

limit value.

Detection of interference voltage in the off state

If dangerous voltage of greater than 50 V is present at the measure-

ment inputs:

– Initialization of the insulation resistance and

low-resistance measurements is disabled.

– Presence of test voltage is indicated.

1

Function testing should be executed at regular intervals (see following section regarding testing the LEDs).

1

10 GMC-I Messtechnik GmbH

Testing the LED which Indicates Detection of Interference Voltage

when Switched Off – OFF Switch Position

Ð

Apply a voltage of greater than 50 V (+ and COM jacks).

Ð Turn the rotary switch to the V position.

Ð Read the voltage value at the analog display.

Ð Turn the rotary switch to the OFF position.

Test results: If applied voltage is unchanged and the LED which

indicates the detection of interference voltage lights up red, the

LED is OK. In this case, the LED reliably indicates interference

voltage even when the instrument is switched off. We recommend executing this test at regular intervals.

Limit Values for Insulation and Low-Resistance Measurements

Limit R

/ R

Limit R

ISO

LO

INS

100 k @ U

500 k @ U

2

50 k @ U

1M @ U

1M @ U

ISO/UINS

ISO/UINS

ISO/UINS

ISO/UINS

ISO/UINS

= 50 V

= 100 V

= 250 V

= 500 V

= 1000 V

Limit LEDs for Insulation Resistance and Low-Resistance

Measuring Ranges

The Limit LED lights up green if the measured insulation resistance

value does not violate the limit value. The Limit LED lights up red, if

the measured insulation resistance value violates the limit value. If

the Limit LED does not light up at all, this means that the selected

test voltage value has not been reached. A battery test is advisable in this case.

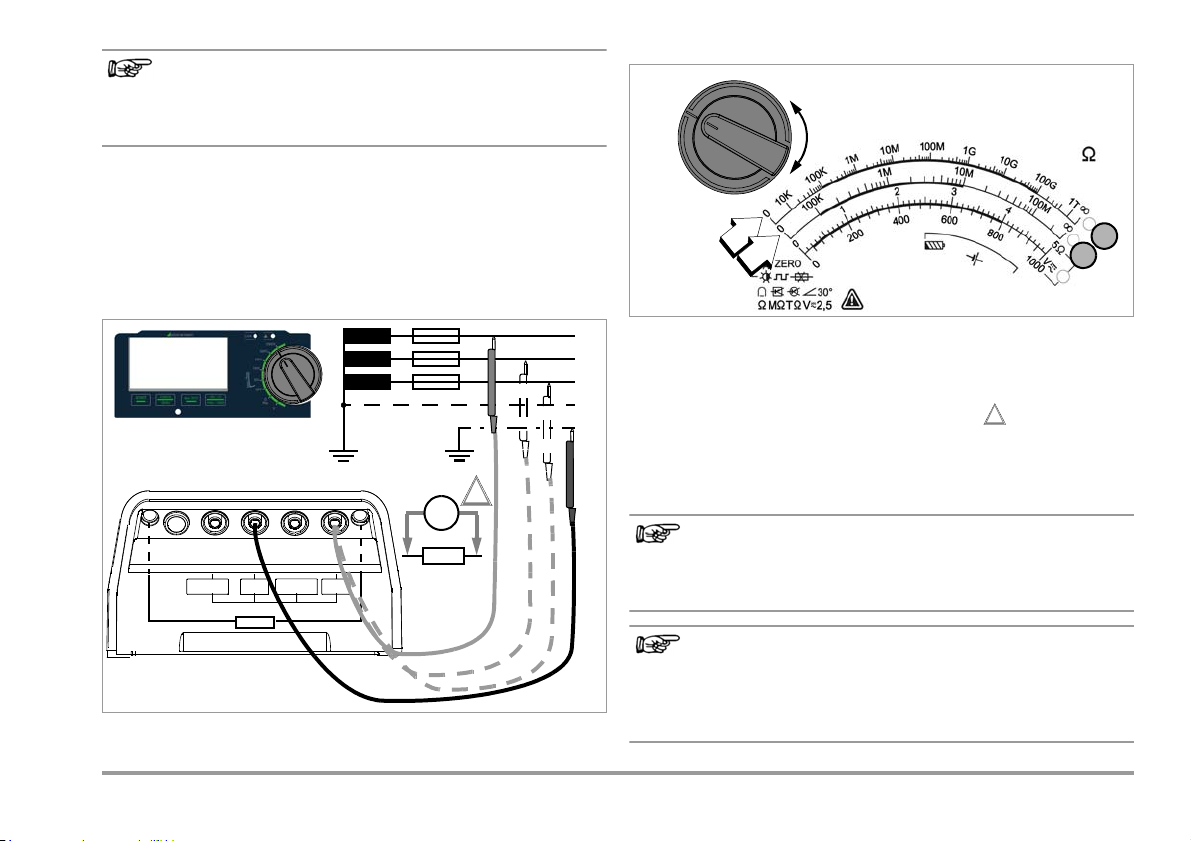

4.2 Analog Display

Insulation Resistance Measuring Ranges

The logarithmic representation of the upper resistance scale

allows for quick recognition of the order of magnitude.

In order to achieve the required accuracy during protective measures testing, the 10k-1T/100k-100M key makes it possible to

switch to the expanded lower measuring range of 100 k

100 M.

The two orange LEDs,

➀ and ➁, indicate which of the two resis-

tance measuring ranges is active at the moment.

Low-Resistance Measuring Range

LED ➃ lights up orange to indicate that low-resistance measurement is active. LED

➃ blinks when the measuring range is

exceeded.

Voltage Measuring Ranges

The two lower scales are for voltage measurement and the battery test (see section 3.1). LED

➃ lights up orange in order to indi-

cate that voltage measurement is active.

Measuring Range Overflow in the Resistance Measuring Ranges

The LED assigned to the respective measuring range, namely ➀,

➁ or ➃ blinks orange in the event of measuring range overflow.

Scale Illumination

Scale illumination is active for about 15 seconds after switching

the instrument on, after a measurement is started and after

changing measuring ranges.

GMC-I Messtechnik GmbH 11

5 Insulation Resistance Measurement

Note

Note

Attention!

!

!

– Riso/Rins Function

5.1 Connection

Checking the Measurement Cables

Before performing insulation measurement, the test

probes on the measurement cables should be short-circuited in order to assure that the instrument displays a

value very close to 0 (see section 7).

This makes it possible to detect interrupted measurement

cables, which simulate high insulation resistance.

Ð Connect the device under test to the + and COM jacks.

Sample connection layouts for insulation resistance measurement

are included in section 13.1.

Insulation resistance can only be measured at voltagefree objects. The measurement cannot be started until

the test probes are in contact with the device under test.

If line voltage or interference voltage of greater than 50 V

is applied to the measurement inputs, this is indicated by

means of a double acoustic signal. Insulation measurement cannot be started as long as interference voltage is

present.

5.2 Executing the Measurement

Note: Condensation must be ruled out when performing measure-

ments at close to the freezing point.

Ð Select the measuring function, as well as the desired test volt-

age depending on the device under test, with the rotary

switch, e.g. R

iSO

100 V.

Do not touch the instrument’s terminal contacts or the

conductive ends of the two test probes during insulation

resistance measurement!

If nothing has been connected to the terminal contacts, or if a

resistive load component has been connected for measurement,

your body would be exposed to a maximum short-circuit current.

The resulting electrical shock is not life endangering. However, the

noticeable shock may lead to injury (e.g. resulting from a startled

reaction etc.).

Ð Start an individual measurement by briefly pressing the START

key, or initiate continuous measurement by briefly pressing

the CONTIN./ZERO key.

Ð Contact the measuring point with both test probes.

A double acoustic signal indicates that measurement has been

started.

The Caution! LED remains illuminated for as long as test voltage

is applied to the test probes.

LED

➀ lights up to indicate that the upper measuring range of

10 k 1T has been complied with (default setting).

Ð Wait until the pointer settles in. Depending on the device

under test, this may take anywhere from several seconds to

half a minute if, for example, large capacitors (long cables)

have to be charged.

Ð Read the measured value from the upper voltage scale

If the Limit LED lights up green, the insulation measurement is

valid and the limit value has not been violated.

If the limit value is fallen short of, the Limit LED lights up red.

➀.

12 GMC-I Messtechnik GmbH

Note

If the Limit

Note

Note

+

COM

+

COM

SHIELD

GUARD

L1

L2

N

PE

L3

R

B

R

E

R

INS

R

x

0V !

!

R

INS

R

INS

1

2

➀

➁

!

selected test voltage value has not been reached. A battery

test is advisable in this case (see section 3.1 on page 9).

Ð Switching to the Measuring Range with Higher Resolution

In order to perform measurement with the enhanced accuracy

required for protective measures testing, select the measuring

range with higher resolution, namely 100 k 100 M, with

the help of the 10k–1T/100k–100M key immediately after the

measured value is displayed. LED

measuring range, lights up.

LED

does not light up at all, this means that the

➁, which is assigned to this

Ð Read the measured value from the lower voltage scale

If the Limit LED lights up green, the insulation measurement is

valid and the limit value has not been violated. If the limit value is

fallen short of, the Limit LED lights up red.

After test voltage is switched off – Caution! LED goes out

(U > 50 V) – the pointer remains frozen in place for about 3 sec-

GMC-I Messtechnik GmbH 13

onds. When the Limit LED and the LED for measuring range

both go out, the measurement has been completed and the

pointer returns to its neutral position.

Three-Phase Systems

All conductors (L1, L2, L3 and N) must be tested against

PE!

The instrument’s batteries are exposed to excessive

stress during insulation resistance measurement. For this

reason, it’s advisable to perform individual rather than

continuous measurements.

➁.

➁

Special Case: Capacitive Devices Under Test

Caution!

Note

!

!

+Measurement Cable

–Measurement Cable

Guard Cable

Conductor

Insulation

Material

Guard Rings

Contact Ring

(COM)

A guard cable must be used for measurements within a range of

100 G (10 G) 1T, in order to prevent surface current from

distorting measurement results. The guard rings prevent current

at the surface of the insulation material from flowing from the

If measurement is performed at a capacitive object such

as a long cable, it becomes charged with up to approximately 1000 V (test voltage)! Touching such objects is life

endangering!

+measurement cable to the –measurement cable, instead of

through the insulation material itself.

Ð Insert the plug from the guard cable into the appropriate jack in

the test instrument.

Ð Plug the alligator clip onto the guard cable test probe.

5.3 Ending the Measurement – Safe Discharging

Individual measurement: Measurement is ended automatically as

soon as the measured value has settled in.

Continuous measurement is ended by once again briefly pressing

Ð Connect the alligator clip to the guard ring between the two

measuring points at the insulation material under test.

Ð Refer to section 5.2 on page 12 regarding the measuring se-

quence.

the CONTIN./ZERO key.

When an insulation resistance measurement has been performed

on a capacitive object it’s automatically discharged by the instrument. Contact between the object and the instrument must nevertheless not be interrupted.

Do not disconnect until:

•The Caution! LED (U > 50 V) is no longer illuminated.

As an alternative,

the device under test can be discharged in a

controlled manner (due to touch hazard) by switching to V and

contacting the device under test until the Caution! LED is no

longer illuminated and the measuring movement indicates 0 V.

Do not reverse polarity while discharging, because internal surge

protection will otherwise be triggered.

5.4 Measurements with the Guard Cable

The measurement of very high resistances necessitates extremely

minimal measuring current and may be rendered problematic as a

result of influences such as electromagnetic fields, humidity or

The following materials can be used as guard rings: aluminum foil, copper foil or metallic hose clamps.

surface pollution. An accurate test set-up is thus absolutely

essential.

14 GMC-I Messtechnik GmbH

6 Measuring Direct, Alternating and

Attention!

!

Note

!

+

COM

+

COM

SHIELD

GUARD

L1

L2

N

PE

L3

R

B

R

E

Max.

1.2 kV

U

V

4

Pulsating Voltage – V Function

You can measure direct voltage, as well as sinusoidal alternating voltage with frequencies ranging from 45 to 65 Hz with this test instrument

Pointer deflection at the measuring instrument is always positive

for the measurement of direct voltage, regardless of the polarity of

the connections. Alternating voltage is always indicated as an

RMS value.

Voltage measurement is used to test for the absence of voltage

before performing the insulation resistance measurement, as well

as for automatic discharging of capacitive devices under test. The

falling voltage value can be observed at the display.

Ð Select the V measuring function with the rotary switch, LED ➃

lights up permanently.

Ð Connect the measurement cables to the + and COM jacks.

Ð Contact the measuring point with both test probes.

A double acoustic signal is generated and the Caution!

LED lights up red in order to indicate the presence of

voltage of greater than 50 V.

Ð Read the measured value from the V scale. The measured

value is displayed directly – without pressing the START key.

Ð After completing the measurement, switch the instrument off

by turning the rotary switch to the OFF position.

No more than the maximum permissible voltage of

1000 V may be applied. Input impedance for the voltage

measuring range is roughly 10 M.

The START and CONTIN./ZERO keys have no function in this case.

.

GMC-I Messtechnik GmbH 15

7

Attention!

!

Note

+

COM

+

COM

10 M

GUARD

SHIELD

R

LO

R < 5

R

LO

R

x

0V !

!

R

LO

4

➃

Measuring Low-Resistance of up to 5

– RLO Function

According to the regulations, the measurement of low-resistance at

protective conductors, earth conductors or equipotential bonding

must be performed with (automatic) polarity reversal of the test voltage, or with current flow in one direction, and then in the other.

In the measuring function RLO, measurements are performed with currents higher than 200 mA.

Please check before measuring whether your DUT or

your circuit is designed for these high current values.

Connection

Low-resistance can only be measured at voltage-free

objects.

Ð Connect the device under test to the + and COM jacks.

Ð Select the Rlo measuring function with the rotary switch.

Attention: The measurement cannot be started until the test

probes are in contact with the device under test.

If line voltage or interference voltage of greater than 50 V is

applied to the measurement inputs, this is indicated by means of

a double acoustic signal. Low-resistance measurement cannot be

started as long as interference voltage is present. The display is

not returned to low-resistance measurement until voltage is less

than approximately 8 V. If resistance is greater than 5 , LED ➃

blinks.

Measurement Types

You can choose one of two different types of measurement:

• Measuring sequence with automatic polarity reversal (reversal

of current flow direction) via the START key

• Manual measurement with positive polarity via the CONTIN./

ZERO key

16 GMC-I Messtechnik GmbH

7.1 Measurement with Automatic Polarity Reversal

Limit

< Limit R

LO

= OK 3

Ð Start measurement in both current flow directions by briefly

pressing the START key, the LED ➃ lights up during measurement.

After the measuring sequence has been started, the instrument

performs measurement with automatic polarity reversal, first with

current flow in one direction (), and then in the other ().

Measurement is executed in the background. During both measurements, the pointer briefly moves back towards 0 , indicating

to the user that measurement is being performed with both polarities in the background.

The respectively larger (worse) measured value is displayed when

measurement has been completed (after the relay has audibly

switched two times).

The Limit LED lights up in order to indicate that the measured

value is valid. When the Limit LED and ➃ go out, the measurement has been completed and the pointer returns to its neutral

position.

Limit Value Indication

If the measured value is less than or equal to 2 , the Limit LED

lights up green. If the measured value is greater than 2 , the Limit

LED lights up red.

Resistances which do not demonstrate a stable value until after a

“settling in period” should not be measured with automatic polarity reversal. In this case, measurement with automatic polarity

reversal may lead to varying and/or inflated measurement values,

and thus to an ambiguous reading.

7.2 Measurement with Manual Polarity Reversal

In order to determine whether or not test results are independent

of current flow direction, measurement can be performed manually in one direction of current flow (positive polarity). Measurement in the other direction of current flow (negative polarity) is

then conducted by switching the test probes.

Ð Start continuous measurement by briefly pressing the CONTIN./

ZERO key, the LED ➃ lights up during measurement.

The red or green Limit LED indicates whether or not the limit value

has been violated (see section 7.1).

Measurement takes up to 3 minutes, after which the instrument is

switched to the standby mode. If you want to stop measurement

prematurely, press the CONTIN./ZERO key once again, after which

the relay switches audibly. Measurement is ended after roughly 5

seconds.

Differing results indicate voltage at the device under test (e.g.

thermovoltage or unit voltages).

Measurement results can be distorted by parallel connected

impedances in load current circuits and by equalizing current,

especially in systems which make use of “overcurrent protection

devices” (previous neutralization) without an isolated protective

conductor. Resistances which change during measurement (e.g.

inductance), or a poor contact, can also cause distorted measurements.

Examples of resistances whose values may change during measurement include:

–Incandescent lamp resistance with changing values caused

by warming due to measuring current

– Resistances with a large inductive component

In order to assure unambiguous measurement results, causes of

error must be located and eliminated.

GMC-I Messtechnik GmbH 17

7.3 Taking Measurement Cables and Extension Cables into

+

COM

+

COM

SHIELD

GUARD

10M

R

ISO/RINS

10 M

Account (up to 5 ) – ZERO Function (Roffset)

Ohmic measurement cable resistance can be subtracted from the

measurement results automatically. Proceed as follows:

Ð Select function Rlo with the rotary selector switch.

Ð Short circuit the test probes at the ends of the measurement

cables.

Ð Press and hold the CONTIN./ZERO key.

Ð Additionally press the measuring range selection key

(10k–1T/100k–100M) until the pointer indicates “0”.

LED ZERO/FUSE

Ð Release both keys.

During the course of subsequent low-resistance measurements,

cable resistance R

as long as the rotary selector switch is not turned to the OFF position. Perform low-resistance measurement as described above in

the preceding pages. The stored value is retained, even if the

instrument has meanwhile been in standby operation provided

that the rotary selector switch position has not been changed.

➅ lights up red permanently:

is taken into consideration, i.e. subtracted,

Offset

8 Test Resistor for Insulation Measurement for

Checking the Insulation Measuring Instrument

According to section 5.3.1.2 of VDE 0105-100 (EN 50110-1), the

following applies: “These measuring instruments must be tested

before, and if applicable after use.”

The two outermost

be connected to each other internally via a 10 M test resistor to

this end.

The sum of test resistor and cable resistance (for both cables),

including test probes, amounts to 10 M ±5%. This value allows

for quick self-testing.

18 GMC-I Messtechnik GmbH

metallic

jacks on the connection panel must

Ð Connect the measurement cables to the + and COM jacks.

Ð

Insert the test probes into the above described metallic jacks.

Ð Select the R

as well as the desired test voltage, e.g. R

Ð Press the start key and view the measurement results.

The pointer should remain frozen at 10 M for about 5 seconds.

When the Limit LED and the LED for measuring range

out, the measurement has been completed and the pointer

returns to its neutral position.

measuring function with the rotary switch,

iso/ins

iSO

100 V.

➀ both go

9 Technical Data

2

134

5

1

2

4

5

3

Meas.

Scale /

Qty.

Standard

VDE 0413

R

INS

R

LO

U

AC/DC

U

BAT

1

Accuracy specified here is only achieved with the following optional accessory:

“shielded high-resistance measurement cable KS-C (article number Z541F)”.

2

Relative to scale length:

Scale 1: 83.13 mm

Scale 2: 75.05 mm

Scales 3 and 4: 67.02 mm

3

Within the identified range on the respective scale (nominal range of use)

4)

with ZERO balancing

5)

0.17 ... 2 : 20%

Measuring

Range

100 k ...

100 M

10 k ... 1 T

0 ... 5 0.17 ... 4

Nominal Range

of Use

100 k ...

10 M

100 k ...

100 G

4)

Nominal / Open-

Circuit Voltage

50 V /100 V:

1.25 U

ISO

250 V /500 V /

1000 V:

1.1 U

ISO

4 V < U0 < 6 V

0 ... 1000 V 10 ... 1000 V — — — 2.5% —

8 ... 12 V 8.5 ... 12 V — — — —

Nominal

Current I

N

Short-

Circuit Cur-

rent I

Intrinsic Uncertainty

K

under Reference

Conditions

2.5%

1 mA 5 mA

2.5%

Test current IN 200 mA 2.5%

Measuring

2

Uncertainty

Overload

3

Capacity

30% of

measured value

1

5)

10%

measured value

of

1000 V AC/DC

TRMS

1000 V AC/DC

TRMS

1000 V AC/DC

TRMS

GMC-I Messtechnik GmbH 19

Displays

!

Analog display

Measuring movement Moving-coil mechanism with core magnet

Scale length 83.13 mm (longest scale)

Limit LED LED lights up red to indicate an exceeded

limit value. LED lights up green to indicate

compliance with the limit value.

LED LED lights up red to indicate the presence

of interference voltage (when instrument is

switched off), test voltage during insulation

measurement or residual voltage after

insulation testing (U > 50 V)

Analog display LEDs Description see page 5

Reference Conditions

Reference temperature

Relative humidity 40 ... 75%

Measured quantity

frequency

Measured quantity

waveform Sine, deviation between TRMS and recti-

Battery voltage 9.5 V 0.1 V

Test resistor 10 M1%

Normal position

of use 30°

+23 C 3K

45 Hz ... 65 Hz

fied value < 1%

Electrical Safety

Standard

VDE regulation VDE 0411, part 1, 1994-03

Protection class II

Pollution degree 2

Measuring category

Fuses

Fuse link

Electronic fuse for the protection of low-resistance mea-

CAT II 1000 V / CAT III 600 V / CAT IV 300 V

FF315mA/1000V, effective in all resistance

measuring ranges, 1 additional replacement fuse in the battery compartment

surement R

LO

Electromagnetic Compatibility (EMC)

Interference emission EN 61326-1:2006 class B

Interference immunity EN 61326-1:2006

Power Supply

Batteries 8 ea. 1.5 V mignon cell (8 ea. size AA)

Nominal range of use

Battery test

Battery saver circuit

Service life For R

Safety shutdown

(alkaline manganese per IEC LR14) or 8

rechargeable NiMH batteries (must be

recharged externally)

8.5 ... 12 V

Battery capacity display via the Bat. TEST key

Standby function

(1000 V / 1 M) and RLO with 20

INS

s on-time and 1 measurement each for a

duration of 5 s

– With batteries (alkaline manganese):

900 measurements

– With rechargeable batteries (2000 mAh):

850 measurements

If supply voltage is too low, the instrument

is switched off, or cannot be switched on.

When the rotary switch is set to the OFF

position, the instrument is completely disconnected from the batteries (after

approximately 10 seconds).

20 GMC-I Messtechnik GmbH

Ambient Conditions

Accuracy temp. range

Operating temperature

Storage temp. range –25 ... +70 C (without batteries)

Relative humidity Up to 75% (max. 85% during storage/

Elevation Max. 2000 m

Calibration interval 1 year (recommended)

0 ... +40 C

–10 ... +50 C

transport), no condensation allowed

Mechanical Design

Dimensions 225 x 130 x 140 mm

Weight Approx. 1.5 kg with batteries

Protection Housing: IP 52, measurement cables and

connectors: IP 40 per DIN VDE 0470,

part 1 / EN 60529, housing category 2

Excerpt from Table on the Meaning of IP Codes

IP XY

st

(1

digit X)

2 12.5 mm dia. 2 Dripping (at 15 angle)

3 2.5 mm dia. 3 Spraying water

4 1.0 mm dia. 4 Splashing water

5 Dust protected 5 Jet-water

6 Dust-proof 6 Powerful water jets

Protection Against

Foreign Object Entry

IP XY

(2nd digit Y)

Protection Against

Penetration by Water

GMC-I Messtechnik GmbH 21

Display Values in Consideration of Measuring Uncertainty

100

Ux/V

R

x

/k

U

N

= 100 V

0

20

40

60

80

100

250

Ux/V

R

x

/k

U

N

= 250 V

0

50

100

150

200

250

Table for determining minimum display values for insulation resistance in consideration of the instrument’s measuring uncertainty:

Limit Value

020 k 025 k

100 k 111 k 100 M 111 M

200 k 219 k 200 M 219 M

500 k 541 k 500 M 541 M

0.20 M 0.25 M

0.50 M 0.57 M

1.00 M 1.11 M 1.00 G 1.11 G

2.00 M 2.19 M 2.00 G 2.19 G

5.00 M 5.41 M 5.00 G 5.41 G

10.0 M 11.1 M 10.0 G 11.1 G

20.0 M 21.9 M 20.0 G 22.6 G

50.0 M 54.1 M 50.0 G 55.9 G

Minimum

Display Value

Limit Value

Minimum

Display Value

Voltage at Device Under Test During Insulation Resistance

Measurement

Measuring voltage Ux at the device under test depending upon its

resistance R

and 1000 V:

at nominal voltage UN = 50 V, 100 V, 250 V, 500 V

x

Table for determining maximum display values for low-value resistance in consideration of the instrument’s measuring uncertainty.

Limit Value

0.15 0.11

0.20

0.16 5.00 4.72

0.50 0.44 10.0 9.47

1.00 0.92 20.0 17.7

2.00 1.87 50.0 44.7

22 GMC-I Messtechnik GmbH

Maximum

Display Value

Limit Value

Maximum

Display Value

10 List of Abbreviations and their Meanings

0

100

200

300

400

500

500

UN = 500 V

Ux/V

R

x

/k

0

200

400

600

800

1000

1

UN = 1000 V

Ux/V

R

x

/M

Voltage

U

ISO

U AC/DC

U

BAT

Current

I

N

I

K

Resistance

LIMIT Limit value for insulation resistance or low-resistance

Offset Correction value for measurement cable resistance

R

ISO

R

LO

Test voltage or nominal voltage

Measured voltage (sinusoidal alternating voltage)

Operating voltage

Nominal current (insulation resistance measurement)

Test current (low-resistance measurement)

Short-circuit current (insulation resistance measurement)

Insulation resistance

Low-resistance (cable resistance)

GMC-I Messtechnik GmbH 23

11 Maintenance

Note

Attention!

!

Attention!

!

11.1 Battery and Rechargeable Battery Operation

When only one filled segment remains in the battery symbol,

install a new set of batteries or charge the rechargeable batteries.

Check to make sure that no leakage has occurred at batteries or

rechargeable batteries at short, regular intervals, or after the

instrument has been in storage for a lengthy period of time.

We recommend removing the batteries during lengthy

periods of non-use (e.g. vacation). This prevents excessive battery depletion or leakage, which may result in

damage to the instrument under unfavorable conditions.

If leakage has occurred, the electrolyte must be carefully and

completely removed with a damp cloth before installing new batteries.

Replacing the Batteries

See section 3.2 and section 11.3.

11.2 Fuses

If a mechanical or electronic fuse has blown due to faulty operation or overload depending on the measuring function, the ZERO/

FUSE LED blinks. The instrument’s voltage measuring ranges are

nevertheless still functional.

11.2.1 Fuse Link – ZERO/FUSE LED

This fuse is active in all resistance measuring ranges except for

voltage measurement. A replacement fuse is included in the battery compartment (FF315mA/1000V).

Disconnect the instrument from the measuring circuit before opening the battery compartment lid in order to replace the fuse (refer to page 5 for location)!

Checking the Fuse

If a resistance measuring range is selected with the rotary switch

and measurement is started with a blown or defective fuse in the

instrument, the ZERO/FUSE LED blinks. Prerequisite: The + and

COM measurement jacks are not short circuited.

After eliminating the cause of error and replacing the defective

fuse, the

again been switched on from rotary switch position OFF.

ZERO/FUSE LED goes out after the instrument has once

Incorrect fuses may cause severe damage to the instrument.

Only original fuses from GMC-I Messtechnik GmbH assure the required protection by means of suitable blowing characteristics.

Short-circuiting of fuse terminals or the repair of fuses is

prohibited!

The instrument may be damaged if fuses with incorrect

ampere ratings, breaking capacities or blowing characteristics are used!

24 GMC-I Messtechnik GmbH

Replacing the Fuse

Pb Cd Hg

Ð Open the battery compartment lid by loosening the two

screws.

Ð Remove the blown fuse and insert a new one. A replacement

fuse is included in the battery compartment.

Ð Insert the new fuse.

Ð Replace the battery compartment lid and retighten the

screws.

11.2.2 Electronic Fuse – ZERO/FUSE LED

This fuse only protects low-resistance measurement (Rlo) from

overloading (electronic hardware circuit).

As the electronic fuse blows faster than the mechanical fuse in the

event of faulty operation of the instrument with live components,

not only the instrument, but also the fuse link is protected in the

low-resistance measuring range.

This means that, if interference voltage occurs during low-resistance measurement, the electronic fuse is blown. The measurement is aborted and the ZERO/FUSE LED blinks.

After eliminating the cause of error, the ZERO/FUSE LED goes out

after the instrument has once again been switched on from rotary

switch position OFF.

11.3 Housing

No special maintenance is required for the housing. Keep outside

surfaces clean. Use a slightly dampened cloth or a plastic cleaner

for cleaning. Avoid the use of cleansers, abrasives or solvents.

Return and Environmentally Sound Disposal

The instrument is a category 9 product (monitoring and control

instrument) in accordance with ElektroG (German electrical and

electronic device law). This device is subject to the RoHS directive. Furthermore, we make reference to the fact that the current

status in this regard can be accessed on the Internet at

www.gossenmetrawatt.com by entering the search term WEEE.

We identify our electrical and electronic devices in

accordance with WEEE 2012/19EU and ElektroG using

the symbol shown at the right per DIN EN 50419.

These devices may not be disposed of with the trash.

Please contact our service department regarding the return of old

devices (see address in section 14).

If the (rechargeable) batteries used in your instrument are depleted,

they must be disposed of properly in accordance with valid

national regulations.

Batteries may contain pollutants and heavy metals such as lead

(Pb), cadmium (Cd) and mercury (Hg).

The symbol to the right indicates that batteries must not

be disposed of with the trash, and must be brought to a

designated collection point.

GMC-I Messtechnik GmbH 25

12 Recalibration

L1

L2

L3

N

PE

Between each active conductor and ground

L1

L2

L3

PEN

Between each active conductor and the PEN conductor

13 Appendix

The measuring tasks performed with your instrument, and the

stressing it’s subjected to, influence aging of its components and

may result in deviation from the specified levels of accuracy.

In the case of strict measuring accuracy requirements, as well as

in the event of use at construction sites with frequent stress due

to transport and considerable temperature fluctuation, we recommend a relatively short calibration interval of once per year. If your

instrument is used primarily in the laboratory and indoors without

considerable climatic or mechanical stressing, a calibration interval of once every 2 to 3 years is sufficient as a rule.

During recalibration at an accredited calibration laboratory (DIN

EN ISO/IEC 17025), deviations from traceable standards demonstrated by your measuring instrument are documented. Ascertained deviations are used to correct display values during later

use of the instrument.

We would be happy to perform DAkkS or factory calibration for

you at our calibration laboratory. Further information is available at

our website:

www.gossenmetrawatt.com ( Company DAkkS Calibration

Center or FAQs Questions and Answers Regarding Calibration).

Recalibration of your instrument at regular intervals is essential for

the fulfillment of requirements according to quality management

systems per DIN EN ISO 9001.

* Examination of the specification, as well as adjustment, are not included in calibra-

tion. However, in the case of our own products, any required adjustment is performed and adherence to the specification is confirmed.

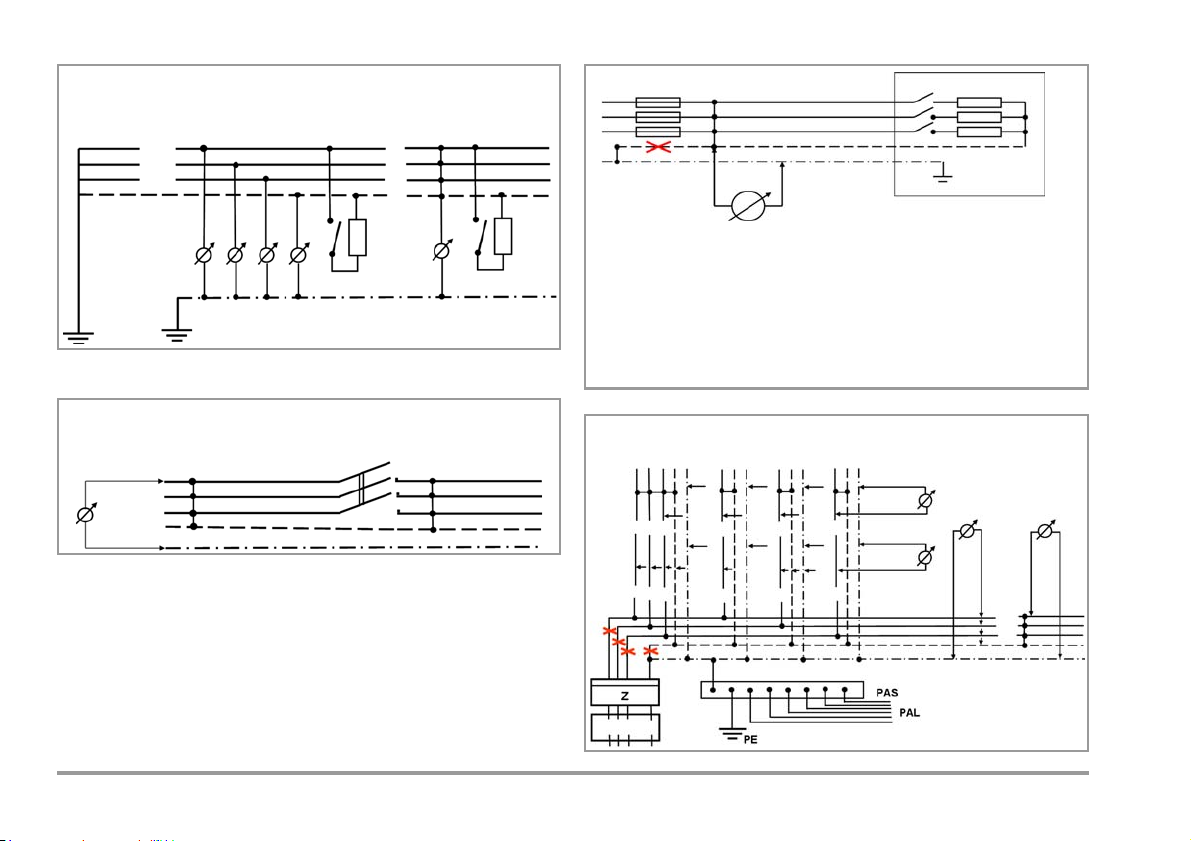

13.1 Sample Connection Layouts for Insulation Resistance Measurement

Insulation Resistance Measurement per DIN VDE 0100, Part 600

26 GMC-I Messtechnik GmbH

L1

L2

L3

N

PE

Between each active conductor (phase and neutral

conductors) and ground

L1

L2

L3

PEN

Between each active conductor and the PEN conductor

TN–S

• With or without consumer

•N – PE, separately

TN–C

• With or without consumer

• N – PE, together

Insulation Resistance Measurement in Different Types of Systems

GMC-I Messtechnik GmbH 27

TT

• With or without consumer

3-phase current (switched at all poles)

Caution:

– Open the overcurrent protective device.

– Disconnect the N conductor.

– Jumper the L and N conductors.

– Insulation measurement between L conductors and N to

PE.

In the distributor: individual and combined measurements

28 GMC-I Messtechnik GmbH

13.2 Attaching the Test Probe Holder to the Carrying Strap

1

Bottom Right

Detach the strap from the instrument:

Turn out the slotted screw (M3) at the

bottom.

Bottom Left

Strap

Clasp

Clasp

Front View

2

Slide the strap through the test probe

holder.

Eyelet for Attachment to Tester

Side View

(METRISO INTRO, BASE, TECH, PRO, XTRA)

GMC-I Messtechnik GmbH 29

13.3 Technical Data for Measurement Cables

Attention!

!

3

Front

Feed the strap through from the front

of the test instrument and secure it

with the slotted screw (M3).

Back

(scope of delivery: KS17-4 safety cable set)

Electrical Safety

Maximum rated voltage 600 V

Measuring category

Max. rated current: 1 A 1 A 16 A

With safety cap attached

Without safety cap ——

CAT IV CAT III CAT II

1000 V

Ambient Conditions (EN 61010-031)

Tem pe rat ur e – 20 C ... + 50 C

Relative humidity Max. 80%

Pollution degree

2

Using the KS17-4

1000 V

—

Measurements per DIN EN 61010-031 may only be performed in environments in accordance with measuring

categories III and IV with the safety cap attached to the

test probe at the end of the measurement cable.

In order to establish contact inside 4 mm jacks, the safety caps

have to be removed by prying open the snap fastener with a

pointed object (e.g. the other test probe).

30 GMC-I Messtechnik GmbH

Observe the instrument’s maximum values for electrical safety.

13.4 Optional Accessories (not included)

ISO Calibrator 1 (material no. M662A)

Calibration adapter for testing the accuracy of instruments used for measuring insulation resistance and

low-resistance for test voltages of up to 1000 V (per

VDE 0413, parts 1, 2, 4 and 10).

KS-C (material no. Z541F)

Cable set consisting of measurement cable and

shielded high-resistance measurement cable

surements in the G-

KS24 (material no. GTZ3201000R0001)

Cable set consisting of a 4 m long extension cable with

a permanently attached test probe at one end and a

contact protected socket at the other end, and 2 alligator clips which can be plugged onto the test probe

1081 Probe (material no. GTZ3196000R0001)

Triangular probe for floor measurements

per EN 1081,

lation)

Z550A (material no. Z550A)

Optional plug-on measurement cable with measurement key on the test probe and an additional key for

illuminating the measuring point, including shielded,

plug-in connector cable and test probe holder for

attachment to the carrying strap.

range

DIN VDE 0100-600 (standing surface insu-

for mea-

14 Repair and Replacement Parts Service

Calibration Center* and Rental Instrument Service

If required please contact:

GMC-I Service GmbH

Service Center

Thomas-Mann-Str. 20

90471 Nuremberg, Germany

Phone: +49 911 817718-0

Fax: +49 911 817718-253

e-mail service@gossenmetrawatt.com

www.gmci-service.com

This address is only valid in Germany. Please contact our representatives or subsidiaries for service in other countries.

* DAkkS calibration laboratory for electrical quantities, registration no.

D-K-15080-01-01, accredited per DIN EN ISO/IEC 17025:2005

Accredited quantities: direct voltage, direct current value, direct current resistance,

alternating voltage, alternating current value, AC active power, AC apparent power, DC

power, capacitance, frequency and temperature

GMC-I Messtechnik GmbH 31

Competent Partner

GMC-I Messtechnik GmbH is certified in accordance with

DIN EN ISO 9001:2008.

Our DAkkS calibration laboratory is accredited by the Deutsche

Akkreditierungsstelle GmbH (national accreditation body for the

Federal Republic of Germany) under registration number D-K15080-01-01 in accordance with DIN EN ISO/IEC 17025:2005.

We offer a complete range of expertise in the field of metrology:

from test reports and factory calibration certificates right on up to

DAkkS calibration certificates.

Our spectrum of offerings is rounded out with free test equipment

management.

An on-site DAkkS calibration station is an integral part of our service

department. If errors are discovered during calibration, our specialized personnel are capable of completing repairs using original

replacement parts.

As a full service calibration laboratory, we can calibrate instruments from other manufacturers as well.

Edited in Germany Subject to change without notice PDF version available on the Internet

15 Product Support

If required please contact:

GMC-I Messtechnik GmbH

Product Support Hotline

Phone, +49 911 8602-0

Fax: +49 911 8602-709

e-mail:

support@gossenmetrawatt.com

GMC-I Messtechnik GmbH

Südwestpark 15

90449 Nürnberg,

Germany

Phone: +49 911 8602-111

Fax: +49 911 8602-777

e-mail: info@gossenmetrawatt.com

www.gossenmetrawatt.com

Loading...

Loading...