Page 1

Operating Instructions

METRISO 1000A

Insulation tester

3-348-773-37

8/5.15

Page 2

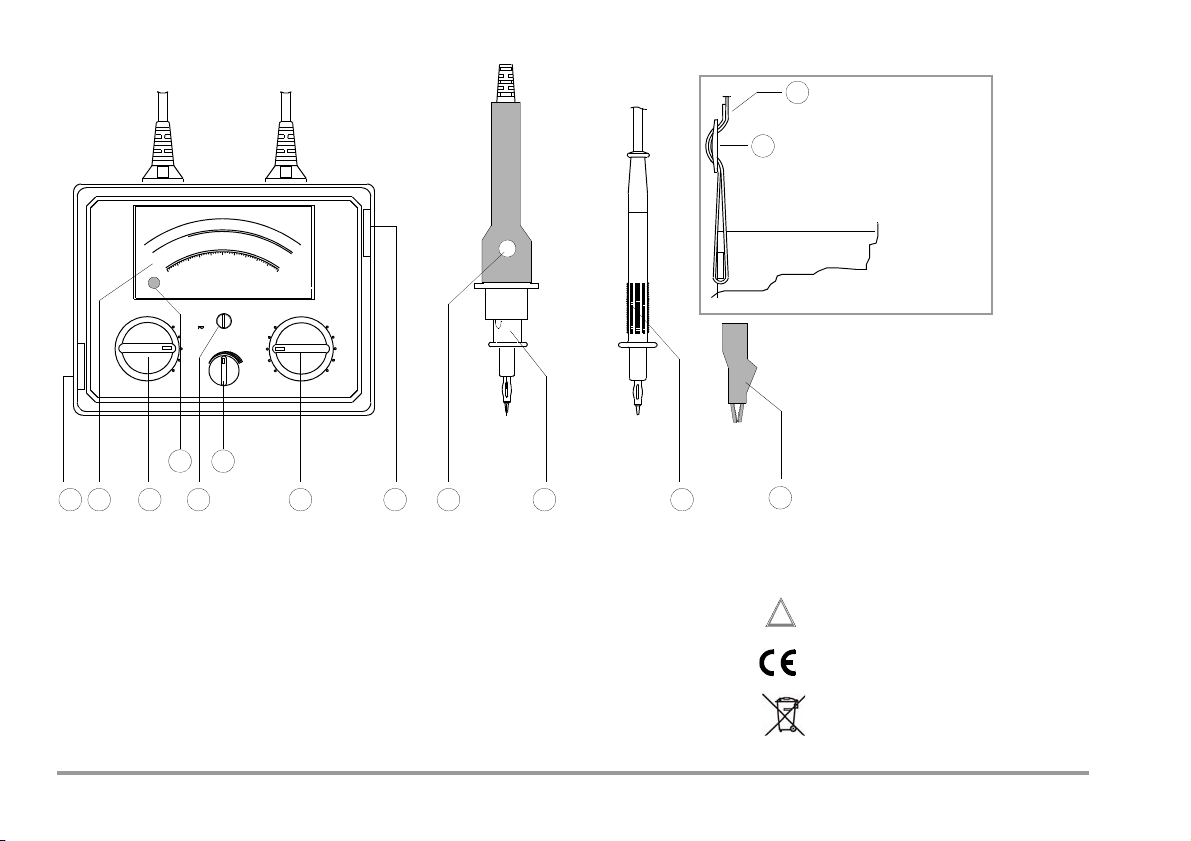

1 2

3

6

5

47

12

13

8 9 107

11

Housing

Attaching the

Strap to the

Housing

METRISO

1000A

MΩ

V

8

8

R3

R2

R1

V

Ω

600

400

200

800

0

1000

1000V

4Ω

R1

R2

R3

x0,5

x1

x2

x0,2

x0,1

1000V

500V

250V

100V

50V

BATT

METRISO 1000A

Ω

!

1 Analog display

2 Function selector switch

3 Battery voltage indicator lamp

4 Adjusting screw for mechanical zero adjustment

5 Rotary knob for electrical zero adjustment

6 Rotary switch for nominal voltage selection

7 Studs for fastening the carrying strap

8 Measurement key

9 Test probe with lamp

10 Test probe

11 Alligator clip

12 Latch

13 Carrying strap

Meanings of Symbols on the Instrument

Warning concerning a point of danger

(Attention: observe documentation!)

Indicates EC conformity

This device may not be disposed with the

trash. For further details on the WEEE marking,

please refer to our website www.gossenmetrawatt.com and enter search key ’WEEE’.

2 GMC-I Messtechnik GmbH

Page 3

Contents Page

Attention!

!

1 Safety Precautions .......................................................................... 3

2 Applications .................................................................................... 4

3 Initial Start-Up ................................................................................4

3.1 Battery Installation ...........................................................................................4

3.2 Testing the Batteries .......................................................................................4

3.3 Switching the Tester On and Off .......................................................................4

3.4 Analog Display ................................................................................................4

3.5 Fusing ............................................................................................................4

3.5.1 Checking the Fuse ..........................................................................................4

4 Measuring Direct and Alternating Voltage ......................................5

5 Measuring Insulation Resistance .................................................... 5

5.1 Measurement Procedure .................................................................................5

5.2 Evaluation of Measurement Values ...................................................................6

5.3 Rapid Testing of Insulation Resistance ..............................................................6

6 Measuring Low-Impedance Resistance (0 to 4 Ω) ......................... 6

7 Characteristic Values ..................................................................... 7

8 Maintenance ................................................................................... 8

8.1 Batteries .........................................................................................................9

8.2 Replacing the Fuse ..........................................................................................9

8.3 Testing for Functionality and Accuracy ..............................................................9

8.4 Housing ..........................................................................................................9

8.5 Carrying Bag .................................................................................................10

9 Repair and Replacement Parts Service

Calibration Center

and Rental Instrument Service ..................................................... 10

10 Product Support ............................................................................ 10

1 Safety Precautions

This instrument fulfills the requirements of the applicable European and

national EC guidelines. We confirm this with the CE marking. The relevant

declaration of conformity can be obtained from GMC-I Messtechnik

GmbH.

The METRISO 1000A insulation tester has been manufactured and tested

in accordance with the following standards:

IEC 61010-1/EN 61010-1/VDE 0411-1,

DIN VDE 0413 part 1:2007 and part 4:2007,

IEC 61557-2/EN 61557-2/VDE 0413-2

IEC 61557-4/EN 61557-4/VDE 0413-4

In order to maintain flawless technical safety conditions and to assure safe

use, it is imperative that you read the operating instructions carefully and

thoroughly before placing your instrument into service, and that you follow

all points contained therein.

Repair and Parts Replacement

Voltage conducting parts may be exposed when the instrument is

opened. The instrument must be disconnected from all sources of voltage

before repair or replacement of parts. If the repair of an open, live instrument cannot be avoided, this may only be performed by trained personnel

who are familiar with the dangers involved.

Malfunctions and Extraordinary Strains

If it may be assumed that the instrument can no longer be operated

safely, it must be removed from service and secured against unintentional

use. Safe operation can no longer be relied upon:

• If the instrument demonstrates visible damage

• If the instrument no longer functions

• After lengthy periods of storage under unfavorable conditions

• After excessive strain during transport

The permanently attached measurement cables are double insulated with insulation materials of two different colors. Exposure of

the light colored inner insulation is an early indicator of excessive

cable wear.

GMC-I Messtechnik GmbH 3

Page 4

2 Applications

Attention!

!

The METRISO 1000A insulation tester complies with DIN VDE 0413

“Regulations for Devices for the Testing of Protective Measures in Electrical Systems”

Part 1: insulation testers, and

Part 4: ohmmeters.

It is suitable for the measurement of insulation resistance at voltage-free

devices and systems with nominal voltages of up to 1000 V, as well as for

testing resistance at earthing conductors, protective conductors and

bonding conductors including their connections and terminals.

The instrument has also been equipped with a 1000 V measuring range

for direct and alternating voltage. This is especially advantageous for testing for the absence of voltage at devices under test, and for discharging

capacitive devices under test.

3 Initial Start-Up

3.1 Battery Installation

Before opening the housing base make, certain that the function

selector switch has been set to the “1000 V” position, and that

the instrument has been fully disconnected from all external

electrical circuits.

➭ Unscrew the housing base.

➭ Insert 6 commercially available, type IEC R20 or IEC LR20 1.5 V

batteries (single cell) with plus and minus poles aligned in accordance

with the symbols in the battery compartment.

➭ Replace the housing base and screw into place.

Green Lamp: Batteries are OK.

Red Lamp: The batteries are too weak for the currently selected

measurement function.

3.3 Switching the Tester On and Off

The tester remains activated as long as the measurement key in the test

probe is depressed. We recommend setting the function selector switch

to the 1000 V position during transport and maintenance, in order to

prevent the tester from being switched on inadvertently.

3.4 Analog Display

Measurement values are plainly displayed at analog scales. Each of the

function selector switch positions has its own scale. A battery status

indicator lamp is located at the left-hand portion of the scale area.

3.5 Fusing

The instrument is protected with a single common fuse during lowimpedance and insulation resistance measurements. The fuse blows if an

extraneous voltage is inadvertently applied when the instrument is set to

the resistance measuring range.

Voltage measurement is possible regardless of the condition of the fuse.

3.5.1 Checking the Fuse

The Ω and MΩ ranges are no longer functional after the fuse has blown.

Low-Impedance Measuring Range:

The needle remains at the mechanically set zero point when the

measurement key is activated.

Insulation Resistance Measuring Range:

With short-circuited test probes, the needle remains at the mechanically

set zero point when the measurement key is activated.

See chapter 8.2 on page 9, “Replacing the Fuse”.

3.2 Testing the Batteries

Each time the measurement key is activated, the instrument automatically

tests the batteries. Momentary drain on the batteries resulting from the

function selector switch position and the pre-selected nominal voltage are

taken into consideration during this test. Battery condition is indicated by

the color of the indicator lamp at the left-hand portion of the scale area.

4 GMC-I Messtechnik GmbH

Page 5

4 Measuring Direct and Alternating Voltage

Attention!

!

Direct voltages and sinusoidal alternating voltages with frequencies

ranging from 40 to 200 Hz can be measured with this instrument. Needle

deflection is always positive for direct voltage measurements regardless of

polarity at the terminal connections. Alternating voltage is displayed as an

RMS value.

➭ Set the function selector switch to the “1000 V” position.

➭ Make certain that the needle points to the “0” mark at the V scale in

the idle state. Readjust the needle if necessary with the adjusting

screw for mechanical zero adjustment.

➭ Rotary switch position is irrelevant for voltage measurement.

➭ Probe the measuring point with both test probes.

➭ Read the measurement value from the V scale.

Notes

• Allowable overload capacity for the voltage measuring range is

1200 V.

• Input impedance for the voltage measuring range is 0.9 MΩ.

• Devices under test with capacitive charges are automatically

discharged by the test instrument. The corresponding drop in voltage

can be observed at the display.

5 Measuring Insulation Resistance

Before performing measurement, make certain that the device under test

is voltage-free (see chapter 4).

5.1 Measurement Procedure

➭ First set the function selector switch to the R1 position.

➭ Briefly short circuit the test probes and press the measurement key to

check for full-scale deflection for R1 = 0 MΩ (zero adjustment).

The needle must point to the above indicated full-scale deflection

mark in the idle state. Readjust the needle if necessary with the rotary

knob for electrical zero adjustment.

➭ Depending upon the nominal voltage of the device under test, select a

test voltage of either 50 V, 100 V, 250 V, 500 V or 1000 V with the

rotary switch.

Note

Full-scale deflection must be tested in the following cases, and must be

readjusted if required in order to attain a measuring accuracy of 1.5%:

• Each time a different nominal voltage is selected

• For resistance measurements of long duration

➭ Probe the measuring point with both test probes.

➭ Press the measurement key and read the measurement value from

the appropriate scale.

➭ If needle deflection is insufficient, switch to the next highest

measuring range, i.e. R2 or R3, with the function selector switch.

➭ Multiply the displayed value by the conversion factor which appears

opposite the selected nominal voltage:

Nominal Voltage: 50 V 100 V 250 V 500 V 1000 V

Conversion

Factor:

Do not touch the conductive ends of the two test probes after the

instrument has been activated for the measurement of insulation

resistance.

If measurement is being performed at a purely ohmic device

under test, current may flow over your body, which, although it

does not reach life endangering levels, causes a clearly

discernible shock.

When measurements are made at capacitive devices under test,

e.g. cables, the DUT may be charged with voltages of up to

approximately 1200 V, depending upon selected nominal voltage.

Contact with the device under test after measurement is, in this

case, life endangering!

For this reason, the DUT must be discharged in a controlled

fashion as described in chapter 4 on page 5.

x 0.1 x 0.2 x 0.5 x 1 x 2

GMC-I Messtechnik GmbH 5

Page 6

5.2 Evaluation of Measurement Values

Attention!

!

In order to assure that insulation resistance values do not fall below those

required by DIN VDE regulations, insulation tester inherent deviation must

be taken into consideration.

Required minimum display values for insulation resistance which take

maximum operational measurement deviation of the METRISO 1000A into

consideration (under nominal conditions of use) can be determined with

the following table. These are the minimum values which must be displayed, in order to assure that actual values do not fall below the required

limit values (DIN VDE 0413 part 1). Intermediate values can be interpolated.

The table applies to a nominal voltage of 500 V. The values in the table must be

multiplied by a conversion factor for other nominal voltages.

Scale R1 Scale R2 Scale R3

Limit Value

[MΩ]

Display Value

[MΩ]

0.1 0.13 0.2 0.25 2 2.5

0.2 0.25 0.3 0.38 3 3.8

0.3 0.38 0.4 0.5 4 5.0

Limit Value

[MΩ]

Display Value

[MΩ]

0.5 0.63 5 6.3

11.251012.5

Limit Value

[MΩ]

Display Value

[MΩ]

5.3 Rapid Testing of Insulation Resistance

In addition to illuminating the measuring point, the lamp in the test probe

can also be used for rapid GO/NO-GO testing of insulation resistance. As

long as the lamp is lit, minimum values for insulation resistance are fulfilled

in accordance with DIN VDE 0100. The signal remains lit as long as

insulation resistance demonstrates the following values:

Insulation

Resistance

Nominal

Voltage

> 0.1 MΩ > 0.2 MΩ > 0.5 MΩ > 1 MΩ > 2 MΩ

50 V 100 V 250 V 500 V 1000 V

6 Measuring Low-Impedance Resistance (0 to 4 Ω)

Make certain that the device under test is voltage-free before

performing measurements in the low-impedance measuring

range.

The measurement key should not be depressed if a highimpedance device under test is probed, or if the test probes are

idle.

➭ Set the function selector switch to the “4 Ω” position.

➭ Briefly short circuit the test probes and press the measurement key to

check for full-scale deflection at “0 Ω”. The needle must point to the

“0” mark at the 4 Ω scale in the idle state. Readjust the needle if

necessary with the adjusting screw for mechanical zero adjustment.

➭ Probe the two points between which low-impedance resistance is to

be measured with the test probes.

➭ Activate the measurement key and read the measurement value from

the 4 Ω scale.

Notes:

• Resistance is measured with direct current.

If it can be expected that the measurement value will be influenced by

the polarity of the measuring current (e.g. if a diode is included in the

measuring circuit), reverse the test probes and repeat the

measurement.

• Resistance values which fluctuate at the beginning of the

measurement include, for example:

– Resistance with a high inductive component

– Incandescent lamp resistance values which change due to

warming caused by the measuring current

– Poor contact resistance at contact points

6 GMC-I Messtechnik GmbH

Page 7

7 Characteristic Values

Measuring

Function

Measuring Range

Inherent Deviation

at Reference

1)

Conditions

Measuring

Error

1000 V 0 ... 1000 V ± 2.5% — — — —

R1, R2, R3

U

= 50 V

N

R1, R2, R3

U

= 100 V

N

R1, R2, R3

= 250 V

U

N

R1, R2, R3

= 500 V

U

N

R1, R2, R3

= 1000 V

U

N

4 Ω 0 ... 4 Ω± 1.5%

1)

As related to scale length

Scale lengths: R1 l = 46 mm

2)

Within the marked area of the respective scale (nominal range of use)

0 ... 40 kΩ

± 1.5%

200 kΩ ... 20 MΩ 40 kΩ

of reading

0 ... 80 kΩ

± 1.5%

400 kΩ ... 40 MΩ 80 kΩ

of reading

0 ... 200 kΩ

± 1.5%

1 MΩ ... 100 MΩ 200 kΩ

of reading

0 ... 400 kΩ

± 1.5%

2 MΩ ... 200 MΩ 400 kΩ

of reading

0 ... 0.8 MΩ

± 1.5%

4 MΩ ... 400 MΩ 800 kΩ

of reading

of reading

R2 l = 71 mm

R3 l = 80 mm

Ω l = 67 mm

Ul = 66 mm

±25 %

±25 %

±25 %

±25 %

±25 %

±10 %

Nominal

Nominal /

Voltage

U

N

Measuring

Current

2)

50 V

100 V 120 V

≥ 1.0 mA

250 V 300 V

I

N

500 V 600 V

1000 V 1200 V

≥ 200

I

m

—

mA

Open-Circuit

Voltage U

Short-Circuit

o

Frequency /

Current I

DC /

40 ... 200 Hz

k

Internal

Resistance

R

i

Switching Value

for Resistance

Overload Capacity

Value Duration

900 kΩ — 1200 V continuous

30 kΩ

60 V

> 100 kΩ 1200 V max. 10 s20 kΩ ... 1 MΩ 10 kΩ

60 kΩ

> 200 kΩ 1200 V max. 10 s40 kΩ ... 2 MΩ 20 kΩ

150 kΩ

<12mA

> 500 kΩ 1200 V max. 10 s100 kΩ ... 5 MΩ 50 kΩ

300 kΩ

> 1 MΩ 1200 V max. 10 s200 kΩ ...10 MΩ 100 kΩ

600 kΩ

> 2 MΩ 1200 V max. 10 s400 kΩ ... 20 MΩ 200 kΩ

9 V > 200 mA — — 0.315 A continuous

Nominal Conditions of Use

Temperature 0 ... 40 °C

Positioning horizontal or vertical

Battery Voltage 7 ... 10 V

GMC-I Messtechnik GmbH 7

Page 8

Reference Conditions

Attention!

!

Ux

Rx [k

Ω

]

[V]

500

0

UN=500V

400

300

200

100

500

1000

R1 Range

Ux

Rx [M

Ω

]

[V]

500

0

UN=500V

400

300

200

100

10

20

R3 Range

600

Ux

Rx [M

Ω

]

[V]

500

0

UN=500V

400

300

200

100

0.5

1

R2 Range

600

1.5

2

Positioning horizontal

Temperature +23 °C ± 2K

Relative Humidity 45 ... 55%

Making Capacity for the Measurement of Insulation Resistance

Electronic voltage limiting prevents voltage at the device under test from

substantially exceeding nominal voltage during the making operation (see

following characteristic curve).

Measured Quantity

Frequency 45 ... 65 Hz

Measured Quantity

Waveshape sine

Deviation between

Effective and Rectified

Values < 0.5%

Battery Voltage 9 V ± 0.5 V

Power Supply

Batteries: 6 ea. 1.5 V single cell (6 x D-size) zinc-coal, type R20 or

alkaline-manganese, type LR 20, in accordance with IEC

Battery Service Life

Number of measurements possible with 6 ea. type R20 batteries (with

indicator lamp in test probe switched off): at least 3000 measurements of

an insulation resistance of 1 MΩ

(U

= 1000 V, 5 s measurement, 25 s pause and so forth)

N

Electrical Safety

Safety Class I I

Nominal Voltage 1000 V

Test Voltage 5.55 kV~

Measuring category II

Pollution Degree 2

Electromagnetic Compatibility (EMC)

Interference Emission/

Interference Immunity EN 61326-1

Mechanical Design

Protection housing: IP 52

Dimensions 165 mm x 125 mm x 110 mm

Weight 1.6 kg with batteries

8 GMC-I Messtechnik GmbH

8 Maintenance

Completely disconnect the instrument from all external electrical

circuits before replacing the batteries or the fuse.

We recommend setting the function selector switch to the 1000 V

position during transport and maintenance, in order to prevent the

tester from being switched on inadvertently.

Page 9

8.1 Batteries

Attention!

!

Pb Cd Hg

The condition of the batteries should be checked from time to time. A

dead or deteriorating battery must be removed from the battery compartment. If battery leakage occurs, electrolyte must be completely removed

from the instrument and the batteries must be replaced.

The batteries must also be replaced if the red lamp at the left-hand portion

of the scale area lights up during the battery test described in chapter 3.2

on page 4. Replace batteries as described in chapter 3.1 on page 4.

Always replace batteries as a complete set!

8.2 Replacing the Fuse

The fuse blows if maximum allowable voltage is exceeded when the test

instrument is connected to the measuring circuit.

A replacement fuse is located in the battery compartment.

Use only specified, original type FF 0.315 A/1000 V fuses!

Bridging the fuse holder or repairing fuses is prohibited!

Instrument components may be damaged if fuses with other

current ratings, other breaking capacities or other blowing

characteristics are used!

The fuse is replaced as follows:

➭ Unscrew the housing base.

➭ Screw the threaded cap out of the fuse holder with the help of a

screwdriver.

➭ Screw the threaded cap back into place along with a new fuse.

➭ Replace the housing base and screw into place.

8.3 Testing for Functionality and Accuracy

Using the tester ISO-Kalibrator 1 (accessories: article number M662A),

you can quickly and rationally test measuring instruments for insulation

resistances and low-ohmic resistances for their functionality and accuracy, and thus ensure their proper function.

8.4 Housing

No special maintenance is required for the housing. Keep outside

surfaces clean. Use a slightly dampened cloth for cleaning. Avoid the use

of cleansers, abrasives or solvents.

Opening of Equipment / Repair

The equipment may be opened only by authorized service personnel to

ensure the safe and correct operation of the equipment and to keep the

warranty valid.

Even original spare parts may be installed only by authorized service personnel.

In case the equipment was opened by unauthorized personnel, no warranty regarding personal safety, measurement accuracy, conformity with

applicable safety measures or any consequential damage is granted by

the manufacturer.

Device Return and Environmentally Compatible Disposal

The instrument is a category 9 product (monitoring and control instrument) in accordance with ElektroG (German Electrical and Electronic

Device Law). This device is subject to the RoHS directive. Furthermore,

we make reference to the fact that the current status in this regard can be

accessed on the Internet at www.gossenmetrawatt.com by entering the

search term WEEE.

We identify our electrical and electronic devices in accordance

with WEEE 2012/19/EU and ElektroG with the symbol shown to

the right per DIN EN 50419 .

These devices may not be disposed with the trash. Please contact our service department regarding the return of old devices (address

see chapter 9 on page 10).

If you use batteries or rechargeable batteries in your instrument or accessories which no longer function properly, they must be duly disposed of in

compliance with the applicable national regulations.

Batteries or rechargeable batteries may contain harmful substances or

heavy metal such as lead (PB), cadmium (CD) or mercury (Hg).

They symbol shown to the right indicates that batteries or

rechargeable batteries may not be disposed of with the trash, but

must be delivered to collection points specially provided for this

purpose.

GMC-I Messtechnik GmbH 9

Page 10

8.5 Carrying Bag

Figure 1 Figure 2

1

2

The measuring instrument can be securely fixed in the bag by pulling the

carrying strap of the instrument through the internal studs situated on the

right and left of the housing. The studs can be released for this purpose

on one side by pressing the silver push-buttons.

The flap of the bag serves as a place for keeping documents, or else, for

example, as a writing pad (see Figure 1). Moreover, the flap can be turned

beyond its rear attachment and folded away under the bottom of the bag

where it can be fixed with a lock (Figure 2).

Edited in Germany • Subject to change without notice • A pdf version is available on the internet

9 Repair and Replacement Parts Service

Calibration Center

and Rental Instrument Service

We recommend a recalibration after 1 ... 3 years, depending on the use of

the tester.

When you need service, please contact:

GMC-I Service GmbH

Service Center

Thomas-Mann-Strasse 20

90471 Nürnberg, Germany

Phone +49 911 817718-0

Fax +49 911 817718-253

E-mail service@gossenmetrawatt.com

www.gmci-service.com

This address is only valid in Germany.

Please contact our representatives or subsidiaries for service in other

countries.

10 Product Support

When you need support, please contact:

GMC-I Messtechnik GmbH

Product Support Hotline

Phone +49 911 8602-0

Fax +49 911 8602-709

E-mail support@gossenmetrawatt.com

GMC-I Messtechnik GmbH

Südwestpark 15

90449 Nürnberg •

Germany

Phone +49 911 8602-111

Ffax +49 911 8602-777

E-Mail info@gossenmetrawatt.com

www.gossenmetrawatt.com

Loading...

Loading...