Page 1

Operating Instructions

03

Version 2/06.16

METRA win 90

3-349-929-

Calibration Software

Page 2

METRAwin 90 - Operating Instructions

Purpose of the Program

METRAwin 90

calibrators for electrical quantities

calibration results.

Contents of these

Operating Instructions

This document describes the use of the general program functions provided by the

software.

The program

eparate documents whic h

can be accessed, depending on the currently selected device type, by clicking

Device Functions

Further information regarding device

instructions for the respective de

Target Group

These instructions are intended for users of the software.

The software is designed for use with the Microsoft Windows

interface. Users must be familiar with basic Windows

Scope of Validity

These instructions

Note

The version number can be displayed by clicking

Support

If you have any questions about using this software, please contact:

•

•

e-mail: support@gossenmetrawatt.com

Copyright

Copyright © 2003 - 2013 GMC-I Messtechnik GmbH. All rights reserved.

These operating instructions, as well as the software described herein, are protected by copyright.

Duplication of this document and/or the software is prohibited without previous express consent.

Violators are liable for compensation of damages.

Trademark

METRAwin®90 is a registered trademark of GMC-I Messtechnik GmbH.

Products from other manufacturers are mentioned in these operating instructions for strictly

informational purposes, and their mention does not represent any misuse of the respective

trademarks.

Exclusion of Liability

The texts and illustrations included herein have been compiled with the greatest of care. Despite all

of these efforts, errors can never be entirely prevented. For this reason, no guarantee can be made

for the correctness of the contents of this document. We assume no legal responsibility or liability

of any sort for incorrect entries or their consequences. We appreciate your suggestions for

improvement, as well as any information regarding errors.

We make every effort to keep these instructions up-to-date in accordance with the latest software

version. It is nevertheless possible that differences may exist between the software and the

instructions. Further information may be provided in a

“README.TXT” file included on the provided

data storage medium, or in the program directory after the software has been installed.

Subject to change without notice.

Preface

calibration software is a Windows program for controlling various

with the help of a PC, and for documenting

’s device-specific functions are described in s

in the Help menu.

-specific functions is included in the operating

vices.

are valid for METR Awin 90 as of version 4.00.

i

Your GOSSEN METRAWATT sales partner

The address which can be accessed by clicking About in the Help menu

GMC-I Messtechnik GmbH

GOSSEN MET RA WATT 2

Product Support Hotline

Phone : +49 911 8602-0

®

®

functions.

About in the Help menu.

graphic user

Page 3

METRAwin 90 - Operating Instructions

Table of Contents

Preface ................................................................................................................................ 2

Table of Contents............................................................................................................... 3

1 Product Description ...................................................................................................... 4

1.1 Variants and Their Use ............................................................................................................................. 4

METRAwin® 90-2 ................................................................................................................................... 4

METRAwin® 90-F ................................................................................................................................... 4

METRAwin® 90-FJ ................................................................................................................................. 5

1.2 Common Features .................................................................................................................................... 5

1.3 System Requirements .............................................................................................................................. 6

Operating System .................................................................................................................................. 6

Hardware Requirements ........................................................................................................................ 6

Other Required Software ....................................................................................................................... 6

2 Installing, Registering and Uninstalling the Program ................................................ 7

2.1 Installation ................................................................................................................................................. 7

2.2 Registration ............................................................................................................................................... 7

2.3 Uninstalling the Software ......................................................................................................................... 8

3 Operation ....................................................................................................................... 9

3.1 Starting and Exiting the Program ............................................................................................................ 9

3.2 Structure of the User Interface .............................................................................................................. 10

3.3 Overview of Menu Functions ................................................................................................................. 11

3.3.1 File Menu Functions ............................................................................................................................... 12

New ...................................................................................................................................................... 12

Open .................................................................................................................................................... 12

Save ..................................................................................................................................................... 13

Print test report .................................................................................................................................... 14

Printer settings ..................................................................................................................................... 15

Export test data .................................................................................................................................... 15

3.3.2 Help Menu .............................................................................................................................................. 18

Program Functions ............................................................................................................................... 18

Device Functions ................................................................................................................................. 18

Online Support ..................................................................................................................................... 18

Display License Agreement ................................................................................................................. 18

Info ....................................................................................................................................................... 18

3.4 Basic Program Settings ......................................................................................................................... 18

3.4.1 Changing the User Interface Language ................................................................................................. 18

3.4.2 Selecting the Type of Calibrator to be Controlled .................................................................................. 18

3.4.3 Port Settings ........................................................................................................................................... 19

a) For METRAtop 90C / FLUKE D9000, D9100, 5100A, 5500A, 5520A and 5700A

multifunction calibrators ............................................................................................... 19

b) For METRAHit CAL and METRACAL MC process calibrators ..................................... 19

c) For METRAHit 28C and 28C light process calibrators ................................................. 20

d) For METRAHit 18C process calibrator ......................................................................... 20

3.4.4 Showing and Hiding the Multimeter Display ........................................................................................... 21

3.4.5 Showing and Hiding the Command Line ................................................................................................ 21

3.4.6 Showing and Hiding the Toolbar ............................................................................................................ 21

3.4.7 Specifying the Temperature Unit of Measure ......................................................................................... 21

3.4.8 Specifying the Thermocouple Cold Junction .......................................................................................... 22

3.5 DIRECT Operating Mode for Interactive Calibrator Operation ........................................................... 23

3.6 TEST Operating Mode ............................................................................................................................ 24

3.6.1 Creating a Cali brat ion Pr ocedure ........................................................................................................... 24

3.6.2 Executing a Calibration Procedure ......................................................................................................... 26

GOSSEN MET RA WATT 3

Page 4

METRAwin 90 - Operating Instructions

METRAwin® 90-2

Calibration Software for the Following GOSSEN METRAWATT Process Calibrators:

METRACAL MC, METRAHIT CAL, METRAHIT 28C, METRAHIT 28C light and METRA

These calibra

instruments and equipment in the field of process measuring and control technology.

They include the following functions: direct voltage simulator, current source and

sink, as well as

PTCs). The METRACAL MC and METRAHIT 28C versions also include a TRMS

multimeter (V, mA,

functions, or by incorporating a separate

METRAHIT) 18S, 28S, 29S, 30M, X

with infrared interface into the calibration system, automated calibration of buffer

amplifiers,

The software executes interactive

controlled

(TEST operating mode)

the help of the BD232 or SI232

the USB

values entered manually or read in from the multimeter via the port, and

documentation and archiving of calibration results in a calibration report.

Calibration procedures for

tested with the program in an uncomplicated fashion. In the case of the METRAHIT

18C and 28C, procedures can also be transferred to the calibrator’s memory module,

from which they can be executed auto

mA) acquired by the METRAHIT 28C can be saved to memory automatically and

subsequently read out and displayed at a PC, and inserted into a calibration report.

METRAwin® 90-F

Calibration Software for FLUKE D9100, 5100B, 5500A, 5520A and 5700A Multifunction

Calibrators

The above mentioned calibrators are used primarily for the calibration of indicating

measuring instruments such as multimeters, laboratory recorders, current clamps,

panel

etc., and include the various electrical quantities

required to this end. By incorporating a separate METRA

METRAHIT) 18S, 28S, 29S, 30M, X

with infrared interface into the calibration sys

amplifiers,

The software executes interactive

controlled

(TEST operating mode)

interface, automatic analysis of measured values entered manually or read in from

the multimeter via an RS

results in a calibration report. The program calculates the test uncertainty ratio (TUR)

for each calibration point based upon the calibrators

are integrated into the software, or overall measuring uncertainty in accordance with

directive DKD

A calibration procedure for the

tested in an uncomplicated fashion. Tested calibration procedures for numerous

multimeters from our current and previous product spectrum are included with the

software.

1 Product Description

1.1 Variants and Their Use

METRAwin®90 calibration software is a multilingual Windows program for controlling various calibrators for

electrical quantities with the help of a PC, and for documenting calibration results.

The program is available in the following variants:

Hit 18C

tors are used primarily for testing and calibrating electrical measuring

simulation of resistors and temperature sensors (thermocouples and

Ω, F, Hz, °C/°F). Thanks to inclusion of these multimeter

METRAHit (in some cases written

-TRA, EXTRA or ENERGY precision multimeter

temperature measuring transducers and the like can be performed.

(DIRECT o per ati n g mode ) or sequence-

setup of the calibrator from the PC via an RS 232 port (with

-II interface adapter) or a USB port (with the help of

-HIT or USB-XTRA interface adapter), automatic analysis of measured

each respective calibration object can be generated and

nomously (without PC). Measured values (V,

GOSSEN MET RA WATT 4

-mount measuring instruments

-TRA, EXTRA or ENERGY precision multimeter

tem, automated calibration of buffer

isolating transformers, measuring transducers and the like can be performed.

(DIREKT o per ati n g mode ) or sequence-

-3 (WECC 19-1990).

setup of the calibrator from the PC via an IEEE488

232 port, and documentation and archiving of calibration

respective calibration object can be generated and

Hit (in some cases written

’ accuracy specifications which

Page 5

METRAwin 90 - Operating Instructions

METRAwin® 90-FJ

Calibration and Adjusting Software for FLUKE D9100, 5100B, 5500A, 5520A and 5700A

Multifunction Calibrators

Above and beyond this, METRA

automatically adjusted via t heir inf r ared inter f ace

(suitable

procedures required to this end are included with the software.

• Convenient, interactive control of the calibrator which is connected to the PC with

•

•

•

•

•

analog measured value

•

the calibration system, as well as a tabular list of calibration values and associated

•

•

1.2 Common Features

direct data entry as an individual value

Uncomplicated and fast generation, testing and execution of calibration

procedures

Simple operation: even semiskilled workers can execute qualified calibration

tasks.

Display of procedural instructions which have been generated automatically or

defined by the user before execution of the respective procedure step

With interconnected multimeter: display and continuous refreshing of the

measured value read in via the port

Outstanding flexibility with calibration signal correction (for

indicators, recorders etc.) by entering a displayed measured value with the

keyboard, or by querying the measured value from the multimeter via the port

ISO-9000 compliant calibration documentation as a standardized or user

configured report with all necessary entries regarding the calibration object and

Hit 22-29S/M handheld multimeters can be

with the METRAwin®90-FJ version

calibrators: 5500A and 5520A). Type and function-specific adjusting

evaluations for each calibration point

Dynamic data transfer to report templates created by the user with Micros of t®

Excel

™ or Microsoft® Word™ (e.g. with company logo)

Secure archiving of procedures to an external data storage medium

GOSSEN MET RA WATT 5

Page 6

METRAwin 90 - Operating Instructions

Operating System

METRAwin

®

Hardware Requirements

METRAwin

®

respective operating system:

•

•

•

232 COM port for the connection of 1 to 3 BD232 interface

•

•

•

•

Other Required Software

For registering the software:

•

•

For the creation of individualized calibra

report layouts:

•

•

For viewing and/or printing out the integrated help files in PDF format:

•

1.3 System Requirements

CD ROM drive

Microsoft compatible mouse or other pointing device

For controlling METRAHit 18C, 28C or 28C light process calibrators and for reading in

measured values from METRAHIT 2X multimeters with METRAwin

A least 1 free serial RS

adapters or SI232-II memory adapters

Or USB port(s) for the connection of 1 to 3 USB-HIT interface adapters

For controlling METRAHit CAL or METRACAL MC process calibrators and for reading in

measured values from METRAHIT Starline multimeters with METRAwin

USB port(s) for the connection of 1 to 3 USB-XTRA interface adapters

For controlling FLUKE multifunction calibrators with METRAwin®90-F/-FJ:

1 installed or external GPIB controller interface (IEEE488) with National

Instruments

for example:

National Instruments PCI-GPIB NI-488.2 or

National Instruments GPIB-USB-B NI-488.2

For printing reports:

Local or network printer which is supported by Windows

90 can be run with Microsoft® Windows XP, Vista and 7 (32 or 64-bit).

90 can be used on PCs which fulfil the minimum requirements of the

®

90-2:

®

90-2:

™ compatible protocol and drivers suitable for the Windows system,

Microsoft® Word 97, 2000, 2003, 2007 or 2010 or another word processing

program for the automatic creation of a fax form in RTF file format (rich text

format)

Or Microsoft® Outlook or another e-mail program for the automatic creation of an

e-mail with registration data

tion reports with company logo and/or modified

Microsoft® Word 97, 2000, 2003, 2007 or 2010

Or Microsoft® Excel 97, 2000, 2003, 2007 or 2010

Adobe® Acrobat™ Reader – available free of charge from

www.adobe.com/acrobat

GOSSEN MET RA WATT 6

Page 7

METRAwin 90 - Operating Instructions

Note

METRAwin 90 software is available in a variety of versions for various calibrators. These

software variants can be instal

respective version numbers vary from each other (e.g. 4.04 and 4.01). However, the version

with the highest number must be installed last. The version number can be displayed by

clicking

Setup Menu:

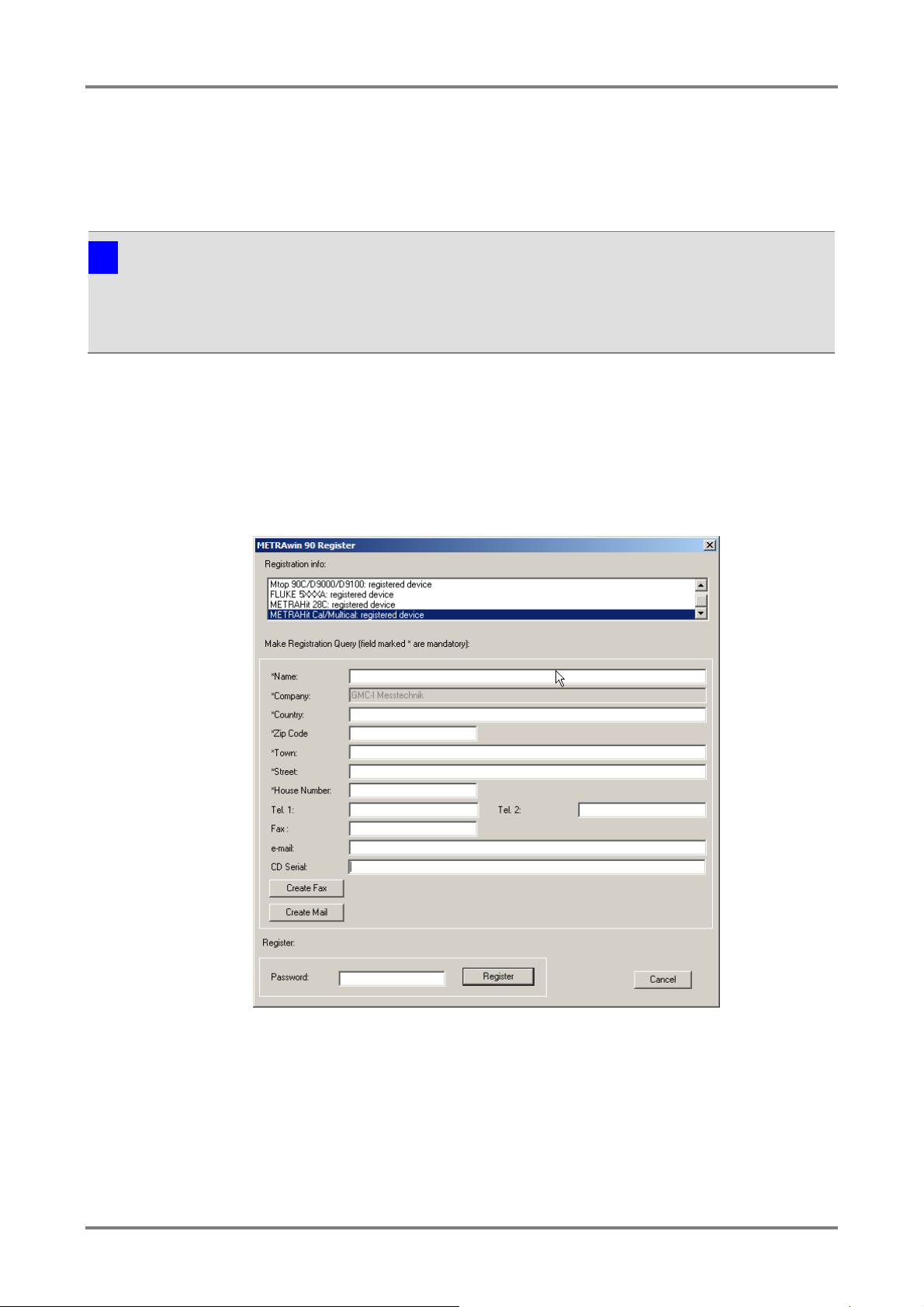

Re

Opens the dialog box for entering the registration data:

►

►

along with your

The license key can be requested by fax or e

2 Installing, Registering and Uninstalling the Program

2.1 Installation

A Setup.exe file is included on the supplied CD ROM. The program is installed in dialog with the user by

executing this file. The installation directory and the program file folder can be selected as desired.

i

led to the same directory, as long as only the last digits of the

About in the Help menu.

2.2 Registration

The software can be tested for 30 days without a license key. In order to be able to use the software with its

full scope of functions after this trial period a license must be purchased, the software must be registered

with the licensor and it must be permanently enabled by entering the license key (password).

The assigned password depends on the entered company name and the type of calibrator. Registration must

thus be repeated for each type of calibrator.

gistration

Enter your address information to the corresponding fields. Be certain to enter

the company name correctly because the registration code is generated from it,

as well as other factors.

Enter the serial number which appears on the included program CD under “CD

Serial”. If you’ve received the software as a download or by e-mail and don’t

GOSSEN MET RA WATT 7

have a CD serial number, you’

registration (copy of the invoice or delivery note as a PDF or image file).

ll have to submit proof of purchase

-mail.

Page 8

►

►

►

⇒

bled

►

⇒

registration

Note 1

Registration is only possible for a single company, but for any desired nu

with a single software license (branch office license). Detailed information regarding licensing

can be viewed by clicking

Note 2

Save the returned e

METRAwin 90 - Operating Instructions

Click the corresponding button: [Create Fax] or [Create Mail].

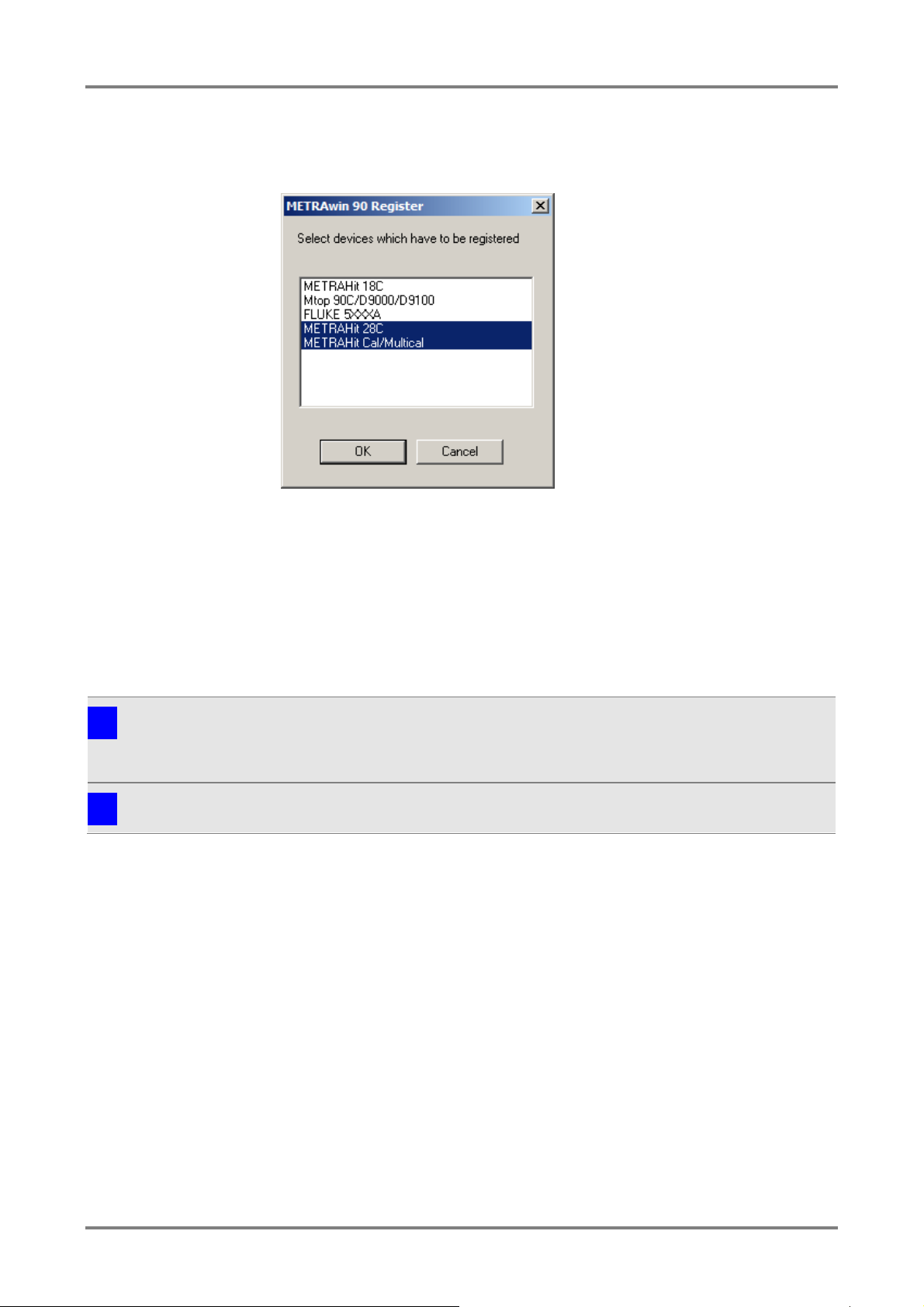

Select the device type(s) for which the software will be registered in the dialog

box which then appears and acknowledge with [OK]. The selection option

depends on the purchased software variant.

Send the fax form or e-mail which then appears to the specified address.

You’ll receive the password with which the program can be permanently ena

for the specified device type(s) without delay.

Open the dialog box for entering the registration information once again to this

end, enter the password to the corresponding field and click the [Register]

button.

The program is then permanently enabled. You can check this in the

information field. Your company name is displayed in the title bar of the program

window after the program has been restarted.

i

mber of installations,

Show License Agreement in the Help menu.

i

-mail with the password in case reinstallation should become necessary!

2.3 Uninstalling the Software

If desired, the program can be uninstalled by selecting Programs from the Start menu and then clicking

Gossen-Metrawatt / METRAwin / Uninstall.

GOSSEN MET RA WATT 8

Page 9

METRAwin 90 - Operating Instructions

Starting the Program

In order to start the program:

►

or

►

⇒

Exiting the Program

In order to exit the program:

►

or

►

or

►

⇒

Note

When the program is exited the selected language and other software setting parameters

(device type, temperature unit of measure, communication parameters etc.) are saved

automatically. When the program is restarted, the last us

3 Operation

3.1 Starting and Exiting the Program

Double click the METRAwin 90 icon on the Windows desktop.

Select the program from the Windows start menu:

Start / Programs / METRAwin 90 / METRAwin 90

The program is started.

Select Close in the File menu.

Simultaneously press the Alt+F4 keys.

Click the Close icon at the upper right-hand corner of the title bar.

The program is exited.

i

ed settings are still valid.

GOSSEN MET RA WATT 9

Page 10

METRAwin 90 - Operating Instructions

The

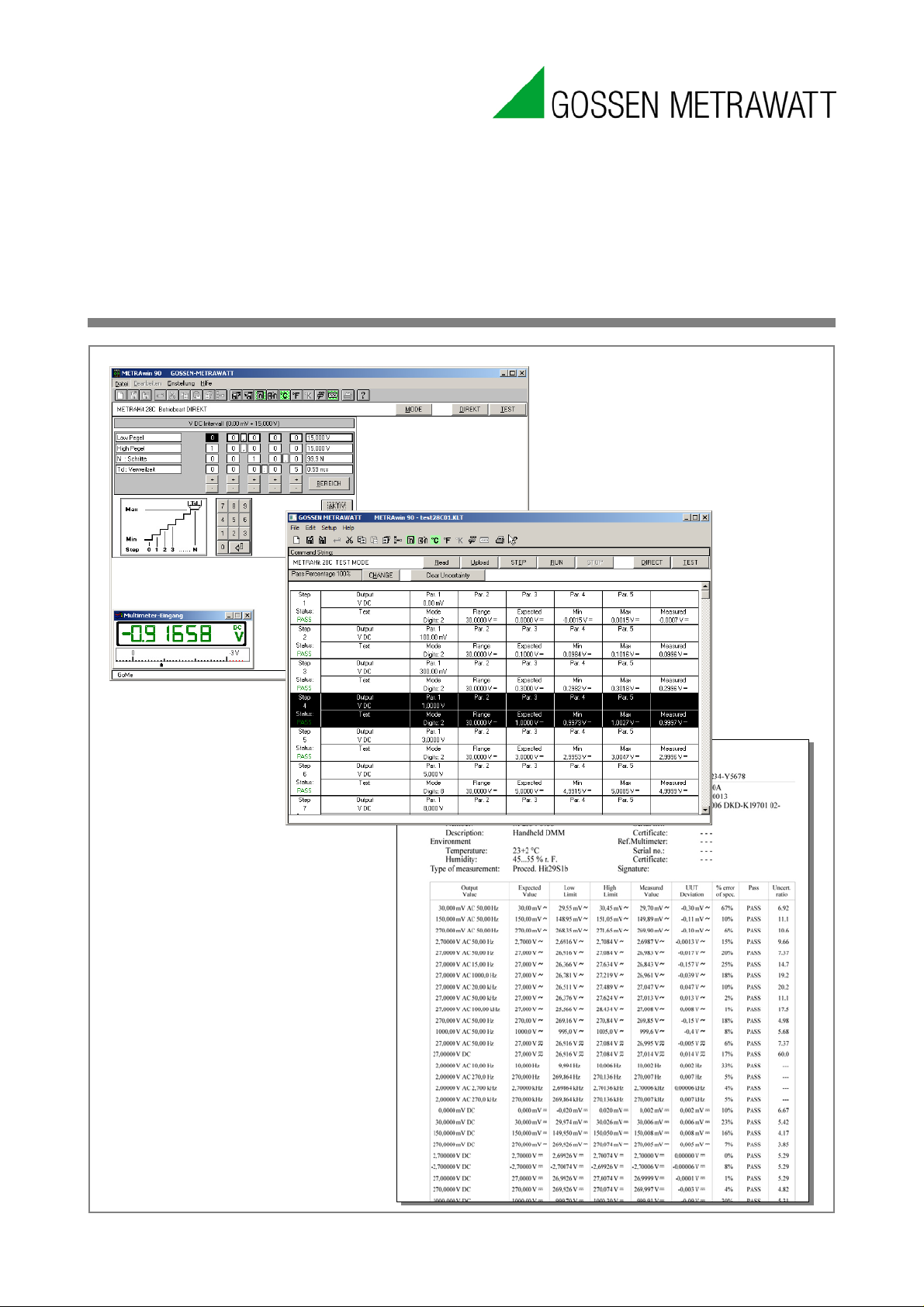

Figure 3.2: Segments of the Program Window

A) Title Bar

The horizontal ba

registration information, as well as the file name of the currently open procedure. It

also includes the system menu at the left which can be opened via the

and buttons (

the program window

at the right.

B) Menu Bar

The menu bar includes the names of the main menus from which the various menu

functions and submenus can be accessed.

C) Toolbar

The smart icons in the toolbar allow for quick acces

and functions. The function of any given icon can be displayed by moving the mouse

pointer to it, and is executed by clicking the icon. After clicking

men

D) Command Line

Commands transmitted to the calibrator appear in this line for double checking. After

clicking

shown.

E) Control Bar

Program operating mo

procedures is made possible using the buttons in the control bar. The type

designation of the currently controlled calibrator is displayed at the far left, which has

been selected via the

F) Workspace

A calibrator control panel appears in this area in the DIRECT operating mode, or a

table is shown in the TEST operating mode which lists the parameters of the test

procedure steps. Various dialog boxes can be opened here

G) Context Menu

A context menu appears after clicking the right mouse button with the mouse pointer

in the workspace. Just like the toolbar, it allows for quick access to frequently

required functions.

B C D

A E F

G

3.2 Structure of the User Interface

METRAwin 90 program window is subdivided into seven segments:

r at the top of the program window shows the program name and

program icon,

) for minimizing, maximizing and closing

s to frequently used commands

Toolbar in the Setup

u, the toolbar can be hidden or shown.

Command Line in the Setup menu, the command line can be hidden or

des are selected, and sequential control of the test

Device Type setting in the Setup menu.

as well.

GOSSEN MET RA WATT 10

Page 11

METRAwin 90 - Operating Instructions

File Menu

New

Data associated with any previously loaded test calibration procedure are deleted after

Open

Opens a calibration procedure file with/without results (*.KLT/*.KLF) in the TEST

Save

Print test report

Prints out a standard calibration report with a predefined structure.

Printer settings

Selects and configures an installed printer for report printing.

Export test data

Exports the calibration data to an individually laid out Word/Excel report template

[Alt+F4]

Exit

Exit the Program

Edit Menu (only available in the TEST/PROCEDURE mode)

Undo

[Ctrl+X]

Cut

Cuts the selected TEST/PROCEDURE line.

Copy

Copies the selected TEST/PROCEDURE line to the clipboard.

[Ctrl+V]

Paste

Duplicate

Duplicates the selected TEST/PROCEDURE line.

Insert line

Adds a new TEST/PROCEDURE line after the selected line.

Insert procedure

Language

Changes the program menus, commands and descriptions to a different language.

Registration

Registers the software for permanent use via e-mail or fax.

Device type

Sets the program to work with another device type.

Port settings

Selects the port(s) for communication between the PC and the device and configure

Multimeter display on

Shows or hides the multimeter display.

Command line

Toolbar.

Shows or hides the toolbar.

Cold junction

°C/°F°K/

Selects the temperature unit of measure.

Help Menu

[F1]

Program functions

Opens a PDF file with a description of general program functions.

Device functions

Opens a PDF file with a description of device-specific program functions.

Online support

Opens a website with information regarding technical support via the Internet.

Show license agreement

Opens a TXT file with a description of the license agreement.

About

3.3 Overview of Menu Functions

[Ctrl+Z]

[CTRL+C]

confirming the security prompt.

operating mode.

Saves a calibration procedure file with/without results (*.KLT/*.KLF) in the TEST

operating mode.

(available after running the KLT2DOC.DOT or KLT2XLS.XLM macro).

Undoes the last editing step. The following can be undone: changes to the parameters

in a procedure line, cut and paste operations, the “Repeat” operation.

The TEST/PROCEDURE line which has been copied to the clipboard is inserted into

the selected line.

Setup Menu

the port parameters.

Shows or hides the command line.

Selects a thermocouple cold junction (internal/external) for the calibrator.

Displays information regarding program version and contact address.

GOSSEN MET RA WATT 11

Page 12

METRAwin 90 - Operating Instructions

File:

New

Deletion of the data associated with a calibration procedure in the TEST operating mode

All of the steps of any previously created or loaded test calibration procedure are

deleted after confirming the sec

File:

Open

Open a calibration procedure file with/without results in the TEST operating mode.

►

⇒

of the file to be opened. As a default function, the last saved or opened

Figure

Calibrating procedure filenames end with

(procedure template without results). Program files which can be loaded to the

METRAHit 18C calibrator

►

to which a connection has been

►

3.3.1 File Menu Functions

urity prompt.

A previously saved calibration procedure file can be selected and loaded to

temporary memory after clicking Open in the File menu while in the TEST

operating mode.

The Open dialog box which then appears prompts you to select or enter the

filename

file is suggested.

3.3.1-a: Dialog Box for Opening a Calibration Procedure File

.KLT (procedure with results) or .KLF

have a filename ending with .KLP.

GOSSEN MET RA WATT 12

Files located on local drives, or on network drives

established, can be opened. Select the directory path to the desired file in the

Look in dialog box.

By clicking a file in the file list, it’s selected as the measurement data file to be

opened. If a comment text was entered when the selected file was saved, the text

appears in the Comment field. Click [Open] in order to open the selected file.

Page 13

METRAwin 90 - Operating Instructions

►

•

•

•

Note 1

When a file is opened which contains data from a calibrator other the one currently selected

under

after acknowledgement of the prompt which appe ars in this c ase. If this progr a m vari ant is not

available, i.e. if the required device

enabled, the following message appears

Note 2

It

Note 3

Further Information regarding elements in this dialog box can be accessed via the direct help

function: First click

is required. A popup window with an appropriate explanation appears. This explanation can

also be display

help

File:

Save

After clicking

saved to a data storage medium so that they

Figure

Additional options can be selected via a further dialog box:

Test Header Only loads only the teat report header parameters of the selected

file for a previously opened/created calibration procedure.

Test Procedure loads the calibrating procedure only without results.

Test Procedure With Results loads the calibration proc edure al ong wit h the

included calibration results.

i

Device Type in t he Setup menu, the program switches to the current device type

i

’s not possible to open more than one calibration procedure file at a time.

i

in the menu which then appears.

-specific program module has not been instal led or

“Device is not installed - <device type designation>”.

? in the title bar of the window, and then click the element for which help

ed by clicking the element with the right mouse button and then clicking Direct

Save in the file menu, temporary procedure data are permanently

’re still available later on.

3.3.1-b: Dialog Box for Saving Procedure Files

GOSSEN MET RA WATT 13

Page 14

METRAwin 90 - Operating Instructions

⇒ You’re prompted to enter a filename in the Save as ... dialog box which then

►

►

been established. Select the desired directory path to which the file will be saved

►

►

Note 1

If the name of an already existing file is entered, a security prompt appears which asks t

user if he want

Note 2

Further Information regarding elements in this dialog box can be accessed via the direct help

function: First click

is required. A popup window with an appropriate explanation appears. This explanation can

also be display

help

File:

Print test report

Print out a standard calibration report with a predefined structure.

⇒

Figure

►

Enter information regarding the device to be calibrated (DUT) and the calibration

►

►

(*.KLT/*.KLF). Click the [Load] button to this end and selec t the file from which the

appears. The KLF file type is used for procedure files without results, and the

KLT file type for procedure files with results.

A text with up to 130 characters including 2 lines can be entered to the

Comment field as a description of the data included in the file. This comment

appears in the Open dialog box before a measurement data file is opened after

the file has been selected from the list.

Files can be saved to local drives, or to network drives to which a connection has

in the Save dialog box.

The file is saved to the selected directory using the desired filename by clicking

the [OK] button.

Saving the file can be aborted by clicking the [Cancel] button or b y pressing the

“ESC” key.

i

i

he

s to overwrite the respective file.

? in the title bar of the window, and then click the element for which help

ed by clicking the element with the right mouse button and then clicking Direct

in the context menu which then appears.

The Test Protocol Header dialog box appears first with numerous entry fields:

3.3.1-c: The Test Protocol Header Dialog Box

GOSSEN MET RA WATT 14

conditions to the entry fields in the left-hand column.

Information regarding the utilized calibration equipment can be entered to the

fields in the right-hand column.

Alternatively, these data can be read in from a previously saved test procedure file

Page 15

METRAwin 90 - Operating Instructions

test report header data will be loaded from the Open dialog box which the n a ppe a rs.

►

If the test procedure includes results in at least one line, the desired printer can

be selected and the standard calibration report can be printed out after clicking the

[Print]

Figure 3.3.1-d: Example of a Standard Calibration Report

Alternatively, a calibration report with individualized layout and content can be

created with the help of the

File:

Printer settings

Select and configure an installed printer for report printing.

This command opens the standard Windows dialog box for printer configuration, in

which the printer to be used for printing out the calibration re

and configured.

File:

Export test data

Export the calibration data to an individually laid out Word/Excel report template

If the standard calibration report doesn

or if you want it to in

header data can be exported to an individually laid out Word or Excel report

The test procedure can be saved to the data storage medium with or without

results by clicking [Save] (see

button. This report is laid out as shown below:

Save in the File menu).

Export Test Data menu function.

clude, for example, a company logo, the calibration and report

’t contain the desired calibration parameters

GOSSEN MET RA WATT 15

port can be selected

.

Page 16

METRAwin 90 - Operating Instructions

template. Corresponding report templates with integrated macros can be found in

the program directory to this end.

Editing the Microsoft

►

and open the Word template with macro (KLT2DOC.DOT)

The included macro (AutoNew.MAIN) can import the following parameters from the

open test procedure with results

Report Header Parameter

Variable Name

Parameter

#lab

Issuing laboratory

#calby

Calibrated by

#caldate

Calibration date

#nextdate

Next calibration date (= calibration date + 12 months)

#uutmake

Manufacturer of the device under test

#uuttype

Type designation of the device under test

#uutnumb

Serial number of the device under test

#uutdsc

Object (type of device under test)

#envtemp

Ambient temperature

#envhmdt

Relative humidity

#meatype

Type of measurement

#certnum

Certificate number

#caldev

Type designation of the calibrator

#calno

Serial number of the calibrator

#calcert

Calibrator certificate number

#muldev

Type designation of the multimeter

#mulno

Serial number of the multimeter

#mulcert

Multimeter certificate number

#refdev

Type designation of the reference multimeter

#refno

Serial number of the reference multimeter

#refcert

Reference multimeter certificate number

Procedure Step Parameter

Variable Name

Parameter

#fun

(Measuring) function (“V DC”, “RTD” ...)

#mrange

Measuring range (“3.0000 V DC”)

#tpoint

Test point

#outval

Output value and unit of measure (“2.50000 V DC”, “100 °C Pt100” …)

#param

Additional parameter (“1.00 kHz” for V AC, “Pt100” for temperature)

#adig

Permissible deviation in digits

#expval

Expected value

#fexpval

Expected value with measuring function (ACDC)

#minval

Lower limit value

#fminval

Lower limit value with measuring function

®

Start Micros of t® Word

located in the program directory.

Word report template included with the program

based on the variable names:

s

#maxval Upper limit value

#fmaxval Upper limit value with measuring function

GOSSEN MET RA WATT 16

s

Page 17

METRAwin 90 - Operating Instructions

#rprc

Measured difference as percentage of the specification

#result

Assessment: pass/limit/fail/---

#text

Comment regarding the test step

#udig

Measuring uncertainty in digits

#uval

Measuring uncertainty (absolute value)

#urat

Measuring uncertainty ratio

General Parameters

Variable Name

Parameter

#passprc

Pass percentage for limit value

#measured

Number of measured steps

#passed

Number of passed steps

#limit

Number of limit steps (between limit value and failure)

#fail

Number of failed steps

►

in accordance with your needs and save the

Running the Word macro and transferring the calibration data t

►

►

⇒

⇒

⇒

⇒

The data are transferred to the Word file and completion is acknowledged with a

Calibration data can be transferred to Excel in a similar way. However, the macro and

the report templates are located in separate files in the p

►

⇒

►

#regval Measured value

#fregval Measured value with measuring function

#rdev Measured difference (absolute value)

#frdev Measured difference with measuring function

#rdig Measured difference in digits

Adapt structure and column content

edited file as a Word 97 or 2003 template (*.DOT), or as Word template with

macros (*.DOTM) with a new name.

Start Micros of t® Word and open the desired Word template with macro.

Start the included AutoNew.MAIN macro by clicking Macros and then View

Macros in the View menu.

Respond to the prompt asking whether or not you want to receive data from the

calibration program with [Yes]:

In the window which then appears, you’re prompted to open a test procedure

file. If this file has already been opened, click [Cancel].

Now you ’re prompted to start calibration (if you haven’t already done so) and

then to select the export test data menu command.

ready message.

o the Word report template

Start Micros of t® Excel and open the KLT2DOC.XLM Excel macro file.

Two icons now appear underneath the add-ins with the designations KLT:Get

calibrator data and KLT:Close.

Click the KLT:Get calibrator data icon and select the report template file

(KLT2XLSx.XLT) to be opened in the window which then appears.

GOSSEN MET RA WATT 17

rogram directory in this case.

Page 18

METRAwin 90 - Operating Instructions

Program Functions

Opens a PDF file with a description of general program functions.

This menu command starts Adobe

file

Device Functions

Opens a PDF file with a description of device-specific program functions.

This menu command starts Adobe

document which includes des c riptio

characteristics with reference to the measuring instrument which is currently

selected under

Online Support

Opens a website with information regarding technical support via the Internet.

This menu command starts your Inter net bro wser and opens a webs ite wit h

information on how our technical support team can provide you with support via the

Internet.

Display License

A

Opens a TXT file with a description of the license agreement.

Th

new window.

Info

Displays information regarding program version and contact address.

This menu command opens a window which displays information regarding the

revision level o

technical support.

When the program is started for the first time, the language which was selected

during installation is use

selecting

with the last selected language.

Select the type of calibrator t

The various calibrators which are available for selection depend on which version of

the program you purchased and which device(s) your chose during installation.

An image of the selected calibrator appe

after

with specific connection and operating instructions can be opened by clicking Device

Functions

3.3.2 Help Menu

which includes descriptions of general program functions.

®

Reader™ in a new window, and opens a PDF

®

Reader™ in a new window and opens a PDF

ns of specific program functions and

Device Type in the Setup menu.

greement

is menu command starts your text editor and displays the license agreement in a

f the utilized program version, as well as the contact address for

3.4 Basic Program Settings

3.4.1 Changing the User Interface Language

d for the user interface. This language can be changed by

English / Deutsch / ... in the Setup menu. The program always starts up

3.4.2 Selecting the Type of Calibrator to be Controlled

o be controlled under Device Type in the Setup menu.

the device type has been changed. Depending on the device type, a PDF file

ars as an initial window in the workspace

in the Help menu.

METRAHit 18C METRAHit 28C/28C light METRAHit Cal/Multical

GOSSEN MET RA WATT 18

Page 19

METRAwin 90 - Operating Instructions

The corresponding dialog box appears after clicking

Its content depends on which

Device

can be accessed after clicking

Figure

Figure

USB X

METRAtop 90C/D9000/D9100 FLUKE 5100A/5500A/5520A/5700A

3.4.3 Port Settings

type of calibrator is currently selected to be controlled.

-specific port settings are described in a separate document. This document

Device Functions in the Help menu.

a) For METRAtop 90C / FLUKE D9000, D9100, 5100A, 5500A, 5520A and 5700A multifunction calibrators

Port Setup in the Setup menu.

3.4.3-a: Port Settings for FLUKE 5XXXA with METRAHit 1XS and SI232 Adapter

b) For METRAHit CAL and METRACAL MC process calibrators

3.4.3-b: Port Settings for METRAHIT CAL and USB X-TRA with METRAHit X-TRA and

-TRA

GOSSEN MET RA WATT 19

Page 20

METRAwin 90 - Operating Instructions

Figure

Figure

c) For METRAHit 28C and 28C light process calibrators

3.4.3-c: Port Settings for METRAHIT 28C and BD232 with METRAHit 28S and BD232

d) For METRAHit 18C process calibrator

3.4.3-d: Port Settings for METRAHit 18C and BD232 with METRAHit 18S SI232

GOSSEN MET RA WATT 20

Page 21

METRAwin 90 - Operating Instructions

After clicking

menu, a window can be viewed in

the workspace in which the current measured values of the connected multimeter

are display

continuously look back and forth between the monitor screen and the multimeter.

After clicking the minimize icon

display of the measured value is hidden and the meas

numeric

Figure

Figure

Multimeter and an Additional Reference Multimeter

The command line can be shown or hidden with the help of the

function in the

Commands transmitted to the calibrator appear in thi

The toolbar can be shown or hidden with the help of the

Setup

The toolbar contains buttons which can be used to quickly execute commands

without accessing the menu

form of so

Note

Just like the tool bar, the

functions.

You can specify whethe

temperature measurement and simulation after clicking

menu.

Note 1

Only

calibrator.

3.4.4 Showing and Hiding the Multimeter Display

3.4.4-a: Multimeter Display in Normal and Minimized Format

Multimeter Display On in the Setup

ed in analog and digital format. This makes it unnecessary to

in the multimeter input window, the graphic

ured value appears as a

value.

3.4.4-b: Multimeter Displays of the Calibrator-

3.4.5 Showing and Hiding the Command Line

Setup menu.

3.4.6 Showing and Hiding the Toolbar

menu.

s. The functions assigned to the buttons appear in the

-called “quick-info” when the mouse is positioned at the respective button.

i

3.4.7 Specifying the Temperature Unit of Measure

context menu also permits quick access to frequently required

r degrees Celsius, Fahrenheit or Kelvin will be used for

Command Line

s line for double checking.

Toolbar function in the

°C / °F / °K in the Setup

i

GOSSEN MET RA WATT 21

those units of measure are available which are supported by the currently utilized

Page 22

METRAwin 90 - Operating Instructions

Note 2

Temperature is generally saved in °C in the test procedures.

The

to specify whether the

externally

simulation with the calibrator.

If

used to manually enter the measured cold junction temperature (the temperature at

the connection for the simulated thermocouple sensor). If the METRAHit multimeter

with temperature sensor c

measurement, the temperature can be read in online by clicking the

multimeter

activated, the temperature is continuously monitored by the multimeter, forwarded to

the calibrator via the port and taken into account by the calibrator.

Figure

i

3.4.8 Specifying the Thermocouple Cold Junction

Internal/External Cold Junction function in the Setup menu makes it possible

internally measured temperature inside the calibrator or the

measured temperature will be used as the cold junction for thermocouple

external cold junction temperature is selected, a dialog box appears which can be

onnected to the PC is used for this temperature

“Get from

” button. If the “Link Calibrator with Multimeter” checkbox has been

3.4.8-a: Dialog Box for Setting the External Cold Junction Temperature

GOSSEN MET RA WATT 22

Page 23

METRAwin 90 - Operating Instructions

3.5

In this operating mode, the calibrator is interactively controlled by the PC via the

selected port. This is especially helpful during adjustment and balancing of

amplifiers, measuring transducers, analog components

►

►

►

⇒

►

►

The entry of erroneous calibration values is prevented.

The multimeter’s display value can be viewed at the monitor screen at the same time

by clicking

DIRECT Operating Mode for Interactive Calibrator Operation

Click the [DIRECT] button in the control bar.

Then click the [MODE] button in the control bar in order to select the desired

simulation function at the calibrator:

Select the desired output function and operating mode and acknowledge by

clicking the [OK] button.

A control panel for configuring the parameters of the selected function then

appears in the workspace:

and multimeters.

Select the parameters to be configured and enter the setpoint value either

numerically or by adjusting the displayed value at the corresponding decimal

place with the [+] and [-] keys.

After clicking [ACTIVE], the parameter values are transmitted to the calibrator

which is then correspondingly configured. If the active state has already been

initialized, the changes are implemented immediately.

GOSSEN MET RA WATT 23

Multimeter Display On in the Setup menu.

Page 24

METRAwin 90 - Operating Instructions

3.6 TEST Operating Mo de

3.6.1

►

⇒

►

►

⇒

►

⇒

Test Parameters

Creating a Calibration Procedur e

Click the [TEST] button in the control bar.

The first procedure line appears in the workspace which consists of an upper

“output line” for programming the calibration signal and a lower “input line” for

the expected results at the device to be calibrated and the allowable tolerances.

Double click into the procedure line’s Step field in order to select the desired

simulation function at the calibrator.

Select the desired output function and operating mode, and acknowledge by

clicking the [OK] button.

A control panel for configuring the parameters of the selected function then

appears in the workspace:

Select the parameters to be configured and enter the setpoint value either

numerically or by adjusting the displayed value at the corresponding decimal

place with the [+] and [-] keys. Acknowledge your entry with [OK].

The

GOSSEN MET RA WATT 24

dialog box appears.

Page 25

METRAwin 90 - Operating Instructions

►

read in from the multimeter via the PC’s serial port with

After this step has been completed, the next procedure line appears automatically

which is filled out in the same way using the mou

standard Windows tools (copy and paste, or repeat with subsequent modification).

This process is repeated

completed. Suggestions regarding tolerance specifica

step appear automatically in the next step.

Enter or select:

• How the measured value will be entered to the program:

Multimeter Input

The measured value is

the help of an adapter.

Manual Input

The displayed actual value for the device to be calibrated is read and entered

using the PC’s keyboard.

Variable Output

The calibration signal is continuously changed at the monitor or the calibrator

by means of manual tracking with a decade device until the display at the

measuring or recording instrument coincides with the specified setpoint.

• When the measured value read in via the port is valid (Wait)

• Which measured value is expected from the device under test (UUT

Expected Value) and how accurate the value should be (UUT Specification)

• Whether or not an auto-message will app ear at the monitor screen

• Whether or not an individual message will be read out to the user before

executing a procedure step

se, or is created with the help of

for all of the calibration points until the procedure has been

GOSSEN MET RA WATT 25

tions in any given procedure

Page 26

METRAwin 90 - Operating Instructions

►

3.6.2 Executing a Calibration Procedure

Click the [RUN] button in the control bar if you want to execute the procedure

beginning with the selected step, or click the [STEP] button if you only want to

execute the selected step.

Edited in Germany • Subject to change without notice • A PDF version available on the Internet

Phone: +49 911 8602-111

GMC-I Messtechnik GmbH Fax: +49 911 8602-777

Südwestpark 15 e-mail info@gossenmetrawatt.com

90449 Nürnberg • Germany www.gossenmetrawatt.com

Loading...

Loading...