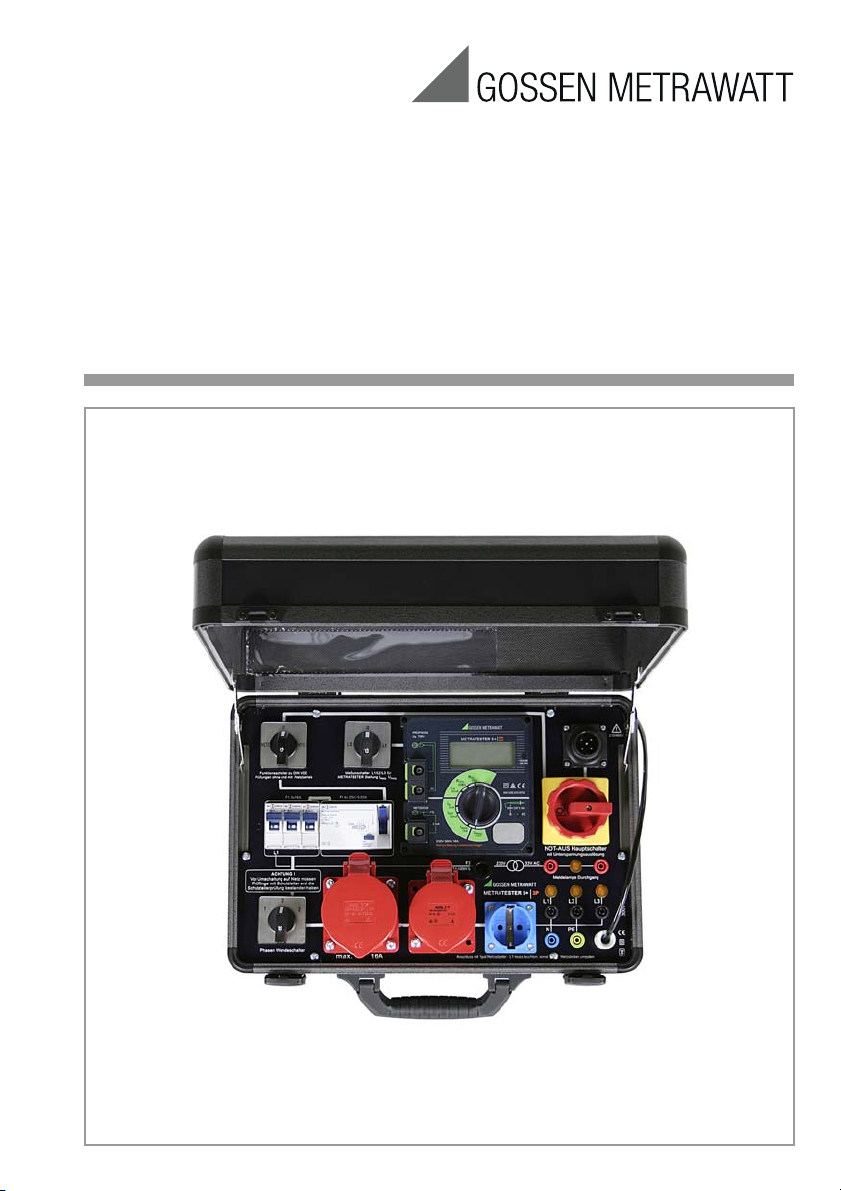

Operating Instructions

METRATESTER 5+3P

Workshop Test Panel for Testing Devices

per DIN VDE 0701-0702 and DIN VDE 0104

3-349-414-03

7/5.13

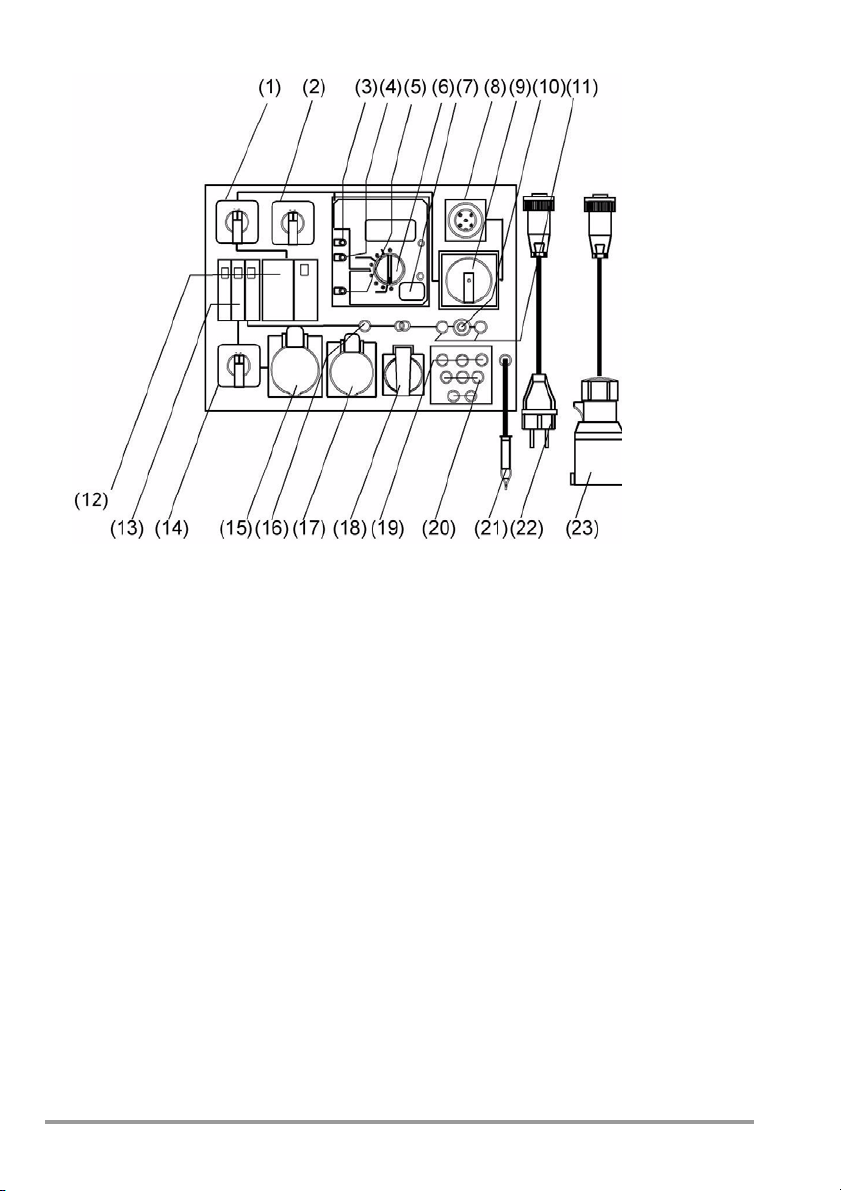

1 NETZ-VDE switch (mains-VDE)

2 Measuring selector switch: L1-L2-L3

3 Connector socket/terminal for DUT

phase conductor (parallel to test sockets)

4 Connector socket/terminal for DUT pro-

tective conductor (parallel to test sockets)

5 Connector socket/terminal for

conductive parts of the DUT for testing

for the absence of voltage in accordance

with DIN VDE 0701–0702, and for

contact current measurement for

protection class II devices

6 Measuring function selector switch for

METRATESTER 5+

7 Contact surface for finger contact

8 Plug connector for mains cables

9 Mains / emergency stop switch,

12 RCD (residual current circuit beaker)

4*25 A, 0.03 A

13 Three circuit breakers, B16 A

14 Polarity reversing switch

15 CEE socket, 3P+N+PE, 32 A, 230/400 V

max. 16 A !

16 Fuse, T 0.1/250G

17 CEE socket, 3P+N+PE, 16 A, 230/400 V

18 Earthing contact outlet

19 Mains indicator lamps, L1-L2-L3

20 Test sockets, L1-L2-L3-N-PE

21 Probe cable with clip / test probe

22 Mains cable with earthing contact plug

and coupling socket

23 Mains cable with CEE 16 A, 5-pole

mains plug and coupling socket

undervoltage trigger can be locked at

zero setting

10 “Durchgang” (continuity) indicator lamp

11 Connector sockets for continuity test

with max. 33 V AC

2 GMC-I Messtechnik GmbH

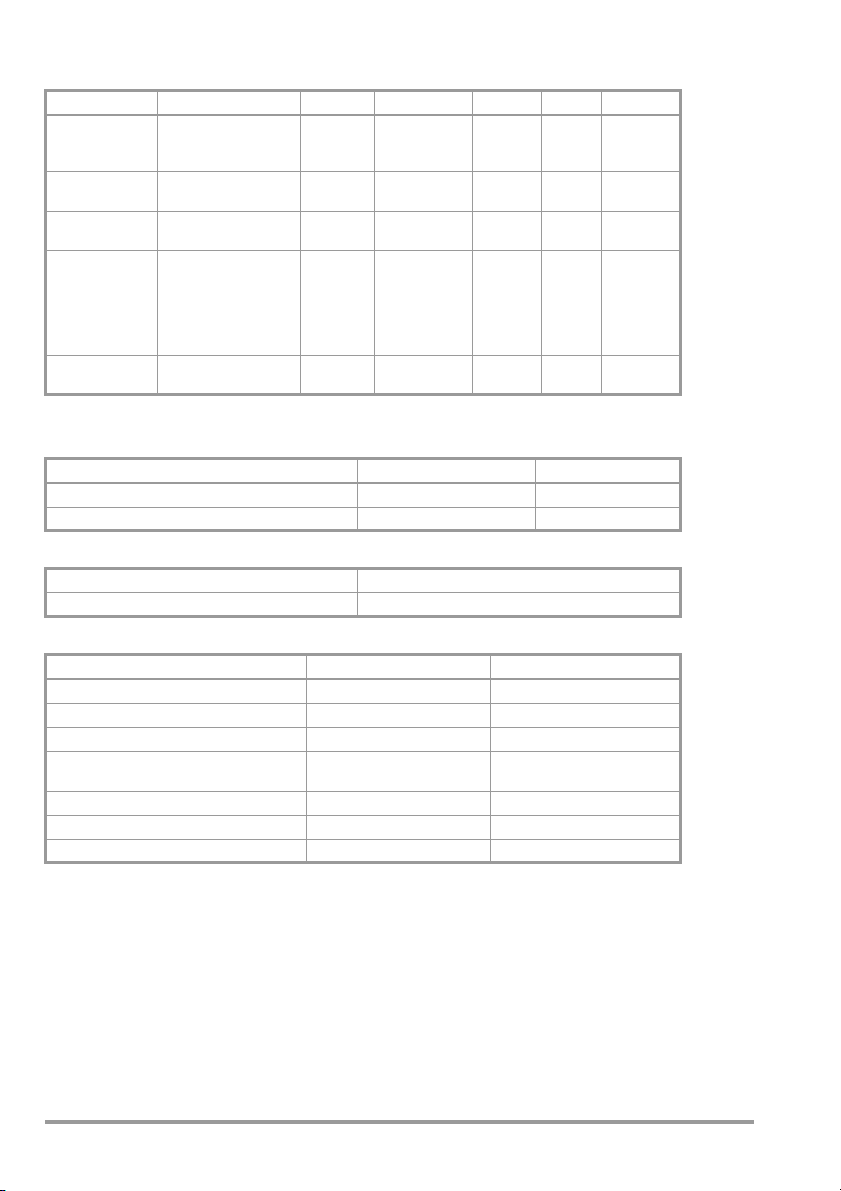

Table of Contents Page

1 Applications ....................................................................................................................4

2 Safety Precautions .........................................................................................................4

3 Standard Equipment and Accessories ............................................................................6

4

Connecting the Test Case to the Mains and Testing the Mains Connection ..........................6

4.1 Connecting the Test Case ................................................................................................................. 6

4.2 Testing Protective Conductor Potential ............................................................................................... 6

4.3 Measuring Line Voltage .................................................................................................................... 7

5 Connecting the DUT to the Test Case ............................................................................. 8

5.1 Protection Class I Devices ................................................................................................................. 8

5.2 Protection Class II and III Devices ...................................................................................................... 9

5.3 Devices with Single or Multi-Phase Connection without Plug ............................................................... 9

5.4 Stationary Devices for Protective Conductor Testing via the Supply Mains .......................................... 10

5.5 Data Processing Equipment ............................................................................................................ 10

5.6 Extension Cables with the VL2 E Accessory ..................................................................................... 11

5.7 Setting the Switches at the Test Case .............................................................................................. 11

5.8 Setting the Switches at the Device Under Test ................................................................................. 11

6 Testing Devices in Accordance with DIN VDE 0701-0702 ............................................12

6.1 Measuring Protective Conductor Resistance for Protection Class I Devices ......................................... 12

6.2 Measuring Insulation Resistance ..................................................................................................... 13

6.3 Measuring Protective Conductor Resistance ..................................................................................... 15

6.3.1 Equivalent Leakage Current ............................................................................................................ 15

6.3.2 Differential Current Measurement for Protection Class I Devices ........................................................ 16

6.4 Measuring Contact Current ............................................................................................................. 17

6.4.1 Contact Current Measurement – Differential Current ........................................................................17

6.4.2 Testing in Accordance with the Direct Method ................................................................................. 17

6.5 Measuring Load Current and Voltage at the Consumer ..................................................................... 18

7 Testing Extension Cables with the VL2 E Accessory ....................................................19

7.1 DIN VDE Tests for Extension Cables ................................................................................................. 19

7.2 Function Test for Extension Cables .................................................................................................. 19

8 Continuity Test with Extra-Low Voltage ........................................................................ 20

9 Display and Indicators at the Test Instruments ............................................................20

9.1 Indication of Errors and Limit Values ................................................................................................ 20

10 Technical Data ..............................................................................................................21

10.1 Test case ...................................................................................................................................... 21

10.2 METRATESTER 5 + Test Instrument ................................................................................................. 22

11 Maintenance – Recalibration ........................................................................................ 25

11.1 Housing Maintenance ..................................................................................................................... 25

11.2 Recalibration .................................................................................................................................. 25

11.3 Periodic Self-Test of the Connector Cable for Protective Conductor Continuity .................................... 26

11.4 Testing the Integrated RCD (residual current circuit breaker) ............................................................. 26

GMC-I Messtechnik GmbH 3

11.5 Fuse Replacement .......................................................................................................................... 26

11.6 Return and Environmentally Sound Disposal ..................................................................................... 26

12 Repair and Replacement Parts Service

Calibration Center * and Rental Instrument Service .....................................................27

13 Product Support ............................................................................................................28

1 Applications

The portable test case, manufactured in accordance with “guidelines for equipment required

for electrical installation operations”, is intended for use by qualified electricians for

measuring and testing electrical devices after repair or modifications, as well as for periodic

testing, in accordance with DIN VDE 0701-0702.

According to these regulations, protective conductor resistance, insulation resistance,

differential current, contact current and equivalent leakage current must be measured, and

testing for the absence of voltage must be executed at user accessible conductive parts at

data processing equipment and office machines.

Further applications for the substantiation of correct functioning of electrical equipment

include the measurement of operating voltage and current consumption at devices under

test. Beyond this, the protective conductor at the mains connection can be tested for the

absence of voltage and line voltage can be measured. Extension cables can be tested after

connecting the VL2 E accessory.

2 Safety Precautions

The test case is equipped with a METRATESTER 5+ test instrument, and has been

manufactured and tested in accordance with the following regulations:

IEC 61010-1,

DIN EN 61010-1,

VDE 0411-1 “Regulations for electronic testers and controllers,

Part 1: safety measures for electronic measuring instruments”

and DIN VDE 0404 “Devices for technical safety testing of electrical equipment, part 1:

General requirements,

and part 2: Devices for periodic testing”

If used for its intended purpose, safety of the test case and of the user is assured. Their

safety is however not guaranteed, if the test case is used improperly or handled carelessly.

In order to maintain flawless technical safety conditions, and to assure safe use, it is

imperative that you read these operating instructions thoroughly and carefully before placing

the test case into service, and that you follow all instructions contained herein.

4 GMC-I Messtechnik GmbH

Observe the following safety precautions:

Attention!

!

• Measurements within electrical systems are prohibited!

• The test case may only be connected to 230/400 V mains system with 50 Hz and a 16 A

fuse via the 5-pole (23) or 3-pole (22) mains cable.

• In order to avoid undesired shutdown in the event of a defective device under test, the

mains outlets should be separately fused if at all possible!

A defect in the DUT may trip the mains power RCD (residual current circuit breaker), and

thus cause a service interruption. If DUTs are being tested which cannot be

disconnected from the mains intermittently, an RCD (residual current circuit breaker) can

also trip the power supply circuit (test per section 6.4.1).

The manufacturer of the test case assumes no liability for loss of data or other damage

which results from its use.

• Be prepared for the occurrence of unexpected voltages at devices under test. For

example, capacitors may be dangerously charged.

• If the test case is connected via the earthing contact mains adapter, phase conductor L1

may be connected to the N safety socket if poled accordingly! If this is the case, reverse

polarity of the plug at the mains adapter (see section 4.1).

• Before connecting the device under test to the test case, subject it to a thorough visual

inspection first. Devices under test with visibly damaged insulation must be repaired

before metrological testing is performed.

• If the test case and/or its connector cables demonstrate visible damage, no longer

function, have been stored for a lengthy period of time under unfavorable conditions or

have been subjected to excessive stress during transport, it must be assumed that

hazard-free operation is no longer possible. If this is the case, remove the test case from

service and secure it against inadvertent use, for example by locking it up.

The NETZ-VDE switch (2) may only be set to the “NETZ” (mains) position after devices

under test with a protective conductor have passed the protective conductor test.

For reasons of safety, the device under test must be turned off before switching to “Netz”

(mains), so that dangerous devices under test (e.g. a circular saw) can only be switched on

intentionally.

• Due to the fact that the test case is laid out in accordance with DIN VDE 0404, the “PE”

safety socket and the “PE” contacts in the outlet may only be connected to the mains

protective conductor after the NETZ-VDE switch has been set to the “Netz” (mains)

position.

• In order to assure compliance with technical safety requirements, the test case may only

be repaired by a qualified electrician, who is preferably employed by the manufacturer.

• Before opening the test case in order to carry out repairs, it must be disconnected from

the mains by pulling the plug from the electrical outlet.

• Disconnect the test case from the mains whenever work is interrupted and secure it

against unauthorized use, for example by locking the cover.

• Use recommended accessories only!

GMC-I Messtechnik GmbH 5

Meaning of Symbols on the Instrument

!

Warning concerning a source of danger

(attention: observe documentation!)

EC label of conformity

This device may not be disposed of with the trash. Further information regarding

the WEEE mark can be accessed on the Internet at www.gossenmetrawatt.com

by entering the search term WEEE.

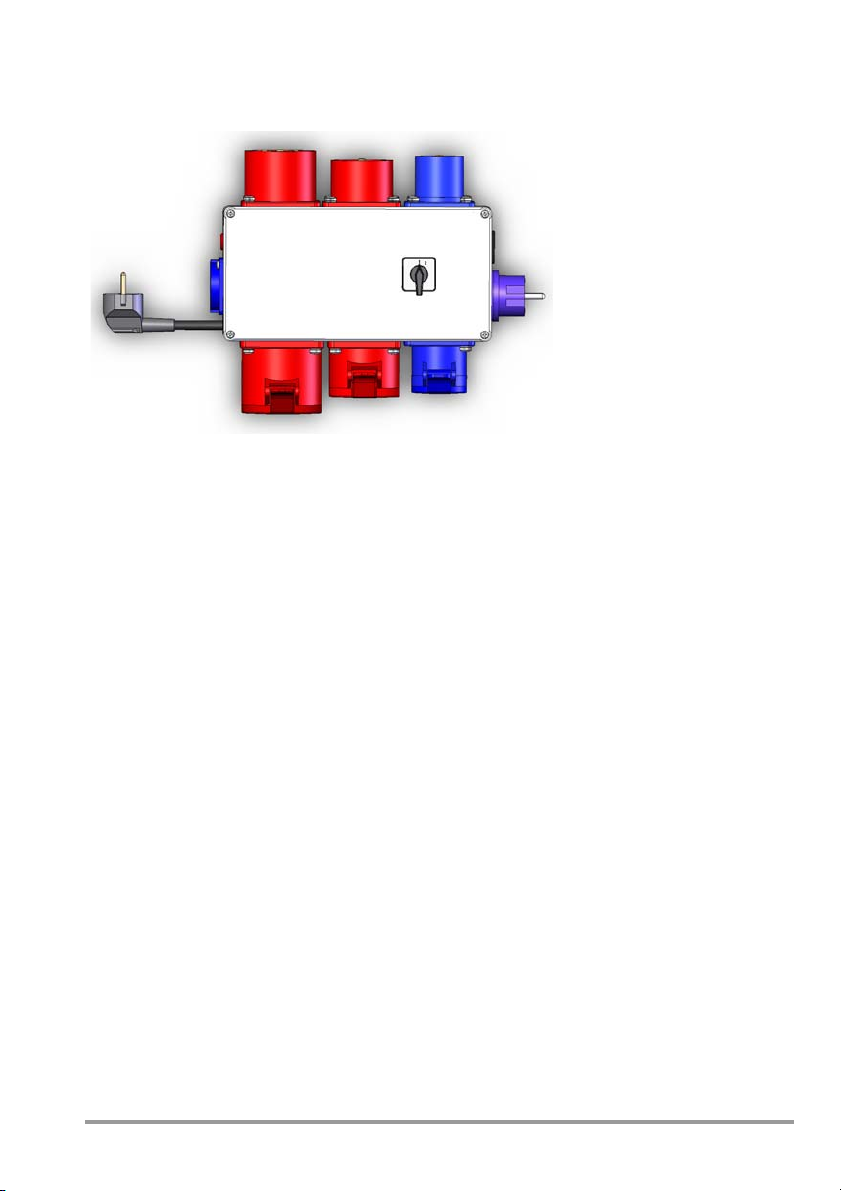

3 Standard Equipment and Accessories

Scope of Delivery

1 test case

2 mains cables (Schuko and CEE16A)

1 measurement cable with test probe, 1 alligator clip

1 set of operating instructions

Accessories

SECU-cal 10 calibration adapter (M662A)

VL2 E test adapter for testing cables (Z745W)

4 Connecting the Test Case to the Mains and Testing the Mains Connection

4.1 Connecting the Test Case

Set the switches as follows before connecting to the mains:

Set the NETZ–VDE switch (1) to “NETZ”, set the METRATESTER 5 + measuring function

selector switch (6) to “250 V”, set the polarity reversing switch (14) to “1”, set the L1-L2-L3

measuring selector switch (2) to “L1” and then connect the test case to the mains. Set the

mains switch (9) and the RCD (residual current circuit breaker) (12) to “EIN” (on). According

to the manufacturer, the emergency stop switch may generate minor humming noises with

the U coil in certain armature positions. If this is the case, quickly turn the emergency stop

switch on and off several times.

When connected via the 5-pole CEE mains adapter (23), indicator lamps L1, L2 and L3 (19)

must light up, and when connected via the earthing contact mains adapter (22), only

indicator lamp L1 should light up. Mains polarity is tested for this type of connection, i.e. if

lamp L1 does not light up, the polarity of the earthing contact plug must be reversed in the

mains outlet.

If this is not the case, immediately disconnect the test case from the mains.

The fault at the mains connection or the test case must be eliminated before executing any

tests.

4.2 Testing Protective Conductor Potential

Touch the contact surface (7) with your finger, and touch a grounded object at the same time

(e.g. a water pipe). The PE indicator lamp may not light up! If this is the case, potential between

the protective conductor at the mains plug (22/23) and the contact surface (7) is 100 V.

6 GMC-I Messtechnik GmbH

When connected via the 5-pole CEE mains plug (23), indicator lamps L1, L2 and L3 (19)

Note!

Attention!

!

Note!

must light up. When connected via the earthing contact mains adapter (22), only indicator

lamp L1 should light up. Mains polarity is tested for this type of connection, i.e. if lamp L1 does

not light up, the polarity of the earthing contact plug must be reversed in the mains outlet. If this is not

the case, immediately disconnect the test case from the mains. The fault at the mains connection

or the test case must be eliminated before executing any further tests.

If the PE signal lamp lights up when you touch the contact surface (7), potential between the

protective conductor at the mains plug (22/23) and the contact surface (7) is 25 V, i.e. the

protective conductor is conducting voltage.

Depending upon handling, potential transfer may occur which causes the PE signal

lamp to light up. For example, this could be the case if you touch a device under test

with the NETZ-VDE switch (1) in the “VDE” position, thus creating a capacitive voltage

divider.

If, while testing protective conductor potential, you determine that the mains

protective conductor is conducting voltage, no measurements may be performed

with the test case. If this is the case, potentially dangerous voltage is also present at

the user accessible earthing contacts at the outlets, the “PE” socket (20) and the jack

(4). Immediately disconnect the test case from the mains and arrange to have the

fault eliminated at the mains connection. Voltage in the mains protective conductor

also results in incorrect measured values when testing for the absence of voltage in

accordance with DIN VDE 0701-0702 (see section 6.4.1).

4.3 Measuring Line Voltage

• Set the measuring function selector switch (6) to “250 V~”.

• If connected via the 5-pole CEE mains adapter, set the measuring selector switch (2) to

the L1, L2 and L3 settings, one after the other, and if connected via the earthing contact

mains adapter set the switch to L1 and read the measured value from the LCD panel for

each switch setting.

Line voltage must always lie within the permissible range of 207 to 253 V.

If line voltage is present, values are displayed at the with the measuring function

selector switch (6) in each of its respective positions, even if no device under test has

been connected.

The display of such numbers indicates that line voltage is present, regardless of the

position to which the measuring function selector switch (6) has been set. If the

selector switch has been set to “250 V~”, these numbers represent the actual line

voltage value. In all other detented switch positions – if no device under test has been

connected – these numbers do not represent actual measured values.

If the test case has been connected via the earthing contact mains adapter, all tests and

measurements can be performed except tests at 3-phase current devices under mains

operating conditions.

GMC-I Messtechnik GmbH 7

5 Connecting the DUT to the Test Case

Mains Connection Sockets

Switch the DUT on!

Either

Depending upon its plug, connect the DUT to one of the outlets, or to the connector sockets

in the case of loose wire ends.

It is absolutely mandatory to execute the tests in the order in which they are specified here!

1 Visual inspection

2 Measurement of protective conductor resistance for protection class I devices

3 Measurement of insulation characteristics if technically feasible, i.e. if the DUT does not

include any electrically actuated, all-pole switches:

– Insulation resistance followed by protective conductor or equivalent leakage current

– Otherwise: leakage current during operation, differential current, protection class I

devices

Contact current for protection class II devices

Safety extra-low voltage (only at point of connection of safety extra-low voltage

generated in the DUT)

4 Function Test

5 Labeling inspection

6 Documentation

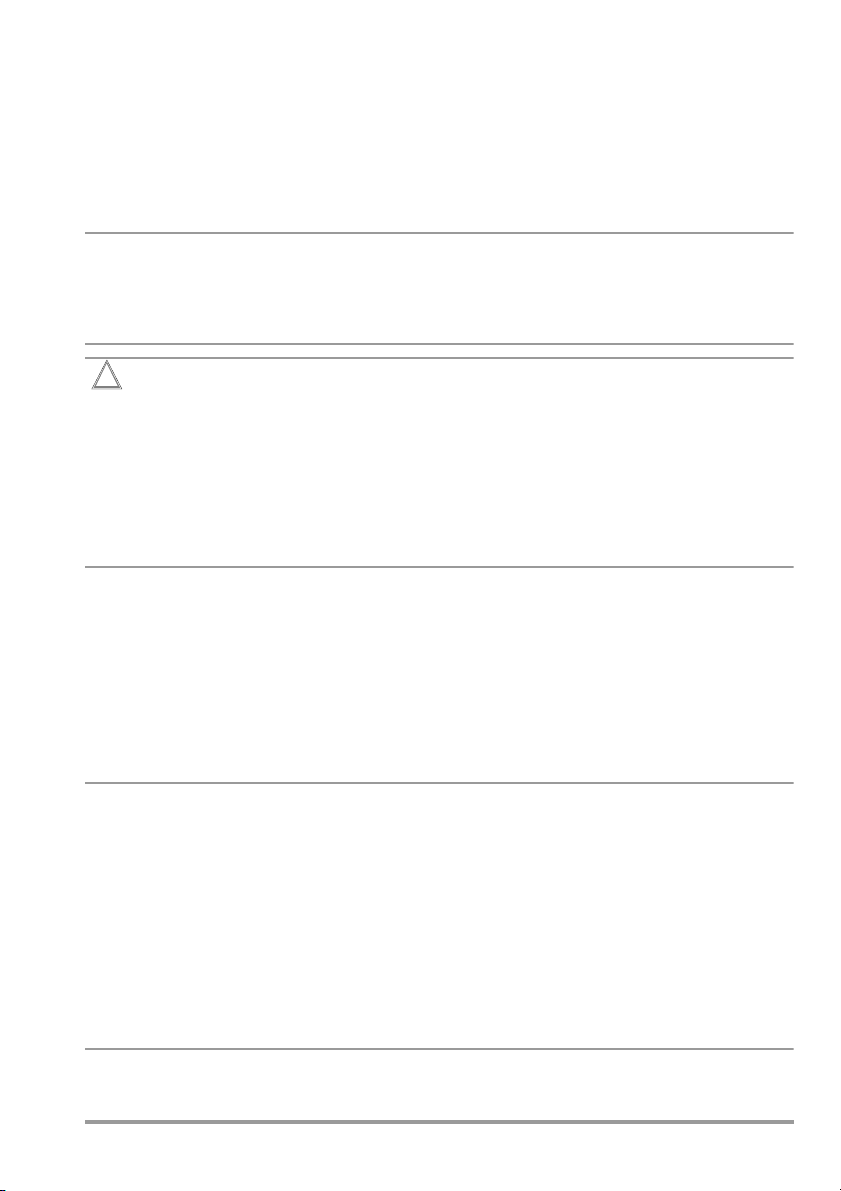

5.1 Protection Class I Devices

8 GMC-I Messtechnik GmbH

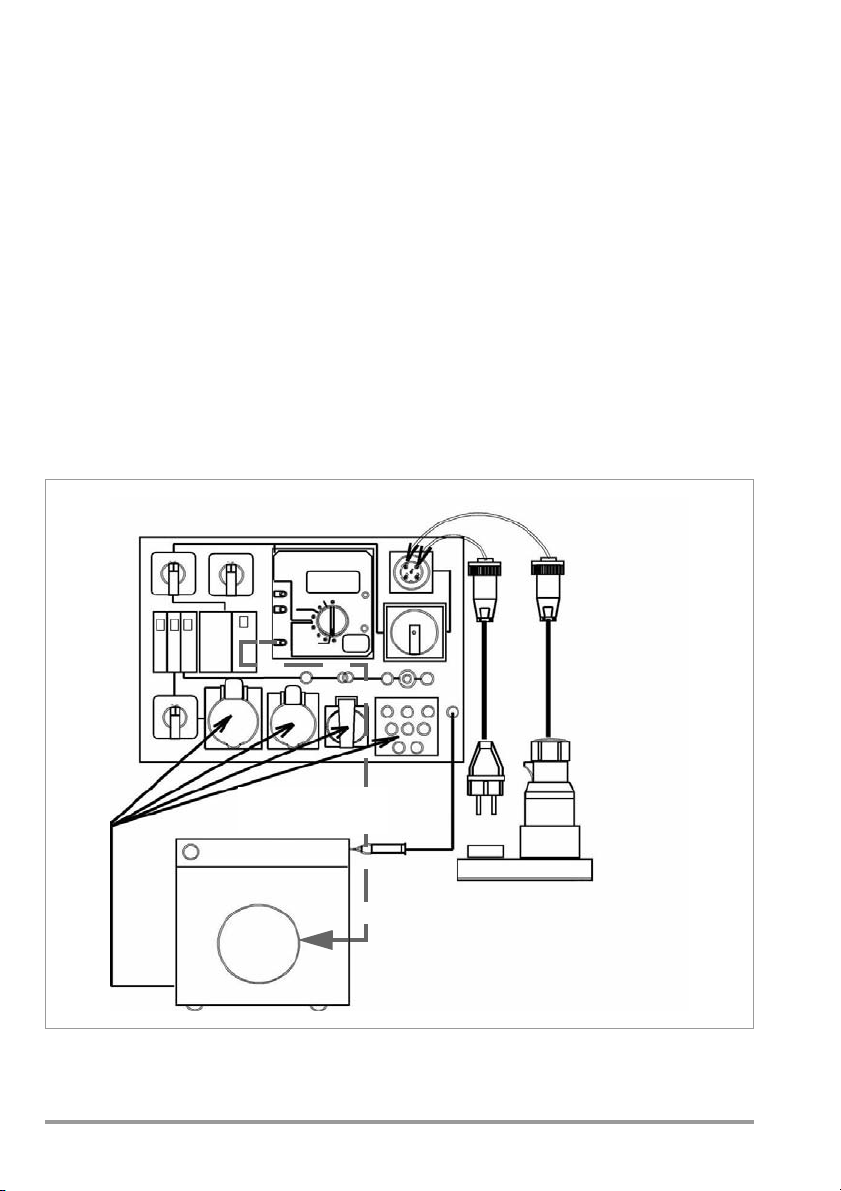

5.2 Protection Class II and III Devices

Connect the DUT, for example to the

earthing contact outlet, or to the connector sockets in the case of loose wire ends.

Switch the DUT on!

Mains Connection Sockets

To Accessible

Metal Parts

Either

Mains Connection Sockets

Switch the DUT on!

Either

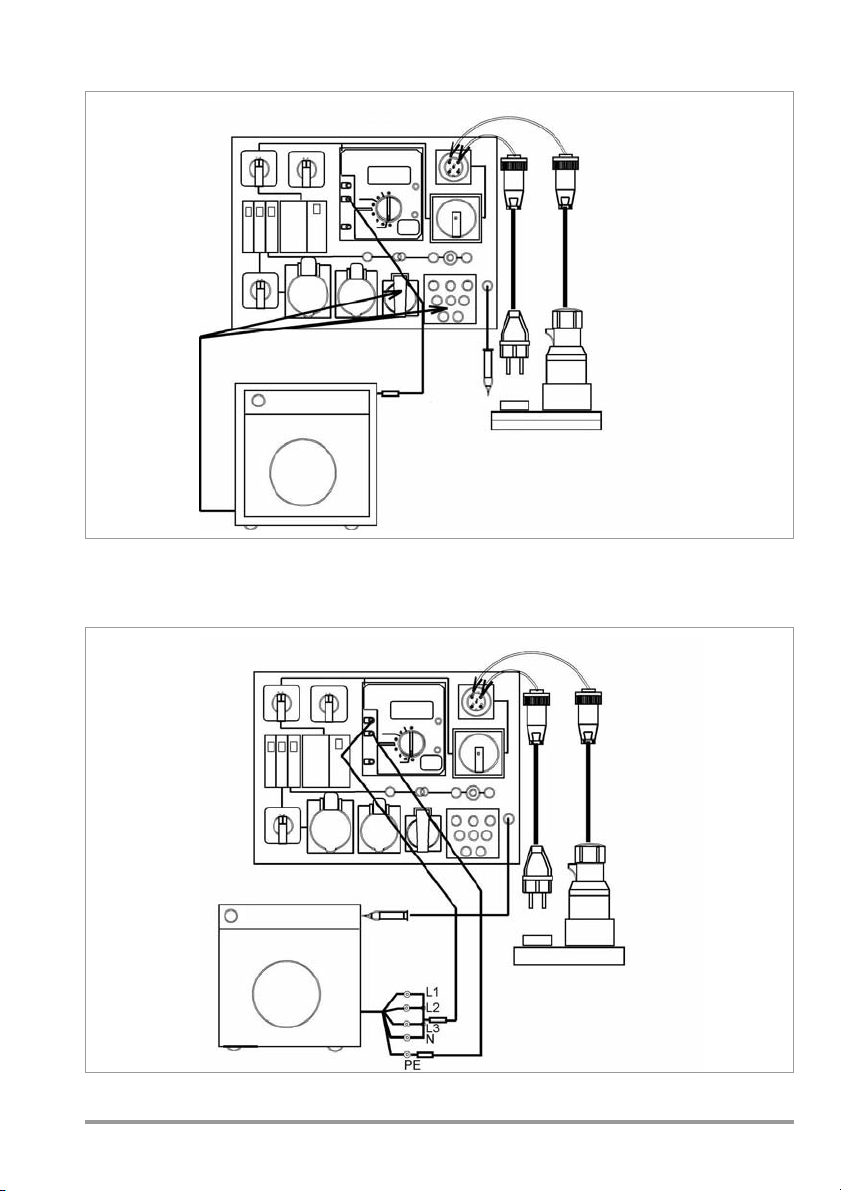

5.3 Devices with Single or Multi-Phase Connection without Plug

GMC-I Messtechnik GmbH 9

5.4 Stationary Devices for Protective Conductor Testing via the Supply Mains

Either

Mains Connection Sockets

Switch the DUT on!

To M ai n s

Protective Conductor

Mains Connection Sockets

Switch the DUT on!

5.5 Data Processing Equipment

Either

10 GMC-I Messtechnik GmbH

5.6 Extension Cables with the VL2 E Accessory

Either

Mains Connection Sockets

VL2 E Test Adapter

5.7 Setting the Switches at the Test Case

The following settings must be made after visual inspection has been passed, and before the

DUT is connected to the corresponding plug connectors at the test case, as well as before

each new test:

NETZ–VDE switch (1) Set to “VDE”

METRATESTER 5 + function selector switch (6) Set to “I

Polarity reversing switch (14) Set to “1”

Measuring selector switch L1-L2-L3 (2) Set to “L1”

20 mA”

EA

5.8 Setting the Switches at the Device Under Test

Connect the device under test to the test case and switch all of its functions on, making sure

that, for example, thermostat contacts are closed etc.

GMC-I Messtechnik GmbH 11

6 Testing Devices in Accordance with DIN VDE 0701-0702

Note!

Note!

Always measure protective conductor resistance first for safety class I devices under test.

Measurement of insulation resistance, equivalent leakage current and protective conductor

current is not possible without a properly functioning protective conductor. This

measurement is of special importance because a defective or reversed protective conductor

may represent a hazard for the user!

Please note that the display indicates overloading when measuring protective

conductor resistance and insulation resistance, if the terminals are open or if the

upper range limit is exceeded. Only “O.L” appears at the display in this case.

The limit values specified in the following sections correspond to the current status at

the time or printing. Please note that normative legislation is continuously updated to

meet the safety requirements necessitated by changing market situations, and that

the listed limit values are thus subject to change.

6.1 Measuring Protective Conductor Resistance for Protection Class I Devices

Connect the single-pole probe cable with test probe and clip (21) to the housing of the DUT

in accordance with section 5.1. Assure good contact. In the case of stationary DUTs,

measurement can be performed without interrupting the mains connection. To this end,

connection must first be established from the protective conductor socket (4) at the METRATESTER 5+ to a protective conductor which has been previously tested for the absence of

voltage – for example at an outlet within the electrical system – which is

connected with the protective conductor of the DUT. When testing in accordance with

DIN VDE 0701-0702, DUTs with external connections such as data cables etc. can be

tested within their entire configuration at the installation site (see section 5.4 regarding

connection).

However, due to the fact that this test does not provide any indication as to the safety of the

device under test, complete testing via the connector sockets at the test case must be

performed as soon as disconnection from the mains and the connector cables is possible –

insofar as permitted by the device.

Ð Set the measuring function selector switch (6) to the “20 Ohm” range.

Ð Read the measured value in Ohms at from the LCD panel, and compare it to permissible

values in accordance with DIN VDE 0701-0702.

Protective conductor resistance may not exceed the following resistance values:

Maximum Permissible Values for Protective Conductor Resistance Relative to Cable Length

(per DIN VDE 0701-0702:2008)

Lengths up to [m] 5 12.5 20 27.5 35 42.5 50 More than 50

Max. resistance [] 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0

A value of 1 may not be exceeded on any case. The table applies to cable reels and extension cables

as well.

In the case of longer cables, 0.1 Ohms is added per additional 7.5 m cable length regardless

of conductor cross-section.

12 GMC-I Messtechnik GmbH

Attention!

!

The connector cable must be shaken back and forth, section by section over its

Attention!

!

Attention!

!

entire length, during measurement (for permanently installed devices only insofar as

the connector cable is accessible during repair, modification or testing).

Unrealistic, continuously changing measured values indicate poor contact, a damaged

protective conductor or a broken core in the probe cable (21) in the event that it has been

excessively stressed! If brief or continuous interruption of the protective conductor occurs

during the manual step of the continuity test, the limit value indicator at the

METRATESTER 5 + test instrument lights up and an acoustic warning signal is generated. In

such cases, the interruption must be repaired in a professional manner and measurement

must be repeated.

Measurement of protective conductor resistance is of course impossible for devices which

are not equipped with a protective conductor (e.g. protection class II and III devices).

6.2 Measuring Insulation Resistance

This test must be performed on all DUTs for which all insulation is checked during testing

without applying mains voltage (practically all DUTs without electrically actuated switches

and relays). If this is only possible after applying mains voltage, testing in accordance with

section 6.3.2/section 6.4.1 must be performed. If there is any doubt about performing

measurement with insulation voltage, for example at electronic devices, measurement must

also be performed in accordance with section 6.3.2/section 6.4.1.

It must be assured that all switches, thermostats etc. are closed!

Do not touch the instrument’s terminal contacts during insulation resistance

measurements!

If nothing has been connected to the terminal contacts, or if a resistive load component has

been connected for measurement, your body would be exposed to a current of approx.

1 mA at a voltage of 500 V. The resulting electrical shock is not life endangering. However,

the noticeable shock may lead to injury (e.g. resulting from a startled reaction etc.).

If measurement is performed at a capacitive object such as a long cable, it becomes

charged with up to approx. 500 V! Touching such objects is life endangering!

In accordance with DIN VDE 0701-0702, L1, L2, L3 and N (short-circuited) are measured

against PE during this test (connection per section 5.2).

Ð Switch the DUT on in all functions.

Ð Set the NETZ-VDE switch to “VDE”.

Ð Set the measuring function selector switch (6) to the “20 MOhm” range.

Ð Read the measured value in MOhms at from the LCD panel, and compare it to

permissible values in accordance with DIN VDE 0701-0702.

GMC-I Messtechnik GmbH 13

Limit Values per DIN VDE 0701-0702, Part 1: 2008

Attention!

!

Note!

Limit Value, M Min. Display Value

0.25 0.33

0.3 0.38

0.5 0.60

1.0 1.15

2.0 2.25

7.0 7.75

10.0 11.05

Device Type Limit Values Min. Display Value

Protection class I devices 1M 1.15 M

Protection class I devices with heating elements 0.3 M

Protection class II devices 2.0 M 2.25 M

Protection class II I and battery powered devices

1)

If the limit value is fallen short of, an equivalent leakage current measurement must be performed and

passed.

1)

1000/V and 250 k

0.38 M

Note: “OL” at the display means measured value > 20 M.

Evaluation of Measured Values

Device measuring error must be taken into

consideration in order to make absolutely sure that

the limit values for insulation resistance have not

been fallen short of. The following table allows for

calculation of the required minimum value for

insulation resistance which must be displayed at the

device in consideration of maximum measuring error

(under nominal conditions of use), in order to assure

that the required limit values are not fallen short of

(DIN VDE 0413, part 1). Intermediate values can be

interpolated.

Insulation resistance must be measured with a test probe connected to the

appropriate socket (4) in accordance with figure 5.2 at all exposed, conductive parts

for protection class II and III devices, as well as for battery powered devices.

This test is omitted for protection class III and battery powered devices which fulfill the

following conditions:

Nominal power 20 VA

Nominal voltage 42 V

Batteries must be disconnected during testing of battery powered devices.

In the event of long-term short-circuiting in the 20 MOhm range, measuring current is

reduced after approximately 10 minutes. This is indicated by a triangle which appears

at the top left-hand portion of the display panel. A nominal current of 1 mA, as

specified by DIN VDE 0413 and DIN VDE 0701-0702, is no longer assured when the

triangle appears. After the short-circuit has been eliminated and a brief cool-down

period has elapsed, the triangle disappears and measurements once again comply

with VDE conditions.

14 GMC-I Messtechnik GmbH

6.3 Measuring Protective Conductor Resistance

Attention!

!

Note!

6.3.1 Equivalent Leakage Current

In accordance with DIN VDE 0701-0702:2008, protective conductor resistance must be

measured after the performance of the insulation resistance measurement. We recommend

equivalent leakage current measurement.

The limit value is:

• 3.5 mA for protection class I devices whose exposed conductive parts are connected to

the protective conductor.

• 1 mA per kW of heating power for protection class I devices with heating elements with a

total connected load of greater than 3.5 kW , whose exposed conductive parts are

connected to the protective conductor.

Do not touch the instrument’s terminal contacts during equivalent leakage current

measurement!

Ð Connection is the same as for insulation resistance measurement.

Ð Set the NETZ-VDE switch to “VDE”.

Ð Set the measuring function selector switch to “I

Ð Switch all DUT functions on and make sure, for example, that all thermostat contacts

and the like are closed.

Ð Read the measured value in “mA” from the LCD panel.

In accordance with DIN VDE 0701-0702, the displayed current value between parts to

which voltage is applied during operation and exposed metal parts may not exceed

3.5 mA, or 1 mA per kW for devices with 3.5 kW heating power.

20 mA”.

EA

Leakage current measurement in accordance with the respective device regulations is

usually not possible, because the device would have to be set up in an electrically

isolated fashion, or connected to an earth isolated power supply to this end.

Equivalent leakage current is measured for this reason. Resultant measured values

are not directly comparable with the leakage current values set forth in the device

regulations.

GMC-I Messtechnik GmbH 15

6.3.2 Differential Current Measurement for Protection Class I Devices

Attention!

!

Note!

This test must be executed for all devices for which it is not possible to measure insulation

resistance at all safety relevant parts (practically all DUTs with electrically actuated switches

and relays), or where there is any doubt regarding measurement with insulation voltage, for

example at electronic devices. If the DUT is equipped with a non-polarized mains plug, the

test must be performed with the mains plug poled in both directions. The measurement of

residual current includes the sum of instantaneous current values in L1, L2, L3 and N.

The DUT is placed into operation, and this test may not be performed until the

protective conductor test has been passed.

Ð Turn off the device under test.

Plug the DUT into the appropriate surface mount socket (15, 17, 18) at the test case.

Ð

Ð Set the L1/L2/L3 switch (2) to “L1”.

Ð Set the NETZ-VDE switch (1) to “NETZ”.

Ð Signal lamps L1, L2 and L3 (19) indicate the presence of line voltage.

Ð Place the device under test into service by switching it on.

Ð Set the measuring function selector switch (6) at the METRATESTER 5+ test instrument

to the “I

at the test instrument.

The limit value is 3.5 mA, or 1 mA per kW of heating power for DUTs with heating elements

with a with a total connected load of greater than 3.5 kW.

20 mA” position and read the differential current value in mA from the display

Diff

For devices with permissible protective conductor current of greater than 3.5 mA in

accordance with the device standards, special protective conductor connection must

be observed and the following warning sign must be present: “High leakage current!

– connect protective conductor before connecting to the mains” (DIN 4844).

Measurements must be performed with the mains plug poled in both positions (if the

plug is reversible). The larger of the two measured values is deemed valid. The

possibility of a symmetrical error must be taken into consideration with multi-phase

devices. Data cables, as well as gas and water supply lines with potential to ground,

for example, do not have to be disconnected from the DUT for this measurement.

If no device under test has been connected, numbers appear at the digital display which do

not represent any actual measured value.

16 GMC-I Messtechnik GmbH

6.4 Measuring Contact Current

Attention!

!

Note!

6.4.1 Contact Current Measurement – Differential Current

This test must be executed for all protection class II devices, as well as protection class I

devices with exposed conductive parts which are not connected to the protective conductor

(practically all DUTs with electrically actuated switches and relays). If the DUT is equipped

with a non-polarized mains plug, the test must be performed with the mains plug poled in

both directions. Connection per section 5.1.

The larger of the two measured values is deemed valid. Testing in accordance with the

differential current measuring method.

The DUT is placed into operation.

Ð Turn off the device under test.

Ð Plug the DUT in to the appropriate surface mount socket at the test case.

Ð Connect a measurement cable with test probe to the socket/terminal (5), and contact all

exposed conductive parts at the DUT, or all conductive parts which are not connected to

the protective conductor at protection class I devices.

Ð Set the L1/L2/L3 switch (2) to “L1”.

Ð Set the NETZ-VDE switch (1) to “NETZ”.

Ð Signal lamps L1, L2 and L3 (19) indicate the presence of line voltage.

Ð Place the device under test into service by switching it on.

Ð Set the measuring function selector switch (6) at the METRATESTER 5 + test instrument

to the “I

at the test instrument.

20 mA” position and read the differential current value in mA from the display

Diff

The limit value is 0.5 mA.

6.4.2 Testing in Accordance with the Direct Method

The DUT can remain connected to the mains for this test. When testing in accordance with

DIN VDE 0701-0702, DUTs with external connections such as data cables etc. can be

tested within their entire configuration at the installation site. However, due to the fact that

this test does not provide any indication as to the safety of the device under test, complete

testing via the connector sockets at the test case must be performed as soon as

disconnection from the mains and the connector cables is possible – insofar as permitted by

the device.

If the DUT is defective, the electrical system’s RCD (residual current circuit breaker)

may be tripped during this test which would result in interruption of supply power.

Ð Connect the test case to an electrical outlet within the same power supply circuit to

which the device under test is also connected to this end.

GMC-I Messtechnik GmbH 17

Ð Connect a measurement cable with test probe to the socket/terminal (5), and contact all

Note!

exposed conductive parts at the DUT, or all conductive parts which are not connected to

the protective conductor at protection class I devices.

Ð Set the measuring function selector switch (6) at the METRATESTER 5+ test instrument

to the “I

test instrument.

The limit value is 0.5 mA.

If no device under test has been connected, numbers appear at the digital display which do

not represent any actual measured value.

2 m” position and read the contact current value in mA from the display at the

A

6.5 Measuring Load Current and Voltage at the Consumer

Ð Turn off the device under test.

Ð Plug the DUT into the appropriate surface mount socket (15, 17, 18) at the test case.

Ð Set the L1/L2/L3 switch (2) to “L1”.

Ð Set the NETZ-VDE switch (1) to “NETZ”.

Ð Signal lamps L1, L2 and L3 (19) indicate the presence of line voltage.

Ð Place the device under test into service by switching it on.

Ð Set the measuring function selector switch (6) to “16 A~” for the measurement of current

consumption, and to “250 V~” for the measurement of voltage against the neutral

conductor.

Ð The phase (L1, L2 or L3) at which current consumption and voltage is to be measured

can be selected for three-phase consumers with the measuring selector switch (2).

During measurement of current consumption by switching to the various phases, the

DUT may be switched off if it’s equipped with, for example, an undervoltage trigger.

The DUT must be switched back on again in this case.

18 GMC-I Messtechnik GmbH

7 Testing Extension Cables with the VL2 E Accessory

Testing in accordance with the wiring diagram in section 5.6

7.1 DIN VDE Tests for Extension Cables

Always set the NETZ-VDE switch (1) to “VDE” for these tests.

Protective Conductor Resistance Measurement

Perform test as described in section 6.1. The probe cable (21) is connected to the SI socket

in the VL2 E test adapter.

Insulation Resistance Measurement

The rotary selector switch remains in position 1.

Perform test as described in section 6.2. A value of 2 MOhm should not be significantly

exceeded.

7.2 Function Test for Extension Cables

Execute this test in accordance with the operating instructions for the 0701-0702 test

instrument, using the test described under “Measuring Insulation Resistance”.

The following characteristics can be tested with this procedure:

• Testing of AC cables for short-circuiting and continuity and

• Additional testing of 3-phase cables and caravan cables for reversed wiring of L1, L2, L3

and N (clockwise rotation).

Ð Set the rotary selector switch to position 2.

Ð Read the measured value.

GMC-I Messtechnik GmbH 19

The display can settle in within a range of 0 Ohm (if all cores are short-circuited) up to, for

example, infinity (in the event of overload) if one core is interrupted. Due to good insulation

assured by undamaged cables, a test value of 10 MOhm with a tolerance of 20% has been

established for this rational test procedure.

All values within a range of 8 to 12 MOhm thus indicate that the test has been passed.

In the event of an error, the actual defect, i.e. core short-circuiting, core interruption, core

reversal or too little insulation, must be determined. Do not touch the connector plugs of long

extension cables after testing, because they may be electrically charged.

8 Continuity Test with Extra-Low Voltage

Objects can be tested for continuity with the help of the “Durchgang” (continuity) indicator

lamp (10). Connect the DUT to the two connector sockets (11) to this end. Testing is

conducted with safety extra-low voltage of no greater than 33 V AC.

9 Display and Indicators at the Test Instruments

METRATESTER 5+ Display and Indicating Devices

PE Indicator Lamp

Indicates whether or not voltage is present.

Error Lamp

The red error lamp indicates exceeded limit values when measuring protective conductor

current, insulation resistance, equivalent leakage current, contact current, leakage current

and differential current.

Piezo Buzzer

In the event that the error lamp lights up in order to indicate that the respective, critical limit

value has been exceeded, the buzzer also generates an acoustic signal.

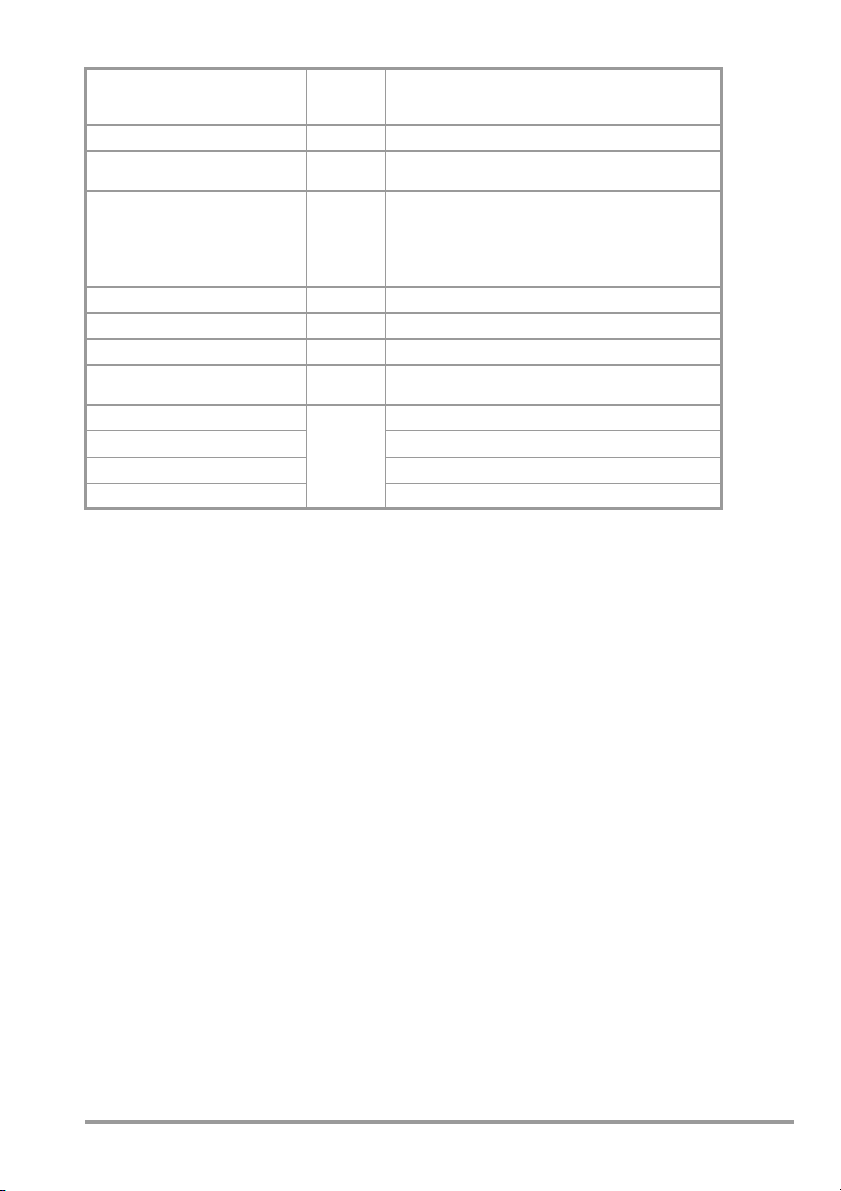

9.1 Indication of Errors and Limit Values

Error Message Condition PE Indicator Lamp

Mains protective conductor potential U

20 GMC-I Messtechnik GmbH

25 V When the contact surface is

B

touched

The following limit values are indicated:

Indication of Exceeded Limit Value

Measurement

Protective conductor resistance

Insulation

resistance

Equivalent leakage

current

Leakage/contact

current (verification of absence of

voltage)

Differential current I

1)

Resistance between housing and mains plug for connector cables up to 5 meters long

2)

0.1 is added for each additional 7.5 meters of cable length, up to a maximum of 1

3)

For protection class I devices with activated heating elements

(if heating power > 3 kW and R

4)

This limit value refers to all-pole switches (corresponds to doubling the limit value or cutting actual

Fault Condition per

Standard

>0.3

R

SL

>1

R

SL

3)

Heater

R

<0.3M

ISO

PCI:

R

<1.0M

ISO

PCII:

R

<2.0M

ISO

>3.5mA ——

I

EA

1)

2)

:

Continuously Lit

Red Error Lamp

>0.3 —

>1

<0.5M

<2.0M —

—<2.0M —

>7.0mA

>0.25mA >0.25mA —

I

A

I

>0.5mA >0.5mA

A

3.5 mA —

Diff

<0.3M: leakage current measurement is required)

ISO

measuring current in half)

at the Test Instrument

Display of Limit

Values

4)

Continuous

Buzzing (beeper)

10 Technical Data

10.1 Test case

Power Supply

Nominal line voltage 230/400 V 50 Hz

Mains connection 230 V 1P+N+PE 16 A earthing contact plug with coupling socket

Throughput rating:

Rated input per phase

Measuring category 300 V CAT II

Pollution degree 2

RCD (RCCB)

4-pole, IN 25 A, IA 0.03 A

Protection, case: IP 40 per DIN VDE 0470, part 1, connections: IP 20

Dimensions (WxHxD) Approx. 380 x 300 x 220 mm with cover

Weight Approx. 7.5 kg

GMC-I Messtechnik GmbH 21

or

230/400 V 3P+N+PE 16 A CEE plug with coupling socket

or

230/400 V 3P+N+PE 32 A CEE plug with coupling socket, max. 16 A !

16/20 A, 10 min., protection class I

10.2 METRATESTER 5+ Test Instrument

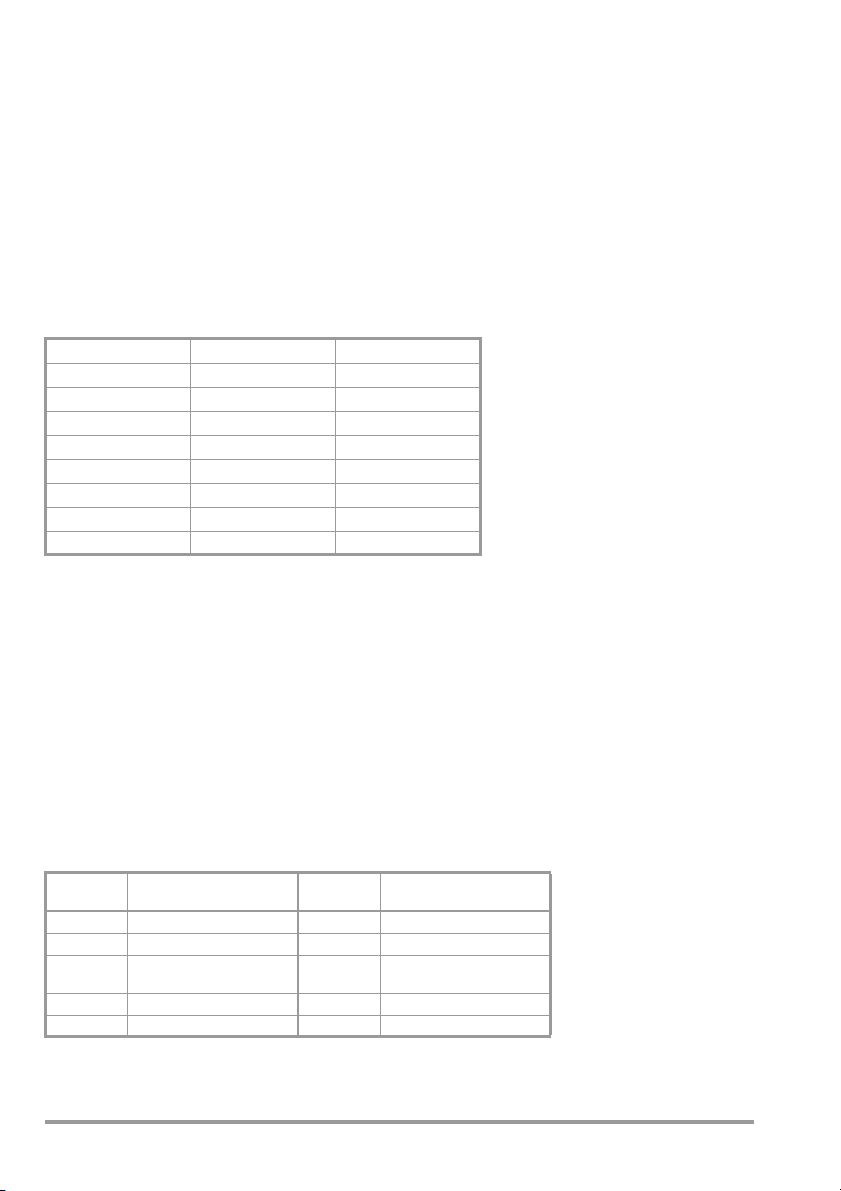

Measuring Qty. Measuring Range Resolution U

Protective

conductor

resistance

Insulation

resistance

Equivalent

leakage current,

Contact current

(verification of

absence of voltage by means of

current measurement)

Differential

current

0 19.99 10 m < 20 V — > 200 mA

0.05 19.99 M 10 K 600 V Approx.

0 19.99 mA 10 A 28 V 2k <20mA —

0 1.999 mA 1 A2k

0,01 19.99 mA ~ 10 A

no-load

R

i

100 k

I

K

<10mA > 1 mA

Measurements During Operation

Measuring Quantity Measuring Range Resolution

Line voltage 207 253 V ~ 1 V

Load current via mains outlet 0 16.00 A ~ 10 mA

Overload Capacity

Load current via mains outlet, differential current 19 A, 5 min.

All other measured quantities 250 V continuous

Intrinsic Uncertainty and Measuring Uncertainty

Measured Quantity Intrinsic Uncertainty Measuring Uncertainty

Protective conductor resistance

Insulation resistance, 0 19.99 M

Equivalent leakage current

Verification of absence of voltage by means

of current measurement (contact current)

Differential current

Line Voltage

Load current via mains outlet

(2.5% rdg. + 2 d) (10% rdg. + 5 d)

(2.5% rdg. + 2 d) (10% rdg. + 5 d)

(2.5% rdg. + 2 d) (10% rdg. + 5 d)

(2.5% rdg. + 2 d) (10% rdg. + 5 d)

(4% rdg. + 5 d) (10% rdg. + 5 d)

(2.5% rdg. + 2 d) (10% rdg. + 5 d)

(2.5% rdg. + 2 d) (10% rdg. + 5 d)

I

N

Reference Conditions

Ambient temp. + 23 C 2K

Relative humidity 40 60%

Line voltage 230 V 1%

Measured quantity

frequency 50 Hz 0.2 %

Measured quantity

waveshape Sine (deviation between effective and rectified value: 0.5%)

22 GMC-I Messtechnik GmbH

Influencing Quantities and Influence Error

Influencing Quantity /

Sphere of Influence

Change of position E1

Change to test equipment supply

voltage

Temperature fluctuation

0 21 C and 25 40 C

Amount of current at DUT E4

Low frequency magnetic fields E5

DUT impedance I6

Capacitance during insulation

measurement

Waveshape of measured current

49 51 Hz

45 100 Hz

Designation

per DIN VDE

0404

E2

E3

E7

E8

Influence Error

% of the measured values

—

2.5

Specified influence error valid starting with

temperature changes as of 10 K:

1 for protective conductor resistance

0.5 for all other measuring ranges

2.5

2.5

2.5

2.5

2 with capacitive load (for equiv. leakage current)

1 (for contact current)

2.5 for all other measuring ranges

Display and Indicating Devices

LCD

Display range 0 1999 digits, 3½ places

Character height 17 mm and special characters

Overflow Indicated by displaying “OL”

Overtemp. R

ISO

PE Indicator Lamp

Indicates whether or not voltage is present.

In case of long-term short-circuit:

“R

” and “M” segments blink

ISO

Error Lamp

The red error lamp indicates exceeded limit values when measuring protective conductor

current, insulation resistance, equivalent leakage current, contact current, leakage current

and differential current.

Piezo Buzzer

In the event that the error lamp lights up in order to indicate that the respective critical limit

value has been exceeded, the buzzer also generates an acoustic signal.

Power Supply

Line voltage 230 V / 50 Hz

Throughput rating Max. 3700 VA, depending upon load at the mains outlet

GMC-I Messtechnik GmbH 23

Electrical Safety

Protection class II

Nominal line voltage 230 V

Test Voltage Mains + PE (mains) + 2 mA socket for testing for absence of voltage

at test socket, connector sockets for phase and protective

conductors, as well as clip: 3 kV mains to PE (mains) + 2 mA socket

1.5 kV

Measuring category

II

Pollution degree 2

Safety shutdown If test instrument overheats

Electromagnetic Compatibility (EMC)

Product standard EN 61326-1: 2006

Interference Emission Class

EN 55022 A

Interference Immunity Test Value Feature

EN 61000-4-2

EN 61000-4-3 10 V/m B

EN 61000-4-4

EN 61000-4-5

EN 61000-4-6 Mains connection – 3 V B

EN 61000-4-11 0.5 period / 100% A

Contact/atmos. – 4 kV / 8 kV

Mains connection – 2 kV

Mains connection – 1 kV

B

B

A

Ambient Conditions

Operation 10 ... + 55 C

Storage 25 ... + 70 C

Humidity Max. 75%, no condensation allowed

Elevation To 2000 m

Mechanical Design

Dimensions W x H x D: 190 x 140 x 95 mm

Weight 1.3 kg

Protection Housing: IP 40, connections: IP 20

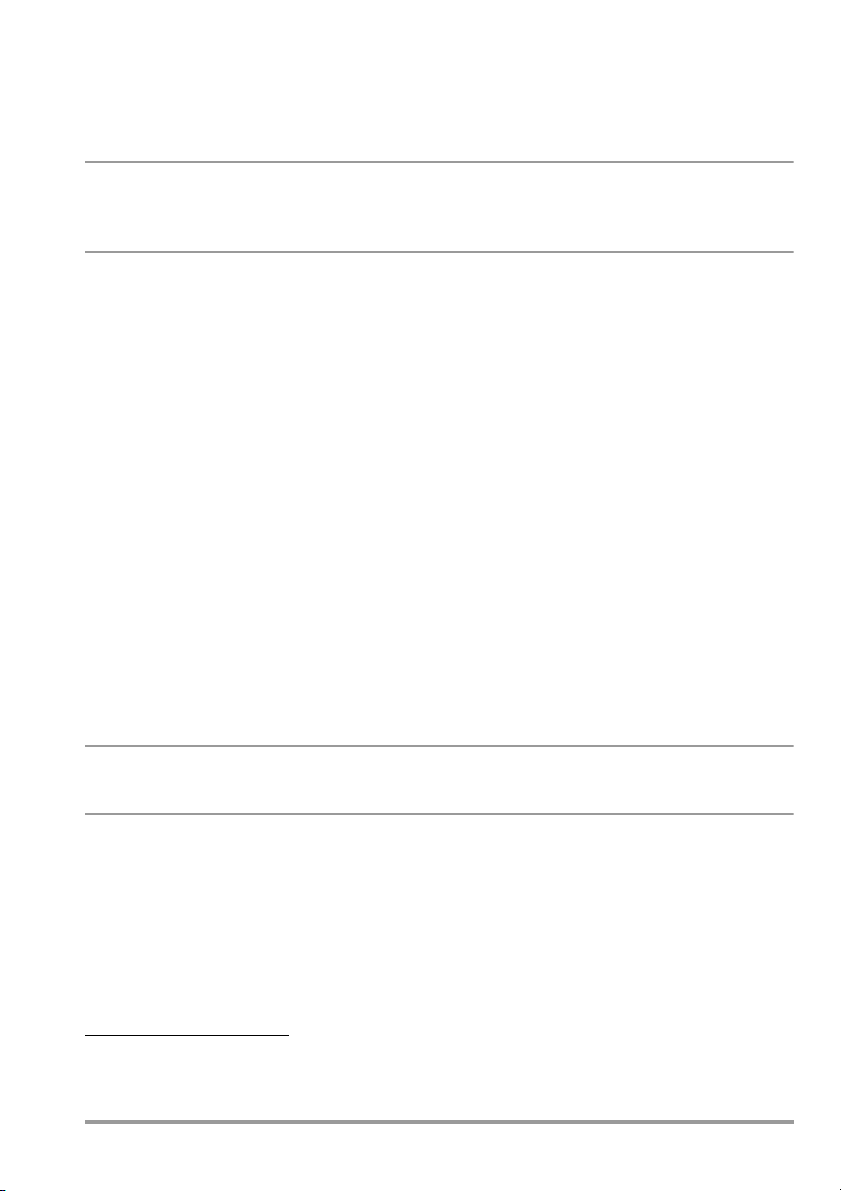

Table Excerpt Regarding Significance of IP Codes

IP XY

st

char. X)

(1

0 not protected 0 not protected

1 50.0 mm diameter 1 vertically falling drops

2 12.5 mm diameter 2 vertically falling drops with

3 2.5 mm diameter 3 spraying water

4 1.0 mm diameter 4 splashing water

24 GMC-I Messtechnik GmbH

Protection against

foreign object entry

IP XY

(2nd char. Y)

Protection against the

penetration of water

enclosure tilted 15°

11 Maintenance – Recalibration

Note!

Note!

11.1 Housing Maintenance

No special maintenance is required. Keep outside surfaces clean and dry. Use a slightly

dampened cloth for cleaning. Avoid the use of solvents, cleansers and abrasives.

If the test case has not been used for a long period of time, the switches may

demonstrate increased contact resistance depending upon storage conditions.

If this is the case, actuate the switches several times.

11.2 Recalibration

The respective measuring task and the stress to which your measuring instrument is subjected affect the ageing of the components and may result in deviations from the guaranteed

accuracy.

If high measuring accuracy is required and the instrument is frequently used in field applications, combined with transport stress and great temperature fluctuations, we recommend a

relatively short calibration interval of 1 year. If your measuring instrument is mainly used in the

laboratory and indoors without being exposed to any major climatic or mechanical stress, a

calibration interval of 2-3 years is usually sufficient.

During recalibration* in an accredited calibration laboratory

(DIN EN ISO/IEC 17025) the deviations of your instrument in relation to traceable standards

are measured and documented. The deviations determined in the process are used for correction of the readings during subsequent application.

We are pleased to perform DAkkS or factory calibrations for you in our calibration laboratory.

Please visit our website at www.gossenmetrawatt.com ( Company DAkkS Calibration

Center or FAQs Calibration questions and answers).

By having your measuring instrument calibrated regularly, you fulfill the requirements of a

quality management system per DIN EN ISO 9001.

These tests can be performed on-site with the SECU-cal 10 calibration adapter

accessory.

*

Verification of specifications or adjustment services are not part of the calibration. For products from

our factory, however, any necessary adjustment is frequently performed and the observance of the relevant specification is confirmed.

GMC-I Messtechnik GmbH 25

11.3 Periodic Self-Test of the Connector Cable for Protective Conductor Continuity

Connect the probe cable (21) to a grounding contact which has been previously tested for

absence of voltage (e.g. at an electrical outlet), and which is connected to the protective

conductor in the connector cable, and set the NETZ-VDE switch (1) to “NETZ”. Then

measure protective conductor resistance as described in section 5.4. If an excessively high

protective conductor resistance value is displayed at the LCD panel or if overloading is

indicated (only “O.L” appears), protective conductor resistance is too high or the protective

conductor is interrupted. Eliminate the interruption (in the cable or at the NETZ-VDE switch).

11.4 Testing the Integrated RCD (residual current circuit breaker)

Test on a regular basis. The integrated RCD (residual current circuit breaker) can be tested

by pressing the test key. Breaking current value and time can be measured with test

instruments for DIN VDE 0413, part 6.

11.5 Fuse Replacement

All fuses can be accessed from outside. Only fuses with the breaking characteristics and

rated current values specified on the front panel may be used.

11.6 Return and Environmentally Sound Disposal

The METRATESTER 5+3P is a category 9 product (monitoring and control instrument) in

accordance with ElektroG (German electrical and electronic device law). This device is not

subject to the RoHS directive.

In accordance with WEEE 2002/96/EG and ElektroG, we identify our electrical

and electronic devices (as of Aug. 2005) with the symbol in accordance with

DIN EN 50419 which is shown at the right. Devices identified with this symbol

may not be disposed of with the trash.

Please contact our service department regarding the return of old devices (see

address below).

26 GMC-I Messtechnik GmbH

12 Repair and Replacement Parts Service

Calibration Center * and Rental Instrument Service

If required please contact:

GMC-I Service GmbH

Service Center

Thomas-Mann-Str. 20

90471 Nürnberg, Germany

Phone +49 911 817718-0

Fax +49 911 817718-253

E-mail service@gossenmetrawatt.com

www.gmci-service.com

This address is only valid in Germany. Please contact our representatives or subsidiaries for

service in other countries.

* DAkkS Calibration Laboratory for Measured Electrical Quantities

D-K-15080-01-01 accredited per DIN EN ISO/IEC 17025:2005

Accredited measured quantities: direct voltage, direct current values, DC resistance, alternating voltage, alternating

current values, AC active power, AC apparent power, DC power, capacitance, frequency and temperature

Competent Partner

GMC-I Messtechnik GmbH is certified in accordance with DIN EN ISO 9001:2008.

Our DAkkS calibration laboratory is accredited by the Deutscher Kalibrierdienst (German Calibration Service) in accordance with DIN EN ISO/IEC 17025:2005 under registration number

D-K-15080-01-01.

We offer a complete range of expertise in the field of metrology: from test reports and factory

calibration certificates, right on up to DAkkS calibration certificates.

Our spectrum of offerings is rounded out with free test equipment management.

An on-site DAkkS calibration station is an integral part of our service department. If errors are

discovered during calibration, our specialized personnel are capable of completing repairs

using original replacement parts.

As a full service calibration laboratory, we can calibrate instruments from other

manufacturers as well.

GMC-I Messtechnik GmbH 27

13 Product Support

If required please contact:

GMC-I Messtechnik GmbH

Product Support Hotline

Phone +49 911 8602-112

Fax +49 911 8602-709

E-mail support@gossenmetrawatt.com

Edited in Germany • Subject to change without notice • PDF version available on the Internet

GMC-I Messtechnik GmbH

Südwestpark 15

90449 Nürnberg •

Germany

Phone: +49 911 8602-111

Fax: +49 911 8602-777

e-mail: info@gossenmetrawatt.com

www.gossenmetrawatt.com

Loading...

Loading...