Page 1

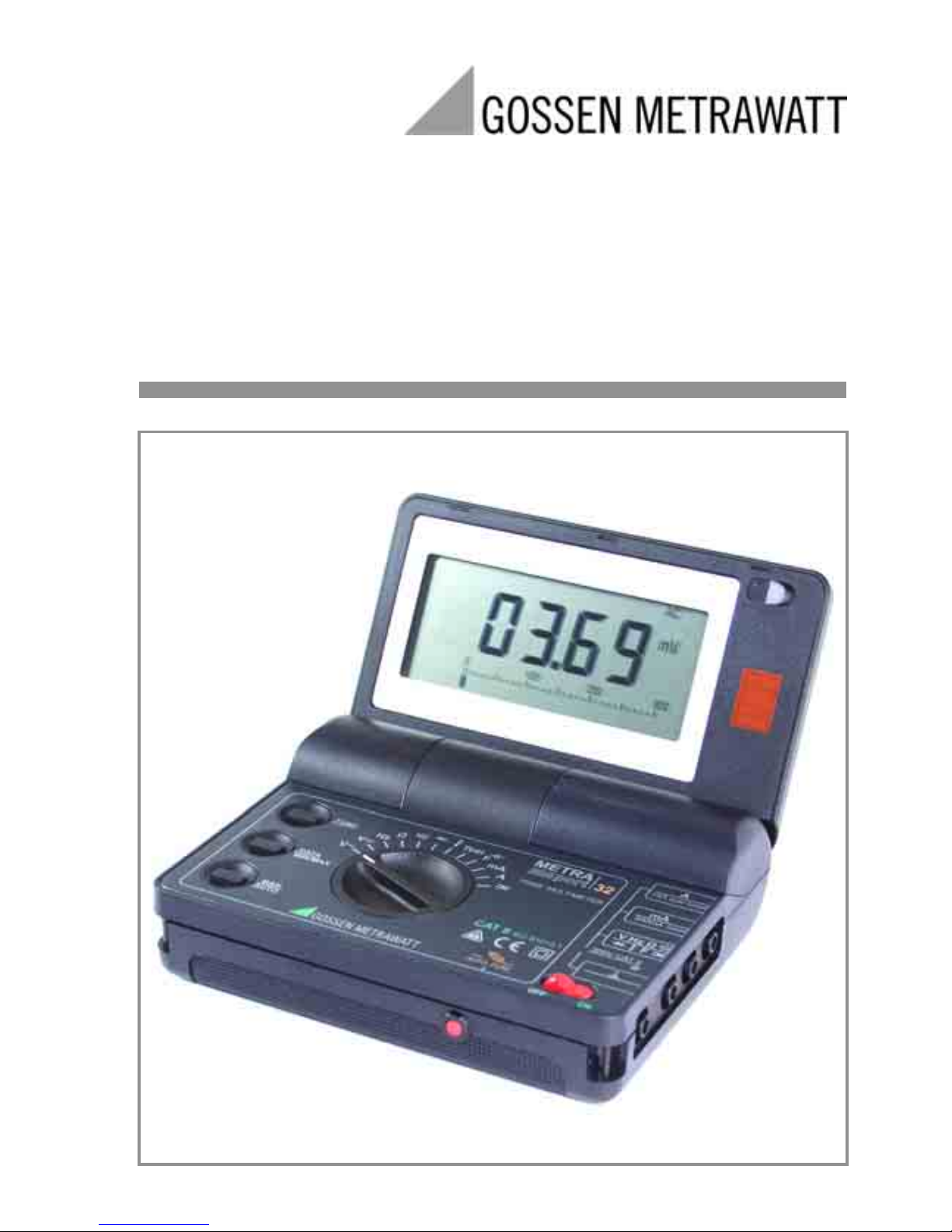

METRAport

32 XS

Digital Multimeter

3-349-281-02

6/3.04

Operating Instructions

Page 2

2 GOSSEN METRAWATT GMBH

Control Elements

1LCD

2 Battery compartment cover

3 “Max. 15 A (max. 5 min)” connector jack for highest current range

4 “Max. 300 mA” connector jack for mA range

5 Connector jack for all measuring ranges except current measuring ranges

6“⊥” connector jack for all measuring ranges

7 OFF/ON: ON/OFF switch

8 Resettable miniature circuit breaker (AUTO FUSE)

9 Rotary switch for function selection

10 Eyelet for carrying strap

11 MAN/AUTO: Key for manual and automatic measuring range selection

12 DATA and MIN/MAX: Key for measured value storage

13 FUNC: Multifunction key

3

4

5

6

1

2

7

9

10

12

13

11

8

3

4

5

6

Page 3

GOSSEN METRAWATT GMBH 3

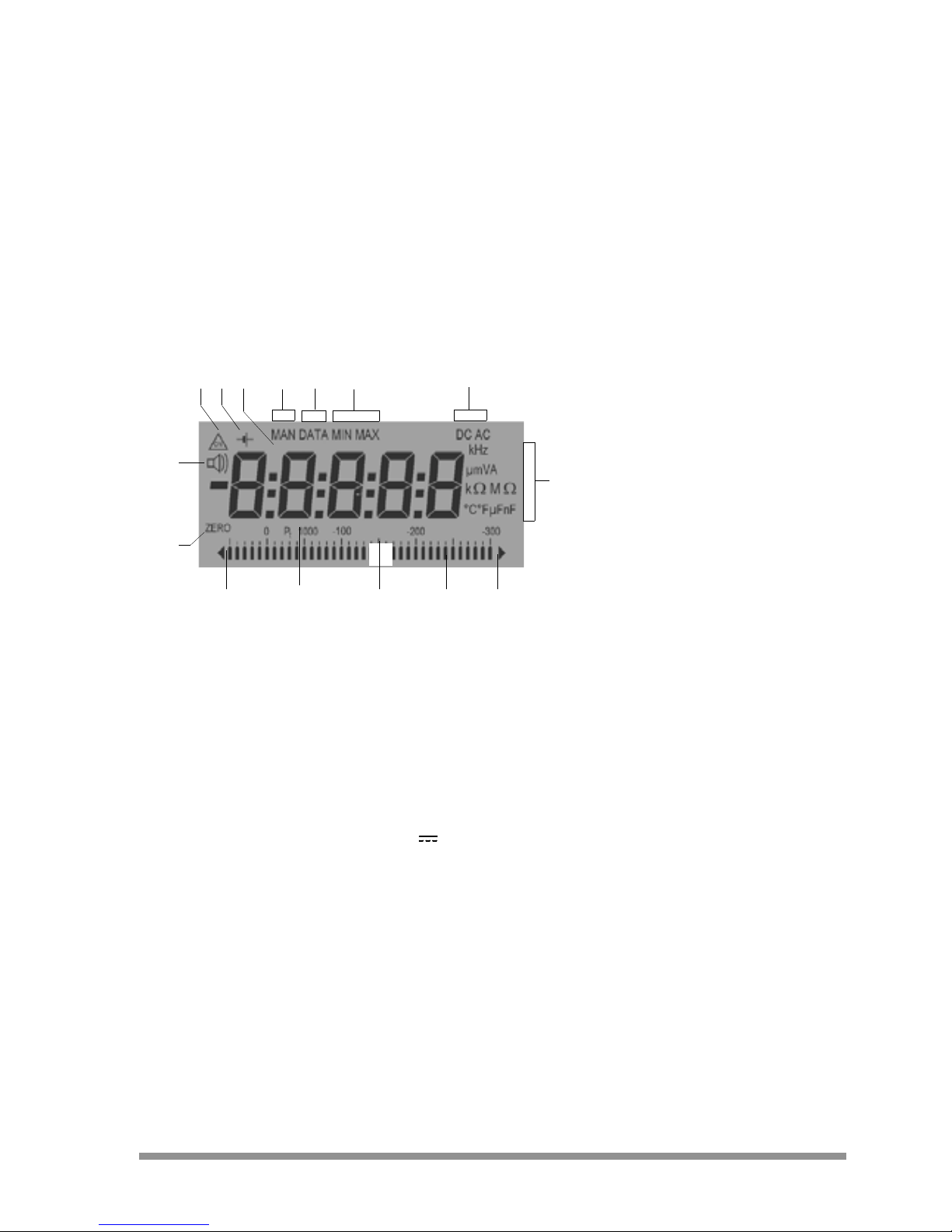

Digital Display Symbols

1 Continuous operation

2Low battery

3 Digital display with indication of decimal place and polarity

4 Manual measuring range selection

5 Display memory, “freeze measured value”

6MIN-MAX storage

7 Selected current type, DC

() or AC (~)

8Unit of measure

9Over-ranging

10 Pointer for analog display

11 Analog display scale

12 Resistance thermometer: Pt100 / Pt1000

13 Negative analog display range exceeded

14 Zero balancing active

15 Acoustic signal activated (e.g. for continuity testing)

134

7

8

9101113

14

15

5 62

12

Page 4

4 GOSSEN METRAWATT GMBH

Contents......................................................................................................................... Page

1 Safety Features and Precautions ............................................................................5

2 Initial Start-Up .........................................................................................................7

3 Selecting Measuring Functions and Measuring Ranges .........................................8

3.1 Automatic Measuring Range Selection ........................................................................8

3.2 Manual Measuring Range Selection – MAN/AUTO Key .................................................8

3.3 Quick Measurements .................................................................................................9

4 Display (LCD) ...........................................................................................................9

4.1 Digital Display ...........................................................................................................9

4.2 Analog Display ..........................................................................................................9

5 Measured Value Storage – DATA / MIN-MAX Key .................................................10

5.1 DATA (hold / compare) .............................................................................................10

5.2 Storage of Minimum and Maximum Values “MIN-MAX” with Time Stamp ....................11

6 Voltage Measurement ...........................................................................................12

6.1 Transient Overvoltages .............................................................................................13

6.2 Measuring Voltages of Greater than 300 V ................................................................13

7 Current Measurement ...........................................................................................13

7.1 Current Measurement with Current Transformers with Voltage Output ........................15

8 Resistance Measurement ......................................................................................16

9 Continuity Testing .................................................................................................16

10 Diode Testing ........................................................................................................17

11 Capacitance Measurement ...................................................................................18

12 Frequency Measurement ......................................................................................18

13 Temperature Measurement with Pt100 and Pt1000 .............................................19

14 Characteristic Values .........................................................................................20

15 Maintenance .........................................................................................................26

15.1 Batteries .................................................................................................................26

15.2 Fuses ......................................................................................................................26

15.3 Housing ..................................................................................................................27

16 Multimeter Messages ...........................................................................................27

17 Repair and Replacement Parts Service

DKD Calibration Lab and Rental Instrument Service .............................................28

18 Product Support ....................................................................................................28

Page 5

GOSSEN METRAWATT GMBH 5

1 Safety Features and Precautions

You have selected an instrument which provides you with a high level of safety.

This instrument fulfills the requirements of the applicable European and national

EC guidelines. We confirm this with the CE marking. The relevant declaration of

conformity can be obtained from GOSSEN METRAWATT GMBH.

The analog/digital multimeter has been manufactured and tested in accordance

with safety regulations IEC 61010–1:2001/DIN EN 61010–1:2001/VDE 0411–

1:2002. If used for its intended purpose, safety of the operator, as well as that of

the instrument, is assured. However, safety cannot be guaranteed if the instrument is used improperly or handled carelessly.

In order to maintain flawless technical safety condition, and to assure safe use, it is

imperative that you read the operating instructions thoroughly and carefully before placing your instrument into service, and that you follow all instructions contained therein.

For your safety, as well as for protection of your multimeter, the instrument is

equipped with a miniature circuit breaker for the 15 A current measuring range.

Observe the following safety precautions

• The instrument may only be operated by persons who are capable of recognizing contact hazards and implementing appropriate safety precautions.

Contact hazards exist anywhere, where voltages of greater than 33 V RMS

may occur.

• Avoid working alone when taking measurements which involve contact

hazards. Be certain that a second person is present.

• Maximum allowable voltage between terminals (3), (4), (5), (6) and ground is equal to

300 V, category I I.

• The current measuring range A is equipped with a magnetic circuit breaker.

Max. allowable voltage at the meas. circuit (= miniature circuit breaker nominal

voltage) is equal to 240 V~ (AC) and 50 V (DC) against earth in the “mA”

and “A” ranges.

• The instrument may only be used for current measurement in power systems if the

electrical circuit is protected with a fuse or a circuit breaker with a rating of up to

20 A, and if nom. voltage at the system does not exceed 240 V~ (AC) or 50 V (DC).

In order to conform to the CAT requirements, an additional slow-blowing fuse link

(T16A/500V) has been fitted in series with the miniature circuit breaker which can

only be replaced by service personnel once it is tripped.

• Be prepared for the occurrence of unexpected voltages at devices under test

(e.g. defective devices). For ex., capacitors may be dangerously charged.

• Make certain that the measurement cables are in flawless condition, e.g. no

damage to insulation, no interruptions in cables or plugs etc.

• No measurements may be made with this instrument in electrical circuits

with corona discharge (high-voltage).

• Special care is required when measurements are made in HF electrical

circuits. Dangerous pulsating voltages may be present.

• Measurements under moist ambient conditions are not permitted.

Page 6

6 GOSSEN METRAWATT GMBH

• Be absolutely certain that the measuring ranges are not overloaded beyond

their allowable capacities. Limit values can be found in the “Measuring

Ranges” table in chapter 14, “Characteristic Values”.

Meaning of symbols on the instrument

Warning concerning a point of danger

(Attention: observe documentation!)

Earth

Continuous doubled or reinforced insulation

CAT II Measurement category I I device

Indicates CE conformity

DKD calibration certificate (red label):

Repairs, Parts Replacement and Balancing

When the instrument is opened, voltage conducting parts may be exposed. The

instrument must be disconnected from the measuring circuit before repair,

replacement of parts or balancing. If repair or balancing of a live, open instrument

is required, this may only be carried out by trained personnel who are familiar

with the dangers involved.

Defects and Extraordinary Strains

If it may be assumed that the instrument can no longer be operated safely, it

must be removed from service and secured against unintentional use.

Safe operation can no longer be relied upon:

• If the instrument demonstrates visible damage

• If the instrument no longer functions

• After long periods of storage under unfavorable conditions, e.g. humidity,

dust, excessive temperature (see “Ambient Conditions” on page 25).

!

Consecutive number

Registration number

Date of calibration (year - month)

German calibration service – calibration laboratory

B0730

01-08

DKD-K19701

Page 7

GOSSEN METRAWATT GMBH 7

2 Initial Start-Up

Installing Batteries

Attention!

!

Disconnect the instrument from the measuring circuit at all poles before

opening the battery compartment!

➭ Fold the instrument closed.

➭ Insert a coin or a similar object into the slot between the housing and the

battery compartment cover and press down until the battery compartment

cover snaps open.

➭ Fold the instrument open as far as it will go and remove the battery

compartment cover.

➭ Insert two 1.5 V mignon batteries per IEC R6 or IEC LR6 into the battery

compartment, making sure they are poled in accordance with the symbols.

➭ Replace the battery compartment cover and press into position until it

audibly snaps into place.

Switching the Instrument On

➭ Set the toggle switch to the “ON” position.

Activation of the instrument is acknowledged with an acoustic signal.

If the instrument has been shut down automatically, press either the FUNC, DATA or

MAN key to switch the multimeter back on, or set the toggle switch to the “OFF”

position and leave it there for at least 5 s before returning it to the “ON” position.

Note!

☞

Electrical discharges and high frequency interference may lead to erroneous display values, and may disable the measuring sequence. Reset

the instrument by switching it off and then, after 5 s, back on again.

Switching the Instrument Off Manually

➭ Set the toggle switch to the “OFF” position and fold the instrument closed. The

battery is automatically disconnected when the multimeter is folded closed.

Automatic Shutdown (standby)

The instrument switches itself off automatically if the measured value remains

constant for a long period of time (maximum measured value fluctuation approx.

0.8% of the measuring range per minute, or 1° Celsius or 1° Fahrenheit per

minute), and if no keys are activated for a period of approximately 10 minutes.

Shutdown is acknowledged by a brief acoustic signal. Exception: continuous

operation mode.

Note!

☞

Electrical power is supplied to the processor even after the instrument

has been switched off automatically. A closed-circuit current of about

300 µA remains. The instrument is only disconnected from the batteries

after it has been switched off manually with the toggle switch or with the

instrument folded.

Page 8

8 GOSSEN METRAWATT GMBH

Disabling Automatic Shutdown

The instrument can be switched to “CONTINUOUS ON”.

➭ Press the FUNC key while switching the instrument on with the toggle switch

until an acoustic signal is generated. The “CONTINUOUS ON” function

is indicated at the display with the symbol.

3 Selecting Measuring Functions and Measuring Ranges

3.1 Automatic Measuring Range Selection

The multimeter is equipped with auto-ranging for all measuring ranges except for

temperature measurement, diode and continuity testing and the 15 A range.

Auto-ranging is always activated as soon as the instrument is switched on.

Depending upon the measured quantity, the device automatically selects the

measuring range which allows for best possible resolution.

The instrument automatically switches to the next highest or next lowest

measuring range for the following measured quantities:

1)

28 digits - 1 digit for switching from the 300 kHz to the 3 kHz range

3.2 Manual Measuring Range Selection – MAN/AUTO Key

Auto-ranging can be deactivated and ranges can be set manually in accordance

with the following table.

The manual mode is deactivated by pressing and holding the MAN/AUTO key for

about 1 s, by turning the rotary switch or by switching the instrument off and

back on again.

Measuring Ranges Resolution

Switching to the next

highest range occurs

at ±(... d + 1 d)

Switching to the next

lowest range occurs

1)

at ±(... d –1 d)

V~, V , mA , mA~, Ω,

Hz,30 nF … 3 mF,

3 ¾ 3 100 280

Key

MAN/AUTO

Function

Acknowledgement

Visual Acoustic

brief Manual mode active: utilized measuring range is fixed MAN 1 x

brief

Switching sequence for:

V: 300 mV → 3V→ 30 V → 300 V → 600 V → 300 mV → …

mA: 300 µA → 3mA→ 30 mA → 300 mA → 300 µA …

Ω:30MΩ→ 300 Ω→ 3kΩ→ 30 kΩ→ 300kΩ→ 3MΩ→

30 MΩ…

F: 30 nF → 300 nF → 3 µF → 30 µF → 300 µF →

3000 µF → 30 000 µF → 30 nF …

Hz: 300 Hz → 3kHz→ 300 kHz → 300 Hz …

: 3.000 → 30,00 → 300,0 → 3,000 …

MAN 1 x

long Return to automatic measuring range selection — 2 x

Page 9

GOSSEN METRAWATT GMBH 9

3.3 Quick Measurements

If you wish to perform quicker measurements than those possible with the automatic measuring range selection function, make sure to establish the appropriate

measuring range:

•by manual measuring range selection, i. e. by selecting the measuring range

with the best resolution, see chapter 3.2.

or

•via DATA function, see chapter 5. After the first measurement, the proper

measuring range will be automatically determined so that measurements are

performed more rapidly from the second measured value onwards.

With both functions, the established measuring range is maintained for the subsequent series mode measurments.

4Display (LCD)

4.1 Digital Display

The measured value appears at the digital display with decimal point and sign (+

or -). The selected unit of measure and the type of current are displayed as well.

A minus sign is displayed to the left of the value for the measurement of zerofrequency quantities if the positive pole of the measured quantity is applied to the

⊥ jack.

If the measuring range upper limit is exceeded for the following measured

quantities, “OL” (overload) is displayed:

V (DC), I (DC), Ω, Hz, V~ (AC), I~ (AC), 30 nF

… 3 mF: 3099 digits

30 mF: 30999 digits

The digital display is refreshed at different rates for the individual measured

quantities (see “Display Refresh Rates” on page 24.

4.2 Analog Display

The analog display with simulated pointer and dynamic response equivalent to

that of a moving-coil mechanism, is refreshed 20 times per second. This display

is especially advantageous for the observation of measured value fluctuations,

and during balancing.

The analog display is equipped with a polarity indicator. The scale is extended 5

segments into the negative range for the measurement of zero-frequency

quantities, allowing for precise observation of measured value fluctuation around

the zero point. If the measured value exceeds the display range, a triangle is first

display at the left, and polarity at the display is reversed approximately 0.7

seconds later. If the measuring range is exceeded (> 3099 digits, in

the 30 mF range: > 30999) a triangle is displayed at the right.

Scaling at the analog display is automatic, which is quite helpful for manual

measuring range selection.

Page 10

10 GOSSEN METRAWATT GMBH

5 Measured Value Storage – DATA / MIN-MAX Key

5.1 DATA (hold / compare)

Measured values can be automatically frozen at the display with the DATA (hold)

function. This is especially useful when full attention is required for contacting the

measuring point. After the measured value has been applied to the multimeter

and the “condition” indicated in the following table has been fulfilled, the measured value is frozen at the digital display and an acoustic signal is generated.

The test probes can then be removed from the measuring point, and the measured value can be read from the digital display. If the measured value is less

than the limit value shown in the table, the instrument is reactivated for a new

measurement with the DATA hold function.

If the new measured value deviates from the previous value by less than 10 digits, the acoustic signal sounds twice (DATA compare).

1)

Reactivation occurs if the indicated measured value limits are fallen short of.

2)

Double acoustic signal after the first measured value has been stored.

Thereafter, double acoustic signal only occurs if the currently frozen value deviates from the

first stored value by less than 10 digits.

3)

Exception: 10% at 300 Ω

The DATA function has no effect on the analog display, which continues to

indicate the current measured value. However, it must be observed that the

decimal place is fixed when the digital display is “frozen”.

The DATA function can be deactivated by pressing and holding the DATA key for

about 1 second, by turning the function selector switch or by switching the

instrument off and back on again.

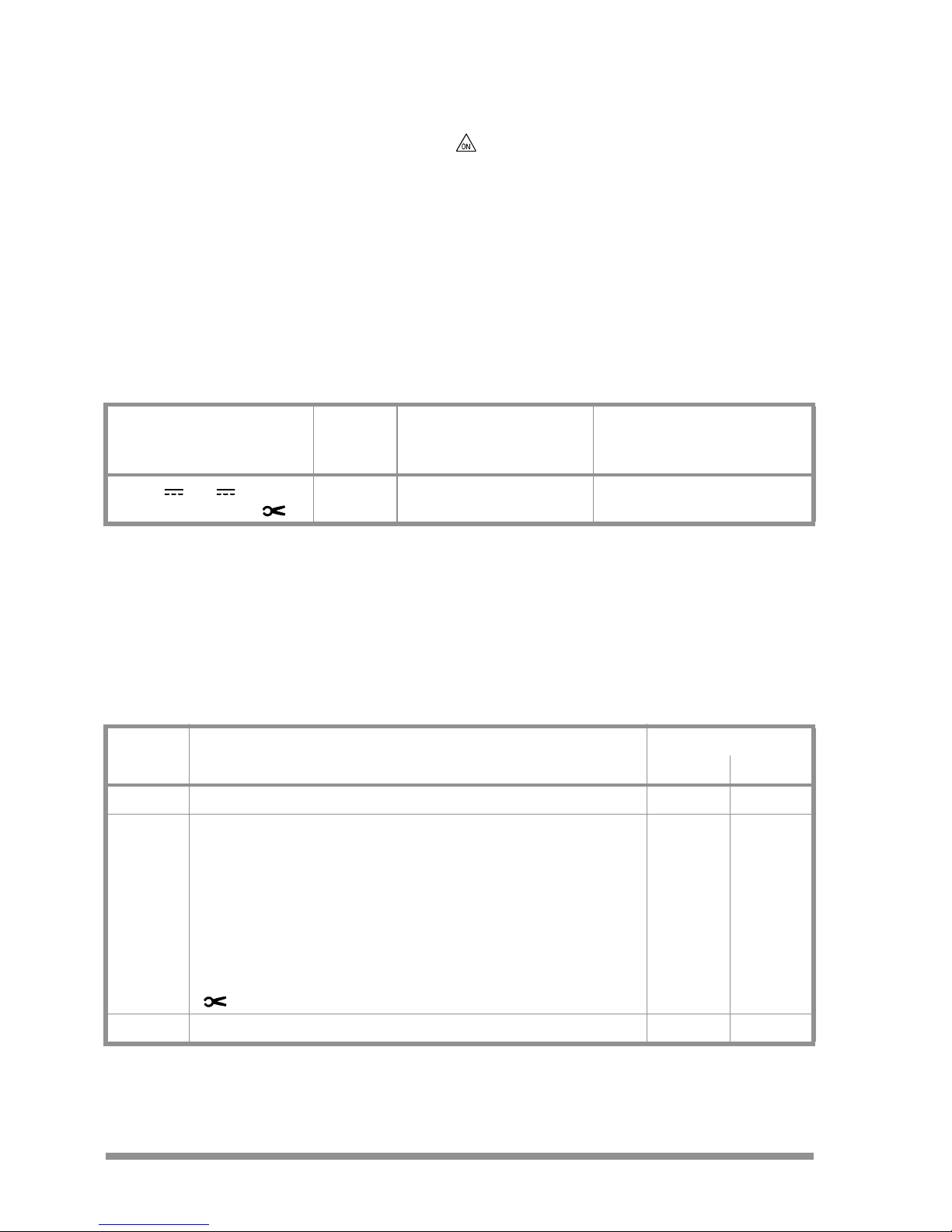

Function

DATA

Key

DATA

Condition Reaction at Instrument

Measuring

Ranges

Measured Value

Limits

(digits)

Display

Acoustic

Signal

Measured

Value, Digital

DATA

Activate brief blinks 1 x

Hold

V, A, Ω, F, H z

, ,

> 3.3% of range

OL

3)

> 3.3%

3)

of range

is

displayed

is

displayed

1 x

2 x

2)

Reactivate

1)

V, A, Ω, F, H z

, ,

< 3.3% of range

OL

3)

< 3.3% 3)

of range

frozen

measured

value

blinks

Deactivate long

is

cleared

is

cleared

2 x

Page 11

GOSSEN METRAWATT GMBH 11

5.2 Storage of Minimum and Maximum Values “MIN/MAX” with Time Stamp

Minimum and maximum measured values which occur at the input of the measuring instrument after the MIN/MAX function has been activated can be saved

to memory. The most important application for this function is the determination

of minimum and maximum values during long-term observation of measured

quantities (same function as the slave pointer at an analog display).

The “MIN/MAX” function can be activated for all measuring ranges.

The MIN/MAX function has no effect on the analog display, which continues to

indicate the current measured value.

Apply the measured quantity to the instrument and select the measuring range

before activating the MIN/MAX function.

Measuring ranges can only be selected manually after the function has been

activated, and stored MIN/MAX values and time stamps are deleted in doing so.

The MIN/MAX function is deactivated by pressing and holding the DATA key for

about 1 second, by turning the function selector switch or by switching the

instrument off and back on again.

Function

MIN-MAX

Key

DATA

MIN and MAX

Measured Values /

Time Stamps

Reaction at Instrument

Display

Acoustic

Signal

Measured Value,

Digital

MIN MAX

1.

Activate and

Save

2 x brief are saved

current measured

value

MIN and MAX

blink

2 x

2.

Save and

Display

brief

Storage continues

in background,

new MIN and MAX

values and time

stamps are displayed

stored MIN value MIN 1 x

brief

time elapsed to

stored MIN value

MIN and h:mm:ss 1 x

brief MIN and hh:mm 1 x

brief stored MAX value MAX 1 x

brief

time elapsed to

stored MAX value

MAX and h:mm:ss 1 x

brief MAX and hh:mm 1 x

3.

Return to 1.

brief

same as 1.,

stored values are not

deleted

same as 1. same as 1. 1 x

Deactivate long are deleted is deleted is cleared 2 x

Page 12

12 GOSSEN METRAWATT GMBH

6 Voltage Measurement

➭ Set the rotary switch to either V (TRMS) or V , depending upon the

voltage to be measured.

➭ Connect the measurement cables as shown. The ⊥ jack must be grounded.

Note!

☞

An intermittent acoustic signal warns the operator if the measured value

exceeds the measuring range upper limit in the 600 V range.

Attention!

!

Make certain that neither of the current measuring ranges is selected

(“mA” or “A”) and that the measuring cables are connected to the right

“V” und “^” jacks when the multimeter is connected for voltage measurement! Both the operator and the instrument are in danger if the

breaking thresholds for the fuses are exceeded due to operator error!

Zero Balancing in the

300 mV Measuring Range

➭ Select the 300 mV

measuring range.

➭ Connect the measure-

ment cables to the instrument and connect the

free ends to one another.

➭ Briefly press the FUNC key.

The instrument acknowledges

zero balancing with an

acoustic signal, and “000

.0”

(±1 digit) and the ZERO

symbol appear at the LCD.

The voltage displayed at the

moment the key was pressed

is used as a reference value

(max. ±200 digits which

corresponds to 20 mV).

This value is automatically subtracted from all subsequently measured values.

➭ Zero balancing can be cleared:

– by pressing and holding the FUNC key,

after which clearing is acknowledged by

– a twice repeated acoustic signal,

by switching the instrument off.

– (+)~+ (–)

~

Page 13

GOSSEN METRAWATT GMBH 13

6.1 Transient Overvoltages

The multimeter is protected against transient voltages of up to 4 kV with front

and half times of up to 1.2 and 50 µs respectively. Due to the fact that powerful

overvoltages must be reckoned with during measurement, for example in power

systems, at transformers or motors, we recommend the use of our KS30 measuring adapter in such cases. It offers protection against transient overvoltages

of up to 6 kV with front and half times of up to 10 and 1000 µs respectively.

Continuous load capacity is equal to 1200 V

eff

. Additional measuring error

due to use of the KS30 measuring adapter amounts to approximately –2 %.

6.2 Measuring Voltages of Greater than 300 V

Voltages of greater than 300 V can be measured with a high-voltage measuring

probe, for example the HV3

1)

of the HV302) from GOSSEN METRAWATT GMBH.

The bonding terminal must be grounded in this case. Observe all applicable

safety precautions!

1)

HV3: 3 kV

2)

HV30: 30 kV for (DC) voltage only

7 Current Measurement

➭ First disconnect supply power from the measuring circuit or the power

consumer and discharge all capacitors, if any are present.

➭ Select range A with the rotary switch for currents of greater than 300 mA, or

range mA for currents of less than d 300 mA. Always start with measuring

range A when measuring current of an unknown magnitude.

➭ Select the current type which corresponds to the measured quantity by

briefly pressing the FUNC key. Each time the key is pressed, the instrument is

alternately switched back and forth between (DC) and ~ (AC), which is

acknowledged with an acoustic signal. The symbol for the selected current

type, (DC) or ~ (AC), appears at the LCD. Direct current ( ) is always

active immediately after the instrument is switched on, and after range

selection with the rotary switch.

➭ Connect the measuring instrument securely to the power consumer in

series as shown in the diagram (without transition resistor).

black

black

red

x1000

x100

Measuring voltages of greater than 300 V

with the HV3 high-voltage probe

Page 14

14 GOSSEN METRAWATT GMBH

Notes Concerning Current Measurement:

• The instrument may only

be used in power installations if the electrical

circuit is protected with

a fuse or a circuit

breaker with a rating of

up to 20 A, and if nominal voltage at the system does not exceed

240 V~ (AC) or

50 V (DC).

• Set up the measuring

circuit in a mechanically secure fashion

such that it cannot be

inadvertently interrupted. Use conductors with an adequate cross section

and connectors of

adequat e s ize in orde r

to prevent excessive warming.

• An intermittent acoustic signal warns the operator if the measured value

exceeds the measuring range upper limit in the 300 mA and 15 A ranges.

• All current measuring ranges up to 300 mA are protected with a FF1A/380V

AC fuse, and the 300 mA range is protected with a fuse (T2.5A/250V) in

combination with damping diodes. The breaking capacity of the slow-blow

fuse is equal to 10 kA at a nominal voltage of 380 V AC with a resistive load.

• The 15 A current measuring range is protected with a resettable miniature

circuit breaker: 15A/240V AC / 50V DC.In order to conform to the CAT

requirements, an additional slow-blowing fuse link (T16A/500V) has been fitted in series with the miniature circuit breaker which can only be replaced by

service personnel once it is tripped.

• If a fuse or circuit breaker in the active current measuring range is tripped,

FUSE appears at the digital display, and an acoustic signal is generated

simultaneously.

• Eliminate the cause of overload after the fuse or breaker is tripped before

placing the instrument back into service!

• Fuse replacement is described in chapter 15.2, on page 26.

Note!

☞

Motors with high starting current cause tripping of the circuit breaker,

except for measurement with clip-on ammeters.

– (+) / ~ + (–) / ~

Page 15

GOSSEN METRAWATT GMBH 15

7.1 Current Measurement with Current Transformers with Voltage Output

If a current sensor is connected to the multimeter, all current values are displayed

correctly in consideration of the transformer ratio. This presupposes that the current transformer is equipped with the required sensitivity, and that the

appropriate ratio is selected before measurement is performed.

➭ Turn the rotary switch to the position

.

➭ Select a current type, ~ (AC) or (DC), by pressing the FUNC key.

➭ Simultaneously press the FUNC and the MAN/AUTO keys. The currently

selected transformation ratio is displayed. The transformer ratio can be

changed by pressing the MAN or the DATA key, or the currently selected value

can be retained by pressing the FUNC key.

➭ Connect the (clip-on) current transformer or the clip-on current sensor to the

and the ⊥ jacks.

Attention!

!

If the secondary side of the current transformer with voltage output

remains open during operation, e.g. if cables are defective or have not

been connected, or due to a blown device fuse or incorrect

connection, dangerous voltages may occur at the terminals.

Maximum allowable operating voltage is equal to the nominal voltage of the

current transformer. Additional error caused by the clip-on ammeter must be

taken into consideration.

transformer ratio

max. measuring range

switch clip-on

current transf.

LCD

multimeter

A A~

1 mV/ 1 mA 1:1 mA

1 mV/ 10 mA 1:10 mA

1 mV/ 100 mA (Z13B) 60 A 40 A 10 mV/A 1:100 mA

1 mV/ 1 A (Z13B) 600 A 400 A 1mV/A 1:1 A

V/~

M

I(A)

Z13B

Page 16

16 GOSSEN METRAWATT GMBH

8 Resistance Measurement

➭ Set the rotary switch to the Ω

position. Overload is indicated

if no device under test has been

connected: “0.L MΩ”.

➭ Before connecting the device under

test, make sure that it is voltagefree. Interference voltages distort

measurement results! Perform a

voltage test first if required.

➭ Connect the device under test as

shown in the diagram.

Zero Balancing in the 300 Ω and 3 kΩ Measuring Ranges

Resistance at cables, as well as contact resistances, can be eliminated for the

measurement of low-resistance values in the 300 Ω and 3 kΩ ranges by means

of zero balancing:

➭ Connect the measurement cables to the instrument and connect the free

ends to one another (short circuit the test probes).

➭ Briefly press the FUNC key.

The instrument acknowledges zero balancing with an acoustic signal, and

“000

.0 Ω” or “0.000 kΩ” and the ZERO symbol appear at the LCD.

Resistance measured at the moment the key is pressed is used as a

reference value (max. 200 digits). This value is automatically subtracted from

all subsequently measured values.

➭ Zero balancing can be cleared:

– by pressing and holding the FUNC key, after which clearing is acknowledged

by a twice repeated acoustic signal,

– by switching the instrument off.

9 Continuity Testing

With the “acoustic signal” function activated, and exclusively in the 0 to 310 Ω

measuring range, the instrument generates a continuous acoustic tone for

measured resistance within a range of 0 to approximately 10 Ω.

➭ Turn the selector switch to the position. The and Ω symbols appear at

the LCD.

➭ Connect the measurement cables to the device under test.

Note!

☞

Continuity testing is very fast (< 50 ms) and is suitable for locating

connections with poor contact (e.g. due to vibration) in automotive

service applications.

R

x

Voltage Drop

Page 17

GOSSEN METRAWATT GMBH 17

10 Diode Testing

➭ Turn the selector switch to the position. Overload is indicated if no

device under test has been connected: “.0L V”.

➭ Make sure that the device under test is voltage-free. Interference voltages

distort measurement results! Perform a voltage test first if required.

➭ Connect the device under test as shown in the diagram.

Conducting Direction or Short-Circuiting

Conducting state voltage is displayed in volts at the measuring instrument. As

long as voltage drop does not exceed the maximum allowed display value of

1.8 V, several elements or reference diodes with minimal reference voltage can

be connected in series for testing. If “.0L” appears at the display, either the circuit

is interrupted or conducting state voltage is greater than 1.8 V.

Blocking Direction or Interruption

“.0L” is displayed at the instrument. If a value of less than 1.8 V is displayed, this

generally indicates that the diode’s blocking direction is defective.

Note!

☞

Resistors and semiconductor paths which have been connected in

parallel to the diode distort measurement results!

Conducting

Direction

Blocking

Direction

Page 18

18 GOSSEN METRAWATT GMBH

11 Capacitance Measurement

➭ Make sure that the device

under test is voltage-free.

Interference voltages distort

measurement results!

➭ Turn the rotary switch to the

“F” position.

➭ Connect the (discharged!)

device under test to the ⊥

and V jacks with the

measurement cables.

Zero Balancing in the 30 nF Measuring Range

Intrinsic capacitance at the measuring instrument and cables can be eliminated

for the measurement of small capacitance values in the 30 nF range by means of

zero balancing:

➭ Connect the measurement cables to the measuring instrument without a

device under test.

➭ Briefly press the FUNC key.

The instrument acknowledges zero balancing with an acoustic signal and

“00

.00 ” and the ZERO symbol appear at the LCD. Capacitance measured

at the moment the key is pressed is used as a reference value (max.

200 digits). This value is automatically subtracted from all subsequently

measured values.

➭ Zero balancing can be cleared:

– by pressing and holding the FUNC key, after which clearing is acknowledged

by a twice repeated acoustic signal,

– by switching the instrument off.

12 Frequency Measurement

➭ Turn the rotary switch to the Hz position.

➭ Apply the measured quantity as described under voltage measurement.

➭ Smallest measurable frequencies and maximum allowable voltages are

listed in chapter 14, “Characteristic Values”.

+

–

Page 19

GOSSEN METRAWATT GMBH 19

13 Temperature Measurement with Pt100 and Pt1000

➭ Turn the rotary switch to

the “ ” position.

➭ Select either °C or °F by

pressing the FUNC key.

➭ Connect the P

t sensor to

the ⊥ and V jacks. The

instrument automatically

recognizes type of

connected sensor (Pt100

or Pt1000), and displays

measured temperature in

the selected unit of

measure.

Note!

☞

The characteristic cable resistance for the temperature sensors which

are available as accessories is automatically taken into consideration for

this measurement.

Temperature Measurement

with Compensation for Sensor Cable Resistances from 0.1 Ω to 50 Ω

Sensor cable resistances with values other than100 mΩ can be compensated

for values of up to 50 Ω as follows:

➭ Briefly press the FUNC and the MAN/AUTO keys simultaneously. The currently

selected cable resistance is displayed. This value can be increased with the

DATA key, or reduced with the MAN/AUTO key. Each time one of these keys is

briefly activated, the value is changed by 10 digits (0.1 Ω). The value can be

changed by means of rapid scrolling by pressing and holding the key.

➭ Switch back to temperature measurement by briefly acknowledging with the

FUNC key.

The new cable resistance value is retained, even after the instrument has been

switched off.

Note!

☞

The default setting is Pt100 with a cable resistance of 0.1 Ω.

Z3409

Page 20

20 GOSSEN METRAWATT GMBH

14 Characteristic Values

1)

Up to max. 1.8 V diode voltage, “OL” (overload) is displayed for higher values.

2)

Smallest measurable frequency for sinusoidal measuring signal symmetric to zero point.

3)

Exception: Pt1000: – 100.0 °C

4)

corresponds to 600 V CAT I

Key: d = digit(s), rdg. = reading, MUL = measuring range upper limit

Measuring

Function

Measuring Range

Resolution at MUL Input Impedance

3 000

~

V

300 mV 100 µV > 20 MΩ 5MΩ //<50pF

3V 1mV 11MΩ 5MΩ //<50pF

30 V 10 mV 10 MΩ 5MΩ //<50pF

300 V 100 mV 10 MΩ 5MΩ //<50pF

600 V

4)

1 V 10 MΩ 5MΩ //<50pF

Approximate Voltage Drop at MUL

A

300 µA 100 nA 160 mV

3mA 1µA 160 mV

30 mA 10 µA 200 mV

300 mA 100 µA 300 mV

15 A 10 mA 700 mV

Open-Circuit Voltage

Measuring Current

at MUL

Ω

300 Ω 100 mΩ 0.6 V max. 250 µA

3kΩ 1 Ω 0.6 V max. 45 µA

30 kΩ 10 Ω 0.6 V max. 4.5 µA

300 kΩ 100 Ω 0.6 V max. 1.5 µA

3MΩ 1kΩ 0.6 V max. 150 nA

30 MΩ 10 kΩ 0.6 V max. 15 nA

300 Ω 0.1 Ω max. 3 V max. 1.2 mA

3V

1)

1 mV max. 3 V max. 1.2 mA

Discharge

Resistance

U

0 max

F

30 nF 10 pF 10 MΩ 3V

300 nF 100 pF 1 MΩ 3V

3 µF 1 nF 100 kΩ 3V

30 µF10nF11kΩ 3V

300 µF 100 nF 2 kΩ 3V

3000 µF1µF2kΩ 3V

30000 µF1µF2kΩ 3V

f

min

2)

Power Limit

Hz

300.0 Hz 0.1 Hz 1 Hz

3 x 106 V x Hz3.000 kHz 1 Hz 1 Hz

100.0 kHz 100 Hz 1 Hz

°C/°F

Pt100/

Pt1000

– 150.03)...

+100.0 °C

0.1 °C

+ 100.0 ...

+850.0 °C

Page 21

GOSSEN METRAWATT GMBH 21

1)

At 0 ° to + 40 °C

2)

Values < 5 digits are suppressed, intrinsic error values valid as of 100 digits except for 7).

15 (20) … 45 ... 65 Hz … 1 kHz sine, see page 22 for influences.

3)

15 A – 5 min

4)

If “zero balancing” function is active, ZERO appears at display.

5)

Plus sensor error

6)

Sinusoidal input voltage at least 3 kHz > 50 mV, 3 kHz at least 100 kHz > 200 mV

7)

Indicated intrinsic error values valid for 3 to 100% of the mV measuring range

Measuring

Range

Intrinsic Error for Max. Resolution

under Reference Conditions

Overload Capacity

1)

±(… % rdg. + … d) ±(… % rdg. + … d)

~

2)

Value Duration

300 mV 0.5 + 2

4)

0.5+5

7)

600 V

(DC)

~ (AC)

eff sine

continuous

3 V 0.5+2 0.5+5

30 V 0.5+2 0.5+5

300 V 0.5+2 0.5+5

600 V 0.5 + 2 0.5 + 5 600 V CAT I

~

2)

300 µA 0.5+2 0.5+5

0.36 A

continuous

3 mA 0.5+2 0.5+5

30 mA 0.5+2 0.5+5

300 mA 0.5+2 0.5+5

15 A 0.5 + 2 0.75 + 5 10 A

3)

300 Ω 0.5+2

4)

300 V

(DC)

~ (AC)

eff

sine

max. 10 s

3kΩ 0.5+2

4)

30 kΩ 0.5+2

300 kΩ 0.5+2

3MΩ 0.5+2

30 MΩ 2+2

0.5+3

3 V 0.5 + 3

30 nF 1 + 6

4)

300 V

(DC)

~ (AC)

eff

sine

max. 10 s

300 nF 1 + 6

3 µF 1 + 6

30 µF 1 + 6

300 µF 5 + 6

3 mF 5 + 6

30 mF 5 + 60

Max. Measuring Voltage

300.00 Hz

0.1 + 2

6)

300 V

300 V continuous

3.0000 kHz 300 V

<30kHz 100V

>30kHz 30V

Pt 100/

Pt1000

–150.0 ... + 100.0 °C 1 K + 3

5)

300 V (DC) /

~ (AC)

eff sine

max. 10 s

+100.0 ... + 850.0 °C 1% + 3

5)

Page 22

22 GOSSEN METRAWATT GMBH

Influence Quantities and Influence Error

1)

With zero balancing

2)

Indicated error applies as of a display value of 10% of the measuring range.

Influence

Quantity

Sphere of

Influence

Measured Quantity /

Measuring Range 1)

Influence Error

(… % + … d) / 10 K

Temperature

0 °C …

+21 °C

and

+25 °C …

+40 °C

V 0.2 + 1

V ~ 0.4 + 1

300 µA … 300 mA

+ ~

0.5 + 1

3 A / 10 A + ~ 1 + 1

300 Ω … 300 kΩ 0.2 + 1

3MΩ 0.2 + 1

30 MΩ 1 + 1

30 nF … 30 µF 0.5 + 1

Hz 0.5 + 1

°C (Pt100) 0.5 + 1

Influence

Quantity

Sphere of

Influence

(max. resolution)

Frequency

Intrinsic Error 2)

± (… % rdg. + … d)

Frequency

V~

(AC)

300.0 mV

3.000 V

30.00 V

300.0 V

> 15 Hz ... 45 Hz 2 + 5

> 65 Hz ... 1 kHz 1 + 5

Influence

Quantity

Sphere of

Influence

(max. resolution)

Frequency

Intrinsic Error

2)

±(… % rdg. + … d)

Frequency

I~

(AC)

300.0 µA

...

15.00 A

> 15 Hz ... 45 Hz

1 + 5

> 65 Hz ... 1 kHz

Page 23

GOSSEN METRAWATT GMBH 23

1)

Except for sinusoidal waveshape

Influence

Quantity

Sphere of

Influence

Measured Quantity /

Measuring Range

Influence Error

1)

Measured

Quantity

Waveshape

3)

Crest

factor

CF

1 … 2

V ~, A ~

± 1% rdg.

>2 ...4 ± 5% rdg.

>4 ...5 ± 7% rdg.

Influence

Quantity

Sphere of

Influence

Measured Quantity /

Measuring Range

Influence Error

Relative

Humidity

75%

3 days

device off

V, A , Ω

F, H z

°C

1 x intrinsic error

Influence

Quantity

Sphere of Influence

Measuring

Range

Damping

Common-

Mode

Interference

Voltage

interference quantity max. 300 V V > 90 dB

interference quantity max. 300 V ~

50 Hz, 60 Hz sine

300 mV ...

30 V ~

> 60 dB

300 V ~ > 60 dB

Series-Mode

Interference

Voltage

interference quantity V ~

nom. value, respective measuring range,

max. 300 V ~, 50 Hz, 60 Hz sine

V > 40 dB

interference quantity max. 300 V

nom. value, respective measuring range

V ~ > 50 dB

1

2

3

4

5

CF

0

Voltage and Current

Measurement

Allowable crest factor CF for the

periodic quantity to be measured

depends upon the displayed value:

Digits

1000 2000 3000

Page 24

24 GOSSEN METRAWATT GMBH

Reference Conditions

Ambient Temperature +23 °C ±3K

Relative Humidity 40

… 60%

Measured Qty. Frequency 45

… 65 Hz

Measured Qty. Waveshape sinusoidal

Battery Voltage 3 V ±0.1 V

Response Time (after manual range selection)

Display

LCD window (95 mm x 40 mm) with analog and digital display, including display

of unit of measure, current type and various special functions

Analog:

Display LCD scale with pointer

Scale length 80 mm for V and A ;

67 mm for all other ranges

Scaling 5

… 0 … ± 30 with 35 scale graduations for ,

0 ... 30 with 30 scale graduations for all other ranges

Polarity Display with automatic switching

Overload Display triangle appears

Sampling Rate 20 measurements per second

Digital:

Display/Char. Height 7 segment characters / 20 mm

Number of Places 3¾-place 3100 steps

Overload Display “0L” appears

Polarity Display “–” is displayed if plus pole is connected to ⊥ jack

Sampling Rate 2 measurements per second

Display Refresh Rates

V (DC), V~ (AC), A, Ω, ,

°C (Pt100, Pt1000) twice per second

Hz once per second

Measured Quantity /

Measuring Range

Digital Display

Response Time

Measured Quantity

Jump Function

V , V ~,

A, A~

1.5 s

from 0 to 80%

of the measuring range upper limit

300 Ω … 3MΩ 2s

from ∞ to 50%

of the measuring range upper limit

30 MΩ 5s

Continuity < 50 ms

1.5 s

30 nF … 300 µF max. 2 s

from 0 to 50%

of the measuring range upper limit

3 000 µF max. 7 s

30 000 µF max. 14 s

>10 Hz max. 1.5 s

°C max. 3 s

Page 25

GOSSEN METRAWATT GMBH 25

Power Supply

Batteries 2 ea. 1.5 V mignon cell

alkaline-manganese per IEC LR6

or zinc-carbon per IEC R6

Service Life with alkaline-manganese batteries: approx. 100 hours

with zinc-carbon batteries: approx. 50 hours

Battery Test symbol is displayed automatically if battery voltage

drops to below approximately 2.3 V.

Battery Saving Circuit

The instrument is switched off automatically if the measured value remains

unchanged for a period of approximately 10 minutes, and if none of the control

elements are operated during this period. Automatic shutdown can be disabled.

Fuses

Range up to 300 mA FFF1A/380VAC, 5 mm x 20 mm

Switching capacity 10 kA at 380 V AC and ohmic load;

protects, in combination with power diodes, all current

measuring ranges up to 300 mA

15 A range

– Resettable 15A/240VAC/50VDC miniature circuit breaker,

– additionally, a fuse link has been joint in series with

the m.c.b.: T16A/500VAC, 6.3 mm x 32 mm

Switching capacity 1.5 kA at 500 V AC and ohmic load

Electrical Safety

Safety Class II per IEC/EN 61010-1:2001/VDE 0411-1:2002

Measurement Category

II

Operating Voltage 300 V

Contamination Level 2

Test Voltage 2.3 kV~ per IEC/EN 61010-1:2001/VDE 0411-1:2002

Electromagnetic Compatibility (EMC)

Interference Emission EN 61 326:2002 Class B

Interference Immunity EN 61326:2002

IEC 61000-4-2:1995/A1:1998, Feature A

8 kV atmospheric discharge

4 kV contact discharge

IEC 61000-4-3:1995/A1:1998, Feature B; 3 V/m

Ambient Conditions

Operating Temp. − 10 °C

… +50 °C

Storage Temperature −25 °C

… +70 °C (without batteries)

Relative Humidity max. 75%, no condensation allowed

Elevation to 2000 m

Deployment indoors, outdoors: only within the specified

ambient conditions

Page 26

26 GOSSEN METRAWATT GMBH

Mechanical Design

Protection housing: IP 40, connector jacks: IP 20

Dimensions 146 mm x 118 mm x 44 mm

Weight approx. 450 gr. with batteries

15 Maintenance

Attention!

!

Disconnect the instrument from the measuring circuit before opening to

replace batteries or fuses!

15.1 Batteries

Make sure that no battery leakage has occurred before placing your instrument

into service for the first time, or after long periods of storage. Repeat this

inspection on a regular basis thereafter.

If battery leakage has occurred, clean the electrolyte from the device completely

and carefully with a dampened cloth and install new batteries before placing the

instrument back into service.

If the symbol appears at the display, replace the batteries as soon as possible.

The instrument requires two 1.5 V batteries in accordance with IEC R 6 or

IEC LR 6.

Replacing the Batteries

Attention!

!

Disconnect the instrument from the measuring circuit at all poles before

opening the battery compartment!

➭ Fold the instrument closed.

➭ Insert a coin or a similar object into the slot between the housing and the

battery compartment cover and press down until the battery compartment

cover snaps open.

➭ Fold the instrument open as far as it will go and remove the battery

compartment cover.

➭ Insert two 1.5 V mignon batteries per IEC R6 or IEC LR6 into the battery

compartment, making sure they are poled in accordance with the symbols.

➭ Replace the battery compartment cover and press into position until it

audibly snaps into place.

➭ Please dispose of depleted batteries in an environmentally sound fashion!

15.2 Fuses

Eliminate the cause of overload after a fuse or breaker is tripped before placing

the instrument back into service!

Page 27

GOSSEN METRAWATT GMBH 27

mA Range

If the FF1A/380V AC fuse link for the active mA current measuring range is

tripped, FUSE appears at the digital display and an acoustic signal is generated

simultaneously.

Replacing Fuses for mA Ranges

➭ Open the instrument as described for battery replacement.

➭ Remove the blown fuse, which is situated under the batteries, e.g. with the

help of a test probe or a similar object, and replace it with a new fuse.

Attention!

!

Only fuses with the specified characteristics may be used (see chapter

14, “Characteristic Values”)! The use of fuses with other tripping characteristics, current ratings or breaking capacities represents a hazard

for damping diodes, resistors and other device components. The use

of repaired fuses and short-circuiting of the fuse holder are prohibited.

15 A Range

A humming sound originating from the 15 A circuit breaker is normal when

measuring high value alternating current.

If the miniature 15 A circuit breaker for the active current measuring range is

tripped, FUSE appears at the digital display and an acoustic signal is generated

simultaneously. Make sure that the red pin is popped out in the tripped condition,

i.e. that no adhesion or fusion has taken place. Short circuit the Ω and 15 A jacks

with the selector switch set to the continuity test position, and “0L” must appear

at the display.

Attention!

!

Inspect the measuring circuit and eliminate the cause of overload

before activating the reset button at the miniature circuit breaker.

15.3 Housing

No special maintenance is required for the housing. Keep outside surfaces clean.

Use a slightly dampened cloth for cleaning. Avoid the use of cleansers, abrasives

or solvents.

16 Multimeter Messages

Message Function Significance

FUSE Current measurement Blown fuse or tripped miniature circuit breaker

In all operating modes Battery voltage less than 2.3 V

OL In all measuring modes Indicates overload

Page 28

Edited in Germany • Subject to change without notice • A pdf version can be found on the internet

GOSSEN METRAWATT GMBH

Thomas-Mann-Str. 16-20

90471 Nürnberg • Germany

Phone+49-(0)-911-8602-0

Fax +49-(0)-911-8602-669

E-Mail info@gossenmetrawatt.com

www.gossenmetrawatt.com

17 Repair and Replacement Parts Service

DKD Calibration Lab* and Rental Instrument Service

When you need service, please contact:

GOSSEN METRAWATT GMBH

Service-Center

Thomas-Mann-Str. 20

90471 Nürnberg • Germany

Phone +49-(0)-911-8602-0

Fax +49-(0)-911-8602-253

E-Mail service@gossenmetrawatt.com

This address is only valid in Germany.

Please contact our representatives or subsidiaries for service in other countries.

* Calibration Laboratory for Electrical Quantities

DKD– K–19701 accredited per DIN EN ISO/IEC 17025

Accredited measured quantities: direct voltage, direct current values, DC

resistance, alternating voltage, alternating current values, AC active power, AC

apparent power, DC power, capacitance and frequency

18 Product Support

When you need support, please contact:

GOSSEN METRAWATT GMBH

Product Support Hotline

Phone +49-(0)-911-8602-112

Fax +49-(0)-911-8602-709

E-Mail support@gossenmetrawatt.com

DKD Calibration Certificate Reprints

If you order a DKD calibration certificate reprint for your instrument, please

provide us with the reference numbers indicated in the upper and lower most

fields of the calibration mark. We do not need the instrument’s serial number.

Loading...

Loading...