Page 1

Operating instructions

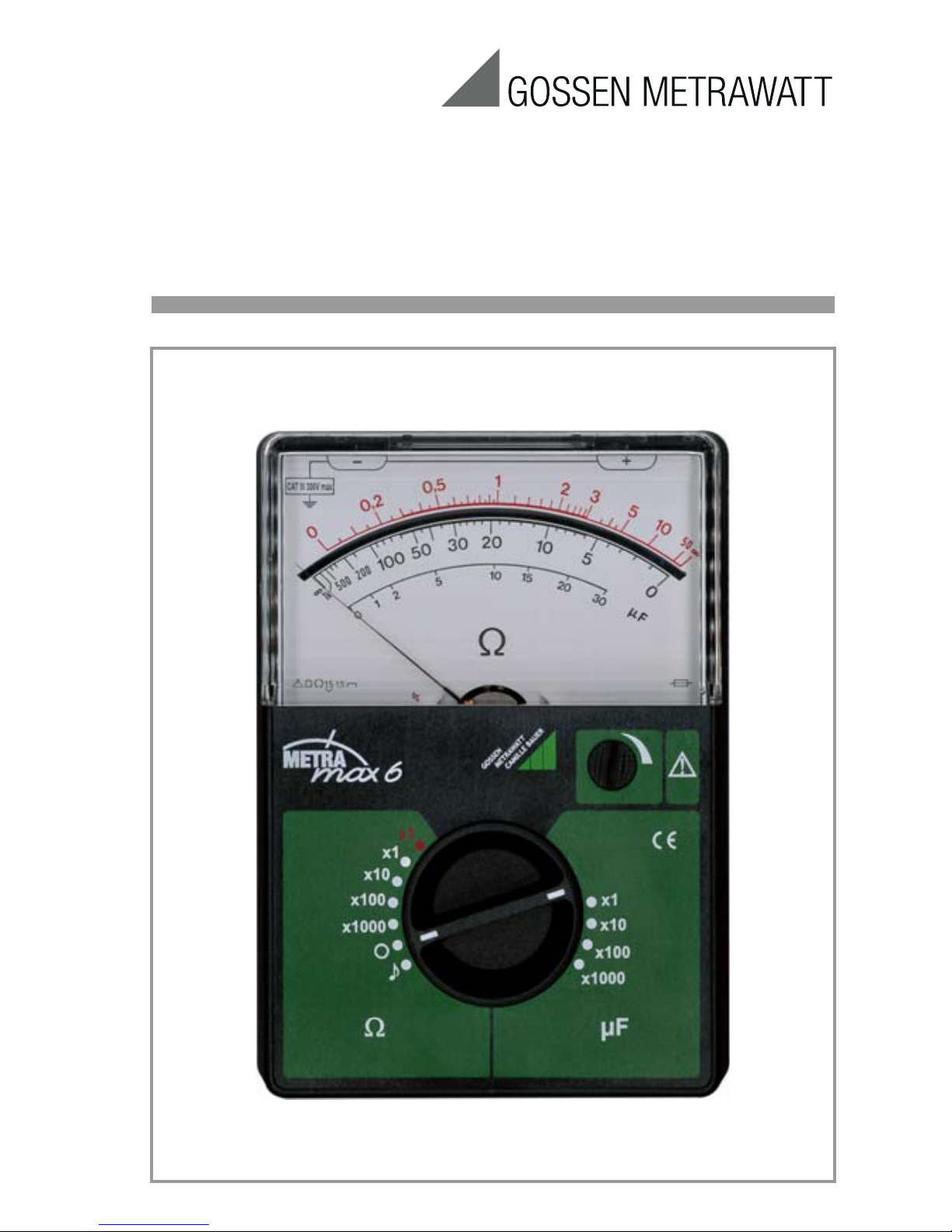

METRAmax 6

Analog Multimeter

3-348-602-02

6/10.15

Page 2

2 GMC-I Messtechnik GmbH

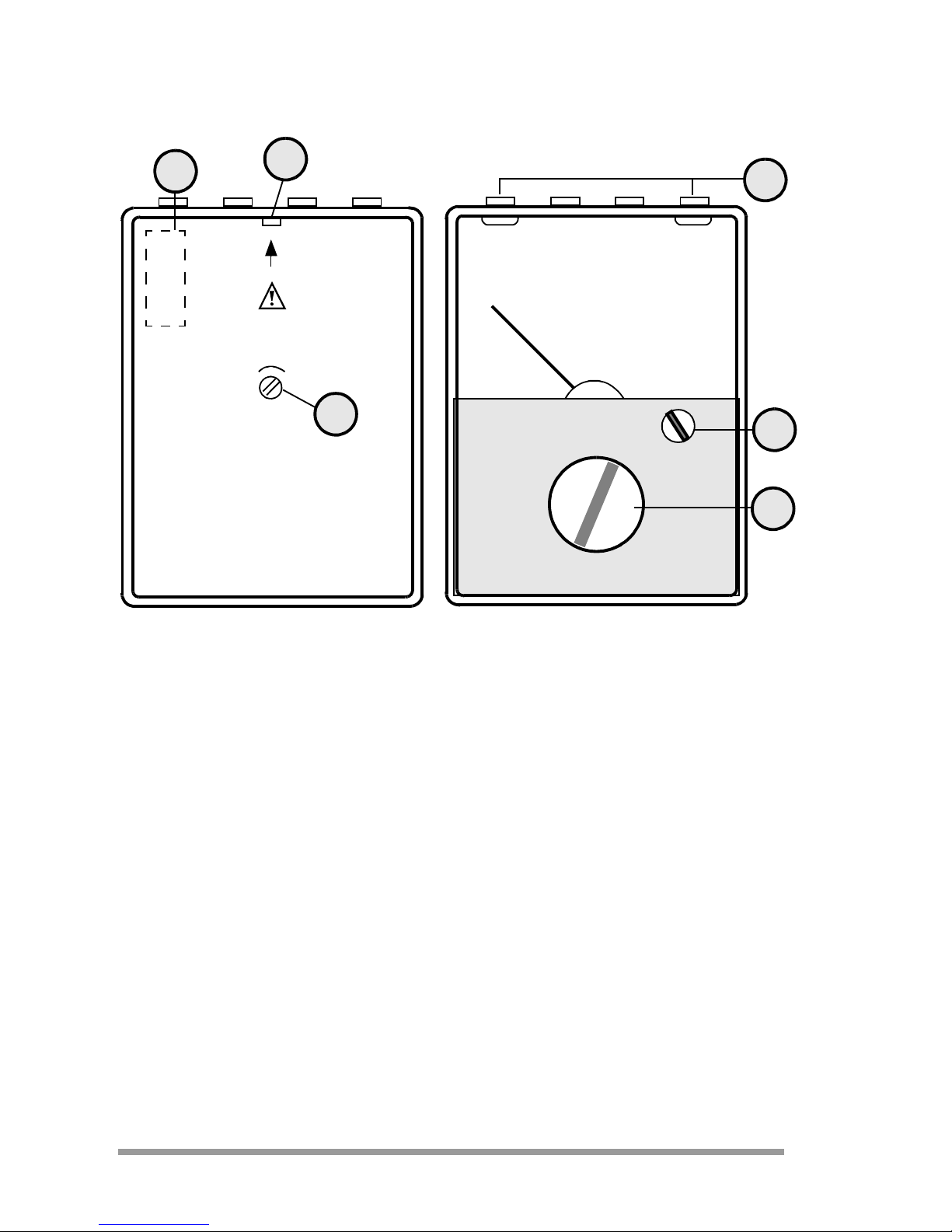

Operating Controls

1 Range selector switch

2 Rotary knob to adjust the full-scale deflection

3 Socket connectors

4 Battery compartment

5 Nose to open the meter

6 Adjustment screw for the mechanical zero

(

∞ on black scale)

6

1

2

3

5

4

1,5 V

R6

Page 3

GMC-I Messtechnik GmbH 3

Table of Contents

Page

1 Safety Features and Precautions ........................................ 4

2 Description ......................................................................... 6

3 Operation ............................................................................ 7

3.1 Inserting the Battery .......................................................................... 7

3.2 Checking the Mechanical Zero ........................................................... 8

3.3 Battery Test ...................................................................................... 8

4 Measurement ..................................................................... 9

4.1 Resistance Measurement .................................................................. 9

4.1.1 Measuring in the Range up to 50 Ω (Ω x 1, red) .............................. 10

4.1.2 Measuring in the Ranges up to 1 MΩ

(Ω x 1/10/100/1000, black) ............................................................ 10

4.2 Rough Capacitance Measurement .................................................... 11

4.3 Diode and Transistor Test ................................................................ 12

4.4 Acoustic Continuity Test .................................................................. 13

5 End of Measurement ........................................................ 13

6 Characteristic Values ........................................................ 14

7 Maintenance ..................................................................... 16

7.1 Battery ........................................................................................... 16

7.2 Fusible Link .................................................................................... 16

7.2.1 Fuse Replacement .......................................................................... 16

7.3 Housing .......................................................................................... 17

7.4 Device Return and Environmentally Compatible Disposal ................... 17

8 Repair and Replacement Parts Service

Calibration Center and Rental Instrument Service ........... 18

9 Product Support ................................................................ 20

Page 4

4 GMC-I Messtechnik GmbH

1 Safety Features and Precautions

This instrument fulfills the requirements of the applicable

European and national EC guidelines. We confirm this with

the CE marking. The relevant declaration of conformity can

be obtained from GMC-I Messtechnik GmbH.

The analog multimeter METRAmax 6 is manufactured in

accordance with safety regulations IEC 61010-1/EN

61010-1/VDE 0411-1. When used for its intended purpose, the safety of the operator, as well as that of the

instrument, is assured. Their safety is however not guaranteed if the instrument is used improperly or handled carelessly. It is therefore imperative that you read the operating

instructions thoroughly and carefully before placing the

METRAmax 6 into service, and that you follow all instructions contained therein.

Observe the following safety precautions:

• The instrument may only be operated by persons who

are capable of recognizing contact hazards and taking

the appropriate safety precautions.

• Contact hazards exist anywhere, where voltages of

greater than 30 V may occur (effective value).

• Be prepared for the occurrence of unexpected voltages

at devices under test (e.g. defective devices).

For example, capacitors can be dangerously charged!

• Housing and measurement cables may not be damaged, e.g. by cracks or ruptures.

• No measurements may be made with the METRAmax 6 in

electrical circuits with corona discharge (high-voltage).

• Special care is required when measurements are made

in HF electrical circuits. Dangerous pulsating voltages

may be present.

Page 5

GMC-I Messtechnik GmbH 5

• Measurements under moist ambient conditions are not allowable. Hands, shoes, floor and workplace must be dry.

• Be absolutely certain that the measuring ranges are not

overloaded beyond their allowable capacities.

Meaning of Symbols on the Instrument

indicates EC conformity

Warning concerning a point of danger.

(Attention: observe documentation!)

This device may not be disposed of with the trash.

Further information regarding the WEEE mark can be

accessed on the Internet at

www.gossenmetrawatt.com by entering the search

term ’WEEE’.

Measuring Categories and their Significance per IEC 61010-1

The measuring category and the maximum rated voltage

which is printed on the device apply to your measuring

instrument, 300 V CAT III.

CAT Definition

I

Measurements in electrical circuits which are not directly connected to

the mains: e.g. electrical systems in motor vehicles and aircraft,

batteries etc.

II

Measurements in electrical circuits which are electrically connected to the

low-voltage mains: via plug, e.g. in household, office and laboratory

applications

III

Measurements in building installations: stationary consumers, distributor

terminals, devices connected permanently to the distributor

!

Page 6

6 GMC-I Messtechnik GmbH

2 Description

The METRAmax 6 is a battery-powered ohmmeter. It

excels by its handy size, ease of use, and a large measuring span. It is meant for measurement of resistances

between 0.05

Ω and 1 MΩ, for rough capacitance mea-

surements between 1

μF and 30,000 μF, and for continuity

tests with beeper.

The METRAmax 6 offers 9 measuring ranges for resistance

and capacitance measurements. The measuring ranges

are selected with a range switch.

The meter has a rugged movement with spring-loaded

jewels. It is widely insensitive to vibrations and shocks.

The scale is mirror-backed for exact reading of the measured values.

The measuring range

Ω x 1, marked in red, and the scale

marked in red are provided for measurements of small

resistance values (0.05 Ω bis 50 Ω). To measure higher

resistance values, there are 4 measuring ranges which

have a common black scale.

A part of the two scale arcs is boldly marked. The measuring error, referred to the actual resistance value, is smallest

on these marked indicating ranges.

For rough capacitance measurements, there are 4 measuring ranges with a common scale.

A beeper is incorporated for audible continuity tests.

The connectors are protected against accidental contact. It

is recommended to use measuring leads with shockproof

connection plugs (4 mm diameter).

Page 7

GMC-I Messtechnik GmbH 7

3 Operation

Attention!

!

Only voltage-free devices under test may be measured!

Prior to each measurement, check mechanical

zero and full-scale deflection.

3.1 Inserting the Battery

Prior to starting the METRAmax 6, insert a 1.5 V mignon

cell into the battery compartment. This requires removal of

the lower part of the case.

Attention!

!

Disconnect the measurement cables from the

measuring circuit before opening the meter!

➭ Press the nose (5) on the rear of the meter inwards,

using an adequate tool, and remove the lower part.

➭ Insert a leakproof 1.5 V mignon cell according to IEC

R6 into the battery compartment (4), paying attention to

the polarity markings. Verify that reliable contact is

made.

➭ Replace the lower part of the case and press the two

parts together until they engage.

Page 8

8 GMC-I Messtechnik GmbH

3.2 Checking the Mechanical Zero

➭ Place the METRAmax 6 into a horizontal position.

➭ Set the range selector switch (1) to the "O" position

(OFF).

➭ The pointer has to be exactly over the bar code of the

full-scale deflection (∞ on the black scale).

➭ Correct deviations with the adjusting screw (6) on the

rear of the meter with a screwdriver, if required.

3.3 Battery Test

➭ Set the range selector switch (1) to the "Ω x 1" position

(red marking).

➭ With the rotary knob (2), adjust the movement pointer

on the red scale to full-scale deflection (∞).

If the pointer can no longer be adjusted to full-scale deflection, or if the indication is instable after the adjustment, the

battery is exhausted and has to be replaced with a new

one, see chapter 3.1.

Page 9

GMC-I Messtechnik GmbH 9

4 Measurement

4.1 Resistance Measurement

Resistance is measured with DC voltage from the inserted

1.5 V mignon cell. The maximum measuring currents at

full-scale deflection, with a battery voltage of 1.5 V, are

listed in the range table (see chapter 6 "Characteristic Values").

If possible, select the measuring range in such a way that

indication is in the range of the boldly drawn scale arc. The

measuring error, referred to the actual resistance value, is

smallest in this range.

During prolonged resistance measurements, occasionally

check for full-scale deflection (0 Ω or ∞).

When switching the range selector switch (1) to another

resistance range, always check for full-scale deflection and

adjust with the rotary knob (2), if required.

Page 10

10 GMC-I Messtechnik GmbH

4.1.1 Measuring in the Range up to 50 Ω (Ω x 1, red)

➭ Set the range selector switch (1) to Ω x 1 (red marking).

➭ With the rotary knob (2), adjust the pointer to full-scale

deflection (

∞) on the red scale.

➭ Connect the unknown resistance R

x

to be measured

and read the resistance value on the red scale.

4.1.2 Measuring in the Ranges up to 1 MΩ

(Ω x 1/10/100/1000, black)

➭ Set the range selector switch (1) to one of the measur-

ing ranges Ω x 1 ... Ω x 1000, depending upon the resistance value to be measured.

➭ Short-circuit the measuring leads.

➭ With the rotary knob (2), set the pointer to full-scale

deflection (0 Ω) on the black scale.

➭ Connect the resistance R

X

to be measured to the measuring leads and read the resistance value on the black

scale. The indicated value must be multiplied by the

specified factor in line with the selected measuring

range.

R

X

Page 11

GMC-I Messtechnik GmbH 11

4.2 Rough Capacitance Measurement

➭ Set the range selector switch (1) to one of the measur-

ing ranges μFx1...μF x 1000, depending upon the

capacitance value to be measured.

➭ Capacitance is measured according to the ballistic

method. Connect the capacitor a few times to the measuring leads with changing polarity and read the largest

pointer deflection on the μF scale.

With this method, the capacitance of the capacitor to be

measured can only roughly be determined. The measured

value can deviate from the actual value by up to ±25 %.

Page 12

12 GMC-I Messtechnik GmbH

4.3 Diode and Transistor Test

The resistance range Ω x 1000 is suited for a rough functional check on semiconductor elements. A resistance

measurement is an easy way to find a short circuit or an

interruption on a diode and/or a diode junction between

base, collector and emitter. The polarity of a diode and the

base connection of a transistor can also be determined by

this test.

This measurement does not destroy semiconductor elements to be tested as the 1.75 V voltage and the 100 μA

current are not exceeded.

Page 13

GMC-I Messtechnik GmbH 13

4.4 Acoustic Continuity Test

The continuity test (range selector switch (1) set to position

is suitable for testing low-ohmic connections with a

resistance value of ≤1.5 Ω.

No external voltage must be applied during the measure-

ment!

The forward direction of semiconductor elements should

not be tested by the audible continuity test but only

according to the deflection method (see chapter 4.3).

When using the audible continuity test, inductive voltage

spikes appear at the meter connectors which could damage the semiconductors.

5 End of Measurement

After the measurement, the range selector switch (1)

should be set to "0" to conserve the battery life.

Page 14

14 GMC-I Messtechnik GmbH

6 Characteristic Values

Measuring Ranges

1)

with a battery voltage 1.5 V

Acoustic Continuity Test

Response range 0 ... 1.5 Ω (integrated beeper)

Response current 365 mA

Operating current 170 mA

Accuracy

Error limit ±1.5 % of scale length

± 8.2 % as a function of the actual

resistance value in the display

range with boldly marked scale arc.

Reference Conditions

Ambient temperature +20 °C

Position of use horizontal

Resistance

Measuring Range

Span

Mid-scale

Value

(Ri)

Max. Measuring

Current

I

max

1)

approx.

Ω x 1

(red scale)

0.05 Ω ... 50 Ω 1 Ω 75 mA

Ω x1 1 Ω ... 1 kΩ 20 Ω 75 mA

Ω x 10 10 Ω ... 10 kΩ 200 Ω 7.5 mA

Ω x 100 100 Ω ... 100 kΩ 2 kΩ 0.75 mA

Ω x 1000 1 kΩ ... 1MΩ 20 kΩ 0.075 mA

Capacitance

Measuring Range

Measuring Range Span

Max. Measuring

Current

I

max.

1)

μF x 1 0 ... 30 μF 0.075 mA

μF x 10 0 ... 300 μF 0.75 mA

μF x 100 0 ... 3 000 μF 7.5 mA

μF x 1 000 0 ... 30 000 μF 75 mA

Page 15

GMC-I Messtechnik GmbH 15

Display

Scale mirror-backed

Scale length approx. 90 mm

Pointer deflection ∠ 0° ... 100°

Ambient Conditions

Storage temperatures –25 ... 65 °C (without battery)

Relative humidity

max. 75%, no condensation allowed

Power Supply

Battery 1 mignon cell 1.5 V per IEC LR6 (AA),

leak-proof

Overload Protection

Fusible link F 6.3 H/250 V per DIN VDE 0820

part 22/EN 60127-2, embedded

Electrical Safety

Protection class II per IEC 61010-1/EN 61010-1/

VDE 0411-1

Measuring category CAT III 300 V max

Contamination degree 2

Test voltage 2 kV∼

EMC Electromagnetic compatibility

Interference emission/

interferene immunity

EN 61326-1

Mechanical Design

Protection Housing IP50, terminals IP20

Extract from table on the meaning of IP codes

Dimensions 100 mm x 140 mm x 35 mm

Weight approx. 0.3 kg (without battery)

IP XY

(1

st

digit X)

Protection against

foreign object entry

IP XY

(2nd digit Y)

Protection against the

penetration of water

2 ≥ 12,5 mm ∅ 0 not protected

5 dust protected 0 not protected

Page 16

16 GMC-I Messtechnik GmbH

7 Maintenance

7.1 Battery

The state of the battery should be ckecked from time to

time. An exhausted or deteriorating battery must not

remain in the battery compartment. Check and replace the

battery as described in chapter 3.1 on page 7.

7.2 Fusible Link

The holder for the fuse link is soldered to the circuit board.

See chapter 6, "Overload Protection" for the specified fuse.

7.2.1 Fuse Replacement

• Disconnect the meter from the measuring circuit!

• Remove the lower part of the case, see chapter 3.1 on

page 7.

• Changing the fuse it is possible to put the holder carefully to side or to desolder it.

Attention!

!

Please make definitely sure that only the specified

fuse is inserted! Using a fuse with other cut-out

characteristics, other nominal current or other

switching capacity may endanger the user and

damage protective diodes, resistors and other

components.

The use of mended fuses or short-circuiting of the fuse

holder is not permitted.

Page 17

GMC-I Messtechnik GmbH 17

7.3 Housing

The meter may only be cleaned with a soft cloth or brush.

Possible static charges of the glass pane can be removed

with an antistatic agent or a moist cloth.

7.4 Device Return and Environmentally Compatible Disposal

The METRAmax 6 is a category 9 product (monitoring and

control instrument) in accordance with ElektroG (German

Electrical and Electronic Device Law). This device is subject

to the RoHS directive. Furthermore, we make reference to

the fact that the current status in this regard can be

accessed on the Internet at www.gossenmetrawatt.com

by entering the search term WEEE.

We identify our electrical and electronic devices in

accordance with WEEE 2012/19/EU and

ElektroG with the symbol shown to the right per

DIN EN 50419.

These devices may not be disposed with the trash. Please

contact our service department regarding the return of old

devices, see chapter 8 on page 18.

If you use batteries or rechargeable batteries in your instru-

ment or accessories which no longer function properly,

they must be duly disposed of in compliance with the

applicable national regulations.

Batteries or rechargeable batteries may contain harmful

substances or heavy metal such as lead (PB), cadmium

(CD) or mercury (Hg).

They symbol shown to the right indicates that batteries or rechargeable batteries may not be disposed of with the trash, but must be delivered to

collection points specially provided for this purpose.

Pb Cd Hg

Page 18

18 GMC-I Messtechnik GmbH

8 Repair and Replacement Parts Service

Calibration Center *

and Rental Instrument Service

When you need service, please contact:

GMC-I Messtechnik GmbH

Service Center

Thomas-Mann-Strasse 20

90471 Nürnberg • Germany

Phone +49 911 817718-0

Fax +49 911 817718-253

E-Mail service@gossenmetrawatt.com

www.gmci-service.com

This address is only valid in Germany.

Please contact our representatives or subsidiaries for service in other countries.

* DAkkS Calibration Laboratory

for Electrical Quantities D-K-15080-01-01

accredited per DIN EN ISO/IEC 17025

Accredited measured quantities: direct voltage, direct current values, DC

resistance, alternating voltage, alternating current values, AC active

power, AC apparent power, DC power, capacitance, frequency and temperature

Page 19

GMC-I Messtechnik GmbH 19

Competent Partner

GMC-I Messtechnik GmbH is certified in accordance with

DIN EN ISO 9001:2008.

Our DAkkS calibration laboratory is accredited by the

Deutsche Akkreditierungsstelle GmbH (National accreditation body for the Federal Republic of Germany) in accordance with DIN EN ISO/IEC 17025:2005 under registration

number D-K-15080-01-01.

We offer a complete range of expertise in the field of

metrology: from test reports and proprietary calibration certifi-

cates right on up to DAkkS calibration certificates.

Our spectrum of offerings is rounded out with free test

equipment management.

An on-site DAkkS calibration station is an integral part of our

service department. If errors are discovered during

calibration, our specialized personnel are capable of completing repairs using original replacement parts.

As a full service calibration laboratory, we can calibrate

instruments from other manufacturers as well.

Page 20

Edited in Germany • Subject to change without notice • A pdf version is available on the

Internet

GMC-I Messtechnik GmbH

Südwestpark 15

90449 Nürnberg •

Germany

Phone +49 911 8602-111

Fax +49 911 8602-777

E-Mail

info@gossenmetrawatt.com

www.gossenmetrawatt.com

9 Product Support

When you need support, please contact:

GMC-I Messtechnik GmbH

Product Support Hotline

Phone +49 911 8602-0

Fax +49 911 8602-709

E-Mail support@gossenmetrawatt.com

Loading...

Loading...