Operating Instructions

METRALINE ISO

CHECK

Insulation Resistance Tester

3-349-691-03

2/4.13

Table of Contents

!

!

Page

1 Introduction ...................................................................... 2

1.1 Scope of Delivery ...........................................................................2

1.2 Optional Accessories ......................................................................2

1.3 Safety Precautions .........................................................................2

1.4 Applications ..................................................................................3

1.5 Applicable Standards .....................................................................3

1.6 Environment ..................................................................................3

2 Device Description ........................................................... 3

2.1 Housing ........................................................................................3

2.2 Control Panel .................................................................................3

2.3 Initial Start-Up ...............................................................................3

3 Performing Measurements .............................................. 4

3.1 Switching the Instrument On and Off, Energy-Saving Mode,

Automatic Shutdown ......................................................................4

3.2 Instructions and Principles with Validity for

All Measurements ..........................................................................4

3.3 Measuring Functions ......................................................................4

3.3.1 Voltage Measurement ....................................................................4

3.3.2 Insulation Resistance Measurement ................................................5

3.3.3 Measurements at Varistors (surge protection devices) ......................5

3.4 Further Device Functions ................................................................6

3.5 Device Reset Function ....................................................................7

4 Technical Data ................................................................. 7

4.1 Measuring Functions ......................................................................7

4.2 General Data .................................................................................7

5 Maintenance .................................................................... 7

5.1 Device Power Supply .....................................................................7

5.1.1 Inserting and Replacing the Batteries ..............................................7

5.1.2 Recharging the Batteries ................................................................8

5.2 Cleaning .......................................................................................8

5.3 Recalibration .................................................................................8

6 Repair and Replacement Parts Service,

Calibration Center and Rental

Instrument Service ........................................................... 8

7 Product Support ............................................................... 8

1 Introduction

1.1 Scope of Delivery

1 Test instrument with mobile test probe

4 Batteries (AAA)

1Pouch

1 Condensed operating instructions

1

CD ROM with operating instructions in available languages

1 Factory calibration certificate

1.2 Optional Accessories

4 ea. rechargeable AAA NiMH batteries (Z507B)

1 battery charger (Z507A)

1.3 Safety Precautions

Read the operating instructions thoroughly and carefully before

using your instrument. Follow all instructions contained therein.

Make sure that the operating instructions are available to all users

of the instrument.

Meanings of Symbols on the Instrument

This device is equipped with double or reinforced insulation.

Danger of injury due to electrical current,

warning regarding dangerous electrical voltage

Warning concerning a source of danger

(attention, observe documentation!)

EC mark of conformity: This instrument fulfills all

requirements of applicable European directives.

Before using the instrument, it must be assured that it is safe. Do

not use if:

• Visible damage is apparent

• The battery compartment lid is missing

• The device has been stored under unfavorable conditions for

a lengthy period of time

• The device has been handled impermissibly, e.g. has been

dropped from a height of 1 meter or more

• The test instrument does not function as described in these

operating instructions (if this is the case, we recommend

resetting the device as described in section 3.5 on page 7)

CAUTION

• Do not touch electrically conductive parts, test probes etc.

when the device is switched on and voltage might still be conducted by a test probe – DANGER OF INJURY!

• Only use test probes which are included with the instrument

or are available as accessories.

• The device must be switched off and no voltage may be

applied when exchanging accessories.

• It is absolutely essential to adhere to all safety precautions,

regulations and standards when performing measurements.

• No keys may be pressed when connecting the instrument to a

device under test.

• The test instrument may not be subjected to the influence of

aggressive substances, gases, vapors, liquids or dust.

• The test instrument may only be used under the conditions

listed in the technical data in section 5 on page 7.

• If the device is moved from a colder to a warmer room, condensation may occur, in which case a brief period of acclimatization is advisable.

• We recommend removing the batteries during lengths periods

of storage.

• Two relatively strong magnets are integrated into the test

instrument. Avoid close proximity to magnetically sensitive

objects such as watches, credit cards and the like.

• The illustrations in these operating instructions are drawings

and may therefore deviate from reality.

• Use original accessories only.

• Maximum permissible voltage between test probe and ground

is 300 V!

• Maximum permissible (externally applied) voltage between the

test probes is 600 V!

Opening of Equipment / Repair

The equipment may be opened only by authorized service personnel to ensure the safe and correct operation of the equipment

and to keep the warranty valid.

Even original spare parts may be installed only by authorized service personnel.

In case the equipment was opened by unauthorized personnel,

no warranty regarding personal safety, measurement accuracy,

conformity with applicable safety measures or any consequential

damage is granted by the manufacturer.

2 GMC-I Messtechnik GmbH

1.4 Applications

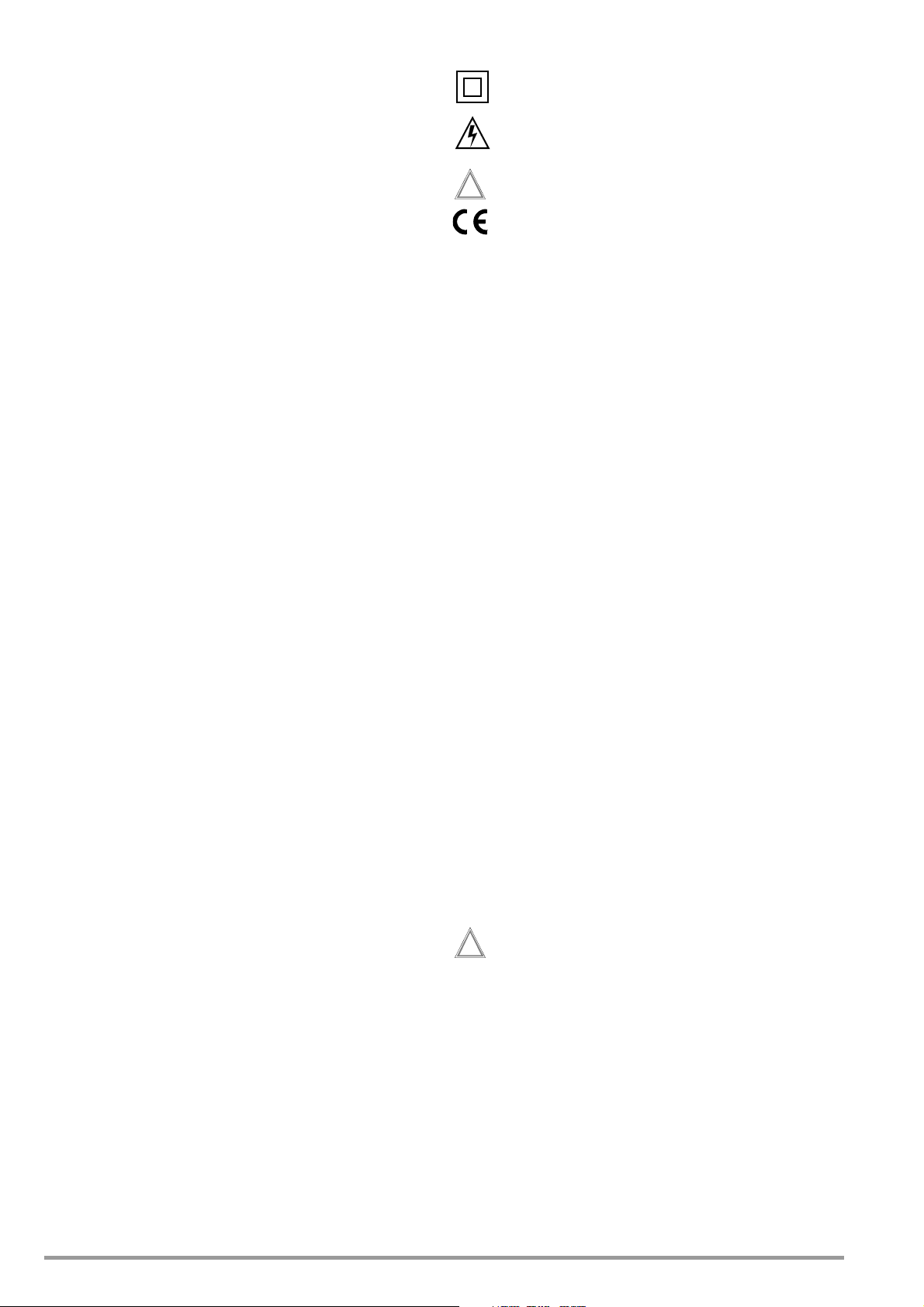

Fixed Test Probe Attached to the Device

LED

OLED Display

Socket for Flexible Test Probe

Socket for Charger

P

l

u

g

-

I

n

M

o

b

i

l

e

T

e

s

t

P

r

o

b

e

Plastic

Control Panel

Housing

Screws for Battery Compartment Lid

Battery Compartment Lid

Serial Plate

3

1

2

4

5

6

The test instrument consists of a compact housing with a patented means of retaining the second test probe.

The high-contrast, four-color OLED display assures excellent legibility. When performing measurements under unfavorable light

conditions, measuring point illumination can be switched on –

white LED at the front.

The test instrument is capable of the following measurements:

– Insulation resistance with test voltages of 50 to 1000 V

– Surge protection devices with test voltages of 50 to 1000 V

– Direct and alternating voltages

1.5 Applicable Standards

Measurement EMC Safety

EN 61557-1 EN 55022 class B EN 61010-1

EN 61557-2 EN 61326-1 EN61010-031

1.6 Environment

The shipping package is made of recyclable cardboard.

Batteries must be disposed of in accordance with applicable

regulations.

This device may not be disposed of with the trash. Further

information regarding the WEEE mark can be accessed

on the Internet at www.gossenmetrawatt.com by entering

the search term “WEEE”.

2 Device Description

2.1 Housing

Figure 2.2: Detail View of the Back Panel with Battery

Compartment Lid

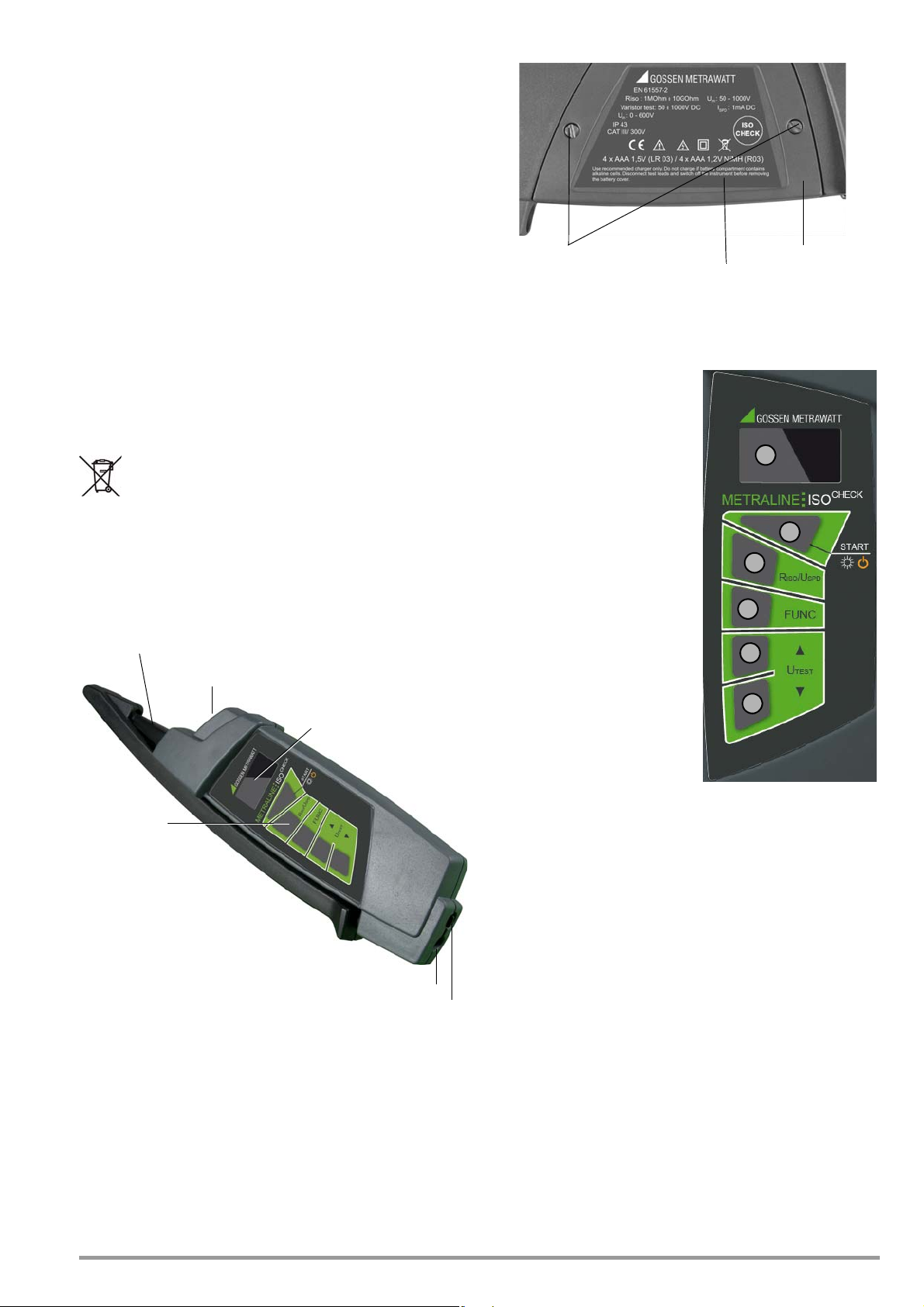

2.2 Control Panel

1 Graphic OLED display

2 START key:

– Switch on:

Press and hold until the display lights up.

– Start measurement:

Press and hold until measurement starts.

– Measurement point illumina-

tion:

Press briefly to switch illumination on and off.

– Switch off:

Press twice briefly to switch

the instrument off.

3 R

ISO/USPD KEY:

For switching between insulation resistance and surge protection measurement

4The FUNC key allows for selec-

tion of the desired type of

surge protection when USPD

is activated.

5 U

TEST ▲ key for selecting

measuring voltage

TEST ▼ key for selecting

6 U

measuring voltage

Figure 2.1: Top View

For transport purposes, the movable test probe can be attached

to the housing and retained by a magnet such that both metal tips

are simultaneously recessed and protected.

In order to charge batteries which have been inserted into the

instrument, the flexible test probe’s connector plug must be

removed and the slide must be pushed to the left, so that the

socket at the right is made accessible and the charger can be

plugged into it.

GMC-I Messtechnik GmbH 3

Figure 2.3: Control Panel and OLED Display

2.3 Initial Start-Up

After inserting the batteries in accordance with section 5.1 on

page 7, the measuring instrument is ready for operation.

3 Performing Measurements

!

3.3 Measuring Functions

3.1 Switching the Instrument On and Off, Energy-Saving Mode, Automatic Shutdown

The instrument is switched on by pressing and holding the START

key. Briefly press the START key twice in order to switch the instru-

ment off, during which no voltage may be applied to the test

probes! The instrument is switched to the standby mode after

several seconds (reduced brightness), if none of the keys has

been pressed and no voltage is applied to the test probes. The

instrument is switched out of the standby mode (i.e. back to full

brightness) by pressing any key or applying voltage to the test

probes. The instrument is shutdown automatically if it has

remained inactive for about 1 minute, i.e. if no keys have been

pressed and no voltage has been applied to the test probes during this time.

3.2 Instructions and Principles with Validity for All Measurements

• The desired functions or parameters are selected with the

R

ISO/USPD, FUNC, UTEST ▲ and UTEST ▼ keys. Measurement is

triggered by pressing the START key. All selected functions or

parameters remain valid until they are changed.

• If (interference) voltage of greater than 10 V is applied to the

test probes, this is indicated at the display in the UIN field

along with the measured value, as well as the “!” symbol. If

this is the case, the START key is disabled.

Attention!

• Each time before measuring insulation resistance or surge

protection, make sure that the device under test is voltagefree!

• Do not touch the device under test or the test probes during

measurement, and for a short time thereafter as long the DUT

is being discharged.

• The DUT may be charged with as much as 1000 V during

measurement, for which reason contact to the DUT must be

maintained after measurement has been completed until it is

fully discharged! Residual voltage appears at the display along

with the “!” warning symbol.

• Do not remove the test probes until voltage has dropped to a

safe level and the “!” warning symbol has been cleared from

the display.

• All consuming devices must be disconnected and the

switches must be turned on when measuring insulation resistance between conductors.

3.3.1 Voltage Measurement

➭ Connect the test instrument to the device under test.

Bild 3.1 (Interference) Voltage Display

• If battery voltage is too low (only the red field is lit up in the

battery symbol), measurement cannot be started. After pressing the START key, the depleted battery symbol appears for

about 1 second (see figure below). Replace the batteries as

described in section 5.1 on page 7.

Figure 3.2: Low Battery

Voltage

➭ When measuring high insulation resistance, the measurement

cables should be laid unobstructed in the room, or placed

upon a material with good insulating properties.

➭ Contact the device under test with the test probe before trig-

gering measurement with the START key, thus causing any

possible interference voltage to appear at the display.

➭ Do not remove the test probes prematurely during the course

of the measurement, because this may lead to distorted measurement results.

Figure 3.3: Low Battery

Voltage: Display

After Pressing the

START Key

Figure 3.4: Connection Example for Voltage Measurement

• If a voltage of greater than about 10 V is present in the measured electrical circuit, its value is displayed in the U

the “~” symbol appears for AC or polarity is displayed for DC.

The “+” symbol lights up if the positive pole is connected to

the fixed test probe, and “–” appears if the negative pole is

connected to the fixed test probe. “!” appears at the same

time as a warning. The START key is disabled!

IN field and

After insulation measurement has been completed, any remaining

residual voltage is displayed as U

capacitance. Contact to the device under test must be maintained for as long as a capacitive DUT is being discharged via the

test instrument’s internal resistor. The falling voltage value can be

observed directly at the U

until voltage U

4 GMC-I Messtechnik GmbH

IN is less than 25 V!

IN , which may result from cable

IN display. Do not disconnect the DUT

Figure 3.5: Display of (Inter-

ference) Voltage

(Riso function)

Figure 3.6: Voltage

Measurement

SPD function)

(U

3.3.2 Insulation Resistance Measurement

Note

Note

Note

Note

Switch to off position!

USER

USER

USER

USER

➭ Switch insulation measurement on by pressing the RISO/USPD

key.

Figure 3.7: Setting Test Voltage

➭ Select the required measuring voltage with the help of the

▲

UTEST and ▼ UTEST keys. By briefly pressing the respective

key, voltage is increased or decreased to one of the following

nominal values: 50, 100, 250, 500 or 1000 V. The selected

test voltage appears at the display in the U

vidualized value settings, press and hold either the

TEST field. For indi-

▲ UTEST or

▼ UTEST key until the value can be changed in 1 V steps

within a range of 50 to 1000 V. The desired value is then selected by once again briefly pressing the respective key. Several seconds after one of these two keys has been activated

for the last time, the test instrument is returned to the mode

which allows for switching amongst nominal values of 50,

100, 250, 500, 1000 V only.

➭ Contact the device under test with both test probes.

➭ Read the measured insulation resistance value.

The device under test may not be disconnected from the

test instrument as long as the “!” warning symbol is lit up.

Discharging large capacitances may take several tens of

seconds!

Figure 3.9: Sample Results for an

Insulation Measurement (the DUT is

being discharged)

Figure 3.10: Insulation Measure-

ment Results (the DUT

has been fully

discharged: U

IN = 0 V)

Whistling or hissing noises may emanate from the test

instrument during measurement.

3.3.3 Measurements at Varistors (surge protection devices)

For this measuring function, the test instrument generates a rising

direct voltage within a range of 50 to 1000 V and, at the same

time, measures current flowing through the device under test. As

soon as current reaches a level of 1 mA, voltage is no longer

increased and the voltage value for the so-called milliampere

point appears at the display. In accordance with the respective

function which has been selected with the FUNC key, results for

overcurrent protection devices are also evaluated automatically

and listed as shown in the following table.

Note

If the DCMAX function has been selected, the upper voltage

limit for automatic results evaluation can be adjusted with the

▲ UTEST and ▼ UTEST keys.

If the DCMIN function has been selected, the lower voltage

limit for automatic results evaluation can be adjusted with the

▲ UTEST and ▼ UTEST keys.

Figure 3.8: Connection Example

If an interference voltage of greater than about 10 V is

present in the measured electrical circuit, its value is displayed and the START key is disabled (see section 3.3.1

on page 4). Eliminate the source of interference voltage

before continuing with the measurement.

➭ Trigger measurement by pressing the START key. Release the

key as soon as measurement is started.

Rising measuring voltage is displayed by means of a bar

graph (this may take several tens of seconds in the case of

large capacitances). At the same time, the value appears at

the display in the UIN field. The measuring cycle is ended automatically.

If measurement needs to be continued for a longer period

of time, the START key has to be pressed and held for the

entire duration.

In contrast to this, the automatic cycle can be ended prematurely by briefly pressing the START key. No results are

displayed in this case.

For actual measurement or evaluation, it doesn’t matter which of

these two functions is selected, i.e. either DCMAX or DCMIN.

Symbol in the Display and its Meaning

Selected function

DC Voltage at the milliampere point

DCMAX

DCMIN

SPD LIST * Voltage at the milliampere point

* Table for Surge Protection Device

is measured

Voltage at the milliampere point

is within the specified range

is within the specified range for

the selected type of surge protection device

Voltage at the milliampere point

is outside of the measuring

range

Voltage at the milliampere point

is outside of the specified range

Voltage at the milliampere point

is outside of the specified range

for the selected type of surge

protection device

If the SPD LIST function is selected (SURGE PROTECTION DEVICE

TABLE), a specific type and manufacturer/distributor is suggested

at the display, voltage at the milliampere point is displayed and

further information may appear as well.

The required type of surge protection device can be selected with

the

▲ UTEST and ▼ UTEST keys.

GMC-I Messtechnik GmbH 5

If the symbol is included in the description of the surge pro-

Note

Note

!

tection device, the manufacturer’s instructions must be observed

for the respective device type.

The actual measurement is performed as follows:

➭ Select measurement of surge protection devices with the

ISO/USPD key, and select the desired sub-function with the

R

FUNC key (see also description above). Example:

After insulation measurement has been completed, any remaining

residual voltage is displayed as UIN, which may result from cable

capacitance. Contact to the device under test must be maintained for as long as the capacitive DUT is being discharged via

the test instrument’s internal resistor. The falling voltage value can

be observed directly at the UIN display. Do not disconnect the

DUT until voltage U

IN is less than 25 V!

Figure 3.11: Surge Protection Device Measurement Menu,

DC Function

➭ Connect the test probes to the surge protection device in ac-

cordance with the manufacturer’s instructions.

Figure 3.13: Sample Results

for the USPD

Measurement

(discharging is

active: residual

voltage = 144 V)

Figure 3.14: Further Sample

Results for the

SPD Measure-

U

ment (DUT is fully

discharged: residual voltage = 0 V)

Comments

• Before measuring surge protection devices, disconnect them

from the installation.

• It’s advisable to study the circuit before performing measurement. Surge protection devices are currently equipped with

integrated interference suppression filters and the like, which

may influence measurement results.

3.4 Further Device Functions

Select Language, Query Firmware Version

Before selecting a language or querying the firmware version, disconnect both test probes from the device under test / measuring

circuit and switch the test instrument off.

➭ Press and hold the R

strument on.

The firmware version and other service information appears at the

display, as well as the language selection menu.

➭ Select the desired language with the corresponding key

(EN = English, CZ = Czech).

ISO/USPD key while switching the test in-

Figure 3.12: Connection Example

Figure 3.15: Language Selection Menu

Note

If a voltage of greater than about 10 V is present at the measured

surge protection device, its value is displayed and the START key is

disabled (see section 3.3.1 on page 4). Eliminate the source of

interference voltage before restarting the measurement.

The instrument is switched back to normal operation after a language has been selected.

Measuring Point Illumination with White LED

➭ Trigger measurement by pressing the START key. Release the

START key as soon as measurement is started. Rising current

at the surge protection device is displayed by means of a bar

graph. At the same time, the measuring voltage value appears

at the display in the U

IN field. Measurement is ended automat-

ically.

➭ Read voltage measured at the milliampere point.

The device under test may not be disconnected from the

test instrument as long as the “!” warning symbol is lit up.

6 GMC-I Messtechnik GmbH

The LED can be switched on and off by briefly pressing the START

key.

No voltage may be applied to the test probes.

3.5 Device Reset Function

Caution: Dangerous Voltage!

Note

If the test instrument does not function as described in these

instructions, we recommend a device reset. The test instrument

must be switched off and neither of the test probes may be connected to a DUT. If device functions are still incorrect after switching the instrument back on again, remove the batteries as

described in section 5.1 on page 7, wait at least 10 seconds and

then reinsert the batteries (or replace them with new ones).

If the test instrument still does not function as described, remove

the batteries and contact our service department.

4 Technical Data

4.1 Measuring Functions

Insulation Resistance

Nominal Range per EN 61557-2: 0.100 M – Rmax*

Range Resolution Intrinsic Uncertainty Measuring

0.100 to 9.999 M 0.001 M (2% rdg. + 10 d) (3 % rdg. + 20 d)

10.00 to 99.99 M 0.01 M (2% rdg. + 10 dd) (3% rdg. + 20 d)

100.0 to 999.9 M 0.1 M (2% rdg. + 10 d) (3% rdg. + 20 d)

1.000 G ... Rmax* 0.001 G (4% rdg. + 15 d) (5% rdg. + 25 d)

* The Rmax value depends on the selected test voltage:

Nominal voltage of 50 to 99 V Rmax = 1.999 G

Nominal voltage of 100 to 249 V Rmax = 3.999 G

Nominal voltage of 250 to 1000 V Rmax = 9.999 G

Nom. measuring voltage 50 to 1000 V

Adjustable in steps of 1 V

Measuring voltage -0%/+10% of nominal voltage

Nom. measuring current 1 mA (where Umes > Unom)

Short-circuit current < 3 mA

Automatic discharging

of the DUT Yes

Number of

measurements Approx. 250 (with new alkaline batter-

ies)

Surge Protection

Range Resolution Intrinsic Uncertainty Measuring

40 to 1050 V 1 V (2% rdg. + 2 d) (3% rdg. + 3 d)

Measuring method Rising DC voltage when measuring the so-

called milliampere point

Direct and Alternating Voltage (frequency range: 45 to 65 Hz)

Range Resolution Intrinsic Uncertainty Measuring

0 to 600 V 1 V (2% rdg. + 2 d) (3% rdg. + 3 d)

Key

a) The TRMS value for alternating voltage is measured.

b) rdg. means reading, i.e. measured value.

d = digits (i.e. number of the decimal place with the least significance)

4.2 General Data

Reference Conditions

Temperature 23 ± 2° C

Relative humidity 40 to 60%

Device position Any

Uncertainty

Uncertainty

Uncertainty

Ambient Conditions

Operating Conditions

Operating temperature0 to 40° C

Relative humidity Max. 85%, no condensation allowed

Device position Any

Storage Conditions

Temperature -10 to 70° C

Relative humidity Max. 90% at -10 to +40° C

Max. 80% at +40 to +70° C

Device position Any

Power Supply

Batteries 4 ea. AAA (LR03), 1.5 V alkaline or

1.2 V NIMH (with at least 750 mAh)

Number of

measurements with batteries at 800 mAh:

approx. 1,000 measurements

(with 500 V test voltage on 500 k

Electrical Safety

Measuring category with safety cap applied to test probe:

CAT III 300 V

without safety cap applied to test probe:

CAT I I 300 V

Pollution degree 2

Protection class II

Mechanical Design

Display OLED, multicolored, graphic

Protection IP 43

Dimensions Approx. 260 x 70 x 40 mm

Weight Approx. 0.36 kg with batteries

5 Maintenance

5.1 Device Power Supply

Dangerous voltage in battery compartment!

Disconnect the test probes from the device under test and

switch the instrument off before removing the battery compartment lid.

The instrument may not be placed into service if the battery

compartment lid has not been inserted and secured with

the screws.

Either alkaline batteries or rechargeable NiCD/NiMH batteries may

be used to supply the instrument with electrical power (4 each,

size: AAA, type: LR03).

The battery charge level is continuously displayed (see section 3.2

on page 4).

If too little voltage is indicated, replace the batteries.

We recommend removing the batteries during lengthy

periods of non-use (e.g. vacation). This prevents excessive battery depletion or leakage, which may result in

damage to the instrument under unfavorable conditions.

5.1.1 Inserting and Replacing the Batteries

Loosen the two screws for the battery compartment lid at the

back of the instrument and remove the lid. Insert the batteries

with correct polarity (refer to the embossed symbols at the bottom of the battery compartment).

Always replace all four batteries at once, and use high quality batteries. Replace the battery compartment lid and retighten the

screws.

GMC-I Messtechnik GmbH 7

5.1.2 Recharging the Batteries

Attention!

!

Attention!

!

instrument is used primarily in the laboratory and indoors without

considerable climatic or mechanical stressing, a calibration interval of once every 2 to 3 years is sufficient as a rule.

Use only the charger (Z507A) which is offered as an optional accessory for this instrument to charge the batter-

ies inserted in the instrument.

Make sure that the following conditions have been fulfilled before connecting the charger to the charging socket:

– rechargeable batteries have been inserted with correct

polarity, no normal batteries

– The test instrument has been disconnected from the

measuring circuit at all poles

– The instrument must remain off during charging.

Recharging of the batteries begins as soon as the charger is connected to the mains and to the charging socket (see figure 2.1).

Charging takes approximately 5 hours and 30 minutes (integrated

safety timer) if the batteries have been fully depleted.

Safety Precautions

• Do not attempt to recharge alkaline batteries: they may leak,

explode etc. The test instrument may be severely damaged or

destroyed as a result.

• After initially charging new batteries and after rechargeable

batteries have not been used for a lengthy period of time (several months), operating hours after charging may be significantly less than usual. If this is the case, repeat the charging

procedure several times.

Autonomous, intelligent charging stations execute charging/

discharging cycles of this sort automatically (see instructions

included with the charging station). This procedure increases

the capacity of the batteries, thus making longer periods of

operation possible between charging cycles.

• If no improvement is achieved in this way, one or more of the

rechargeable batteries may no longer fulfill the original specifications. If this is the case, the defective rechargeable battery

should be identified, e.g. with the help of the voltage measurement, and replaced.

• Battery capacity is gradually reduced as a result of long and

frequent use. When you notice that this is the case, all of the

rechargeable batteries should be replaced.

During recalibration at an accredited calibration laboratory

(DIN EN ISO/IEC 17025), deviations from traceable standards

demonstrated by your measuring instrument are documented.

Ascertained deviations are used to correct display values during

later use of the instrument.

We would be happy to perform DAkkS or factory calibration for

you at our calibration laboratory. Further information is available at

our website:

www.gossenmetrawatt.com ( Company DAkkS Calibration

Center or FAQs General – Calibration Questions and

Answers).

Recalibration of your instrument at regular intervals is essential for

the fulfillment of requirements according to quality management

systems per DIN EN ISO 9001.

* Examination of the specification, as well as adjustment, are not included

in calibration. However, in the case of our own products, any required

adjustment is performed and adherence to the specification is confirmed.

6 Repair and Replacement Parts Service,

Calibration Center and Rental

Instrument Service

If required please contact:

GMC-I Service GmbH

Service Center

Thomas-Mann-Str. 20

90471 Nürnberg, Germany

Phone: +49 911 817718-0

Fax: +49 911 817718-253

e-mail service@gossenmetrawatt.com

www.gmci-service.com

5.2 Cleaning

Use a soft cloth and soapy water for cleaning. Do not place the

test instrument back into service until its surface is completely dry.

Do not use cleaning agents which contain benzine or alcohol! Prevent liquids from penetrating into the test instrument’s interior.

5.3 Recalibration

The measuring tasks performed with your instrument, and the

stressing it’s subjected to, influence aging of its components and

may result in deviation from the specified levels of accuracy.

In the case of strict measuring accuracy requirements, as well as

in the event of use at construction sites with frequent stress due

to transport and considerable temperature fluctuation, we recommend a relatively short calibration interval of once per year. If your

Edited in Germany • Subject to ch ange without notice • PDF version available on the Internet

GMC-I Messtechnik GmbH

Südwestpark 15

90449 Nürnberg •

Germany

Phone: +49 911 8602-111

Fax: +49 911 8602-777

E-mail: info@gossenmetrawatt.com

www.gossenmetrawatt.com

This address is only valid in Germany. Please contact our representatives or subsidiaries for service in other countries.

7 Product Support

If required please contact:

GMC-I Messtechnik GmbH

Product Support Hotline

Phone: +49-911-8602-0

Fax: +49 911 8602-709

e-mail support@gossenmetrawatt.com

Loading...

Loading...