Operating Instructions

METRAHITWORLD

International TRMS Multimeter

3-349-529-03

10/6.17

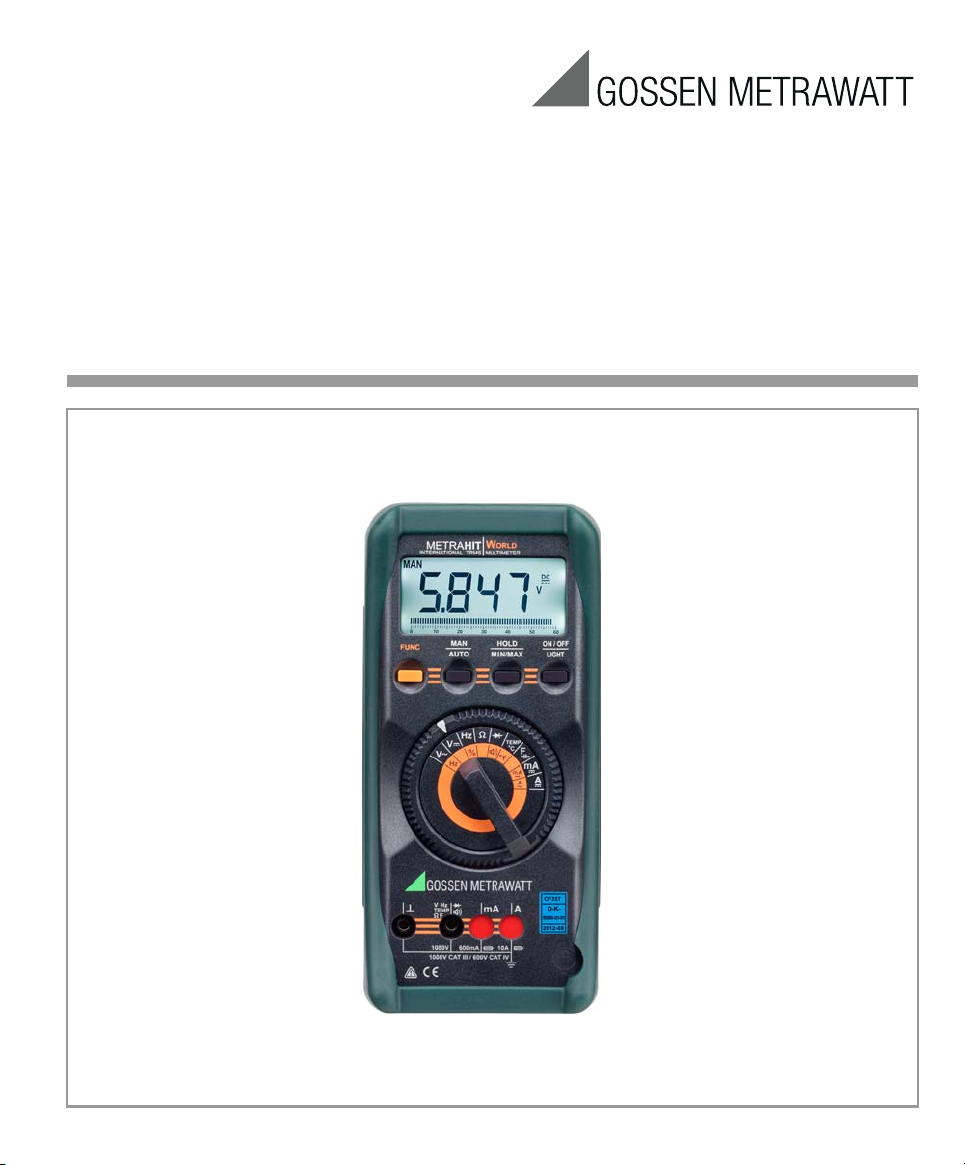

1 Display (LCD)

1

2

3

4

5

6

7

Max.

1000 V !

14

542

12

13

9

1516

19

18

21

71 3

10

17

20

8

6

11

2 ON / OFF

3 HOLD Key for the following functions: save

4 MAN / AUTO Key for manual measuring range selection

5 FUNC Key for selecting ranges or functions

6 rotary selector switch for measuring functions

7 Connector jacks

Light

Key for ON / OFF and display illumination

ON / OFF

measured value, delete and MAX-MIN

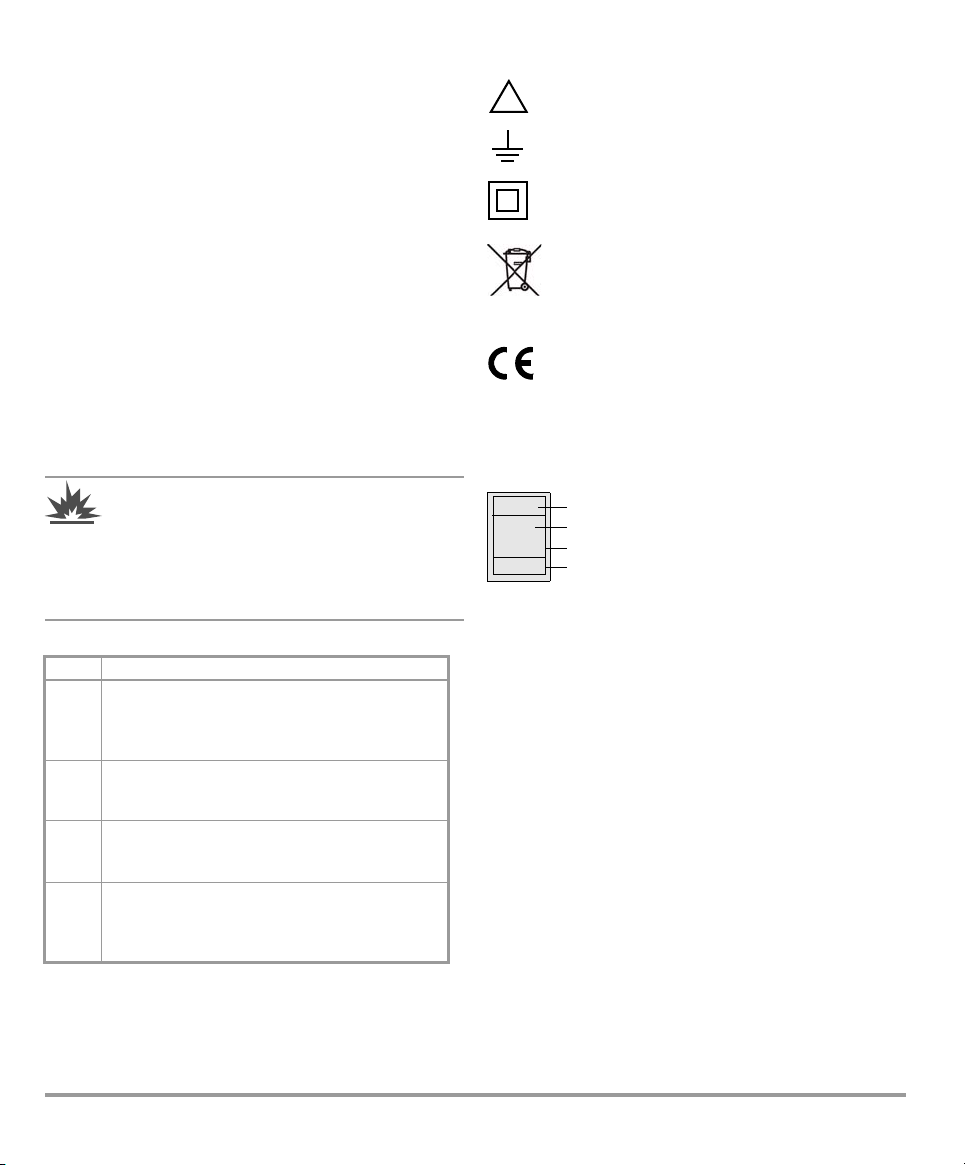

Symbols used in the Digital Display

1 MAN: manual measuring range selection is active

2 MAX/MIN value storage

3 HOLD: display memory, “freeze” measured value

4 Digital display with decimal point and polarity display

5 Diode measurement selected

6 Display Duty Cycle Measurement

7 appears when acoustic signal is active

8 Selected type of current

9 interface active

10 Unit of measure

11 Unit of measure C / F for temperature measurement

12 Rotation Per Minute measurement selected

13 Triangle appears: indicates overranging

14 Pointer for analog display

15 REL: relative measurement with reference to offset

16 Scale for analog display

17 Indicates that the negative analog display range has been exceeded

18 Warning regarding dangerous voltage: > 40 V AC / 60 DC

19 Display in case of defective fuse

20 Low battery display

21 Symbol for continuous duty

2 GMC-I Messtechnik GmbH

Standard Equipment

1 TRMS-digital multimeter

1 Protective rubber holster

2 1.5 V AA size batteries

1 Set of measurement cables KS17-2

1 DAkkS calibration certificate

1 Short-form operating instructions

Table of Contents

Page Page

1 Safety Features and Precautions ...............................3

2 Initial Start-Up ............................................................5

3 Selecting Measuring Functions and Measuring

Ranges .......................................................................5

3.1 Automatic Measuring Range Selection .....................................5

3.2 Manual Measuring Range Selection .........................................5

3.3 Quick Measurements ..............................................................5

3.4 Relative Measurement D REL ................................................... 6

4 LCD .............................................................................6

4.1 Digital Display ......................................................................... 6

4.2 Analog Display ........................................................................ 6

4.3 Display Illumination .................................................................6

5 Measured Value Memory “HOLD” ..............................6

6 Saving Minimum or Maximum Values

“MIN/MAX” Hold .........................................................6

7 Voltage Measurement ................................................7

7.1 Sub-function Hz ...................................................................... 7

8 Current Measurement ................................................8

8.1 Measuring Alternating Current with (Clip-On) Current

Transformers ........................................................................ 10

8.1.1 Transformer Output mA / A ...................................................10

8.1.2 Transformer Output V ............................................................ 10

9 Resistance Measurement .........................................10

10 Continuity and Diode Testing ...................................11

11 Capacitance Measurement ......................................12

12 Frequency Measurement –

Duty Cycle Measurement .........................................12

12.1 Duty Cycle Measurement ....................................................... 12

12.2 RPM Measurement ...............................................................12

13 Temperature Measurement ......................................13

14 Characteristic Values ...............................................14

15 Maintenance ............................................................17

15.1 Battery ................................................................................. 17

15.2 Fuses ...................................................................................17

15.3 Housing ................................................................................ 17

16 Recalibration ............................................................18

17 Accessories ............................................................. 18

17.1 General ................................................................................ 18

17.2 Technical Data for Measurement Cables

(included: KS17-2 safety cable set) ........................................ 18

18 Repair and Replacement Parts Service,

Calibration Center and Rental Instrument Service ... 19

19 Manufacturer’s Guarantee ....................................... 19

20 Product Support ....................................................... 19

1 Safety Features and Precautions

You have selected an instrument which provides you with a

high level of safety.

This instrument fulfills the requirements of the applicable EU

guidelines and national regulations. We confirm this with the

CE marking. The relevant declaration of conformity can be

obtained from GMC-I Messtechnik GmbH.

The analog-digital multimeter is manufactured and tested in

accordance with safety regulations IEC 61010–1:2010/

DIN EN 61010–1:2011/VDE 0411–1:2011. When used for its

intended purpose, safety of the operator, as well as that of

the instrument, is assured. Their safety is however not

guaranteed, if the instrument is used improperly or handled

carelessly.

In order to maintain flawless technical safety conditions, and to

assure safe use, it is imperative that you read the operating

instructions thoroughly and carefully before placing your instrument

into service, and that you follow all instructions contained therein.

In the interest of your own safety and in order to protect the

instrument, the multimeter is equipped with an automatic

socket blocking mechanism. This mechanism is linked to the

function selector switch and only allows access to those

jacks which are actually required for the selected function. It

also prevents the user from turning the selector switch to

impermissible functions after the measurement cables have

already been plugged in.

Observe the following safety precautions:

• The instrument may only be operated by persons who

are capable of recognizing contact hazards and taking

the appropriate safety precautions.

anywhere, where voltages of greater than 33 V

• Avoid working alone when taking measurements which

involve contact hazards. Be certain that a second person

is present.

• Maximum allowable voltage between any of the connector

jacks and earth is 1000 V, category III or 600 V CAT IV.

Nominal voltage at the system may not exceed 600 V.

For the application of measuring cables see chap. 17.2.

Contact hazards exist

may occur.

RMS

GMC-I Messtechnik GmbH 3

Voltage measurement may only be performed with the

Warning!

!

Consecutive number

Registration number

Date of calibration (year - month)

Deutsche Akkreditierungsstelle GmbH – calibration laboratory

XY123

2012-07

D-K-

15080-01-01

selector switch set to the V= or the V~ position.

• Be prepared for the occurrence of unexpected voltages

at devices under test (e.g. defective devices). For

example, capacitors may be dangerously charged.

• Make certain that the measurement cables are in flawless

condition, e.g. no damage to insulation, no interruptions

in cables or plugs etc.

• No measurements may be made with this instrument in

electrical circuits with corona discharge (high-voltage).

• Special care is required when measurements are made in

HF electrical circuits. Dangerous pulsating voltages may

be present.

• Measurements under moist ambient conditions are not

permitted.

• Be absolutely certain that the measuring ranges are not

overloaded beyond their allowable capacities. Limit values

can be found in the “Measuring Ranges” table in chapter

14 “Characteristic Values”.

• All current measuring ranges are protected with fuses.

Maximum allowable voltage for the measuring current

circuit is 1000 V in all “mA” and “A” ranges.

The standard instrument may not be operated in

explosive atmosphere, or connected to intrinsically

safe electrical circuits.

There is a special type World IS which is certified for

this application.

Measuring Categories and their Meaning per IEC 61010-1

CAT Definition

Measurements in electrical circuits not directly

connected to the mains system:

I

e. g. power systems in motor vehicles or

aeroplanes, batteries ...

Measurements in electrical circuits directly

II

connected to the low-voltage system:

via plug, e.g. in households, offices, laboratories ...

Measurements in facility installations:

III

stationary consumers, distributor connections,

devices attached to a distributor

Measurements at the source of low-voltage

installations:

IV

Meters, main terminal, primary overcurrent

protection devices

The measurement category and the relevant maximum rated

voltage (e. g. 1000 V CAT III) which are shown on the

instrument casing apply to your measuring instrument.

Meanings of symbols on the instrument:

Warning concerning a source of danger

(attention: observe documentation)

Earth terminal

Continuous, doubled or reinforced

insulation

This device may not be disposed of with the

trash. Further information regarding the WEEE

mark can be accessed on the Internet at

www.gossenmetrawatt.com by entering the

search term ’WEEE’.

Indicates EC conformity

CAT III / IV

Repair, Parts Replacement and Balancing

When the instrument is opened, voltage conducting parts

may be exposed. The instrument must be disconnected from

the measuring circuit before the performance of repairs, the

replacement of parts or balancing. If balancing, maintenance

or repair of a live open instrument is required, this may only

be carried out by trained personnel who are familiar with the

dangers involved.

Defects and Extraordinary Strains

If it may be assumed that the instrument can no longer be

operated safely, it must be removed from service and

secured against unintentional use.

Safe operation can no longer be relied upon:

• If the device demonstrates visible damage

• If the instrument no longer functions

• After lengthy periods of storage under unfavorable

Maximum allowable voltage

connector jacks and earth is

600 V category IV

DAkkS Calibration Upon Request:

conditions (e.g. humidity, dust, temperature), see

ambient conditions on page 16

between the

1000 V, category III or

.

4 GMC-I Messtechnik GmbH

2 Initial Start-Up

Note!

Battery

Your instrument is supplied with two 1,5 V AA size batteries in

accordance with IEC LR 6, and is ready for operation. Be sure

to refer to chapter 15.1 “Battery”, before initial start-up, or after

your device has been in storage for a lengthy period of time.

Switching the Instrument On

➭ Press the ON / OFF key.

Power-up is acknowledged with an acoustic signal. All of

the segments at the liquid crystal display (LCD) are

illuminated shortly. The LCD is shown in the diagram on

page 2.

Electrical discharge and high frequency interference

may cause incorrect displays to appear, and may

disable the measuring sequence. In such cases,

switch the instrument off and back on again in order

to reset. If the problem persists, briefly dislodge the

battery from the connector contacts.

Disconnect the instrument from the measuring circuit before

opening and refer to chapter 15 “Maintenance”!

Automatic Shutdown

The instrument switches itself off automatically if neither one

of the keys nor the rotary selector switch are activated for a

period of approximately 15 minutes.

Disabling Automatic Shutdown

The instrument can be set to continuous duty. Press the

FUNC key and the ON / OFF key simultaneously when

switching the instrument on to this end. Continuous duty is

indicated at the LCD by means of the symbol.

Switching the Instrument Off

Press the ON / OFF key.

3 Selecting Measuring Functions and Measuring Ranges

The function selector switch is linked to the automatic socket

blocking mechanism, which only allows access to two

connector jacks for each function. Be certain to remove the

appropriate plug from its respective jack before switching to

and from the “mA” or the “A” function. The socket blocking

mechanism prevents the user from inadvertently turning the

selector switch to impermissible functions after the

measurement cables have been plugged in to the instrument.

3.1 Automatic Measuring Range Selection

The multimeter is equipped with automatic measuring range

selection for all ranges except the 600 mV range. Autoranging is active as soon as the instrument is switched on.

The instrument automatically selects the measuring range

which allows for highest possible resolution of the applied

quantity.

The instrument is automatically switched to:

– The next highest range at typically (6039 digits + 1 digit)

– The next lowest range at typically (560 digits – 1 digit)

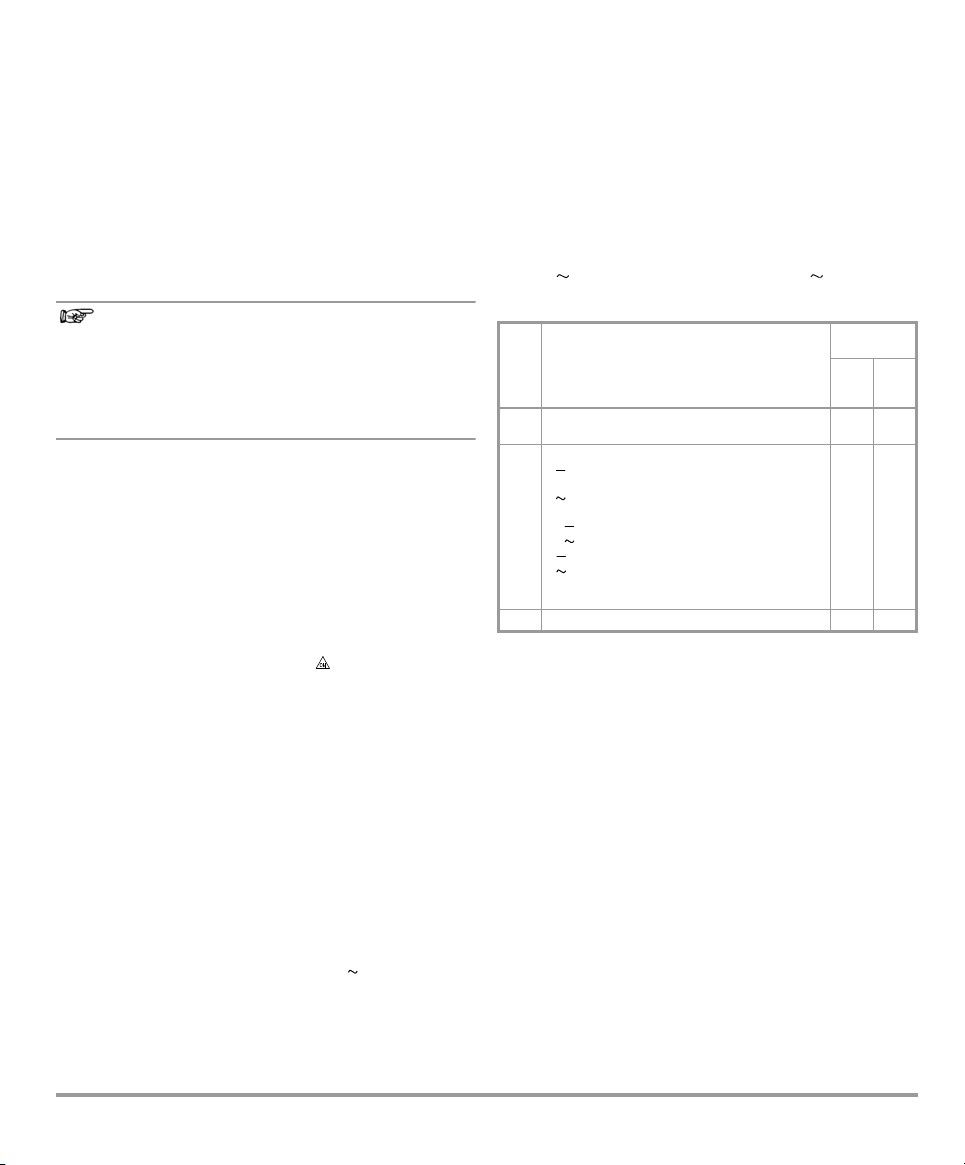

3.2 Manual Measuring Range Selection

Auto-ranging can be deactivated and measuring ranges can

be selected manually in accordance with the following table.

Manual operation is deactivated by pressing and holding the

MAN / AUTO key (approx. 1 s), by activating the

rotary selector switch, or by switching the instrument off and

then back on again.

If the instrument is switched back to auto-ranging in the

600 mV range, the respective range or 6 V is selected

automatically.

AUTO/

MAN

(4)

brief

V : 600 mV 6V 60 V 600 V 1000 V

600 mV...

V : 6V 60 V 600 V 600 mV 6V

1000 V...

mA : 60 mA 600 mA ...

brief

mA : 60 mA 600 mA ...

A : 6A 10 A 6A ...

A : 6A 10A 6 A ...

:60M 600 6k60 k

600 k 6M 60 M ...

long Return to automatic range selection — 2 x

Function

Manual mode active:

utilized measuring range is fixed

Range switching sequence for:

Acknowledge-

ment

Acou-

Dis-

stic

play

Signal

MAN

1 x

(10)

MAN

1 x

(10)

3.3 Quick Measurements

Measurements performed using a suitable fixed measuring

range are executed more quickly than those which utilize

automatic range selection. Quick measurement is made

possible with the following two functions:

• Manual measuring range selection, i.e. selection of the

measuring range with best resolution (see chapter 3.2)

or

•With the HOLD function (see chapter 5). In this way, the

correct measuring range is selected automatically after

the first measurement and all further measurements are

executed more quickly.

The selected measuring range remains active for the

subsequent series of measurements with these two

functions.

GMC-I Messtechnik GmbH 5

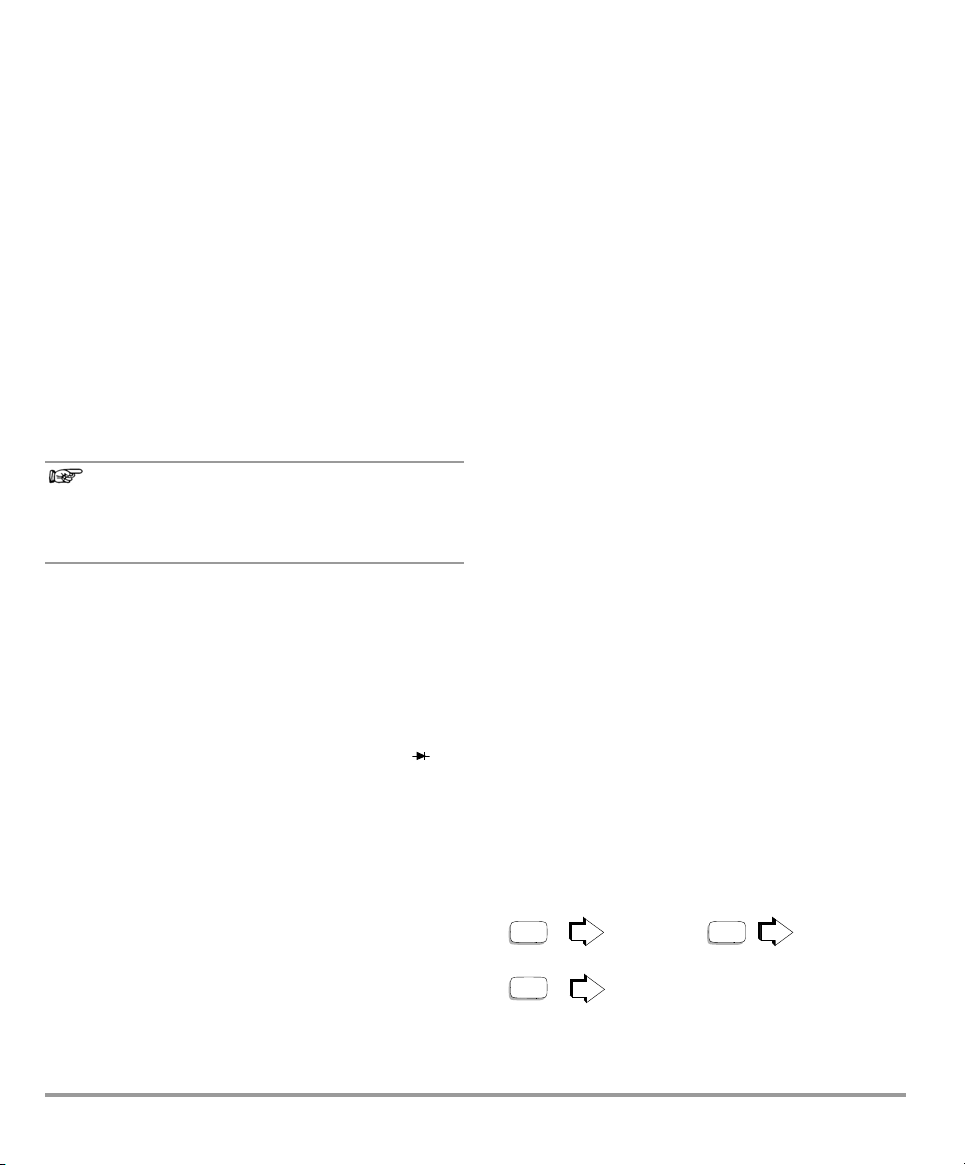

3.4 Relative Measurement REL

Note!

MAX MIN

MAN / AUTO *

HOLDHOLD x 2

HOLD long

A reference value for relative measurements can be stored to

memory with the keys MAN / AUTO and HOLD.

The applicable reference or correction value is substracted

individually for the respective measuring function as an offset

from all subsequent measurements, and remains in memory

until deleted, or until the multimeter is switched off.

Reference value setting is only possible for the respective

manually selected measuring range.

Setting the Reference Value

➭ Plug the measuring cable into the instrument and

measure a reference value.

➭ Press the MAN / AUTO key and the HOLD key

simultaneously.

The instrument acknowledges storage of the reference

value with an acoustic signal, and the REL symbol

appears at the LCD. The value measured at the

moment the keys are pressed serves as a reference

value.

➭ The reference value can be cleared by once again

pressing the MAN / AUTO and HOLD keys.

4.3 Display Illumination

After the instrument has been switched on, background

illumination can be activated by briefly pressing the

ON / OFF LIGHT key. Illumination is switched back off by once

again pressing the same key, or automatically after

approximately 1 minute.

5 Measured Value Memory “HOLD”

By pressing the HOLD key, the currently displayed

measurement value can be “frozen” in the display, and “Hold”

is simultaneously indicated. Automatic shutdown is

deactivated during this process.

The Hold display is deactivated if:

•the HOLD key is pressed and held

•the rotary selector switch is activated

•the FUNC multifunction key is pressed for a change of

function, e.g. AC

Hz.

6 Saving Minimum or Maximum Values

“MIN/MAX” Hold

Minimum and maximum measured values applied to the

measuring instrument’s input after the MAX/MIN function has

been activated, can be “frozen” at the display with the MAX/

Relative measurement effects the digital display only.

Relative measurement is not active during overflow.

In the case of relative measurement, quantities may

MIN function. The most important use of this function is the

determination of minimum or maximum values during longterm measured quantity observation.

also appear as negative values.

➭ Select the measurement function with the

4LCD

4.1 Digital Display

The measured value with decimal and plus or minus sign

appears at the digital display. The selected unit of measure

and the current type are displayed as well. A minus sign

appears to the left of the value during the measurement of

zero-frequency quantities, if the plus pole of the measured

quantity is applied to the “” input. “OL” is displayed if the

upper range limit of 6039 is exceeded (or 1999 in the

range).

The digital display is refreshed twice per second during V, A

and measurements.

4.2 Analog Display

The analog display with simulated pointer and the same

dynamic performance as a moving-coil mechanism is

rotary selector switch and, if appropriate, with the FUNC

multifunction key.

➭ Connect the device under test as described in the

following measurement instructions.

➭ Press the HOLD key twice.

MAX is displayed. The measuring instrument continually

updates and digitally displays the largest occurring

measured value.

➭ Press the HOLD key.

MIN is displayed. The measuring instrument continually

updates and digitally displays the lowest occurring

measured value. Pressing HOLD once more switches this

function back to MAX.

➭ Press and hold the HOLD key for approx. 2 seconds, to

quit the HOLD function.

refreshed 20 times per second during V, A and

measurements. This display is especially advantageous for

observing measured value fluctuation, and for balancing

procedures.

The analog display has its own polarity indicator. If the

measured value exceeds the display range, polarity at the

analog display is switched after approximately 0.7 seconds.

Overranging is indicated by the triangle at the right (> 6039

digits).

* range selection is not provided for with MAN + MIN / MAX

6 GMC-I Messtechnik GmbH

7 Voltage Measurement

Note!

Attention!

!

MAN

AUTO

brief

V=

– (+)

+ (–)

max. 1000 V

V=: 600 mV 1000 V

Measuring Ranges:

!

>60V:

> 1000 V:

20.00

V

DC

acoustic signal

6V 60 V

60 V 600 V

600 V 1000 V

600 mV 6V

1000 V 600 mV

MAN

AUTO

brief

V~

Max. 1000 V (2 kHz)

V~: 600 mV 1000 V

(30 Hz 2kHz)

Measuring Ranges:

~

!

> 1000 V:

* manual only

>40V:

acoustic signal

6V 60 V

60 V 600 V

600 V 1000 V

600 mV* 6V

1000 V 600 mV*

20.00

V

~

AC

TRMS

➭ Depending upon the voltage to be measured, set the

rotary selector switch to V

➭ Connect the measurement cables as shown. The “”

connector jack should be grounded.

The 600 mV measuring range can only be selected

manually with the MAN / AUTO key.

If the measured value exceeds 60 V DC or 40 V AC

the symbol appears at the display.

An intermittent acoustic signal warns the operator if

the measured value exceeds the upper range limit

value of 1000 V in the 1000 V range.

Make sure than none of the current measuring ranges

(neither “mA” nor “A”) are activated when connecting

the multimeter for the performance of voltage

measurements! If fuse trip limits are exceeded as a

result of operator error, both the operator and the

instrument are in danger!

or V .

Zero Balancing REL in the V AC und V DC Measuring Range

You can select the reference point in the V AC and V DC

measuring range:

➭ Plug the measuring cables into the instrument and

connect the free ends to each other.

➭ After selecting the measuring range, briefly press the two

HOLD and MAN / AUTO keys.

The instrument acknowledges zero balancing with an

acoustic signal and „0“ ( 1digit) and REL appears at the

LCD, depending on the measuring range. The voltage

displayed at the moment the key is pressed is automatically

substracted from all subsequent measured values.

Zero balancing can be deleted:

– by briefly pressing the MAN / AUTO key, which is

acknowledged with an acoustic signal,

– by switching the instrument off.

GMC-I Messtechnik GmbH 7

7.1 Sub-function Hz

➭ Turn t h e rotary selector switch to V

➭ Briefly press the FUNC multifunction key to display the

frequency (max. 2_kHz) of the AC voltage.

➭ Press the FUNC key once again to quit the Hz function.

8 Current Measurement

FUNC

brief

1x

A

...6 A

!

00.00

A

Current

~ ~

1

3

2

A: 6A 10.00 A

Measuring Range:

MM

>11A:

!

0.000

A

acoustic signal

acoustic

signal

...10 A

DC AC~

AC ~ DC

DC

AC ~

TRMS

DC

AC ~

TRMS

➭ First disconnect supply power from the measuring circuit

or the consuming device, and discharge any included

capacitors.

➭ Select the A range with the rotary selector switch for

current greater than 600 mA, or the mA range for

current less than 600 mA. Activate the highest measuring

range first when measuring current of an unknown

magnitude.

➭ Select the current type appropriate for the measured

quantity by briefly pressing the FUNC key. Each time the

key is pressed, DC and AC are alternately selected, and

switching is acknowledged with an acoustic signal. The

selected current type is indicated at the LCD by means of

the DC and AC symbols.

DC current is always active immediately after range

selection with the rotary selector switch.

➭ Securely connect the measuring instrument to the

consuming device in series as shown (without transfer

resistor).

8 GMC-I Messtechnik GmbH

connector jacks.The following symbol appears at the

FUNC

brief

Measuring Range:

mA

... 600 mA

000.0

mA

~

R

x

~

R

x

1

3

2

> 600 mA:

!

Current

DC AC~

AC ~ DC

1x

mA: 60 mA 600,0 mA

00.00

mA

... 60 mA

acoustic signal

acoustic

signal

DC

AC ~

TRMS

DC

AC ~

TRMS

digital display in this case: .

• If a fuse blows, eliminate the cause of overload before

placing the instrument back into service!

• Refer to chapter 15 “Maintenance”, regarding fuse

replacement.

Zero Balancing REL during Current Measurement

You can select the reference point in the mA AC / DC and

A AC / DC measuring range:

➭ Plug the measuring cables into the instrument and

connect the free ends to each other.

➭ After selecting the measuring range, briefly press the two

HOLD and MAN / AUTO keys.

The instrument acknowledges zero balancing with an

acoustic signal and „0“ ( 1digit) and REL appears at the

LCD, depending on the measuring range. The voltage

displayed at the moment the key is pressed is automatically

substracted from all subsequent measured values.

Zero balancing can be deleted:

– by briefly pressing the MAN / AUTO key, which is

acknowledged with an acoustic signal,

– by switching the instrument off.

Notes Regarding Current Measurement:

• The measuring circuit must be mechanically stable and

must be secured against accidental interruption. Select

conductor cross-sections and connectors such that no

overheating occurs.

• An intermittent acoustic signal warns the operator if the

measured value exceeds the upper range limit in the

600 mA and 10 A measuring ranges.

• Measuring ranges up to 600 mA are protected against

short-circuit current of up to 25 A with an FF 1.6 / 1000 V

fuse link in combination with power diodes. The fuse has

a breaking capacity of 10 kA at a nominal voltage of

1000 V and ohmic load.

• The 6A and 10 A current measuring ranges are protected

with a 10 A / 1000 V fuse link. The fuse has a breaking

capacity of 30 kA at a nominal voltage of 1000 V and

ohmic load.

• If one of the fuses blows, this condition is indicated at the

LCD as soon as a measured quantity with a voltage of

greater than 4 V is applied to the corresponding

GMC-I Messtechnik GmbH 9

8.1 Measuring Alternating Current with (Clip-On) Current

Attention!

!

~

R

x

~

R

x

1

3

Current

V~

05.00

V

Z13B

2

0.5

k

R

x

: 600 40 M

Measuring Range:

+–

R

x

0V !

!

Tra nsf orme rs

8.1.1 Transformer Output mA / A

If current transformers are operated without being

connected at the secondary side (e.g. as a result of

defective or missing cables, a blown device fuse or

incorrect connection), dangerously high voltages

may occur at the connector jacks. For this reason,

make sure that the measuring instrument’s current

path and the transformer’s secondary coil connected

to the instrument constitute an uninterrupted circuit,

and connect this circuit to the and mA or A jacks.

Maximum allowable operating voltage is equal to the current

transformer’s nominal voltage. Do not forget to consider the

transformer’s transformation ratio and additional display error

when reading measured values.

8.1.2 Transformer Output V

Some transformers are equipped with a voltage output

(designation mV/A). The secondary terminals must thus be

connected to and V.

9 Resistance Measurement

➭ Make sure that the device under test is voltage-free.

Interference voltages distort measurement results!

➭ Set the rotary selector switch to .

➭ Connect the device under test as shown.

Zero Balancing REL in the entire resistance measuring range

Cable and contact resistances can be eliminated during

resistance measurement by means of zero balancing:

➭ Plug the measuring cables into the instrument and

connect the free ends to each other.

➭ Press the MAN / AUTO and HOLD keys after selecting the

measuring range.

The instrument acknowledges zero balancing with an

acoustic signal and „0“ (+1 digit) and REL appears at

the LCD, depending on the measuring range. The

resistance value measured at the moment the key is

pressed is automatically subtracted from all subsequent

measured values.

Zero balancing can be deleted:

– by briefly pressing the MAN / AUTO key, which is

acknowledged by an acoustic signal,

– by switching the instrument off.

10 GMC-I Messtechnik GmbH

10 Continuity and Diode Testing

Note!

0.654

0L

Conducting Direction

Reverse Direction

0.000

V

FUNC

brief

0V !

Continuity

R < 40

!

030.0

acoustic

signal

➭ Make sure that the device under test is voltage-free.

Interference voltages distort measurement results!

➭ Set the rotary selector switch to .

➭ Connect the device under test as shown.

Conducting Direction and/or Short-Circuit:

The instrument displays conducting-state voltage in volts. As

long as voltage drop does not exceed the maximum display

value of 1,999 V, several series connected components or

reference diodes can be tested with a small reference

voltage.

Reverse Direction or Interruption:

The measuring instrument indicates overflow “OL”.

Resistors and semiconductors which are connected

in parallel to the diode distort measurement results!

Sub-function Continuity Test with Acoustic Signal

If the sub-function “continuity test with acoustic signal” is

activated, a continuous acoustic signal is generated by the

instrument within a display range of R < 40.

Acoustic Signal ON:

➭ Briefly press the FUNC key.

Activation is acknowledged with an acoustic signal.

The symbol appears at the display as well.

Acoustic Signal OFF:

➭ Briefly press the FUNC key once again.

Deactivation is acknowledged with an acoustic signal.

The symbol is cleared from the display.

The acoustic signal function is always inactive immediately

after the “continuity test” function has been selected with the

rotary selector switch. The acoustic signal can be activated

and deactivated by repeatedly and briefly pressing the FUNC

key. If the key is pressed and held, the acoustic signal is

always deactivated, which is acknowledged with two

acoustic signals.

GMC-I Messtechnik GmbH 11

11 Capacitance Measurement

Note!

Note!

+

–

F

00.00

nF

F: 40 nF 400 μF

Messbereich:

Duty Cycle (%) = ——————— • 100

Pulse Duration

Period

➭ Make sure that the device under test is voltage-free.

Interference voltages distort measurement results!

➭ Turn the rotary switch to the “F” position.

➭ Connect the (discharged!) device under test to the and V

jacks with the measurement cables

12 Frequency Measurement – Duty Cycle Measurement

➭ Turn the rotary switch to the Hz position.

➭ Apply the measured quantity as described under voltage

measurement.

➭ Smallest measurable frequencies and maximum

allowable voltages are listed in chapter 14 “Characteristic

Values”.

The “–“ pole of polarized capacitors must be

connected to the „“ jack.

Resistors and semiconductor paths connected in

parallel to the capacitor distort measurement results!

12.1 Duty Cycle Measurement

The pulse-period ratio can be ascertained for square-wave

signals with the duty cycle measurement.

➭ Turn the rotary swith to Hz position

➭ Briefly press the multifunction FUNC key twice. The

instrument is switched to duty cycle measurement. The

duty cycle, i.e. the pulse duration of a signal as a

percentage, is displayed at the LCD.

The applied frequency must remain constant during

duty cycle measurement.

12.2 RPM Measurement

RPM is measured by acquiring pulses. The number of

measurable pulses per revolution varies depending upon the

type of engine.

➭ Set the rotary switch to Hz.

➭ Press the multifunction key FUNC twice until unit of

measure RPM appears.

The measured value then appears, for

example

“244.3 RPM”.

12 GMC-I Messtechnik GmbH

13 Temperature Measurement

Note!

023.2

C

TC Measuring Range

Type_K –50 +400 C

+401 ... +800C

C

FUNC

brief

TYPE K

C F

The multimeter provides for the measurement of

temperatures within a range of – 50°C to + 800°C with the

help of a type K temperature sensor.

➭ Set the rotary selector switch to „°C“.

➭ Connect the sensor to the two accessible jacks.

The device indicates the measured temperature in C at

the digital display.

➭ Briefly press the FUNC key to switch between C and F.

The cold junction temperature (reference

temperature) is measured with a Pt100 temperature

sensor inside the instrument. It is displayed when the

measuring input is short-circuited. Due to internal

heating or a change from warm to cold environment

or vice versa, the reference temperature may differ

from the ambient temperature.

GMC-I Messtechnik GmbH 13

14 Characteristic Values

Meas.

FunctionMeasuring Range

Resolution

Input Impedance

6000

600 mV 100 V10M // < 40 pF 8.1 M // 50 pF 0.5 + 5

6V 1mV5.2M // < 40 pF 4.6 M // 50 pF 0.5 + 5

V

60 V 10 mV 5 M // < 40 pF 4.4 M // 50 pF 0.5 + 5

600 V 100 mV 5 M // < 40 pF 4.4 M // 50 pF 0.5 + 5

1000 V 1 V 5 M // < 40 pF 4.4 M // 50 pF 0.5 + 5

Voltage drop at approx. range limit

60 mA 10 A 100 mV 100 mV

A

600 mA 100 A 700 mV 700 mV

6 A 1 mA 200 mV 200 mV

10 A 10 mA 300 mV 300 mV

Open-circuit

voltage

Meas. current at

range limit

600 100 m max. 1 V max. 250 A1 + 5

6k 1 max. 1 V max. 100 A 0.7 + 3

60 k 10 max. 1 V max. 12 A 0.7 + 3

600 k 100 max. 1 V max. 1,2 A 0.7 + 3

6M 1k max. 1 V max. 120 nA 0.7 + 3

40 M 10 k max. 1 V max. 50 nA 2.0 + 3

2V 1mV max. 3V 1.0 + 5

600 0.1 max. 1 V max. 250 A 1.0 +5

-50,0 ...

TYP K

C

+400 C

+ 401 ...

+800 C

0,1 C 1.0 + 5 K

0,1 C 5.0 + 7 K

Power limit (... % rdg. + ... d)

Hz

V

Hz

100 Hz 0,1 Hz

1000 Hz 1 Hz

100 Hz 0,1 Hz

1000 Hz 1 Hz

6

V x Hz @ U > 100 V 0.1 + 2

3 x 10

6

3 x 10

V x Hz @ U > 100 V

1000 kHz 1 kHz

Power limit

30 Hz ... 1KHz: 2,0 ... 98,0

1 kHz ... 4 kHz: 5,0 ... 95,0 0.2% v.MUL/kHz + 8 D

%

6

3 x 10

V x Hz @ U > 100 V

40 kHz ... 10 kHz:10,0 ...90,0 0.2% v.MUL + 8 D

Intrinsic Uncertainty at Max. Resolution

under Reference Conditions

(... % rdg. + ... d) (... % rdg. + ... d)

1.0 + 5 (> 10 D) 1.5 + 5 (> 10 D)

(... % rdg. + ... d)

(... % rdg. + ... K)

2)

3)

3)

0.1 + 2

0.2% v.MUL + 8 D

1 + 5

Overload Capacity

1)

5)

5)

Value Time

1000 V

DC

AC

eff

Sinus

Cont.

Meas.

Function

V

1.0 A Cont.

10 A

1000 V

DC

AC

eff

Sinus

1000 V

DC/AC

eff

Sinus

1000 V

1000 V

1000 V

4)

Cont.

max. 10 s

max. 10 s

max. 10 s

max. 10 s

max. 10 s

A

C

Hz

V

Hz

%

Rpm

60 ... 99.99 k 1 Rpm 2 Rpm

1000 V

max. 10 s

Rpm

Discharge Resistance (... % rdg. + ... MR)

40 nF 10 pF 10 M 2.0 + 10 with zero active

400 nF 100 pF 1 M 1.0 + 6

F

4 μF 1 nF 100 M 1.0 + 6

40 μF 10 nF 12 M 2.5 + 6

1000 D

DC

AC

max. 10 s

F

400 μF 100 nF 3 M 5.0 + 6

1)

At 0 C ... + 40 C

2)

with zero balancing, + 35 digits without zero balancing

3)

without sensor

4)

12 A 5 minutes, 16 A 30 seconds

5)

1 ... 35 d from the zero point due to TRMS converter when probe tips are shortcircuited

Key

rdg. = reading (measured value); d = digit

MUL = upper range limit; MR = measuring range

14 GMC-I Messtechnik GmbH

Influencing Quantities and Influence Error

Influencing

Temperature

Measured

Frequency

Influencing

MIN / MAX — V , A 2Digits

1)

2) With zero balancing

3) After the symbol appears at the display

Sphere of Influence

Quantity

0 C ... +21 C

and

+25 C... +40 C

> 30 Hz ... 45 Hz A 2.0 + 10

> 65 Hz ... 1 kHz

Quantity

Quantity

Battery

Volta ge

Relative

Humidity

For temperature: specified error valid starting with t emperature changes as of 10 K.

For frequency: specified error valid starting with display values as of 300 digits.

> 30 Hz ... 45 Hz

> 65 Hz ... 500 Hz 600 mV 35 + 20

>65Hz...800Hz

Sphere of

Influence

3)

... < 2.9 V

> 3.1 V ... 3.6 V

75%

3 days

Instrument off

HOLD — 1Digits

Measured Quantity /

Measuring Range

600 mV 1.0 + 3

6 ... 600 V 0.15 + 1

1000 V 0.2 + 1

V0.4+2

2)

0

2)

600

6k ... 6 M 0.15 + 1

40 M 1.0 + 1

mADC, ADC 0.5 + 1

mAAC, AAC 0.75 + 1

– 50 ... + 200 C 0.5 K + 2

+ 200 ... + 400 C 0.5 + 2

60 / 600 mA / 6 A 1.5 + 10

10 A 2 + 10

600 mV 3 + 10

6 / 60 /600 V 2.5 + 10

1000 V 3.5 + 20

6 / 60 V 2.5 + 10

600 V 3 + 20

1000 V 3.5 + 20

Measured Quantity /

Measuring Range

V 2Digits

V 4Digits

A 4Digits

A 6Digits

60 / 600 / C 4Digits

6k ... 40 M3Digits

V

A

C

Influence Error 1)

(... % rdg. + ... digits)

0.15 + 2

0.25 + 2

Influence Error

1 x intrinsic uncertainty

Influencing

Quantity

Common

Mode

Interference

Volt age

Series Mode

Interference

Volt age

Sphere of Influence

Interference quantity max. 600 V V > 120 dB

Interference quantity max. 600 V

50 Hz, 60 Hz sine

Interference quantity: V ,

respective nominal value

of the measuring range,

max. 600 V , 50 Hz, 60 Hz sine

Interference quantity max. 600 V V > 110 dB

Measuring

Range

6V ,

60 V

600 V > 70 dB

V > 50 dB

Crestfaktor CF

Test signal: Rectangle 55 Hz, no DC component

Influencing

Quantity

Crest factor CF

Sphere of Influence

1.5 < CF 2

2 < CF 4 5% rdg.

Measured Quantity /

Measuring Range

6 V, 60 V, 600 V,

1000 V

The admissible crest factor CF of the alternating quantity to

be measured depends on the display value.

Crest factor 4 at the end of range, it is increased accordingly

when the range is reduced. However, due to input protection,

voltage is limited to 1000 V, therefore the admisible crest factor in the 600 V ranges is half as high.

When the waveform is unknown, measurement is to be performed with manual range selection in the case of higher frequency signals.

Power limiting: voltage x frequency max. 3 x 10

6

Response Time (after manual range selection)

Measured

Quantity/

Measuring Range

V , V ,

A , A

600... 6 M 1.5 s 2 s

40 M 4 s 5 s

C—*max. 3 s

F—*max. 5

* without bargraph

Response Time

Analog Display Digital Display

0.7 s 1.5 s

— * 1.5 s

— * < 50 ms

Measured Quantity

Step Function

from 0 to 80%

of the upper range limit

from to 50%

of the upper range limit

from 0 to 50%

of the upper range limit

Damping

>80dB

Influence Error

1% rdg.

V x Hz.

GMC-I Messtechnik GmbH 15

Reference Conditions

Ambient temperature + 23 C 2K

Relative humidity 40 % ... 60 %

Measured quantity

frequency 45 Hz ... 65 Hz

Measured quantity

waveshape sinusoidal

Battery voltage 3 V 0.1 V

Display

LCD panel (65 mm x 30 mm) with analog and digital display

including unit of measure, type of current and various special

functions

Analog

:

Display LCD scale with pointer

Scale length 55 mm in all ranges

Scaling 0 ... 60 with 61 scale divisions in

all ranges

Polarity display With automatic switching

Overflow display Triangle

Measuring rate 30 measurements per second

Digital

:

Display / char. height 7-segment characters / 15 mm

Number of places 3

6

/7-place 6000 steps

Overflow display “OL” appears

Polarity display “–” sign is displayed if plus pole is

connected to “”

Measuring rate 3 measurements per second

Power Supply

Battery 2 x 1.5 V AA size batteries

alkaline manganese per IEC LR6 or

equivalent rechargeable NiCd

battery

Service life With alkaline manganese:

approx. 750 hours for V , A

approx. 200 hours for V , A

Battery test is displayed automatically if

battery voltage drops to below

approx. 2.1 V.

Electrical Safety

Safety class II per IEC 61 010-1:2010/

DIN EN 61010-1:2011/

VDE 0411-1:2011

Overvoltage category 1000 V CAT III, 600 V CAT IV

Nominal voltage 1000 V

Fouling factor 2

Test voltage 6.7 kV~ per IEC 61010-1:2010/

DIN EN 61010-1:2011

Electromagnetic Compatibility (EMC)

Interference emission EN 61 326-1: 2013 class B

Interference immunity

EN 61326-1: 2013

EN 61326-2-1: 2013

Fuses

Fuse links for all

ranges up to 600 mA FF(UR) 1.6 A/1000 V;

mm,

6.3 mmx32

switching capacity: 10 kA at

1000 V~ with ohmic load, protects

all current measuring ranges up to

600 mA in combination with power

diodes

Fuse links for all

ranges up to 10 A FF(UR) 10 A/1000 V;

10 mmx 38 mm,

switching capacity: 30 kA at

1000 V with ohmic load, protects

6 A and 10 A ranges to 600 V

Refer to chapter 15

“Maintenance”, regarding fuse

manufacturers and types.

Ambient Conditions

Accuracy range 0 C ... + 40 C

Operating temperature –10 C ... + 50 C

Storage temperature – 25 C ... + 70 C without batteries

Relative humidity

45 ... 75%, no condensation allowed

Elevation to 2000 m

Deployment indoors only, except within

specified ambient conditions

Mechanical Design

Protection IP 40

(IP 54 special type WORLD_IS)

per DIN VDE 0470 part 1 /

EN 60529

Extract from table on the meaning of IP codes

IP XY

st

(1

Protection against

digit X)

foreign object entry

0 not protected 0 not protected

1 50.0 mm dia. 1 vertically falling drops

2 12.5 mm dia. 2

3 2.5 mm dia. 3 spraying water

4 1.0 mm dia. 4 splashing water

IP XY

(2nd digit Y)

Protection against the

penetration of water

vertically falling drops

with enclosure tilted 15

Dimensions 84 mm x 195 mm x 35 mm

Weight approx. 350 gr. with battery

16 GMC-I Messtechnik GmbH

15 Maintenance

Attention!

!

Attention!

!

(b) (a)

Disconnect the instrument from the measuring circuit

before opening to replace batteries or fuses!

15.1 Battery

Make sure that no battery leakage has occurred before initial

start-up, and after long periods of storage. Continue to

inspect the batteries for leakage at short, regular intervals.

If battery leakage has occurred, carefully and completely

clean the electrolyte from the instrument with a damp cloth,

and replace the batteries before using the instrument.

If the symbol appears at the display , the batteries should

be replaced as soon as possible. You can continue working

with the instrument, but reduced measuring accuracy may

result.

The instrument requires 2 x 1.5 V AA size batteries or two

equivalent NiCd rechargeable batteries.

Replacing the Battery

➭ Set the instrument face down onto a flat working surface,

loosen the two screws at the back and lift off the housing

base, starting at the bottom. The housing top and

housing base are held together with the help of snap

hooks at the top front.

➭ Remove the batteries from the battery compartment.

➭ Insert two new 1.5 V AA size batteries into the battery

compartment, making sure that the plus and minus poles

match up with the provided polarity symbols.

➭ Important for reassembly: First set the housing base onto

the housing top and align accurately (see photo below).

Then press the two housing halves together, first at the

bottom front (a), and then at the top front (b).

➭ Secure the housing base with the two screws.

➭ Please dispose of depleted batteries in accordance with

environmental protection regulations!

15.2 Fuses

If one of the fuses blows, this condition is displayed at the

LCD as soon as a measured quantity with a voltage of greater

than 4 V is applied to the corresponding connector jacks. The

following symbol appears at the digital display in this case:

.

The 16 A fuse interrupts the 6 A and 10 A ranges, and the

1.6 A fuse interrupts all other current measuring ranges. All

other measuring ranges remain functional.

If a fuse should blow, eliminate the cause of overload before

placing the instrument back into service!

Replacing the Fuse

➭ Open the instrument as described under “Replacing the

Battery”.

➭ Remove the blown fuse with the help of an object such

as a test probe, and replace it with a new fuse.

The following fuses are approved for use:

– For current measuring ranges up to 600 mA:

Type FF 1.6 A / 1000 V AC (10 kA),

6.3 mm x 32 mm

– For 6 A and 10 A current measuring ranges:

FF 10 A/1000 V AC (30 kA),

10 mm x 38 mm

Use specified fuses only! If fuses with other blowing

characteristics, other current ratings or other

breaking capacities are used, the operator is placed

in danger, and protective diodes, resistors and other

components may be damaged.

The use of repaired fuses or short-circuiting the fuse holder is

prohibited.

15.3 Housing

No special maintenance is required for the housing. Keep

outside surfaces clean. Use a slightly dampened cloth for

cleaning. Avoid the use of cleansers, abrasives and solvents.

Device Return and Environmentally Compatible Disposal

The instrument is a category 9 product (monitoring and control

instrument) in accordance with ElektroG (German Electrical

and Electronic Device Law). This device is subject to the

RoHS directive. Further-more, we make reference to the fact

that the current status in this regard can be accessed on the

Internet at www.gossenmetrawatt.com by entering the

search term WEEE.

We identify our electrical and electronic devices in

accordance with WEEE 2012/19/EU and ElektroG

with the symbol shown to the right per DIN EN

50419.

GMC-I Messtechnik GmbH 17

These devices may not be disposed of with the trash. Please

Attention!

!

Pb Cd Hg

contact our service department regarding the return of old

devices.

If you use batteries or rechargeable batteries in your instrument

or accessories which no longer function properly, they must

be duly disposed of in compliance with the applicable

national regulations.

Batteries or rechargeable batteries may contain harmful

substances or heavy metal such as lead (PB), cadmium (CD)

or mercury (Hg).

They symbol shown to the right indicates that

batteries or rechargeable batteries may not be

disposed of with the trash, but must be delivered to

collection points specially provided for this purpose.

16 Recalibration

The respective measuring task and the stress to which your

measuring instrument is subjected affect the ageing of the

components and may result in deviations from the

guaranteed accuracy.

If high measuring accuracy is required and the instrument is

frequently used in field applications, combined with transport

stress and great temperature fluctuations, we recommend a

relatively short calibration interval of 1 year. If your measuring

instrument is mainly used in the laboratory and indoors

without being exposed to any major climatic or mechanical

stress, a calibration interval of 2-3 years is usually sufficient.

17 Accessories

17.1 General

The extensive accessories available for our measuring

instruments are checked for compliance with currently valid

safety regulations at regular intervals, and are expanded as

required for new applications. Currently up-to-date

accessories which are suitable for your measuring instrument

are listed at the following web address along with photo,

order number, description and, depending upon the scope of

the respective accessory, data sheet and operating

instructions: www.gossenmetrawatt.de

(Products Measuring Technology – Portable Multimeter

Accessories )

or

(Products Measuring Technology – Portable Digital

Multimeters METRA HIT ... Accessories).

17.2 Technical Data for Measurement Cables (included: KS17-2 safety cable set)

Electrical Safety

Maximum Rated Voltage 600 V

Measuring Category

CAT IV CAT II I CAT II

Maximum Rated Current 1 A 1 A 16 A

with safety cap applied —

without safety cap applied — —

1000 V

1000 V

During recalibration* in an accredited calibration laboratory

(DIN EN ISO/IEC 17025) the deviations of your instrument in

relation to traceable standards are measured and

documented. The deviations determined in the process are

used for correction of the readings during subsequent

Ambient Conditions (EN 61010-031)

Temperature –20C ... + 50C

Relative humidity max. 80%

Pollution degree 2

application.

We are pleased to perform DAkkS or factory calibrations for

Application KS17-2

you in our calibration laboratory. Please visit our website at

www.gossenmetrawatt.com ( Company DAkkS

Calibration Center or FAQs Calibration questions and

answers).

By having your measuring instrument calibrated regularly, you

fulfill the requirements of a quality management system per

DIN EN ISO 9001.

Please observe the maximum values of the electrical safety

of the device.

In conformity with standard DIN EN 61010-031,

measurements in an environment according to

measuring category II I and IV may only be performed

with the safety cap applied to the test probe of the

measurement cable.

For establishing contact in 4 mm jacks you have to remove

the safety cap by levering out the snap lock of the safety cap

with another sharp object (e.g. the second test probe).

*

Verification of specifications or adjustment services are not part of the

calibration. For products from our factory, however, any necessary adjustment

is frequently performed and the observance of the relevant specification is

confirmed.

18 GMC-I Messtechnik GmbH

18 Repair and Replacement Parts Service,

Calibration Center* and Rental Instrument Service

If required please contact:

GMC-I Service GmbH

Service Center

Thomas-Mann-Str. 20

90471 Nürnberg • Germany

Phone +49 911 817718-0

Fax +49 911 817718-253

E-Mail service@gossenmetrawatt.com

www.gmci-service.com

This address is only valid in Germany.

Please contact our representatives or subsidiaries for service

in other countries.

* DAkkS Calibration Laboratory for Electrical Quantities

Competent Partner

GMC-I Messtechnik GmbH is certified in accordance with

DIN EN ISO 9001.

Our DAkkS calibration laboratory is accredited by the

Deutsche Akkreditierungsstelle GmbH (National accreditation

body for the Federal Republic of Germany) in accordance

with DIN EN ISO/IEC 17025 under registration number D-K15080-01-01.

We offer a complete range of expertise in the field of

metrology: from test reports and factory calibration certificates,

right on up to DAkkS calibration certificates.

Our spectrum of offerings is rounded out with free test

equipment management.

D-K-15080-01-01 accredited per

DIN EN ISO/IEC 17025

Accredited quantities: direct voltage, direct current value, direct

current resistance, alternating voltage, alternating current value,

alternating current active power, alternating current apparent power,

DC power, capacitance, frequency, temperature

An on-site DAkkS calibration station is part of our service

department. If errors are discovered during calibration, our

specialized personnel are capable of completing repairs using

original replacement parts.

As a full service calibration lab, we can calibrate instruments

from other manufacturers as well.

DAkkS Calibration Certificate Reprints (upon request)

If you order a DAkkS calibration certificate reprint for your

instrument, please provide us with the reference numbers

indicated in the upper and lower most fields of the calibration

seal. We do not need the instrument’s serial number.

19 Manufacturer’s Guarantee

All METRAHIT digital multimeters and calibration instruments

are guaranteed for a period of 3 years after shipment. The

manufacturer’s guarantee covers materials and

workmanship. Damages resulting from use for any other than

the intended purpose or operating errors, as well as any and

all consequential damages, are excluded.

The calibration certificate confirms that the product

conformed to the specified technical data at the time of

calibration. We guarantee the observance of the specified

technical data within the admissible tolerance limits for a

period of 12 months from delivery.

20 Product Support

If required please contact:

GMC-I Messtechnik GmbH

Hotline Produktsupport

Phone +49 911 8602-0

Fax +49 911 8602 709

E-Mail support@gossenmetrawatt.com

GMC-I Messtechnik GmbH 19

Edited in Germany • Subject to change without notice • A pdf version is available on the Internet.

GMC-I Messtechnik GmbH

Südwestpark 15

90449 Nürnberg •

Germany

Phone +49 911 8602-111

Fax +49 911 8602-777

E-Mail info@gossenmetrawatt.com

www.gossenmetrawatt.com

Loading...

Loading...