Gossen MetraWatt METRAHIT ENERGY TRMS System Multimeter, METRAHIT ENERGY, METRAHIT ENERGY M249A Operating Instructions Manual

Page 1

METRAHITENERGY

TRMS System Multimeter

Operating Instructions

3-349-576-03

3/9.11

Page 2

2 GMC-I Messtechnik GmbH

Standard Equipment – Contact Persons

Scope of Delivery

1 TRMS system multimeter METRAHIT ENERGY (M249A)

1 KS29 measurement cable set (Z229A)

2 Batteries

1 Condensed operating instructions

1 CD ROM (with operating instructions, data sheet and more)

1 DKD calibration certificate

1 Rubber holster and carrying strap

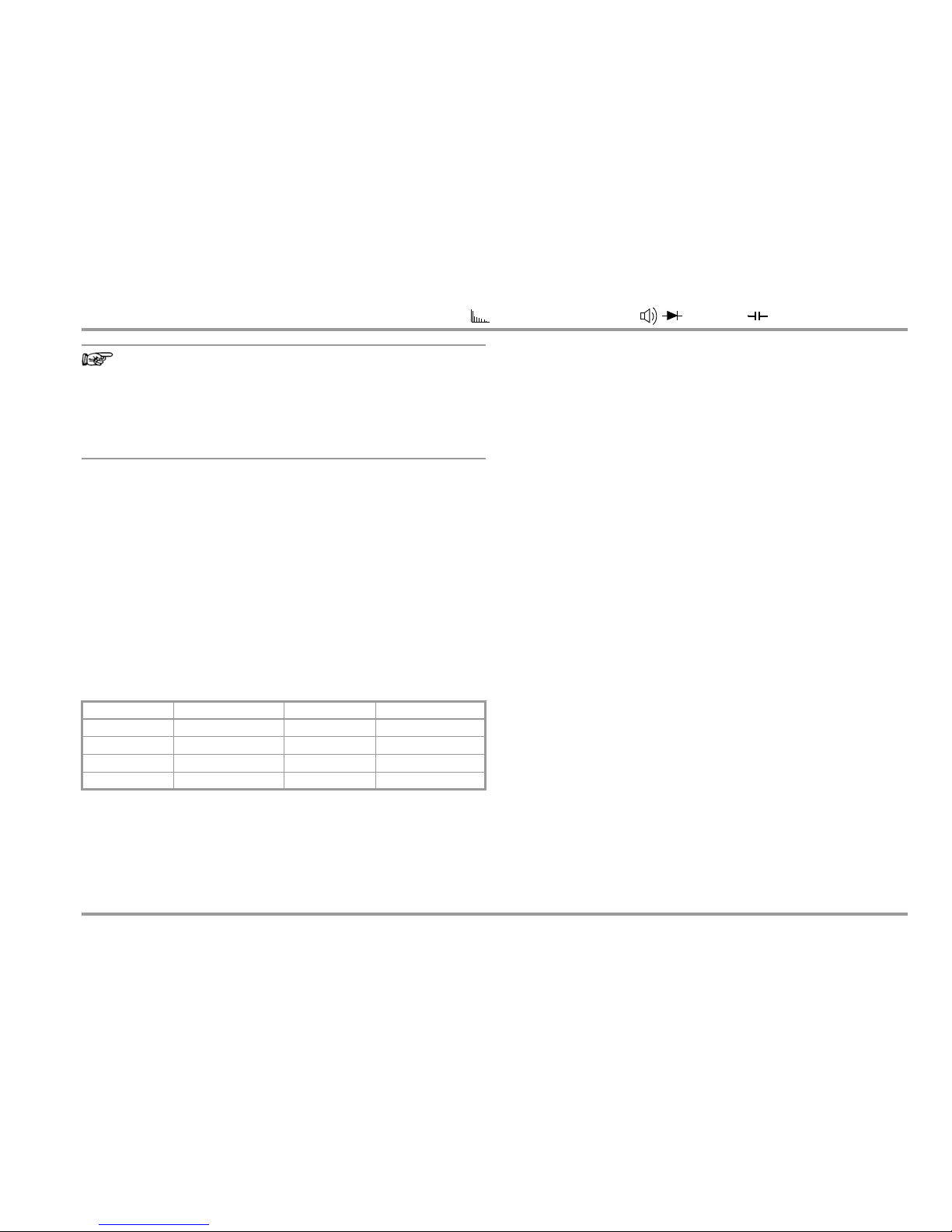

Overview

1

16 Mbit = 2048 kByte = up to 300,000 measured values,

sampling rate adjustable from 0.5 second to 9 hours

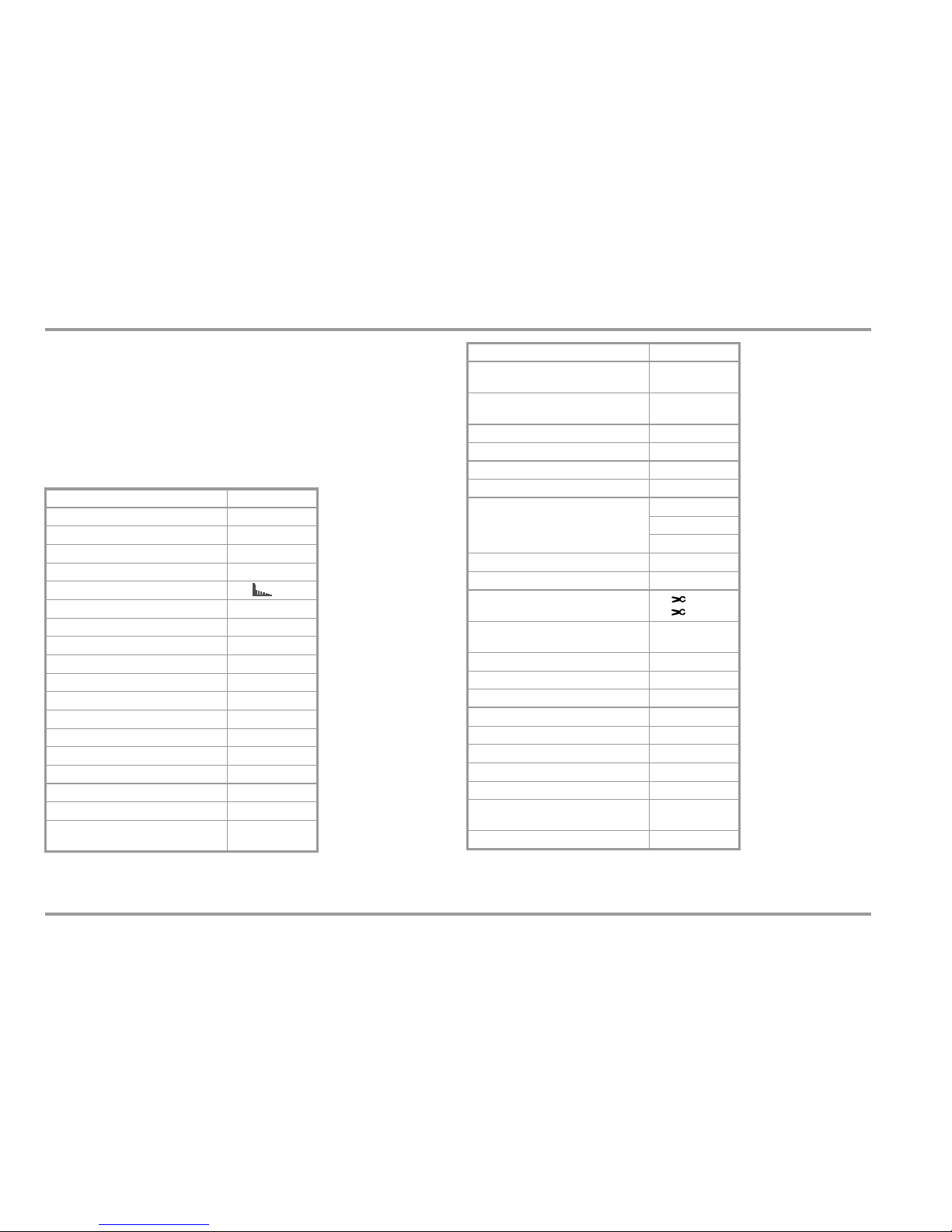

Function

Power measurement W (Var, VA, PF)

Energy measurement Wh (varh, VAh)

Events recording DC / AC events

Power disturbance recording PQ

Harmonic analysis V, A

Voltage (Ri 17 M) V

DC

Voltage (Ri 9 M) V

AC

TRMS

Voltage (Ri 9 ... 17 M) V

AC+DC

TRMS

Crest factor (1 CF 11) 3

Frequency in Hz with V

AC

... 300 kHz

Low-pass filter 1 kHz with VAC

Bandwidth for V

AC+DC

or V

AC

100 kHz

Pulse frequency in MHz at 5V

TTL 1 Hz...1 MHz

Duty cycle as % 2.0% ... 98%

Voltage level measurement in dB 3

Resistance

Conductivity nS

Low-resistance measurement

where I

CONST

= 3 mA

R

SL

Continuity test

where I

CONST

= 1 mA

3

Diode test

where I

CONST

= 1 mA

3

Temperature °C/°F with T

C

Type K

Temperature °C/°F R

TD

Pt100/Pt1000

Capacitance in F 3

Cable length in m 3

Current A

DC

AAC TRMS

A

AC+DC

TRMS

Bandwidth for A

AC+DC

or A

AC

10 kHz

Frequency in Hz for A

AC

... 60 kHz

Current clamp measurement with

adjustable transformation ratio

mV / A

mA / A

Relative value measurement

(ref. value measurement) REL

3

Zero point 3

Data logger function

1

(memory) 16 MBit

Min-Max / data hold 3

IR interface (38.4 kBd) 3

Power pack socket 3

Rubber holster 3

Fuse 10 A / 1000 V

Protection

3

IP 52

Measuring Category 600 V CAT III

300 V CAT IV

Calibration DKD

Function

Page 3

GMC-I Messtechnik GmbH 3

Standard Equipment – Contact Persons

Accessories (sensors, plug inserts, adapters, consumable materials)

The accessories available for your instrument are checked for

compliance with currently valid safety regulations at regular intervals, and are amended as required for new applications. Currently

up-to-date accessories which are suitable for your measuring

instrument are listed at the following web address along with

photo, order number, description and, depending upon the

scope of the respective accessory, data sheet and operating

instructions:

www.gossenmetrawatt.com

See also section 10 on page 89.

Product Support

Technical queries

(use, operation, software registration)

If required please contact:

GMC-I Messtechnik GmbH

Product Support Hotline

Phone: +49 911 8602-0

Fax: +49 911 8602-709

e-mail support@gossenmetrawatt.com

Software Enabling for METRAwin10 (as of version 6.xx)

GMC-I Messtechnik GmbH

Front Office

Phone: +49 911 8602-111

Fax: +49 911 8602-777

e-mail info@gossenmetrawatt.com

Page 4

4 GMC-I Messtechnik GmbH

Standard Equipment – Contact Persons

Recalibration Service

Our service center calibrates and recalibrates (e.g. after one year as

part of your test equipment monitoring system, prior to use etc.)

all instruments from GMC-I Messtechnik GmbH and other manufacturers, and offers free test equipment management.

Repair and Replacement Parts Service

Calibration Center* and Rental Instrument Service

If required please contact:

GMC-I Service GmbH

Service Center

Thomas-Mann-Str. 20

90471 Nürnberg, Germany

Phone: +49 911 817718-0

Fax: +49 911 817718-253

e-mail: service@gossenmetrawatt.com

This address is only valid in Germany. Please contact our

representatives or subsidiaries for service in other countries.

* Calibration laboratory for measured electrical quantities,

DKD – K – 19701, accredited in accordance with

DIN EN ISO/IEC 17025:2005

Accredited quantities: direct voltage, direct current value, direct current

resistance, alternating voltage, alternating current value, AC active

power, AC apparent power, DC power, capacitance, frequency,

temperature

Competent Partner

GMC-I Messtechnik GmbH is certified in accordance with

DIN EN ISO 9001:2000.

Our DKD calibration laboratory is accredited by the Deutscher

Kalibrierdienst (German Calibration Service) under registration

number DKD–K–19701 in accordance with DIN EN ISO/

IEC 17025:2005.

We offer a complete range of expertise in the field of metrology:

from test reports and proprietary calibration certificates right on up to

DKD calibration certificates.

Our spectrum of offerings is rounded out with free test equipment

management.

As a full service calibration laboratory, we can calibrate instruments from other manufacturers as well.

Page 5

GMC-I Messtechnik GmbH 5

Table of Contents

Contents Page Contents Page

1 Safety Features and Precautions ........................................ 7

1.1 Use for Intended Purpose .................................................................9

1.2 Meanings of Danger Symbols ........................................................... 9

1.3 Meanings of Acoustic Warning Signals .............................................. 9

2 Operating Overview – Connections, Keys, Rotary Switch, Symbols . 10

3 Initial Start-Up ................................................................... 14

3.1 Inserting Batteries or Rechargeable Batteries ................................... 14

3.2 Switching the Instrument On ...........................................................14

3.3 Setting the Operating Parameters ................................................... 14

3.4 Switching the Instrument Off ..........................................................15

4 Control Functions ..............................................................16

4.1 Selecting Measuring Functions and Measuring Ranges ....................16

4.1.1 Automatic Measuring Range Selection (auto-ranging) ....................... 16

4.1.2 Manual Measuring Range Selection ................................................ 16

4.1.3 Peak Value Monitoring

for Automatic and Manual Measuring Range Selection ..................... 17

4.1.4 Quick Measurements (MAN or DATA function) ................................. 18

4.2 Zero Offset / Relative Measurements – ZERO/Delta REL Function ..... 18

4.3 Display (LCD) .................................................................................19

4.4 Measured Value Storage: DATA (auto-hold / compare) ..................... 20

4.4.1 Saving Minimum and Maximum Values – Min/Max Function ............. 21

4.5 Measurement Data Recording – Memory Mode Operation, STORE Menu

Function ........................................................................................ 22

4.5.1 Rapid Momentary Value Acquisition for U DC and I DC ..................... 24

4.5.2 Power and Energy Measurement in the Memory Mode ..................... 24

5 Measurements ..................................................................25

5.1 Voltage Measurement .................................................................... 25

5.1.1 Direct Voltage, Pulsating Voltage and Crest Factor Measurement

– V DC, V (DC+AC) and CF ............................................................ 26

5.1.2 Alternating Voltage and Frequency Measurement V AC and Hz

with Selectable Low-Pass Filter, V AC + FILTER and dB V AC ........... 30

5.1.3 Mains Monitoring / Mains Disturbance Recording – PQ .................... 33

5.1.4 Mains Disturbance Recording in Memory Mode Operation ................ 35

5.1.5 Harmonic Analysis (voltage measurement) ..................................... 36

5.1.6 Frequency and Duty Cycle Measurement ........................................ 38

5.2 Resistance, Conductivity and Low-Resistance Measurement ............ 39

5.2.1 Conductivity Measurement ............................................................. 40

5.2.2 Low-Resistance Measurement with Constant Current (RPE) .............. 40

5.3 Continuity Test with Constant Current of 1 mA ............................... 41

5.4 Diode Testing with Constant Current of 1 mA ................................. 42

5.5 Temperature Measurement ............................................................ 43

5.5.1 Measurement with Thermocouples, Temp TC .................................. 43

5.5.2 Measurement with Resistance Sensors ........................................... 44

5.6 Measuring Capacitance and Cable Length in km ............................ 45

5.6.1 Cable Length Measurement in m .................................................... 46

5.7

Measurement of Active, Apparent and Reactive power – W, VA, VAr

Measurement of Active, Apparent and Reactive Energy – Wh, VAh, VArh 47

5.8 Current measurement .................................................................... 52

5.8.1 Direct Current Measurement .......................................................... 53

5.8.2 Current Measurement with Current Clamp Sensor ........................... 56

5.8.3 Current Measurement with Current Clamp Transformer ................... 58

6 Device and Measuring Parameters ...................................60

6.1 Paths to the Various Parameters .................................................... 61

6.2 List of all Parameters, Main Menus and Submenus ......................... 62

Page 6

6 GMC-I Messtechnik GmbH

Table of Contents

Contents Page Contents Page

6.3 Querying Parameters – InFo Menu (as moving letters) ................63

6.4 Entering Parameters – SETUP Menu ................................................64

6.4.1 SYSTEM Submenu .........................................................................64

6.4.2 EVEntS Submenu ...........................................................................65

6.4.3 General Parameters ........................................................................66

6.4.4 EnErGY Submenu ...........................................................................68

6.4.5 MAinS Submenu ............................................................................69

6.4.6 HArM Submenu ..............................................................................71

6.4.7 StorE Submenu – Parameters for Memory Mode Operation ...............72

6.5 Default Settings (factory settings) – Reset ........................................74

7 Interface Operation ........................................................... 75

7.1 Activating the Continuous Transmission Mode ..................................75

7.2 Configuring Interface Parameters ....................................................76

8 Technical Data .................................................................. 77

9 Maintenance and Calibration ........................................... 85

9.1 Displays – Error Messages .............................................................85

9.2 Batteries ........................................................................................85

9.3 Fuse ..............................................................................................86

9.4 Housing Maintenance .....................................................................87

9.5 Return and Environmentally Sound Disposal .....................................87

9.6 Recalibration ..................................................................................87

9.7 Manufacturer’s Guarantee ..............................................................88

10 Accessories ...................................................................... 89

10.1 General ..........................................................................................89

10.2 Technical Data for Measurement Cables

(KS17-2 safety cable set included with instrument) .......................... 89

10.3 NA X-TRA Power Pack (Z218G: not included) ...................................89

10.4 PMA 16 Power Measuring Adapter (Z228A: not included) .................90

10.5 Interface Accessories (not included) ................................................90

11 Glossary – Abbreviations of Measuring Functions and Mea-

suring Parameters with their Meanings ........................... 92

12 Index ................................................................................. 96

Page 7

GMC-I Messtechnik GmbH 7

Safety Precautions

1 Safety Features and Precautions

You have selected an instrument which provides you with high

levels of safety.

This instrument fulfills all requirements of applicable European and

national EC directives. We confirm this with the CE mark. The

relevant declaration of conformity can be obtained from GMC-I

Messtechnik GmbH.

The TRMS digital multimeter has been manufactured and tested

in accordance with the following safety regulations:

IEC 61010–1:2001 / DIN EN 61010–1/VDE 0411–1:2002. When

used for its intended purpose (see page 9), safety of the operator,

as well as that of the instrument, is assured. Their safety is however not guaranteed, if the instrument is used improperly or

handled carelessly.

In order to maintain flawless technical safety conditions, and to assure

safe use, it is imperative that you read the operating instructions

thoroughly and carefully before placing your instrument into service, and

that you follow all instructions contained therein.

The multimeter is equipped with an automatic socket blocking

mechanism for your safety, and in order to safeguard your instru-

ment. This mechanism is linked to the rotary switch and only

allows access to those jacks which are actually required for the

selected function (exception: the voltage jack is open during current measurement, but a visible red ring warns the user of possible incorrect connection). The socket blocking mechanism also

prevents the user from turning the rotary switch to impermissible

functions after the measurement cables have already been

plugged in.

If dangerous voltages are applied in the high-impedance voltage

measuring functions (switch position V or PQ), switching to lowimpedance measuring functions (switch position MHz, , continuity, temperature or capacitance) causes “HiVoLt” to appear at

the display and the respective measurement is disabled.

Hazardous contact voltages are not detected when the ohm or

capacitance measurement is selected.

If the instrument switches itself off in the event that hazardous

contact voltage is applied (only possible during memory mode

operation), the high-voltage warning symbol remains visible at the

display.

Measuring Categories and their Significance per IEC 61010-1

The measuring category and the associated maximum rated voltage which are printed on the device apply to your measuring instrument, e.g. 600 V CAT III.

Observe the following safety precautions:

• The multimeter may not be used in potentially explosive

atmospheres.

• The multimeter may only be operated by persons who are ca-

pable of recognizing contact hazards and taking the appropriate

safety precautions. Contact hazards according to the standard

exist anywhere, where voltages of greater than 33 V TRMS or

70 V DC may occur. Avoid working alone when taking measurements which involve contact hazards. Be certain that a

second person is present.

CAT Definition

I

Measurements in electrical circuits which are not directly connected to the

mains, e.g. electrical systems in motor vehicles and aircraft, batteries etc.

II

Measurements in electrical circuits which are directly connected to the lowvoltage mains via plug, e.g. in household, office and laboratory applications etc.

III

Measurements in building installations: Stationary consumers, distributor

terminals, devices connected permanently to the distributor

IV

Measurements at power sources for low-voltage installations:

meters, mains terminals, primary overvoltage protection devices

Page 8

8 GMC-I Messtechnik GmbH

Safety Precautions

• Maximum permissible voltage

between the voltage measuring sockets or all connector sockets and ground is 600 V for measuring category III and 300 V

for measuring category IV.

• Be aware of the fact that dangerous voltage peaks with significant frequency components of greater than 1 kHz are not displayed when the low-pass filter is activated. We recommend

measuring voltage without the low-pass filter first, in order to

be able to detect any dangerous voltages.

• Be prepared for the occurrence of unexpected voltages at devices under test (e.g. defective devices). For example, capacitors may be dangerously charged.

• Make certain that the measurement cables are in flawless condition, e.g. no damage to insulation, no interruptions in cables

or plugs etc.

• No measurements may be made with this instrument in electrical circuits with corona discharge (high-voltage).

• Special care is required when measurements are made in HF

electrical circuits. Dangerous pulsating voltages may be present.

• Measurements under moist ambient conditions or with an instrument with condensation are not permissible

• Be absolutely certain that the measuring ranges are not overloaded beyond their allowable capacities. Limit values are included in section 8, “Technical Data”, in the table entitled

“Measuring Functions and Measuring Ranges” in the “Overload Capacity” column.

• The multimeter may only be operated with installed batteries or rechargeable batteries. Dangerous currents and voltages are otherwise

not indicated, and the instrument may be damaged.

• The instrument may not be operated if the fuse cover or the

battery compartment lid has been removed, or if its housing is

open.

• The input for the current measuring range is equipped with a

fuse link. Use specified fuses only (see page 84)! The fuse

must have a breaking capacity of at least 30 kA.

• Observe optical and acoustic warning signals (see section 1.2

and section 1.3).

Repair and Parts Replacement

When the instrument is opened, voltage conducting parts may be

exposed. The instrument must be disconnected from the measuring circuit before performing repairs or replacing parts. If repair of

a live open instrument is required, it may only be carried out by

trained personnel who are familiar with the dangers involved.

Defects and Extraordinary Strains

If it may be assumed that the instrument can no longer be operated safely, it must be removed from service and secured against

unintentional use.

Safe operation can no longer be relied upon:

• If the device demonstrates visible damage

• If the instrument no longer functions, or if malfunctioning

occurs

• After long periods of storage under unfavorable conditions (e.g.

humidity, dust or extreme temperature (see “Ambient Conditions” on page 84).

Page 9

GMC-I Messtechnik GmbH 9

Safety Precautions

1.1 Use for Intended Purpose

• The multimeter is a portable device which can be held in the

hand during the performance of measurements.

• Only those types of measurements described in section 5 may

be performed with the measuring instrument.

• The measuring instrument, including measurement cables and

plug-on test probes, may only be utilized up to the maximum

specified measuring category (see page 84 and the table on

page 7 regarding significance).

• Overload limits may not be exceeded. See technical data on

page 77 for overload values and overload limits.

• Measurements may only be performed under the specified

ambient conditions. See page 84 regarding operating temperature range and relative humidity.

• The measuring instrument may only be used in accordance

with the specified degree of protection (IP code) (see page 84).

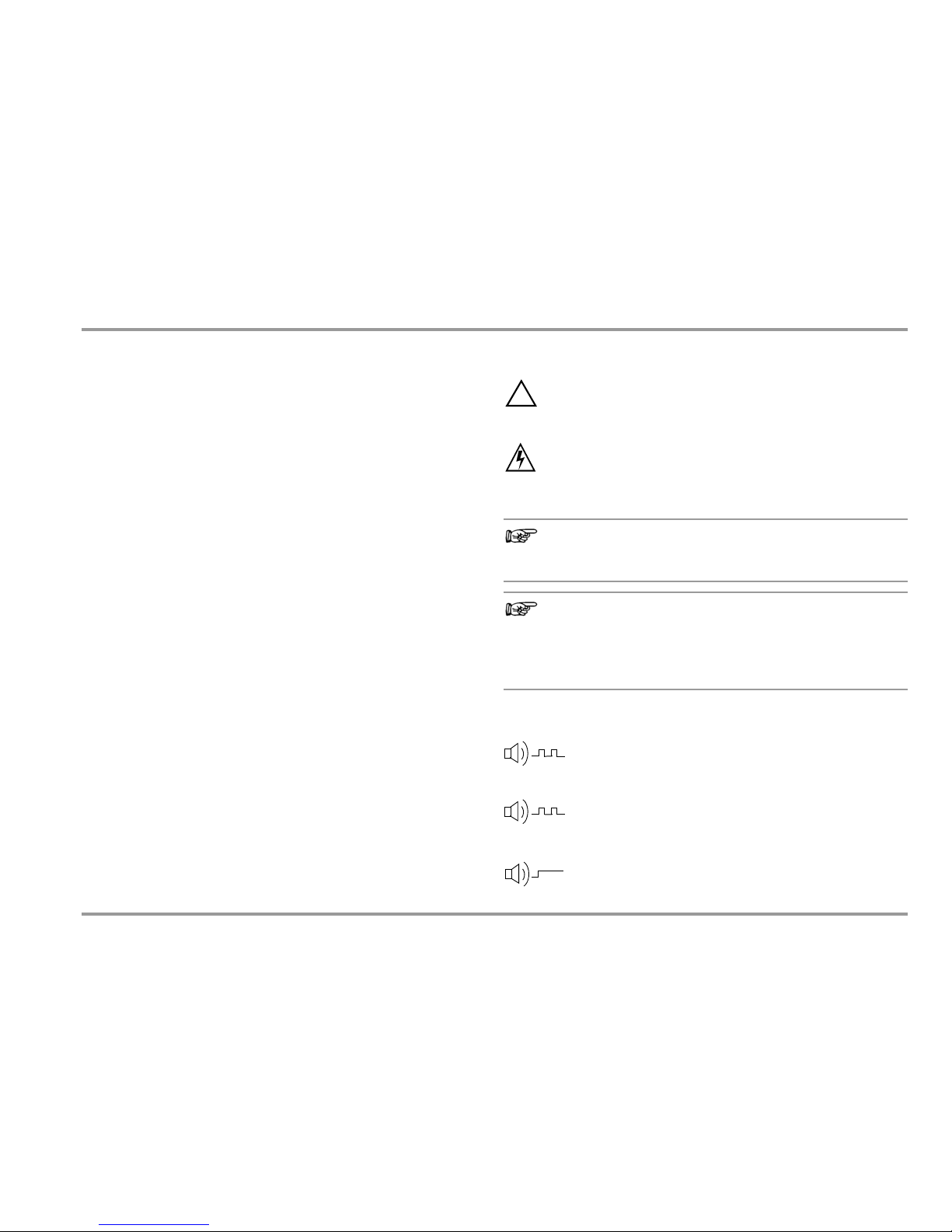

1.2 Meanings of Danger Symbols

Warning concerning a source of danger

(attention: observe documentation!)

Warning at the display regarding dangerous contact voltage

at the voltage measuring input (jacks 8 and 10, see page 10):

U > 30 V AC or U > 35 V DC

Note

For safety reasons, the instrument cannot be switched off

when dangerous contact voltages are being applied.

Note

Electrical discharge or high frequency interference may

cause incorrect displays to appear. To reset the instrument,

switch it off and then back on again. See also section 6.5

with regard to restoring the factory settings.

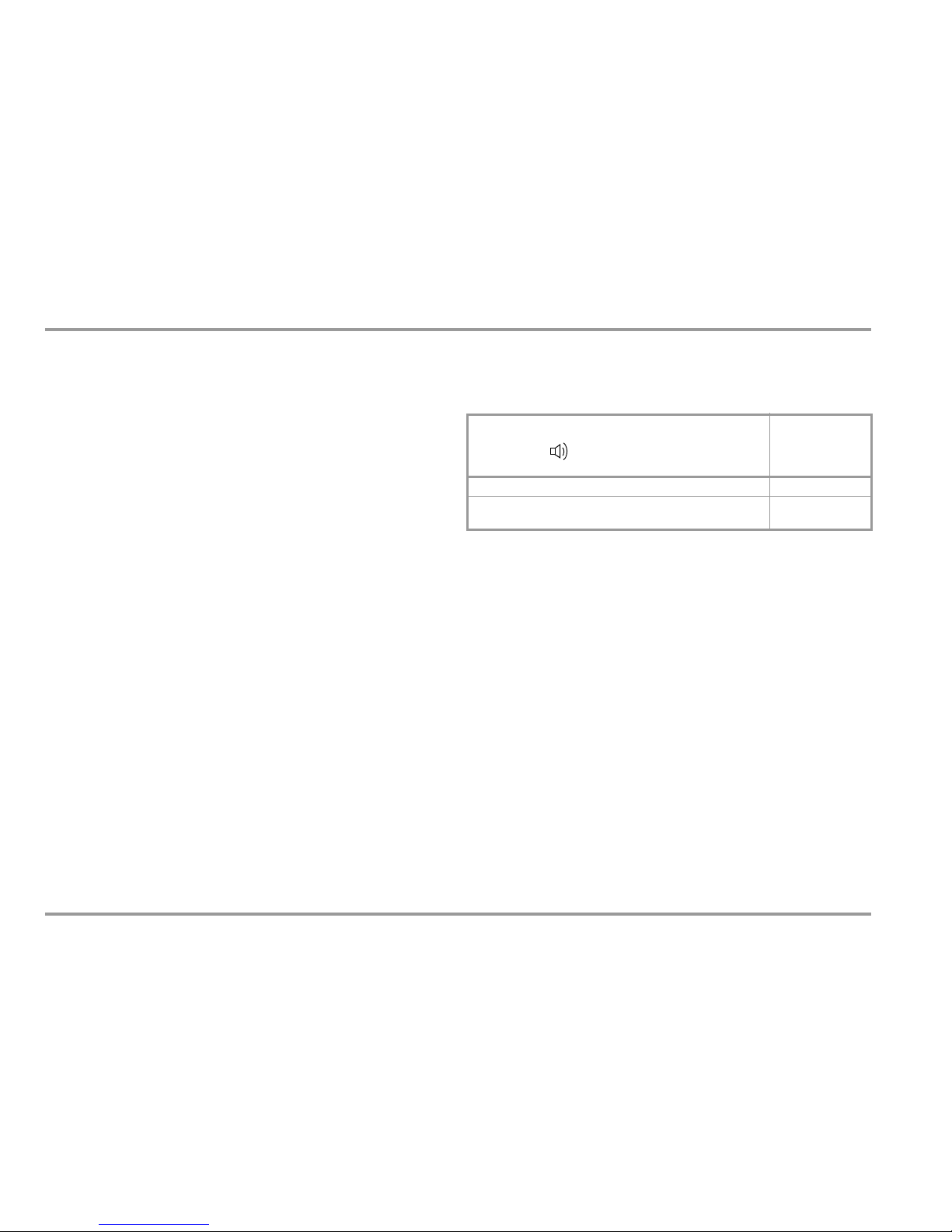

1.3 Meanings of Acoustic Warning Signals

Voltage warning: > 600 V (intermittent acoustic signal)

Current warning: > 10 A (intermittent acoustic signal)

Current warning: > 16 A (continuous acoustic signal)

!

Page 10

10 GMC-I Messtechnik GmbH

Operating Overview – Connections, Keys, Rotary Switch, Symbols

2

Operating Overview – Connections, Keys, Rotary Switch, Symbols

1 Display (LCD) (see page 12 for significance of symbols)

2 MAN/AUTO: shift key for manual/automatic measuring range selection

Increase parameter values

Operating mode menu:

selection of indiv. menu entries against direction of flow

3

ON / OFF | LIGHT

: key for switching device and display illumination on and off

4 FUNC | ENTER Multifunction key

Operating mode menu: acknowledge entry (ENTER)

5

Increase measuring range or move decimal point to the right (MAN function)

Power measurement: change displayed unit of measure

6 Rotary switch

for meas. functions

(see significance of symbols on

page 13)

7 DKD calibration mark

8 Connector socket for ground / connected to ground

9 Socket connector for direct current measurement and current clamp

transformer, with automatic blocking

10 Connector socket for voltage, resistance, temperature, diode and capacitance

measurement, and current

clamp

sensor

11 DATA/MIN/MAX: key for freezing, comparing and deleting measured value,

and for Min-Max function

Decrease values

Operating mode menu: s

election of indiv. menu entries in direction of flow

12 MEASURE | SETUP: key for switching back and forth between measuring

and menu function

13 ZERO | ESC

Key for zero balancing

Operating mode menu: Exit current menu level and

return to a higher level.

Exit parameters entry function

without saving.

14

Reduce meas. range or move decimal point to the left (MAN function)

Power measurement: change displayed unit of measure

15 Power pack connector jack

16 Infrared interface

1

3

4

16

5

6

9

*

*

sec. 4.3

sec. 3

sec. 5

sec. 7

sec. 6

sec. 3 ff.

sec. 3

13

12

sec. 4.1

10

2

sec. 4.1.2

14

8

Max. 600 V!

11

15

sec. 4.1

sec. 4.4

sec. 6

sec. 3

sec. 6

sec. 3.1

7

sec. 1.2

Page 11

GMC-I Messtechnik GmbH 11

Operating Overview – Connections, Keys, Rotary Switch, Symbols

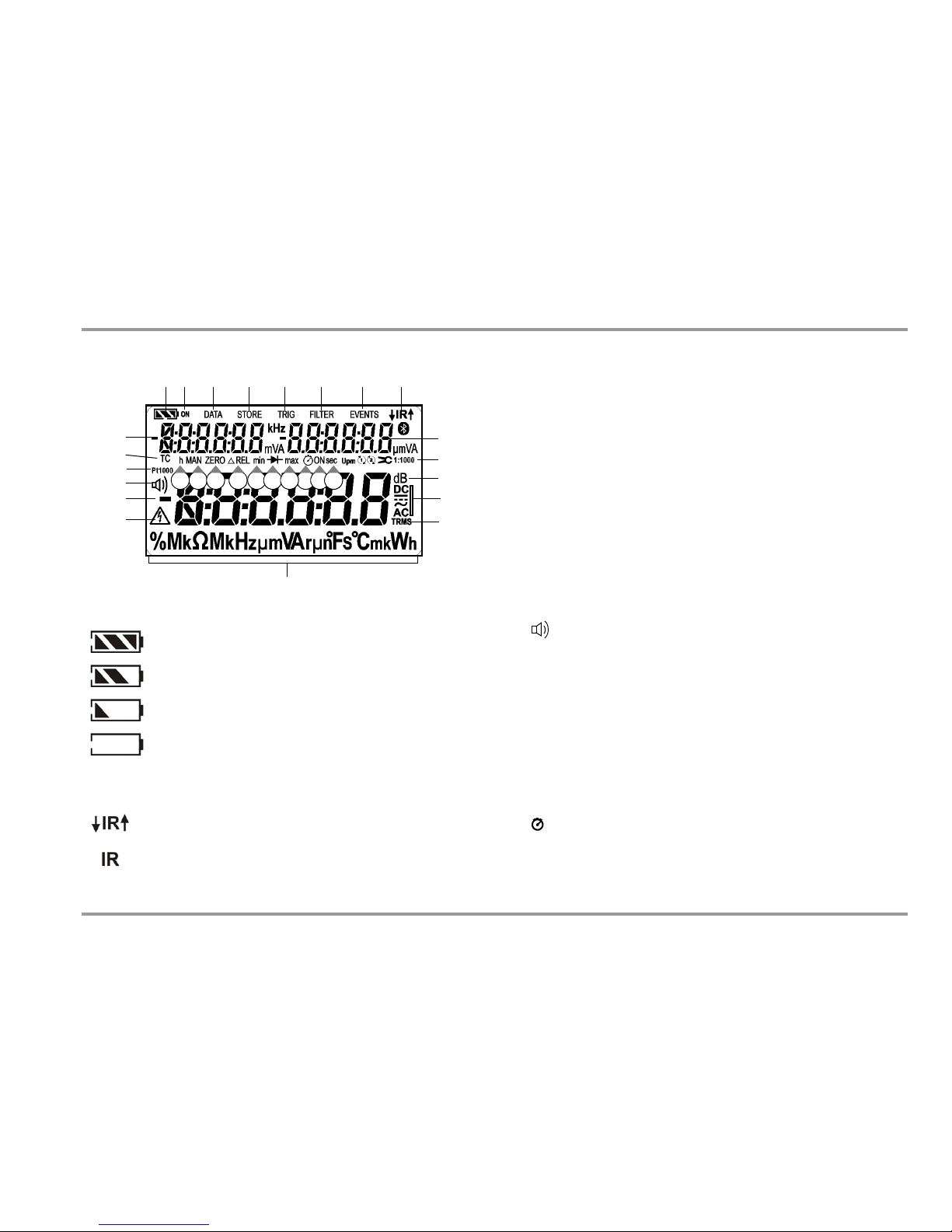

Symbols Used in the Digital Display 1 Battery level indicator

2 ON: continuous operation (automatic shutdown deactivated)

3 DATA: display memory, “freeze measured value”

4 STORE: memory mode active

5 TRIG: synchronized storage

6 FILTER: low-pass filter active

7 EVENTS: events measurement

8 IR: infrared interface indicator

9 Auxiliary display: digital display with decimal point and polarity display

10 Transformation ratio (factor for current clamp sensorc and transformers)

11 dB: alternating voltage level measurement

12 Selected type of current

13 TRMS measurement

14 Unit of measure

15 Warning regarding dangerous voltage: U > 30 V AC or U > 35 V DC

16 Main display: digital display with decimal point and polarity display

17 Continuity test with acoustic signal active

18 Pt100/Pt1000: selected platinum resistance sensor with automatic

selection of Pt100 / Pt1000

19 TC: temperature measurement with type K thermocouple (NiCr-Ni)

20 h (hours): unit of time

21 MAN: manual measuring range selection active

22 ZERO: zero balancing active

23 REL: relative measurement with reference to offset

24 min: minimum value storage

25 Diode measurement selected

26 max: maximum value storage

27 Stopwatch active or time since beginning of measurement

28 ON: together with the symbol in item 27: elapsed time since activation of the

respective function

29 sec (seconds): unit of time

Battery full

Battery OK

Battery weak

Battery (almost) dead, U < 1.8 V

Data transmission to / from multimeter, active

IR interface active (ready to receive starting

commands)

Battery Level Indicator

Interface Indicator

1 28

9

14

15

17

54 6

9

3

11

13

10

19

24 272120

18

16

25

12

7

22 23 26 2829

Page 12

12 GMC-I Messtechnik GmbH

Operating Overview – Connections, Keys, Rotary Switch, Symbols

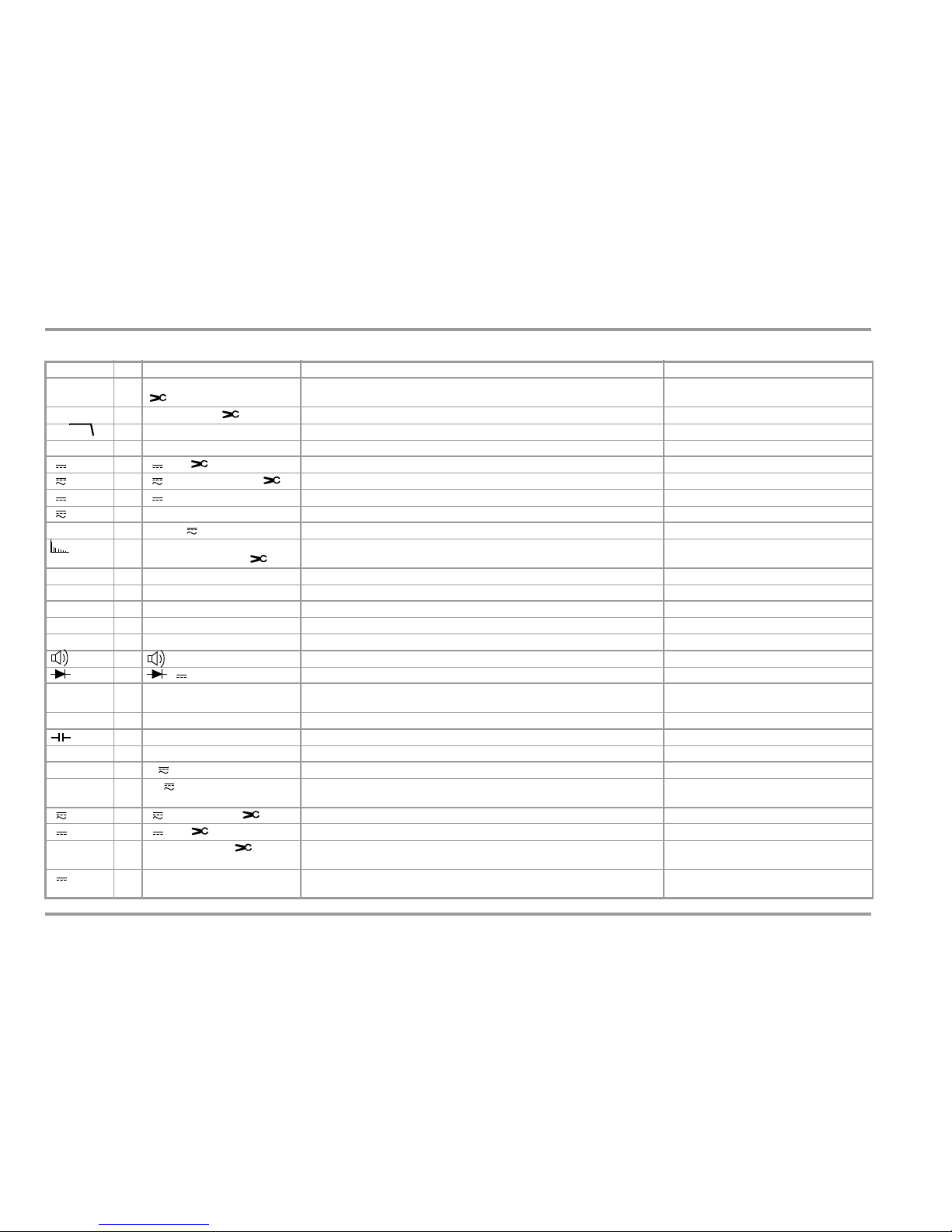

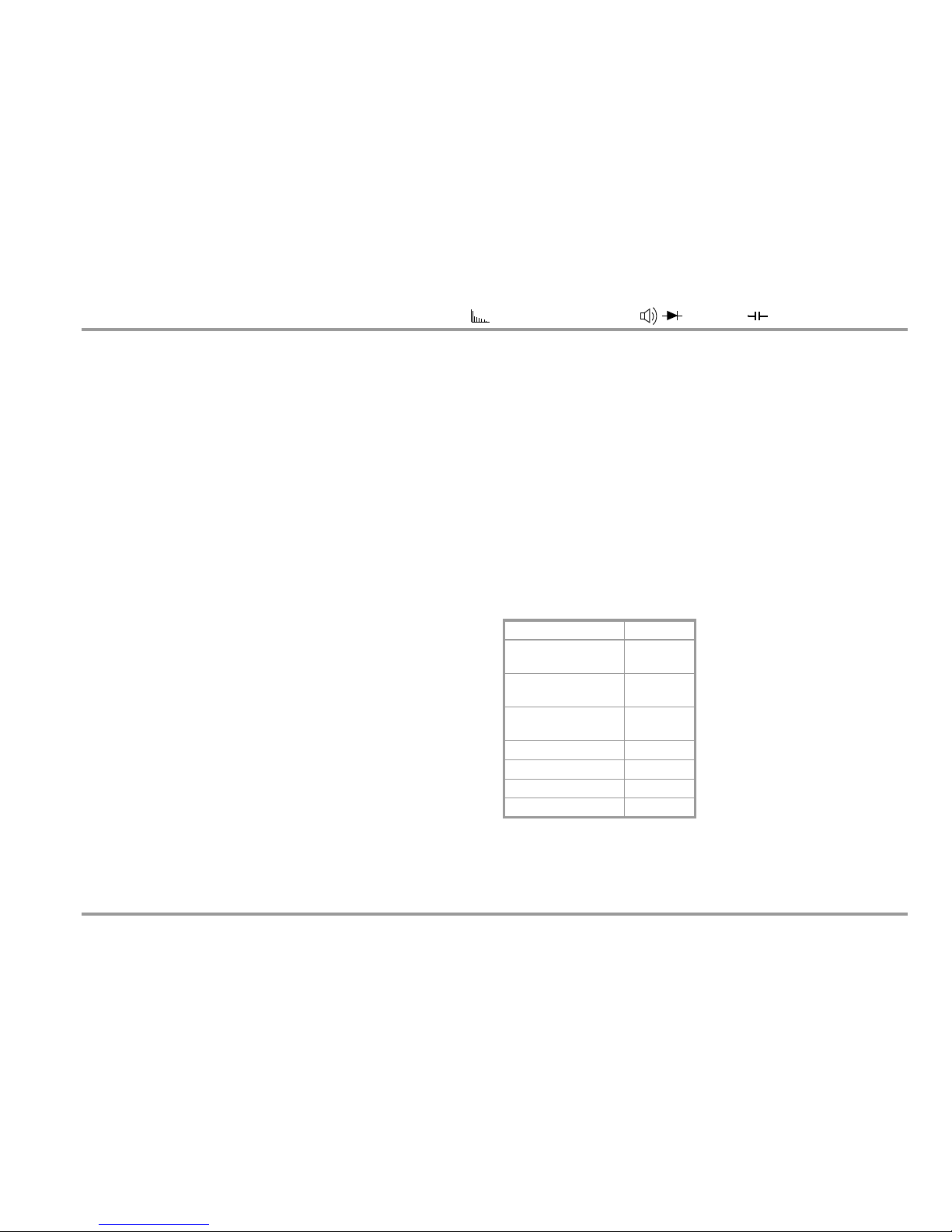

Symbols and Functions for Rotary Switch Positions (MD: main display, AD: auxiliary display, MR: measuring range)

Switch

FUNC

Display Measuring function Sub-Function

V~ 0/4 V~AC TRMS / HZ

A~AC TRMS (0/2)

CLiP=OFF: alternating voltage, AC TRMS, full bandwidth

CLiP=ON: alternating current via current clamp sensor, TRMS AC value

DATA/MIN/MAX, MAN/AUTO, ZERO

V~ 1 Hz ~AC TRMS / (1) CLiP=oFF: voltage frequency, to 300 kHz / CLiP=ON current frequency sensor DATA/MIN/MAX, MAN/AUTO, ZERO

V~ 2 V filter ~AC TRMS / Hz man Alternating voltage, AC TRMS, with low pass filter (1 kHz) DATA/MIN/MAX, MAN/AUTO, ZERO

dB 3 dB ~AC TRMS Alternating voltage level measurement DATA/MIN/MAX

V 0/4 V DC / (0/2) CLiP=OFF: direct voltage measured directly / CLiP=ON: via current clamp sensor DATA/MIN/MAX, MAN/AUTO, ZERO

V 1 V DC+ AC TRMS / CF / (1)

CLiP=OFF: pulsating voltage, direct, TRMS / CLiP=ON: via current clamp sensor

DATA/MIN/MAX, MAN/AUTO, ZERO

V 2 V DC EVENTS Direct voltage events DATA/MIN/MAX, MAN/AUTO

V 3 V~AC TRMS EVENTS Alternating voltage events DATA/MIN/MAX, MAN/AUTO

PQ 0/2 MAinS: V DC+AC TRMS Mains quality: events (type, start time, date, duration, value) Event querying: keys

1 thd % ~AC TRMS / V /

thd % ~AC TRMS / A / (0/2)

Main display: total harmonic distortion relative to fundamental frequency as %

Auxiliary display: RMS value for the total signal in V

Query harmonics 1 through 15: RMS values

and distortion via keys

MHz 0/2 MHz (High) Frequency at 5 V~ up to 1 MHz DATA/MIN/MAX, MAN/AUTO

% 1 % Duty cycle at 5 V~ DATA/MIN/MAX

0/3 (DC) resistance DATA/MIN/MAX, MAN/AUTO, ZERO

nS 1 nS Conductivity (in nano-Siemens) DATA/MIN/MAX

2RPE Low-resistance measurement with acoustic signal where Iconst = 3 mA DATA/MIN/MAX, ZERO

0/2 Continuity test, , with acoustic signal where Iconst = 1 mA DATA/MIN/MAX, ZERO

1 V DC Diode voltage up to max. 6 V where Iconst = 1 mA DATA/MIN/MAX

Temp . TC 0/2

C, type K

Temperature, type K thermocouple DATA/MIN/MAX

Temp . RT D 1°Pt100 Temperature with Pt100 / Pt1000 resistance sensor DATA/MIN/MAX, MAN/AUTO, ZERO

0/2 nF Capacitance DATA/MIN/MAX, MAN/AUTO, ZERO

m 1 km Cable length DATA/MIN/MAX, MAN/AUTO, ZERO

W 0/2 W DC+ AC TRMS / V+A / PF Power (active, reactive, apparent power) / voltage + current / power factor

DATA/MIN/MAX, MAN/AUTO

, W – VA – VAr: vw

Wh 1 Wh DC+ AC TRMS energy time Energy: energy (active, reactive, apparent energy) / on-time

Mean: average power / max: maximum power

MAN/AUTO, Wh – VAh – VArh:

vw

keys

Energy – Mean – max: , ZERO = reset

A 0/4 A DC+ AC TRMS / (2)

CLiP=OFF: pulsating current, direct, TRMS AC+DC, CLiP=ON: current clamp transformer

DATA/MIN/MAX, MAN/AUTO, ZERO

A/~ 1A DC / (3)

CLiP=OFF: direct voltage, direct, CLiP=ON: direct voltage via current clamp trans.

DATA/MIN/MAX, MAN/AUTO, ZERO

A~ 2 A~AC TRMS / Hz / (0/4) CLiP=OFF: alternating current direct, TRMS AC / current frequency,

CLiP=ON: alternating current via current clamp trans. // temperature: MB 6 A and 10 A

DATA/MIN/MAX, MAN/AUTO, ZERO

A/~ 3 thd % ~AC TRMS / A (1) Main display: total harmonic distortion relative to fundamental frequency as %

Auxiliary display: RMS value for the total signal in A

Query harmonics 1 through 15: RMS values

and distortion via keys

1kHz

Page 13

GMC-I Messtechnik GmbH 13

Operating Overview – Connections, Keys, Rotary Switch, Symbols

User Interface Symbols in the Following Sections

... Scroll through main menu

... Scroll through submenu

Select decimal point

Increase/decrease value

time Submenu/parameter (7-segment font)

1nFo Main menu (7-segment font, boldface)

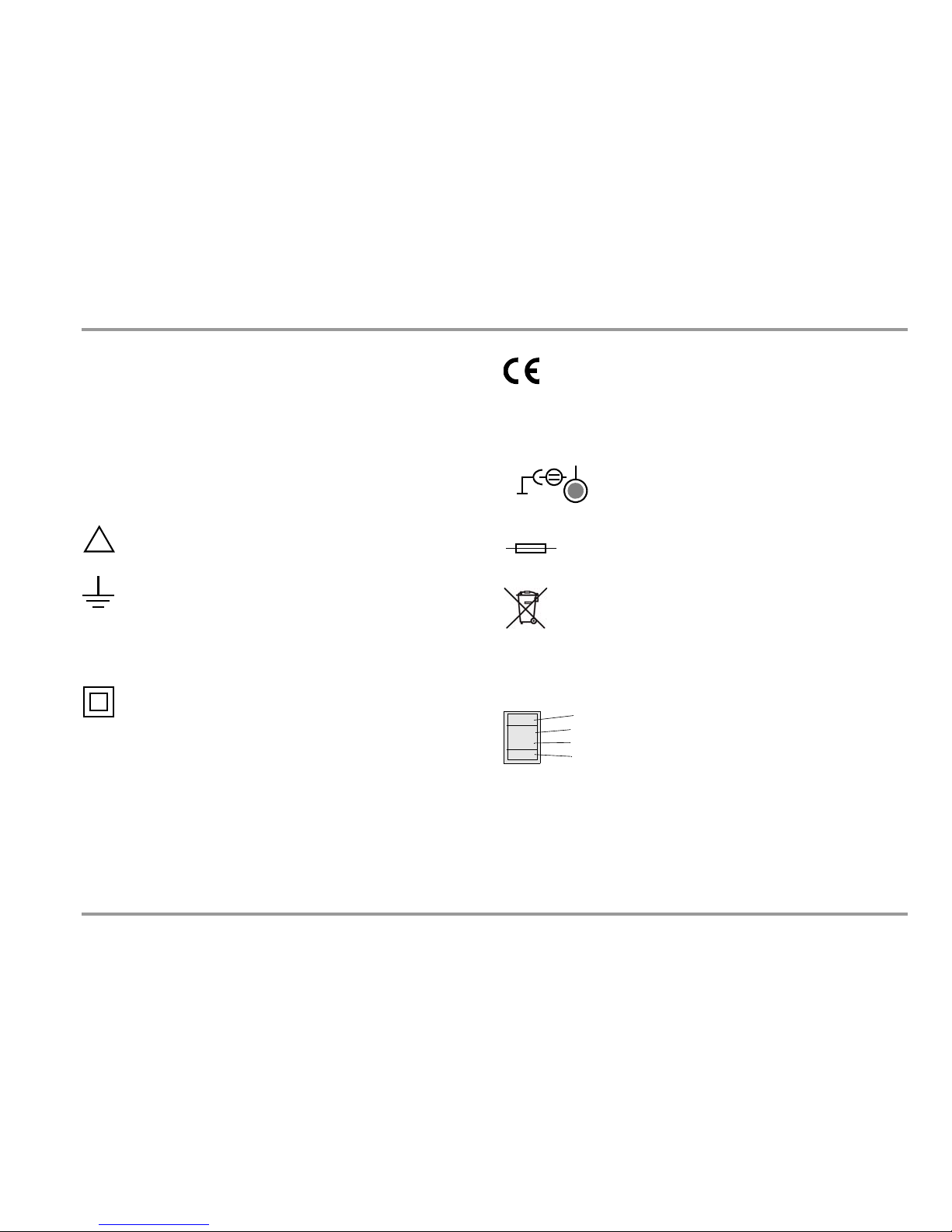

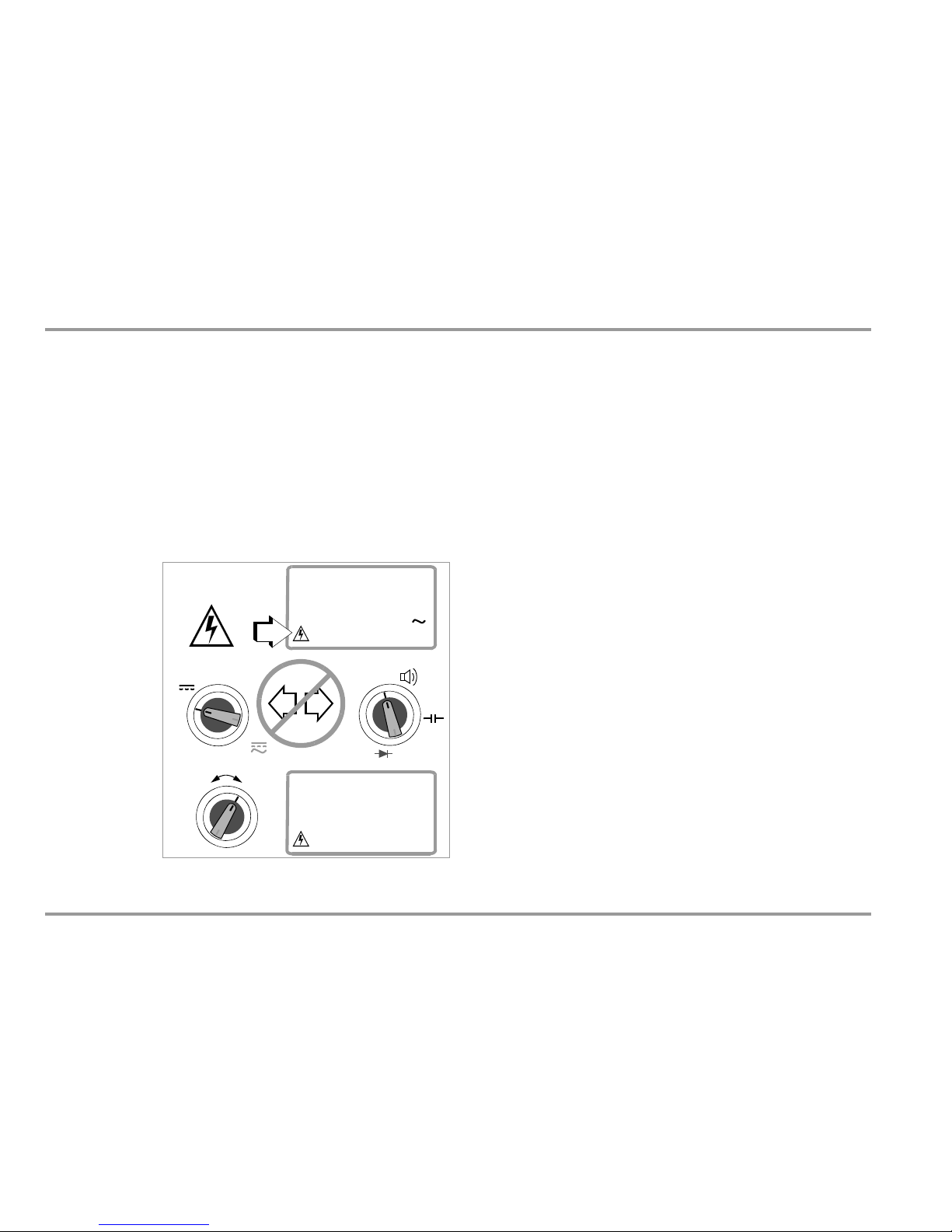

Symbols on the Device

Warning concerning a source of danger

(attention: observe documentation!)

Ground

CAT III / IV Measuring category III or IV device, see also

“Measuring Categories and their Significance per IEC

61010-1” on page 7

Continuous, doubled or reinforced insulation

EC mark of conformity

s

IR

t

Position of the infrared interface, window on the top of the

instrument

See also section 3.1 regarding location of the

power pack adapter socket.

Fuse for current measuring ranges, see section 9.3

This device may not be disposed of with the trash.

Further information regarding the WEEE mark can be

accessed on the Internet at

www.gossenmetrawatt.com under the search term

WEEE (see also section 9.5).

Calibration seal (red seal):

See also “Recalibration” on page 87.

!

5V/600mA

Consecutive number

Registration number

Date of calibration (year – month)

German Calibration Service – calibration laboratory

B0730

10-02

DKD-K-

19701

Page 14

14 GMC-I Messtechnik GmbH

Initial Start-Up – Setup

3 Initial Start-Up

3.1 Inserting Batteries or Rechargeable Batteries

Be certain to refer to section 9.2 regarding correct battery

installation.

Momentary battery voltage can be queried in the Info menu (see

section 6.3).

Attention!

!

Disconnect the instrument from the measuring circuit before opening the battery compartment lid in order to replace the batteries.

Operation With Power Pack (not included, see section 10.3)

Installed batteries are disconnected electronically if the NA X-TRA

power pack is used, and need not be removed from the instrument. If rechargeable batteries are used, they must be recharged

externally.

If the external power supply is switched off, the device is switched

to battery operation without interruption.

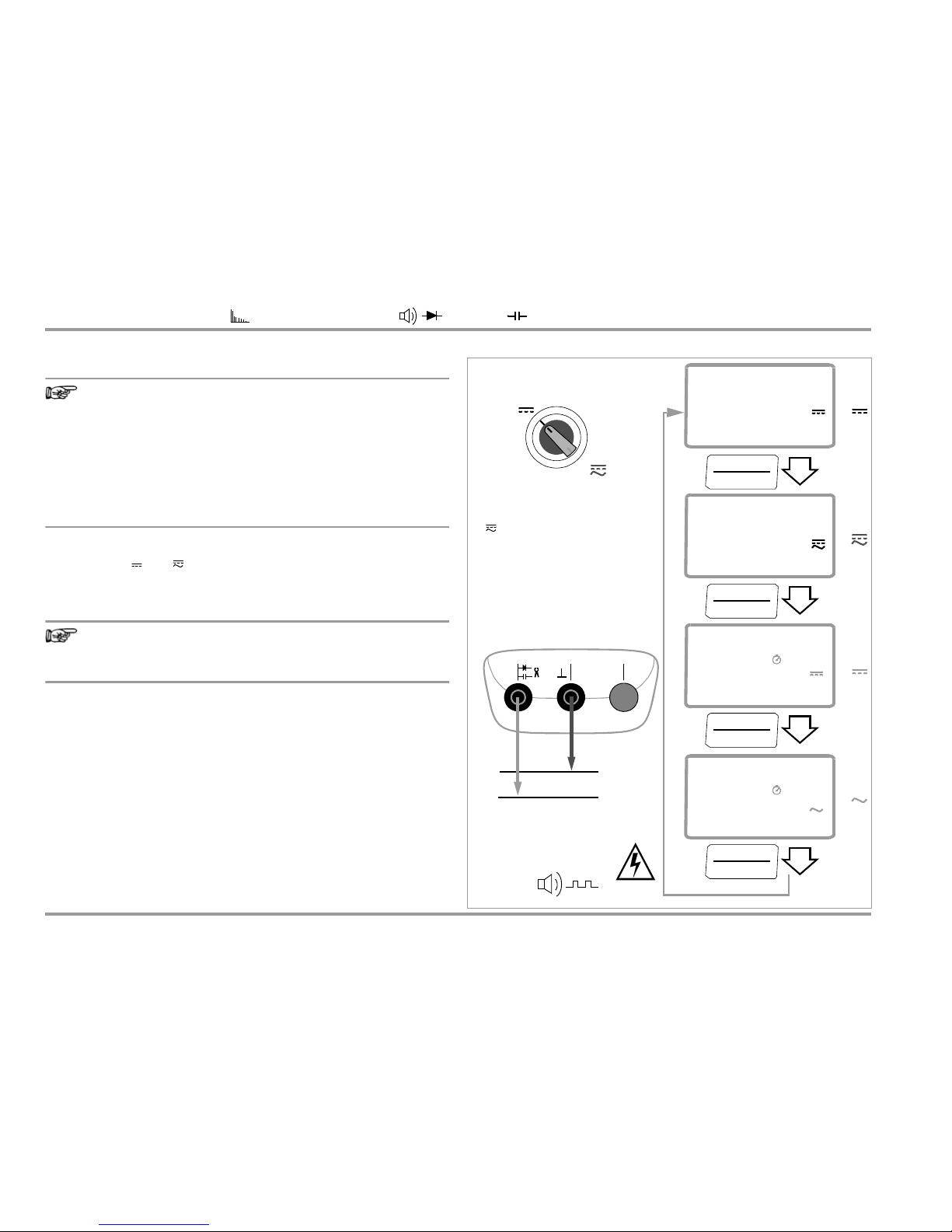

3.2 Switching the Instrument On

Switching the Instrument On Manually

Ð Press the ON / OFF | LIGHT key until the display appears.

Power-up is acknowledged with a brief acoustic signal. As

long as the key is held depressed, all of the segments at the

liquid crystal display (LCD) are illuminated.

The LCD is depicted on page 11.

The instrument is ready for use as soon as the key is released.

Display Illumination

After the instrument has been switched on, background illumination can be activated by briefly pressing the ON / OFF | LIGHT key.

Illumination is switched back off by once again pressing the same

key, or automatically after approximately 1 minute. If necessary,

automatic deactivation of background illumination can be disabled with the appropriate parameter setting (see bLiGht parameter

in SYStEM submenu) or via the interface.

Switching the Instrument On with a PC

The multimeter is switched on after transmission of a data block

from the PC, assuming that the “irStb” parameter has been set to

“on” (see section 6.4).

However, we recommend using the power saving mode: “off”.

Note

Electrical discharge and high frequency interference may

cause incorrect displays to appear, and may disable the

measuring sequence.

Disconnect the device from the measuring circuit. Switch the

instrument off and back on again in order to reset. If the

problem persists, briefly dislodge the battery from the connector contacts (see also section 9.2).

3.3 Setting the Operating Parameters

Setting Time and Date

See the “t iME” and “dAtE” parameter in section 6.4.

Page 15

GMC-I Messtechnik GmbH 15

Initial Start-Up – Setup

3.4 Switching the Instrument Off

Switching the Instrument Off Manually

Ð Press the ON / OFF | LIGHT key until 0FF appears at the display.

Shutdown is acknowledged with a brief acoustic signal.

If hazardous contact voltage has been detected (HV symbol

appears), the instrument cannot be switched off.

Automatic Shutdown

The instrument is switched off automatically if the measured value

remains unchanged for a long period of time (maximum measured

value fluctuation of approx. 0.8% of the measuring range per

minute or 1C or 1F per minute), and if none of the keys or the

rotary switch have been activated before a selected period of time

in minutes has elapsed (see “APoFF” parameter on page 64). Shutdown is acknowledged with a brief acoustic signal.

Automatic shutdown is disabled in the following operating modes:

continuous operation, mains analysis, power or energy measurement and whenever dangerous contact voltage has been detected (exception: memory mode).

Disabling Automatic Shutdown

The instrument can be set to continuous operation.

Ð Simultaneously press the

and keys to this end.

The “Continuous On” function is indicated at by means of the

ON

display to the right of the battery symbol.

The “Continuous On” setting can only be canceled by changing the respective parameter (see “APoFF” on page 64 regarding instrument shutdown via parameter) or by switching the instrument off manually.

In this case, the parameter is reset to 10 minutes.

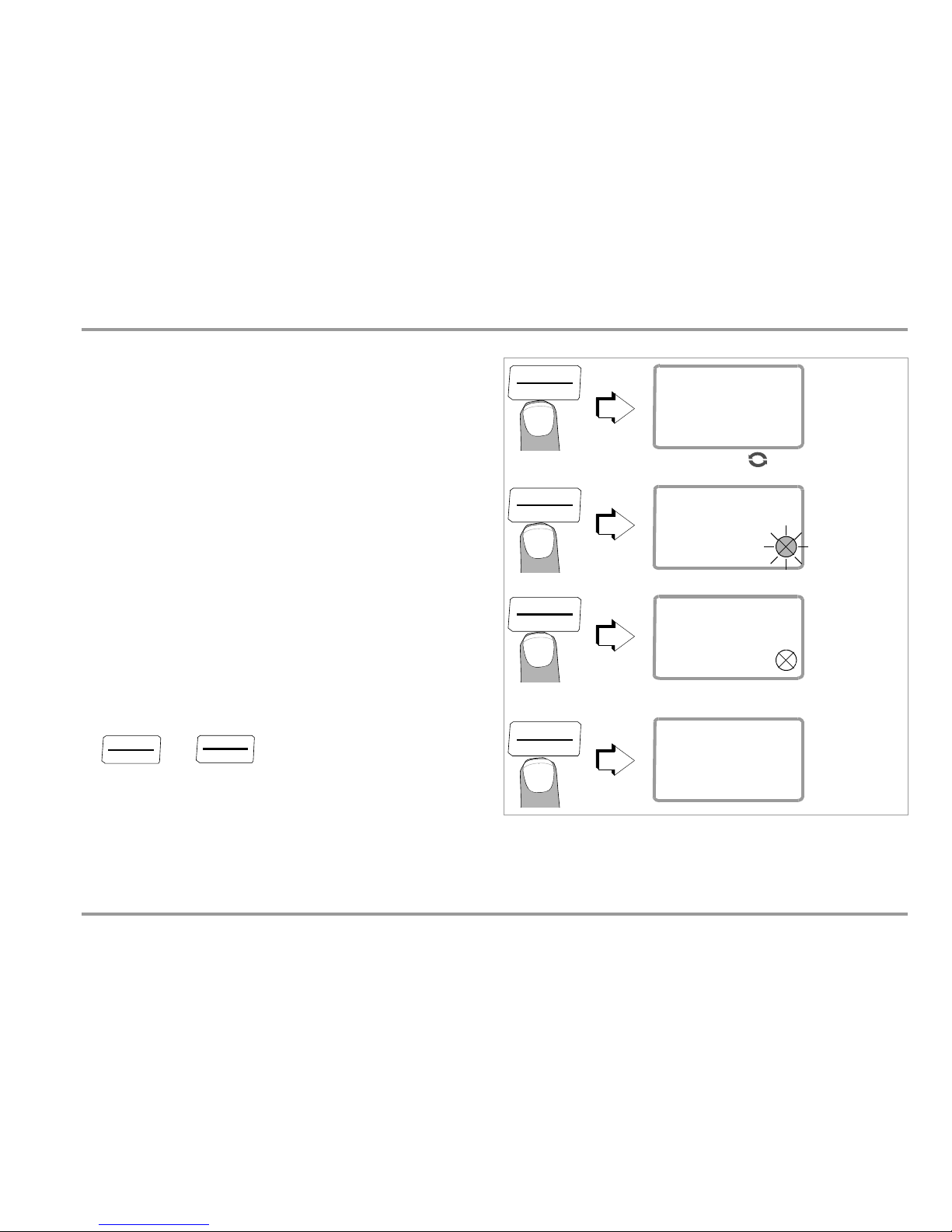

ON / OFF

LIGHT

FUNC

ENTER

ON / OFF

LIGHT

Auto-Range

8.8.8.8.8

Illumination On

000.00

ON / OFF

LIGHT

Illumination Off

000.00

ON / OFF

LIGHT

0ff

ON / OFF

LIGHT

Long

(1 s)

Page 16

16 GMC-I Messtechnik GmbH

Control Functions

4 Control Functions

4.1 Selecting Measuring Functions and Measuring Ranges

The rotary switch is linked to an automatic socket blocking mechanism which only allows access to two jacks per function (exception: the voltage jack is open during current measurement, but a

visible red ring warns the user of possible incorrect connection).

Be certain to remove the appropriate plug from its respective jack

before switching to and from the “A” functions. The socket blocking mechanism prevents the user from inadvertently turning the

selector switch to impermissible functions after the measurement

cables have been plugged in to the instrument.

Presence of Dangerous Contact Voltages

If dangerous voltages are applied in

the high-impedance voltage measuring functions

(switch position V

or PQ), switching

to low-impedance

measuring functions (switch position MHz, , conti-

nuity, temperature

or capacitance)

causes “HiVoLt” to

appear at the display and the

respective measurement is disabled. The measuring function is not switched until dangerous contact voltage is

no longer applied to the input.

If the instrument switches itself off in the event that hazardous

contact voltage is applied (during memory mode operation with

large sampling period), the high-voltage warning symbol remains

visible at the display.

4.1.1 Automatic Measuring Range Selection (auto-ranging)

The multimeter is equipped with auto-ranging for most measuring

functions. Auto-ranging is active as soon as the instrument is

switched on. The instrument automatically selects the measuring

range which allows for highest possible resolution of the applied

quantity. When the instrument is switched to frequency measurement, the previously selected voltage measuring range remains

active.

AUTO-Range Function

The multimeter is switched automatically to the next higher range

at (61000 d + 1 d 06100 d) and to the next lower range at

(05400 d - 1 d 53999 d).

Exceptions: capacitance and cable length measurement

The multimeter is switched automatically to the next higher range

at (6100 d + 1 d 00 610 d) and to the next lower range at

(0540 d 5399 d).

4.1.2 Manual Measuring Range Selection

Auto-ranging can be deactivated and measuring ranges can be

selected manually in accordance with the following table by

pressing the

MAN / AUTO butt

on. The desired measuring range can

then be selected with the

or scroll key (exceptions: power

and energy measurement, see next page).

230.00

V

050.00

AC

TRMS

Hz

U > 35 V:

V~

V

V

PQ

MHz

%

Te mp

TC

Temp

RTD

nS

m

hivolt

Page 17

GMC-I Messtechnik GmbH 17

Control Functions

The instrument is automatically returned to automatic range

selection when the MAN / AUTO key is pressed, the rotary switch is

activated or the instrument is switched off and back on again.

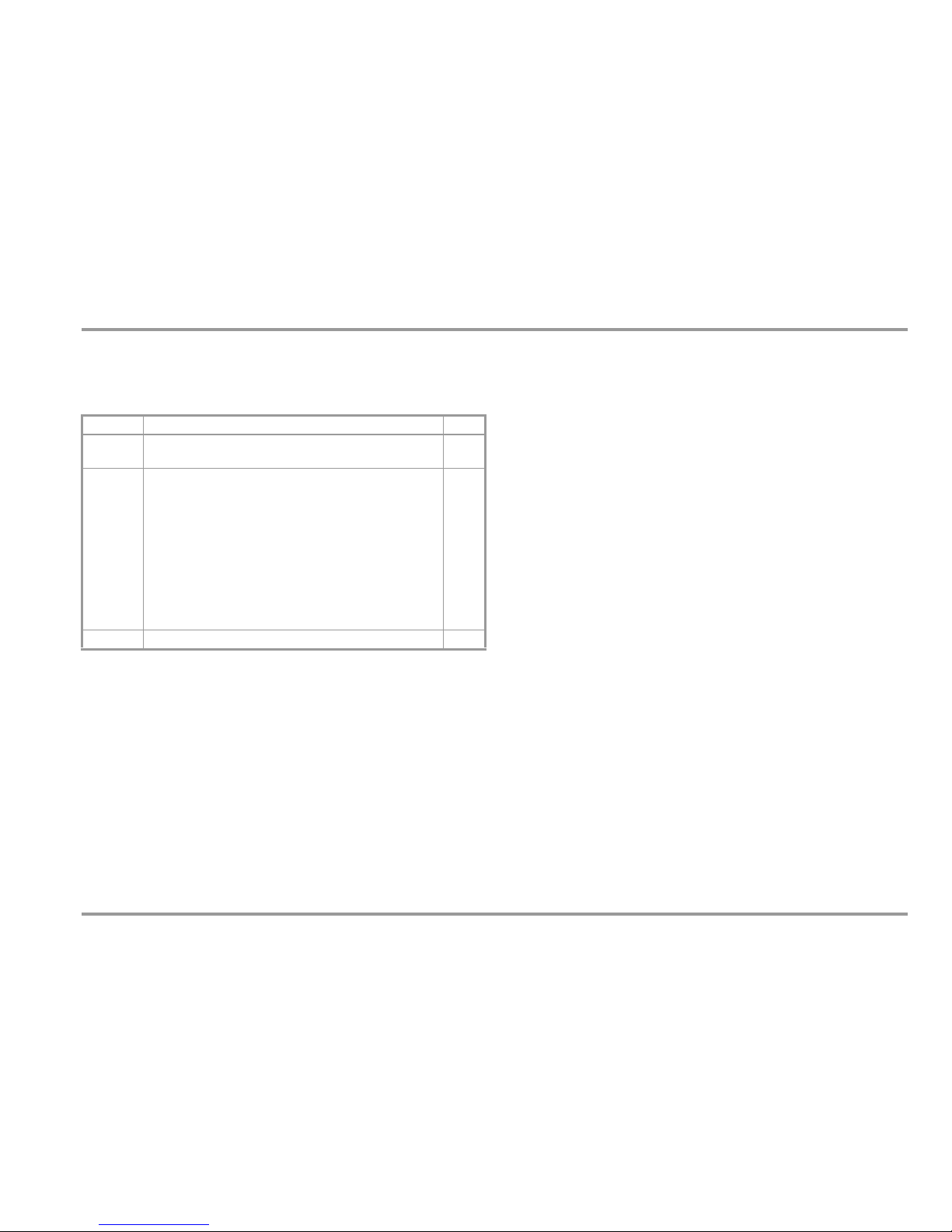

Overview: Auto-Ranging and Manual Range Selection

* Via manual measuring range selection only

“Intelligent” MAN Function

If a small measurement value occurs, the instrument can be

switched to a measuring range with higher resolution by pressing

the MAN / AUTO key.

Power and Energy Measurements

In the power meaurement function of Metrahit Energy, you can

choose between automatic measuring range selection or fixed

voltage and current measuring ranges.

In contrast to the other measuring functions, however, manual

measuring range selection is not possible in this case, as the

instrument cannot distinguish whether the voltage or current

measuring range is to be changed. The practical procedure is

therefore to start by applying the highest anticipated voltage and

current values in the case of automatic measuring range selection

and then to lock in the resulting measuring ranges by pressing the

MAN / AUTO key. Locking is disabled by pressing the key once

again.

The voltage and current measuring ranges can be selected individually when the multimeter is remote-controlled via its IR interface by using the USB X-TRA adapter (and the METRAwin10-Hit

software or control command via terminal program).

Mains and Harmonic Analysis

The measuring range for mains analysis (switch position PQ) is

specified in the menu (Set > MAinS > rAnGE).

The measuring range for harmonic analysis can be selected as a

fixed setting in the menu (Set > HArM > U.rAnGE and Set > HArM

> I.rAnGE, clamp factor is not taken into consideration!), or autoranging can be activated.

4.1.3 Peak Value Monitoring

for Automatic and Manual Measuring Range Selection

The peak value is measured in addition to RMS measurement in

the V / A DC, AC and AC+D functions, as well as for power measurement. If the peak value exceeds the valid range of the corresponding measuring path, the instrument is switched up one

range, even if the displayed measured value has not yet reached

the threshold value. If the momentary range is manually selected,

(-)OL is displayed.

This assures that, in these functions, measurement is always performed in the correct range (e.g. during measurement of a signal

with a high crest factor or measurement of the DC component of

a mixed signal with a large AC component).

Function Display

MAN / AUTO

Manual mode active:

utilized measuring range is fixed

MAN

or

Range switching sequence for:

V DC:

60 mV* 600 mV* 6 V 60 V 600 V

V AC/AC+DC:

600 mV* 6 V 60 V 600 V

Hz (V AC):

600 Hz 6 kHz 60 kHz 600 kHz

MHz

600 Hz 6 kHz 60 kHz 600 kHz 1 MHz

:

600 W 6 kW 60 kW 600 kW 6 MW 60 MW

A:

600 mA 6 mA 60 mA 600 mA 6 A 10 A (16 A)

Hz (A AC):

600 Hz 6 kHz 60 kHz 600 kHz

F:

60 nF 600 nF 6 mF 60 mF 600 mF

m:

6 km 60 km

MAN

MAN / AUTO

Return to automatic measuring range selection —

Page 18

18 GMC-I Messtechnik GmbH

Control Functions

4.1.4 Quick Measurements (MAN or DATA function)

Measurements performed using a suitable fixed measuring range

are executed more quickly than those which utilize automatic

range selection. Quick measurement is made possible with the

following two functions:

• Manual measuring range selection, i.e. selection of the measuring

range with the best resolution (see section 4.1.2)

or

•With the DATA function (see section 4.4) In this way, the appro-

priate measuring range is selected automatically after the first

measurement and the second measurement is executed more

quickly.

The selected measuring range remains active for the subsequent

series of measurements with these two functions.

4.2 Zero Offset / Relative Measurements – ZERO/Delta REL Function

Zero offset or a reference value for relative measurements can be

stored to memory depending upon deviation from the zero point:

The relevant reference or correction value is deducted individually

for the respective measuring function as an offset from all future

measurements and remains in memory until deleted, or until the

multimeter is switched off.

Zero balancing and reference value adjustment can be used for

auto-ranging, as well as for manual measuring range selection.

Zero Balancing

Ð Plug the measurement cables into the instrument and connect

the free ends to each other, except for capacitance

measurement in which case the ends of the cables are not

connected to each other.

Ð Briefly press the ZERO | ESC key.

The instrument acknowledges zero balancing with an acoustic

signal, and the “ZERO REL” symbol appears at the LCD. The

value measured at the moment the key is pressed serves as a

reference value.

Ð Zero balancing can be cleared by once again pressing the

ZERO | ESC key.

Deviation from Zero Point

– with short-circuited measurement cables

for V, , R

PE

, , A

– with open input for capacitance unit of measure (F)

Display

(0 ... 200) digits ZERO REL

(200 ... 25000) digits

(10 A measuring range: up to 5000 digits)

REL

Page 19

GMC-I Messtechnik GmbH 19

Control Functions

Setting the Reference Value

Ð Plug the measurement cables into the instrument and measure

a reference value (max. 25,000 digits, or 5000 digits in 10 A

range)

Ð Briefly press the ZERO | ESC key.

The instrument acknowledges storage of the reference value

with an acoustic signal, and the “ZERO REL” or the “REL”

symbol appears at the LCD. The value measured at the moment the key is pressed serves as a reference value.

Ð The reference value can be cleared by once again pressing the

ZERO | ESC key.

Notes Regarding Relative Measurement

• Relative measurement effects the main display only.

• In the case of relative measurement, , F or AC quantities may

also appear as negative values.

4.3 Display (LCD)

Measured Value, Unit of Measure, Type of Current, Polarity

The measured value with decimal and plus or minus sign appears

at the digital display. The selected unit of measure and current

type are displayed as well. A minus sign appears to the left of the

value during the measurement of zero-frequency quantities, if the

plus pole of the measured quantity is applied to the “” input.

Overranging

“0L” (overload) is displayed as of 61,000 digits.

Exceptions: “OL” appears at the display as of 6100 digits for measuring functions with a measuring range span of 6000 digits.

Page 20

20 GMC-I Messtechnik GmbH

Control Functions

4.4 Measured Value Storage: DATA (auto-hold / compare)

An individual measured value can be automatically “frozen” with

the DATA function (auto-hold). This is useful, for example, when

contacting the measuring points with the test probes requires

your full attention. After the measuring signal has been applied

and the measured value has settled in in accordance with the

“condition” listed in the table below, the measured value is frozen

at the digital display and an acoustic signal is generated. The test

probes can now be removed from the measuring points, and the

measured value can be read from the digital display. If the measuring signal falls below the value specified in the table, the function is reactivated for storage of the next value.

Measured Value Comparison (DATA compare)

If the currently frozen value deviates from the first saved value by less

than 100 digits, the acoustic signal is generated twice. If deviation is

greater than 100 digits, only a brief acoustic signal is generated.

Note

The selected measuring range cannot be manually changed

as long as the DATA function is active.

The DATA function is deactivated by pressing and holding the

DATA/MIN/MAX key (approx. 1 second), when the measuring function is changed, or when the instrument is switched off and back

on again.

DATA Function in Memory Mode Operation (rAtE parameter = dAtA)

If dAtA is selected as the storage rate under the StorE > rAtE measuring parameter setting, and if memory mode operation is then

started, measured values “frozen” with activated DATA function are

automatically saved to permanent memory with time stamp.

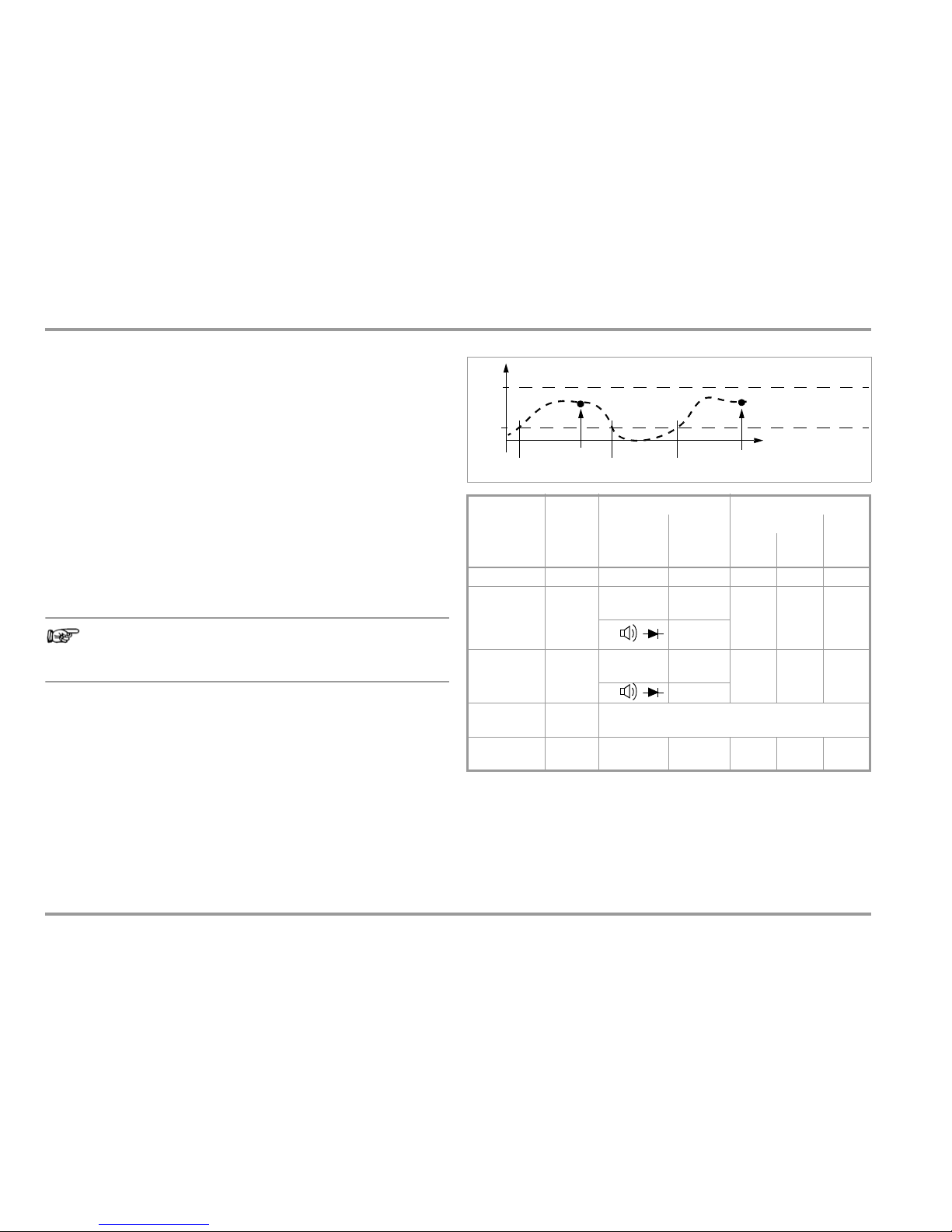

1

Reactivation results from falling short of specified measured value limits.

2

Two acoustic signals are generated the first time a measured value is saved as a

reference value. For subsequent data hold, two acoustic

signals are only generated if the currently frozen value deviates from the first saved

value by less than 100 digits.

Key: MV = measured value, MR = measuring range

Function

DATA

Data/

Min/Max

Key

Condition Response from Instrument

Measuring

Function

Measuring

Signal

Display

Acous-

tic

Digital

MV

DATA

Activate Brief Blinks Once

Save

(stabilized

measured

value)

V, A, Hz, dB,

F, M H z, %

> 10%

rdg.

Is

dis-

played

Static

Once

Twi ce

2

0L

Reactivate

1)

V, A, Hz, dB,

F, M H z, %

< 10%

rdg.

Stored

MV

Blinks

= 0L

Change to

Min/Max

Brief See table in section 4.4.1

Exit Long

Is

deletedIsdeleted

Twi ce

V, A , Hz

t [s]

60,000

6000

Activated

Reactivated

Save

Save

dB, F, MHz, %

Digits

Digits

100% of measuring range

10% of measuring range

Page 21

GMC-I Messtechnik GmbH 21

Control Functions

Example

The voltage measuring range is set manually to 6 V. The first measured value is 3 V and is stored to memory because it is greater

than 10% of the measuring range (6000 digits = 0.6 V), and is

thus reliably above the background noise level. As soon as the

measured value drops to less than 10% of the measuring range

(6000 digits), i.e. amounts to less than 6 V which corresponds to

removal of the test probes from the measuring point, the instrument is ready to store a new value.

4.4.1 Saving Minimum and Maximum Values – Min/Max Function

Minimum and maximum measured values applied to the measuring instrument’s input after the Min-Max function has been activated can be “frozen” at the auxiliary display along with time of

occurrence. The most important use of this function is the determination of minimum and maximum values during long-term measured value observation.

Except during power measurement, the Min-Max function has no

effect on the main display, at which the current measured value

continues to appear.

Apply the measured quantity to the instrument and set the measuring range with the MAN / AUTO key before activating the Min-

Max function.

The Min-Max function is deactivated by pressing and holding the

DATA/MIN/MAX key (approx. 1 second), when the measuring function is changed, or when the instrument is switched off and back

on again.

Note

Extreme values can be reset by pressing the ZERO key.

Power Measurement (special case)

Instantaneous power is displayed with the switch in the W setting.

The Min-Max function is activated with the DATA/MIN/MAX key. The

minimum and maximum values for active, reactive and apparent

power are displayed as of the beginning of the power measurement, along with time of occurrence (date and time).

Previous Min-Max values can be cleared without exiting the function by pressing the ZERO key.

This function differs from the general Min-Max function insofar as

measurement is performed continuously in the background, even

if the Min-Max display is not shown, and while the instrument is in

the energy measuring mode

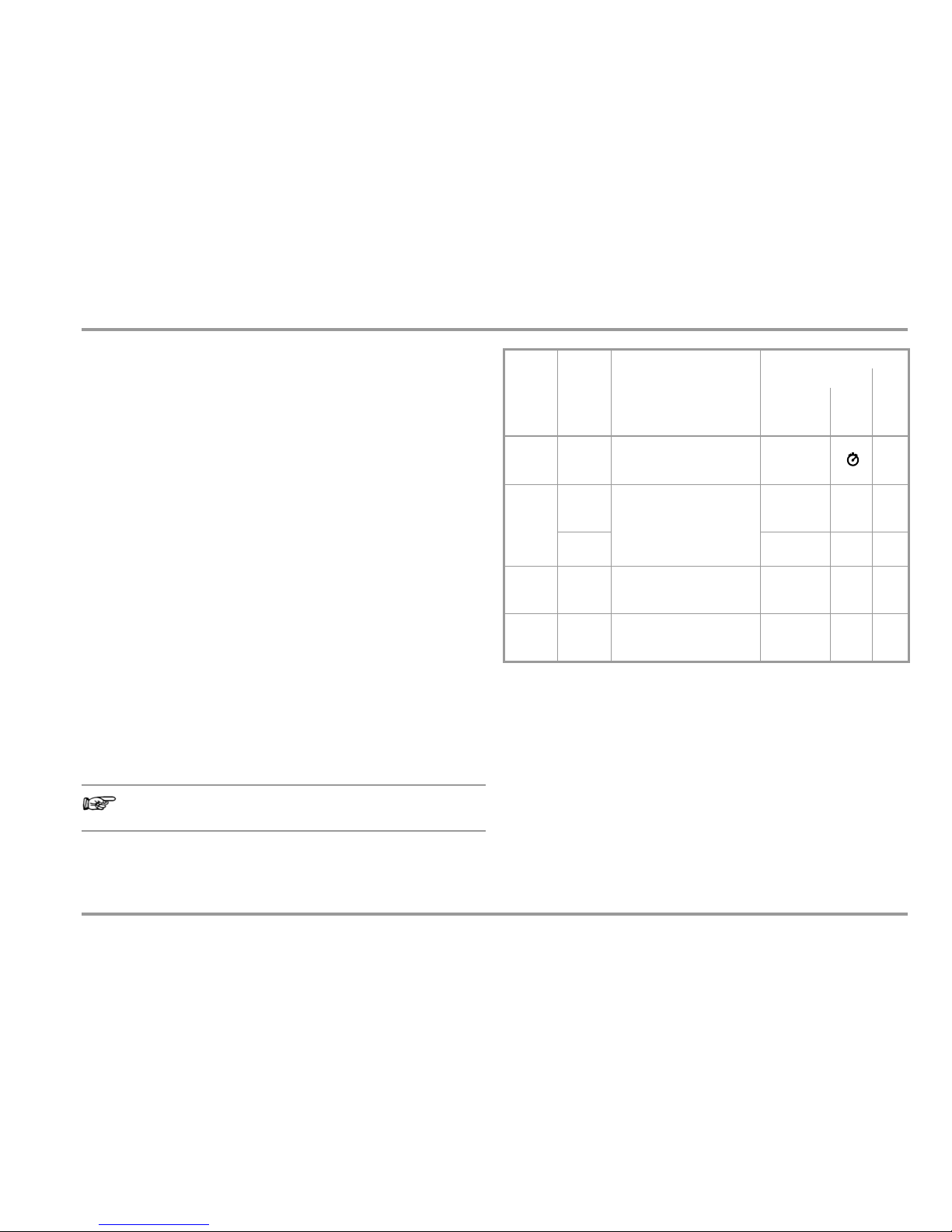

Min-Max

Function

Data/

Min/Max

Key

Min. and Max.

Measured Values

Response from Instrument

Display

Acous

tic

Sig-

nal

Digital

Measured

Valu e

Max.

Min.

1

Activate

and save

DATA/

MIN/MAX

1 x brief

Are

saved

Current

measured

value

Once

2

Save and

display

DATA/

MIN/MAX

Brief

Storage continues in the back-

ground, new min. and max.

values are displayed together

with time.

Saved min.

value

Min. Once

Brief

Saved max.

value

Max. Once

Reset

ZERO/

ESC

Brief

Are deleted

Saved min.max. values

min/

max

1

Stop

DATA/

MIN/MAX

Long

are deleted

and function is exited

Current

measured

value

Is dele-

ted

Twi ce

Page 22

22 GMC-I Messtechnik GmbH

Control Functions

4.5 Measurement Data Recording – Memory Mode Operation, STORE

Menu Function

The system multimeter is capable of recording measurement data

using an adjustable sampling rate for long periods of time in the

form of measurement series. Data are stored to permanent memory, an68: EnErGY Submenud are retained even after the multimeter is switched off, as well as after battery replacement.

Stored measured values can subsequently be read out at the

computer. The only prerequisite is a PC which is connected by

means of an interface cable to the USB X-TRA bidirectional interface adapter, which is plugged onto a system multimeter. See

also section 7, “Interface Operation”.

Memory Parameters Overview

Preparing for Recording – Parameter Settings

Ð First set the sampling rate for memory mode operation (see

section 6.4 the rAtE parameter).

Ð Set hysteresis for efficient use of available memory space.

During memory mode operation, new measured data are only

saved if they deviate from the previously stored value by an

amount which exceeds the selected hysteresis value (see

section 6.4, “hyst” parameter).

Ð Set “t.StorE” in order to limit recording duration.

Ð First select the desired measuring function and an appropriate

measuring range.

Ð Check the battery charge level before starting long-term mea-

surement recordings (see section 6.3).

Connect the NA X-TRA power pack if applicable.

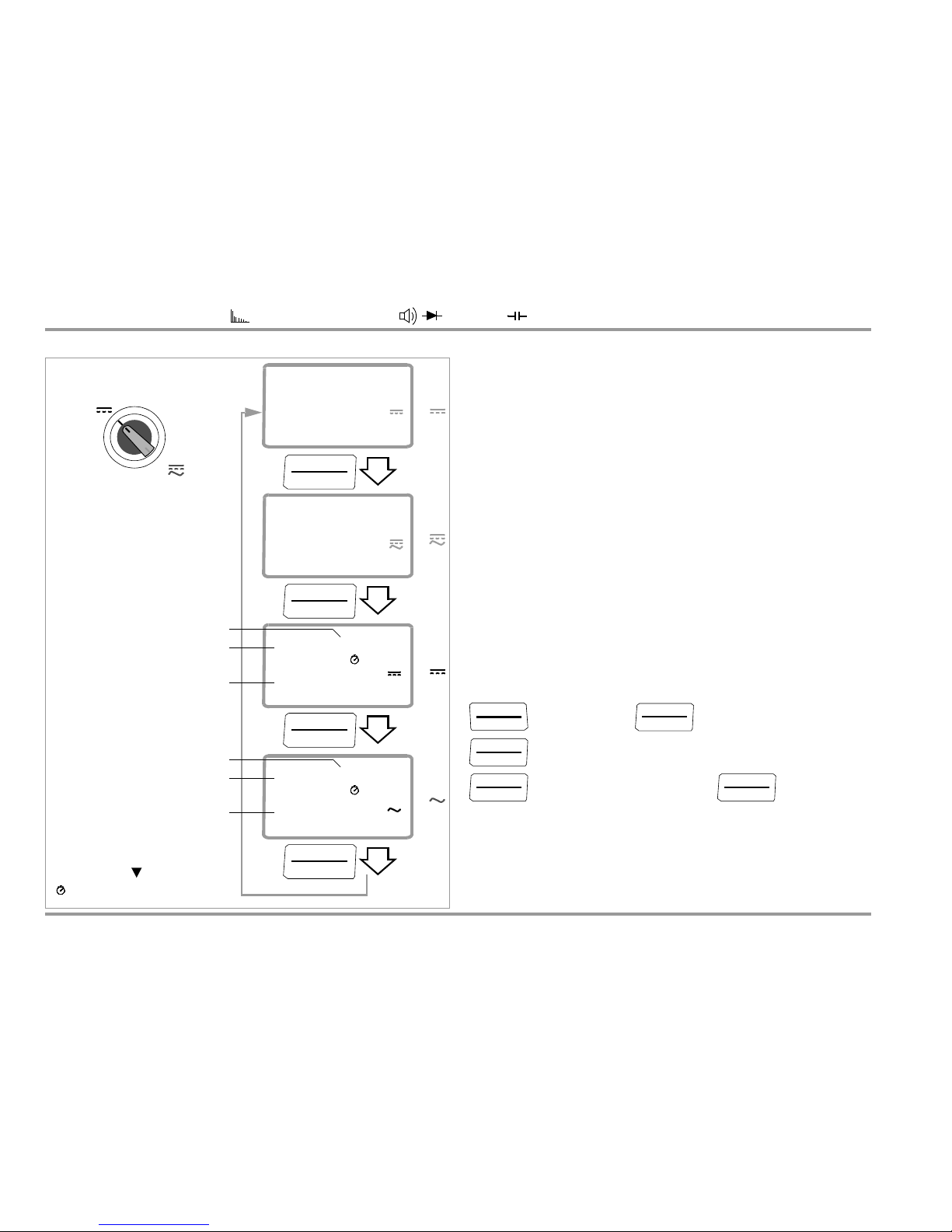

Starting Recording via Menu Functions

Ð Switch to the “SET” mode by pressing MEASURE | SETUP and

select the “StorE” menu.

1nFo

... StorE store off StArt (blinks)

store

Ð Memory mode operation is started by acknowledging the

blinking “start” prompt at the main display with the FUNC |

ENTER key. The

STORE display segment appears in the header

and indicates that the memory mode has been activated.

“store” appears at the main display.

Ð Press the MEASURE | SETUP key in order to return to the measur-

ing function.

Parameter Page: Header

CLEAr

23: Clear Memory

dEMAnd

tiME

66: tEMP unit – Select a Unit of Measure for Temperature

EMpty

23: Clear Memory – appears after CLEAr

hyst

73: HYSt – Hysteresis (parameter for memory mode operation)

0CCvP

23: Querying Memory Occupancy

rAtE

68: EnErGY Submenu

StArt

22: Starting Recording via Menu Functions

StoP

23: Ending Recording

t.store

74: tStorE – Recording Time (parameter for memory mode operation)

MEASURE

SETUP

FUNC

ENTER

FUNC

ENTER

Page 23

GMC-I Messtechnik GmbH 23

Control Functions

Note

The StorE > StArt and StorE > CLEAr menu functions can

only be selected a long as memory is not completely full

(StorE > StArt), or not completely empty (StorE > CLEAr).

Ending Recording

Ð If the instrument is in the measuring mode, return to the menu

function by pressing the MEASURE | SETUP key. Select “StorE”

again and acknowledge by pressing the FUNC | ENTER key.

“StoP” blinks at the main display.

store on StoP store

Ð Acknowledge the “StoP” display by pressing FUNC | ENTER.

The

STORE display segment in the header is cleared, indicating

that recording has been ended.

Ð Press the MEASURE | SETUP key in order to return to the measur-

ing function.

Ð Memory mode operation can also be exited by switching the

multimeter off.

Querying Memory Occupancy

Memory occupancy can be queried during recording with the

help of the “1nFo” menu (see also section 6.3).

Memory occupancy range: 000.1% to 099.9%.

1nFo

bAtt

x.x V

...

0CCvP :

017.4

%

Clear Memory

This function deletes all measured values from memory! (blinks)

It’s advisable to execute this function before starting a new

measurement data recording.

1nFo

... StorE store off StArt (blinks)

store CLEAr no yes empty store

Storage of Individual Values Using the SAMPLE or dAtA Sampling Rate

If only individually selected values need to be saved, the SAMPLE

value must be selected as the StorE > rAtE sampling value. If

memory mode operation is then started, a single measured value

is saved to permanent memory with time stamp when the DATA/

MIN/MAX key is pressed and held until two rapidly repeating

acoustic signals are generated (not in the case of mains analysis).

If dAtA is selected as the StorE > rAtE sampling rate, and if memory mode operation is then started, measured values ascertained

with activated DATA function are automatically saved to permanent memory with time stamp.

FUNC

ENTER

MEASURE

SETUP

FUNC

ENTER

MEASURE

SETUP

FUNC

ENTER

FUNC

ENTER

Page 24

24 GMC-I Messtechnik GmbH

Control Functions

4.5.1 Rapid Momentary Value Acquisition for U DC and I DC

Rapid momentary value acquisition is only activated during memory mode operation in the U DC and I DC functions, and only after

selecting a sampling period of 0.5, 1, 2, 5, 10, 20 or 50 ms: All

trigger and hysteresis functions are available, although the

momentary value is acquired with a separate measuring circuit.

This allows for the recording of the waveshapes of low-frequency

signals with reduced resolution and accuracy (typically < 1% of the

measuring range under reference conditions, not specified).

Roughly 300,000 measured values can be saved in this mode.

Values of up to about 1.9 x Umax or Imax are recorded (with fixed

range, range-dependent fluctuations), and thus the range limit

can be exceeded by approximately 90%.

Note

The ZERO/REL function is not taken into consideration for

rapid momentary value acquisition!

4.5.2 Power and Energy Measurement in the Memory Mode

The value selected for the SEt > EnErGY > StorE menu parameter

specifies which values from power and energy measurements will

be saved during memory mode operation:

• SEt > EnErGY > StorE = normal (default setting):

Momentary values for current, voltage, active, reactive and

apparent power, as well as power factor, are acquired and

saved to memory at the selected sampling rate (at least 0.5 s).

• SEt > EnErGY > StorE = demand:

The instrument only saves mean power values at the end of the

dEMAnd tiME observation period

(see section 6.4.4, “dEMAnd tiME” parameter).

• SEt > EnErGY > StorE = all:

Momentary values are saved at the selected sampling rate and

mean power values are saved at the end of each dEMAnd

tiME observation period

(see section 6.4.4, “dEMAnd tiME” parameter).

Ð Set the dEMAnd tiME interval for memory mode operation

before you start recording.

Page 25

GMC-I Messtechnik GmbH 25

Measurements: V/Hz/dB – PQ/ – MHz/% – /nS/RSL

– / –

Temp – /m – W/Wh – A/Hz/thd

5 Measurements

5.1 Voltage Measurement

Notes Regarding Voltage Measurement

• The multimeter may only be operated with installed batteries or rechargeable batteries. Dangerous voltages are otherwise not indicated,

and the instrument may be damaged.

• The multimeter may only be operated by persons who are capable of recognizing contact hazards and taking the appropriate

safety precautions. Contact hazards exist anywhere, where voltages of greater than 33 V (RMS) may occur.

The test probes may only be only gripped up to the finger guard.

Do not touch the metallic test probes under any circumstances.

• Avoid working alone when taking measurements which involve

contact hazards. Be certain that a second person is present.

• Maximum permissible voltage between the connector sockets, (9

and 10) and ground (8) is 600 V for measuring category III and

300 V for measuring category IV. An acoustic signal is generated

at a display value of greater than 600.0 V in the 600 V range (intermittent acoustic signal: 250 ms on, 250 ms off).

• Power limiting: < 6 x 10

6

Volts x Hertz.

• Be prepared for the occurrence of unexpected voltages at devices

under test (e.g. defective devices). For example, capacitors may

be dangerously charged.

• No measurements may be made with this instrument in electrical circuits with corona discharge (high-voltage).

• Special care is required when measurements are made in HF

electrical circuits. Dangerous pulsating voltages may be present.

• Be aware of the fact that dangerous voltage spikes are not displayed

during measurement with the low-pass filter.

We recommend measuring voltage without the low-pass filter first, in

order to be able to detect any dangerous voltages.

• Be absolutely certain that the measuring ranges are not overloaded beyond their allowable capacities. Limit values are included in section 8, "Technical Data”, in the table entitled

“Measuring Functions and Measuring Ranges” in the “Overload

Capacity” column.

• With the rotary switch in the V position, the instrument is

always in the 6 V measuring range immediately after it’s

switched on. As soon a the MAN / AUTO key is pressed, and assuming the measured value is less than 600 mV, the instrument

is switched to the mV measuring range.

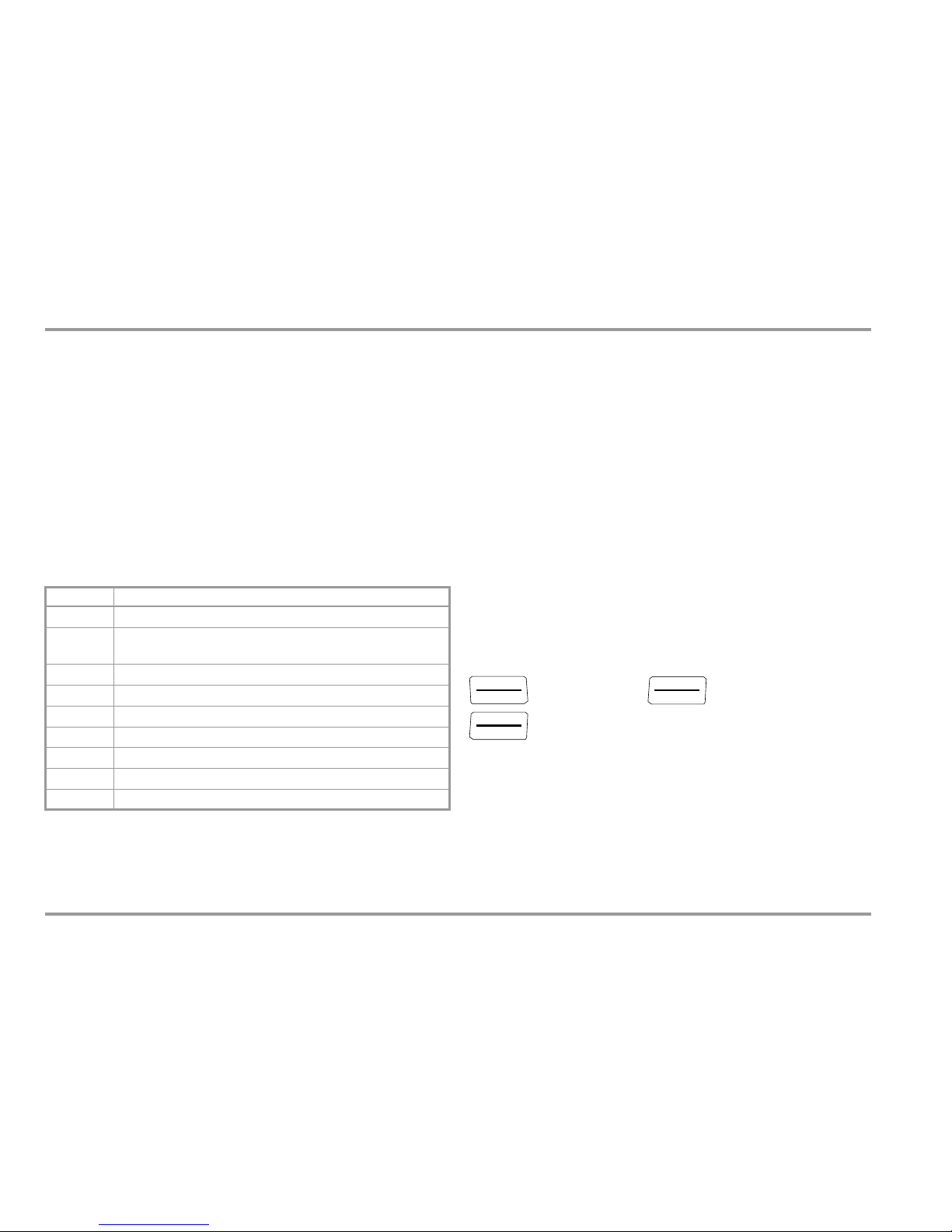

Scope of Functions, Voltage Measurement

1

A 1 kHz low-pass filter can be used in this case, in order to filter out high frequency

pulses of greater than 1 kHz, for example when performing measurements at

pulsed motor drives.

Function

V AC / Hz TRMS, dB

(Ri 9 M)

1

V AC / TP-Filter 1 kHz

1

(Ri 9 M) TRMS

V AC+DC TRMS

(Ri 9 M)

V DC (Ri 17 M)

MHz at 5 V AC

Duty cycle as %

Frequency bandwidth

100 kHz

Page 26

26 GMC-I Messtechnik GmbH

Measurements: V/Hz/dB – PQ/ – MHz/% – /nS/RSL

– / –

Temp – /m – W/Wh – A/Hz/thd

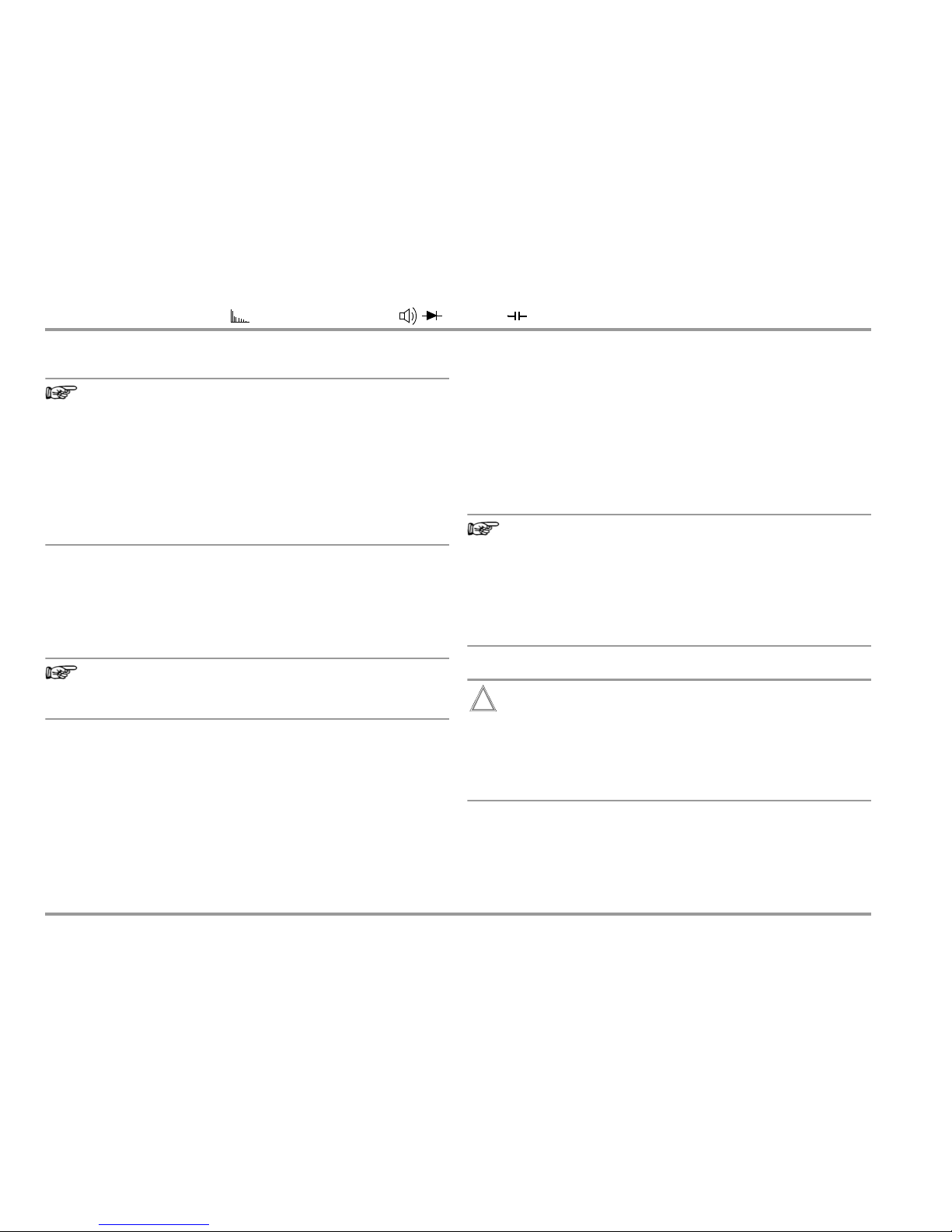

5.1.1 Direct Voltage, Pulsating Voltage and Crest Factor Measurement

– V DC, V (DC+AC) and CF

Note

Set the CL iP parameter to 0FF in the current clamp setup

menu. Otherwise all measured values are displayed in

amperes, corrected by the amount resulting from the

selected transformation ratio for an interconnected current

clamp sensor. The clamp symbol is also displayed. Refer to

section 6.4, "Entering Parameters – SETUP Menu”

,

regarding adjustment.

Ð In accordance with the voltage to be measured, turn the rotary

switch to V or V .

Ð Connect the measurement cables as shown.

The “” connector jack should be grounded.

Note

An intermittent acoustic signal warns the operator if the measured value exceeds the upper range limit in the 600 V range.

Make sure that a current measuring range (“A”) has not been activated when the multimeter is connected for voltage measurement!

If the fuse’s blowing limits are exceeded as a result of operator

error, both the operator and the instrument are in danger!

With the rotary switch in the V position (auto-ranging), the multimeter is always in the 6 V measuring range immediately after it’s switched on. As soon a the MAN / AUTO key is pressed, and assuming

the measured value is less than 600 mV, the instrument is switched to the 600 mV measuring range. Press the

key in order to

switch to the 60 mV measuring range.

COM

V

Tem p

– (+)

+ (–)

V= : 60 mV 600 V

20,000

V

DC

AC

TRMS

20,000

V

DC

V

V

V

V

> 30 V AC or > 35 V DC:

> 600 V:

Warnings regarding dangerous

max. 600 V (< 10 kHz)

V: 600 mV 600 V

max. 100 V (> 10 kHz)

P

max

= 6 x 106 V x Hz

Measuring ranges:

000000

20.000 00:00:00

V

Cf: 01.0

EVENTS

MAN

DC

000000

00.000 00:00:00

V

EVENTS

MAN

AC

TRMS

voltage:

V

V

FUNC

ENTER

FUNC

ENTER

FUNC

ENTER

FUNC

ENTER

CL ip = 0FF

!

CF: 1.0 ... 11.0

Page 27

GMC-I Messtechnik GmbH 27

Measurements: V/Hz/dB – PQ/ – MHz/% – /nS/RSL

– / –

Temp – /m – W/Wh – A/Hz/thd

Note

60 mV range:

Thermovoltages occur in the event of temperature fluctuation, which appear as additional voltage offset. It may be

necessary to repeat zero offsetting in order to achieve the

specified degree of accuracy.

Crest Factor Display

Crest factor is displayed for voltages in the V (AC+DC) function

along with the measured voltage value. The voltage value is measured simultaneously in a separate measuring circuit to this end,

and crest factor is displayed within a range of 1.0 to 11.0.

This value indicates the quality of the applied signal. The only prerequisite is a periodic signal with a valid frequency (see table).

Measuring range: 1.0

CF 11.0; resolution: 0.1

Typical (not specified) maximum deviation

for U 5% of the measuring range:

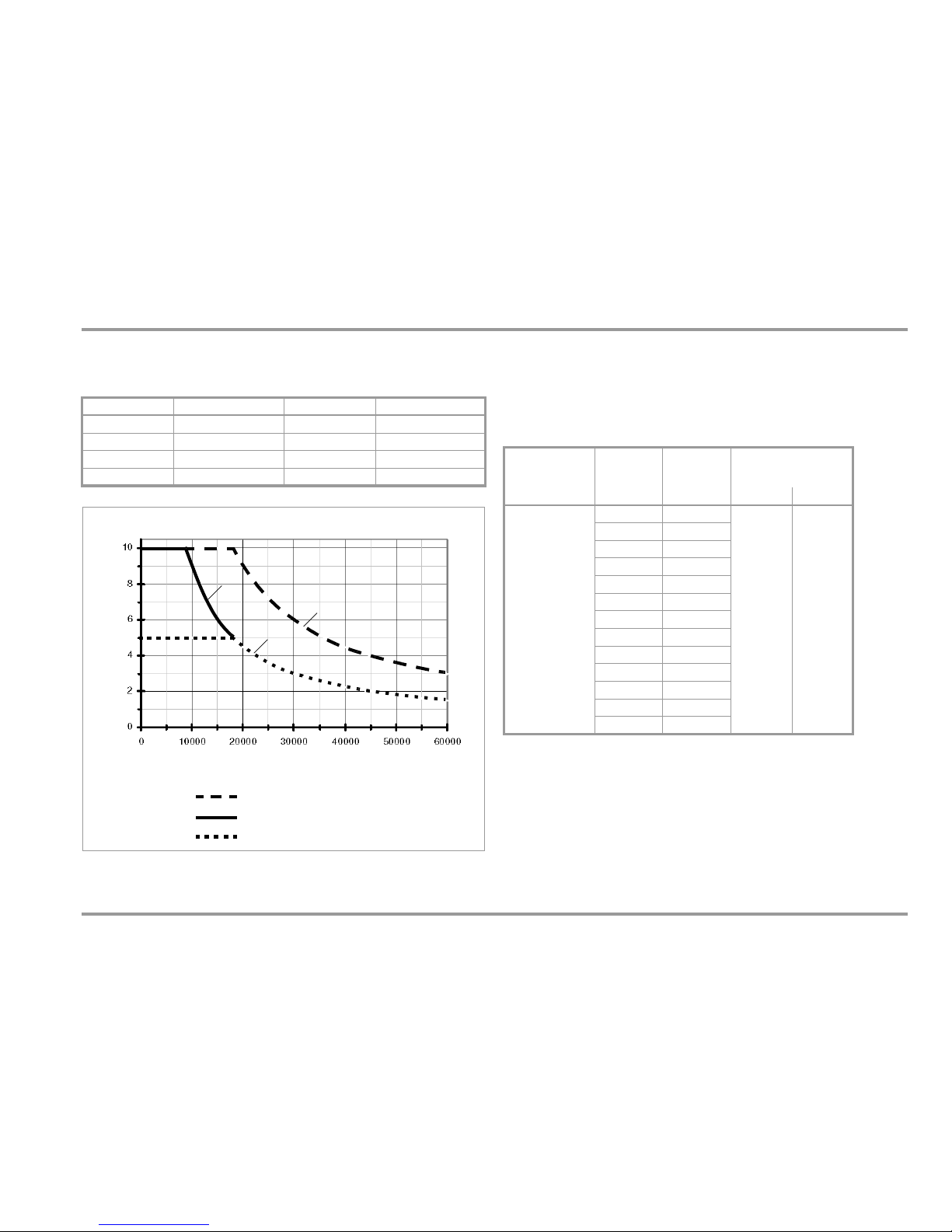

Frequency CF 3.0 3.0 < CF 5.0 5.0 < CF 10.0

10 to 70 Hz 02 02 05

70 to 440 Hz 02 05 Not valid

440 Hz to 1 kHz 05 Not valid Not valid

> 1 kHz: Not valid Not valid Not valid

Page 28

28 GMC-I Messtechnik GmbH

Measurements: V/Hz/dB – PQ/ – MHz/% – /nS/RSL

– / –

Temp – /m – W/Wh – A/Hz/thd

Events Recording “EVEntS” Events recording can be activated with DC or AC coupling in the

V DC switch position. The auto-ranging function is deactivated,

and the respective valid measuring range must be selected manually in the left-hand auxiliary display.

The following can be measured and displayed:

• Number of events

An event is recorded whenever at least 1 measured value has

fallen short of the L-trig threshold and subsequently at least 1

measured value has exceeded the H-trig threshold.

Voltage signals with a repetition frequency of less than 500 Hz

or 2 Hz are recorded (event rate or period of 0.001 s or 0.5 s).

• Total time for all events

Time during which measured voltage was above the upper

trigger threshold.

• Total time elapsed since event recording was started

Event Recording Parameter with DC Coupling – DC Sampling Rate

Ð Enter the desired sampling rate in the parameter settings

menu:

1nFo ... SET system ... events

events trig / events rate DC

events rate : 0 ..001 /0..5 s

20.000

V

DC

AC

TRMS

20.000

V

DC

V

V

V

V

000.000

20,000 00:00:00

V

Cf: 01.0

EVENTS

MAN

DC

000.000

00,000 00:00:00

V

EVENTS

MAN

AC

TRMS

V

V

FUNC

ENTER

FUNC

ENTER

FUNC

ENTER

FUNC

ENTER

CL ip = 0FF

!

Number of elements

Time elapsed since recording start

Event value

DC coupling

Number of elements

Time elapsed since recording start

Event value

AC coupling

(sampling rate: 0.5 s / 1 ms)

(sampling rate: 0.5 s)

Total time for all eventsOn

DATA/MIN/MAX

MEASURE

SETUP

FUNC

ENTER

FUNC

ENTER

FUNC

ENTER

FUNC

ENTER

Page 29

GMC-I Messtechnik GmbH 29

Measurements: V/Hz/dB – PQ/ – MHz/% – /nS/RSL

– / –

Temp – /m – W/Wh – A/Hz/thd

Note

1 ms sampling is executed with reduced resolution and

accuracy (approx. 1% of the measuring range under reference conditions).

Events Measurement Parameter – Trigger Thresholds

Ð Enter upper threshold H-trig and lower threshold L-trig in digits in

the parameter settings menu (see table with examples below):

1nFo

... SET system ... events

events rate DC / events trig

h-trig set : -60000 ... +60000

l-trig set : -60000 ... +60000

Examples of Trigger Threshold Entries

Selecting the Measurement

Ð In accordance with the voltage to be measured, turn the rotary

switch to V or V .

Ð Manually select the measuring range for the event value in the

left-hand auxiliary display.

Ð Apply the signal as you would for a voltage measurement.

Ð Repeatedly press the multifunction key (FUNC | ENTER) until

EVENTS (DC) or EVENTS (AC) appears at the display.

You can switch back and forth between two times with the DATA/

MIN/MAX key:

Total time elapsed since event recording was started

ON Total time of all events (voltage above H-triG)

Entered Value:

H-trig or L-trig Trigger Threshold in Digits

20 000 02 000 00 200

Meas. range Effective trigger threshold

600 mV 200 mV 20 mV 2 mV

6 V 2 V 200 mV 20 mV

60 V 20 V 2 V 200 mV

600 V 200 V 20 V 2 V

MEASURE

SETUP

FUNC

ENTER

FUNC

ENTER

FUNC

ENTER

FUNC

ENTER

FUNC

ENTER

Page 30

30 GMC-I Messtechnik GmbH

Measurements: V/Hz/dB – PQ/ – MHz/% – /nS/RSL

– / –

Temp – /m – W/Wh – A/Hz/thd

5.1.2 Alternating Voltage and Frequency Measurement V AC and Hz

with Selectable Low-Pass Filter, V AC + FILTER and dB V AC

Note

Set the CL iP parameter to 0FF in the current clamp setup

menu.

Otherwise all measured values are displayed in amperes,

corrected by the amount resulting from the selected transformation ratio for an interconnected current clamp sensor.

The clamp symbol is also displayed. Refer to

section

6.4, "Entering Parameters – SETUP Menu”

,

regarding adjustment.

Ð In accordance with the voltage or frequency to be measured,

turn the rotary switch to V~.

Ð Connect the measurement cables as shown.

The “” connector jack should be grounded.

Voltage measurement

Note

An intermittent acoustic signal warns the operator if the measured value exceeds the upper range limit in the 600 V range.

Make sure that a current measuring range (“A”) has not been activated, when the multimeter is connected for voltage measurement!

If the fuse’s blowing limits are exceeded as a result of operator

error, both the operator and the instrument are in danger!

Ð You can switch back and forth between voltage measurement

with and without low-pass filter.

Ð Repeatedly press the multifunction key (FUNC | ENTER) until the

unit of measure V, or V and FILTER, appears at the display.

Frequency Measurement

Signal frequency appears at the left-hand auxiliary display when

the instrument executes alternating voltage measurements. A

separate frequency measurement can be additionally performed

by pressing the FUNC | ENTER key, which allows for use of the DATA

and Min-Max functions.

If the measuring signal is too low, switch manually to a lower

range.

Lowest measurable frequencies and maximum allowable voltages

are listed in section 8, "Technical Data”.

Note

For measurements close to the trigger threshold: display

error or zero. Select a lower voltage measuring range. In the

case of measured values which are many times greater than

the expected results, the input signal may be distorted. If this

is the case, perform a measurement with activated 1 kHz

low-pass filter.

Measurement with Low-Pass Filter

Attention!

!

Be aware of the fact that dangerous voltage spikes are not

displayed during this type of measurement (see also

“Voltage Comparator”. We recommend measuring voltage

without the low-pass filter first, in order to be able to detect

any dangerous voltages.

A 1 kHz low-pass filter can be activate if required, in order to filter

out high frequency pulses of greater than 1 kHz, for example when

performing measurements at pulsed motor drives, i.e.

undesired voltages of greater than 1 kHz can be suppressed.

Page 31

GMC-I Messtechnik GmbH 31

Measurements: V/Hz/dB – PQ/ – MHz/% – /nS/RSL

– / –

Temp – /m – W/Wh – A/Hz/thd

The active low-pass filter is indicated by the FILTER display. The

multimeter is automatically switched to manual measuring range

selection.

Specified measuring accuracy is not reached with signals of greater than 100 Hz when the filter is active.

Voltage Comparator for Displaying Dangerous Voltage

The input signal or measuring signal is checked by a voltage

comparator for dangerous spikes, because these do not appear at

the display when the low-pass filter is used.

At voltages of greater than 30 V AC or 35 V DC, a danger symbol

appears at the display: .

COM

V

Tem p

max. 600 V (< 10 kHz)

V~: 600 mV 600 V

Hz: 1 Hz ¼ 300 kHz

~

max. 100 V (> 10 kHz)

P

max

= 6 x 106 V x Hz

Measuring ranges:

> 30 V AC or > 35 V DC:

> 600 V:

Warnings regarding dangerous voltage:

for U > 100 V

V~

Hz

V~

V~ & Filter

1 kHz

V~

049.45

AC

!

FUNC

ENTER

FUNC

ENTER

FUNC

ENTER

FUNC

ENTER

dB

dB

TRMS

230.00

V

050.00

AC

TRMS

1 kHz

dB

Hz

050.00

Hz

AC

TRMS

230.00

V

050.00

AC

TRMS

Hz

FILTER

CL ip = 0FF

!

R:00.775

V

230.0

V

Reference value

Current measured value

MAN

Page 32

32 GMC-I Messtechnik GmbH

Measurements: V/Hz/dB – PQ/ – MHz/% – /nS/RSL

– / –

Temp – /m – W/Wh – A/Hz/thd

Alternating Voltage Level Measurement (dB)

Voltage level measurement is used in order

to ascertain overall attenuation or boosting of

a transmission system (shown here as a 4pole setup).

Where U

1

= U

REF

(reference level)

Result > 1: boosting

Result < 1: attenuation

Ð Manually select the measuring range for the voltage amplitude.

When the instrument is switched to dB measurement, the previously selected voltage measuring range remains active.

Ð Repeatedly press the multifunction key FUNC | ENTER until the

unit of measure dB appears at the display.

Lowest measurable frequencies and maximum allowable voltages are included in section 8, "Technical Data”.

The level measurement function is now activated. The measured

value is calculated based upon the RMS value of the alternating

voltage component relative to the measuring range (600 mV

600 V), and displayed.

The default setting for the reference level is 0 dB = 0.775 V (1 mW

to 600 ). This value van be adjusted in the “SET” menu (see also

section 6.4):

1nFo

... SET system ... dbrEF

dbrEF set: 00 ..001 ... 99 V

Note

No terminal resistors have been integrated into the device. It

performs measurement with a high input impedance of at

least 9 M (see technical data).

In order to be able to perform correct measurement at nonterminated devices under test, the terminating resistor must

be connected to the terminals. Be sure to take power loss at

the terminating resistor into consideration!

U

1

U

2

Voltagelevel dB20

U

2

U

1

------log=

MEASURE

SETUP

FUNC

ENTER

FUNC

ENTER

FUNC

ENTER

Page 33

GMC-I Messtechnik GmbH 33

Measurements: V/Hz/dB – PQ/ – MHz/% – /nS/RSL

– / –

Temp – /m – W/Wh – A/Hz/thd

5.1.3 Mains Monitoring / Mains Disturbance Recording – PQ

Overview

The METRAHIT ENERGY is equipped with an operating mode for

mains disturbance recording in the PQ switch position. Input

voltage is simultaneously measured with a different measuring

circuit to this end.

• The RMS value of the applied voltage is measured and

displayed continuously. (This measurement corresponds to

DC+AC TRMS measurement, see section 5.1.2.) The

measurement is used for precise detection of overvoltages and

undervoltages.

• Additionally, the voltage is sampled at 1.2 kS/s and a half-cycle