Page 1

Operating Instructions

METRA 18C

Calibrator

3-348-715-15

5/1.02

Page 2

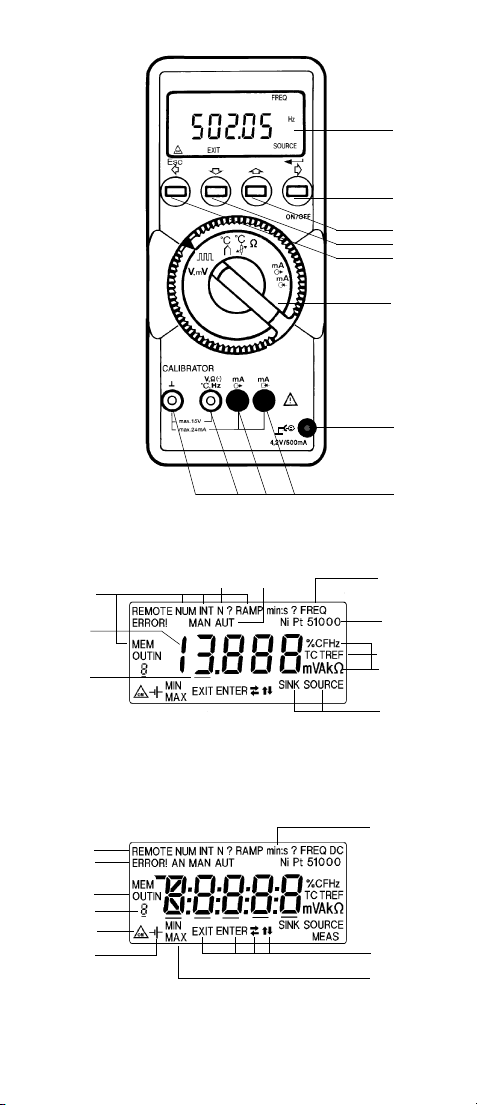

(1)

(2)

(3)

(4)

(5)

(6)

(7)

(8)

9)

10)

7)

8)

1)

6)

5)

2)

4)

3)

11)

16)

17)

12)

13)

18)

19)

14)

15)

2 GOSSEN-METRAWATT

Page 3

Operating Instructions

(1) LC display

(2) ON/OFF key, cursor right ENTER

(3) Key for digit increment, increasing step

(4) Key for digit decrement, decreasing step

(5) Key for cursor left, EXIT

(6) Functions selector for basic functions

V, mV = V, mV-source

= frequency, pulse

°C = thermocouple (TC) simulation

°C = RTD sensor simulation

W = resistance simulation

mA = mA-SOURCE

mA = mA MEAS, mA SINK

(7) Jack for plug type mains unit

(8) Jacks with automatic interlocking

LC Display

1) 5-digit numeric display, 1st digit indicates type of thermocouple

2) Cursor field

3) Menu guidance symbols for basic functions

SOURCE = source, i.e. simulation of signals

SINK = sink, i.e. for simulating a 2-terminal transmitter

4) Measurement units for measured values

5) Menu guidance symbols

TC = basic function ”°C “, for thermocouple simulation

TREF = setting the reference temperature

6) Type of simulated RTD sensor, e.g. Pt100 in the basic function ”°C “

7) FREQ = pointing to the basic function ” “ = frequency or

8) Menu guidance symbols for types of signal output

NUM = numerical entry for the output signal

INT = intervals, output in N steps

RAMP = ramp output

MEM = memory, output from the non-volatile memory

9) N? = request for entry of the number of steps in output type INT

10) Menu guidance symbols for output method MEM using

MAN = number of steps by manual key action

AUT = number of automatic steps with selectable time per step

11) min:s = flashing menu guidance symbol for time entries

12) Menu guidance symbols for output method MEM using

OUT = output from memory

IN = input to memory

13) Number of the memory value or number of the procedure

14) Menu guidance symbols for permissible key operations

EXIT = key (5) for EXIT function (Esc)

ENTER = key (2) for ENTER function

15) MIN and MAX simultaneously

pointing out the ranges with selectable lower and upper range limits

MIN or MAX flashing

Menu guidance symbol when entering the lower range limit (MIN) or

the upper range limit (MAX) for output types INT and RAMP

MAX flashing

Upon entering the upper range limit during current measurement

16) Menu guidance symbol for REMOTE operation via the serial interface

17) ERROR ! = warning symbol for error states

18) = pointing out the inhibited automatic cut-out

19) = indication of "battery low" or for battery voltage indication

GOSSEN-METRAWATT 3

pulse output

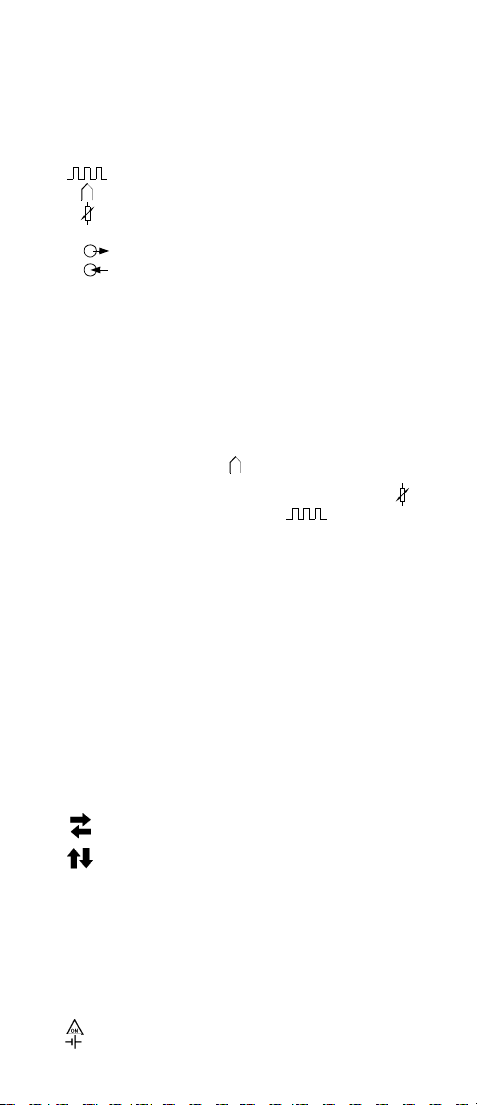

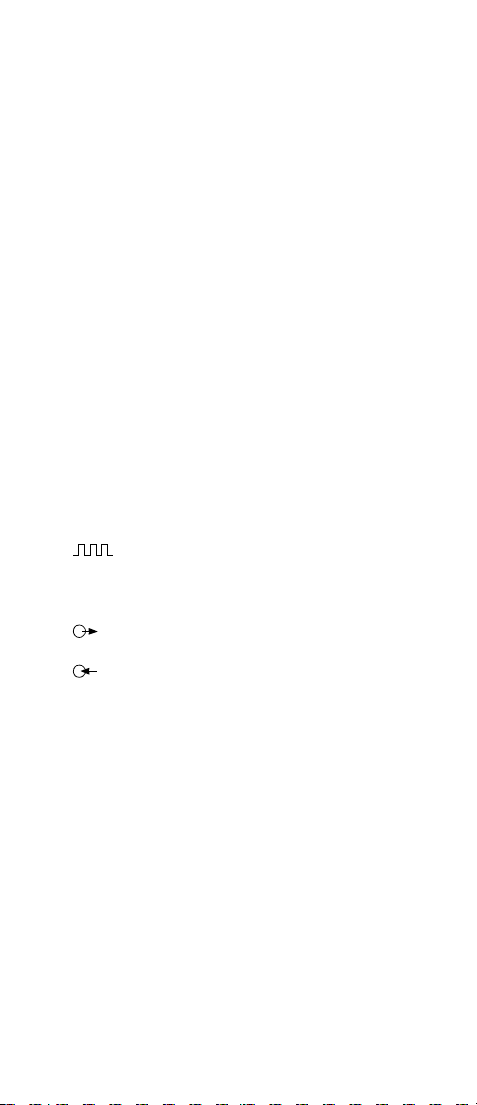

= keys (2) and (5) moving the cursor to the right (2)

or to the left (5)

= keys (3) and (4) for menu selection on the same level

modifying digits or step function

Page 4

Contents

Page

1 Safety Features and Precautions ....................................... 5

2 Putting into Operation ........................................................ 7

3 General Advice for Operation ............................................. 9

3.1 Key Panel ............................................................................. 9

3.2 Menu Structure and Key Operations ..................................... 10

3.3 LC display .......................................................................... 11

3.4 Operating Assistance by the LC Display ............................... 13

3.5 Entering Digits .................................................................... 13

3.6 Non-Volatile Saving of Menu Positions and Configurations .... 14

4 Types of Output Signals ................................................... 15

4.1 Menu Structure .................................................................. 15

4.2 Numerical or Manual Entries for the Output Signal (NUM) ...... 15

4.3 Intervals, Output in N Steps (INT) ......................................... 15

4.4 Output as Periodic Ramp (RAMP) ......................................... 18

4.5 Output from the Non-Volatile Memory (MEM) ........................ 20

4.6 Output by Prozedures Saved in the Non-Volatile Memory ...... 22

4.7 Output via the Serial Interface (REMOTE) .............................. 23

5 Basic Functions ................................................................ 25

5.1 General Notes .................................................................... 25

5.2 Supervisory Circuits ............................................................ 25

5.3 [V, mV], Voltage Source ...................................................... 28

5.4 , Pulse Generator ................................................... 28

5.5 [°C], Thermocouple Simulation ............................................ 31

5.6 [

°C], RTD Sensor Simulation ............................................... 33

5.7 [

W], Resistance Simulation ................................................. 34

5.8 , Current Source ......................................................... 34

5.9 Current Measurement [mA] ................................................. 35

5.10 , Current Drain, Simulation of a Transmitter

with two Leads ................................................................... 36

6 Technical Data ................................................................. 38

7 Maintenance .................................................................... 41

7.1 Batteries ............................................................................ 41

7.2 Housing ............................................................................. 42

8 Appendix .......................................................................... 43

8.1 Errors in [°C] in Thermocouple Simulation ............................ 43

9 Repair and replacement parts service ............................. 44

10 Product Support .................................................................44

4 GOSSEN-METRAWATT

Page 5

1 Safety Features and Precautions

This chosen instrument will provide a high degree of safety.

The calibrator is designed and tested in accordance with the safety regulations

IEC 61010-1 / DIN VDE 0411.

When used in accordance with the regulations, it will ensure the safety of the

operating personnel and protection of the instrument. However, safety is not

ensured when the instrument is operated improperly or treated carelessly.

To maintain a proper state of safety, and to ensure a hazard-free

use, the operating instructions must be read carefully and completely prior to the use of the instrument, and all points in the operating instructions must be complied with.

For the purpose of personal safety, and for the protection of the instrument, the

calibrator is provided with automatic jack interlocking.

This is coupled with the functions selector, and makes only those jacks accessible

that are required for the selected function. Furthermore, it inhibits switching into

wrong basic functions when the measurement leads are plugged in. Hence, only

the correct polarity of the connection as marked at the jacks need be verified.

Please observe the following safety precautions:

Attention!

The meter has been designed for safe use when not connected to

circuits which conduct hazardous contact voltages of greater than

42 V to earth.

• Never mistake the calibrator for the similarly housed multimeters.

The calibrator is distinguished from the multimeter by its YELLOW jack

sleeves and leads; the multimeter has red jack sleeves and red and black

leads.

• When intending to connect the instrument with a circuit, the absence of haz-

ardous touch voltages must be verified first, if necessary with a multi-meter.

• Please observe the maximum permissible voltages for the protection of the

instrument stated at the jacks.

Except during operation for resistance simulation and mA-SINK, the connected

signal circuits should not feed currents or voltages back into the calibrator.

In order to prevent major damages to the instrument when extraneous voltages

(within the permissible limits) are applied, the measuring circuit for mA-SINK

and mA-SOURCE is provided with a PTC resistor overload protection that turns

these measuring circuits into high resistance ones during the overload period

when higher currents occur during a fault.

Warning!

The instrument shall not be used in explosion endangered zones or

inserted in self-protected circuits.

GOSSEN-METRAWATT 5

Page 6

Repairs, Exchange of Parts, and Calibration

Voltage-carrying parts can be found exposed when the instrument is opened. The

instrument must be disconnected from measuring circuits before any repair,

exchange of parts or calibration. When repair or calibration work under voltage

and with an opened instrument is unavoidable, then this shall only be carried out

by a skilled person aware of the dangers that may arise.

Faults and Extraordinary Loading

When a continued hazard-free use of the instrument is doubtful, it must be made

inoperable and protected against inadvertent use.

A hazard-free use is no longer ensured when

• the instrument shows visible damage,

• the instrument no longer operates,

• the instrument has been kept in storage under adverse conditions,

• the instrument has been subjected to severe transport conditions,

• measurement leads or probe tips ar e damaged.

6 GOSSEN-METRAWATT

Page 7

2 Putting into Operation

Inserting Batteries

3 alkaline cells size IEC LR6, 1.5 V / 2.2 Ah are supplied inserted in the instrument. It is ready for operation.

Please note Section 7.1 Maintenance – Battery" prior to operating

the instrument.

In there, the additional statement is made that externally rechargeable batteries

may be used.

One of the accessories is a plug type mains power supply that permits driving the

instrument with power from the mains.

The internal batteries will be disconnected from the circuit when the plug is

inserted into the instrument. Thus, they cannot draw power from the mains power

supply.

Only this plug type power supply that is matched to the instrument

in respect of voltage and power, may be used.

Switching the Instrument On

➭ Press the "ON/OFF" key (2).

The switched-on state is acknowledged by a signalling tone.

Pressing the "ON/OFF" key (2) for a short period will cause the firmware ver-

sion stored in the EPROM and, subsequently, the battery or power supply voltage to be briefly displayed during switching on process, before the instrument

becomes operational in the operational mode selected with the functions

selector (6).

Pressing the "ON/OFF" key (2) for a longer period will cause all segments of

the LC display (1) shown in Section 3.3 to be displayed.

The instrument becomes operational when the key is released.

Attention!

The following can occur when the charge state of the batteries is

low: the internal battery voltage supervision causes the instrument

– not to switch on

– to switch off immediately afterwards

– to switch off when the output is loaded or

the internal change-over selects a higher auxiliary voltage

(e.g. 10/15 V range, 20 mA / 750

See also Section 5.2 and Section 7.1.

In this case, the batteries should be replaced

in accordance with Section 7.1 or

the plug type mains unit may be used, if possible.

When the instrument is operational, the last menu position will be saved in the

non-volatile memory (NVRAM) before the instrument is switched off.

Provided the position of the functions selector has not been changed during the

switched-off period, the instrument will, immediately after switching on, revert to

the menu position used prior to switching off.

Jumping to the highest menu level is achieved in the simplest way by turning the

functions selector into an adjacent position and back.

This switching process is also recommended after wrong menu operations or

uncertainties in respect of the actual menu setting.

W).

GOSSEN-METRAWATT 7

Page 8

+

Automatic Switching Off

The instrument is switched off automatically, if none of the keys or the function

selector have been activated for a period of approx. 10 min.

Inhibiting the Automatic Switching Off

The instrument can be set to "PERMANENTLY ON".

➭ When switching ON, the "ON/OFF" key (2) and the yellow "ESC" key (5) must

Note:

The function "PERMANENTLY ON" is indicated by the symbol on the LC display (1).

Automatic switching off is inhibited also when the instrument is set to REMOTE

operation via the serial interface in accordance with Section 6.

Switching the Instrument Off

Press the ON/OFF key (2) for at least 1 second.

Note!

Electrical discharge and RF interference may cause incorrect readings and disrupt the measuring sequence.

Then the instrument should be switched off and switched on in a

different position of the functions selector; this will reset the operation of the instrument.

Should this attempt fail, then the batteries should be disconnected

from the circuit for a short period. This can be done by plugging in

the power supply without opening the instrument.

Prior to opening the instrument, the latter must be disconnected

from the circuit to be measured, and Section 7 "Maintenance" must

be observed!

be pressed simultaneously.

8 GOSSEN-METRAWATT

Page 9

3 General Advice for Operation

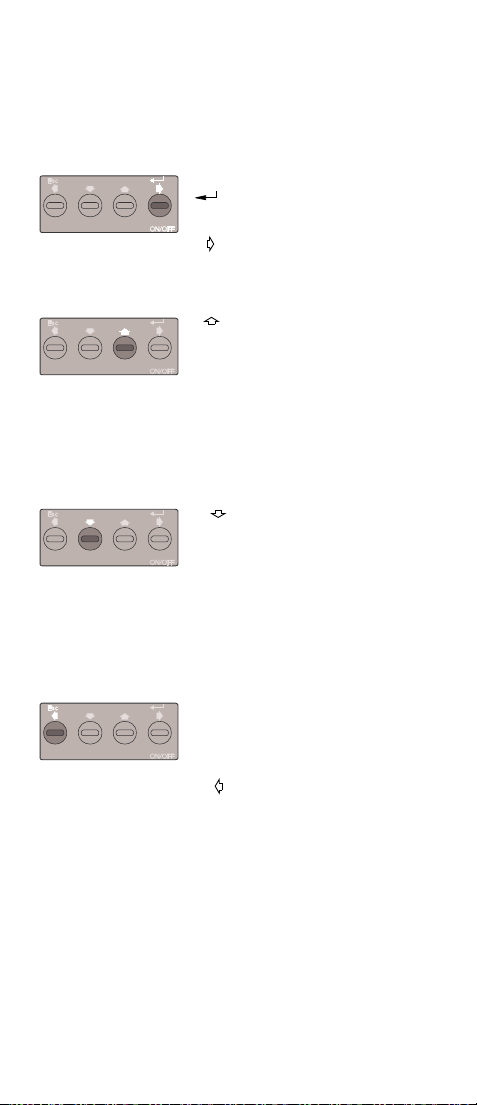

3.1 Key Panel

The control operations required for the comprehensive facilities for signal outputs

are executed by using only the four keys (2) to (5) after the basic function has

been selected by means of the functions selector. Their effect depends on the

actual setting of the menu position, but follows a general control principle

described in Section 3.2.

• Switching ON/OFF

ON/OFF

ENTER-function,e.g.

• Entering a sub-menu

(1)

• Loadng an entered number digit

• Moving the cursor to the right

when entering digits

• Incrementing a digit

• Stepping to an adjacent menu

(2)

(3)

on the same menu level

• Starting ramps and interval steps

upwards and stopping them

• Jumping back to the preceding program step (RECORD) under the basic

function PROCEDURES in accordance with Section 4.6

• Decrementing a digit

• Stepping to an adjacent menu

on the same menu level

• Starting ramps and interval steps

downwards and stopping them

• Jumping forward to the next program

step (RECORD) under the basic function PROCEDURES in accordance

with Section 4.6

Esc

EXIT-function, i.e.

• Back to the higher menu level

• Terminating ramps, automatic interval

(4)

GOSSEN-METRAWATT 9

stepping, frequency and back to the

higher menu level

• Moving the cursor left when entering

digits

Page 10

3.2 Menu Structure and Key Operations

The menu structure is designed on a uniform concept for nearly all basic functions.

The highest menu level comprises the basic functions that can be selected with

the functions selector (6). All other operations are executed by using the 4 keys in

accordance with a structure shown in Figure 1.

Menü 1

Menu 1 Menu 2 Menu A

Esc

Menu 1.1

Menü 1.1

Esc

Other sub-menus depending on the type of operation and output

Weitere Untermenüs je nach Betriebs- und Ausgabeart

1)

1. Key panel menu level of the selected type of operation (ranges or type of sensor)

1)

1. Tastatur-Menüebene der eingestellten Betriebsart (Bereiche oder Sensortypen)

2)

2. Key panel menu level, method of output for the selected range or type of sensor

2)

Figure 1 Concept of the Menu Structure

-

Menü 2

Esc Esc

Menu 1.1 Menu 1.1

Esc

Menü A

Menü 1.BMenü 1.2

Esc

1)

Menus X.Y

Menüs X.Y

X=2-A, Y=1-B

X=2-A, Y=1-B

Esc

The basic function “ “ and the “mA MEAS” function are excepted from

this menu structure.

Furthermore, the following is carried out between the 1st and 2nd menu levels in

the basic functions:

”°C “ selection of the internal and external reference temperature and

its entry, as well as

”°C “ entering the lead resistance

The following functions are associated with the various menu levels:

1st Menu Level 2nd Menu Level Other Menu Levels

Selection of the signal

ranges or of the types of

sensor depending on the

basic function selected

with the functions selector

Selection of the method

of signal output:

NUM = numerical Manual numerical input

INT- = subdivision of a

specified range into a number

of similar steps. The sequence

can be manual (MAN) or automatic (AUTO) with an adjustable

time per step

RAMP = output as an

ascending or descending ramp

with a dwell time at the upper

and lower range limits

MEM = output of 10 signal

values per range or type of

sensor that have been saved

earlier in the non-volatile

memory (NVRAM)

of the output value

Input of the lower and upper

range limits (these are already

defined for the standard r anges

0 ... 10 V, 0/4 ... 20 mA)

as well as entering the number

of steps. Under AUTO:

entering the time per step,

starting and stopping steps

Entering the lower and upper

range limits as well as ramp

duration ( ) and dwell

time ( ) Starting and

stopping the ramps

Entering

signal values into the

non-volatile memory (NVRAM)

and output from the NVRAM

2)

10 GOSSEN-METRAWATT

Page 11

The menu structure with the functions on the menu levels is printed in an summarizing format (Figure 2) on the underside of the housing.

1st menu level

for the key panel

2nd menu level for the key panel

Other menu levels

Figure 2 Illustration of the Menu Structure Printed on the

Underside of the Housing

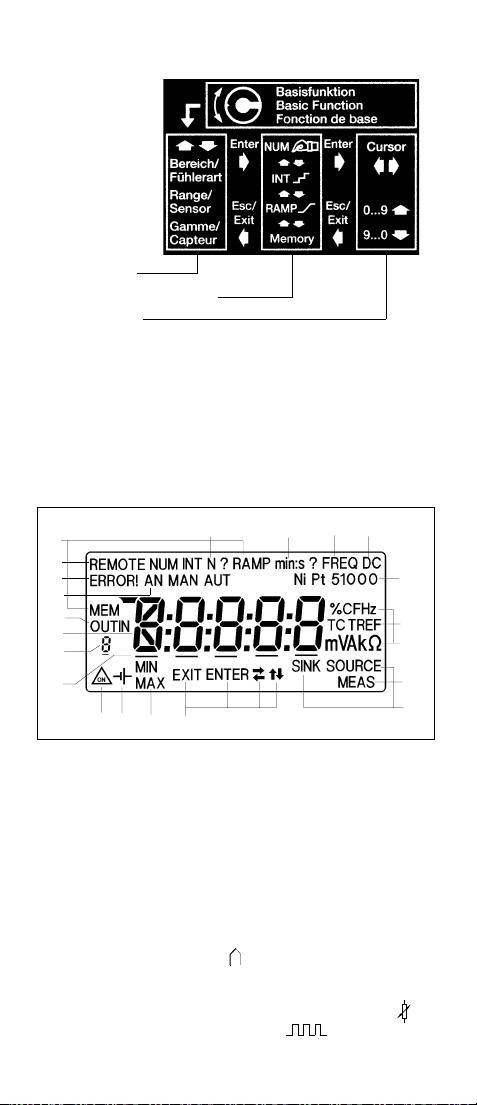

3.3 LC display

The LC display is an important element in the user guidance in which, in addition

to numerical displays, various symbols show the actual menu position and give

advice on actions to be taken.

Figure 3 shows the LC display with all its symbols that are displayed during a segment test mentioned in Section 2.

9

8

16

17

kF

12

1

13

2

18 19

Figure 3 LC Display

The symbols have the following significance:

1) 5-digit number display,

1st digit for an additional indication of the type of thermocouple

2) Cursor field

3) Menu guidance symbols for basic functions

SOURCE = source, i.e. simulation of signals

SINK = sink, i.e. for simulating a 4-terminal transmitter

MEAS = measuring the current signal 0 ... 24 mA DC

4) Measurement units for measured values

5) Menu guidance symbols

TC = basic function “°C “, for thermocouple simulation

TREF = setting the reference temperature, (internal or external

6) Type of simulated RTD sensor, e.g. Pt100 in the basic function “°C “

7) FREQ = pointing to the basic function ” “ = frequency

GOSSEN-METRAWATT 11

1415

cold junction)

or pulse output

10

7

11

kF

6

5

4

kF

3

Page 12

8) Menu guidance symbols for methods of signal output

NUM = numerical entry for the output signal

INT = intervals, output in N steps

RAMP = ramp output

MEM = memory, output from the non-volatile memory

9) N? = flashing menu guidance symbol when entering

10) Menu guidance symbols for output method MEM

MAN = number of steps using manual key operation

AUT = number of automatic steps with selectable time per step

11) min:s = flashing menu guidance symbol for time entries

12) Menu guidance symbols for method output MEM

OUT = output from memory

IN = entry for memory

13) 7-segment digit indicating the number of the memory value output method

MEM or the procedure No. under the basic function PROCEDURE

14) Menu guidance symbols for permissible key operations

EXIT = key (5) for EXIT function (Esc)

ENTER = key (2) for ENTER function

15) Menu guidance symbols

MIN and MAX simultaneously

MIN or MAX flashing

MAX flashing

16) Menu guidance symbol for REMOTE operation via the serial interface

17) ERROR ! = warning symbol for error states

18) = symbol for "PERMANENTLY ON“.

the number of steps in output method INT

for method output INT, AUT and RAMP

= keys (2) and (5) moving the cursor to the right (2)

or to the left (5)

= keys (3) and (4) for menu selection on the same level,

changing digits or step function

pointing out the ranges with selectable lower and upper range

limits on the 1st menu level of the basic functions ”V, mV, mA“

menu guidance symbol when entering the lower range limit (MIN)

or the upper range limit (MAX) for output method INT and RAMP

upon entering the upper range limit during current measurement

19) = indication of "battery low" or for battery voltage indication

kF) = no function, symbols are not used.

12 GOSSEN-METRAWATT

after switching on

Page 13

3.4 Operating Assistance by the LC Display

Symbols are displayed on the LC display as a function of the selected menu to

support the user of the instrument during the control operation as follows:

• Where am I ?

i.e. confirmation of the basic function and the data functions selected with

keys, e.g. output method and type of quantities to be entered

• Keys for further processing ?

Key operations required for continuing a process are indicated by the menu

guidance symbols (14) in accordance with Section 3.1 Inadmissible key operations are pointed out by a single tone pulse.

• Special events, e.g.

= low battery voltage,

ERROR ! = wrong operational states, pointed out in more detail by

assisting text.

3.5 Entering Digits

Manual entering of numerical values is carried out in the following manner

= moving the cursor to the right (2).

When the cursor is already positioned beneath the last digit, then this

key has the function ENTER for saving the entered value.

= incrementing a digit (3).

Pressing this key briefly will increment the value of the digit by 1.

Keeping this key pressed will increase the indicated value by 1 every

0.4 sec. from the cursor position to the left after a short tone pulse.

= Decrementing a digit (4).

Pressing this key briefly will decrement the value of the digit by –1.

Keeping this key pressed will decrease the indicated value by 1 every

0.4 sec. from the cursor position to the left after a short tone pulse.

= moving the cursor to the left (5).

When the cursor is already positioned beneath the first digit, then this

key has the function EXIT, i.e. the next pressing causes a jump to the

next higher menu level.

• When a digit is incremented from 9 to 0, the next digit to the left is increased

by +1. When decrementing a digit from 0 to 9, the next digit to the left is

decreased by –1 (counting function).

• Each digit entry is limited within a maximum and a minimum in accordance

with the technical data. A change of a digit that would lead to a violation of

these limits, is signalled by a short tone. In this case, the numerical value will

be set to the range limit.

GOSSEN-METRAWATT 13

Page 14

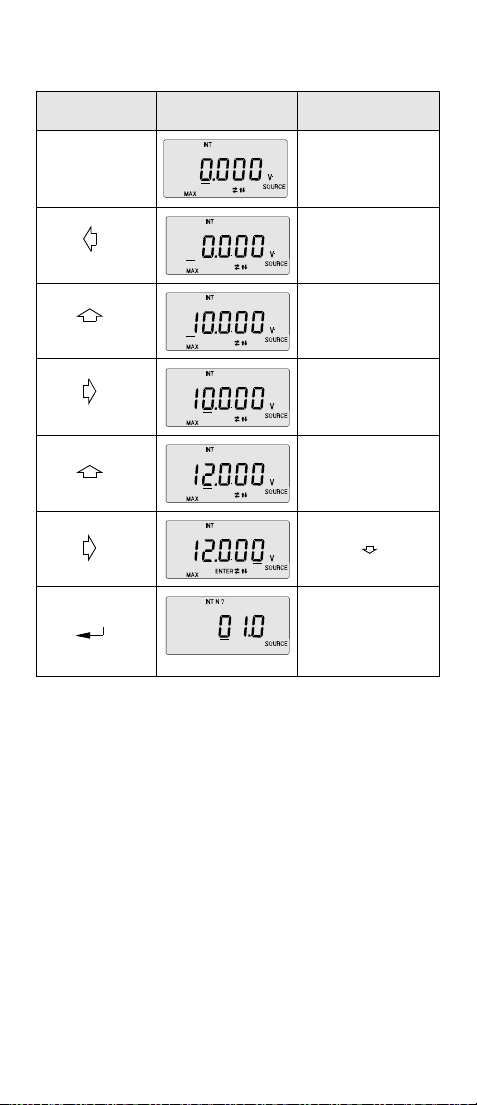

Example of Entries

Entering the upper interval limit (MAX) = 12 V in the basic function, "V, mV

SOURCE" in the range 0...15 V under the output method "Intervals" (INT).

See also Section 4.2.

Key Operation Display Notes

Various key operations

see Section 4.2

Ready for entering

the MAX value;

Cursor and MAX are

flashing

Cursor to the left;

Further movement to the left

causes a jump back to entering

the MIN value

Further incrementing would set

the value to the upper range

limit of 15 V after a short tone

Moving the cursor to the right

MAX set to 12 V

2x

Key (2) now has the function

3x

of ENTER.

Pressing key would set

the value to 11.999 V

Ready for entering the number

N of intervals

"N?" flashe s

3.6 Non-Volatile Saving of Menu Positions and Configurations

The METRAHit 18Cis fitted with a non-volatile memory (NVRAM) in which current

menu positions (LAST MENU) and configurations remain saved after switching off.

When switched off, the NVRAM is supplied with power from 3 small batteries.

During a battery replacement in accordance with Section 7.1, a special supporting capacitor acts in a bridging function for 3 minutes.

As mentioned in Section 2, the instrument will, when switched on again, resume

exactly the last menu position prior to switching off, provided the functions selector position has remained unchanged. This saves time-consuming key operations

for entering complex menus. Furthermore when used on site, this will

reduce the load on the batteries, when the instrument is switched

off whenever it is not in active use.

In all basic functions, the configurations once set for a range or type of sensor, will

be saved in the non-volatile memory when the instrument is switched off, e.g.

MIN/MAX values in INT, RAMP, RAMP timing.

14 GOSSEN-METRAWATT

Page 15

4 Types of Output Signals

4.1 Menu Structure

The methods of outputting signals described in Section 4.2 to Section 4.5 apply to

all basic functions that can be selected with the functions selector (6), except the

basic function ” “. Figure 4 shows their menu structure.

Range or

Bereich oder

Sensortyp 1

Sensor 1

Esc

NUM

2.000 V

Esc

weiter nach

Continue as

in Sect. 4.2

Kap. 4.2

1)

1)

Bei Betriebsart "˚C " und " ˚C "erfolgen zwischen den beiden Menüebenen zusätzliche

Additional entries in accordance with Sect. 5.3 and 5.4 are made

Eingaben gemäß Kap. 5.3 und 5.4

between the two menu levels in the operational modes „°C “ and „°C “

Range or

Bereich oder

Sensortyp 2

Sensor 2

INT

weiter nach

Continue as

in Sect. 4.3

Kap. 4.3

Range or

Bereich oder

Sensortyp A

Sensor A

Esc

Esc

RAMP

weiter nach

Continue as

in Sect. 4.4

Kap. 4.4

Esc

MEM

wie ab Bereich

As from range

ab NVRAM

weiter nach

Kap. 4.5

Esc

oder Sensortyp 1)

or Sensor Type

from NVRAM

Esc

Continue as

in Sect. 4.5

Figure 4 Menu Structure

4.2 Numerical or Manual Entries for the Output Signal (NUM)

The most simple method for outputting signals is by a numerical or manual entry

of the output signal value.

After the range or type of sensor and possible additional entries for ”°C“ have

been selected, the key ” “ (2) must be pressed again when the symbol NUM

appears.

The value 0 or the lowest possible signal value will appear on the number field (1),

and the cursor flashes for further digit settings.

The signal value can be modified within limits in accordance with Section 3.5, and

the displayed value will immediately be present at the jacks (8).

Holding the key (3) or (4) pressed will cause a change of the signal

value regularly by 1 every 0.4 seconds left of the cursor position in small to large

steps up or down depending on the cursor position.

1)

4.3 Intervals, Output in N Steps (INT)

This output method permits subdividing a range into N intervals. This is particularly useful for controlling items under test with digitally or linearly divided analog

displays.

The range limits of standard signals 0 ... 10 V and 0/4 ... 20 mA are fixed. In

other ranges, they can be entered within the whole range.

The number of steps can be set from 1 ... 99.9 (steps), i.e. non-integer steps can

be set. This useful in the particular case when analog displays or recorders with

non-standard full-scale values are connected.

The steps can be triggered manually (MAN) using the keys (3) and (4),

or automatically (AUT) with a dwell time per step that can be selected.

Figs. 5 and 6 show 2 examples of such range divisions.

GOSSEN-METRAWATT 15

Page 16

Betriebsart "˚C, " TC J

Operational mode “°C, ,” TC J

˚C

MAX =

450

350

250

150

MIN =

50

N = 4

Betriebsart "mA ", 4 ... 20 mA

Operational mode “mA “, 4 ... 20m A

mA

20

MAX =

19

14

9

4

MIN =

Scale [bar]

Skala [bar]

N = 3.2

6.4

6

4

2

0

Figure 5 Range Divisions N = 4 Figure 6 Range Divisions

N= 3.2

The MIN/MAX limits in Figure 5 have been entered to cover the whole range

from –200 to + 1200 °C. The range divisions into 3.2 intervals for connection of

an item under test with a scale of 0 ... 6.4 bar, corresponding to a range of

4 ... 20 mA with fixed range limits, is shown in Figure 6. Figure 7 shows the general menu struct. starting with the menu pos. in accordance with Figure 4 in

which the output method 'Intervals' (INT) is ready for a selection.

INT

Esc

Eingabe von Bereichs-

Entering the lower

untergrenze MIN mit

range limit MIN with

und

+

(MIN blinkend)

(MIN flashes)

*

Entering the up per

range limit MAX with

Entering a number of

Eingabe von Anzahl Inter-

intervals N (0–99.9) with

vallen N (0 - 99.9) mit

manuell (INT MAN)

Eingabe von Bereichs-

obergrenze MAX mit

+

und

(MAX flashes)

(MAX blinkend)

+

und

(N? flashes)

(N? blinkend)

Interval step

Intervallschritt

manual (INT MAN)

Esc

Esc

Esc

Entering MIN/MAX is omitted

*

Bei Normbereichen 0...10 V, 0/4..20 mA

in the stan dard ranges

entfällt MIN-/MAX-Eingabe

0 ...10 V, 0/4 ... 20 mA

Interval step

Intervallschritt

automatic (INT AUT)

automatisch (INT AUT)

Esc

Running through MIN-

Durchlaufen des

MIN-/MAX-Bereichs in

MAX range in

N Stufen mit

N steps with

according to Fig. 8

nach Fig. 8

Figure 7 General Operator Control Structure in the Output

Method 'Intervals' (INT)

Enter the dwell time per

Eingabe der Zeit pro Stufe

step fr. 1 s to 60 min with

von 1 s bis 60 min mit

Periodic run through

Periodisches Durchlaufen

the MIN/MAX range in

des MIN-/MAX-Bereichs in

N steps, start/stop with

N-Stufen, Start/Stop mit

und

+

(< flashes)

( blinkend)

acc. to Fig 9

nach Fig. 9

Esc

Esc

16 GOSSEN-METRAWATT

Page 17

Manual Run through the MIN/MAX Range in N Steps (INT, MAN)

The steps can be triggered with the keys (3) and (4) after all parameters in accordance with the menu structure in Figure 7 for the output method

INT, MAN have been entered.

The relationship between the output signal and the key operations can be derived

from the two examples shown in Figure 8 and Figure 9.

Example: Basic function „V, mV“ range 0-15 V, MIN = 2 V, MAX = 10 V, N = 3

Ausgabe (V)

Output (V) Output (V)

MAX = 10

7.33

4.67

MIN = 2

Taste

Key

Ausgangslage

Start position

MAX = 10

MIN = 2

Ausgabe (V)

7.33

4.67

Figure 8 Figure 9

Automatic Run through the MIN/MAX Range in N Steps (INT, AUT)

The automatic run through a programmed range is particularly useful in all cases

in which the feed for a signal circuit and reading on the periphery equipment to be

tested are spatially separated.

The interval time per step over the range from 1 second to 60 minutes can be

entered after the menu "INT AUT" has been selected, and the step sequence can

be stopped by means of the keys (3) and (4) in accordance with

Figure 10.

Example: Basic function „V, mV“, range 0-15 V, MIN = 2 V, MAX = 10 V, N = 3

10

15

time per step = 5 s

t1+t2 = 5 s

t1

25

20

oder

or

t2

Esc

4) 5)

MAX = 10

7.33

4.67

MIN = 2

Keys

Tasten

Legend

Legende

Output (V)

Ausgabe (v)

0

5

0

2) 3)

1)

Figure 10 Example of a Step Function Sequence

Legend:

1) Starting position after the time per step = 5 s has been entered.

The output signal is 2 V.

2) Start of the steps with ” “from 2 V at the bottom upwards.

When using ” “, the starting point is 10 V at the top downwards.

3) Stop with ” “ or ” “,

The time t1 elapsed since the last step remains saved.

4) Continue upwards with ” “ after t2 = 5 s – t1

5) Abort the step function with "Esc" and jump back to the entry of a new inter-

val dwell time. The output signal is approx. 0 V.

The following information on the current status is available during the run through

the step function:

• Flashing segment or in the first digit from the left.

signifies the next step upwards,

signifies the next step downwards

This auxiliary indication is not possible when the first position is already claimed

by a figure > 0, e.g 10.000 V.

• Using the key ” “ (2) causes the residual time to the next step to appear

instead of the current numeric output value.

This residual time is switched off by pressing the key ” “ (2) again.

GOSSEN-METRAWATT 17

Page 18

4.4 Output as Periodic Ramp (RAMP)

Ramp-shaped signals permit checking the time-dynamic behavior of items under

test or of whole measured circuits. One example is the behavior of a control circuit

when the nom. value is entered via the analog nom. value input of the controller.

The instrument can, in this output method, replace expensive hardware and software solutions for long duration test assemblies with cyclic sequences.

The input parameters for the periodic ramp shown in Figure 11 are:

• Lower (MIN) and upper (MAX) range limits that are fixed for the standard range.

0 ... 10 V and 0/4 ... 20 mA, but are otherwise selectable within the whole

range

• Rise and decay time t1 that can be selected between 1 second and 60 minutes

• Dwell time t2 at the upper and lower range limit, and selectable between 0 and

60 minutes

Output

Ausgabe

MAX

MIN

t1

t2 t2t1

Figure 11 Example of a Periodic Ramp

Figure 12 shows the menu structure for entering ramp parameters after the

method of output RAMP (see Figure 4) has been selected.

RAMP

Esc

Eingabe von Bereichs-

Entering the lower range

untergrenze MIN mit

limit MIN with

und

+

(MIN blinkend)

(MIN flashes)

*

Entering the upper range

limit MAX with

Eingabe von Bereichsobergrenze MAX mit

und

+

(MAX blinkend)

(MAX flashes)

Esc

Entering MIN/MA X is omitted

*

Bei Normbereichen 0...10 V, 0/4..20 mA

in the stan dard ranges

entfällt MIN-/MAX-Eingabe

0 ... 10 V, 0/4 ... 20m A

t

Esc

Eingabe der

Entering the

Anstiegs-/Abfallzeit t1 mit

rise/decay time t1 with

und

+

( blinkend)

(< flashes)

Esc

Eingabe der Verweilzeit t2 mit

Enter dwell time t2 with

+

und

( blinkend)

flashes)

Esc

Starting and stopping

Start und Stop der Rampen mit

the ramps with

Figure 12 Menu Structure for Entering Ramp Parameters

18 GOSSEN-METRAWATT

Page 19

When all ramp parameters have been entered in accordance with the menu structure in Figure 12, the ramp is started and stopped with the keys (3) and

(4).

+

Press "Esc" to jump back to entering a dwell time t2.

The output signal is approx. 0 V.

The following information relating to the current status will be available during the

run along the ramp:

• Flashing segments , , or signify:

• Key ” “ (2) causes the residual time to the end of the ramp or the residual

Note!

Interruptions of periodic ramp cycles caused by pressing the

or the key should be avoided.

Uncontrolled sudden changes may otherwise result.

or , ramp running up or down

or , dwelling at the upper (MAX) or lower (MIN) limit.

This auxiliary indication is not possible when the first position is already

claimed by a digit > 0, e.g. 20.000 mA.

dwell time to the start of the next ramp to be displayed instead of the current

numerical output value. This display of the residual time can be switched off

with the key ” “.

Attention!

For reasons of a critical timing, the internal supervisory facilities

described in Section 5.1 (e.g. output load too high) are inactive during the ramp sequence with t1 = 10 s. Hence, error conditions will

in such cases be displayed with a delay until after the end of the

ramp has been reached.

GOSSEN-METRAWATT 19

Page 20

4.5 Output from the Non-Volatile Memory (MEM)

This output method permits entering manually up to 10 signal values or sensor

types, and calling up the values stored in the non-volatile memory. This provides

the possibility of storing measurement series having non-linear intervals. This can

be very helpful when simulating sensors or transducers for various physical and

chemical quantities.

The menu structure shown in Figure 13 from the selection of the type of output

MEM onwards is split into one type of output in which the value is only called up,

and a second type of output in which the value is called up and can be modified.

MEM

MEM

from NVRAM

ab NVRAM

Esc

Output only

Nur Ausgabe

(MEM OUT)

(MEM OUT)

Output of stored values

Ausgabe Speicherwerte

0....9 mit

0 ... 9 with

Esc

Output and input

Aus- und Eingabe

(MEM OUT IN)

(MEM OUT IN)

Selectin g memory No. wi th

Wahl der Speicher-Nr. mit

Output and modification

Ausgabe und Veränderung

der Speicherwerte mit

of memory v alues with

und

+

Esc

Figure 13 Menu Structure from the Method of Output (MEM)

Onwards

The detailed key operations can be copied from the following examples of entering operations.

20 GOSSEN-METRAWATT

Page 21

Example: Basic Function „V, mV“, Range 0...10 V.

Key Operation Display Notes

Ready for output method MEM

1x , 3x

Esc

MEM, OUT, only outputting

possible

Memory No. 0 (small segment

digit left) comprises the value

5 V, available immediately at

the jacks. Memory No. a nd

Keys and can be used

3x

Esc

Esc

to call up other mem. numbers

in steps, and their values are

immediately available at the

jacks

Back to menu selection

MEM OUT for the purpose

of changing to MEM OUT IN,

outputting and entering

(values can be modified)

Ready for output

MEM OUT IN

memory No. that is to be output

or modified.

are flashing.

can be used to select the

The value 2.5 V in memory

No. 3 is available at the jacks

and can be modified.

The value in memory No. 3 has

,3x

been modified to 3.5 V and is

saved with ( )

can be used to select a

new memory No. for outputting

and modification.

GOSSEN-METRAWATT 21

Page 22

4.6 Output by Procedures Saved in the Non-Volatile Memory

This output method permits saving in the non-volatile memory repetitive

sequences during a simulation of process signals such as those occurring e.g.

during periodic checking or during the validation of systems. 10 procedures with

up to 99 program steps each (records) are available for saving such sequences.

The program steps within a procedure can be selected freely via basic functions,

ranges and output methods.

The PC software „METRAwin 90“ is offered as an ancillary program with an interface adapter for transferring a procedure from the PC to the instrument, so that

procedures can be created.

Working with procedures is explained by way of examples in the following

sequences.

Keys,

Functions selector (6)

and

simultaneously for at

least 1 second

3x

2x

Functions selector (6) is

already in position ”V, mV“

Display Notes

Change to "Procedures"

from any menu position.

Ready for selecting

procedure No. 1.

No procedure stored

under No. 4.

Selecting procedure No. 2

with 10 records.

1 record in procedure No. 2 =

output of 2.5 V DC.

Small digit on the left (13) =

procedure No.

Briefly displaying the next

record No.

Subsequently

New basic function „°C „ is

displayed flashing when t his

does not comply with the position of the functions selector

Function selector (6)

in basic function

„°C „

9x

and

simultaneously

Record No. 2 = output thermocouple type K, 1200 C with the

internal reference temperature

("0" top right). Key leads

back to record No. 1

End" is signalled shortly after

the last record No. 10.

Subsequently

Ready for entering procedure

No. 3 or selection of a different

procedure No.

Switching the output off via procedures, and jump to the highest menu level of the set basic

function.

22 GOSSEN-METRAWATT

Page 23

+

Note!

When switching off, output method "Procedures" remains saved in

the non-volatile memory , i.e. the last menu position is set when the

instrument is again switched on. This results in a battery-saving

operation during location changes on sites.

Consequently, switching this basic function off is possible only like

switching on via the keys “ “ (3) and “ “ (4) pressed

simultaneously for at least 1 second.

The display of "REMOTE MAN" is an acknowledgement that the output method "Procedures" is set.

4.7 Output via the Serial Interface (REMOTE)

The calibrator in its standard version is fitted with infrared diodes permitting communicating with a PC via a DC-decoupled connection with an interface adapter.

This adapter in conjunction with an efficient "Windows" communication software

„METRAwin 90“, covering many valuable applications, is offered as a cost efficient ancillary item.

Switching the Interface On

➭ When pressing the keys "ON/OFF" (2) and ” “ (3) simultaneously, oper-

ation via the interface will be acknowledged with the symbol "REMOTE" (16).

At the same time, an automatic switching off of the equipment will be inhibited,

and this is indicated by the symbol ” “ (18).

For this reason, the plug type mains supply should be used for long operational

periods. This avoids an automatic switching off by the battery supervisory circuit.

Operating Controls in REMOTE Operation

The instrument will not respond to any key operation when set to REMOTE operation. One exception is given by switching off the equipment with the ”ON/OFF“ key

(2). Only by switching the instrument on with this key will cause it to resume local

control operation.

LC Display in REMOTE Operation

The instructions sent by the PC during direct operation will be executed by the

instrument directly, provided the basic function set by the message complies with

that set on the functions selector (6). The LC display will acknowledge the programmed signal value and the output method after each message.

Wrong settings of the functions selector

are signalled by a flashing display of the

scheduled basic function. The new

instruction will be executed immediately

when the functions selector (6) has been

set to the scheduled basic function.

Scheduled basic function

Message Read-Out during

Current Measurements in the LOCAL Operating Mode

In this operating mode a message with the measurement value in ASCII format is

transmitted via the serial interface with a frequency of approximately 6 measurements per second. The format corresponds to the LCD, e.g. „17.35 mA“.

If overload occurs, the message is expanded via “overrange” to include the content: “24.00mA”.

Interface parameters are as follows:

Format: 8 data bits, no parity, 1 stop bit

Baud rate: 9600 baud

GOSSEN-METRAWATT 23

Page 24

Signal LED on the Interface Adapter

One green and one red signal diode on the interface adapter indicate the following

information and warning:

• Green LED:

This will be lit briefly when instructions are transferred from the PC to the

instrument.

• Red LED:

This will be lit during the transfer of messages from the instrument to the PC.

This occurs after each switching on and when a message received from the PC

is acknowledged. This response, as well as a signalling tone, give a confirmation indicating a correct physical communication between PC and instrument.

24 GOSSEN-METRAWATT

Page 25

5 Basic Functions

5.1 General Notes

The 7 basic functions that can be set manually with the functions selector (6),

form the highest menu level in the instrument. However, a signal output within the

set basic function occurs only after the signal range or the sensor type, and the

output method have been selected, and further key operat. have been executed.

In all menu positions in which the output signal is not defined, e.g. parameter

entries, the output signal will be set to the following symbols:

• approx. 0 V in”V, mV“, ” “, ”°C “, ”mA “ and ”mA “,

as well as

• approx. 100

Similar values will also be present at the jacks when a jump back into a higher

menu position is executed by using the "Esc" key (5). The jacks are open-circuited

in all intermediate positions of the functions selector, i.e. they are not connected

internally with the circuit.

➭ The lowest possible range for the output signals to be simulated on the

uppermost menu level should always be selected in the basic functions ”V,

mV“, ”mA “ and ”mA “. This produces the best possible accuracy,

and the

battery drain will be lower.

W in ”°C “ and ”W“.

5.2 Supervisory Circuits

Various internal measurement and supervisory circuits are continuously testing

the external and internal conditions of the instrument under which the selected

output signal available at the jacks is within the technical specifications.

These are:

• Measurement of the Battery Voltage

This leads to an LC display with the symbol ” “ (19) when the voltage has

dropped below approx. 3.4 V, and switches the instrument off when the voltage

drops further below approx. 3.2 V.

The battery voltage measurement has the additional purpose of compensating

the effect from the battery voltage on the accuracy of the instrument.

+

Note!

The load is heavier when the load current and voltage is high as well

as in the voltage range 0 ... 10 V or 0 ... 15 V respectively. This can

lead to an immediate internal cut-out when the batteries are weak

or used at the end of their useful life.

• Measurement of the Output Load in the Basic Functions „V, mV“ and „TC, “

The illustrated flashing warning

display ”ERROR MAX LOAD“ will

appear above a current drain of

approx. 15 mA

Above approx. 18 mA, the flashing

display of ”ERROR OUT MAX LOAD“

indicates that the stabilization in the

instrument is no longer ensured.

This error message will also appear during a short-circuit on the jacks with the

following exception:

The current state makes a detection of a short-circuit impossible

with a nominal output voltage of approx. 4 mV and within approx.

0.7 to 2.5 V.

GOSSEN-METRAWATT 25

Page 26

• Measurement of the Sensor Current in the Basic Functions „°C “ and „W“

A correct electronic resistance simulation depends on the magnitude of the

sensor current (from the item under test) and its polarity.

The operating range for current is Is = 0.05 ... 0.1 ... 1

The specified tolerance applies to Is = 0.1 ... 1 mA

Twice the tolerance applies to Is = 0.05 ... 0.1 mA and 1 ... 1.4 mA

Sensor current outside the permissible range is indicated by the following

error messages:

Is < 0.05 mA, but > 0.015 mA

„ERROR MIN“

Is < 0.015 mA,

Input open-circuit or wrong polarity.

„ERROR OUT MIN POL.“

Is > 1.4 mA

„ERROR OUT MAX“

When these described warning messages appear, the resistance simulation

will continue to function, but without reliable accuracy.

In such cases, additional means should be employed (e.g. selected precision

resistors) to ensure an operational usefulness in principle, and an accuracy

required for practical applications

• Supervision of the Current Regulation and the Actual Current in the Basic

Function “ “

The regulating circuit for the internal current source is supervised.

A deviation of nominal/actual values due to too high an output load will trigger

the display of an error. This supervision of the regulating circuit is also used for

a switching action from a low auxiliary voltage, normally used for reducing the

battery drain, to a higher voltage as a function of the external load.

The current source normally works with an internal auxiliary voltage that allows

a voltage drop of 4 V max. across the external load. Exceeding this voltage

drop will

– either cause a change to a higher auxiliary voltage for a voltage drop up to

15 V (20 mA x 750

– or trigger the display of an error message without switching the auxiliary

voltage, when the external load is above approx. 5 k

broken.

The internally switched auxiliary voltage is indicated at the top edge of the LC

display (* in the example illustrations) by a "0" for a low auxiliary voltage, or a

"1" for a high auxiliary voltage.

W) when the external load drops below approx. 5 kW .

... 1.4 mA

W or when the circuit is

The following examples of sequences show the various LC displays as a function of the external load.

26 GOSSEN-METRAWATT

Page 27

1st Example: Range 4 ... 20 mA, external ´load = 1 kW

Process Display

Nominal value 4 mA,

Ua = 4 mA x 1 k

= 0 = low auxiliary voltage

*

W = 4 V

*

Increase to 5 mA, i.e. Ua > 4 V

With a brief display of

”ERROR MAX burd“ a change to

a higher auxiliary voltage is made

= 1

*

Increase to 20 mA, i.e. Ua > 15 V

The nominal/actual value deviation

triggers the error display

”burd“ = load too heavy

Note: When switching from a higher auxiliary voltage back to a lower one, the

signal output must be aborted to go to a higher menu level using "Esc" (5) or a

change at the functions selector is necessary, even when Ua

2nd Example: Range 4 ... 20 mA, external load = 0

Process Display

Nominal value 4 mA,

Ua = 0 V

= 0 = low auxiliary voltage

*

The circuit will be broken.

The measurement of the actual value

finds Ra > approx. 5 k

Hence ”ERROR OUT MAX burd“.

The auxiliary voltage is not increased,

because a fault has been detected in

the output circuit.

The error message disappears when the circuit is closed.

• Supervision of the Current Regulation in the Basic Function „ “

A nominal/actual deviation in the basic function ” “ can occur when the

external signal circuit does either not exhibit the programmed nominal current

or when the voltage on the jacks is too low.

These fault conditions are pointed out by the following displays:

The actual current is less than the

value set on the instrument, but higher

than approx 1 mA.

Reason: Current limiting in the ext.

circuit or the voltage is too low.

The actual current is less than the

value set on the instrument, but lower

than approx 1 mA.

Reason: Current limiting in the ext.

circuit or the voltage is too low.

W .

£ 4 V.

W

*

*

GOSSEN-METRAWATT 27

Page 28

5.3 [V, mV], Voltage Source

➭ Set the functions selector (6) to "V, mV"

➭ Connect the item under test in accordance with Figure 14 using test leads.

Once the instrument is switched on, the

4 signal ranges 0-10 / 15 / 1.5 V /

150 mV on the uppermost menu leve

will be available for selection, and the

wanted signals can be simulated in the 4

output methods NUM, INT, RAMP, and

MEM.

The first range 0-10 V applies as a standard signal in process techniques.

In this range, MIN/MAX entries are not

required under output methods INT and

RAMP. These are fixed at MIN = 0 V and

MAX = 10 V. The output of the instrument is protected against short-circuits,

and loads with more than approx. 15 mA

or approx. 18mA respectively are

detected and displayed by the internal

supervision in accordance with Section

V, mV

+

–

V

5.2. The short-circuit current is

approx. 23 mA.

Figure 14 Connections for Use

as a Voltage Source

5.4 , Pulse Generator

Description of the Function, Applications

This basic function is designed for typical requirements in processing techniques,

such as e.g. simulation of initiators, pulses from flow counters, rev-counters,

energy or frequency control and event counters in the low frequency region. The

maximum pulse amplitude of 15 V is usually adequate, even for inputting pulses

into control circuits (SPS) using 24 V logic inputs.

The instrument produces positive square waves with a pulse duty factor of 1:1

(duty cycle 50 %). The output can be selected as continuous or as a time-limited

number of pulses.

°C

Menu Structure

Figure 15 on the following page shows the menu structure which deviates from

the basic scheme of the other basic functions.

The input parameters are: amplitude, frequency, and a selected number of positive (LO-HI) or negative (HI-LO) pulses.

28 GOSSEN-METRAWATT

Page 29

1)

Esc

2)

Esc

3)

Esc

4) 5)

Esc Esc

6) 7)

Figure 15 Menu Structure for the Pulse Generator

Legend for the individual menu positions in Figure 15

1) Selection of the basic function ” ” makes the frequency range

of 0.01 ... 999.99 Hz available

2) Entering an amplitude of 0 ... 15 V

3) Entering a frequency of 0.01 ... 999.99 Hz

4) Selecting continuous pulse output

5) Selecting an output of N pulses at a prescribe pulse frequency

6) Continuous pulse output with 502.05 Hz

Stopping the pulse output with ” “

Note:

The nearest possible frequency for nominal value entry is calculated from

the limited timer resolution of the microprocessor.

7) Entering the number of pulses

Esc

8) 9)

Esc Esc

10)

11)

10)

11)

GOSSEN-METRAWATT 29

Page 30

8) The pulse output starts with

U

a low level in accordance with the

upper timing diagram in Figure 16.

9) The pulse output starts with a high

level in accordance with the lower

timing diagram in Figure 16.

U

N

t

" " = Start

N

t

Figure 16 Timing Diagram

10) Output of the pulse series with the selected parameters and the nearest

possible frequency in accordance with menu position 6).

After the output of the pulses, the instrument is ready for a new start from

menu positions 8) or 9).

11) Pressing the ” “ key (2) will cause the display for approx. 1 second of

the number of pulses remaining at the time of pressing that key, instead of

the frequency.

+

Note!

This change-over will lead to a short duration break in the pulse output at the jacks (only noticeable at higher frequencies).

Operator Control

➭ Set the functions selector (6) to „ “.

➭ Connect the item under test by means of test leads as shown in Figure 17.

➭ Continue with further settings in accordance with the menu structure

described above.

+

–

t/min

Rpm

Upm

Figure 17 Connection of the

Tes t Lea ds

Attention!

For reasons of a critical timing, the automatic cut-out and supervision of the battery voltage as well as of the loading are switched off

during the output of pulses. However, the output is protected

against short-circuits, and the output current is limited to

approx. 25 mA.

30 GOSSEN-METRAWATT

Page 31

5.5 “°C “, Thermocouple Simulation

Description of the Function, Applications

10 types of thermocouple are available for selection and can be simulated over

the full temperature range specified by IEC/DIN.

The internally measured reference temperature can be used or the temperature of

an external reference for –50 to +100 °C can be entered.

Important Advice relating to the Reference Temperature

The internal reference temperature is continuously measured by using a built-in

temperature sensor coupled with the jack ” “ (8).

The reference temperature for Items under test having a thermocouple measurement input terminal is usually measured at the terminals for the thermocouple.

The two measurements may differ from each other, and the difference fully enters

the simulation as an error. The following methods will help to reduce this error:

• The connections from the item under test to the jacks of the instrument

are made with a compensating lead for the thermocouple to be simulated

(Figure 18).

• The temperature is measured with a precision temperature measuring instrument at the thermocouple terminals of the item under test, and this value is

entered into the instrument as an external reference temperature (Figure 19).

The connection between the calibrator and the measuring instrument is made

by using copper leads.

Entering the external reference temperature is also used in all cases in which the

temperature measurement in the item under test is carried out via a reference

point with a stabilized temperature (end of the compensating lead for the thermocouple).

Item

under

test

Compensating lead,

e.g. NICr/NiAl for type K

Item under test

Temperature

measurement instrument

Copper lead

Terminal block

for temperature

at the terminals

Figure 18 Temp. measure-

ment via comp. lead

Figure 19 Entering the refer-

ence temperature

Operator Control

➭ Set the functions selector (6) to

°C “

„

➭ Select the wanted thermocouple type

using the keys ” “ (3) or” “

(4) . For an accurate designation and

ranges see Section 6.

°C

➭ The internal reference temperature

will be displayed after entering this

with the ” “ key (2). The choice

between internal or external reference

is explained further down by an application example.

➭ Connect the item under test to the

jacks in accordance with Figure 20,

–

Compensating

lead when using an

internal ref. temperature

+

and note the advice given above for

the reference temperature in respect

of the connecting leads.

°C

Figure 20 Connections of the

measurement Leads

GOSSEN-METRAWATT 31

Page 32

Example for Inputting a Specified Reference Temperature

Key Operation Display Notes

After switching ON or

adding the connection

using the functions

selector (6)

, 2x

, 5x

1)

1)

Ready for selecting the type of

thermocouple

Display of the internally measured reference temperature

1) I = internal ref. temperature

2) 0 = pointing out the int. ref.

temp. in other menu positions

2)

Selecting the internal reference temperature for the following simulations

2)

Numerical change of the value

= entering an external ref.

temp.

1) E = external ref. temperature

2) 1 = pointing out the ext. ref.

temp. in other menu positions

2)

Selecting the external reference temperature 20°C for the

following simulations.

2)

Notes!

• A change from °C to °F may be made by keeping the keys ” “ (4) and

” “ (2) pressed simultaneously when switching on the instrument.

• The output load is supervised, and an output current of approx. 15 mA is signalled by a flashing display of ”ERROR MAX LOAd“ or in the case of approx.

18 mA it is signalled by ”ERROR OUT MAX LOAd“.

The output is protected against short-circuits. The short-circuit current is

approx. 23 mA.

• In the case of low-impedance items under test, e.g. moving coil meters or

recorders, a signal distortion by the output resistance R

W max.) can lead to significant errors.

DU = I

(Error

x Ra, e.g. 1 mV with I

out

= 5 mA, Ra = 0.2)

out

of the equipment (0.2

a

32 GOSSEN-METRAWATT

Page 33

5.6 “[°C] “, RTD Sensor Simulation

Function and Applications

The electronic resistance simulation is, in principle, a measurement of the sensor

current Is, that is fed by the item under test into the instrument, and a voltage U

depending the programmed resistance R

applies to the voltage: U

This simulation operates within limited ranges for sensor current and resistance

that are aimed at a simulation of commonly used RTD temperature sensors. How-

= Rp x I

a

ever for this range of application, the electronic simulation realized in the instrument, offers a flexibility of the signal output that is far superior to conventional

resistance sources.

Operator Controls

➭ Set the Functions selector (6) to ”°C “

➭ Set the wanted type of RTD sensor using the keys ” “ (3) or ” “ (4).

Their temperature ranges are stated in Section 6.

➭ The lead resistance ROFFS (Roffset) is displayed after entering the above with

the ” “ key (2). Entering between –9.99 and +99.99

resistance is added to the later programmed resistance value in accordance

with the sensor characteristic. The value can be modified or a jump to the type

of output can be made by twice pressing key (2) (” “ and ” “).

➭ Connect the item under test with the

jacks in accordance with Figure 21 and

observe the following notes relating to

sensor current supervision which is additionally described in detail in Section 5.2.

1)

Sensor cables for 4-wire connection

Note Relating to Sensor Current Supervision

When items under test with unknown sensor current are connected and/or the polarity of the sensor current is not marked at t he point of connection, error messages can

be generated at the output that can be interpreted in the following manner:

„ERROR OUT MIN POL.“

The item under test does not supply a

sensor current (<10

connected with the wrong polarity. The

mA) or the sensor is

polarity must be reversed and the item

under test must be measured separately

when this is unsuccessful.

„ERROR MIN“

The sensor current is too low (<50

Resistance simulation will operate, but

compliance with the specified limit is not

ensured.

„ERROR OUT MAX“

The sensor current is too high (>1.4 mA).

Resistance simulation will operate up to

approx. 2 mA, but compliance with the

specified limit is not ensured.

Note the tolerance figures in Section 5.2 that are dependent on the

sensor current !

is applied to the jacks, the following

p

s

W is possible. This

°C

I

1)

S

+

°C

Figure 21 Connection of the

Measurement Leads

mA).

1)

–

a

GOSSEN-METRAWATT 33

Page 34

5.7 ”W“, Resistance Simulation

This basic function differs from ”°C “ only in the fact that a resistance value

within the range 30.0

Hence:

➭ Set the functions selector (6) to ”

➭ Take further information for operator control from Section 5.6 relating to the

basic function " C ", simulation of RTD sensors.

W to 2000.0 W is entered directly and can be simulated.

W“.

+

Note!

Simulation will also work below 30 W to 0 W . However,

the data in respect of inherent deviation of the instrument are not ensured.

5.8 “ “, Current Source

➭ Set the function selector to ” “

➭ Connect the item under test by

means of the measurements accordance with Figure 22.

3 signal ranges 4-20 / 0-20 / 0-24 mA

are available for selection after the

instrument has been switched on, and

signals in the 4 methods of output NUM,

INT, RAMP and MEM can be simulated in

these ranges.

Figure 22Connection of the

The first two ranges apply as standard signals to process techniques. No entries

of the MIN/MAX limits are required for the output methods INT and RAMP,

because these are fixed to MIN = 4 or 0 mA respectively and MAX = 20 mA.

A supervision of a correct current regulation and a two-stage matching of the

internal auxiliary voltage to the load by the external circuit is carried out during the

output of current.

For this reason, please read the detailed description of this supervision in

Section 5.2 , and check the external circuit when error messages described there

are displayed.

Note:

The little figure 6) at the top left on the LC display signifies:

0 Low battery drain reducing auxiliary voltage for external loads up to 200

at 20 mA

1 Higher auxiliary voltage for external loads up to 750

The switching from a low to a high auxiliary voltage is carried out

when the voltage at the jacks exceeds approx. 4 V.

+

–

%

Measurement Leads

W at 20 mA

W

34 GOSSEN-METRAWATT

Page 35

5.9 Current Measurement [mA]

Functions Description

Two basic functions are possible in the “mA “ selector switch position:

• Current measurement (basic function: MEAS)

• Active current control (basic function: SINK, see Section 5.10).

The measurement input for the MEAS function is unipolar and encompasses a

current measuring range of 0 ... 24 mA DC.

Operation

➭ Set the function selector

switch (6) to “ “.

➭ Complete the circuit with

correct polarity (+ to

““).

➭ Activate the “ “ key

(2); input current is displayed

at the instrument.

+^

Periphery

Voltage

Source

+

+

–

–

+

Figure 23 Measurement Cable

Note!

Current measurement includes unipolar display only. “0” appears at

the display if polarity is reversed, and the power circuit is disabled

by a diode.

Connection

Attention!

Input currents of greater than 24 mA are limited by the instrument

to 24.00 mA by means of a semiconductor; entry into the upper

limit range is indicated by blinking characters at the display and the

MAX menu guidance symbol.

The voltage drop from the external circuit caused at the jacks in the

event of an overload may not exceed 27 V DC.

GOSSEN-METRAWATT 35

Page 36

5.10 “ “, Current Drain, Simulation of a Transmitter

with two Leads

Description of the Function, Applications

In this basic function, the current selected between 0 and 24 mA flows into the

instrument, independent from the DC voltage (4 ... 27 V) present at the jacks. The

most important application of this function as a current drain is the simulation of

4-terminal transmitters.

4-terminal transmitters are measurement transducers for measuring quantities in

process techniques. In an operation as a drain, they accept a constant current

between 4 - 20 mA depending on the measured quantity and independent from

the applied voltage (Figure 24). The measuring circuit is fed from the signal of

4 - 20 mA. 4-terminal transmitters are particularly useful in systems with long

distances between the components, e.g. on board of ships, in chemical industry

plants or refineries, because additional lines for auxiliary voltages can be omitted

in this case.

Mains

power

supply

24 V

Peripheral equipment

+

–

4 ... 20 mA = 0 ... 100 °C

Figure 24 Example of a Meas. Circuit for 4-Terminal Transmitters

Tests on peripheral equipment by means of simulation of a 4-terminal transmitter

in a measuring circuit are described in the following paragraphs of these operating instructions.

Operator controls

➭ Switch on the instrument.

After the instrument is switched on the

basic function

„“ MEAS. is

active.

➭ Change with the key (3) to the basic

„“ SINK.

function

3 signal ranges 4 - 20 mA, 0 - 20 mA

or 0 - 24 mA are available for the

selection in the same menu level.

After selection of the range the signal can

be simulated in the following 4 output

methods:

NUM, INT, RAMP and MEM.

The first two ranges apply as standard signals to process techniques. No entries

of the MIN/MAX limits are required for the output methods INT and RAMP,

because these are fixed to MIN = 4 or 0 mA respectively and MAX = 20 mA.

Supervision of correct current regulation is carried out in the instrument. For this

reason, please read the detailed description of this supervision in Section 5.2, and

check the connected circuit for the presence and polarity of the specified voltage

when error messages described there are displayed.

4-terminal

transmitters

+

–

–

Mains power unit 27 V max.

+

°C

Sensor

e.g. Pt100

(disconnected)

+

–T

=

+

Peripheral

equipment

(item under test)

Figure 25Connections with Mea-

surement Leads

36 GOSSEN-METRAWATT

Page 37

Notes:

• Verify that the applied voltage does not exceed 27 V. Otherwise, the instrument

will be thermally overloaded.

• The instrument is protected against wrong polarity.

Wrong polarity or missing voltage is indicated by the flashing error message

"ERROR OUT MIN I:U-in".

Warning!

The instrument shall not be used in explosion endangered zones or

inserted in self-protected circuits.

GOSSEN-METRAWATT 37

Page 38

6 Technical Data

Basic Functions

I Source

Fixed Ranges

Standard signal 4 ... 20 mA, 0 ... 20 mA Resolution 1

Variable range 0 ... 24 mA Resolution 1

Ranges are entered into a non-volatile memory by

means of keys.

Maximum Load 200/750

Overload limited by an internal self recovering PTC resistor

W with automatic change-over

(heavier battery drain at 750

for protection

W)

U Source

Fixed range

(Standard signal) 0 V ...10 V Resolution 1 mV

Variable ranges 0 V ... 15 V Resolution 1 mV

0 V ... 1.5000 V Resolution 0.1 mV

0 mV ... 150.00 mV Resolution 0.01mV

Range entry by keys

Load

Output resistance 0.2

³ 1 kW (max. 15 mA at 15 V)

W

RTD source

Sensor Pt 100 Range –180 ... + 850 °C Resolut. 0.1 °C/°F

Pt 1000 Range –180 ... + 250 °C Resolut. 0.1 °C/°F

Ni 100, Ni 1000 Range –60 ... + 180 °C Resolut. 0.1 °C/°F

Operating conditions Sensor current 0.05 ... 0.1 ... 1

... 1.4 mA

Setting °C or °F

Entry of signal offset range – 9.99 ... +99.99

W

(e.g. for power cable resistance)

R Source

Range covered 30 ... 2000.0 W Resolution 0.1 W

Operating conditions Sensor current 0.05 ... 0.1 ... 1

... 1.4 mA

Thermocouples (according to DIN/IEC584)

Thermocouples Ty pe Range Resolution

Fe-CuNi Type J

Fe-CuNi Type L

Cu-CuNi Type T

Cu-CuNi Type U

NiCr-NiAl Type K

NiCr-CuNi Type E

Pt10Rh-Pt Type S

Pt13Rh-Pt Type R

Pt30Rh-Pt6Rh Type B

Nicrosil-Nisil Type N

– 200 ... + 1200°C

– 328 ... + 2192°F

– 200 ... + 900°C

– 328 ... + 1652°F

– 250 ... + 400°C

– 418 ... + 752°F

– 200 ... + 600°C

– 328 ... + 1112°F

– 250 ... + 1350°C

– 418 ... + 2462°F

– 250 ... + 1000°C

– 418 ... + 1832°F

– 50 ... + 1750°C

– 58 ... + 3182°F

– 50 ... + 1750°C

– 58 ... + 3182°F

+ 50 ... + 1800°

+ 122 ... + 3272°F

– 240 ... + 1300°C

– 400 ... + 2372°F

D/A-resolution 3 mV

Setting °C or °F

Reference- temperature internal via a temperature sensor at the terminals

external, entry – 50 ... + 100 °C

38 GOSSEN-METRAWATT

mA

mA

1 °C/°F

1 °C/°F

1 °C/°F

1 °C/°F

1 °C/°F

1 °C/°F

1 °C/°F

1 °C/°F

1 °C/°F

1 °C/°F

Page 39

I Measurement

Measuring Range 0 ... 24 mA unipolar, resolution 0.05 mA

Voltage Drop approx. 0.5 V DC + I (mA) x 125

W

Sampling Rate approx. 6 measurements/sec.

Overload Capacity Input current is limited to 24 mA. Entry into the upper

range limit is signalled.

Max. Input Voltage

±27 V DC

I-Drain (Simulation of 4-Terminal Transmitters)

Fixed ranges

Standard signal 4 ... 20 mA, 0 ... 20 mA Resolution 1

Variable range 0 ... 24 mA Resolution 1

mA

mA

Ranges are entered by means of operator keys.

Input voltage/

Input power 4 ... 27 V, max 0.6 VA

Overload internal self-recovering PTC resistor

Frequency (Squarewave Pulses)

Frequency range 0.01 ... 999.99 Hz Resolution 0.01 Hz

Pulse amplitude selectable 0 ... 15 V

Resolution 1 mV

Duty cycle 50 %

Pulse Series

(as for frequency, but the number of pulses are selected)

Number of pulses 1 ... 99999

Start selected for start from a high or a low level

Output Methods for Source and Drain Functions

Numerical by means of keys

Interval subdivision of a fixed (standard signal)

or a variable range into N intervals

Interval step switched manually or automatically

Dwell time per step programmable over 1 s ... 60 min

Ramp periodic, positive or negative going ramp time

and dwell time

each programmable over 1 s ... 60 min

Memory (10 for each individual values stored in a non-volatile

range and type of sensor) memory can be output in steps

Error limits (for Tu = 23 ± 3°C)

I Measurement 0.25% of the value

I source/drain 0.05 % of the value + 2

±0.05 mA

mA

V source (15 V) 0.05 % of the value + 2 Digit

Thermocouples

ext. ref. temp. 0.1 % of the value