Gossen Metrawatt METRAFLEX 3000, METRAFLEX 3001, METRAFLEX 3001XL, METRAFLEX 3003, METRAFLEX 3003XL User guide

Page 1

______________________________________________________________

3-349-530-37

2/1

2.09

Operating Instructions

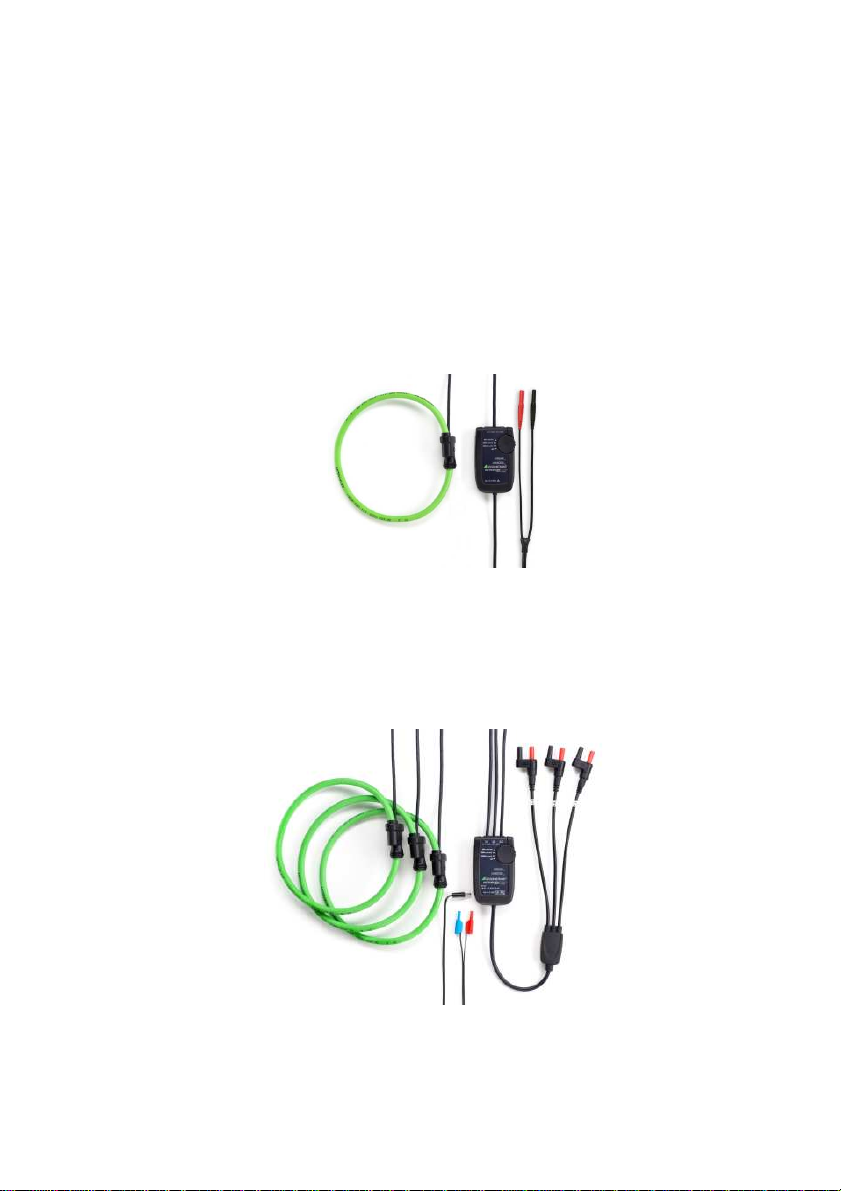

METRAFLEX 3000

METRAFLEX 3001 / 3001XL

METRAFLEX 3003 / 3003XL (3-Phase Set)

Flexible AC Current Probe

_______________________________________________________________

17

Page 2

_______________________________________________________________

Order Reference Order No.

METRAFLEX 3000 Flexible AC Current Probe 30/300/3000A ............ Z207E

61 cm (24”), battery supply,

3V output on 4mm safety plugs

METRAFLEX 3001 Flexible AC Current Probe 30/300/3000A ............ Z207F

61 cm (24”), battery/external supply,

3V output on 4mm safety plugs;

incl. supply cable for MAVOWATT|50

METRAFLEX 3001XL Flexible AC Current Probe 30/300/3000A ............Z207H

61 cm (24”), battery/external supply,

1.5V output on Hypertronics plug

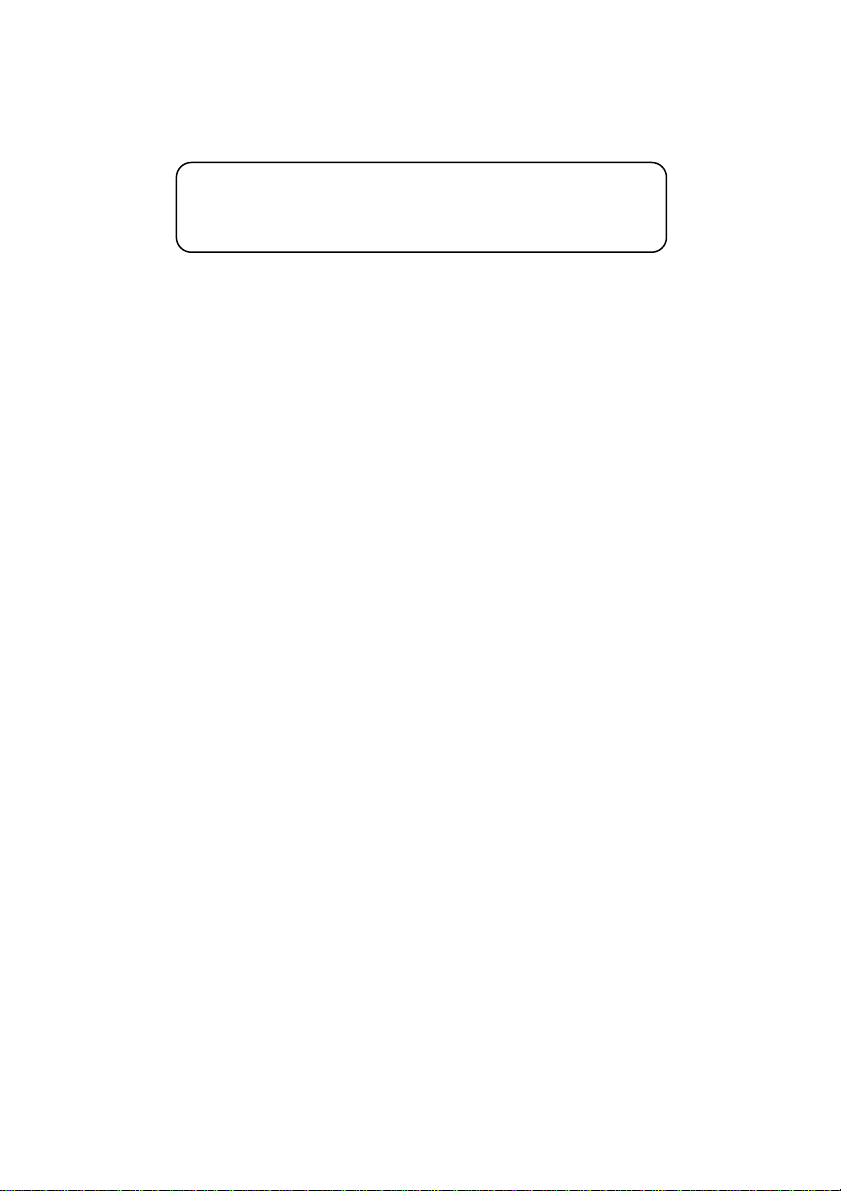

METRAFLEX 3003 Flexible AC Current Probe 30/300/3000A ............Z207G

61 cm (24”), battery/external supply,

3V output on 4mm safety plugs;

incl. supply cable for MAVOWATT|50

METRAFLEX 3003XL Flexible AC Current Probe 30/300/3000A ..............Z207I

61 cm (24”), battery/external supply,

1.5V output on Hypertronics plug

Other head lengths available on request.

_______________________________________________________________

Page 3

______________________________________________________________

For safety reasons and optimum use of this instrument

read through the operating instructions very carefully.

Thank you for buying this product.

Table of Contents

1. SAFETY ........................................................................................20

2. INTRODUCTION...........................................................................22

3. SPECIFICATIONS ........................................................................23

4. OPERATION................................................................................. 26

4.1 BATTERY INSTALLATION AND BATTERY STATUS..................26

4.2 EXTERNAL POWER SUPPLY .....................................................27

4.3 CONNECTING TO MEASURING DEVICE...................................28

4.4 CONNECTING TO THE CIRCUIT TO BE MEASURED...............29

4.5 MEASUREMENT..........................................................................30

5. MAINTENANCE............................................................................31

6. WARRANTY..................................................................................31

7. PRODUCT SUPPORT ..................................................................32

8. REPAIR AND REPLACEMENT PARTS SERVICE DKD CALIBRATION

CENTRE AND RENTAL INSTRUMENT SERVICE ...................... 32

_______________________________________________________________

19

Page 4

_______________________________________________________________

1. SAFETY

The following symbols appear on the products:

Attention! Refer to Manual

Double/Reinforced Insulation

Do not apply around or remove from HAZARDOUS LIVE

conductors without additional protective means.

“Additional protective means” can be:

- de-energizing the circuit

- wearing protective clothing suitable for high voltage work.

Do not dispose of this product as unsorted municipal

waste. Contact a qualified recycler for disposal.

Indicates EC conformity

_______________________________________________________________

Page 5

______________________________________________________________

The flexible current transformer is manufactured and tested in accordance with

safety regulations IEC/EN 61010-1 / -031 /-2-032. If used for its intended

purpose, safety is assured for the user, the device and the DUT.

Read the operating instructions carefully and thoroughly before placing

the device into operation. Observe and follow all points included therein.

Make the operating instructions accessible to all users.

In particular, observe the following safety instructions.

• Always inspect the electronics unit, connecting cable, and flexible

probe for damage before using this product. Do not use product if

damaged.

• This product must be used only by qualified personnel practising

applicable safety precautions.

• Never apply the probe around bare conductors with hazardous

voltages without having the appropriate permission to perform

such work and without wearing protective clothing and gloves as

required.

• Never apply the probe around bare conductors with voltage levels

over 1000V to ground.

• Always connect electronics unit to measuring device before

installing the flexible measuring head.

• Never change batteries while measurement head is installed on

conductor.

• Never connect or disconnect the external power supply while the

measurement head is installed on a conductor.

• Never connect the output to any equipment with a common mode

voltage to earth greater than 30 Volts.

• If the probe is used in a manner not specified by the

manufacturer the protection provided by the equipment may be

impaired.

_______________________________________________________________

21

Page 6

_______________________________________________________________

2. INTRODUCTION

The METRAFLEX are AC current probes utilising Rogowski

principle. They can be used to measure AC current up to 3000A

by being connected to an appropriate measuring device

(multimeter, data logger, power analyser etc.). The flexible probe

allows current measurements on conductors that are hard to

reach.

The probes provide an AC output voltage of 0…3V (METRAFLEX

3000/3001/3003) or 0…1.5V (METRAFLEX 3001XL/3003XL),

proportional to the current being measured with three selectable

ranges.

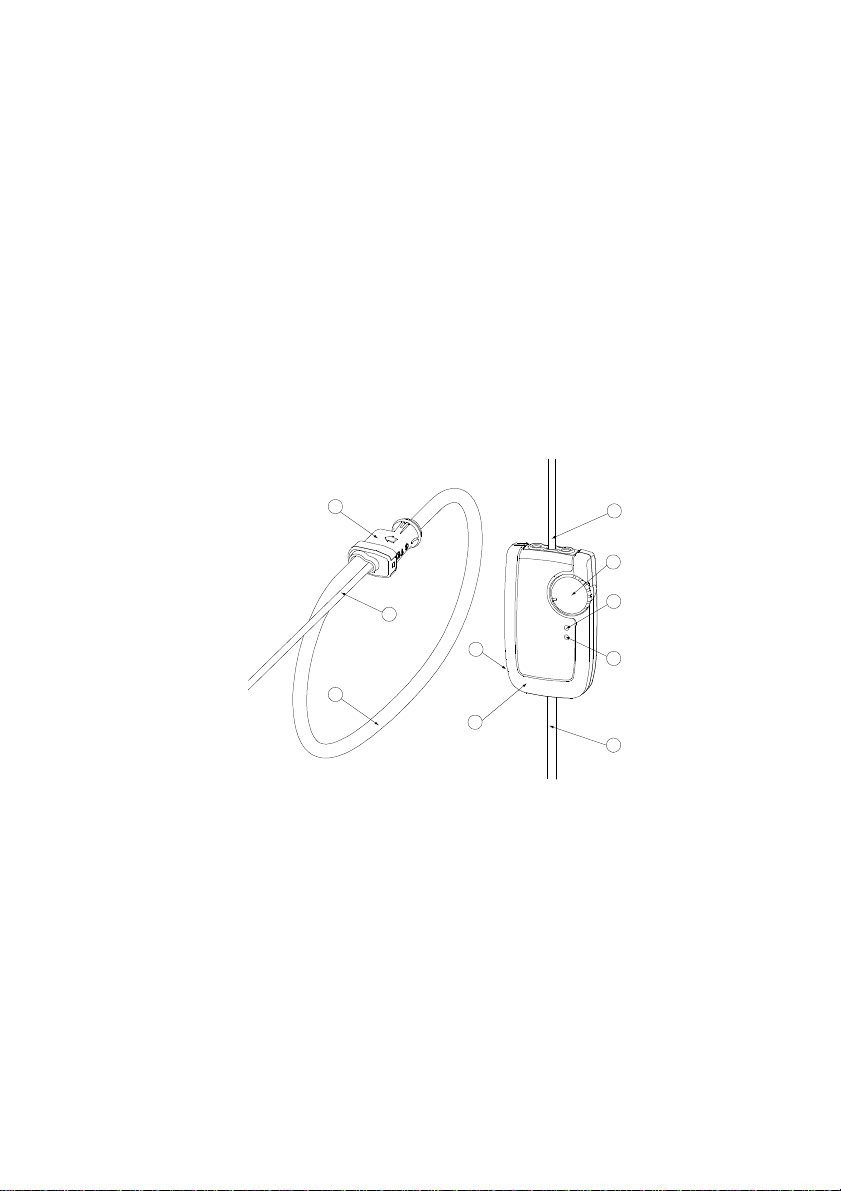

1

2

7

3

8

2

4

5

6

9

1. Probe Coupling

2. Probe Output Cable

3. Flexible Current Probe

4. Power On / Range Switch

5. RED LED – Overload

6. ORANGE LED – Low Battery

7. External Power Supply Input

8. Integrator Housing

9. Output Cable

_______________________________________________________________

Fig 1

Page 7

______________________________________________________________

.

3. SPECIFICATIONS

METRAFLEX 3000

METRAFLEX 3001

METRAFLEX 3003

METRAFLEX 3001XL

METRAFLEX 3003XL

Measuring ranges 30A 300A 3000A 30A 300A 3000A

Scaling factor 10 100 1000 20 200 2000

Output sensitivity 100mV/A

Accuracy (45-65Hz) ±1% of rdg.

Noise 8 mVrms

10mV/A 1mV/A 50mV/A 5mV/A 0,5mV/A

±0,1A

±1% of rdg

±1A

2 mVrms 8 mVrms

±1% of rdg.

±0,1A

2 mVrms

±1% of rdg.

±1A

Output Connector 1 pair 4mm safety plugs 4 pin Hypertronics plug

Power Supply

Battery

Battery Life (typ.)

external*

Connector*

2x AA MN1500 LR6 Alkaline

2000 hrs (M’FLEX 3000/3001)

1000 hrs (M’FLEX 3003)

)

3,5…12VDC/max. 100mA 2…3VDC/max. 100mA

)

Barrel plug socket 5,5/2,1mm

minus at center pin

*) not available for METRAFLEX 3000

2x AA MN1500 LR6 Alkaline

2000 hrs (M’FLEX 3001XL)

1000 hrs (M’FLEX 3003XL)

Barrel plug socket 5,5/2,1mm

minus at center pin

Output load ≥100 kΩ for specified accuracy

Frequency range 10 Hz to 20 kHz (-10% attenuation)

Phase angle error <±1° (45-65Hz)

Position sensitivity ±2% of reading

External field ±0.2% of range with cable >200mm

(8") from the probe

Temperature coeff. ±0.1% / °K

Low battery Indicated by an orange LED

Overload Indicated by a red LED

_______________________________________________________________

23

Page 8

_______________________________________________________________

Enclosure

Material ARNITE T06-200 SNF, UL94 V0

Degree of Protection IP40

Dimensions 110 (l) x 65 (w) x 23 (d) mm

Output connection 0.5m coax cable terminated with 4 mm safety plugs

Probe

Probe length 61 cm (24 inches), double insulated

on request: 91 cm (36 inches),122 cm (48 inches)

Probe diameter 9.9mm (0.39 inches)

Output cable 2m long (78.7 inches), probe to integrator

Material Alcryn 2070 NC, LATI LATENE 7H2W V0

Degree of Protection IP65

General Characteristics

Operating temp. -20°C to +65°C (-4°F to +149°F)

Storage temp. -40°C to +75°C (-40 °F to +167°F)

Operating humidity 15% to 85% (non-condensing)

Safety standards

EN 61010-1:2001

EN 61010-031:2002

EN 61010-2-032:2002

EMC standards

Emmision EN 61326-2:2006 Class B

Immunity EN 61326-2:2006

1000 V

, Category III, 600 V

RMS

, Category IV, Pollution Degree 2

RMS

(Probe and Integrator)

30V maximum between output and earth

ROHS and WEEE compliant

Rated for continuous use

_______________________________________________________________

Page 9

______________________________________________________________

METRAFLEX Frequency Response

2,00

0,00

10

-2,00

100

1000

10000

100000

Relative op % ref 50Hz

Phase error degrees

-4,00

-6,00

-8,00

-10,00

20

15

10

-5

30A range

300A range

Frequency Hz

METRAFLEX Phase Response

100000

30A range

300A range

5

0

10

100

1000

10000

-10

Frequency Hz

_______________________________________________________________

25

Page 10

_______________________________________________________________

4. OPERATION

4.1 BATTERY INSTALLATION AND BATTERY

STATUS

Never replace batteries with flexible measuring head

installed on conductor to be tested or output connected to a

measuring device.

Never operate the unit without the battery cover fitted.

The METRAFLEX require two AA MN1500 LR6 alkaline batteries

for operation. The battery compartment is accessed from the rear

of the electronics enclosure.

Battery status is indicated by an orange LED on the front of the

integrator module. This LED will flash one time when the unit is

switched ON. The length of time the LED is lit will increase as

battery life decreases. Continuous lighting of LED indicates low

battery and requires batteries to be replaced.

Should you suspect a depleted battery or the low battery LED

blinking, proceed as follows.

1. Turn “OFF” all power to the unit and measurement circuits.

2. Set the probe selector switch to the “OFF” position.

3. Remove the flexible current probe from around the conductor

of your measurement circuit. Disconnect the output from the

measuring unit. Remove the external power supply cable.

4. Rotate the battery lock screw (1/4 turn) until it aligns with the

unlock symbol. The battery cover can now be removed.

5. Install the replacement batteries into the battery holder.

Observe correct polarity.

6. Replace the battery cover and turn the battery lock until it

aligns with the lock symbol.

_______________________________________________________________

Page 11

______________________________________________________________

4.2 EXTERNAL POWER SUPPLY

Alternatively, the METRAFLEX can also be supplied by an

external DC voltage source (except METRAFLEX 3000). The

connection is made at the connector on the side of the electronics

housing. Supply voltage range, see Technical Data.

Polarity:

(+ terminal)

For safety reasons and to ensure the specified accuracy, the

current sensors should be supplied exclusively by using the

external power supply modules offered from us as an option.

Our Power Analysers MAVOWATT|50 und MAVOSYS 10 have a

power supply output for active current sensors.

MAVOWATT|50: Up to 4 pcs. METRAFLEX 3001 or 1 pc.

METRAFLEX 3003 and 1 pc. METRAFLEX 3001 can be supplied

by the 9V output named „Aux Supply“. The required connection

cable is supplied with these current sensors. Take care when

connecting the plugs to the Aux. Supply jacks on the correct

polarity (color coding)!

MAVOSYS 10: Up to 3 pcs. METRAFLEX 3003XL and 3 pcs.

METRAFLEX 3001XL can be supplied by the 3V output on the

10 pin socket being located on the rear panel over the mains

switch. The required connection cables are available as

accessories: DC3VFLEX (117067-G1) for up to 4 pcs.

METRAFLEX; RR/PS/4A for expanding to another 3 pcs.

METRAFLEX.

(- terminal)

_______________________________________________________________

27

Page 12

_______________________________________________________________

Read safety section of instructions before operating

4.3 CONNECTING TO MEASURING DEVICE

this product.

METRAFLEX 3000: Plug the output cable of the current sensor

into the voltage measuring input terminals of the multimeter

(black to GND, red to V) and switch it to V AC.

METRAFLEX 3001/3003: Plug each output cable of the current

sensor to the current measuring input terminals “I” on the

MAVOWATT|50. Observe the polarity (color) and with

METRAFLEX 3003 also the phase labeling L1, L2, L3.

METRAFLEX 3001XL/3003XL: Plug each output cable of the

current sensor to the current measuring input terminals on the

MAVOWATT 20/30/40/70 or MAVOSYS 10. With METRAFLEX

3003XL observe the phase labeling.

_______________________________________________________________

Page 13

______________________________________________________________

It is strongly recommended to de

-

energize the c

ircuits to

4.4 CONNECTING TO THE CIRCUIT TO BE

MEASURED

be measured when making connections to the

installation. If it is necessary to make connections on

energized circuits they must be made by qualified and

authorized personnel only observing the required safety

precautions..

Never apply the probe around bare conductors with

voltage levels over 1000V (CAT III) or 600V (CAT IV) to

ground.

Always connect electronics unit to measuring device

before installing the flexible measuring head.

Open the probe coupling and slip the measuring head over the

conductor carrying the current to be measured.

Close the probe coupling such that it visibly and audibly snaps

into place.

An accurate measurement is assured under the following

conditions:

– The conductor is centered within the measuring head.

– The measuring head forms a perfect circle.

– The probe coupling is not located close to other conductors

carrying high current.

_______________________________________________________________

29

Page 14

_______________________________________________________________

4.5 MEASUREMENT

To activate unit, move the rotary switch from the “off” position to

the required measuring range. If the value of current being

measured is unknown, first select the highest range and then

reduce accordingly.

The red and the orange LED might flash when the unit is

switched on or when the measuring range is changed.

To obtain correct results set the scaling factor on the meter or

analyser for each measurement channel corresponding to the

selected measuring range; see table under SPECIFICATIONS.

When measuring active power you also must observe the

direction of the current flowing through the measuring head.

Check the correct polarity at the power analyzers based on the

vector representation of voltage and current, or by the polarity of

the values for active power. These have to be positive for

consumer measurements.

_______________________________________________________________

Page 15

______________________________________________________________

5. MAINTENANCE

Do not use METRAFLEX if damaged.

Always inspect the integrator unit, connecting cable, and flexible

probes for damage before use.

To avoid electric shock, keep the METRAFLEX clean and free of

surface contamination.

Use Isopropyl alcohol to clean the electronics unit and the probe.

Make sure the flexible probe, connecting cable, and electronics

enclosure are dry before further use.

6. WARRANTY

Your METRAFLEX is guaranteed for two years from the date of

purchase against defective material or workmanship. If the unit fails

during the warranty period, we shall at our discretion, repair or

replace it with a new or reconditioned unit provided we are satisfied

that the failure is due to defective material or workmanship. To make

a claim under warranty, the probe should be returned to us, postage

prepaid, with a description of the defect. The use of a battery or

external power supply, other than that specified invalidates this

warranty.

Goods alleged by the buyer to be defective shall not form the subject

of any claim for injury, loss, damage, or any expense howsoever

incurred whether arising directly or indirectly from such alleged

defects other than death or personal injury resulting from the seller‘s

negligence.

No condition is made or to be implied nor is any warranty given or to

be implied as to the life or wear of goods supplied or that they will be

suitable for any particular purpose or for use under specific

conditions, notwithstanding that such purpose or conditions may be

made known to the seller.

_______________________________________________________________

31

Page 16

_______________________________________________________________

7. PRODUCT SUPPORT

If required please contact:

GMC-I Messtechnik GmbH

Product Support Hotline

Phone: +49 911 86 02-0

Fax: +49 911 86 02-7 09

E-mail: support@gossenmetrawatt.com

8. REPAIR AND REPLACEMENT PARTS

SERVICE DKD CALIBRATION CENTRE AND

RENTAL INSTRUMENT SERVICE

If required please contact:

GMC-I Service GmbH

Service Center

Thomas-Mann-Strasse 20

90471 Nürnberg, Germany

Phone: +49 911 817718-0

Fax: +49 911 817718-2 53

E-mail: service@gossenmetrawatt.com

This address is only valid in Germany. Please contact our

representatives or subsidiaries for service in other countries.

_______________________________________________________________

Page 17

______________________________________________________________

GMC-I Messtechnik GmbH

Südwestpark 15

D-90449 Nürnberg

DEUTSCHLAND

Tel. +49 (0)911 8602-111

Fax +49 (0)911 8602-777

e-mail: info@gossenmetrawatt.com

www.gossenmetrawatt.com

METRAFLEX MM Rev 3

_______________________________________________________________

33

Loading...

Loading...