Page 1

Operating Instructions

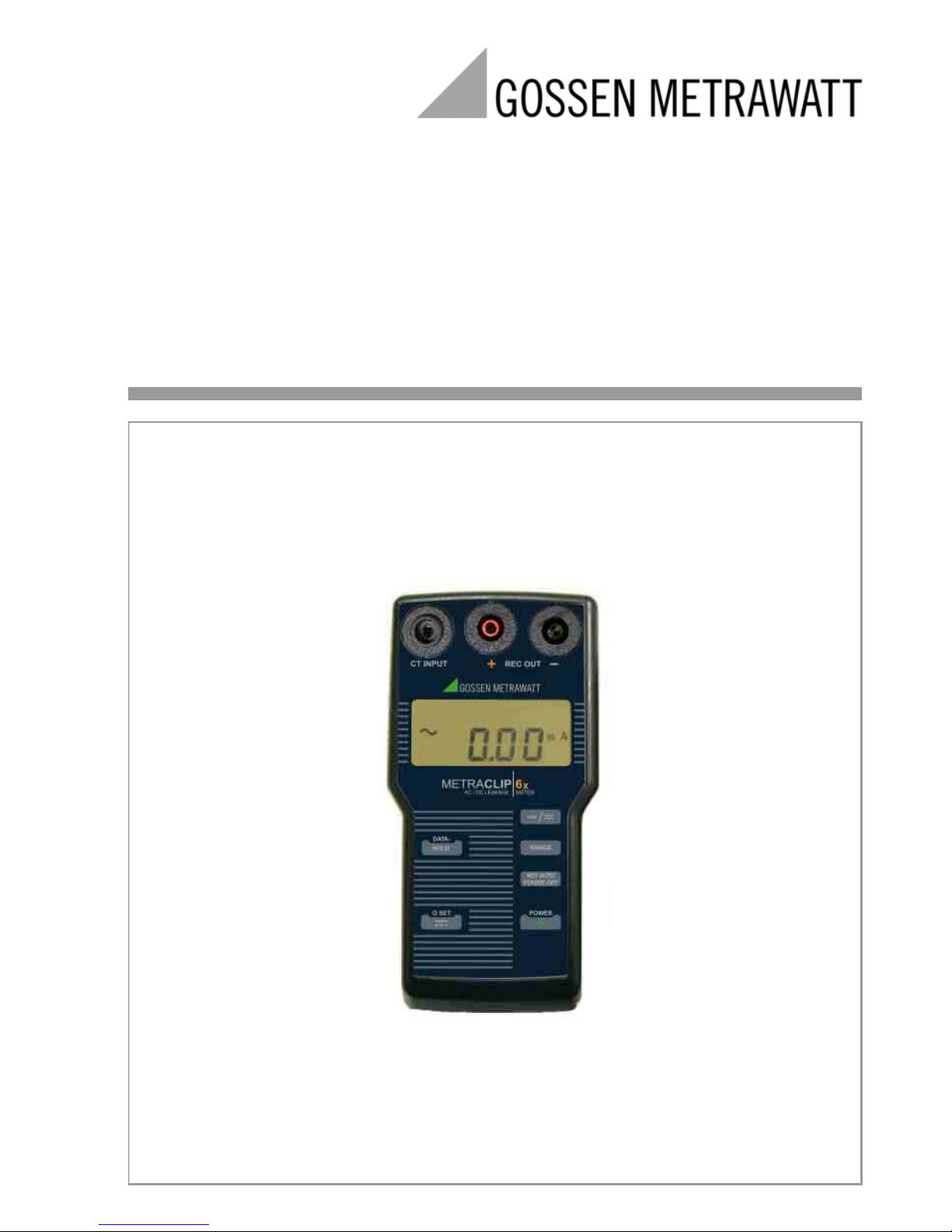

METRACLIP⏐63 / 64

Milliampere Current Clamp

for Measuring Fault, Leakage and Stray Current

3-349-488-03

1/10.08

Page 2

2 GMC-I Messtechnik GmbH

1 CT INPUT: Current clamp connector socket

2 REC OUT: Connector sockets for data logger

3 LCD panel

4 AC / DC: Selector key for direct or

alternating current

5 Range: Measuring range selector key

6

NOT AUTO

POWER OFF

: Key for deactivating auto-shutdown

7 POWER: On/off key

8 0SET: Zero balancing key

9 DATA HOLD: Key for saving measured values

Scope of Delivery

1 measuring instrument

4 LR6 batteries (AA)

1 current clamp

1 carrying pouch

1 set of operating instructions

1

2

3

4

5

6

7

8

9

Measuring Instrument

1

Current Clamp

METRACLIP 63

Current Clamp

METRACLIP 64

1 Arrow must point in

direction of current

flow

2 Safety collar

3 Locking lever

4 Slider for opening

the clamp

Description in

section 4.1

1 Arrow must point in

direction of current

flow

2 Safety collar

3 Key for opening the

clamp

2

3

4

3

1

2

Page 3

GMC-I Messtechnik GmbH 3

Table of contents

1 Safety Precautions .............................3

1.1 General .......................................................3

1.1.1 Meaning of Symbols on the Instrument ..........4

2 Applications ........................................4

3 Initial Start-Up ....................................4

4 Operation ............................................5

4.1 Using the METRA CLIP 63 Current Clamp .....5

4.2 Direct Current Measurement .........................5

4.3 Alternating Current Measurement .................6

4.4 Measuring Leakage and Stray Current ...........6

4.5 Using a Data Logger .....................................7

5 Characteristic Values ..........................8

6 Maintenance .....................................10

6.1 Housing .....................................................10

7

Repair and Replacement Parts Service,

DKD Calibration Laboratory and Rental

Instrument Service .......................................10

8 Product Support ................................11

1 Safety Precautions

1.1 General

You have selected an instrument which

provides you with high levels of safety.

This instrument fulfills all requirements of

applicable European and national EC

guidelines. We confirm this with the CE

mark. The relevant declaration of conformity

can be obtained from GMC-I Messtechnik

GmbH.

The METRACLIP 63 / 64 current clamp is

manufactured and tested in accordance with

safety regulations

IEC 61010-1/EN 61010-1/VDE 0411-1 and

IEC 61010-2-032/EN 61010-2-032/

VDE 0411-2-032

. When used for its

intended purpose, safety of the operator, as

well as that of the instrument, is assured.

Their safety is however not guaranteed, if the

instrument is used improperly or handled

carelessly.

In order to maintain flawless technical safety

conditions, and to assure safe use, it is imperative

that you read the operating instructions

thoroughly and carefully before placing your

instrument into service, and that you follow all

instructions contained therein.

Observe the following safety precautions:

• Avoid excessive mechanical stress such

as impact and vibration, as well as high

temperatures and humidity, because this

may result in damage to the instrument.

• Do not use this instrument in close

proximity to acids, alkaline salts, organic

solutions, corrosive gases etc.

• Do not use this instrument in proximity to

devices which generate strong magnetic

and/or electrical fields, because this may

result in malfunctioning.

• Do not use this instrument in operating

environments where dust or splash

water occur.

Attention!

!

Do not perform measurements at

cables with voltages of greater

than 600 V AC.

Before using the instrument, test the

voltage of the electrical circuit to be

measured.

Do not perform measurements on bare

wires!

Do not subject the input and output

sockets to voltages of greater than

10 V AC.

The current clamp may not be used:

• If the device, the housing or the cable is

damaged

• If the battery compartment lid has been

removed

• For current values which are

impermissible high for the current clamp

• In the rain, with wet hands, in the

presence of splashing water or in moist

environments

Page 4

4 GMC-I Messtechnik GmbH

1.1.1 Meaning of Symbols on the

Instrument

Meaning of Symbols on the Instrument

Warning concerning a source of

danger (attention: observe

documentation)

EC label of conformity

This device may not be disposed of

with the trash. Further information

regarding the WEEE mark can be

accessed on the Internet at

www.gossenmetrawatt.com by

entering the search term WEEE.

CA

TII/III

Measuring category

II

or

III

device

Closing the clamp around

dangerously active conductors is

permissible.

2 Applications

The instrument is capable of measuring

direct and alternating current, and is

equipped with a connectable current clamp.

In the case of direct current measurement,

conventional current clamps are not capable

of performing accurate measurement in the

light current range due to influences resulting

from magnetization and geomagnetism. This

device is a current clamp measuring

instrument which is capable of very accurate

measurement of direct and alternating

current thanks to the use of highly sensitive

materials and a magnetization method.

Attention!

!

The specified maximum input

quantities may not be exceeded in

order to prevent damage to the

instrument and injury to the user:

voltage range: 600 V AC/DC,

current range: 10 A AC/DC.

3 Initial Start-Up

Batteries

Your instrument requires four 1.5 V batteries

(size AA) in accordance with IEC LR6.

Make sure that no battery leakage has

occurred before initial start-up, as well as

after long periods of storage. Continue to

inspect the batteries for leakage at short,

regular intervals.

If battery leakage has occurred, carefully and

completely clean the electrolyte from the

instrument with a damp cloth, and replace

the batteries before using the instrument.

If the “B” symbol appears at the LCD panel,

the batteries should be replaced as soon as

possible.

Battery Replacement

Attention!

!

Disconnect the current clamp from

the measuring circuit before opening

the device in order to replace the

batteries!

Remove the screw from the battery

compartment lid with a screwdriver. Push

the battery compartment lid in the direction

indicated by the arrow and remove it.

Remove the 4 batteries and replace them.

Return the battery compartment lid to its

original position and tighten the screw.

Do not use battery sets consisting of old and

new batteries, or batteries with different

brand names.

!

Page 5

GMC-I Messtechnik GmbH 5

Automatic Shutdown

After switching the device on, “APO” appears

at the LCD (automatic power off). The device

is switched off automatically after 10

minutes if none of its keys have been

activated during this time.

Disabling Automatic Shutdown

The instrument can be set to continuous

operation.

➭ Press the NOT AUTO POWER OFF key to this

end.

4Operation

Attention!

!

For reasons of safety, use the

instrument on electrical circuits with

less than 500 V only. Be sure to

ascertain the voltage level of the

circuit to be measured before starting

the instrument.

Do not activate the 0SET key with open

current clamp. This may lead to erroneous

measurements.

Do not apply direct currents of more than

1.5 A. This may result in measurement error

and damage to the device.

4.1 Using the METRACLIP 63

Current Clamp

Opening and Closing the Clamp

➭ Press the locking lever down in order to

unlock the device.

➭ Press the slider down in order to open

the clamp.

➭ Press the slider up in order to close the

clamp.

➭ Slowly press the locking lever up in order

to securely lock the clamp.

Note!

Correct measurement is only

possible when the current clamp is

fully closed.

Figure 1: Operation, METRACLIP 63

4.2 Direct Current Measurement

➭ Connect the current clamp to the

CT INPUT socket at the measuring

instrument.

➭ Press the POWER key. At first, the 100 mA

measuring range is

displayed.

➭ Select a suitable measuring range at the

measuring instrument with the Range key.

➭ Position the current clamp in proximity to

the conductor to be measured and fully

close it.

➭ Press the 0SET key in order to execute

zero balancing.

The “0” display may be unsteady due to

geomagnetism or external magnetic fields,

but this condition does not indicate

malfunctioning.

If the measuring range is changed, zero

balancing must be executed again.

➭ Open the current clamp and close it

around the conductor to be measured.

➭ Make sure that the direction of the arrow

on the current clamp corresponds with

the flow direction of the current to be

measured.

Locking

Lever

Slider

Slider

Locking

Lever

Open

Close

Page 6

6 GMC-I Messtechnik GmbH

➭ Fully close the current clamp.

➭ Read the displayed value. In the event of

overloading, “OL” appears at the display.

➭ Complete measurement and remove the

clamp from the conductor.

4.3 Alternating Current Measurement

➭ Connect the current clamp to the

CT INPUT socket at the measuring

instrument.

➭ Press the POWER key. At first, the 100 mA

measuring range is

displayed.

➭ Press the AC / DC key. The 100 mA

range is displayed.

➭ Select a suitable measuring range at the

measuring instrument with the Range key.

➭ Open the current clamp and close it

around the conductor to be measured.

➭ Fully close the current clamp.

➭ Read the displayed value. In the event of

overloading, “OL” appears at the display.

➭ Press the DATA HOLD key in order to

freeze the measured value at the display.

“DH” appears at the display.

➭ Press the DATA HOLD key again in order to

return to the measurement.

➭ Complete measurement and remove the

clamp from the conductor.

4.4 Measuring Leakage and

Stray Current

Measuring DC Leakage Current

➭ Measurement is executed in the same

way as for direct current.

➭ However, the clamp is closed around

two conductors simultaneously.

Measuring AC Leakage Current with

Grounded Conductors

➭ Measurement is executed in the same

way as for alternating current.

Measuring AC Leakage Current in Single or

3-Phase Systems, with the Exception of the

Ground Conductor

➭ Proceed in the same way as for the

alternating current measurement,

except that in the case of

single phase systems

2 conductors are simultaneously

enclosed by the current clamp,

and in the case of

3-phase systems

3 conductors are simultaneously

enclosed by the current clamp.

Page 7

GMC-I Messtechnik GmbH 7

4.5 Using a Data Logger

If current measurements will be executed

over a period of hours, the output signal

can be redirected to a data logger (e.g. a

multimeter with memory).

➭ Connect the data logger to the REC OUT

sockets.

➭ Connect the current clamp to the

CT INPUT socket at the measuring

instrument.

➭ Switch the measuring instrument on by

pressing the POWER key.

➭ Press the NOT AUTO POWER OFF key in

order to deactivate automatic

shutdown.

“APO” is cleared from the display.

➭ Switch the data logger on.

➭ Select the appropriate settings for the

desired measurement.

➭ Close the current clamp around the

conductor to be measured.

➭ Select a suitable measuring range (see

output signal under “Device Data” on

page 9) and start recording.

Before changing the measuring range for a

direct current measurement, first remove the

current clamp from the conductor under

test, press the 0SET key and close the

current clamp around the conductor once

again in order to perform a new

measurement.

Please refer to the section entitled “Direct

Current Measurement” for further details.

The output signal for the data logger

corresponds to 100 mV DC full scale for all

ranges.

In the event of overloading amounting to

more than 110% of the selected range, the

output signal generates a display of “0 mV”

in order to draw attention to this situation.

Page 8

8 GMC-I Messtechnik GmbH

5 Characteristic Values

Direct Current (after zero balancing with the 0 SET key)

Key

rdg. = reading (measured value)

d = digit(s)

Reference Conditions

Ambient temperature: +23° C ±5° C

Relative humidity: Max. 85% (no condensation allowed)

Influencing Quantities

Geomagnetism influence: Less than ±0.5 mA

Magnetization influence: Less than ±0.5 mA at 1.5 A DC on/off

Influence caused by open/

closed current clip: Less than ±0.7 mA

Maximum input current: 1.5 A DC (if current greater than 1.5 A DC is applied,

current clamp output is reduced and “OL” does not appear

at the display.

Alternating Current

Maximum input current:20 AAC

METRACLIP 63

Range Measuring Range Resolution Accuracy

100 mA 0.1 ...±50.00 mA 0.01 mA ±1% rdg. ± 5 d

±50.01 ...±99.99 mA ±1% rdg. ±10 d

1000 mA 1 ... ±300 mA 0.1 mA ±1% rdg. ±10 d

±300 ... ±700 mA ±2% rdg. ±10 d

±700 ...±999.9 mA ±3% rdg. ±10 d

METRACLIP 64

Range Measuring Range Resolution Accuracy

100 mA 0.1 ...±99.99 mA 0.01 mA ±1% rdg. ±10 d

1000 mA 1 ... ±300 mA 0.1 mA ±1% rdg. ±10 d

±300 ... ±700 mA ±2% rdg. ±10 d

±700 ...±999.9 mA ±3% rdg. ±10 d

Range Measuring Range Resolution Accuracy

100 mA 0 ... 99.99 mA 0.01 mA ±1% rdg. ±10 d (50/60 Hz)

1000 mA 0 ... 999.9 mA 0.1 mA ±1% rdg. ±10 d (50/60 Hz)

10 A 0 ... 9.999 A 0.001 mA ±1% rdg. ±10 d (50/60 Hz)

Page 9

GMC-I Messtechnik GmbH 9

Device Data

Measuring function: Alternating current / direct current

Measuring method: Current clamp

Measuring ranges: DC: 100 mA / 1000 mA

AC: 100 mA / 1000 mA / 10 A (45 Hz ... 65 Hz)

Detection of alternating current: Average sampling

A-D converter: Dual integration method

Display: LCD, up to 2000 with signal generator

Overload display: “OL” appears at the LCD

“Data Hold” display: “DH” appears at the LCD

Sampling rate: 6 per second for AC and 1 per second for DC

Output signal: 100 mV DC full scale for each range; converted to an

analog signal which becomes zero if it exceeds 110% of

the measuring range in order to indicate overloading

(output impedance: less than 10 kΩ)

Power supply: 4 alkaline batteries (LR6), size AA

Current consumption: Approx. 9 mA (roughly 200 operating hours)

Operating voltage:

Light current range, less than 600 V AC / DC

Operating temperature: 0 ... 50° C, < 85% relative humidity

(no condensation allowed)

Storage temperature: 10 ... 60° C, < 70% relative humidity

(no condensation allowed)

Dielectric strength: 3700 V AC / 1 minute between current clamp core and

handle

Insulation value: 100 MΩ for 500 V DC insulation test between current

clamp core and handle

Safety standard: EC 61010-1/ 61010-2-032,

CAT II 600 V or CAT III 300 V

Dimensions and weight: W x H x D: 78 x 155 x 32 mm, approx. 280 g

Current Clamp Transformer Data for METRACLIP 63

Clamp jaw opening capacity: 5 mm diameter

Dielectric strength: 3700 V AC / 1 minute between metal core and handle

Cable length: 1.2 meters

Safety standard: EC 61010-2-032, CAT || 600 V or CAT ||| 300 V

Dimensions and weight: W x H x D: 19 x 113 x 28 mm, approx. 100 g

Current Clamp Transformer Data for METRACLIP 64

Clamp jaw opening capacity: 30 mm diameter

Dielectric strength: 3700 V AC / 1 minute between metal core and handle

Cable length: 1.2 meters

Safety standard: EC 61010-2-032, CAT || 600 V or CAT ||| 300 V

Dimensions and weight: W x H x D: 33 x 170 x 24 mm, approx. 165 g

Page 10

10 GMC-I Messtechnik GmbH

6 Maintenance

6.1 Housing

No special maintenance is required for the

housing. Keep outside surfaces clean. Use a

slightly dampened cloth for cleaning. Avoid

the use of cleansers, abrasives and solvents.

Return and Environmentally Sound Disposal

The instrument is a category 9 product

(monitoring and control instrument) in

accordance with ElektroG (German electrical

and electronic device law).

This device is not subject to the RoHS

directive.

We identify our electrical and

electronic devices (as of August

2005) in accordance with WEEE

2002/96/EC and ElektroG using the symbol

shown at the right per DIN EN 50419.

These devices may not be disposed of with

the trash. Please contact our repair and

replacement parts service department

regarding the return of old devices.

7

Repair and Replacement

Parts Service,

DKD Calibration Laboratory * and

Rental Instrument Service

If required please contact:

GMC-I Service GmbH

Service Center

Thomas-Mann-Str. 20

90471 Nürnberg, Germany

Phone: +49 911 8602-0

Fax: +49 911 8602-253

e-mail: service@gossenmetrawatt.com

This address is only valid in Germany. Please

contact our representatives or subsidiaries

for service in other countries.

* Calibration Laboratory for Electrical

Quantities

DKD – K – 19701 accredited per

DIN EN ISO/IEC 17025:2005

Accredited quantities: direct voltage, direct

current value, direct current resistance,

alternating voltage, alternating current value,

AC active power, AC apparent power,

DC power, capacitance, frequency, temperature

Competent Partner

GMC-I Messtechnik GmbH is certified in

accordance with DIN EN ISO 9001:2000.

Our DKD calibration laboratory is accredited

by the Physikalisch Technische Bundesanstalt (German Federal Institute of Physics

and Metrology) and the Deutscher Kalibrierdienst (German Calibration Service) in accordance with DIN EN ISO/IEC 17025 under

registration number DKD–K–19701.

We offer a complete range of expertise in the

field of metrology: from test reports and

proprietary calibration certificates right on up to

DKD calibration certificates.

Our spectrum of offerings is rounded out

with free test equipment management.

Our DKD calibration laboratory is part of our

service department. If errors are discovered

during calibration, our specialized personnel

Page 11

GMC-I Messtechnik GmbH 11

are capable of completing repairs using

original replacement parts.

As a full service calibration laboratory, we

can calibrate instruments from other

manufacturers as well.

8 Product Support

If required please contact:

GMC-I Messtechnik GmbH

Product Support Hotline

Phone +49 911 8602-0

Fax: +49 911 8602 709

E-mail: support@gossenmetrawatt.com

Page 12

Edited in Germany • Subject to change without notice • PDF version available on the Internet

GMC-I Messtechnik GmbH

Südwestpark 15

90449 Nuremberg •

Germany

Phone: +49 911 8602-111

Fax: +49 911 8602-777

e-mail: info@gossenmetrawatt.com

www.gossenmetrawatt.com

Loading...

Loading...