Page 1

Operating Instructions

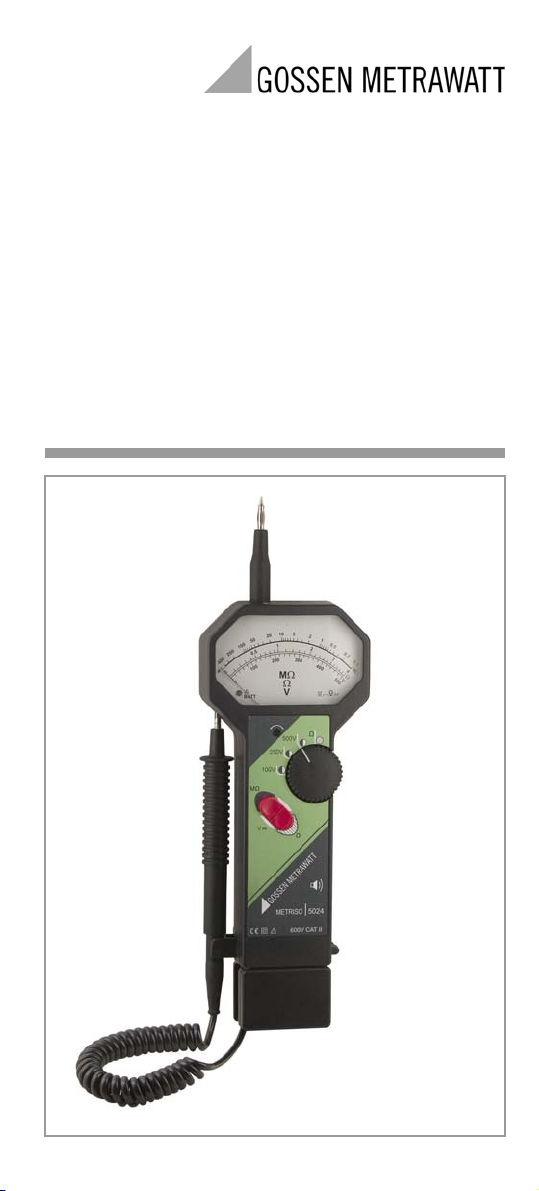

METRISO5024

Insulation and Resistance Measuring Instrument

with Voltage Measuring Range

3-349-346-03

3/3.11

Page 2

1

2

3

4

8

5

7

10

9

6

2a

Figure 1 Controls

1 Measuring probe on housing (positive pole)

2Scale

2a Adjusting screw for mechanical zero balancing

3 Rotary switch for

– Ω : Low-resistance measurement (toggle switch in Ω position)

– 100 V/250 V/500 V:

Toggle switch in neutral position:

• Voltage measurement

• Test for absence of voltage and discharge capacitive DUTs

Toggle switch in MΩ position:

• Insulation measurement with the selected test voltage

4 Tog g l e s w i t c h for switching amongst V, Ω and MΩ

(with illuminated scale when Ω or MΩ is selected)

5Carrying strap

6 Battery compartment

7 Detaining fork

8 Test probe on coil cord (negative pole)

9 Opening for securing the test probe

10 LED for indicating device and battery status

(see chapter 4.2 and 4.3)

2 GMC-I Messtechnik GmbH

Page 3

Meanings of symbols on the instrument:

!

Indicates EC conformity

Continuous, doubled or reinforced insulation

Warning concerning a source of danger

(attention: observe documentation!)

CAT I I Maximum allowable voltage between the test probes (1 and 8)

and earth is 600 V, category II.

This device may not be disposed of with the trash. Further

information regarding the WEEE mark can be accessed on

the Internet at www.gossenmetrawatt.com by entering the

search term ’WEEE’.

Table of Contents Page

1 Safety Precautions ...............................................................4

1.1 Defects and Excessive Stressing .......................................................... 4

2 Device Description ................................................................4

2.1 Using Device ......................................................................................4

2.2 Design Description .............................................................................. 4

3 Preparation for Device Operation .........................................5

3.1 Unpacking the Device .........................................................................5

3.2 Power Supply – Battery Replacement ................................................... 5

3.3 Checking the Mechanical Zero Point ....................................................5

3.4 Checking Device Functions .................................................................. 6

4 Operation ..............................................................................7

4.1 Voltage Measurement ......................................................................... 7

4.2

Insulation Resistance Measurement (VDE 0413, part 2 / EN 61557, part 2) ....... 8

4.3

Low-Resistance Measurement (VDE 0413, part 4 / EN 61557, part 4) ............... 9

5 Maintenance – Recalibration ..............................................10

5.1 Housing ........................................................................................... 10

5.2 Batteries ..........................................................................................10

5.2.1 Details on Power Consumption and Operating Time ............................ 10

5.3 Replacing the Fuse ...........................................................................10

5.4 Recalibration .................................................................................... 11

5.5 Device Return and Environmentally Compatible Disposal .....................12

6 Characteristic Values ..........................................................12

7 Repair and Replacement Parts Service

Calibration Center

and Rental Instrument Service ........................................... 14

8 Product Support .................................................................14

GMC-I Messtechnik GmbH 3

Page 4

1 Safety Precautions

The METRISO 5024 insulation measuring instrument is

manufactured and tested in accordance with the following

standards:

IEC 61010-1/EN 61010-1/VDE 0411-1,

IEC 61557-2/EN 61557-2/VDE 0413-2

IEC 61557-4/EN 61557-4/VDE 0413-4

IEC 61326-1/EN 61326-1

IEC 61000-4-2/EN 61000-4-2

IEC 61000-4-3/EN 61000-4-3

IEC 61000-4-4/EN 61000-4-4

IEC 61000-4-5/EN 61000-4-5

IEC 61000-4-6/EN 61000-4-6

IEC 61000-4-8/EN 61000-4-8

In order to maintain flawless technical safety conditions, and to

assure safe use, it is imperative that you read these operating

instructions thoroughly and carefully before placing your instrument

into service, and that you follow all instructions contained herein.

1.1 Defects and Excessive Stressing

If it can be assumed that safe operation is no longer possible, the

instrument must be removed from service and secured against

inadvertent use. It must be assumed that safe operation is no longer

possible:

• If the device demonstrates visible damage

• If the instrument no longer functions

• After long periods of storage under unfavorable conditions

• After extraordinary stressing due to transport

2 Device Description

2.1 Using Device

The METRISO 5024 measuring instrument is a battery operated

combination device with direct display. It is suitable for the following

measurements:

• AC and DC voltages without indication of polarity within a range of

0 to 500 V. This function is especially well suited for testing DUTs

for absence of voltage before performing resistance or insulation

measurements.

• Low resistance measurement within a range of 0 to 4 Ω.

Advantageous for resistance measurements at coils, over

contacts, and at equipotential bonding conductors and

protective conductors.

• Measurement of insulation resistance within a range of 100 kΩ to

400 MΩ. The device is suitable for measuring and testing

insulation resistance at electrical systems and devices and

allows for the selection of the following nominal voltages: 100 V,

250 V or 500 V DC.

2.2 Design Description

Thanks to its design and the use of two-hand operation (Figure 1),

the device is well suited for safe, daily use. It can be secured against

dropping with the attached carrying strap.

The METRISO 5024 includes two switches for device operation:

• Toggle switch for function selection (4)

• Rotary switch (3)

Measured values are displayed at three analog scales (2). Figure 1

shows these scales in detail. Insulation resistance is displayed at the

4 GMC-I Messtechnik GmbH

Page 5

uppermost scale, low-resistance at the middle scale and voltage at

the bottom scale. The device’s operating status and battery charge

level are indicated with the 2-color LED in the scale (Figure 1).

The battery compartment is located in the housing base (6). The

procedure for replacing batteries is described in 3.2.

All measurements are performed with two test probes:

• One test probe (1) is permanently attached to the housing –

positive pole.

• The other (8) is attached to a coil cord – negative pole

This test probe (8) can be inserted into the opening (9) and secured

by snapping the handle into the detaining fork (7).

As long as the toggle switch (4) is in the neutral middle position, the

METRISO 5024 can be utilized as a voltmeter.

The rotary switch must be set either to the 100 V, 250 V or 500 V

position in order to perform voltage measurements. No batteries are

required for this function.

The rotary switch must be set to the Ω position in order to perform

low-resistance measurements. Measurement is performed with the

toggle switch (4) in the Ω position. Voltage cannot be measured as

long as the rotary switch (3) remains in this position.

The desired test voltage must be selected with the rotary switch (3)

before performing insulation measurements. Measurement is

performed with the toggle switch (4) in the MΩ position.

3 Preparation for Device Operation

3.1 Unpacking the Device

Check for mechanical damage after unpacking the device. The

device is ready for use as soon as the batteries have been inserted

into the battery compartment.

3.2 Power Supply – Battery Replacement

The METRISO 5024 is operated exclusively with batteries for safety

reasons. Batteries are inserted or replaced as follows:

Ð First disconnect the measurement cables from the device under

test.

Ð Loosen the fastening screw at the bottom of the battery

compartment (6) and remove the battery compartment.

Ð Remove the depleted batteries and replace them with new or

fully charged batteries. Make sure that battery polarity is not

reversed during insertion (see printed symbols on the

compartment).

Ð Push the battery compartment back in and secure it with the

screw.

Recommended batteries: 4 ea. alkaline batteries per LR6, mignon

cells, AA cells, 1.5 V, at least 2300 mAh

3.3 Checking the Mechanical Zero Point

Ð Lay the device horizontally onto a work surface.

Ð Check the pointer for correct zero point adjustment and reset

with the adjusting screw (2a) if necessary.

The device may not be connected to a measuring circuit during

this procedure, and the toggle switch may not be activated.

Don’t forget: Negative pointer deflection is suppressed by the

scale’s limit stop. Always turn the adjusting screw clockwise for

this reason, and then slowly turn it counterclockwise until the 0 Ω

or 0 V position is reached.

GMC-I Messtechnik GmbH 5

Page 6

3.4 Checking Device Functions

The METRISO 5024 functions as a voltmeter when the toggle switch

(4) is in the neutral position:

Ð The voltmeter function can be checked by applying a voltage to

both test probes (1 and 8), e.g. line voltage from a mains outlet.

The rotary switch must be set to any of positions 100 V, 250 V or

500 V.

Ð When the toggle switch (4) is in either the Ω or MΩ position, the

batteries are activated and the METRISO 5024 remains in the

selected function as long as the toggle switch is activated.

Measurements in the Ω and MΩ ranges are evaluated by means

of the green LED (10), the beeper and the pointer.

Ð The ohmmeter function – ro tary switc h i n the Ω position and toggle

switch in the Ω position – can be tested by short-circuiting the

two test probes (1 and 8): 0 Ω appears at the display,

continuous acoustic signal from the beeper.

Avoid open test probes (resistance approaching ∞), (pointer

oscillates, periodic sequence of acoustic signals from the

beeper).

Ð The insulation measuring function – rotary switch in the xxx V

position and toggle switch in the MΩ position – can be tested

with the help of the two limit values: Short-circuit the two test

probes (1 and 8): Pointer oscillates, periodic sequence of

acoustic signals from the beeper, green LED blinks; separate the

test probes: ∞ appears at the display, continuous acoustic signal

from the beeper, green LED lights up.

Display accuracy can be tested using the ISO Calibrator 1 (article no.

M662A) as an accessory by connecting it to the low or high value

resistor.

6 GMC-I Messtechnik GmbH

Page 7

4Operation

Attention!

!

Ω

500 V

250 V

100 V

Ω

MΩ

V

– (+)

~

+ (–)

~

4.1 Voltage Measurement

Before connecting the measuring instrument to an external

source of voltage, make sure that the battery compartment

has been correctly secured to the housing because the

battery connector terminals are electrically connected to the

measuring circuit!

No auxiliary power is required for voltage measurement, i.e. no

batteries need to be inserted into the battery compartment.

Direct and alternating voltages of up to 500 V can be measured

without switching between zero-frequency and periodic quantities.

Pointer deflection is always positive for the measurement of direct

voltage, regardless of polarity.

Devices under test can be conveniently tested for absence of voltage

using the voltage measuring function without activating any of the

controls. Immediately after connecting the device under test, the

instrument indicates whether or not external voltage is present.

The voltage measuring range can also be used for discharging

capacitive devices under test. The falling voltage value can be

observed at the display.

Adhere to the prescribed sequence for the performance of voltage

measurement:

Ð Set the rotary switch (3) to the xxx V position.

The rotary switch may be set to any position other than Ω!

Ð Leave the toggle switch (4) in its neutral position (do

not press).

Ð Contact the device under test with the test probes

(1 and 8). Read the measured value from the voltage

scale within a range of 0 to 500 V.

Ð End the measurement by removing the test probes from the

device under test.

GMC-I Messtechnik GmbH 7

Page 8

4.2

Attention!

!

Attention!

!

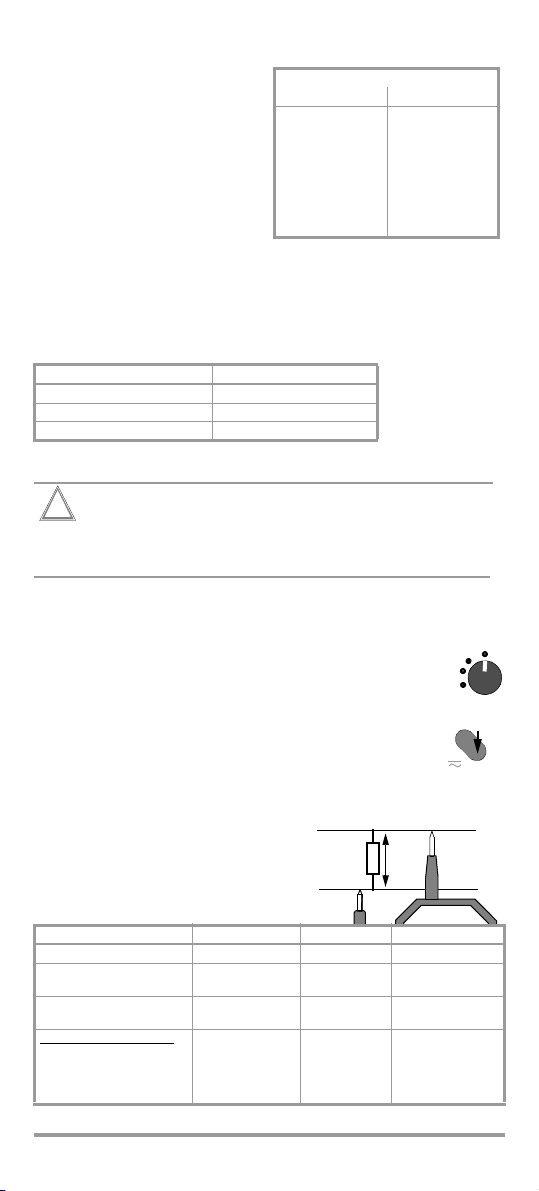

Ω

500 V

250 V

100 V

Ω

MΩ

V

Insulation Resistance Measurement (VDE 0413, part 2 / EN 61557, part 2)

Insulation resistance measurements may only be performed

on voltage-free system components and devices!

Adhere to the prescribed sequence:

Ð Set the rotary switch (3) to the desired test voltage:

100 V, 250 V or 500 V.

Ð Contact the device under test with the test probes

(1: positive pole and 8: negative pole).

Ð When the toggle switch is in the neutral position, the

METRISO 5024 functions as a voltmeter for testing for the absence

of voltage.

Immediately after contacting the device under test, the user can

determine whether or not it is voltage-free.

A capacitively charged device under test is discharged directly

via the voltmeter’s internal resistance. Discharging can be

observed at the display. However, if the voltage value remains

constant insulation resistance cannot be measured until the

device under test has been disconnected from all sources of

voltage.

If zero voltage is displayed, measurement can be performed

immediately.

Ð Insulation resistance measurement is performed for as

long as the toggle switch is held in the MΩ position.

Read the measured value from the logarithmic scale

within a range of 100 kΩ to 400 MΩ.

Ð End the measurement by releasing the toggle switch. Capacitive

devices under test which have been charged by direct test

voltage are discharged by the voltmeter.

Ð Remove the test probes from the device under test.

When insulation resistance is measured at capacitive devices under

test, e.g. cables, they may be charged with an open-circuit voltage

of up to approximately 700 V, and may retain this charge for a

lengthy period of time. This is a life endangering voltage, and the

device under test must be discharged after measurement for this

reason (see “testing for the absence of voltage” above).

Insulation Resistance Scale LED Beeper

Measured value ≥ limit value is displayed green continuous signal

Meas. value < 250 kΩ with UN=250 V

Meas. value < 500 k

Measurement not possible:

– < 100 kΩ

– Battery voltage too low

– Rotary or toggle switch

not adjusted correctly

Ω

with UN=500 V

value is displayed green periodic sequence

pointer oscillates

pointer oscillates

pointer oscillates

green blinks

red

green blinks

of signals

periodic sequence

of signals

no signal

no signal

Evaluating Measured Values

According to DIN VDE 0100, the insulation resistance of system

components must have a value of at least 1000 Ω per V nominal

voltage without any current-consuming apparatus in the line section

between two overcurrent protection devices or switches, or

downstream from the last overcurrent protection device, for example

8 GMC-I Messtechnik GmbH

Page 9

380 kΩ at an operating voltage of 380 V.

Attention!

!

* Minimum display values for

insulation resistances with specified

limit values in consideration of

maximum measuring error.

MΩ Range

Limit value Min. Display *

0.10 MΩ

0.25 MΩ

0.40 MΩ

0.50 MΩ

0.60 MΩ

0.70 MΩ

0.80 MΩ

1 MΩ

2 MΩ

0.130 MΩ

0.325 MΩ

0.520 MΩ

0.650 MΩ

0.780 MΩ

0.910 MΩ

1.040 MΩ

1.300 MΩ

2.600 MΩ

Ω

500 V

250 V

100 V

Ω

MΩ

V

R

x

Voltage Drop

In order to assure that the

insulation resistance limit values

specified in the applicable

standards are not exceeded,

maximum measuring error of the

measuring instrument must be

taken into consideration. The

required minimum display values

for various limit values are listed in

the following table. Intermediate

values can be interpolated in a

linear fashion.

Test Vo ltages

During measurement of insulation resistance, a test voltage U is applied

to the device under test, which lies between the nominal voltage U

selected with the rotary switch (3), and open-circuit voltage U

UN Position at Rotary Switch (3) Test Voltage at DUT

100 V 100 V < U < 110.8 V

250 V 250 V < U < 277.0 V

500 V 500 V < U < 554.0 V

N

:

0

4.3 Low-Resistance Measurement (VDE 0413, part 4 / EN 61557, part 4)

Resistance measurements may only be performed on

voltage-free devices under test, because interference

voltages distort measurement results.

Adhere to the prescribed sequence:

Ð Make sure that the device under test is voltage-free in

accordance with chapter 4.1.

Ð Set the rotary switch to Ω.

Ð Contact the device under test with the test probes (1:

positive pole of the 200 mA constant current source

and 8: negative pole of the constant current source).

Ð Measurement is performed for as long as the toggle

switch is held in the Ω position. Observe the LED.

Read the measured value from the scale within a

range of 0 to 4 Ω. It is advisable to perform a second

measurement with reversed polarity in order to eliminate

semiconductor circuits.

Ð

End the measurement by

releasing the toggle switch.

Ð

Remove the test probes from

the device under test.

Low Voltage Scale LED Beeper

measured value ≤ 2 Ω value is displayed green continuous signal

2 Ω < measured value ≤ 4Ω value is displayed green periodic sequence

measured value ≥ 4Ω pointer oscillates green blinks periodic sequence

measurement not possible:

– battery voltage too low

– rotary or toggle switch

not adjusted correctly

GMC-I Messtechnik GmbH 9

pointer oscillates

pointer oscillates

red

green blinks

of signals

of signals

no signal

no signal

Page 10

5 Maintenance – Recalibration

5.1 Housing

No special maintenance is required for the housing. Keep outside

surfaces clean. Use a slightly dampened cloth for cleaning. Avoid the

use of cleansers, abrasives and solvents.

5.2 Batteries

Check the batteries at short regular intervals to makes sure no

leakage has occurred. If leakage occurs, electrolyte must be fully

removed from the instrument and new batteries must be installed.

Remove the batteries from the battery compartment if the measuring

instrument will not be used for a lengthy period of time. Refer to

chapter 3.2 regarding battery replacement

Attention: If the LED lights up red before or during measurement, the

batteries must be replaced immediately.

Use only recommended battery types (see chapter 3.2).

5.2.1 Details on Power Consumption and Operating Time

Low-Resistance Measurement

The instrument draws the most power from the batteries when the

value of the contact resistance is the lowest.

Power consumption does not exceed the value of 0.4 A.

Insulation Resistance Measurement

Power consumption from the batteries depends on the selected test

voltage and the actual value of the insulation resistance, i.e. on the

load imposed on the source of the measuring voltage U

below specifies the power consumption from the batteries for the

indicated parameters.

Test Voltage

U

N

500 V 0 kΩ / < 1 A * 0.1 MΩ / < 1.1 A > 1 MΩ / < 0.6 A

250 V 0 kΩ / < 1 A * 0.1 MΩ / < 0.4 A

100 V 0 kΩ / < 1 A * 0.1 MΩ / < 0.2 A

(*if LED lights up green, pointer oscillates and there is no acoustic signal,

RX measured at I

the transformer is overloaded)

(U

BAT

> 500 kΩ / < 0.4 A > 400 MΩ / < 0.2 A

> 200 kΩ / < 0.3 A > 400 MΩ / < 0.2 A

BAT

= 6 V)

The following table lists the number of possible measurements with

one set of alcaline batteries by taking into account the power consumption from the batteries.

The number of possible measurements depends on the following conditions:

• one measurement takes 1 minute

• the insulation resistance complies with the requirements of the

standard

(power consumption from the battery in accordance with

column 3 of the table above).

Test Voltage U

N

500 V > 300 measurements

250 V > 500 measurements

100 V > 750 measurements

AlMn Battery min. 2300 mAh

The table

N.

> 400 MΩ / < 0.3 A

5.3 Replacing the Fuse

The low-resistance measuring range is protected with a fuse, see

chapter 6. The fuse blows if a voltage is applied to the test probes

which may cause damage to the instrument as a result of its

magnitude or polarity.

Adhere to the prescribed sequence when replacing the fuse:

Ð Remove the test probes from the device under test.

Ð Loosen the 3 screws in the housing base.

10 GMC-I Messtechnik GmbH

Page 11

Ð Turn the device over so that the control panel faces up and

Note!

Attention!

!

Note!

remove the housing top (i.e. control panel).

Ð Remove the fuse from its holder with the help of an object such

as a test probe, and replace it with a new fuse.

(A replacement fuse is available in the carrying pouch).

Replace the fuse only in a clean and dust-free environment.

Soiling may possibly impair the correct functioning of the

measuring instrument.

Use specified fuses only! If fuses with other blowing

characteristics, other current ratings or other breaking

capacities are used, the operator is placed in danger, and

resistors and other components may be damaged.

The use of repaired fuses or short-circuiting the fuse holder

is prohibited.

Ð Set the housing top back into place without applying pressure.

Ð Lay the carrying strap over the metal pin.

Make sure that the cable from the measuring element is not

pinched when the housing bottom and the housing top are

fitted together.

Ð Position the measuring instrument so that you view it from the

side with the test probe snapped in to the detaining fork. The

support included on the housing top must slide into the guide in

proximity to the test probe holder, and may not be tilted at the

display module. In this way, the housing top can be pressed

onto the housing bottom without applying excessive force.

Ð Hold the housing top and bottom together and turn the entire

instrument over so that the housing bottom faces up.

Ð Retighten the screws.

5.4 Recalibration

The respective measuring task and the stress to which your

measuring instrument is subjected affect the ageing of the

components and may result in deviations from the guaranteed

accuracy.

If high measuring accuracy is required and the instrument is

frequently used in field applications, combined with transport stress

and great temperature fluctuations, we recommend a relatively short

calibration interval of 1 year. If your measuring instrument is mainly

used in the laboratory and indoors without being exposed to any

major climatic or mechanical stress, a calibration interval of 2-3 years

is usually sufficient.

During recalibration

*

in an accredited calibration laboratory

(DIN EN ISO/IEC 17025) the deviations of your instrument in relation

to traceable standards are measured and documented. The

deviations determined in the process are used for correction of the

readings during subsequent application.

*

Verification of specifications or adjustment services are not part of the

calibration. For products from our factory, however, any necessary

adjustment is frequently performed and the observance of the relevant

specification is confirmed.

GMC-I Messtechnik GmbH 11

Page 12

We are pleased to perform DKD or factory calibrations for you in our

Pb Cd Hg

calibration laboratory. Please visit our website at

www.gossenmetrawatt.com (→ Services → DKD Calibration Center

or → FAQs → Calibration questions and answers).

By having your measuring instrument calibrated regularly, you fulfill

the requirements of a quality management system per

DIN EN ISO 9001.

5.5 Device Return and Environmentally Compatible Disposal

The instrument is a category 9 product (monitoring and control

instrument) in accordance with ElektroG (German Electrical and

Electronic Device Law). This device is not subject to the RoHS

directive.

We identify our electrical and electronic devices (as of

August 2005) in accordance with WEEE 2002/96/EG and

ElektroG with the symbol shown to the right per DIN EN

50419.

These devices may not be disposed of with the trash. Please contact

our service department regarding the return of old devices.

If you use batteries or rechargeable batteries in your instrument or

accessories which no longer function properly, they must be duly

disposed of in compliance with the applicable national regulations.

Batteries or rechargeable batteries may contain harmful substances

or heavy metal such as lead (PB), cadmium (CD) or mercury (Hg).

They symbol shown to the right indicates that batteries or

rechargeable batteries may not be disposed of with the

trash, but must be delivered to collection points specially

provided for this purpose.

6 Characteristic Values

Insulation Resistance Measurement, Measuring Voltages: 100 / 250 / 500 V

Measuring Range Intrinsic

0.1 … 400 MΩ 2.5% * 600 V AC > 1 mA < 10 mA

*

Measuring error under reference conditions relative to scale length (l = 84.6 mm)

Uncertainty

Low-Resistance Measurement, Measuring Voltage: 4.5 V

Measuring Range Intrinsic

0 … 4 Ω 2.5% * 250 V DC >200 mA

* Measuring error under reference conditions relative to upper range value (l = 74.9 mm)

Uncertainty

Voltage Measurement, DC / AC (40 … 200 Hz)

Measuring Range Intrinsic

0 … 500 V 2.5% * 600 V AC 450 kΩ

* Measuring error under reference conditions relative to scale length

(l = 73.3 mm)

12 GMC-I Messtechnik GmbH

Uncertainty

Overload Measuring

Overload Measuring Current

Overload Internal Resistance

Current

Short-Circuit

Current

Page 13

Reference Conditions

Normal position of use horizontal

Ambient temperature + 23 °C ± 2K

Relative humidity 40 ... 60%

Measured quantity frequency 45 ... 65 Hz

(during voltage measurement)

Line voltage waveshape sinusoidal (RMS value)

Battery voltage 5.5 V ±0.5 V

Influence Error under Nominal Conditions of Use

Total error caused by battery,

temperature and normal position of use = 10%

Nominal Conditions of Use

Temperature 0 ... 40 °C

Normal position of use any

Battery voltage 4.4 ... 6.5 V

Ambient Conditions

Storage temperature −25 °C ... + 60 °C (without batteries)

Relative humidity max. 75%, no condensation allowed

Elevation to 2000 m

Deployment indoors only, except within specified

ambient conditions

EMC EN 61326

Interference emission EN 55022 class B

Interference immunity EN 61000 -4-2 power feature A

-4-3 power feature B

Power Supply

Batteries 4 ea. 1.5 V mignon-cell per IEC LR6

(4 x size AA)

Working range 4.4 ... 6.5 V

Battery test by means of LED (see chapter 4.2 and 4.3)

Electrical Safety

Safety class II

Test voltage 3.7 kV

Measuring category II / 600 V

Fouling factor 2

Fuse F0.25A/500V, 6.3x32

Mechanical Design

Protection

IP 40 per DIN VDE 0470 part 1/EN 60529

Extract from table on the meaning of IP codes

IP XY

st

(1

Protection against foreign

digit X)

4 ≥ 1.0 mm dia. 0 not protected

object entry

IP XY

(2nd digit Y)

Protection against the

penetration of water

Dimensions 98 mm x 310 mm x 40 mm

Weight approx. 0.5 kg with batteries

GMC-I Messtechnik GmbH 13

Page 14

7 Repair and Replacement Parts Service

Calibration Center *

and Rental Instrument Service

When you need service, please contact:

GMC-I Service GmbH

Service Center

Thomas-Mann-Strasse 20

90471 Nürnberg • Germany

Phone +49 911 817718-0

Fax +49 911 817718-253

E-Mail service@gossenmetrawatt.com

www.gmci-service.com

This address is only valid in Germany.

Please contact our representatives or subsidiaries for service in other

countries.

* Calibration Laboratory

for Electrical Quantities DKD– K – 19701

accredited per DIN EN ISO/IEC 17025:2005

Accredited measured quantities: direct voltage, direct current values, DC

resistance, alternating voltage, alternating current values, AC active power,

AC apparent power, DC power, capacitance, frequency and temperature

8 Product Support

When you need support, please contact:

GMC-I Messtechnik GmbH

Product Support Hotline

Phone +49 911 8602-0

Fax +49 911 8602-709

E-Mail support@gossenmetrawatt.com

Edited in Germany • Subject to change without notice • A pdf version is available on the internet

GMC-I Messtechnik GmbH

Südwestpark 15

90449 Nürnberg •

Germany

Phone +49 911 8602-111

Fax +49 911 8602-777

E-Mail info@gossenmetrawatt.com

www.gossenmetrawatt.com

Loading...

Loading...