Page 1

Operating Instructions

AT3-III E Safety Tester

For Testing Single and 3-Phase Consumers

and Extension Cables in Combination with

SECUTEST.../SECULIFE ST Test Instruments

3-349-155-37

10/5.12

Page 2

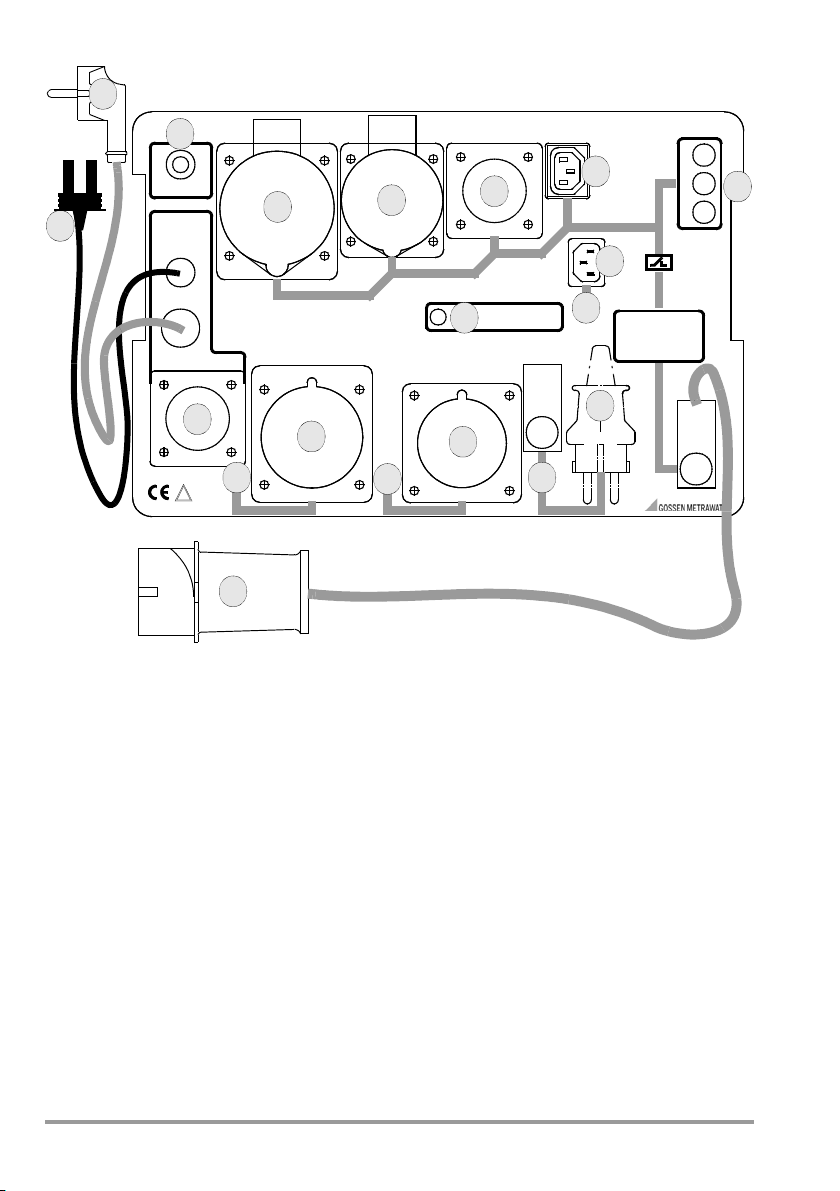

Safety tester AT3-III E

L3

L2

L1

!

1

2

3

4

5

6

12

7

10

11

9

16

15

15

15

8

13

SECUTEST

14

15

Device Plugs and Outlets

1 CEE outlet

3P+N+PE, 32 A, 400 V

2 CEE outlet

Indicator Displays

10 Function LED

2 GMC-I Messtechnik GmbH

3P+N+PE, 16 A, 400 V

3 Earthing contact outlet

1P+N+PE, 16 A, 250 V

4 Device outlet for cable testing

1P+N+PE, 10 A, 250 V

5 CEE plug for cable testing

3P+N+PE, 32 A, 400 V

6 CEE plug for cable testing

3P+N+PE, 16 A, 400 V

7 Earthing contact plug for cable testing

1P+N+PE, 16 A, 250 V

8 Device plug for cable testing

1P+N+PE 10 A 250 V

9 Mains indicator lamps for L1, L2 and L3

Self-Test

11 Test key for triggering I

Connectors for

SECUTEST... (as of version 3.1) Test Instrument

12 Blue earthing contact outlet for power supply to

SECUTEST... test instruments

13 Earthing contact plug with cable, for insertion into the

test socket at SECUTEST... test instruments

14 SECUTEST port: for insertion into sockets 2 and 3 at the

SECUTEST... test instrument

15 Connector sockets for probe cable of the SECUTEST...

test instrument (for testing cables only)

AT3-III E Power Supply

16 Via connector cable with CEE plug

3P+N+PE, 16 A

SECUTEST... series test instruments are not included in

the scope of delivery.

n

(In = residual current)

Page 3

Table of Contents

Note!

Page

1 Applications ...............................................3

2 Safety Precautions .....................................3

3 Connecting the Safety Tester to the Mains ... 4

4 Connecting a Device Under Test

to the Safety Tester ...................................5

5 Testing Devices .........................................5

5.1 Measuring Protective Conductor Resistance ...5

5.2 Measuring Insulation Resistance and

Equivalent Leakage Current .......................... 5

5.3 Measuring Protective Conductor Resistance

with the Residual Current Method .................5

5.4 Testing of Differential Current

during Automatic Testing per Test Standard ..6

5.5 High-Voltage Test ........................................6

6 Testing Extension Cables ...........................6

6.1 Measuring Protective Conductor Resistance ...7

6.2 Measuring Insulation Resistance ...................7

6.3 Testing for Short-Circuits, Interruptions and

Reversed Conductors ...................................7

7 Self-Test ....................................................8

8 Technical Data ...........................................8

9 Maintenance ..............................................9

10 Repair and Replacement Parts Service,

Calibration Center and Rental Instrument

Service .......................................................9

11 Product Support .........................................9

1 Applications

The portable safety tester, which can also be

permanently mounted with the wall bracket, is

used for measuring and testing single and

3-phase electrical devices and extension cables in

combination with SECUTEST... (as of version 3.1)

test instrument.

Suitable instruments are identified in the following

pages with the following abbreviated designation:

SECUTEST....

Testing must be performed by a qualified

electrician with an appropriate test instrument

after repair or modification, and is also required for

periodic testing per DIN VDE 0105/0701-0702.

According to these regulations, testing must be

performed for protective conductor resistance,

insulation resistance, equivalent leakage current,

residual current and contact current, as well as for

the absence of voltage depending upon the type

of device under test.

The following values are tested by the safety tester in

combination with a SECUTEST... test instrument:

• Protective conductor resistance

• Insulation resistance

• Dielectric strength (HV test) *

• Earth leakage current

• Residual current

• Contact current

• Protective conductor current (AC and DC are

tested separately) *

• For extension cables:

– Short-circuit

– Conductor continuity

And for 3-phase extension cables:

– Phase reversal at L1, L2 and L3

for substantiation of clockwise rotation

* Only if the utilized SECUTEST... is capable of performing this

measurement

Measurement results are displayed at the

SECUTEST... test instrument.

The AT3-I I I E safety tester is equipped with

electronic error monitoring which disconnects the

device under test from the mains in the event of

fault currents of greater than 18 mA.

2 Safety Precautions

The safety tester has been manufactured and

tested in accordance with the following

regulations:

IEC 61010-1/DIN EN 61010-1/VDE 0411-1

“Regulations for electronic testers and controllers,

part 1: Safety measures for electrical measuring

instruments”

DIN VDE 0404 “Devices for technical safety

testing of electrical equipment, parts 1 and 2.”

EN 61326-1 product standard EMC requirements.

Safety is only assured for the user and the safety

tester when used for its intended purpose in

combination with SECUTEST... test instruments.

In order to maintain flawless technical safety

conditions, and to assure safe use, it is imperative

that you read these operating instructions

thoroughly and carefully before placing your safety

tester into service, and that you follow all

instructions contained herein.

GMC-I Messtechnik GmbH 3

Page 4

Due to the fact that all tests performed with the AT3-

Attention!

!

Attention!

!

!

II I E must be executed in combination with a

SECUTEST... test instrument, you must also read the

safety precautions and liability limitations included in

the operating instructions for this instrument.

Observe the following safety precautions:

If the red LED (10) remains lit even after

the AT3-III E has been disconnected from

the mains and connected once again, the

safety tester is defective.

the AT3-I I I E must be removed from service

and repaired before it is used again.

• In order to assure compliance with technical

safety requirements, the AT3-I I I E safety

tester should only be repaired by the

manufacturer.

• The AT3-III E must be disconnected from the

mains and from the SECUTEST... test

instrument before it is opened.

Measurements within electrical systems are prohibited!

• The safety tester’s 16 A CEE 3P+N+PE (16)

plug may only be connected to 230/400 V

50 Hz mains power. In order to avoid

undesired shutdown of defective devices

under test, the electrical circuit for the device

under test should be separately fused.

• Before connecting the AT3-I I I E to the mains,

the SECUTEST... test instrument must first be

connected to the AT3-I I I E.

Tests during which mains power is

applied may only be selected with the

function selector switch at the

SECUTEST... test instrument after safety

class I devices under test have passed

the protective conductor test.

If the protective conductor is defective

(interruptions / reversed conductors), line

voltage may be present at the housing of

a defective device under test, at the

earthing contacts of the test plugs (4 – 7)

and at the safety socket (15)!

•For REASONS OF SAFETY, the device under test

must be turned off before switching to

“MAINS” so that dangerous devices under

test (e.g. a circular saw) can only be switched

on intentionally.

• Be prepared for the occurrence of

unexpected voltages at devices under test

(e.g. due to charged capacitors).

If this is the case,

• Before connecting the device under test to

the safety tester, subject it to a thorough

VISUAL INSPECTION first. Damaged devices

under test must be repaired prior to testing.

• Only extension cables which have been

plugged into the test outlets (1 – 4) at the

safety tester may be connected to the device

plugs (4 – 7) at the safety tester.

• Due to safety tester design in accordance

with DIN VDE 0404, the “PE” contacts at the

outlets (1 – 4) are only connected to the mains

protective conductor when the SECUTEST...

test instrument has been set for testing with

mains power.

• If the safety tester and/or its connector cables

demonstrate visible damage, no longer

function, have been stored for a lengthy

period of time under unfavorable conditions or

have been subject to excessive stress during

transport, it must be assumed that hazardfree operation is no longer possible. Remove

the AT3-III E from service and secure it

against inadvertent use in such cases.

Meanings of Symbols on the Instrument

Warning concerning a point of danger

(Attention: observe documentation!)

Indicates EC conformity

This device may not be disposed of

with the trash. Further information

regarding the WEEE mark can be

accessed on the Internet at

www.gossenmetrawatt.com by

entering the search term ’WEEE’.

3 Connecting the Safety Tester to the Mains

The following connections must first be

established before connecting the safety tester to

the mains:

a) Insert the mains plug from the SECUTEST... into

the earthing contact outlet (12) at the AT3-II I E.

b) Insert the earthing contact plug (13) from the

AT3-III E into the test socket at the

SECUTEST....

c) In order to measure protective conductor

current, connect the SECUTEST port (14) of

the AT3-III E into sockets 2 and 3 at the

SECUTEST....

d) In order to test extension cables, insert the test

probe at the end of the SECUTEST... probe cable

into the socket (15) at the AT3-III E.

Connect the safety tester to 230/400 V mains

power. The safety tester now performs a self-test.

If the tester is intact, the red LED lights up briefly.

4 GMC-I Messtechnik GmbH

Page 5

4 Connecting a Device Under Test

Note!

Note!

to the Safety Tester

After the device under test has passed a visual

inspection and before connecting it to the

appropriate plug or socket at the safety tester, as

well as before each new test, the SECUTEST...

test instrument must be returned to its initial

setting depending upon the type of test.

Connect the device under test to the safety tester

and switch all of its functions on, making sure

that, for example, thermostat contacts are closed

etc. Always measure protective conductor

resistance first for safety class I devices, because

if the protective conductor is defective, insulation

resistance, equivalent leakage current and

protective conductor current cannot be

measured, and high-voltage testing cannot be

performed.

5 Testing Devices

Perform testing in accordance with the operating

instructions included with the SECUTEST... test

instrument!

Observe the following instructions when using the

SECUTEST... in combination with the AT3-II I E

during automatic test sequence :

5.1 Measuring Protective Conductor Resistance

The clip or the test probe at the end of the probe

cable from the SECUTEST... test instrument must

be connected to the housing of the device under

test such that good contact is assured.

Connector cable (13) resistance is 0.07 . In

order to compensate for this error, proceed

as described in the operating instructions

included with the

SECUTEST... test instrument under

Individual Measurements Protective

Conductor Resistance Zero Balancing.

If the AT3-III E is out of use for a prolonged period

of time, the earthing contact faces of the plugand-socket connectors and the connecting plug

(13) may corrode, thus leading to slightly elevated

resistance measurement values. In this case, plug

and unplug the connections several times until the

expected values are reached again.

5.2 Measuring Insulation Resistance and Equivalent Leakage Current

L1, L2, L3 and N (short-circuited) are measured

against PE during insulation testing.

5.3 Measuring Protective Conductor Resistance with the Residual Current Method

The DUT is placed into operation during residual

current measurement. The L1, L2 and L3 mains

lamps light up at the AT3-III E during this test.

This measurement may not be performed on

safety class I devices until after the protective

conductor test has been passed in accordance

with chapter 5.1.

Ð Turn off the device under test.

Ð Select the I

SECUTEST....

Ð The line contactor switches mains power to

the test outlets (1 – 4) at the AT3-I I I E. Signal

lamps L1, L2 and L3 indicate the presence of

line voltage.

Ð Now switch on the DUT

(as described in chapter 2).

Contact current is measured by means of residual

current measurement for safety class II devices,

and safety class I devices with accessible

conductive parts which are not connected to the

protective conductor. Contact all accessible

conductive parts at the device under test with the

test probe at the end of the probe cable form the

SECUTEST... to this end.

These measurements must be performed with the

plug in both positions for DUTs with earthing

contact plugs!

This test must be performed in accordance

with the specified test sequence.

must be indicated by signal lamps L1, L2 and L3 (9)

before switching the device under test on.

The test outlets (1 – 4) are disconnected

from the mains by the safety shutdown

function included with the AT3-II I E for

devices under test with fault currents of

greater than 18 mA during measurement of

protective conductor current with residual

current. Mains power may be disconnected

if the AT3-III E is used in systems protected

with RCCBs rated less than 30 mA. Mains

signal lamps L1, L2 and L3 (9) go out. The

function LED (10) blinks.

Disconnect the AT3-III E from the mains to reset.

Reconnect the AT3-III E to the mains. The safety

tester is once again ready for use after a brief

self-test.

The short-circuit test displayed at the

SECUTEST... cannot be performed due to safety

impedances which have been integrated into the

AT3-III E for testing 3-phase devices.

-DI measurement setting at the

L

Mains power

GMC-I Messtechnik GmbH 5

Page 6

Figure 1 Connecting Single and 3-Phase Devices to the AT3-I I I E and the SECUTEST...

Caution: High-Voltage!

Note!

230/400 V 50 Hz

Safety tester AT3-III E

L3

L2

L1

!

SECUTEST

13

5.4 Testing of Differential Current during Automatic Testing per Test Standard

SECUTEST SII / SIII / SECULIFE ST:

Ð Initiate the standard-specific setup.

Ð Select „Sequence“ and deactivate the auto-

matic test method.

During testing according to standard, a menu

appears which proposes two options, i.e. equivalent leakage current and differential current.

Ð Select „Differential current“.

SECUTEST S2N+ / S2N+10 / S2N+W:

Ð Select switch position „active“ here.

Line voltage is applied to the DUT via the AT3-II I E

tester. The differential current of the DUT is measured while allowing for a function test of the DUT.

5.5 High-Voltage Test

Prior to performing the test remove the

probe including probe tip from sockets 4

and 5 of the SECUTEST.... Do not touch

the DUT, the device plug and the earthing

contact cable of the AT3-III E during the

voltage test.

Do not unplug the AT3-III E connector

cable (13) from the test socket at the

SECUTEST...: the device under test may

still be charged, and high voltage may be

present at the earthing contact plug.

During this test, L1, L2, L3 and N (short-circuited)

are measured against PE with the preset high

voltage (max. 1.5 kV!).

Please observe all additional safety precautions

on performing the test as well as the note on the

exclusion of liability in the operating instructions of

the SECUTEST... test instrument.

6 Testing Extension Cables

The SECUTEST port (14) may remain connected

to sockets 2 and 3 at the SECUTEST... during this

test. Perform testing in accordance with the

operating instructions included with the

SECUTEST... test instrument!

Observe the following instructions when using the

SECUTEST... in combination with the AT3-III E:

The test probe at the end of the probe cable of the

SECUTEST... must first be connected to the respective

socket (15) (probe 1 to 4) of the associated plug at the

AT3-III E. In order to test, only connect the plug and

socket at the ends of the respective extension cable to

be tested to the associated device plug and socket at

the AT3-I I I E.

SECUTEST SII / SIII / SECULIFE ST:

Select the following test sequence from the initial

window at the SECUTEST... test instrument:

Extension cable: “X” WITH EL1

Testing cables by means of the AT3-II I E is

only possible with this setting.

6 GMC-I Messtechnik GmbH

Page 7

SECUTEST S2N+ / S2N+10 / S2N+W:

SECUTEST

3

4

4

4

3

230 V 50 Hz

SECUTEST

1

2

21

230/400 V 50 Hz

Ð Select the following switch position:

VDE 0701-0702

Ð Select EL1 as connection type.

6.1 Measuring Protective Conductor Resistance

Testing is performed according to the instructions

included in chapter 5.1.

6.2 Measuring Insulation Resistance

L1, L2, L3 and N (short-circuited) are measured

against PE during insulation testing. Due to good

cable insulation, a value of 2 M should not be

significantly exceeded.

6.3 Testing for Short-Circuits, Interruptions and

Reversed Conductors

Testing of single-phase cables is performed as

described in the instructions included with the

SECUTEST... under (optional EL1 adapter).

The EL1 adapter accessory is included in the

AT3-III E as a subassembly.

Note:

When testing device cable connections (socket 4/

plug 4) polarity L/N is not being checked.

Testing of 3-phase cables is the same, except that it

also includes an additional test for reversing of

conductors L1, L2, L3 and N.

3-phase cables have only passed testing for

short-circuits, interruptions and reversed

conductors (clockwise rotation) if the following test

result appears: “Cable OK”.

Messages such as “interruption / short-circuit”

always indicate that the cable is defective. If this is

the case, conductors L1, L2, L3 and N may also

be reversed. The actual defect must be

determined.

Figure 2 Connecting Single Phase Extension Cables to the AT3-III E with the SECUTEST...

Figure 3 Connecting 3-Phase (or Single Phase) Extension Cables to the AT3-III E with the SECUTEST...

GMC-I Messtechnik GmbH 7

Page 8

7Self-Test

Note!

Because it is so easy to perform, the self-test should

be conducted before each use of the AT3-II I E.

Please be careful to ensure that the case of the

AT3-III E is not being contacted with devices

under PE or earth potential during the self-test.

Performing the Protective Conductor Test

Ð

Insert the mains plug from the SECUTEST... into

the earthing contact outlet (12) at the AT3-II I E.

Ð The earthing contact plug (13) and the SE-

CUTEST port (14) of the AT3-I I I E may not be

plugged into the SECUTEST....

Ð Connect the AT3-III E to mains power.

Ð Set the SECUTEST... to the protective con-

ductor test individual measurement (R

Ð Contact protective conductor potential at the

mains system which is supplying power to the

AT3-III E with the test probe at the end of the

probe cable from the SECUTEST..., e.g. at the

earthing contact of an earthing contact outlet.

If an excessively high value or interruption is

indicated, the protective conductor is interrupted.

The AT3-III E safety tester must be disconnected

from the mains, and the error in the electrical

system or the safety tester must be corrected.

The AT3-III E is equipped with a “Trigger I

key in order to allow for testing the included I

safety shutdown function at any time.

Performing the I

Self-Test

n

Ð Remove the device under test

(device or extension cable).

Ð Set the SECUTEST... to individual measure-

ment.

Ð SECUTEST... (as of version 3.1): Select the

“DI current” sub-menu (residual current).

Ð Signal lamps L1, L2 and L3 indicate the pres-

ence of line voltage.

Ð Activate the “Trigger I

” key (11).

n

Ð The AT3-III E disconnects mains power from

the outlets (1 – 4).

Ð Signal lamps L1, L2 and L3 go out.

Ð The function LED (10) blinks.

Disconnect the AT3-III E from the mains to reset. Reconnect the AT3-III E to the mains.

The safety tester is once again ready for use

after a brief self-test.

If mains power is not switched during this

test, the fuses in the AT3-III E may have

blown. If the AT3-III E still does not function

SL/RPE

” test

n

n

correctly after replacing the fuses, it must be

removed from service and repaired.

Measurement is no longer possible!

8 Technical Data

Equivalent Leakage Current Measuring Function

Measuring Range 0.00 ... 21.00 mA

Intrinsic Uncertainty

Measuring Range 20.1 … 120.0 mA

Intrinsic Uncertainty

Residual Current Measuring Function

Measuring Range 0 20 mA

Transformation Ratio 1 V per 10 mA

Intrinsic Uncertainty (5%

).

Nominal Ranges of Use

Line Voltage

L1/L2/L3/N 207 253 V AC

Frequency 49 51 Hz

Temperature 0 °C +40 °C

Line Voltage

Waveshape sinusoidal

Reference Conditions

Ambient Temperature +23 C 2K

Relative Humidity 50% 5%

Line Voltage 230 V/400 V 10%

Frequency

of Measured Quantity 50 Hz 0.2 %

Ambient Conditions

Operating Temperatures –10 + 40 C

Storage Temperatures –25 + 60 C

Humidity max. 75%, no

Elevation up to 2000 m

Power Supply

Nominal Line Voltage

Connection only permissible with overload

protection device I

Electrical Safety

Standard

Contamination degree 2

Safety Class I

Residual Current

Shutdown (4-pole) at approx. 18 mA

Device Fuses F0315 L250V

5 x 20 T32mA L 250 V

(5%

of rdg.

(15% of rdg. + 5 d) > 10 d

of rdg.

condensation allowed

3~230/400 V/50 Hz/CAT II

= 16 A I2 1.45 I

n

DIN VDE 0404-1/-2:2002-5

IEC/EN 61010-1:2001

DIN EN 60127-2

+ 5 d) > 10 d

+ 0.05 mA)

n

8 GMC-I Messtechnik GmbH

Page 9

Mechanical Design

Note!

Protection case: IP40

terminals: IP20

Extract from table on the meaning of IP codes

IP XY

(1

X)

Protection against

st

foreign object en-

digit

try

0 not protected 0 not protected

1 50.0 mm dia. 1

2 12.5 mm dia. 2

3 2.5 mm dia. 3 spraying water

4 1.0 mm dia. 4 splashing water

IP XY

nd

(2

Y)

Protection against

the penetration of

digit

water

vertically falling

drops

vertically falling

drops with enclo-

sure tilted 15

Device Return and Environmentally Compatible Disposal

The instrument is a category 9 product

(monitoring and control instrument) in accordance

with ElektroG (German Electrical and Electronic

Device Law). This device is not subject to the

RoHS directive.

We identify our electrical and electronic

devices (as of August 2005) in

accordance with WEEE 2002/96/EG and

ElektroG with the symbol shown to the right per

DIN EN 50419.

These devices may not be disposed with the

trash. Please contact our service department

regarding the return of old devices.

Dimensions 405 x 300 x 220 (mm)

with lid

Weight approx. 6.7 kg

Electromagnetic Compatibility

Intrinsic Uncertainty EN 61326-1:2006

class B

Intrinsic Uncertainty EN 61326:2006

9 Maintenance

Front Panel / Housing

No special maintenance is required for the

housing. Keep outside surfaces clean. Use only a

cloth for cleaning, which has been slightly

dampened with water. Avoid the use of cleansers,

abrasives and solvents.

According to DIN VDE 0701-0702,

measuring instruments used for periodic

testing must be tested and calibrated in

accordance with the manufacturer’s

specifications on a regular basis. Depending

upon usage, the manufacturer recommends

an interval of 1 to 3 years for this test

instrument.

10 Repair and Replacement Parts Service,

Calibration Center and Rental Instrument Service

If required please contact:

GMC-I Service GmbH

Service-Center

Thomas-Mann-Str. 20

90471 Nürnberg • Germany

Phone: +49 911 817718-0

Fax: +49 911 817718-253

E-Mail service@gossenmetrawatt.com

www.gmci-service.com

This address is only valid in Germany.

Please contact our representatives or subsidiaries

for service in other countries.

11 Product Support

If required please contact:

GMC-I Messtechnik GmbH

Product Support Hotline

Phone: +49 911 8602-0

Fax: +49 911 8602-709

E-Mail support@gossenmetrawatt.com

GMC-I Messtechnik GmbH 9

Page 10

Printed in Germany • Subject to change without notice • A pdf version is available on the internet

GMC-I Messtechnik GmbH

Südwestpark 15

90449 Nürnberg •

Germany

Phone +49 911 8602-111

Fax +49 911 8602-777

E-Mail info@gossenmetrawatt.com

www.gossenmetrawatt.com

Loading...

Loading...