Page 1

Operating Instructions

GOSSEN

GOSSEN

METRAWATT

METRAWATT

CAMILLE BAUER

CAMILLE BAUER

LINAX 4000M

14082B

1 / 12.95

Page 2

Contents

Page

1 Installation and startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.1 Scope of delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.2 Choosing the mounting site . . . . . . . . . . . . . . . . . . . . . . 3

1.3 Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.4 Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.4.1 Connecting the input signals . . . . . . . . . . . . . . . . . 4

1.4.2 Connecting the power supply . . . . . . . . . . . . . . . . 4

1.5 Chart loading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.5.1 Recording table for roll chart . . . . . . . . . . . . . . . . . 5

1.5.2 Recording table for fanfold chart . . . . . . . . . . . . . . 5

1.6 Installing the fiber pen insert / print insert . . . . . . . . . . . . 6

1.7 Switching the recorder on. . . . . . . . . . . . . . . . . . . . . . . . 6

1.8 Positioning the recording chart . . . . . . . . . . . . . . . . . . . . 6

2 Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1 Removing the recording chart. . . . . . . . . . . . . . . . . . . . . 7

2.2 Removing the recording chart from the take-up roll. . . . . 7

2.3 Changing the chart speed. . . . . . . . . . . . . . . . . . . . . . . . 7

2.4 Standby function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3 Reconfiguration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.1 Changing the measuring ranges . . . . . . . . . . . . . . . . . . . 8

3.1.1 Hardware matching by means of jumpers. . . . . . . 8

3.2 Replacing scales. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.3 Replacing the label for the measuring points. . . . . . . . . . 9

4 Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4.1 Fuse replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Important information for your safety!

It must absolutely be read and followed!

A condition of correct and safe operation of the continuousline recorder LINAX 400M is that it is transported and stored

in a suitable manner, competently installed and started as

well as correctly operated and carefully serviced.

Only those persons must work on the recorder who ar e familiar with installation, startup, operation and servicing of comparable equipment and who have the qualification required

for their work.

The contents of these operating instructions and the safety

notes affixed to the unit are to be observed.

The regulations, standards and directives mentioned in these

operating instructions are for the Federal Republic of Germany. When using the recorder in other countries, relevant

national rules must be followed.

The recorder is constructed and tested according to

DIN EN 61 010-1 "Safety requirements for electr onic measuring instruments", it left the factory in safe and proper condition. To maintain this condition and to ensure safe operation,

the safety notes in these operating instructions with the

heading "Caution" must be followed. Otherwise, persons

could be endangered and the unit itself as well as other

equipment and facilities could be damaged.

If the information contained in these operating instructions

should not be sufficient in certain cases, the GOSSENMETRAWATT Service will be glad to provide further information.

5 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

6 Packing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Reference symbols in the text

<Key> Designation of the keys in the display and control

panel

Display Non-flashing presentation on the display

Display Flashing presentation on the display

The information "right", "left" or "top", "bottom" – unless otherwise stated – is on the understanding that the viewer looks at the

front.

Supplementary documents

Parameterizing instructions LINAX 4000M 14083B

Interface description LINAX 4000M 14084B

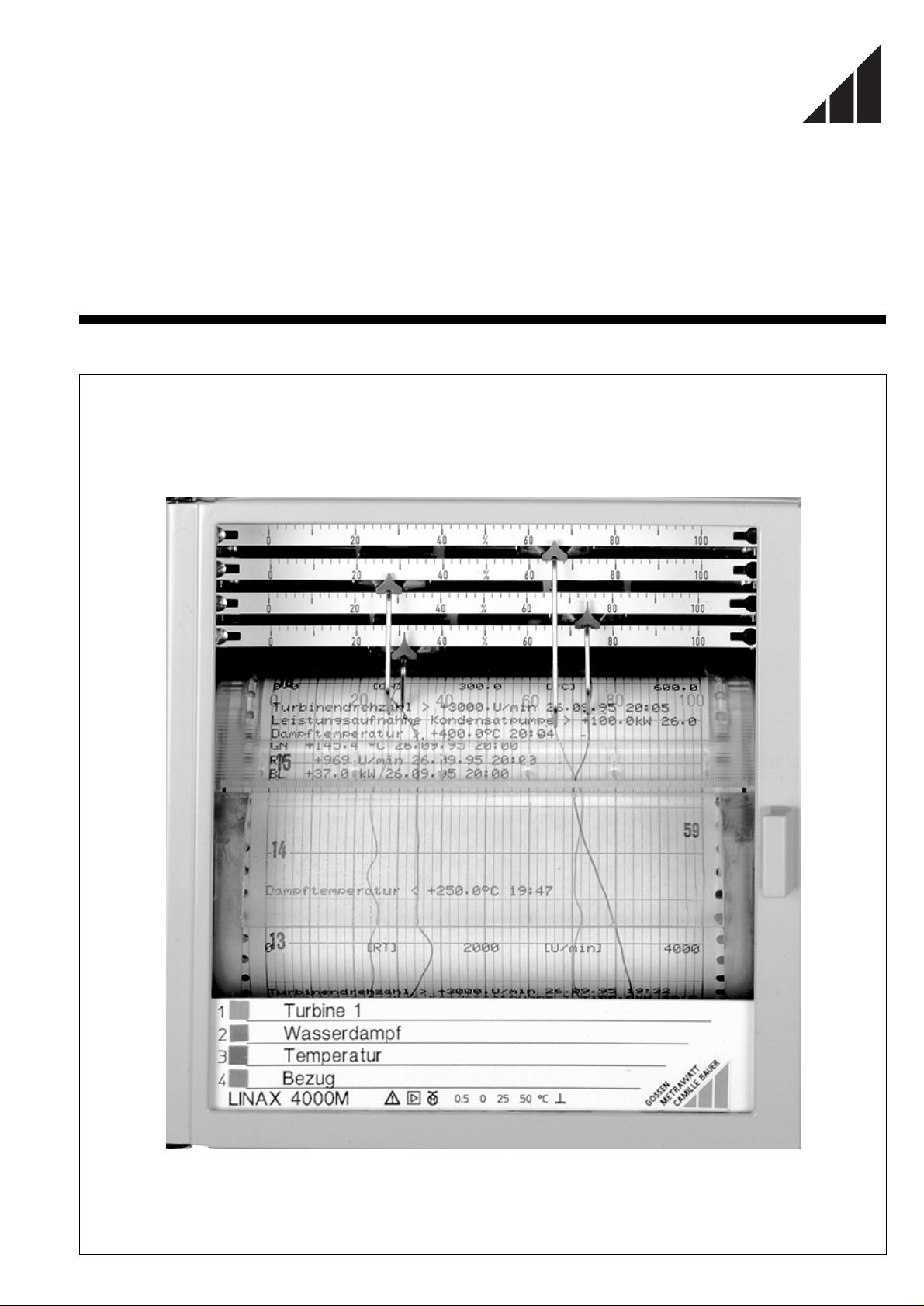

Applications and brief description

The LINAX 4000M is a microprocessor-controlled co ntinuous-line

recorder. It comes in two different versions:

– 1 to 4 line channels,

– 1 to 3 line channels and a printer channel.

The printer channel permits the recording of a measured value

and generates text printouts. The measuring channels are electrically isolated from each other and are floating. The recorder is

connected to transducers and to sensors such as thermocouples

or resistance thermometers. Standard temperature sensor curves

are stored in the firmware of the recorder and linearized with high

accuracy.

In the version "Standard measuring range", the recorder is

matched to the measuring task by means of keys of the display

and control panel or via the RS-485 interface. The version "Universal measuring range" requires additional hardware matching

by means of jumpers.

2 GOSSEN-METRAWATT

Page 3

1 Installation and startup

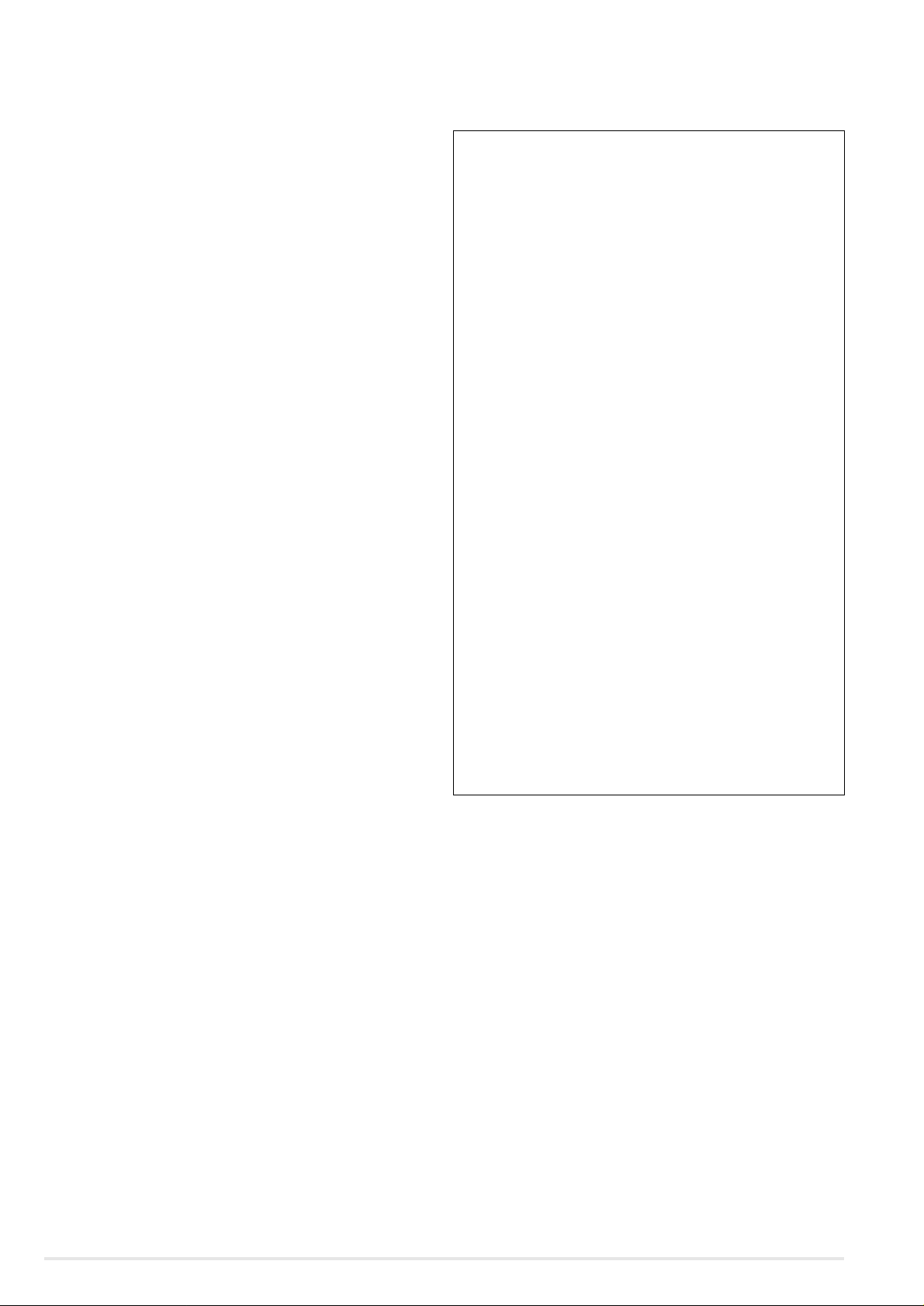

1.1 Scope of delivery

(see figure 1)

The continuous-line recorder LINAX 4000M comes with:

– 1 copy of operating instructions

Be Fastener

De Print insert (Option)

Fe Fiber pen inserts

Fp Fanfold chart

Sk Screw-plug terminals

Sr Chart roll

– 2 fasteners Be

– 1 fiber pen insert Fe per measuring channel

–1 print insert De (Option)

– 1 pack of fanfold chart Fp or 1 roll chart Sr

– 24 jumpers for universal version

– Depending upon the order, the respective number of screw-

plug terminals Sk, Sub-D plug, 9-pin, and reading ruler(s).

Fp

Fe

Figure 1 Scope of delivery of the LINAX 4000M

De

1.2 Selecting the mounting site

Panel cutout

Figure 2 Dimensional drawing LINAX 4000M (dimensions in mm)

Be Sr

Sk

1.3 Installation

(see figure 2 and figure 3)

Installation in switchboards

1. Insert the recorder into the switchboard from the front.

2. At the sides of the case, slide the fasteners Be into the guide

grooves (see figure 3).

Note

The fasteners Be are suited for side-by-side mounting in horizontal or vertical direction.

3. After aligning, equally tighten the fasteners Be.

Position of use Inclination to the side –30°... 0 ... + 30°

Inclination to the rear 20°

Inclination to the front 20°

Ambien t temp. 0 ... 50 °C

Relative humidity ≤ 75 % annual average,

max. 85 %.

Prevent dewing!

Figure 3 Mounting the fasteners

GOSSEN-METRAWATT 3

Page 4

Installation in grid frames

1. Fasten 4 each centering angle bracket (Ordering number

A416A) on the grid frame.

2. Slide the fasteners Be into the guide grooves at the sides of the

case (see figure 3).

3. After alignment, equally tighten the fasteners Be.

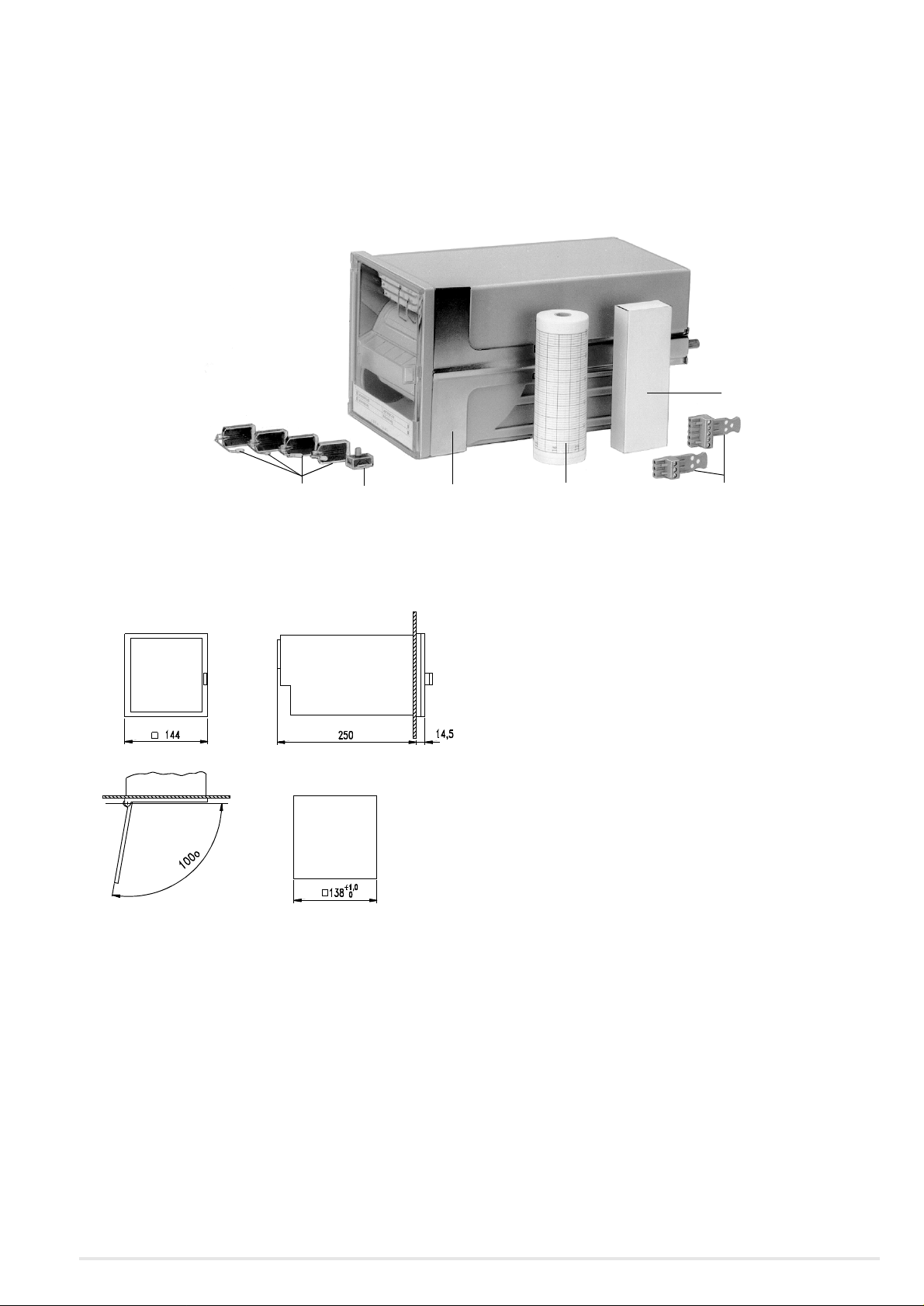

1.4 Connection

(see figure 4)

Caution

Be Fastener

The connection between the protective conductor connection and a protective conductor must be made prior to all other connections.

RS-485 interface

Pin 1: Shield

Pin 3: RXD (+)

Pin 5: Gnd (reference potential)

Pin 6: +5 V

Pin 8: RXD (-)

For bus operation:

The voltage + 5V at pin 6 is required when

the LINAX 4000M is used as bus end device.

The shield is attached to a plug-type

connector on the recorder case.

Signal inputs Limits

Figure 4 Rear panel and wiring diagrams

1.4.1 Connecting the input signals

• Fasten the signal leads in the screw-plug terminals, maximum

cross section 2 × 1mm

2

.

Chart speed circuit (terminals 901, 912, 922

Binary inputs = depending upon the parameterization

for event markers / activation of text print

(terminals 901, 932, 942)

speed 2

speed off

The recorder must only be operated in installed condition.

A power line connection switch of sufficient switching capacity, which

permits all-pole disconnection of the recorder from the power line, must

be provided within reach of the mounting site. It must not annul the protective effect of the protective conductor.

4 GOSSEN-METRAWATT

Page 5

1.5 Chart loading

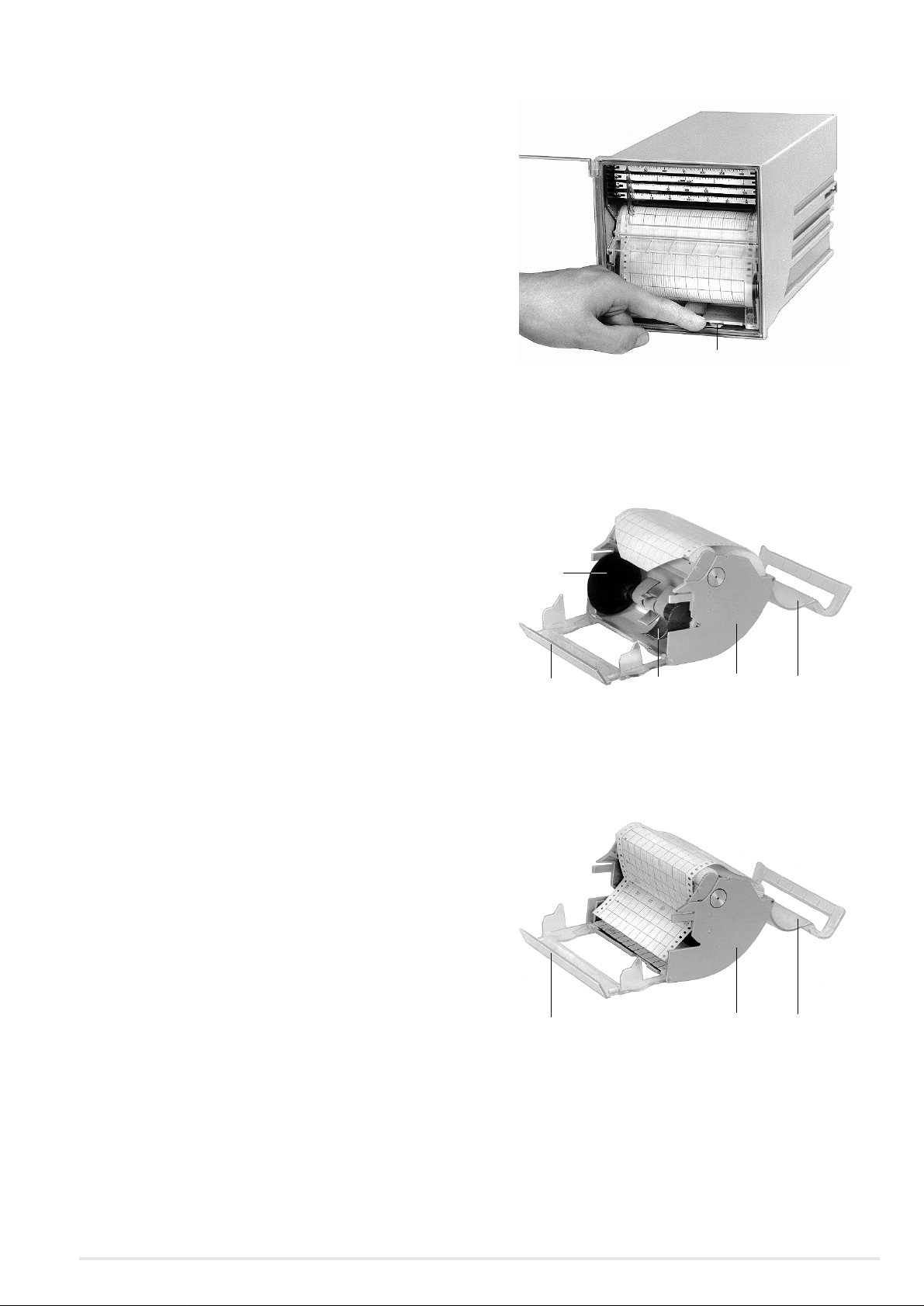

Figure 5 Unlocking the recording table

Eh Unlocking lever

Ar Take-up roll

Ff Guide spring

Pa Paper holddown device

Pf Chart guide

Pm Chart compartment

1.4.2 Connecting the power supply

• Fasten the power supply lines, max. cross section 1 × 4mm2

or 2 × 1.5 mm

the protective conductor must at least correspond to the cross

section of the line power cable.

2

, in the screw terminals. The cross section of

Ar

Pf Ff Pm Pa

Figure 6 Recording table for roll chart

Pa Paper holddown device

Pf Chart guide

Pm Chart compartment

Pf Pm Pa

Figure 7 Recording table for fanfold chart

GOSSEN-METRAWATT 5

Page 6

1.6 Installing the fiber pen insert / print insert

1.5.1 Recording table for roll chart

(see figure 5 and figure 6)

1. Unlock the recording table: Press the unlocking lever Eh downwards (see figure 5). The recording table tilts to the front.

Remove the recording table.

2. Unfold the paper holddown device Pa.

3. Place the chart roll into the chart compartment Pm.

4. Pull the front end of the chart up to the pin platen and place

the perforation onto the pins of the platen. Make sure chart

and pin platen are in parallel!

5. Fold the paper holddown device Pa back.

6. Unfold the chart guide Pf.

7. Insert the take-up roll Ar

8. Fold the chart guide Pf back.

Note

When the recording table has been inserted into the recorder,

the chart automatically winds onto the take-up roll.

9. Swing the recording table into the chassis until it engages.

1. Fold the scales up.

2. Install the fiber pen insert / print insert according to figure 8.

Figure 8 Installing the fiber pen ins e r t / prin t insert

1.5.2 Recording table for fanfold chart

(see fig. 5, fig. 6 and fig. 7)

When changing the recording table for roll chart to fanfold chart,

remove the guide spring Ff (see figure 6).

1. Unlock the recording table: Press the unlocking lever Eh downwards (see figure 5). The recording table tilts to the front.

Remove the recording table.

2. Unfold the paper holddown device Pa.

3. Place the fanfold pack into the chart compartment Pm.

4. Unfold the chart guide Pf.

5. Pull the front end of the chart up to the pin platen and place

the perforation onto the pins of the platen. Two folded layers

must rest on the bottom of the chart compartment. Make sure

chart and pin platen are in parallel!

6. Fold the paper holddown device Pa back.

7. Fold the chart guide Pf back.

8. Swing the recording table into the chassis until it engages.

Figure 9 Display and contro l panel

It is easier to install the fiber pen inserts and the print insert when

the recorder is switched on.

1. Unlock the recording table: Press the unlocking lever Eh downwards (see figure 5). The recording table tilts to the front.

2. Remove the recording table.

3. Press <▲>. The measuring systems travel to the park position.

4. Fold the scales up.

5. Install the fiber pen inserts and the print insert.

6. Fold the scales down.

7. Press < >.

8. Swing the recording table into the chassis until it engages.

6 GOSSEN-METRAWATT

Page 7

1.7 Switching the recorder on

Caution

Prior to switching the power supply on, verify that the operating voltage

of the recorder (see nameplate) and the supply voltage agree.

A power line connection switch of sufficient switching capacity,

which permits all-pole disconnection of the recorder from the

power line, must be provided within reach of the mounting site. It

must not annul the protective effect of the protective conductor.

Date and time are buffered via a capacitor (Super Cap). After

longer periods without auxiliary voltage (e.g. when in stock), date

and time are reset to a default value. At the next start, a note

appears on the display (error message E150X). Date and time

must then be set newly (see parameterizing instructions, orde ring

number 14083).

1.8 Positioning the recording chart

(see figure 10)

1. Press the lower grip boards of the recording table to the rear.

The recording chart is transported with incre ased speed in the

direction of flow.

2. Release the grip boards when the desired time line is reached.

Figure 10 Positioning the recording chart

2Operation

2.1 Removing the recording chart

(see figure 11)

GOSSEN-METRAWATT 7

Page 8

Figure 11 Removing the recording chart

2.2 Removing the rec. chart from the take-up roll

(see figure 12)

The recording table may be left in the unit when removing the

chart.

Recording table for chart rolls

1. Unfold the chart guide downwards.

2. Remove the take-up roll.

3. Eventually separate the chart at the tear-off edge.

Recording table for fanfold chart

1. Unfold the chart guide downwards.

2. Remove the recording chart.

3. Eventually separate the chart at a fold.

Note

Two folded layers of the chart must rest in the chart compartment.

1. Turn the flange without drive pinion through 45° and remove it

from the take-up roll.

2. Grip the chart as shown in figure 12 and pull it off the axle.

3. Re-attach the right flange to the take-up roll and secure it by

turning it through 45° .

4. Insert the take-up roll into the recording table. The drive pinion

must be on the right side.

5. Close the chart guide.

Figure 12 Removing the recording chart from the take-up roll

2.3 Changing the chart speed

When the recorder is fitted with the option "Limit monitor and

binary inputs", two chart speeds are externally selectable. The

desired values for speed 1 and speed 2 are selected in parameterization mode (see parameterizing instructions 14083).

Speed 1 is active after the recorder is switched on.

Speed 2 becomes active by applying a voltage of 24 V DC

between terminals 901 (–) and 922 (+).

2.4 Standby function

When the recorder is fitted with the option "Limit monitor and

binary inputs", the recorder can be switched to standby. This

requires a voltage of 24 V DC to be applied between terminals

901 (–) and 912 (+).

In standby mode, the chart speed is switched off and is 1 mm/h

(depending on the parameterization). The measuring systems are

at the beginning of the scale. Processing of measured data and

limit monitoring are active. When a limit is violated, or when the

applied voltage is disconnected, the standby mode is inactivated.

The recorder starts to record.

8 GOSSEN-METRAWATT

Page 9

3 Reconfiguration

3.1 Changing measuring ranges

3. Unplug the plug to the measuring systems (max. 1...4) and the

plug for the printer channel.

4. Remove the electronic unit (see figure 14).

Standard version

In the version "Standard measuring range", the recorder is

matched to the measuring task via keys of the display and control

panel or via the RS-485 interface. See parameterizing instructio ns

14083.

Universal version

In the version "Universal measuring range", the recorder is

matched to the measuring task via keys of the display and control

panel or via the RS-485 interface. See parameterizing instructio ns

14083.

In addition, hardware matching by means of jumpers is required

on the channel card.

3.1.1 Hardware matching by means of jumpers

(see figure 13))

Ah Locking screw

Removing the channel card (lower circuit board)

1. Undo 4 screws SI (see figure 15).

2. Arrange the jumpers on the wiring side of the channel card in a

channel-specific manner. Figure 16 shows the jumper fields

that are assigned to the channels (X3...X6).

3. Arrange the jumpers in line with the desired measuring mode

and the desired nominal measuring range (see figure 17).

4. Fasten the channel card Kk with the 4 screws SI (see figure 15).

5. Restore the plug connection to the measuring systems.

6. Insert the electronic unit into the recorder.

– Securely engage the locking lever Vh.

7. Slide the carrier of the measuring systems into the case and

tighten th e l oc k i n g sc rew As (see figure 13).

8. Switch the power supply on and parameterize the desired

measuring ranges (see parameterizing instructions 14083).

Sl

Sl

Vh Locking lever

Figure 13

Dk Display card

Ck CPU card

Kk Channel card

Ck

Figure 14 Electronic unit removed (rear view)

Dk

Kk

Sl

Figure 15 Undo the screws SI of the channel card (bottom view)

ANALOG-UNIVERSAL

X3 X4 X5 X6

Channel blue

Channel red

Channel green

1 21 21 21 2

Channel violet

X1

X2

Sl

Figure 16 Arrangement of the jumper fields

Removing the electronic unit

1. Undo the locking screw As (see figure 13) and pull the carrier of

the measuring systems about 2 cm to the front.

2. Lift the locking lever Vh (see figure 13) and at the same time

pull the assembly group to the front.

GOSSEN-METRAWATT 9

Page 10

Current

–20...20 mA

12 12 12 12

Current

0...20 mA

4...20 mA

Thermocouple

Ty pe B,R

S,T

Type E,J, K

L,N, U

7. Check the measuring system zero with beginning of scale.

a. Remove the recording table.

b. Press <↵>. "SYS" is displayed.

The measuring systems travel to electrical zero.

c. Align scale with pointer and tighten the scale screw.

d. Insert the reco rding table.

3.3 Replacing the label for the measuring points

(see figure 19)

Voltage

–75...75 mV

12 12 12 12

Figure 17 Arrangement of jumpers as a relation of measuring mode and

nominal measuring range

Voltage

–20...20 mV

Jumper plugged-in

–50...150 °C

Pt 100

Pt 100

–50...500 °C

3.2 Replacing scales

(see figure 18)

Figure 19 R e p lacing the label f or th e me asuring points

• Remove the flexible label for the measuring points from its

holder and replace it with a new one.

Figure 18 Replacing scales

1. Withdraw the fiber pen inserts.

2. Undo the scale screws at left.

3. Slide the scales to the right and disengage them from the scale

screw.

4. Remove the scales to the left.

5. Install the scales in reverse order.

6. Install the fiber pen inserts.

10 GOSSEN-METRAWATT

Page 11

4 Maintenance

4.1 Fuse replacement

(see figure 20)

Si

Figure 20 Replacing fuse Si

Caution

Make sure that replacement fuses are of the spe ci fied type and the spec ified nominal current rating only. The use of mended fuses or shorting of

the fuse holder is not permissible.

Live parts can be exposed when opening covers or removing parts,

except where this is possible manually. Also connection points may be

live.

1. Unscrew the fuse holder.

2. Replace fuse Si with a new one.

3. Replace the fuse holder.

Fuse values

230 V M 0.16 C

115 V M 0.315 C

24 V M 1.6 E

GOSSEN-METRAWATT 11

Page 12

5 Technical data

Applied rules and standards

A) International standards

IEC 484 Potentiometric recorders

IEC 1010-1 Electrical safety (test vol tages)

IEC 664 Overvoltage category, degree of pollution

IEC 66-2-6 Mechanical stress (vibrations)

IEC 68-2-27 Mechanical stress (shock)

IEC 529 Degrees of protecti on provided by enclosures

IEC 801, EN 60801 Immunity to interference of electromagnetic influences

EN 55011 Radio interference suppression

EN 61010

IEC 721-3-3 Climatic environmental conditions

IEC 742 Classification VDE 0551 safety transformers

B) German standards

DIN 43802 Scales

DIN 16234 Recording paper

DIN 43831 Cases

Symbols and their meaning

Symbol Meaning

X1n / X1 Lower ra nge limit nominal range / lower ra nge limit

X2n / X2 Upper range limit nominal range / upper range limit

X2n – X1n / X2 – X1 Range span nominal range / range span

Analog inputs

Standard v ers ion

DC current 0...20 mA; Ri = 50 Ω

DC voltage ± 10 V; Ri = 1 MΩ

Universal version

DC current 0...20 mA; Ri = 50 Ω

DC voltage ± 10 V; Ri = 1 MΩ

DC voltage ± 10 V; Ri = 1 MΩ

Thermocouples,

Ri ≥ 2 MΩ

Thermocouples,

Ri ≥ 2 MΩ

Resistance thermometer

Pt 100

With 2-wire connection

With 3-wire connection

Safety requirements of measurement and con t rol

equipment

4...20 mA; Ri = 50 Ω

± 20 mA; Ri = 50 Ω

4...20 mA; Ri = 50 Ω

± 20 mA; Ri = 50 Ω

± 60 mV; Ri ≥ 2 MΩ

Type T 0 ... +400 °C

Type J 0 ... +1200 °C

Type L 0 ... +900 °C

Type K 0 ... +1372 °C

Type E 0 ... +1000 °C

Type S 0 ... +1769 °C

Type R 0 ... +1769 °C

Type B 100 ... +1820 °C

Cold junction compensation internally or

externally parameterizable

–50 ... +500 °C; –50 ... 150 °C

Lead resistance 10 Ω max.

Lead resistance 40 Ω max.

Lower range limit parameterizable from X1n ... X1n + 0.8

(X2n – X1n) and range span parameterizeable from 0.2

(X2n – X1n) ... (X2n – X1n).

Deadband 0.25 % of range span

Setting time 2 s

Attenuation of the meas. value with low-pass filter of 1st order;

Time constant 0 ... 60 s per measuring channel, can be parameterized.

Root-extraction function can be parameterized with DC current

and DC voltage measuring ranges.

Accuracy

Deviation for line channels

according to IEC 484

With displacement of lower range limit

and/or upper ran ge limit additionally

Data recording with printer system

according to IEC 484

With internal cold junction compensation ± 4 K, additionally

Class 0.5 referred to range span

± 0.1 % ×

Class 1 referred to range span

X1

X2 – X1

[mV; mA; Ω]

Vari ati ons

Temperature 0.2 % / 10 K, additionally

Humidity Note infl. on rec. paper acc. to DIN 16234

Auxiliary voltage Hn 0.1 % at 24 V DC ± 20 %

AC interference voltages

(see perm. interference voltages)

Magnetic field of external origin 2 mT 0.5 % of range span

Mechanical stress

according to DIN IEC 68-2-6/27

Transport Impact: 30 g/18 ms

Vibration: 2 g/5 ... 150 Hz

In function Vibration:

0.5 g/± 0,04 mm/

5...150 Hz/3 × 2cycles

0.1 % / 10 K with conn. to thermocouple

0.1 % at 24 V AC +10 % / –15 %

0.1 % at 110 V AC +10 % / –15 %

0.1 % at 230 V AC +10 % / –15 %

0.5 % of range span

During and after the effect

± 0.5 % of range span

Reference conditions

Ambient temperature 25 °C ± 1K

Relative humidity 45 ... 75 %

Auxiliary voltage Hn ± 2 %, nominal frequency ± 2%

Mounting position Front upright ± 2°

Warm-up time 30 min

Binary inputs

Number 4

Designation speed 2, speed off, DI 1, DI 2

Auxiliary voltage DC 20 ... 24

...30 V

Input current 6 mA

H signal 20 ... 30V

L signal 0 ... 1.3 V

Outputs for limit monitors (opt ion)

Four potential-free relay contacts (connected with each other on

one side), contact load 30 VA / 100 mA.

Two limits per channel for absolute value monitoring. The four

internal relays can freely be correlated with the limits. Hysteresis

2 % of range span.

Event markers (option)

Only for version with printer channel

Two markers possible

Recording at approx. 2 % and 5 % of the recording width

Control voltage 24 V D C / 6 mA, external

12 GOSSEN-METRAWATT

Page 13

Display

Scale

One graduation per measuring system

Scale face 5 mm wide

Character size 2 mm

Control and display table (only for parameterizing)

Display

5-digit 7-segment display

Size of characters 4 × 7 mm

Operation via 3 keys

Recording

Arrangement of measuring systems and color correlation

Version without printer channel

1234No. of line channels

▲ green

▲ red

▲ blue

▲ violet

Version with printer channel

▲ green

▲ red

▲ blue

violetPrinter channel

1. Line recording

Fiber recording pen with inkwell of approximately 1.4 ml, line

length approximately 1300 m,

distance between the tips of the fiber recording pens 2 mm.

2. Printing

A printer system for printing of texts can be installed in place of

the lower measuring system. Distance between blue fiber pen

and print head 6 mm.

In addition to the text printout, a measured value can be

recorded with the printer system.

Recording of the measured value is made in the form of a dotted line with equidistant dot spacing.

Color supply of the print head approx. 1.5 x 10

Text printout for:

×

×

×

×

×××

×

×

×

1 2 3 No. of line channels

×

×

×××

×

6

dots.

Text printout/recording

Maximum possible chart speed 240 mm/h

Size of characters ca. 1.5 × 2mm

Chart speed 2 chart speeds can be parameterized in

mm/h: 0/2,5/5/10/20/60/120/240/300/

600/1200; can be changed-over and dis-

connected externally (24V DC/6 mA)

Recording chart 32 m roll chart or 16 m fanfold chart

Visible chart length 60 mm

Recording width 100 mm

(chart width 120 mm, DIN 16230)

Chart intake (with roll chart) Via automatic paper take-up device (daily

tear-off or wind-up of the 32 m possible)

Auxiliary voltage

24 V DC ± 20 % or

24/115/230 V AC +10 %/–15 %

Frequency range 47.5 ... 63 Hz

Power consumption with max. fitting approx. 20 W/27 VA

RS-485 interface (optiona lly RS-232 w ith adapter)

a) For parameterizing

b) Linking to host systems for bidirectional data transmission.

Data protocol with reference to the PROFIBUS standard.

Climatic suitability

Ambient temperature 0 ... 25 ... 50 °C

Transport and storage tempera t ure –40 ... +70 °C

Relative humidity ≤ 75 % annual average

max. RH ≤ 85 % in function

Climatic class 3K3 acc. to IEC 721-3-3

Electrical safety

Test according to DIN EN 61010-1 (classifikation VDE 0411)

and/or IEC 1010-1

Protection class I

Overvoltage category III at the power input and degree of pollu-

tion 2 according to VDE 0110 parts 1 and 2

Test voltage

3.75 kV measuring channels to energy supply

2.20 kV protective conductor to energy supply

1. Eight text lines of 16 characters each.

Each text line is supplemented with time printout. Cyclic initia-

Functional extra low voltage with protective iso lation

(PELV according to DIN EN 60950)

tion, in parameterizable intervals or event-depending by internal limits or external stimulation (binary inputs).

2. Printout of chart speed, date and time.

Initiation with recorder ON and with a change in chart speed.

3. Printout of time and date.

Cyclic initiation, in parameterizable time intervals or eventdepending by external stimulation.

4. Printout of actual measured values

Cyclic initiation, in parameterizable time intervals or eventdepending by internal/external stimulation.

5. Printout of double lines correlated with the individual measur-

Between power input – measuring channels, control leads, interface cables acc. to VDE 0100 part 410 and VDE 0106 part 101

Electromagnetic compatibility

The protection goals of the EMC directive 89/336/EWG as to

radio interference suppression according to EN 55011 and as to

immunity to interference according to EN 50082-2 are complied

with.

Radio interference suppression

Limit class B according to EN 55011 and/or

Post Office decree 243/92.

ing points.

First line:

Scaling line with channel designation and printout of the unit.

Second line:

Text specific to the measuring point, max. 32 characters.

6. Listing of all active parameters

Manual initiation in parameterizing mode.

GOSSEN-METRAWATT 13

Page 14

Immunity to interference: Test according to IEC 801

Type of test Test severity Variation Severity level

ESD (1/30ns) 6 kV ≤ 1 % 3

HF field

Radiated 25 MHz ... 1 GHz

Line-guided 0.15 ... 80 MHz

Burst (5/50 ns) on

Power line

Test lead

Surge (1.2/50 µs) on

Power line common

differential

1 MHz pulse on

Power line common

differential

10 V/m

10 V

2kV

1kV

2kV

1kV

2kV

1kV

≤ 1 %

≤ 1 %

≤ 1 %

≤ 1 %

≤ 1 %

≤ 1 %

≤ 1 %

≤ 1 %

3

3

3

3

3

2

3

3

Connection, case and installatio n

Electrical connections

Protection type IP 20

Screw-plug terminals for signal inputs, control inputs and limit

relay outputs

Max. wire cross section 2 x 1 mm

Screw terminals for line connection

Max. wire cross section 4 mm

RS-485 interface via 9-pin SUB-D plug

Case

Molded material for installation in panels or mechanical grids

(see dimensional drawing for dimensions)

Protection type of case according to DIN 40050

IP 54 for the front

IP 20 for the rear

2

2

The NAMUR industry standard EMC is met (Interface cables

shielded).

Permissible interference voltages

Perm. interference

voltage

Series mode interference

voltage peak-to-peak

Push-pull rejection 35dB 35 dB

Common mode

interference voltage

Common mode rejection 70dB 70 dB

Standard version Universal version

≤ 0.3 × meas. span

max. 3 V

60 V DC/42 V AC 60 VDC/42 V AC

≤ 3 × meas. span

max. 3 V

Default parameter setting

If individual parameter setting is not specified when ordering a

recorder, the LINAX 4000M is delivered with the following default

parameter setting:

All measuring channels with 0 ... 20 mA measuring range

Chart speed 1: 20 mm/h

Chart speed 2: 120 mm/h

Chart speed 3: Off

Limits are set to end positions (0 and 20 mA).

Attenuation of measured value, zoom, printer and limit functions are switched off.

No password entered.

This default parameter setting can be re-initialized independent

of the actually set parameters.

Color of case

Silica-gray according to RAL 7032

Door of case

Molded material

Fastening of case

With 2 fasteners (optionally for installation in panel or mechanical grid), centering angle brackets are required for installation

in mechanical grids, (Ordering Number A416A)

Position of use

Inclined to the side [–30° ... 0 ... +30°]

Inclined to the rear 20°,

Inclined to the front 20°

Mounting distance

Horizontal or vertical 0 mm, it must be possible to open the

door of the case through 100°

Weight

3.5 kg, approx.

14 GOSSEN-METRAWATT

Page 15

6Packing

The fiber pen inserts must be removed before the recorder is

transported.

If the original packaging material is no longer available, wrap the

recorder in air-cushion foil or corrugated paper and pack it in a

sufficiently large crate which is lined with shock-absorbing material (foam rubber or smilar material). The thickness of the padding

must be matched to the weight of the device and the type of

packaging. The crate must be marked "Fragile".

When shipped overseas, air-tight welding of the recorder into a

0.2 mm thick polyethylene foil which contains a drying agent is

additionally required. The quantity of the drying agent is to be

chosen in line with the packaging volume and the expected duration of the transport (at least 3 months). The crate must additionally be lined with a layer of double bituminous paper.

GOSSEN-METRAWATT 15

Page 16

Printed in Germany • Subject to change without notice

GOSSEN-METRAWATT GMBH

D-90327 Nürnberg

Company address:

Thomas-Mann-Straße 16-20

D-90471 Nürnberg

Telefon (0911) 8602-0

Telefax (0911) 8602-669

GOSSEN

GOSSEN

METRAWATT

METRAWATT

CAMILLE BAUER

CAMILLE BAUER

Loading...

Loading...