Gorman-Rupp Pumps VS6A60-B User Manual

CDSW

OM‐06014‐01

October 31, 2006

Rev. A 05‐28‐13

INSTALLATION, OPERATION,

AND MAINTENANCE MANUAL

WITH PARTS LIST

ULTRA V PUMP

MODEL

VS6A60-B

INCLUDING: /WW

THE GORMAN‐RUPP COMPANY MANSFIELD, OHIO

www.grpumps.com

GORMAN‐RUPP OF CANADA LIMITED ST. THOMAS, ONTARIO, CANADA Printed in U.S.A.

2006 The Gorman‐Rupp Company

Register your new

Gorman‐Rupp pump online at

www.grpumps.com

Valid serial number and e‐mail address required.

RECORD YOUR PUMP MODEL AND SERIAL NUMBER

Please record your pump model and serial number in the

spaces provided below. Your Gorman‐Rupp distributor

needs this information when you require parts or service.

Pump Model:

Serial Number:

TABLE OF CONTENTS

INTRODUCTION PAGE I - 1.................................................

SAFETY - SECTION A PAGE A - 1...........................................

INSTALLATION - SECTION B PAGE B - 1....................................

Pump Dimensions PAGE B - 1.....................................................

PREINSTALLATION INSPECTION PAGE B - 1............................................

POSITIONING PUMP PAGE B - 1.......................................................

Lifting PAGE B - 1.................................................................

Mounting PAGE B - 2.............................................................

Clearance PAGE B - 2.............................................................

SUCTION AND DISCHARGE PIPING PAGE B - 2.........................................

Materials PAGE B - 2..............................................................

Line Configuration PAGE B - 2......................................................

Connections to Pump PAGE B - 2..................................................

Gauges PAGE B - 2...............................................................

SUCTION LINES PAGE B - 2...........................................................

Fittings PAGE B - 2...............................................................

Strainers PAGE B - 2..............................................................

Sealing PAGE B - 3...............................................................

Suction Lines In Sumps PAGE B - 3.................................................

Suction Line Positioning PAGE B - 3................................................

DISCHARGE LINES PAGE B - 4........................................................

Siphoning PAGE B - 4.............................................................

Valves PAGE B - 4................................................................

Bypass Lines PAGE B - 4..........................................................

AUTOMATIC AIR RELEASE VALVE PAGE B - 5...........................................

Air Release Valve Installation PAGE B - 6............................................

DRIVE ARRANGEMENTS PAGE B - 7...................................................

Dual Motor Drives PAGE B - 7......................................................

Single Motor Belt Drives PAGE B - 7................................................

Single Motor Combination Drives PAGE B - 8........................................

HIGH PUMP TEMPERATURE SHUTDOWN FOR STAGED APPLICATIONS PAGE B - 9........

ALIGNMENT PAGE B - 9..............................................................

Coupled Drives PAGE B - 9........................................................

Drive Belts PAGE B - 10............................................................

DRIVE BELT TENSIONING PAGE B - 10..................................................

General Rules of Tensioning PAGE B - 10.............................................

OPERATION - SECTION C PAGE C - 1......................................

PRIMING PAGE C - 1.................................................................

STARTING PAGE C - 1................................................................

Rotation PAGE C - 1..............................................................

OPERATION PAGE C - 2..............................................................

Lines With a Bypass PAGE C - 2....................................................

Lines Without a Bypass PAGE C - 2.................................................

Leakage PAGE C - 2..............................................................

Liquid Temperature And Overheating PAGE C - 2.....................................

Strainer Check PAGE C - 3.........................................................

i

TABLE OF CONTENTS

(continued)

Pump Vacuum Check PAGE C - 3..................................................

STOPPING PAGE C - 3................................................................

Cold Weather Preservation PAGE C - 3..............................................

BEARING TEMPERATURE CHECK PAGE C - 3..........................................

TROUBLESHOOTING - SECTION D PAGE D - 1..............................

PREVENTIVE MAINTENANCE PAGE D - 3...............................................

PUMP MAINTENANCE AND REPAIR - SECTION E PAGE E - 1................

PERFORMANCE CURVE PAGE E - 1...................................................

PARTS LISTS:

VS6A60-B And VS6A60-B /WW Pump Models PAGE E - 3...........................

Pump Models 46167-041 And 46146-042 PAGE E - 5...............................

46146-001 Ultra Mate Pump Assembly PAGE E - 7...................................

Repair Rotating Assemblies PAGE E - 9.............................................

PUMP AND SEAL DISASSEMBLY AND REASSEMBLY PAGE E - 10.........................

Support Plare Removal PAGE E - 11.................................................

Back Cover And Wear Plate Removal PAGE E - 11.....................................

Rotating Assembly Removal PAGE E - 11.............................................

Impeller Removal PAGE E - 12......................................................

Seal Removal PAGE E - 12..........................................................

Shaft and Bearing Removal and Disassembly PAGE E - 12.............................

Pump Casing and Transition Chamber Removal PAGE E - 13...........................

Pump Casing and Transition Chamber Installation PAGE E - 14.........................

Shaft and Bearing Reassembly and Installation PAGE E - 14............................

Seal Installation PAGE E - 15........................................................

Impeller Installation And Adjustment PAGE E - 18......................................

Rotating Assembly Installation PAGE E - 18...........................................

Back Cover Installation And Adjustment PAGE E - 18..................................

PRESSURE RELIEF VALVE MAINTENANCE PAGE E - 19..................................

Final Pump Assembly PAGE E - 20..................................................

LUBRICATION PAGE E - 20.............................................................

Seal Assembly PAGE E - 20.........................................................

Bearings PAGE E - 20..............................................................

Power Source PAGE E - 20.........................................................

ii

ULTRA V SERIES OM-06014

INTRODUCTION

Thank You for purchasing a Gorman‐Rupp pump.

Read this manual carefully to learn how to safely

install and operate your pump. Failure to do so

could result in personal injury or damage to the

pump. This Installation, Operation, and Mainte

nance manual is designed to help you achieve the

best performance and longest life from your Gor

man‐Rupp pump.

This Installation, Operation, and Maintenance

manual is designed to help you achieve the best

performance and longest life from your Gorman‐

Rupp pump.

Ultra V Series pumps are designed for handling liq

uids containing large entrained solids and slurries.

The basic material of construction for Ultra V Series

pumps is cast iron, with ductile iron impeller and

steel wearing parts.

If there are any questions regarding the pump or

its application which are not covered in this man

ual or in other literature accompanying this unit,

please contact your Gorman‐Rupp distributor, or:

The Gorman‐Rupp Company

P.O. Box 1217

Mansfield, Ohio 44901-1217

Phone: (419) 755-1011

or:

Gorman‐Rupp of Canada Limited

70 Burwell Road

St. Thomas, Ontario N5P 3R7

Phone: (519) 631-2870

dures not addressed in this manual are performed

only after establishing that neither personal safety

nor pump integrity are compromised by such prac

tices.

The following are used to alert maintenance per

sonnel to procedures which require special atten

tion, to those which could damage equipment, and

to those which could be dangerous to personnel:

Immediate hazards which WILL result in

severe personal injury or death. These

instructions describe the procedure re

quired and the injury which will result

from failure to follow the procedure.

Hazards or unsafe practices which

COULD result in severe personal injury

or death. These instructions describe

the procedure required and the injury

which could result from failure to follow

the procedure.

For information or technical assistance on the

power source, contact the power source manufac

turer's local dealer or representative.

This manual will alert personnel to known proce

dures which require special attention, to those

which could damage equipment, and to those

which could be dangerous to personnel. However,

this manual cannot possibly anticipate and provide

detailed precautions for every situation that might

occur during maintenance of the unit. Therefore, it

is the responsibility of the owner/maintenance per

sonnel to ensure that only safe, established main

tenance procedures are used, and that any proce

Hazards or unsafe practices which COULD

result in minor personal injury or product

or property damage. These instructions

describe the requirements and the possi

ble damage which could result from failure

to follow the procedure.

NOTE

Instructions to aid in installation, operation, and

maintenance or which clarify a procedure.

PAGE I - 1INTRODUCTION

ULTRA V SERIES OM-06014

SAFETY - SECTION A

This information applies toUltra V Se

ries pumps. Gorman‐Rupp has no con

trol over or particular knowledge of the

power source which will be used. Refer

to the manual accompanying the power

source before attempting to begin

operation.

Because pump installations are seldom

identical, this manual cannot possibly

provide detailed instructions and pre

cautions for each specific application.

Therefore, it is the owner/installer's re

sponsibility to ensure that applications

not addressed in this manual are per

formed only after establishing that nei

ther operator safety nor pump integrity

are compromised by the installation.

Before attempting to open or service the

pump:

containing large entrained solids or

slurries. Do not attempt to pump vola

tile, corrosive, or flammable materials

which may damage the pump or endan

ger personnel as a result of pump fail

ure.

After the pump has been positioned,

make certain that the pump and all pip

ing connections are tight, properly sup

ported and secure before operation.

Do not operate the pump without the

guards in place over the rotating parts.

Exposed rotating parts can catch cloth

ing, fingers, or tools, causing severe in

jury to personnel.

1. Familiarize yourself with this man

ual.

2. Disconnect or lock out the power

source to ensure that the pump will

remain inoperative.

3. Allow the pump to completely cool

if overheated.

4. Check the temperature before

opening any covers, plates, or

plugs.

5. Close the suction and discharge

valves.

6. Vent the pump slowly and cau

tiously.

7. Drain the pump.

This pump is designed to handle liquids

Do not remove plates, covers, gauges,

pipe plugs, or fittings from an over

heated pump. Vapor pressure within the

pump can cause parts being disen

gaged to be ejected with great force. Al

low the pump to completely cool before

servicing.

Do not operate the pump against a

closed discharge valve for long periods

of time. If operated against a closed dis

charge valve, pump components will

deteriorate, and the liquid could come

to a boil, build pressure, and cause the

pump casing to rupture or explode.

PAGE A - 1SAFETY

ULTRA V SERIESOM-06014

Use lifting and moving equipment in

good repair and with adequate capacity

to prevent injuries to personnel or dam

age to equipment. Suction and dis

charge hoses and piping must be re

moved from the pump before lifting.

Do not install a suction check valve in

the first stage of the VS Series pump

model. Installing a suction check valve

in the first stage of the VS Series pump

model can cause over‐pressurization of

the first stage pump casing, resulting in

possible explosion of the pump and se

rious injury or death to presonnel.

Do not attempt to disengage any part of

an overheated pump unit. Vapor pres

sure within the pump casing can eject

these parts with great force when they

are disengaged. Allow the pump to

completely cool before servicing it.

Pumps and related equipment must be in

stalled and operated according to all na

tional, local and industry standards.

PAGE A - 2 SAFETY

INSTALLATION - SECTION B

OM-06014ULTRA V SERIES

Review all SAFETY information in Section A.

Since pump installations are seldom identical, this

section offers only general recommendations and

practices required to inspect, position, and ar

range the pump and piping.

Most of the information pertains to a standard

static lift application where the pump is posi

tioned above the free level of liquid to be pumped.

If installed in a flooded suction application where

the liquid is supplied to the pump under pressure,

some of the information such as mounting, line

configuration, and priming must be tailored to the

specific application. Since the pressure supplied

to the pump is critical to performance and safety,

be sure to limit the incoming pressure to 50% of

the maximum permissible operating pressure as

shown on the pump performance curve.

For further assistance, contact your Gorman‐Rupp

distributor or the Gorman‐Rupp Company.

Pump Dimensions

Consult the pump Specification Data Sheet or con

sult the factory for the approximate physical dimen

sions of your pump.

PREINSTALLATION INSPECTION

The pump assembly was inspected and tested be

fore shipment from the factory. Before installation,

inspect the pump for damage which may have oc

curred during shipment. Check as follows:

a. Inspect the pump for cracks, dents, damaged

threads, and other obvious damage.

b. Check for and tighten loose attaching hard

ware. Since gaskets tend to shrink after dry

ing, check for loose hardware at mating sur

faces.

Check that the pump shaft rotates counter

clockwise when facing the impeller.

Only operate this pump in the direction in

dicated by the arrow on the pump body

and on the accompanying decal. Refer to

ROTATION in OPERATION, Section C.

d. Check levels and lubricate as necessary. Re

fer to LUBRICATION in the MAINTENANCE

AND REPAIR section of this manual and per

form duties as instructed.

e. If the pump and power source have been

stored for more than 12 months, some of the

components or lubricants may have ex

ceeded their maximum shelf life. These must

be inspected or replaced to ensure maxi

mum pump service.

If the maximum shelf life has been exceeded, or if

anything appears to be abnormal, contact your

Gorman‐Rupp distributor or the factory to deter

mine the repair or updating policy. Do not put the

pump into service until appropriate action has

been taken.

POSITIONING PUMP

Lifting

Pump unit weights will vary depending on the

mounting and drive provided. Check the shipping

tag on the unit packaging for the actual weight, and

use lifting equipment with appropriate capacity.

Drain the pump and remove all customer‐installed

equipment such as suction and discharge hoses

or piping before attempting to lift existing, installed

units.

c. Carefully read all warnings and cautions con

tained in this manual or affixed to the pump,

and perform all duties indicated. Note the di

rection of rotation indicated on the pump.

The pump assembly can be seriously

damaged if the cables or chains used to lift

PAGE B - 1INSTALLATION

OM-06014 ULTRA V SERIES

and move the unit are improperly wrapped

around the pump.

Mounting

Locate the pump in an accessible place as close as

practical to the liquid being pumped. Level mount

ing is essential for proper operation.

The pump may have to be supported or shimmed

to provide for level operation or to eliminate vibra

tion.

Clearance

It is recommended that 18 inches (457 mm) of

clearance be provided in front of the back cover to

permit removal of the cover and easy access to the

pump interior. A minimum clearance of 10-1/2 in

ches (267 mm) must be maintained to permit re

moval of the cover.

SUCTION AND DISCHARGE PIPING

tially increase friction loss. If elbows are necessary,

use the long‐radius type to minimize friction loss.

Connections to Pump

Before tightening a connecting flange, align it ex

actly with the pump port. Never pull a pipe line into

place by tightening the flange bolts and/or cou

plings.

Lines near the pump must be independently sup

ported to avoid strain on the pump which could

cause excessive vibration, decreased bearing life,

and increased shaft and seal wear. If hose‐type

lines are used, they should have adequate support

to secure them when filled with liquid and under

pressure.

Gauges

Most pumps are drilled and tapped for installing

discharge pressure and vacuum suction gauges. If

these gauges are desired for pumps that are not

tapped, drill and tap the suction and discharge

lines not less than 18 inches (457,2 mm) from the

suction and discharge ports and install the lines.

Installation closer to the pump may result in erratic

readings.

Pump performance is adversely effected by in

creased suction lift, discharge elevation, and fric

tion losses. See the performance curve and oper

ating range shown on Page E‐1 to be sure your

overall application allows pump to operate within

the safe operation range.

Materials

Either pipe or hose maybe used for suction and

discharge lines; however, the materials must be

compatible with the liquid being pumped. If hose is

used in suction lines, it must be the rigid‐wall, rein

forced type to prevent collapse under suction. Us

ing piping couplings in suction lines is not recom

mended.

Line Configuration

Keep suction and discharge lines as straight as

possible to minimize friction losses. Make mini

mum use of elbows and fittings, which substan

SUCTION LINES

To avoid air pockets which could affect pump prim

ing, the suction line must be as short and direct as

possible. When operation involves a suction lift, the

line must always slope upward to the pump from

the source of the liquid being pumped; if the line

slopes down to the pump at any point along the

suction run, air pockets will be created.

Fittings

Suction lines should be the same size as the pump

inlet. If reducers are used in suction lines, they

should be the eccentric type, and should be in

stalled with the flat part of the reducers uppermost

to avoid creating air pockets. Valves are not nor

mally used in suction lines, but if a valve is used,

install it with the stem horizontal to avoid air pock

ets.

Strainers

If a strainer is furnished with the pump, be certain

to use it; any spherical solids which pass through a

PAGE B - 2 INSTALLATION

OM-06014ULTRA V SERIES

strainer furnished with the pump will also pass

through the pump itself.

If a strainer is not furnished with the pump, but is

installed by the pump user, make certain that the

total area of the openings in the strainer is at least

three or four times the cross section of the suction

line, and that the openings will not permit passage

of solids larger than the solids handling capability

of the pump.

This pump is designed to handle up to 3 inch (76,2

mm) diameter spherical solids.

Sealing

Since even a slight leak will affect priming, head,

and capacity, especially when operating with a

high suction lift, all connections in the suction line

should be sealed with pipe dope to ensure an air

tight seal. Follow the sealant manufacturer's rec

ommendations when selecting and applying the

pipe dope. The pipe dope should be compatible

with the liquid being pumped.

tion inlet because the inflow will carry air down into

the sump, and air entering the suction line will re

duce pump efficiency.

If it is necessary to position inflow close to the suc

tion inlet, install a baffle between the inflow and the

suction inlet at a distance 1 1/2 times the diameter

of the suction pipe. The baffle will allow entrained

air to escape from the liquid before it is drawn into

the suction inlet.

If two suction lines are installed in a single sump,

the flow paths may interact, reducing the efficiency

of one or both pumps. To avoid this, position the

suction inlets so that they are separated by a dis

tance equal to at least 3 times the diameter of the

suction pipe.

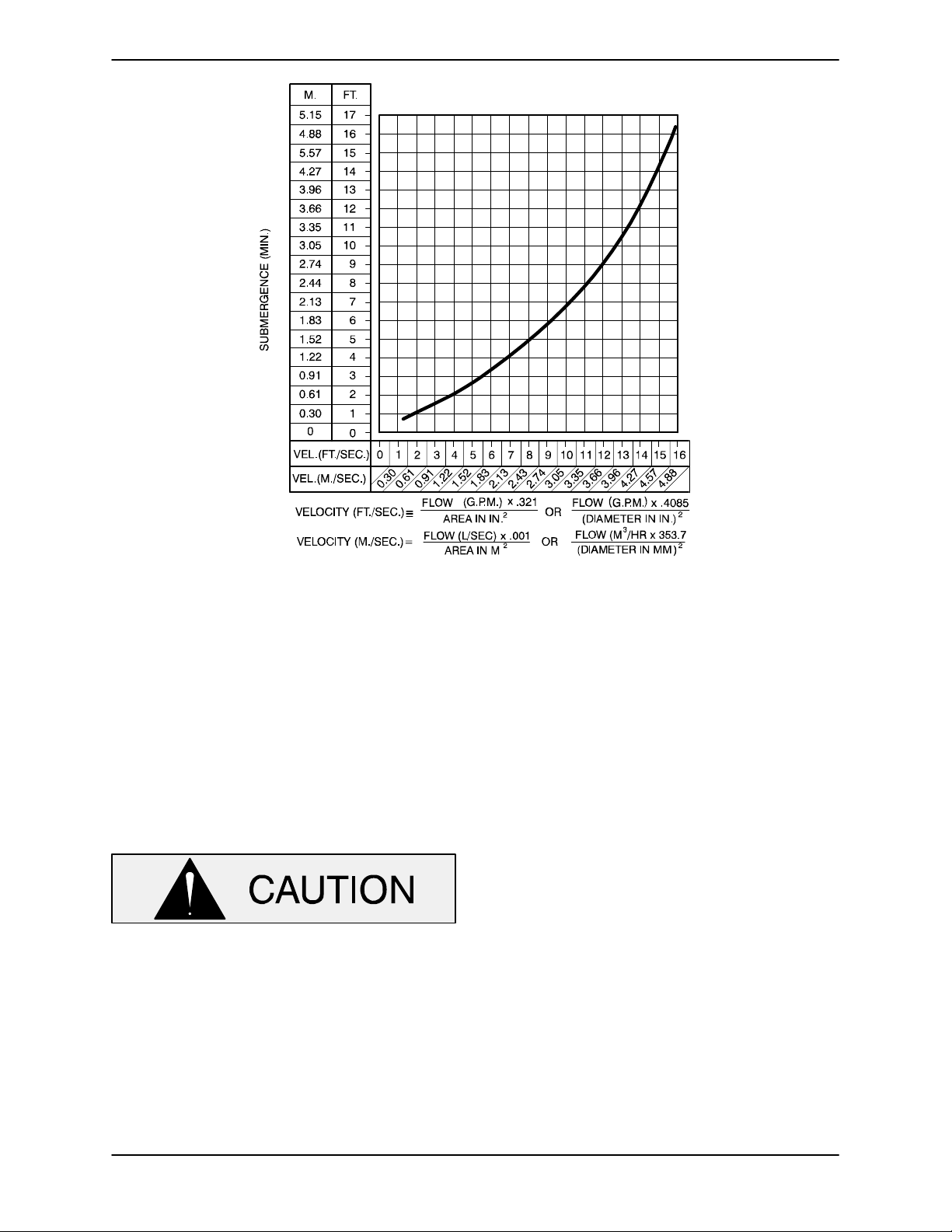

Suction Line Positioning

The depth of submergence of the suction line is

critical to efficient pump operation.

recommended minimum submergence vs. veloc

ity.

Figure 1 shows

Suction Lines In Sumps

If a single suction line is installed in a sump, it

should be positioned away from the wall of the

sump at a distance equal to 1 1/2 times the diame

ter of the suction line.

If there is a liquid flow from an open pipe into the

sump, the flow should be kept away from the suc

NOTE

The pipe submergence required may be reduced

by installing a standard pipe increaser fitting at the

end of the suction line. The larger opening size will

reduce the inlet velocity. Calculate the required

submergence using the following formula based

on the increased opening size (area or diameter).

PAGE B - 3INSTALLATION

OM-06014 ULTRA V SERIES

Figure 1. Recommended Minimum Suction Line Submergence vs. Velocity

DISCHARGE LINES

Siphoning

Do not terminate the discharge line at a level lower

than that of the liquid being pumped unless a si

phon breaker is used in the line. Otherwise, a si

phoning action causing damage to the pump

could result.

Valves

If the application involves a high discharge

head, the discharge throttling valve should

close gradually before the pump is

stopped.

Due to the high discharge head potential

for Ultra V Series pumps, an electronically

controlled or automatic slow‐closing dis

charge throttling valve may be required.

Consult the factory for additional informa

tion on high discharge head applications.

If a throttling valve is desired in the discharge line,

use a valve as large as the largest pipe to minimize

friction losses. Never install a throttling valve in a

suction line.

With high discharge heads, it is recommended that

a throttling valve and a system check valve be in

stalled in the discharge line to protect the pump

from excessive shock pressure and reverse rota

tion when it is stopped.

Bypass Lines

Self‐priming pumps are not air compressors. Dur

ing the priming cycle, air from the suction line must

be vented to atmosphere on the discharge side. If

the discharge line is open, this air will be vented

through the discharge. However, if a check valve

has been installed in the discharge line, the dis

charge side of the pump must be opened to atmos

pheric pressure through a bypass line installed be

tween the pump discharge and the check valve. A

self‐priming centrifugal pump will not prime if

there is sufficient static liquid head to hold the dis

charge check valve closed.

NOTE

The bypass line should be sized so that it does not

PAGE B - 4 INSTALLATION

affect pump discharge capacity; however, the by

pass line should be at least 1 inch in diameter to

minimize the chance of plugging.

In low discharge head applications (less than 30

feet or 9 meters), it is recommended that the by

pass line be run back to the wet well, and located 6

inches below the water level or cut‐off point of the

low level pump. In some installations, this bypass

line may be terminated with a six‐to‐eight foot

length of 1-1/4 inch I.D. smooth‐bore hose; air

and liquid vented during the priming process will

then agitate the hose and break up any solids,

grease, or other substances likely to cause clog

ging.

A bypass line that is returned to a wet well

must be secured against being drawn into

the pump suction inlet.

It is also recommended that pipe unions be in

stalled at each 90 elbow in a bypass line to ease

disassembly and maintenance.

In high discharge head applications (more than

30 feet), an excessive amount of liquid may be by

passed and forced back to the wet well under the

full working pressure of the pump; this will reduce

overall pumping efficiency. Therefore, it is recom

mended that a Gorman‐Rupp Automatic Air Re

lease Valve be installed in the bypass line.

Gorman‐Rupp Automatic Air Release Valves are

reliable, and require minimum maintenance. See

AUTOMATIC AIR RELEASE VALVE in this section

for information about Gorman‐Rupp Automatic Air

Release Valves. Consult your Gorman‐Rupp dis

tributor, or contact the Gorman‐Rupp Company for

selection of an Automatic Air Release Valve to fit

your application.

If the installation involves a flooded suction such as

a below‐ground lift station, a pipe union and manu

al shut‐off valve may be installed in the bleed line to

allow service of the valve without shutting down the

station, and to eliminate the possibility of flooding.

If a manual shut‐off valve is installed anywhere in

the air release piping, it must be a full‐opening ball

type valve to prevent plugging by solids.

OM-06014ULTRA V SERIES

If a manual shut‐off valve is installed in

a bypass line, it must not be left closed

during operation. A closed manual shut‐

off valve may cause a pump which has

lost prime to continue to operate with

out reaching prime, causing dangerous

overheating and possible explosive

rupture of the pump casing. Personnel

could be severely injured.

Allow an over‐heated pump to com

pletely cool before servicing. Do not re

move plates, covers, gauges, or fittings

from an over‐heated pump. Liquid with

in the pump can reach boiling tempera

tures, and vapor pressure within the

pump can cause parts being disen

gaged to be ejected with great force. Af

ter the pump completely cools, drain

the liquid from the pump by removing

the casing drain plug. Use caution when

removing the plug to prevent injury to

personnel from hot liquid.

AUTOMATIC AIR RELEASE VALVE

When properly installed, a Gorman‐Rupp Auto

matic Air Release Valve will permit air to escape

through the bypass line and then close automati

cally when the pump is fully primed and pumping

at full capacity.

Some leakage (1 to 5 gallons [3.8 to 19

liters] per minute) will occur when the

valve is fully closed. Be sure the bypass

line is directed back to the wet well or

tank to prevent hazardous spills.

Consult the manual accompanying the Air Release

Valve for additional information on valve installation

and performance.

PAGE B - 5INSTALLATION

OM-06014 ULTRA V SERIES

Air Release Valve Installation

Staged pump applications generate much higher

operating pressures within the pump casings than

non‐staged pump applications. This high pressure

could cause a suction check valve to fail, resulting

in loss of prime. Therefore, any pump used in a

staged application, whether in the lower or up

per position, must have the suction check valve

removed. The lower stage of the VS Series pump

is designed without a suction check valve, so re

moval of the check valve is not required.

In order to maintain the suction leg and facilitate ini

tial priming (or re‐priming if the suction leg is lost)

without a suction check valve, it is recommended

that staged pump applications be installed using

two discharge check valves, with an automatic Air

Release Valve installed between the two discharge

check valves (see Figure 3). In this manner, when

the liquid level in the sump activates the automatic

liquid level device and starts the pumps, discharge

pressure opens the first discharge check valve, al

lowing any entrained air in the system to escape

through the Air Release Valve. When air in the sys

tem is purged, pressure opens the second dis

charge check valve for full operation.

When the liquid level in the sump lowers enough to

de‐activate the automatic liquid level device and

stop the pumps, the first discharge check valve

closes and creates an air‐tight seal, thus maintain

ing liquid in the pump casing and suction line to al

low the pump to re‐prime when the liquid level in

the sump rises and again activates the automatic

liquid level device.

The second discharge check valve in the staged

application acts as a “shock absorber” to prevent

destructive “water hammer” when the pump shuts

down.

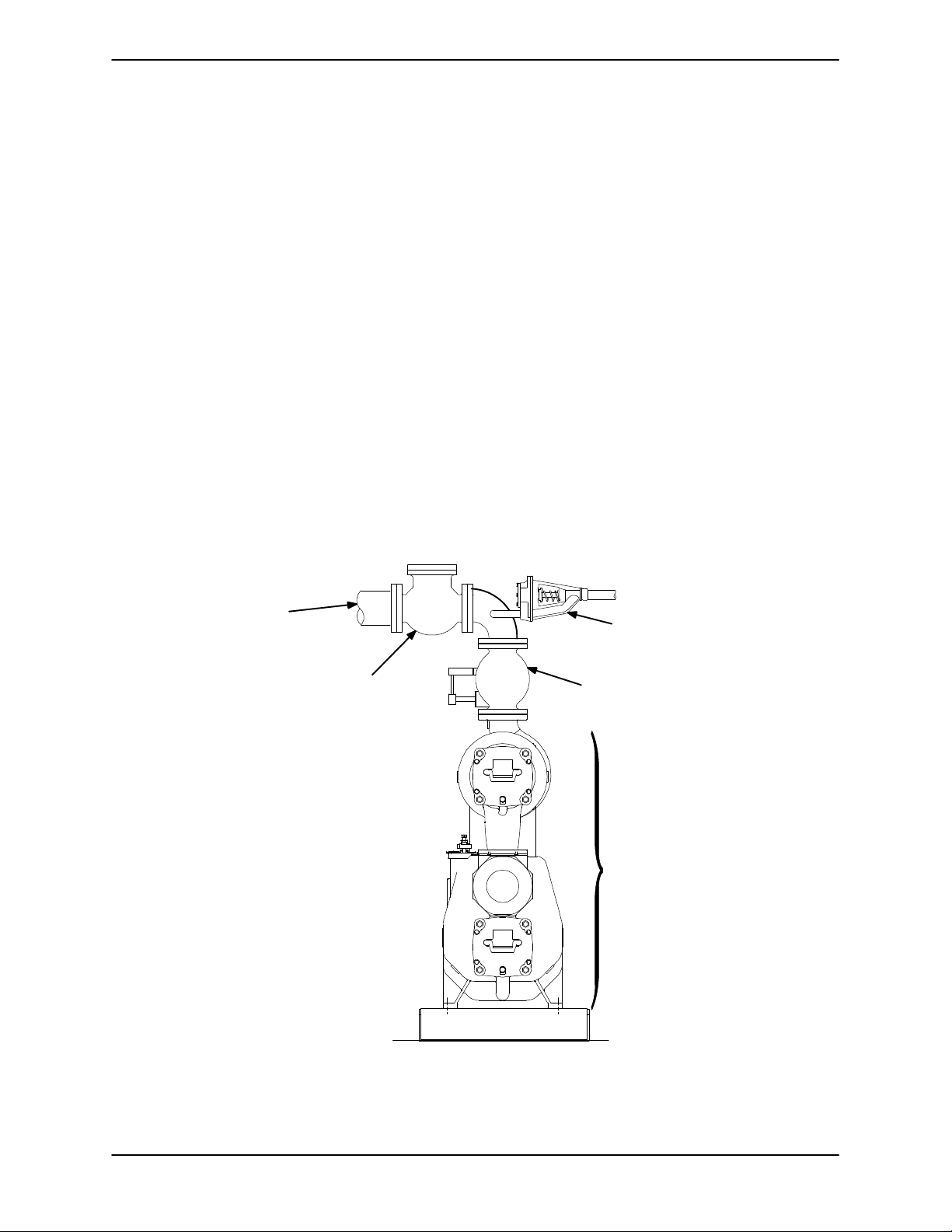

The Automatic Air Release Valve must be inde

pendently mounted in a horizontal position be

tween the discharge check valves. (see Figure 2).

The inlet opening in the Air Release Valve is

equipped with standard 1‐inch NPT pipe threads.

DISCHARGE

PIPE

Figure 2. Typical Automatic Air Release Valve Installation

DISCHARGE

CHECK

VALVE

AIR RELEASE

VALVE

DISCHARGE

CHECK

VALVE

VS SERIES PUMP

NOTE

When installing the Air Release Valve on a staged

pump application, position the Air Release Valve as

PAGE B - 6 INSTALLATION

close as possible to the primary discharge check

valve. Six‐inch and larger discharge check valves

are available drilled and tapped to receive a stan

OM-06014ULTRA V SERIES

dard 1‐inch NPT fitting, or the Air Release Valve may

be installed in a spool flange between the two dis

charge check valves.

Connect the valve outlet to a bleed line which

slopes back to the wet well or sump. The bleed line

must be the same size as the outlet opening or

larger, depending on which Air Release Valve is be

ing used. If piping is used for the bleed line, avoid

the use of elbows whenever possible.

NOTE

For multiple pump installations, it is recommended

that each Air Release Valve be fitted with an inde

pendent bleeder line directed back to the wet well.

If multiple Air Release Valves are installed in a sys

tem, do not direct bleeder lines to a common mani

fold pipe. Contact your Gorman‐Rupp distributor or

the Gorman‐Rupp Company for information about

installation of an Automatic Air Release Valve for

your specific application.

stage pump motor “ramping down” and shutting

off. This “ramp up” and “ramp down” configuration

helps reduce inrush current on startup and de

structive “water hammer” on both startup and shut

down.

DRIVE ARRANGEMENTS

Special consideration must be given to drive ar

rangements for staged pumping applications.

Since pump installations are seldom identical, this

section provides some general recommendations

for selecting drive arrangements for staged

pumps. Consult the factory for information regard

ing your specific application.

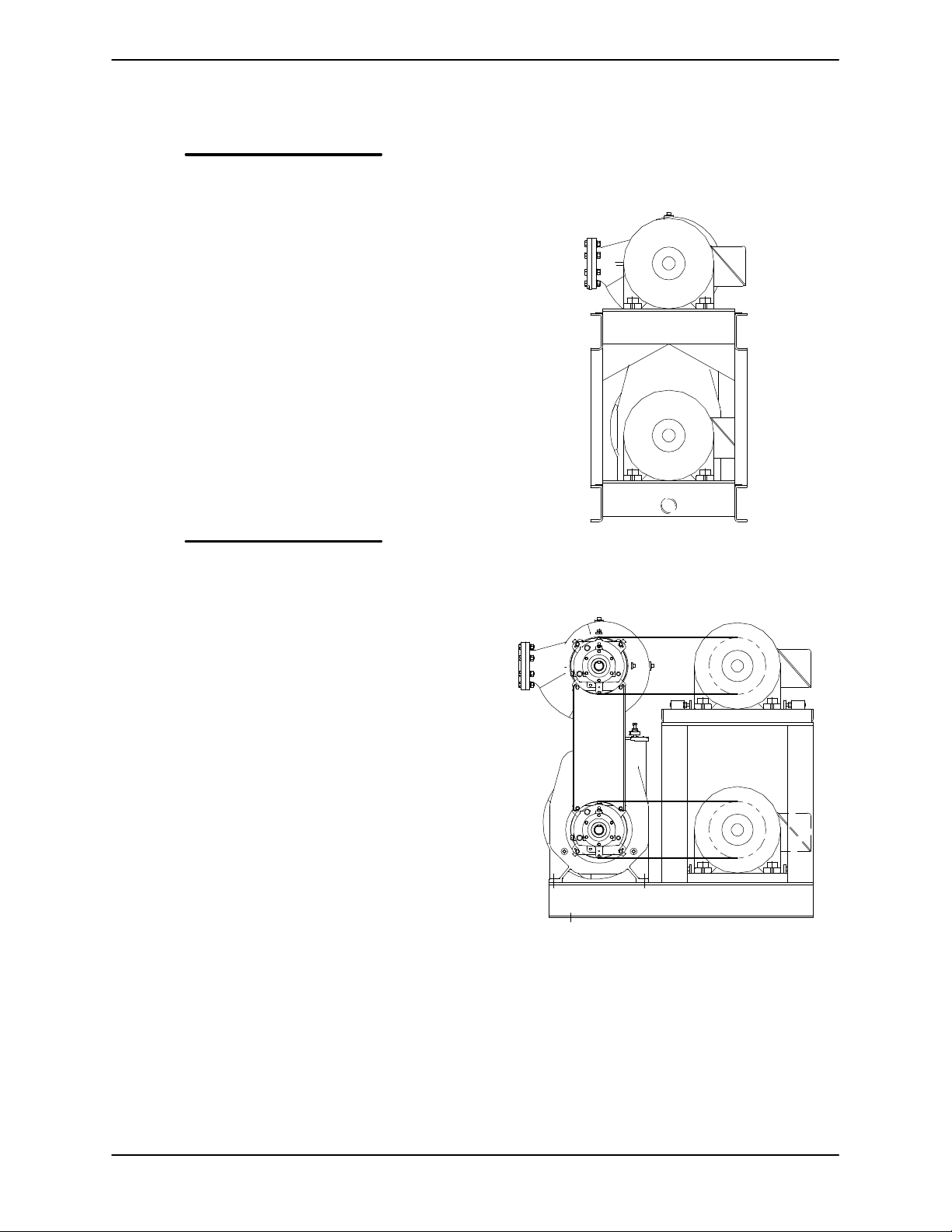

Dual Motor Drives

It is recommended that each pump be directly driv

en by its own electric motor, either through cou

plings (see Figure 3) or a belt arrangement (see

Figure 4).

Each motor should be independently operated

through a reduced voltage solid state (RVSS) start

er, a variable frequency drive (VFD) or an adjust

able speed drive (ASD). In this arrangement, the

motor powering the lower stage pump should be

programmed to start first and “ramp up” to full con

dition speed, then the second stage pump motor

should start and “ramp up” to full condition speed.

Pump motor shutdown should be programmed in

reverse order, with the second stage pump motor

“ramping down” before shutting off, then the first

Figure 3. Recommended Dual Motor Direct

Drive Arrangement

Figure 4. Recommended Dual Motor Belt

Drive Arrangement

Single Motor Belt Drives

In staged applications where both pumps are belt

driven by a single motor (either through a syncro

nous [cog] or V‐belt configuration) certain arrange

ments must be used in order to ensure proper op

eration.

PAGE B - 7INSTALLATION

Loading...

Loading...