GORMAN-RUPP PUMPS S Series, S2E, S2F, S2B Maintenance And Repair Manual

PUBLICATION NUMBER MR-04280

June 29, 1995

Rev. D 05‐15‐12

S SERIES PUMPS

S2B, S2E and S2F

All Materials And Voltages

THE GORMAN‐RUPP COMPANY D MANSFIELD, OHIO

www.grpumps.com

GORMAN‐RUPP OF CANADA LIMITED D ST. THOMAS, ONTARIO, CANADA Printed in U.S.A.

e1995 The Gorman‐Rupp Company

Register your new

Gorman‐Rupp pump online at

www.grpumps.com

Valid serial number and e‐mail address required.

RECORD YOUR PUMP MODEL AND SERIAL NUMBER

Please record your pump model and serial number in the

spaces provided below. Your Gorman‐Rupp distributor

needs this information when you require parts or service.

Pump Model:

Serial Number:

MR-04280 S SERIES PUMPS

INTRODUCTION

Thank You for purchasing a Gorman‐Rupp S

Series Pump. Read this manual carefully to learn

how to safely maintain and service your pump. Fail

ure to do so could result in personal injury or dam

age to the pump.

A set of three manuals accompanies your pump.

The Installation/Operation Manual contains essen

tial information on installing and operating the

pump, and on making electrical connections. The

Parts List Manual provides a performance curve, a

pump model cross‐section drawing, and parts list

for your pump.

This Maintenance and Repair Manual provides

troubleshooting and maintenance instructions re

quired to properly diagnose operational problems,

and to service the pump components. Pump motor

maintenance may be performed only by a Gor

man‐Rupp authorized Submersible repair facility,

or the factory. Otherwise, the pump warranty will be

negated, and damage to the pump, and injury or

death to personnel can result. Contact the factory

for the authorized repair facility closest to you.

As described on the following page, this manual

will alert personnel to known procedures which re

quire special attention, to those which could dam

age equipment, and to those which could be dan

gerous to personnel. However, this manual cannot

possibly anticipate and provide detailed precau

tions for every situation that might occur during

maintenance of the unit. Therefore, it is the respon

sibility of the owner/maintenance personnel to en

sure that only safe, established maintenance pro

cedures are used, and that any procedures not ad

dressed in this manual are performed only after es

tablishing that neither personal safety nor pump in

tegrity are compromised by such practices.

If there are any questions regarding the pump

which are not covered in this manual or in other lit

erature accompanying the unit, please contact

your Gorman‐Rupp distributor or the Gorman‐

Rupp Company:

The Gorman‐Rupp Company

P.O. Box 1217

Mansfield, Ohio 44901-1217

or:

Gorman‐Rupp of Canada Limited

70 Burwell Road

St. Thomas, Ontario N5P 3R7

CONTENTS

SAFETY - SECTION A

TROUBLESHOOTING - SECTION B

ELECTRICAL TESTING PAGE B - 3........................................................

Test Equipment PAGE B - 3...........................................................

Voltage Imbalance PAGE B - 3........................................................

Motor and Power Cable Continuity PAGE B - 4..........................................

Insulation Resistance PAGE B - 4......................................................

PUMP MAINTENANCE AND REPAIR - SECTION C

GENERAL INFORMATION PAGE C - 1.....................................................

Lifting PAGE C - 1....................................................................

TYPICAL PUMP ASSEMBLY PAGE C - 2....................................................

PUMP ASSEMBLY PARTS IDENTIFICATION LIST PAGE C - 3.................................

TERMINAL HOUSING AND CABLE ASSEMBLY PAGE C - 4...................................

TERMINAL HOUSING AND CABLE ASSEMBLY PARTS IDENTIFICATION LIST PAGE C - 5.......

TERMINAL HOUSING AND CABLE ASSEMBLY PAGE C - 6...................................

TERMINAL HOUSING AND CABLE ASSEMBLY PARTS IDENTIFICATION LIST PAGE C - 7.......

PUMP END DISASSEMBLY PAGE C - 8....................................................

PUMP END REASSEMBLY PAGE C - 10....................................................

MOTOR DISASSEMBLY PAGE C - 13......................................................

MOTOR REASSEMBLY PAGE C - 16.......................................................

PAGE I - 1INTRODUCTION

FINAL ASSEMBLY PAGE C - 23...........................................................

VACUUM TESTING PAGE C - 23..........................................................

LUBRICATION PAGE C - 24...............................................................

MR-04280S SERIES PUMPS

RECORDING MODEL AND

SERIAL NUMBERS

Please record the pump model, serial number, volt

age, and motor frame size in the spaces provided

below. Your Gorman‐Rupp distributor needs this

information when you require parts or service.

Pump Model:

Serial Number:

Voltage:

Phase:

WARRANTY INFORMATION

The warranty provided with your pump is part of

Gorman‐Rupp's support program for customers

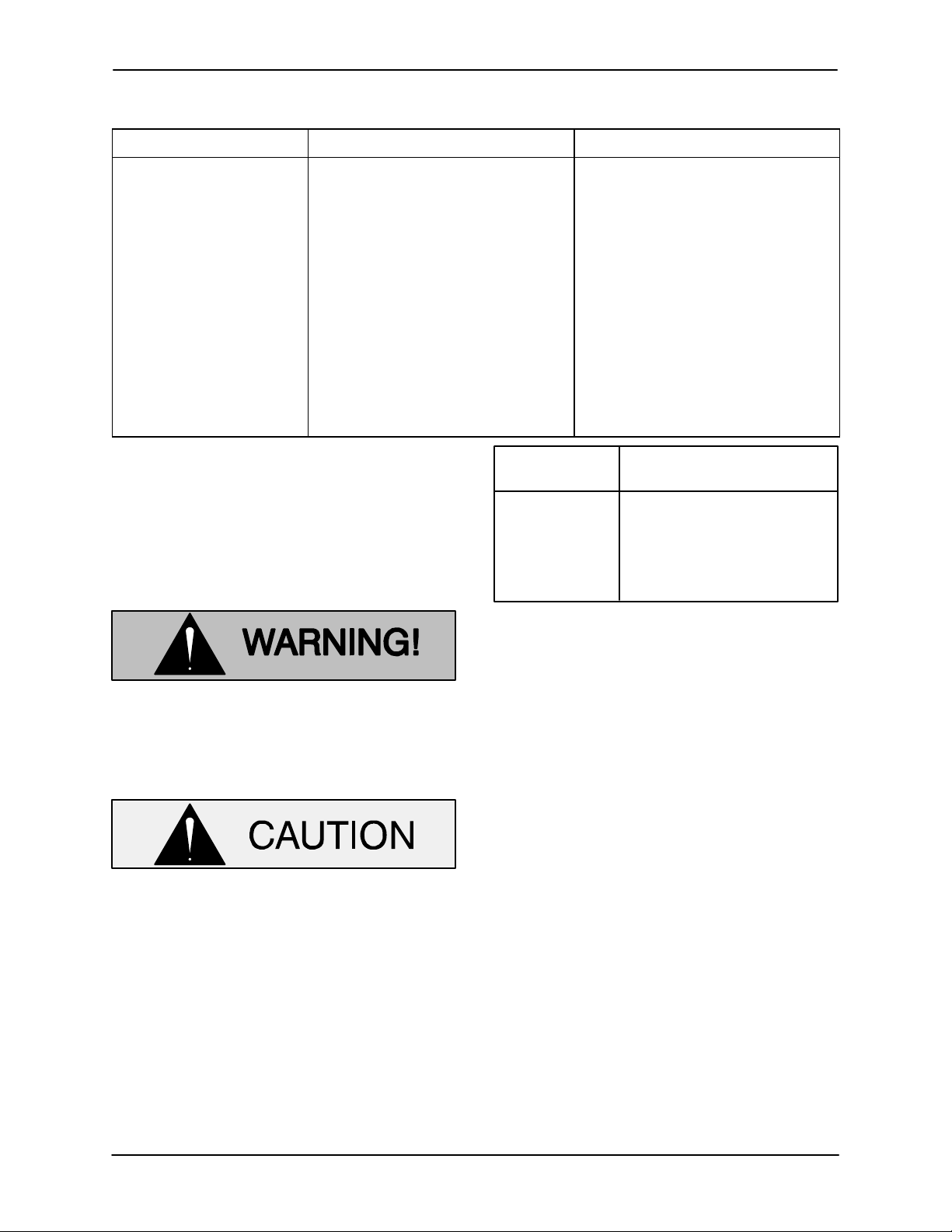

The following are used to alert personnel to procedures which require special attention, to those which

could damage equipment, and to those which could be dangerous to personnel:

who operate and maintain their equipment as de

scribed in this and the other accompanying litera

ture. The integral electric motor must be operated

through the control furnished with the pump as

standard equipment. Please note that should the

equipment be abused or modified to change its

performance beyond the original factory specifica

tions, the warranty will become void and any claim

will be denied.

All repairs to the pump motor must be performed

by a Gorman‐Rupp authorized Submersible repair

facility or the factory. Any repairs to the motor as

sembly performed by the customer or an unautho

rized repair facility negates motor warranty.

Immediate hazards which WILL result in

severe personal injury or death. These

instructions describe the procedure re

quired and the injury which will result

from failure to follow the procedure.

Hazards or unsafe practices which COULD

result in minor personal injury or product or

property damage. These instructions de

scribe the requirements and the possible

damage which could result from failure to

follow the procedure.

NOTE

Hazards or unsafe practices which

Instructions to aid in installation, operation, and

maintenance or which clarify a procedure.

COULD result in severe personal injury

or death. These instructions describe

the procedure required and the injury

which could result from failure to follow

the procedure.

PAGE I - 2 INTRODUCTION

MR-04280 S SERIES PUMPS

SAFETY - SECTION A

The following information applies

throughout this manual to Gorman‐

Rupp S Series submersible motor driv

en pumps.

This manual will alert personnel to

known procedures which require spe

cial attention, to those which could

damage equipment, and to those which

could be dangerous to personnel. How

ever, this manual cannot possibly antici

pate and provide detailed instructions

and precautions for every situation that

might occur during maintenance of the

unit. Therefore, it is the responsibility of

the owner/maintenance personnel to

ensure that only safe, established main

tenance procedures are used, and that

any procedures not addressed in this

manual are performed only after estab

lishing that neither personal safety nor

pump integrity are compromised by

such practices.

4. Close the discharge valve (if

used).

This pump is not designed to pump vol

atile, explosive, or flammable materials.

Do not attempt to pump any liquids for

which your pump is not approved, or

which may damage the pump or endan

ger personnel as a result of pump fail

ure. Consult the factory for specific

application data.

Before connecting any cable to the con

trol box, be sure to ground the control

box. Refer to the Control Box manual for

the suggested grounding methods.

This manual contains essential informa

tion on troubleshooting and maintain

ing the pump. In addition to this manual,

see the separate literature covering in

stallation and operation, pump parts,

and any optional equipment shipped

with the pump.

Before attempting to open or service the

pump:

1. Familiarize yourself with this man

ual.

2. Lock out incoming power to the

control box to ensure that the

pump will remain inoperative.

3. Allow the pump to completely cool

if overheated.

The pump motor is designed to be oper

ated through the control box furnished

with the pump. The control box provides

overload protection and power control.

Do not connect the pump motor directly

to the incoming power lines.

The electrical power used to operate

this pump is high enough to cause inju

ry or death. Obtain the services of a qu

alified electrician to make all electrical

connections. Make certain that the

pump and enclosure are properly

grounded; never use gas pipe as an

electrical ground. Be sure that the in

PAGE A - 1SAFETY

S SERIES PUMPS MR-04280

coming power matches the voltage and

phase of the pump and control before

connecting the power source. Do not

run the pump if the voltage is not within

the limits. If the overload unit is tripped

during pump operation, correct the

problem before restarting the pump.

The electrical power used to operate

this pump is high enough to cause inju

ry or death. Make certain that the control

handle on the control box is in the OFF

position and locked out, or that the pow

er supply to the control box has been

otherwise cut off and locked out, before

attempting to open or service the pump

assembly. Tag electrical circuits to pre

vent accidental start‐up.

Never attempt to alter the length or re

pair any power cable with a splice. The

pump motor and cable must be com

pletely waterproof. Injury or death may

result from alterations.

All electrical connections must be in ac

cordance with The National Electric

Code and all local codes. If there is a

conflict between the instructions pro

vided and N.E.C. Specifications, N.E.C.

Specifications shall take precedence.

All electrical equipment supplied with

this pump was in conformance with

N.E.C. requirements in effect on the

date of manufacture. Failure to follow

applicable specifications, or substitu

tion of electrical parts not supplied or

approved by the manufacturer, can re

sult in severe injury or death and void

warranty.

After the pump has been installed, make

certain that the pump and all piping or

hose connections are secure before op

eration.

Approach the pump cautiously after it

has been running. Although the motor is

cooled by the liquid being pumped, nor

mal operating temperatures can be high

enough to cause burns. The tempera

ture will be especially high if operated

against a closed discharge valve. Never

operate against a closed discharge

valve for long periods of time.

Do not attempt to lift the pump by the

motor power cable or the piping. Attach

proper lifting equipment to the lifting

device fitted to the pump. If chains or

cable are wrapped around the pump to

lift it, make certain that they are posi

tioned so as not to damage the pump,

and so that the load will be balanced.

Obtain the services of a qualified elec

trician to troubleshoot, test and/or ser

vice the electrical components of this

pump.

PAGE A-2 SAFETY

MR-04280 S SERIES PUMPS

TROUBLESHOOTING - SECTION B

Review all SAFETY information in Section A.

The following precautions should be

taken before attempting to service the

pump; otherwise, injury or death could

result.

1. Familiarize yourself with this man

ual and with all other literature

shipped with the pump.

2. Lock out incoming power to the

pump or control box to ensure that

the pump will remain inoperative.

3. Allow the pump to completely cool

if overheated.

4. Check the temperature before

opening any covers, plates or

plugs.

5. Close the discharge valve (if

used).

The electrical power used to operate

this pump is high enough to cause inju

ry or death. Obtain the services of a qu

alified electrician to troubleshoot, test

and/or service the electrical compo

nents of this pump.

NOTE

Many of the probable remedies listed below re

quire use of electrical test instruments; for specific

procedures, see ELECTRICAL TESTING following

the chart.

TROUBLE POSSIBLE CAUSE PROBABLE REMEDY

PUMP FAILS TO START,

OVERLOAD UNIT NOT

TRIPPED

(MANUAL MODE)

(AUTOMATIC MODE)

Table 1. Trouble Shooting Chart

Power source incompatible with con

trol box.

No voltage at line side of circuit

breaker.

Open circuit in motor windings or

power cable.

Defective motor power cable.

Motor defective.

Liquid level device or control circuits

improperly connected to main con

trol box.

Level sensing device(s) improperly

positioned.

Level sensing device(s) fouled with

mud or foreign material.

Correct power source.

Check power source for blown fuse,

open overload unit, broken lead, or

loose connection.

Check continuity.

Replace cable.

Check for and replace defective unit.

Check wiring diagrams; correct or

tighten connections.

Position device(s) at proper level.

Clean sensing device(s).

TROUBLESHOOTING PAGE B - 1

S SERIES PUMPS MR-04280

Table 1. Trouble Shooting Chart (cont.)

TROUBLE

(AUTOMATIC MODE)

(CONT'D.)

OVERLOAD UNIT TRIPS Low or high voltage, or excessive

MOTOR RUNS, BUT

PUMP FAILS TO

DELIVER RATED

DISCHARGE

POSSIBLE CAUSE PROBABLE REMEDY

Float type sensing device(s) tangled

or obstructed.

Defective liquid level sensing de

vice(s) or control panel.

voltage drop between pump and

control box.

Defective insulation in motor wind

ings or power cable; defective wind

ings.

Impeller jammed due to debris or

insufficient clearance.

Bearing(s) frozen.

Discharge head too high.

Low or incorrect voltage.

Check installation for free move

ment of float.

Repair or replace defective unit(s).

Measure voltage at control box.

Check that wiring is correct type,

size, and length. (See Field Wiring

Connections, Section B).

Check insulation resistance; check

continuity.

Disassemble pump and check im

peller.

Disassemble pump and check

bearing(s).

Reduce discharge head, or install

staging adaptor and additional

pump.

Measure control box voltage, both

when pump is running and when

shut‐off.

Discharge throttling valve partially

closed; check valve is installed im

properly.

Discharge line clogged or re

stricted; hose kinked.

Liquid being pumped too thick.

Strainer screen or impeller clogged.

Insufficient liquid in sump or tank.

Worn impeller vanes; excessive im

peller clearance.

Pump running backwards.

Open discharge valve fully; check

piping installation.

Check discharge lines; straighten

hose.

Dilute liquid by heating if possible.

Clear clog(s). Stop pump; back flow

may flush away debris.

Stop pump until liquid level rises.

Check impeller and clearance. See

PUMP END REASSEMBLY.

Check direction of rotation and cor

rect by interchanging any two motor

leads at control box. (See Pump

Rotation, Section C).

TROUBLESHOOTINGPAGE B - 2

MR-04280 S SERIES PUMPS

Table 1. Trouble Shooting Chart (cont.)

TROUBLE

PUMP RUNS WITH

EXCESSIVE NOISE OR

VIBRATION

POSSIBLE CAUSE PROBABLE REMEDY

Pumping entrained air.

Damaged or unbalanced impeller.

Discharge piping not properly sup

ported.

Impeller jammed or loose.

Motor shaft or bearings defective.

Pump cavitation.

ELECTRICAL TESTING

If you suspect that pump malfunctions are caused

by defects in the motor, power cable or control box,

perform the following checks to help isolate the de

fective part.

Check liquid level in sump; check

position of pump and liquid level

sensing device(s).

Replace impeller.

Check piping installation.

Check impeller.

Disassemble pump and check mo

tor and bearings.

Reduce discharge head, or restrict

flow on low head applications.

Equipment Use

Ammeter To check AC Voltage

and current (amperage)

Ohmeter To measure resistance

(ohms) to ground

Obtain the services of a qualified elec

trician to troubleshoot, test and/or ser

vice the electrical components of this

pump.

Be certain to refer to the wiring diagram(s)

in the Installation Section of this manual be

fore reconnecting any electrical compo

nents which have been disconnected.

Test Equipment

A volt/amp/ohmmeter and megohmeter of ade

quate range and quality will be required to conduct

the following electrical tests. The suggested equip

ment indicated below is commercially available, or

an equivalent substitute may be used.

Voltage Imbalance

Each phase of the incoming three‐phase power

must be balanced with the other two as accurately

as a commercial voltmeter will read. If the phases

are balanced, check out the motor as described

below. If the phases are out of balance, contact

your power company and request that they correct

the condition.

a. Use a voltmeter, amprobe, or equivalent me

ter to read the voltage across terminals 1 &

2, 2 & 3, and 1 & 3 in the control box. All three

measured voltages must be the same, as

accurately as the meter will read. If possible,

measure the voltage with the pump off, with

the pump running but out of the water, and

with the pump running in the water at full

load. All the measured voltages at each con

dition must be the same.

b. Use an amprobe or equivalent meter to

measure the current draw of each phase

while the pump is running at full load and at

no load. All three amperage readings must

TROUBLESHOOTING PAGE B - 3

S SERIES PUMPS MR-04280

be the same at each condition, as accurate

ly as the meter will read. Nominal amperage

values are listed in Table 1, but these apply

only when the actual voltage at the site is the

nominal voltage listed.

c. If the voltages are balanced with the pump

off, but are unbalanced when the pump is

running, a thorough check of the power

source, all interconnecting cables, and the

pump motor is required to isolate the defect.

Motor And Motor Power Cable Continuity

To check continuity, zero‐balance the ohmmeter

set at the RX1 scale, and test as follows:

a Disconnect the motor power cable leads

from the control box and connect the test

leads to any two of the three power cable

leads (not to the green ground lead or yellow

ground check lead). If there is a high resis

tance reading on the ohmmeter, there is an

open or broken circuit caused by a break in

the power cable or motor windings, or by a

bad connection between the motor and the

power cable. Switch one test lead to the

third power lead, and test again.

b. If an open or broken circuit is indicated,

check the power cable for obvious damage,

and replace as necessary (see MAINTE

NANCE AND REPAIR). If there is no appar

ent damage to the motor cable, remove the

terminal housing (see MAINTENANCE

AND REPAIR) and check the continuity of

each power cable lead at the terminal posts.

NOTE

When shipped from the factory, the connections be

tween the power cable leads and the terminal posts

were encapsulated in heat shrink tubing and

bonded to the terminal plate to provide a water tight

seal. In service, these connections may have been

potted by the pump operator. Do not cut the tubing

or potting away unless absolutely necessary.

Check the continuity of each lead from the motor

side of the terminal plate. If the continuity is good,

there is no need to remove the tubing or potting ma

terial. If there is no continuity through the lead, re

move the tubing or potting from only that terminal,

and check for a loose connection. Be sure to re

place the tubing or potting and allow adequate dry

ing time before putting the pump back into service.

(See Power Cable Reassembly, Section E).

c. If an open circuit still exists after each lead

(terminal) has been tested and tightened,

then the entire motor power cable must be

replaced. Splicing or other means of repair

are not recommended.

d. If no break is found in the power cable,

check the motor leads for continuity. If the

test reading indicates an open or broken cir

cuit, there is an open circuit in the motor.

NOTE

It is recommended that a pump with a defective mo

tor be returned to Gorman‐Rupp, or to one of the

Gorman‐Rupp authorized Submersible Repair

Centers.

Insulation Resistance

To check insulation, zero‐balance the ohmmeter

set at the RX100K scale, and test as follows:

a. Disconnect the motor power cable leads

from the control box. Connect one test lead

to the power cable green ground lead, and

touch the other test lead to each of the three

power leads in turn.

b. The reading obtained will indicate resis

tance values in both the power cable and the

motor windings. If the resistance reading is

infinity (1), the insulation is in good condi

tion. If the reading is between infinity (1)

and 1 megohm, the insulation is acceptable

but should be rechecked periodically. If the

reading is less than 1 megohm, the insula

tion should be checked more closely; a

reading of zero indicates that the power

cable or the motor is grounded.

c. To determine whether the power cable or

the motor is grounded, remove the terminal

housing (see MAINTENANCE AND RE

PAIR), disconnect the motor leads from the

motor terminals, and test the power cable

leads and motor leads separately.

TROUBLESHOOTINGPAGE B - 4

MR-04280 S SERIES PUMPS

PUMP MAINTENANCE AND REPAIR - SECTION C

GENERAL INFORMATION

Review all SAFETY information in Section A.

Do not attempt to service the pump as

sembly unless all power to the motor

has been shut off at the control box;

otherwise, injury or death could result.

Use a lifting device with sufficient ca

pacity. If slings or chains are used to

move the pump or components, make

sure that the load is balanced; other

wise serious personal injury or death

could result.

The maintenance and repair instructions in this

manual are keyed to the sectional views, Figures

C-1, C-2 or C-3, and the corresponding parts

identification lists. Refer to the separate Parts List

Manual for replacement parts.

formed by a Gorman‐Rupp authorized

Submersible repair facility or the factory.

Any repairs to the motor assembly per

formed by the customer or an unautho

rized repair facility negates the warranty.

This Maintenance and Repair Manual provides

troubleshooting and maintenance instructions re

quired to properly diagnose operational problems,

and to service the pump components. Pump motor

maintenance may be performed only by a Gor

man‐Rupp authorized Submersible repair facility,

or the factory. Otherwise, the pump warranty will be

negated, and damage to the pump, and injury or

death to personnel can result. Contact the factory

for the authorized repair facility closest to you.

Check TROUBLESHOOTING, Section B to deter

mine causes and remedies of pump problems.

Disassemble the pump only as far as required.

Lifting

Select a suitable location, preferably indoors, to

perform required maintenance. All work must be

performed by qualified personnel.

All repairs to the pump motor must be per

Use lifting equipment with a capacity of at least

five times the weight of the pump, including the

weight of any options or customer‐installed acces

sories. The approximate maximum weight for this

group of pumps is 73 lbs. (33 kg.). Discharge

hose or piping must be removed before attempt

ing to lift the pump.

PAGE C - 1MAINTENANCE AND REPAIR

Loading...

Loading...