Page 1

AC

OM-04136

January 21, 1998

Rev. C 09-03-03

INSTALLATION AND

OPERATION MANUAL

WITH P ARTS LISTS

CONTROL BOXES

MODELS

27515--503 27515--504 27515--505 27515--506

27515--507 27515--513 27515--514 27515--515

27515--516 27515--517 27515--524 27515--525

27515--534 27515--535 27515--543 27515--544

27515--545 27515--546 27515--554 27515--571

27515--572

THE GORMAN-RUPP COMPANY F MANSFIELD, OHIO

GORMAN-RUPP OF CANADA LIMITED D ST. THOMAS, ONTARIO, CANADA Printed in U.S.A.

ECopyright by the Gorman-Rupp Company

Page 2

TABLE OF CONTENTS

INTRODUCTION PAGE I --- 1.................................................

SA FE T Y --- SE C TIO N A PA G E A --- 1...........................................

IN STA L LAT ION --- SEC T IO N B PA G E B --- 1....................................

GENERAL INFORMATION PAGE B --- 1..................................................

PREINSTALLATION INSPECTION PAGE B --- 1............................................

CONTROL BOX INSTALLATION P AGE B --- 1.............................................

Enclosure PA GE B --- 1.............................................................

CONTROL BOX DIMENSIONS PAGE B --- 1..............................................

ELECTRICAL CONNECTIONS PAGE B --- 6...............................................

Grounding Methods PAGE B --- 6....................................................

Field Wiring Connections (Incoming Power) P AGE B --- 7...............................

Pump Motor Voltage Limits PAGE B --- 7..............................................

Power Cable Connections PA GE B --- 7...............................................

Control Box Adjustments PAGE B --- 7................................................

WIRING DIAGRAMS PAGE B --- 8.......................................................

Parts Lists:

Control Boxes 27515---503, 27515---513 And 27515---543 PAGE B --- 8...................

Control Boxes 27515---504, 27515---514 27515---544 And 27515---554 PAGE B --- 11........

Control Boxes 27515---505, 27515---515 And 27515---545 PAGE B --- 13...................

Control Boxes 27515---506, 27515---516 And 27515---546 PAGE B --- 15...................

Control Boxes 27515---507 And 27515---517 PAGE B --- 17...............................

Control Boxes 27515---524 And 27515---534 PAGE B --- 19...............................

Control Boxes 27515---525 And 27515---535 PAGE B --- 21...............................

Control Boxes 27515---571 And 27515---572 PAGE B --- 23...............................

Control Box Da ta Chart PAGE B --- 25.................................................

27515---571 And 27515---572 Control Box Data PAGE B --- 26............................

Control Box Torque Values PAGE B --- 26..............................................

OPER AT IO N --- SE C T IO N C PA G E C --- 1......................................

CONTROL BOX FUNCTION PAGE C --- 1.................................................

Component Function P AGE C --- 1...................................................

TR OUB LES HOO TI NG --- SE CTI ON D PA G E D --- 1..............................

ELECTRICAL TESTING PAGE D --- 2.....................................................

Test Equipment PA GE D --- 2........................................................

Voltage Imbalance PAGE D --- 2.....................................................

i

Page 3

OM--04136 CONTROL BOXES

INTRODUCTION

Read this manual carefully to learn how to safely

install and operate your control box. Failure to do

so couldresult in personal injury or damage to the

control box or the pump.

This manual does not include maintenance instructions. Have a qualified electrician perform all

maintenance. Be sure to follow all safety precautionsas outlinedby the NationalElectric Codeand

all local codes.

Thecontrolboxis arainproof enclosure with apadlockable front cover. The enclosure is not de-

signed to be watertight, and should not be submerged. They are designed for use with 200, 230,

460, 575 or 380 volts, depending on your pump.

The integral electric motor of the submersible

pump must be operated through the control box.

The control box is not explosion-proof and should

not be operated in a hazardous atmosphere.

Because pump installations are seldom identical,

this manual cannot possibly provide detailed instructions and precautions for every aspect of

each specific application. Therefore, it is the responsibility of the owner/installer of the pump to

ensure that applications not addressed in this

manual are performed only after establishing that

neither operator safety norpump integrity are compromised by the installation. Pumps and related

equipment must be installed and operated ac-

cording to all national, local and industry standards.

Ifthereareanyquestionsregardingthecontrolbox

which are not covered in this manual or in other literature accompanying the unit, please contact

your Gorman-Rupp distributor or the GormanRupp Company:

RECORD CONTROL BOX NUMBER

Please record the control box number, voltage,

andphasein thespaces providedbelow.YourGorman-Ruppdistributor needs this informationwhen

you require parts or service.

Control Box:

Voltage:

Phase:

WARRANTY INFORMATION

The warrantyprovided with your control box ispart

ofGorman-Rupp’ssupportprogram for customers

who operate and maintain their equipment as described in this and the other accompanying literature. Please note that should the equipment be

abused or modified to change its performance beyond the original factory specifications, the warranty will become void and any claim will be denied.

The following are used to alert personnelto procedures which require special attention, to those

which could damage equipment, and to those

which could be dangerous to personnel:

Immediate hazards whichWILLresultin

severe personal injury or death. These

instructions describe the procedure required and the injury which will result

from failure to follow the procedure.

The Gorman-Rupp Company

P.O. Box 1217

Mansfield, Ohio 44901--1217

or:

Gorman-Rupp of Canada Limited

70 Burwell Road

St. Thomas, Ontario N5P 3R7

INTRODUCTION

Hazards or unsafe practices which

COULDresult in severe personal injury

or death. These instructions describe

the procedure required and the injury

which could result fromfailure to follow

the procedure.

PAGE I -- 1

Page 4

OM--04136CONTROL BOXES

damage which could result from failure to

follow the procedure.

HazardsorunsafepracticeswhichCOULD

resultinminor personalinjuryorproductor

property damage. These instructions describe the requirements and the possible

NOTE

Instructions to aid in installation, operation, and

maintenance or which clarify a procedure.

PAGE I -- 2

INTRODUCTION

Page 5

SAFETY --- SECTION A

The following information applies

throughout this manual to GormanRupp Control Boxes.

CONTROL BOXESOM--04136

Because pump installationsare seldom

identical, this manual cannot possibly

provide detai led instructions and precautions for each specific application.

Therefore, it is the owner/installer’s responsibility to ensure that applications

not addressed in this manual are performed only after establishing that neither operator safety nor pump integrity

are compromised by the installation.

Before attempting to install, operate, or

wire this control box, familiarize yourself with this manual, and with all other

literature shipped with the control box.

Unfamiliarity with all aspects of control

operation covered in this manual could

lead to destructionof equipment,inj ury,

or death to personnel.

Beforeconnectingany cable to thecontrol box, be sure to ground the control

box. See Section B for suggested

grounding methods.

The electrical power used to operate

thiscontrolbox is highenough tocause

injury or death. Obtain the services of a

qualified electrician to make all electrical connections. Make certain that the

enclosure is properly grounded; never

use gas pipe as an electrical ground.Be

sure that the incoming power matches

the voltage and phase of the control before connecting the power source. Do

not make ele ctrical connections if the

voltage is not within the limits. If the

overload unit is tripped during operation, correct the problem before restarting.

The electrical power used to operate

thiscontrolbox is highenough tocause

injury or death. Make certain that the

control handle on the control box is in

the OFF position and locked out, or that

the power supply to the control box has

been otherwise cut off and locked out,

beforeattempting toopen or service the

control box. Tag electrical circuits to

prevent accidental start-up.

The control box provides overload protection and power control. Do not connect the pump motor directly to the incoming power lines. If the power circuit

breakeror overloadrelayis trippedduring operation, correct the problem before resetting or replacing.

SAFETY

Do not install and operate a non-explosion proof control box in an explosive

atmosphere. Install, connect, and operate the control box in accordance with

MSHA Schedule 2G. If there is a conflict

between the instructions in the manual

accompanying the unit and MSHA,

MSHA shall take precedence. All elec-

PAGE A -- 1

Page 6

OM--04136CONTROL BOXES

tricalequipment supplied with this controlboxconformedtoapplicablefederal

regulations and national codes in effect

on the date of manufacture.

Obtain the services of a qualified electrician to troubleshoot, test and/or ser-

vice the electrical components of this

control box.

Do not attempt to repair individual components of the control box. Any component which fails should be replaced.

PAGE A -- 2

SAFETY

Page 7

INSTALLATION --- SECTION B

GENERAL INFORMATION

Review all SAFETY information in Section A.

CONTROL BOXESOM--04136

Thissection is intended only to summarizerecommendedinstallationpracticesfor the controlbox.If

there are any questions concerning your specific

application,contact your Gorman-Ruppdistributor

or the Gorman-Rupp Company.

PREINSTALLATION INSPECTION

The control box was inspected before shipment

from the factory. Before installation, inspect the

controlfor damage which may have occurred during shipment. Check as follows:

a. Inspect thecontrolbox for cracks, dents, and

other obvious damage.

b. Checkthat allcontrolboxcomponentsarese-

curely attached to their mounting surfaces,

and that the electrical connections are tight

and free of corrosion.

c. Compare the amperes, phase, voltage and

hertzindicatedonthepump motornameplate

to the ratings indicated for the control box.

The control box furnished with the

pump is designed to operate the pump.

The control box provides overload protection and power control. Do not connect the pump motor directly to the incoming power lines.

Enclosure

Thecontrolboxis a NEMA Type3Rrainproofenclosurewithapadlockablefrontcover.Theenclosure

is not designed to be watertight, and should not

be submerged.

No mounting hardware is furnished with the controlbox. Securethe controlbox verticallyon alevel

surface, above flood level. The control should be

mounted on a flat surface. If the mounting surface

is not perfecting flat, it may be necessary to use

shims (not supplied) w ith the enclosure.The box

shouldbeeasilyaccessibleto theoperator, and located close enough to the pump to avoid excessive voltage drop due to cable length.

d. Carefully read all tags, decals, and markings

on the control box.

If anything appears to be abnormal, contact your

Gorman-Rupp distributor or the factory to determinethe repair policy. Do not put the controlbox

into service until appropriate action has been

taken.

CONTROL BOX INSTALLATION

The control box provides protection for the pump

motor against excessive heat due to motor overloads and failure to start, as well as short circuit

protection for incoming power lines.

INSTALLATION

Failure to mount the control box vertically

on a level surface may affect operation of

the pump controls.

Afterthe box issecurely installed, make certain t he

front cover latches properly before installing any

electrical lines.

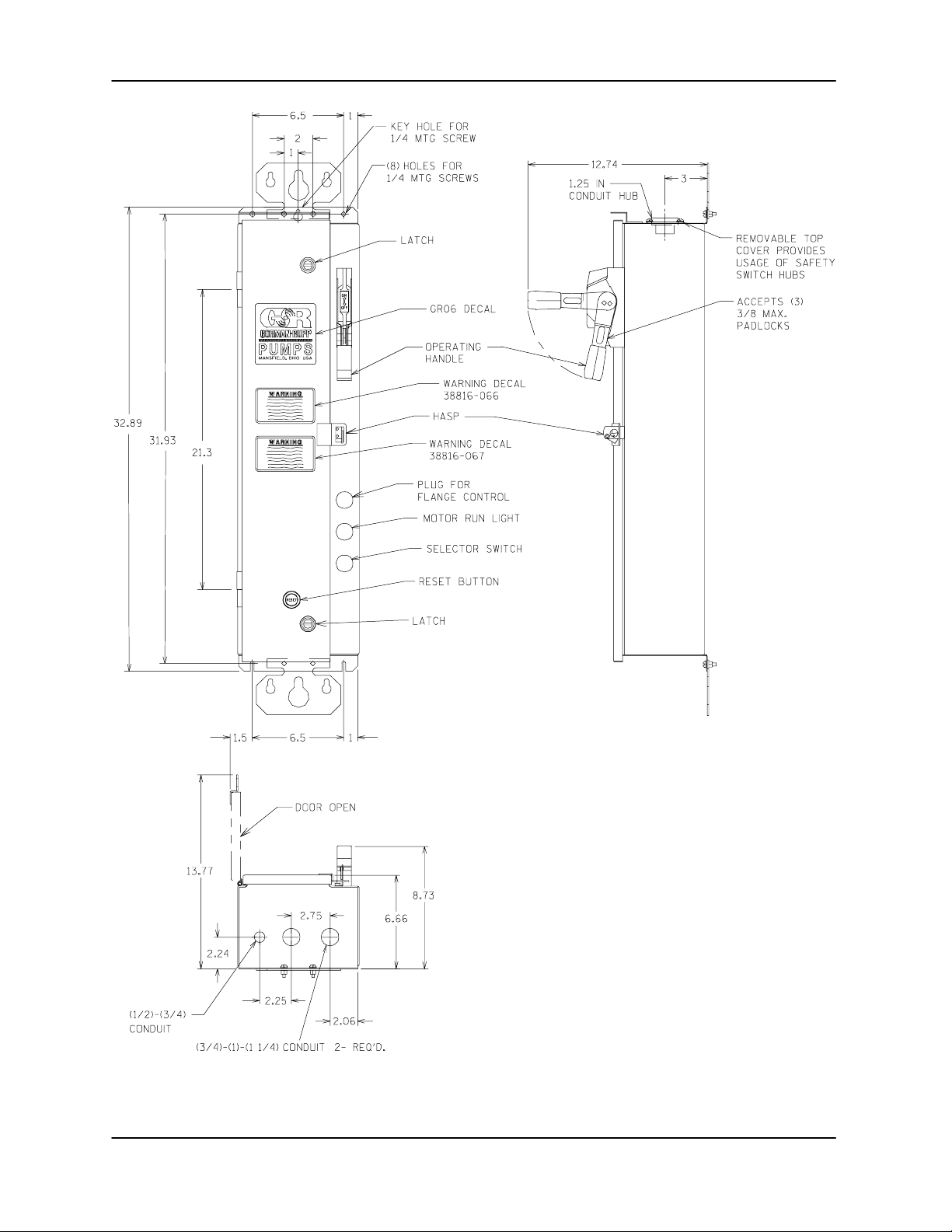

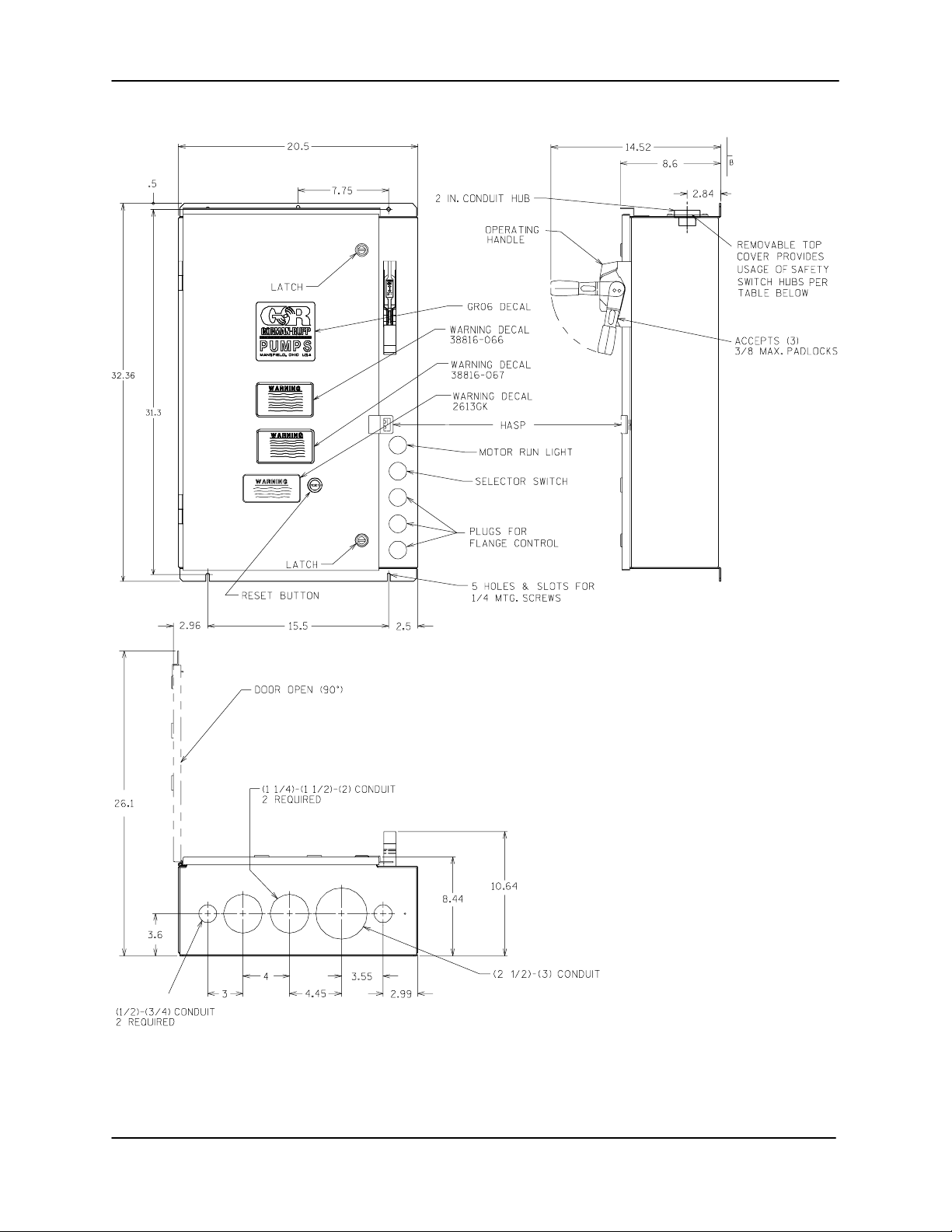

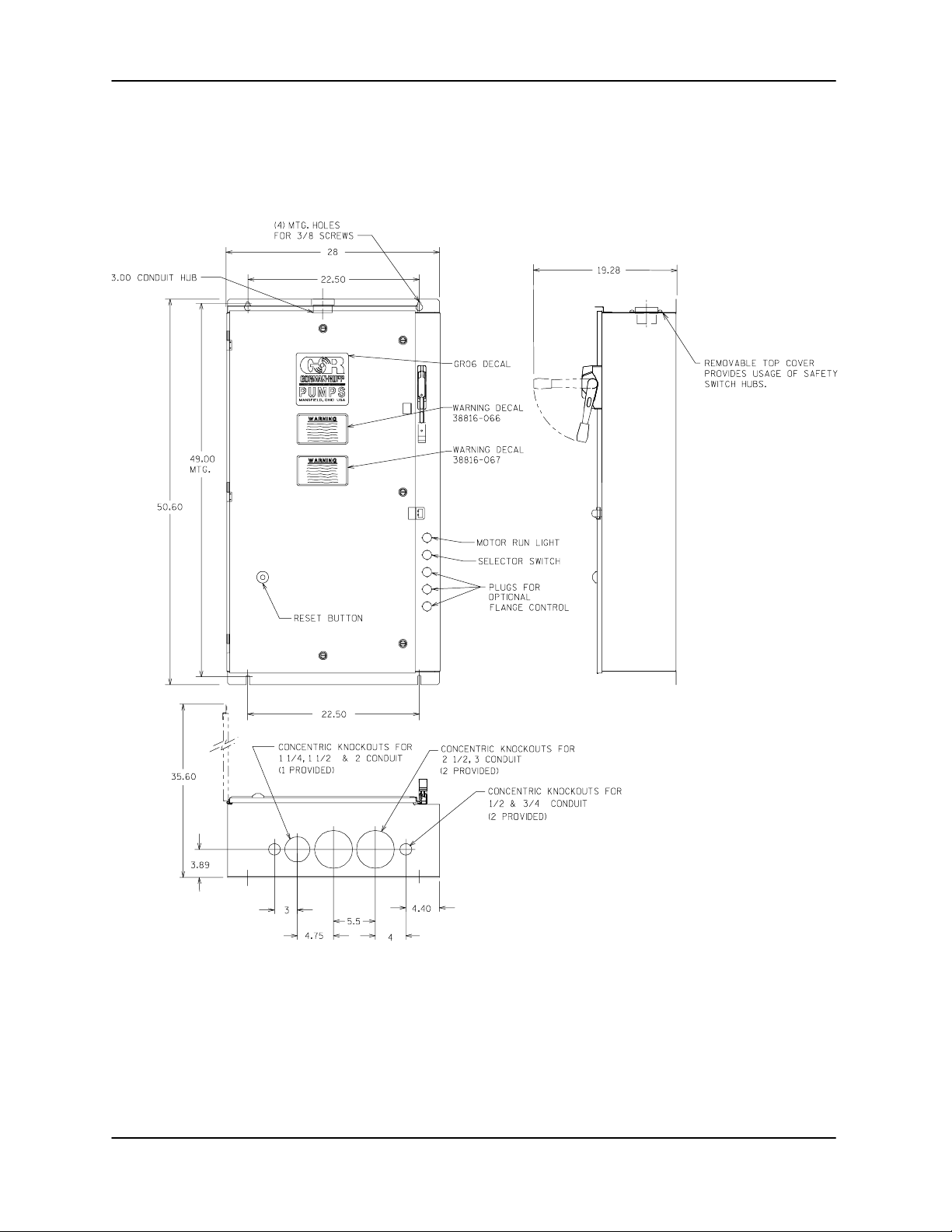

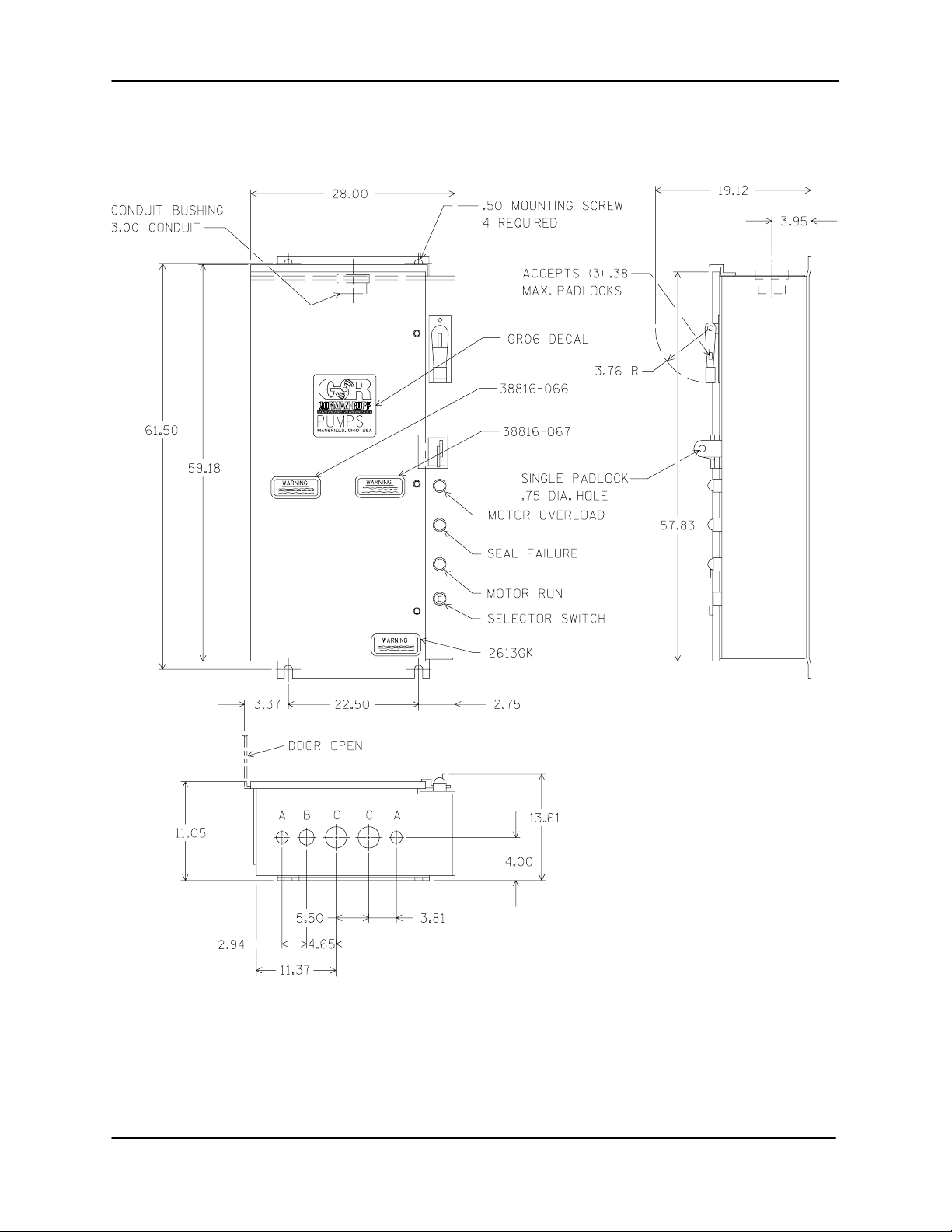

CONTROL BOX DIMENSIONS

For the approximate physical dimensions of your

control box, refer to Figures B --- 1 t hru B --- 4.

PAGE B -- 1

Page 8

OM--04136CONTROL BOXES

Figure B--1. 27515--503, 27515--504, 27515--513, 27515--514, 27515--524, 27515--534,

27515--543, 27515--544 And 27515--554 Control Box Dimensions

PAGE B -- 2

INSTALLATION

Page 9

CONTROL BOXESOM--04136

Figure B--2. 27515--505, 27515--506, 27515--515, 27515--516, 27515--525, 27515--535,

27515--545 And 27515--546 Control Box Dimensions

INSTALLATION

PAGE B -- 3

Page 10

OM--04136CONTROL BOXES

PAGE B -- 4

Figure B--3. 27515--507 And 27515--517 Control Box Dimensions

INSTALLATION

Page 11

CONTROL BOXESOM--04136

INSTALLATION

Figure B--4. 27515--571 And 27515--572 Control Box Dimensions

PAGE B -- 5

Page 12

OM--04136CONTROL BOXES

ELECTRICAL CONNECTIONS

Obtain the services of a qualified electrician to make all electrical connections and to service the control box.

Theelectricalpowerused in thiscontrol

box is high enough to c ause injury or

death. Make certain that the controlbox

is properly grounded after installation.

Make certain that the power source

phase and voltage matches the data on

the control box. Complete all electrical

connections before connecting the

power supply to the control box. Make

certain to ground the appropriate lead

a) PLATE ELECTRODE b) DRIVEN ELECTRODE c) BURIED ELECTRODE

of the power source before connecting

power to the control. Make certain that

the control box is properly grounded after installation.

Grounding Methods

Electricallygroundthe installationbefore connecting the field w iring to the control box. I nstall a

groundingterminaltothe enclosureand connect it

to a properly embedded electrode.

Thematerialusedfortheelectrodemustbe anexcellent conductor of electricity, such as copper. If

ironorsteelis used, it must be galvanizedorotherwise metal plated to resist corrosion. Do not coat

the electrode with any material of poor conductivity, such as paint or plastic.

The electrode must conform to the recommendationsof N.E.C. ARTICLE 250. Followall installation

requirements of the N.E.C., and all applicable

codes. See Figure B---5 for some suggested

grounding methods.

SOIL

1/4 INCH (6,4 MM)

STEEL PLATE 2 SQ.

FEET (1858,1 SQ. CM)

SURFACE AREA

(MINIMUM)

Figure B--5. Suggested Grounding Methods

a. Plate Electrode: An iron or steel plate, 1/ 4

inch (6,4 mm) thick, completely impeded in

the ground. The plate must present a surface

area of at least 2 square feet (1858,1 sq. cm).

b. Driven Electrode: A rod or pipe, 3/4 inch

(19,1mm)indiameterminimum,8feet (2,4m)

long, completely driven into the ground.

c. Buried electrode: If rock or stone prevents

embeddingthe full8 foot (2,4m) length ofthe

ground rod, bury it horizontally in a trench.

PAGE B -- 6

SOIL

3/4 INCH (19,1

MM) NOMINAL

DIAMETER

(MINIMUM)

8 FEET

(2,4 M)

SOIL

ROCK

3/4 INCH ( 19,1 MM)

NOMINAL DIAMETER

(MINIMUM) 8 FEET

(2,4 M) LONG

Space the ground rod or plates at least 6 feet

(1,8 m) from any other electrode or ground

rod, such as those usedfor signal circuits,radio grounds, lightning rods, etc.

Theearthsurroundingthegroundrod or plate

must contain enough moisture to make a

goodelectricalconnection.Indryorsandyareas, pour water around the rod, or consult

qualified personnel to devise a method of improving the connection.

INSTALLATION

Page 13

CONTROL BOXESOM--04136

Field Wiring Connections (Incoming Power)

The electrical power used to operate

this pump is high enough to causeinjury or death. Obtain the services of a qualified electrician to make all electrical

connections. Make certain that the

pump and enclosure are properly

grounded; never use gas pipe as an

electrical ground. Be sure that the incoming power matches the voltage and

phase of the pump and control before

connecting the power source. Do not

run the pump if the voltage is not within

the limits.

The control isdesigned to regulate the power supply. The field wiring must be properly sized to ensure an adequate voltage supply. The voltage

availableatthepumpmotormustbe withinthe indicated range.

Table 1. Pump Motor Voltage Limits

Nominal

Voltage

200 3 180 220

230 3 210 250

380 (50 Hz) 3 350 420

460 3 420 500

575 3 520 630

Phase

Minimum

Voltage

Maximum

Voltage

Power Cable Connections

Theelectricalpowerusedtooperatethe

control box is high enough to cause injury or death. Obtain the services of a

qualified electrician to make all electrical connections. Make certain

comingpowertothecontrolboxisin

that in-

the

off position and locked out, or that the

power supply to the control box has

been otherwise cut off and locked out

before connecting power or accessory

cables.

When necessary to change or connect power

cables to the control box, make certain the incomingpower is OFF and LOCKED OUT.Makecertain

the control box is properly grounded and that the

electrical data on the control matches the pump

motor name plate data.

Connect the power cable to the control box as

shown in the wiring diagrams in this section or inside the control box door. Use conduit or cable

clampsto secure the power and accessorycables

to the control box. Make certain that all connections are tight a nd that cable entry points are

rainproof.

Control Box Adjustments

For control adjustments and settings, refer to the

information inside the control box door.

,

Ifthe voltage isnot withinthe recommendedlimits,

obtain the services of a qualified electrician to determine the correct field wiring size and other details to ensure an adequate voltage supply.

Make certain all connections are tight and that cable entry points are rainproof. Support the cable

weight, if required, to prevent excessive strain on

cable clamps and cable.

NOTE

After the power cables havebeen connected to the

control box, make certain the connection is waterproof.

INSTALLATION

To maintain overcurrent, short circuit

and ground fault protection, the manufacturer’s instructions for selection of

the heater pack and setting of the instantaneous trip circuitbreaker (current

interrupter) or control interface module

mustbefollowed.Failureto followthese

instructionscan resultin damage tothe

pump and/or serious injury to personnel.

PAGE B -- 7

Page 14

CONTROL BOXES OM--04136

Figure B--8. Control Boxes 27515--285 And 27515--286 Pictorial Diagram

For specific control box data information, refer to

the chart at the end of this section.

PAGE B -- 8

INSTALLATION

Page 15

OM--04136 CONTROL BOXES

Figure B--9. Control Boxes 27515--503, 27515--513 And 27515--543 Elementary Wiring Diagram

REPAIR PARTS LIST

ITEM

NO.

10 “MOTOR RUN” LEGEND PLATE10250TM81 1

PART NAME C H PART

NUMBER

1 CIRCUIT BREAKER 30 AMPS HMCP030H1C 1

2 MOTOR STARTER AN16DNOAB 1

3 CONTACTOR --- 3 POLE CN15DN3AB 1

4 RENEWAL CONTACT SET 6---65---2 1

5 COIL 9---2703---1 1

6 OVERLOAD RELAY C306GN3B 1

7 HEATER PACK SEE CHART AT END OF THIS SECTION

8 CONTROL TRANSFORMER C0100G6UFB 1

9 “MOTOR RUN” PILOT LIGHT 10250T34G 1

QTY ITEM

INSTALLATION

PART NAME C H PART

NO.

11 TERMINAL BLOCK 80---5817 2

12 H---O---A SELECTOR SWITCH 10250T21KB 1

13 “HAND-OFF-AUTO” LGND PLT 10250TM51 1

14 OPT LIQ LVL CONTROL RELAY A999AY574 1

15 S ECO N DA RY FUSE 44 --- 79 6 --- 5 1

16 PRIMARY FUSE --- 380V 44-- -2144---17 2

17 PRIMARY FUSE --- 460V 44-- -2144---13 2

18 PRIMARY FUSE --- 575V 44-- -2144---12 2

19 RESET BOOT 35---524 2

20 PUB SHEET 25762 2

NUMBER

PAGE B -- 9

QTY

Page 16

CONTROL BOXES OM--04136

Figure B--10. Control Boxes 27515--503, 27515--513 And 27515--543 Pictorial Diagram

For specific control box data information, refer to

the chart at the end of this section.

PAGE B -- 10

INSTALLATION

Page 17

OM--04136 CONTROL BOXES

Figure B--11. Control Boxes 27515--504, 27515--514, 27515--544 And 27515--554

Elementary Wiring Diagram

REPAIR PARTS LIST

ITEM

NO.

10 “MTR RUN” LEGEND PLATE 10250TM81 1

11 TERMINAL BLOCK 80-- -5817 2

PART NAME C H PART

NUMBER

1 CIRCUIT BREAKER 50 AMPS HMCP050K2C 1

2 MOTOR STARTER AN16GNOAB 1

3 CONTACTOR --- 3 POLE CN15DN3AB 1

4 RENEWAL CONTACT SET 6---65---8 1

5 COIL 9---2703---1 1

6 OVERLOAD RELAY C306GN3B 1

7 HEATER PACK (SEE CHART AT END OF THIS SECTION)

8 CONTROL TRANSFORMER C0100G6UFB 1

9 “MTR RUN” PILOTLIGHT 10250T34G 1

INSTALLATION

QTY ITEM

NO.

12 H---O---A SELECTR SWITCH 10250T21KB 1

13 “H-O-A” LEGEND PLATE 10250TM51 1

14 OPTL FLOAT CNTRL RELAY A999AY574 1

15 SE CONDAR Y F USE 44 --- 79 6 --- 5 1

16 PRIMARY FUSE 575V 44---2144---12 2

17 PRIMARY FUSE 460V 44---2144---13 2

18 PRIMARY FUSE 380V 44---2144---17 2

19 PRIMARY FUSE 230V 44---2144---20 2

20 PRIMARY FUSE 200V 44---2144---22 2

21 RESET BOOT 35---524 1

22 PUB SHEET 25762 1

PART NAME C H PART

NUMBER

QTY

PAGE B -- 11

Page 18

CONTROL BOXES OM--04136

FigureB--12. ControlBoxes27515--504,27515--514, 27515--544 And27515--554 PictorialD iagram

For specific control box data information, refer to

the chart at the end of this section.

PAGE B -- 12

INSTALLATION

Page 19

OM--04136 CONTROL BOXES

Figure B--13. Control Boxes 27515--505, 27515-- 515 And 27515--545 Elementary Wiring Diagram

REPAIR PARTS LIST

ITEM

NO.

10 “MOTOR RUN” LEGEND PLATE10250TM81 1

11 TERMINAL BLOCK 80---5817 3

PART NAME C H PART

NUMBER

1 CIRCUIT BREAKER 100 AMPS HMCP100R3 1

2 MOTOR STARTER AN16KNOA 1

3 CONTACTOR --- 3 POLE CN15KN3A 1

4 RENEWAL CONTACT SET 6---43---2 1

5 COIL (ON COIL) 1

6 OVERLOAD RELAY C306KN3 1

7 HEATER PACK (SEE CHART AT END OF THIS SECTION) 1

8 CONTROL TRANSFORMER C0250G6UFB 1

9 MOTOR RUN” PILOT LIGHT 10250T34G 1

INSTALLATION

QTY ITEM

NO.

12 H---O---A SELECTOR SWITCH 10250T21KB 1

13 “H-O-A” LEGEND PLATE 10250TM5 1

14 230V PRIMARY FUSE 44---2144---29 2

15 380V PRIMARY FUSE 44---2144---26 2

16 460V PRIMARY FUSE 44---2144---23 2

17 575V PRIMARY FUSE 44---2144---21 2

18 S ECO N DA RY FUSE 44 --- 44 --- 796 --- 1 0 1

19 RESET BOOT 32---524 1

20 OPTL FLOAT CONTROL RELAY A999AY574 1

21 PUB SHEET 25773 1

PART NAME C H PART

NUMBER

PAGE B -- 13

QTY

Page 20

CONTROL BOXES OM--04136

Figure B--14. Control Boxes 27515--505, 27515--515 And 27515--545 Pictorial Diagram

For specific control box data information, refer to

the chart at the end of this section.

PAGE B -- 14

INSTALLATION

Page 21

OM--04136 CONTROL BOXES

Figure B--15. Control Boxes 27515--506, 27515-- 516 And 27515--546

Elementary Wiring Diagram

REPAIR PARTS LIST

ITEM

NO.

10 “MOTOR RUN” LEGEND PLATE10250TM81 1

11 TERMINAL BLOCK 80---5817 2

PART NAME C H PART

NUMBER

1 CIRCUIT BREAKER, 150 AMPS HMCP150T4C 1

2 MOTOR STARTER AN16NNOA 1

3 CONTACTOR --- 3 POLE CN15NN3A 1

4 RENEWAL CONTACT SET 6---44---2 1

5 COIL (ON COIL) 1

6 OVERLOAD RELAY C306NN3 1

7 HEATER PACK SEE CHART AT END OF THIS SECTION

8 CNTRL TRANSFORMER C0250G6UFB 1

9 “MOTOR RUN” PILOT LIGHT 10250T34G 1

INSTALLATION

QTY ITEM

NO.

12 H---O---A SELECTOR SWITCH 10250T21KB 1

13 “H-O-A” LEGEND PLATE 10250TM51 1

14 RESET BOOT 32---524 1

15 OPT’L FLOAT CNTROL RELAY A999AY524 1

16 PRIMARY FUSE, 200V 44---2144---31 2

17 PRIMARY FUSE, 230V 44---2144---29 2

18 PRIMARY FUSE, 380V 44---2144---26 2

19 PRIMARY FUSE, 460V 44---2144---23 2

20 PRIMARY FUSE, 575V 44---2144---21 2

21 SECONDARY FUSE 44---796---10 1

22 PUB SHEET 25775 1

PART NAME C H PART

NUMBER

QTY

PAGE B -- 15

Page 22

CONTROL BOXES OM--04136

Figure B--16. Control Boxes 27515--506, 27515--516 And 27515--546 Pictorial Diagram

For specific control box data information, refer to

the chart at the end of this section.

PAGE B -- 16

INSTALLATION

Page 23

CONTROL BOXESOM--04136

Figure B--17. Control Boxes 27515--507 And 27515--517 Elementary Wiring Diagram

REPAIR PARTS LIST

ITEM

NO.

10 “MOTOR RUN” LEGEND PLATE10250TM81 1

11 TERMINAL BLOCK 80---5817 2

PART NAME C H PART

NUMBER

1 CIRCUIT BREAKER, 250 AMPS HMCP250W5C 1

2 MOTOR STARTER AN16SNOAB 1

3 CONTACTOR --- 3 POLE CN15SN3AB 1

4 RENEWAL CONTACT SET 6---45---2 1

5 COIL (ON COIL) 1

6 OVERLOAD RELAY C306DN3 1

7 HEATER PACK SEE CHART AT END OF THIS SECTION

8 CONTROL TRANSFORMER C0250G6UFB 1

9 “MOTOR RUN” PILOT LIGHT 10250T34G 1

INSTALLATION

QTY ITEM

NO.

12 H---O---A SELECTOR SWITCH 10250T21KB 1

13 “H-O-A” LEGEND PLATE 10250TM51 1

14 CURRENT TRANSFORMER 42---3564---2 1

15 RESET BOOT 32---524 1

16 OPT’L FLOAT CNTROL RELAY A999AY574 1

17 PRIMARY FUSE, 460V 44---2144---23 2

18 PRIMARY FUSE, 575V 44---2144---21 2

19 SECONDARY FUSE 44---796---10 2

20 PUB SHEET 25775 2

21 OVERLOAD RELAY ADAPTER 10---6380---2 1

PART NAME C H PART

NUMBER

QTY

PAGE B -- 17

Page 24

OM--04136CONTROL BOXES

Figure B--18. Control Boxes 27515--507 And 27515--517 Pictorial Diagram

For specific control box data information, refer to

the chart at the end of this section.

PAGE B -- 18

INSTALLATION

Page 25

CONTROL BOXESOM--04136

Figure B--19. Control Boxes 27515--524 And 27515--534 Elementary Wiring Diagram

REPAIR PARTS LIST

ITEM

NO.

10 “MOTOR RUN” LEGEND PLATE10250TM81 1

PART NAME C H PART

NUMBER

1 CIRCUIT BREAKER --- 50 AMPS HMCP050K2C 1

2 MOTOR STARTER AN16DNOAB 1

3 CONTACTOR --- 3 POLE CN15GN3AB 1

4 RENEWAL CONTACT SET 6---65---8 1

5 COIL 9---2703---1 1

6 OVERLOAD RELAY C306GN3B 1

7 HEATER PACK SEE CHART AT END OF THIS SECTION

8 CONTROL TRANSFORMER C0100G6UFB 1

9 “MOTOR RUN” PILOT LIGHT 10250T34G 1

INSTALLATION

QTY ITEM

NO.

11 TERMINAL BLOCK 80---5817 2

12 H---O---A SELECTOR SWITCH 10250T21KB 1

13 “H-O-A” LEGEND PLATE 10250TM51 1

14 OPT’L FLOAT CNTROL RELAY A999AY574 1

15 S ECO N DA RY FUSE 44 --- 79 6 --- 5 1

16 PRIMARY FUSE, 460V 44---2144---13 2

17 PRIMARY FUSE, 575V 44---2144---12 2

18 RESET BOOT 35---524 1

19 PUB SHEET 25763 1

PART NAME C H PART

NUMBER

QTY

PAGE B -- 19

Page 26

OM--04136CONTROL BOXES

Figure B--20. Control Boxes 27515--524 And 27515--534 Pictorial Diagram

For specific control box data information, refer to

the chart at the end of this section.

PAGE B -- 20

INSTALLATION

Page 27

CONTROL BOXESOM--04136

Figure B--21. Control Boxes 27515--525 And 27515--535 Elementary Wiring Diagram

REPAIR PARTS LIST

ITEM

NO.

10 “MOTOR RUN” LEGEND PLATE10250TM81 1

PART NAME C H PART

NUMBER

1 CIRCUIT BREAKER, 100 AMPS HMCP100R3C 1

2 MOTOR STARTER AN16DNOA 1

3 CONTACTOR --- 3 POLE CN15GN3A 1

4 RENEWAL CONTACT SET 6---43---2 1

5 COIL (ON COIL) 1

6 OVERLOAD RELAY C306KN3 1

7 HEATER PACK SEE CHART AT END OF THIS SECTION

8 CONTROL TRANSFORMER C0250G6UFB 1

9 “MOTOR RUN” PILOT LIGHT 10250T34G 1

INSTALLATION

QTY ITEM

NO.

11 TERMINAL BLOCK 80---5817 2

12 H---O---A SELECTOR SWITCH 10250T21KB 1

13 “H-O-A” LEGEND PLATE 10250TM51 1

14 OPT’L FLOAT CNTROL RELAY A999AY574 1

15 S ECO N DA RY FUSE 44 --- 79 6 --- 5 1

16 PRIMARY FUSE, 460V 44---2144---13 2

17 PRIMARY FUSE, 575V 44---2144---12 2

18 RESET BOOT 35---524 1

19 PUB SHEET 25774 1

PART NAME C H PART

NUMBER

QTY

PAGE B -- 21

Page 28

OM--04136CONTROL BOXES

Figure B--22. Control Boxes 27515--525 And 27515--535 Pictorial Diagram

For specific control box data information, refer to

the chart at the end of this section.

PAGE B -- 22

INSTALLATION

Page 29

CONTROL BOXESOM--04136

Figure B--23. Control Boxes 27515--571 And 27515--572 Elementary Wiring Diagram

REPAIR PARTS LIST

ITEM

NO.

1 CIRCUIT BREAKER (460V) HMCP600L6W 1

2 IT STARTER S801V65P3S 1

3 HEATER ELEMENT 0T---815---120 2

4 SELECTOR SWITCH 10250T21KB 1

5 PILOT LIGHT 10250T181 3

PART NAME C H PART

NUMBER

CIRCUIT BREAKER (575V) HMCP400X5C 1

POWER SUPPLY PSS55A 1

COVER BOOT 32---524 2

CONTACT BLOCK 10250T2 1

QTY ITEM

INSTALLATION

PART NAME C H PART

NO.

RED LENS 10250TC1N 1

GREEN LENS 10250TC2N 1

AMBER LENS 10250TC19N 1

6 CONT TRANSFORMER C0350G6UFB 1

7 WARRICK CONTROL 1D1ED W/5182 RECTIFIER 1

8 TRANS CONT CIRCUIT 44---2144---24 (3A BUSMAN) 2

SE C. FUSES 44 --- 79 6 --- 1 1 (5A BU SMAN) 1

9 CONTROL RELAY D15CR22AB 1

NUMBER

QTY

PAGE B -- 23

Page 30

OM--04136CONTROL BOXES

Figure B--24. Control Boxes 27515--571 And 27515--572 Pictorial Diagram

For specific control box data information, refer to

the chart at the end of this section.

PAGE B -- 24

INSTALLATION

Page 31

Table 2. Control Box Data Chart

CONTROL BOXESOM--04136

PUMP DATA**

V HP Hz FLA

200 10 60 39 554 A999AY523--15 2 45AMPS 208 H2115B-3 C+1/2 28.3/41.3 C0100G6UFB 27521-321

10 60 34 504 A999AY523--9 2 45 AMPS 207 H2114B-3 C 23.5/34.8 C0100G6UFB 27521-321

25 60 60 505 A999AY524--2 3 90 AMPS 210 H2021--3 C 45.7/62.1 C0250G6UFB 27521-321

230

35 60 80 505 A999AY524--2 3 90 AMPS 211 H2022-3 C 62.2/84.6 C0250G6UFB 27521-321

50 60 124 506 A999AY525--2 4 135 AMPS 213 H2024-3 B 106.0/144.0 C0250G6UFB 27521-321

60 60 130 506 A999AY525--2 4 135 AMPS 213 H2024-3 B 106.0/144.0 C0250G6UFB 27521-321

6.7kw 50 11.5 543 A999AY523-- 8 1 27 AMPS 204 H2111B-3 B 9.60/14.4 C0100G6UFB 27521-321

12kw 50 21 544 A999AY523--11 2 45AMPS 205 H2112B-3 C 14.4/23.8 C0100G6UFB 27521-321

15kw 50 28 544 A999AY523--11 2 45AMPS 207 H2114B-3 B 23.5/34.8 C0100G6UFB 27521-321

25kw 50 46 545 A999AY524-- 4 3 90 AMPS 210 H2021-3 A 45.7/62.1 C0250G 6UFB 27521-321

26kw 50 47 545 A999AY524-- 4 3 90 AMPS 210 H2021-3 A 45.7/62.1 C0250G 6UFB 27521-321

380

41kw 50 76 545 A999AY524-- 4 3 90 AMPS 211 H2022-3 B 62.2/84.6 C0250G 6UFB 27521-321

44kw 50 82 545 A999AY524-- 4 3 90 AMPS 211 H2022-3 C 62.2/84.6 C0250G6UFB 27521-321

51kw 50 96 546 A999AY525-- 4 4 135 AMPS 212 H2023-3 B 84.7/115.0 C0250G6UFB 27521-321

65kw 50 115 546 A999AY525--4 4 135 AMPS 213 H2024-3 A 106.0/144.0 C0250G6UFB 27521-321

10 60 17 503 A999AY523-6 1 27 AMPS 205 H2112B-3 B 14.4/23.8 C0100G6UFB 27521-321

15 60 17 524 A999AY523-12 2 45 AMPS 205 H2112B-3 B 14.4/23.8 C0100G6UFB 27521-321

20 60 26 524 A999AY523-12 2 45 AMPS 206 H2113B-3 B 18.7/28.1 C0100G6UFB 27521-321

25 60 30 504 A999AY523--9 2 45 AMPS 206 H2113B-3 C 18.7/28.1 C0100G6UFB 27521-321

30 60 38.5 524 A999AY523-2 2 45 AMPS 208 H2115B-3 B 28.3/41.3 C0100G6UFB 27521-321

35 60 40 504 A999AY523--9 2 45 AMPS 208 H2115B-3 B 28.3/41.3 C0100G6UFB 27521-321

460

50 60 62 505 A999AY524--2 3 90 AMPS 210 H2021-3 C 45.7/62.1 C0250G6UFB 27521-321

60 60 65 505 A999AY524--2 3 90 AMPS 211 H2022-3 A 62.2/84.6 C0250G6UFB 27521-321

60 60 66 525 A999AY524-6 3 90 AMPS 211 H2022-3 A 62.2/84.6 C0250G6UFB 27521-321

95 60 105 506 A999AY525--2 4 135 AMPS 212 H2023-3 C 84.7/115.0 C0250G6UFB 27521-321

100 60 125 506 A999AY525--2 4 135 AMPS 213 H2024-3 B 106.0/144.0 C0250G6UFB 27521-321

140 60 165 507 A999AY567--5 5 270 AMPS 220 H2107B-3 A 2.30/3.77* C0250G6UFB 27521-321

G-RP/N

27515-

CONTROL BOX DATA

CONTROL P/N HEATERPACK NO.

C.H.P/N

A999AY523

NEMA

SIZE

CONT.

CURRENT

RATING

HEATERPACK REFERENCE DATA

G-RP/N

27521-

C-H.

P/N

HEATER

SETTING

RANGE

(AMPS)

CONTROL

TRANS-

FORMER

C-H.

PARTNO.

OPTIONAL

LIQ. LEVEL

CONTROL

RELAY

10 60 13.6 513 A999AY523--7 1 27AMPS 204 H2111B-3 C 9.60/14.4 C0100G6UFB 27521-321

15 60 14.4 534 A999AY523--13 2 45AMPS 204 H2111B-3 C 9.60/14.4 C0100G6UFB 27521--321

20 60 20.8 534 A999AY523--13 2 45AMPS 205 H2112B-3 B 14.4/23.8 C0100G6UFB 27521-321

25 60 24 514 A999AY523--10 2 45AMPS 206 H2113B-3 B 18.7/28.1 C0100G6UFB 27521-321

30 60 30.8 534 A999AY523--13 2 45AMPS 207 H2114B-3 C/B 23.5/34.8 C0100G6UFB 27521-321

35 60 32 514 A999AY523--10 2 45AMPS 207 H2114B-3 B 23.5/34.8 C0100G6UFB 27521-321

575

50 60 50 515 A999AY524--3 3 90 AMPS 210 H2021-3 A 45.7/62.1 C0250G6UFB 27521-321

60 60 52 515 A999AY524--3 3 90 AMPS 210 H2021-3 B 45.7/62.1 C0250G6UFB 27521-321

60 60 52.8 535 A999AY524--7 3 90 AMPS 210 H2021-3 B 45.7/62.1 C0250G6UFB 27521-321

95 60 84 516 A999AY525--3 4 135 AMPS 211 H2022-3 C 62.2/84.6 C0250G6UFB 27521-321

100 60 100 516 A999AY525--3 4 135 AMPS 212 H2023-3 B 84.7/115.0 C0250G6UFB 27521-321

140 60 132 517 A999AY567--6 5 270 AMPS 219 H2106B-3 A 1.92/3.15* C0250G6UFB 27521-321

* CURRENT TRANSFORMER 300:5

** CONSULT INDIVIDUAL PUMP NAME PLATEFOR SPECIFICATIONS.

SEETABLE2FOR 27515--571 AND 27515--572 CONTROL BOX DATA.

INSTALLATION

PAGE B -- 25

Page 32

Table 3. 27515--571 And 27515--572 Control Bo x Data

OM--04136CONTROL BOXES

PUMP DATA**

V HP Hz FLA

275 60 320 571 84--29709--3 5 600 EMA72 A+7/8 C+1/2 3200 STANDARD

460

575

275 60 256 572 84--29709--4 5 400 EMA72 A+1/3 C+1/2 2625 STANDARD

** CONSULT INDIVIDUAL PUMP NAME PLATEFOR SPECIFICATIONS.

G-RP/N

27515-

CONTROL BOX DATA

CONTROL P/N

C.H.P/N

A999AY523

NEMA

SIZE

CONT.

CURRENT

RATING

CONTROL

INTERFACE

MODULE

C.H.

PARTNO.

SETTING

LOCKING PIN

BREAKER

SETTING

CIRCUIT

DIAL & T RIP

SETTING

Table 4. Control Box Torque Values

POWER TERMINATIONS

NEMA

SIZE

1&2

HEATER PACK

MOUNTING SCREW

RECOMMENDED TORQUE

In.lbs.(m.kg.)

9 (0,10)

LINE SIDE LOAD SIDE

Terminal

Wire Size

(AWG)

Torque

In. lbs. (m. kg.)

Wire Size

(AWG)

Use 60/75_CAlor

Cu Conductors

14 --- 10

8

35 (0,40)

40 (0,46)

14 --- 10

Terminal

Torque

In.lbs.(m.kg.)

Use 60/75_CAlor

Cu Conductors

35 (0,40)

8

40 (0,46)

6 --- 4 45 (0,52) 6 --- 4 45 (0,52)

3 --- 2 50 (0,58)

LIQ. LEVEL

CONTROL

RELAY

3

24 --- 30 (0,28 --- 0,35)

4 24 --- 30 (0,28 --- 0,35)

5 9 (0,10)

Use 75_CAlor

Cu Conductors

14 --- 10

8

35 (0,40)

40 (0,46)

6 --- 4 45 (0,52)

3 --- 1/0 50 (0,58)

Use 75_CCu

Conductors Only

14 --- 10

8

35 (0,40)

40 (0,46)

6 --- 4 45 (0,52)

3 --- 1/0 50 (0,58)

Use75_CCopperorAlumi-

num Conductors only.

Torque terminals to values

given on HMCP nameplate.

Use 75_CAlor

Cu Conductors

14 --- 10

8

35 (0,40)

40 (0,46)

6 --- 4 45 (0,52)

3 --- 1/0 50 (0,58)

Use 75_CCu

Conductors Only

Socket Size

In. (mm)

3/16 (4,76)

1/4 (6,35)

5/16 (7,94)

3/8 (9,53)

120 (1,38)

200 (2,30)

250 (2,88)

550 (6,34)

Use75_CCopperorAluminum Conductors only.

550 (6,34)

PAGE B -- 26

INSTALLATION

Page 33

OM--04136

OPERATION --- SECTION C

Review all SAFETY information in Section A.

Follow the instructions on all tags, labels and

decals attached to the control box.

The electrical power used to operate

thiscontrolbox is highenough tocause

injury or death. Make certain that the

control handle on the control box is in

the OFF position and locked out, or that

the power supply to the control box has

been otherwise cut off and locked out,

beforeattempting toopen or service the

control box. Tag electrical circuits to

prevent accidental start-up.

CONTROL BOXES

The control box provides overload protection and power control. Do not connect the pump motor directly to the incoming power lines.

Since operation of the pump motor is dependentuponthequalityandperformance

oftheelectrical controls,thepumpwarranty is valid only when controls have been

specified or provided by The GormanRupp Company .

Component Function

Obtain the services of a qualified electrician to make all electrical connections, and to troubleshoot, test and/or

servicetheelectricalcomponentsofthe

control box.

CONTROL BOX FUNCTION

Thecontrol box isnotdesignedtobeexplosion-proof. Do not operate in an explosive atmosphere.

Thecontrolbox isprovided tofacilitate operationof

thepump.Itcontainscontrolsforstartingandstopping the pump, and provides overload protection

for the pump motor. The pump control may be

equipped with an optional automatic liquid level

sensing device, in which case the low voltage circuits are also contained within the control box.

The control box contains the following hand-operated switches and controls:

D The control handle operates the control

boxcircuit breakers. In theOFF position, the

controlhandle opens the circuit breakers to

interrupt incoming power through the control box and prevent pump operation. In the

ON position, it closes the circuit breakers to

permit pump operation.The circuit breakers

will open or “trip” automatically in the event

of a short circuit overload current. When

tripped,movethecontrolhandletoOFFand

back to ON to reset the circuit breakers.

D The selector switch controls the mode of

operation.Inthe OFFposition,it preventsall

operationofthepump.IntheHANDposition, it a llows the pump to run continuously.

In the AUTO position, it allows the pump to

be controlled automatically by the optional

liquid level control system, if used.

D The reset pushbuttonresets the motorover-

load after it has been TRIPPED by an overload. Theoverloadrelay willtripautomaticallyif the current drawn by the motor exceeds

design specifications. Allow 10 seconds for

OPERATION PAGE C -- 1

Page 34

CONTROL BOXES

OM--04136

the relay to cool after tripping before pressing the reset.

If replacing the heater pack press the reset

button to set relay.

NOTE

If the circuit breaker trips, do not reset it immediately. Wait at least ten minutes before resetting the

control handle back to the ON position. If the overloadunitcontinues totrip, operational problems exist.

The pump motor will restart as soon as

the RESET pushbutton is pressed, unlessthe selectorswitch isintheOFF position. T urn the selector switch to OFF

and move the control handle to OFF before approaching the pump.

D The liquid level devices (optional equip-

ment) operate in conjunction with the 3-position switch (HAND-OFF-AUTO) supplied

as part of that option. After the level sensors

and circuitry have been installed, pump operation may be automatically controlled for

filling or dewatering functions (see LIQUID

LEVEL DEVICES,SectionB).

D The operational warning lights operate in

conjunction with the 3-position switch

(HAND-OFF-AUTO) supplied as a part of

that option. After the level sensors and circuitry have been installed, pump operations

may be automatically controlled for filling or

dewatering functions.

The green run light is standard equipment

onallthe controlsand indicatesthe pumpis

running. The light will be energized when

the3-positionswitchisintheHANDposition

orwhen the pump is running with the switch

in the AUTO position.

The red motor overheat light (standard

equipment only on some controls) works in

conjunction with a thermostat embedded in

the motor windings. In event of a high temperature condition, the motor is shut-down.

Afterthemotorcools,thedeviceisautomatically reset.

Theamberseal failurelight(standardequipment only on some controls) works in conjunction with a sensor probe located in the

sealoilcavityofthepump anddetects aninflux of moisture into the cavity. Should this

condition occur,the pump motor should remain inoperative until the problem is corrected.

Always terminate incoming power to the control

boxbefore investigatingcontrolbox circuitryproblems.

Always terminate power to the control

box before performing service functions.

Power through the control box may be terminated

by moving the control handle to the OFF position,

thereby opening the circuit breakers. This stops

thepump, butdoes notterminate incomingpower

through the field wiring connected to the control

box.

OPERATIONPAGE C -- 2

Page 35

OM--04136

CONTROL BOXES

TROUBLESHOOTING --- SECTION D

Review all SAFETY information in Section A.

The electrical power used to operate

thiscontrol box is high enoughto cause

injury or death. Obtain the services of a

qualified electrician to troubleshoot,

testand/orservice the electricalcomponents.

Manyofthe probableremedieslistedin thetroubleshootingchart below requireuse ofelectrical test instruments; for specific procedures, see Electrical T esting at the end of the troubleshooting chart.

When troubleshooting, also refer tothe technicalinformationaccompanyingthe pumpand optionalequipment.

TROUBLE POSSIBLE CAUSE PROBABLE REMEDY

PUMP FAILS TO

START, OVERLOAD

UNIT NOT TRIPPED

(MANUAL MODE)

OVERLOAD UNIT

TRIPS

Power source incompatible with control Correct power source.

box.

No voltage at line side of circuit beaker. Check power source for blown fuse,

open overload unit, broken lead, or

loose connection.

No voltage at line terminals on bottom Check power source for blown fuse,

of overload unit in control box. open disconnect, broken wire, or

loose connection.

Low or high voltage, or excessive volt- Measure voltage at control box.

age drop between pump and control Check that wiringiscorrect type, size,

box. and length. (See Field Wiring

Connections,SectionB).

Power input phases not If imbalance exceeds 1 percent,

balanced. notify power company

Control box not compatible with pump. Electrical data on control box and

pump name plate must agree. Replace control box if not in agreement.

Foreign object locking impeller or Remove foreign material or replace

bearing frozen. damaged bearing. If bearing is

damaged, check for water in motor

housing.

Motor windings short-circuited. Check motor windings with

ohmmeter.

TROUBLESHOOTING PAGE D -- 1

Page 36

CONTROL BOXES

OM--04136

ELECTRICAL TESTING

Be certain to refer to the wiringdiagram(s)

intheInstallationSectionofthismanualbefore reconnecting any electrical components which have been disconnected.

Test Equipment

A volt/amp/ohmmeter and megohmeter of adequaterange and qualitywillberequiredtoconduct

theelectricaltests. The suggestedequipment indicatedbelowis commerciallyavailable,oranequivalent substitute may be used.

Equipment Use

Ammeter/

Voltmeter

Ohmmeter To measure resistance

Voltage Imbalance

Each phase of the incoming three-phase power

must be balanced withthe other two as accurately

as a commercial voltmeter will read. If the phases

are out of balance, contact your power company

and request that they correct the condition.

To check AC Voltage

and current (amperage)

(ohms) to ground

TROUBLESHOOTINGPAGE D -- 2

Page 37

For U.S. and International Warranty Information,

Please Visit www.grpumps.com/warranty

or call:

U.S.: 419−755−1280

International: +1−419−755−1352

For Canadian Warranty Information,

Please Visit www.grcanada.com/warranty

or call:

519−631−2870

THE GORMAN-RUPP COMPANY D MANSFIELD, OHIO

GORMAN-RUPP OF CANADA LIMITED D ST. THOMAS, ONTARIO, CANADA

Loading...

Loading...