Page 1

ACDEU

OM-06525-01

February 10, 2012

INSTALLATION, OPERATION,

AND MAINTENANCE MANUAL

WITH PARTS LIST

PA SERIES PUMP

MODEL

PAV3A60C‐B

THE GORMAN‐RUPP COMPANY MANSFIELD, OHIO

www.grpumps.com

GORMAN‐RUPP OF CANADA LIMITED ST. THOMAS, ONTARIO, CANADA Printed in U.S.A.

2012 The Gorman‐Rupp Company

Page 2

Register your new

Gorman‐Rupp pump online at

www.grpumps.com

Valid serial number and e‐mail address required.

RECORD YOUR PUMP MODEL AND SERIAL NUMBER

Please record your pump model and serial number in the

spaces provided below. Your Gorman‐Rupp distributor

needs this information when you require parts or service.

Pump Model:

Serial Number:

Page 3

TABLE OF CONTENTS

INTRODUCTION PAGE I - 1.................................................

SAFETY ‐ SECTION A PAGE A - 1............................................

INSTALLATION - SECTION B PAGE B - 1....................................

Pump Dimensions PAGE B - 1.....................................................

PREINSTALLATION INSPECTION PAGE B - 2............................................

POSITIONING PUMP PAGE B - 2.......................................................

Lifting PAGE B - 2.................................................................

Mounting PAGE B - 2.............................................................

SUCTION AND DISCHARGE PIPING PAGE B - 3.........................................

Materials PAGE B - 3..............................................................

Line Configuration PAGE B - 3......................................................

Connections to Pump PAGE B - 3..................................................

Gauges PAGE B - 3...............................................................

SUCTION LINES PAGE B - 3...........................................................

Fittings PAGE B - 3...............................................................

Strainers PAGE B - 3..............................................................

Sealing PAGE B - 4...............................................................

Suction Lines In Sumps PAGE B - 4.................................................

Suction Line Positioning PAGE B - 4................................................

DISCHARGE LINES PAGE B - 5........................................................

Siphoning PAGE B - 5.............................................................

Valves PAGE B - 5................................................................

ELECTRICAL CONNECTIONS PAGE B - 5...............................................

Grouding Methods PAGE B - 6.....................................................

Field Wiring Connections (Incoming Power) PAGE B - 6...............................

Voltage Imbalance PAGE B - 7.....................................................

Power Cable Connections PAGE B - 7...............................................

Control Box Adjustment PAGE B - 7.................................................

ALIGNMENT PAGE B - 7..............................................................

AUTO‐START PAGE B - 8.............................................................

Float Switch Installation PAGE B - 8.................................................

Submersible Transducer Installation PAGE B - 9......................................

OPERATION - SECTION C PAGE C - 1......................................

STARTING AND OPERATION PAGE C - 1...............................................

Control Box Function PAGE C - 1...................................................

Component Function PAGE C - 1...................................................

Rotation PAGE C - 2..............................................................

Priming PAGE C - 2...............................................................

Leakage PAGE C - 2..............................................................

Pump Vacuum Check PAGE C - 3..................................................

Priming Chamber Discharge Line PAGE C - 3........................................

Liquid Temperature And Overheating PAGE C - 3.....................................

Strainer Check PAGE C - 3.........................................................

STOPPING PAGE C - 3................................................................

Manual Stopping PAGE C - 3.......................................................

i

Page 4

TABLE OF CONTENTS

(continued)

Automatic Stopping PAGE C - 3....................................................

PERIODIC CHECKS PAGE C - 3.......................................................

Seal Cavity and Bearing Lubrication PAGE C - 3......................................

Bearing Temperature Check PAGE C - 3.............................................

Air Compressor Drive Belt PAGE C - 4...............................................

COLD WEATHER PRESERVATION PAGE C - 4...........................................

TROUBLESHOOTING - SECTION D PAGE D - 1..............................

PREVENTIVE MAINTENANCE PAGE D - 3...............................................

PUMP MAINTENANCE AND REPAIR ‐ SECTION E PAGE E - 1.................

STANDARD PERFORMANCE CURVE PAGE E - 1........................................

PARTS LISTS:

Pump Model PAGE E - 3..........................................................

Pump End Assembly PAGE E - 5...................................................

Repair Rotating Assembly PAGE E - 9...............................................

Priming Chamber Kit PAGE E - 10...................................................

Priming Chamber Assembly PAGE E - 11.............................................

Air Compressor Assembly PAGE E - 12...............................................

PUMP AND SEAL DISASSEMBLY AND REASSEMBLY PAGE E - 13.........................

Priming Chamber Removal And Disassembly PAGE C - 14..............................

Discharge Check Valve Removal and Disassembly PAGE C - 14.........................

Back Cover Plate and Wear Plate Removal PAGE C - 14................................

Separating Pump And Drive Assembly From Engine PAGE C - 14........................

Draining Oil From Seal Cavity PAGE C - 15............................................

Loosening Impeller PAGE C - 15.....................................................

Pump Casing Removal PAGE C - 15.................................................

Impeller Removal PAGE C - 16......................................................

Seal Removal PAGE C - 16..........................................................

Shaft and Bearing Removal and Disassembly PAGE C - 16.............................

Shaft and Bearing Reassembly and Installation PAGE C - 17............................

Seal Reassembly and Installation PAGE C - 18........................................

Impeller Installation And Adjustment PAGE C - 20......................................

Pump Casing Installation PAGE C - 20................................................

Securing Pump End To Power Source PAGE C - 20....................................

Wear Plate and Back Cover Installation And Adjustment PAGE C - 20....................

Discharge Check Valve Reassembly And Installation PAGE C - 21.......................

Priming Chamber Assembly And Installation PAGE C - 22...............................

LUBRICATION PAGE C - 22.............................................................

Seal Assembly PAGE C - 22.........................................................

Bearings PAGE C - 22..............................................................

ii

Page 5

PA SERIES OM-06525

INTRODUCTION

Thank You for purchasing a Gorman‐Rupp pump.

Read this manual carefully to learn how to safely

install and operate your pump. Failure to do so

could result in personal injury or damage to the

pump.

This pump is a PA Series, priming‐assisted centrif

ugal model. The unit is designed for handling non‐

volatile, non‐flammable liquids containing speci

fied entrained solids. The basic material of con

struction is ductile iron, with stainless steel shaft

and ductile iron wearing parts.

This manual will alert personnel to known proce

dures which require special attention, to those

which could damage equipment, and to those

which could be dangerous to personnel. However,

this manual cannot possibly anticipate and provide

detailed precautions for every situation that might

occur during maintenance of the unit. Therefore, it

is the responsibility of the owner/maintenance per

sonnel to ensure that only safe, established main

tenance procedures are used, and that any proce

dures not addressed in this manual are performed

only after establishing that neither personal safety

nor pump integrity are compromised by such prac

tices.

The following are used to alert maintenance per

sonnel to procedures which require special atten

tion, to those which could damage equipment, and

to those which could be dangerous to personnel:

Immediate hazards which WILL result in

severe personal injury or death. These

instructions describe the procedure re

quired and the injury which will result

from failure to follow the procedure.

Hazards or unsafe practices which

COULD result in severe personal injury

or death. These instructions describe

the procedure required and the injury

which could result from failure to follow

the procedure.

For information or technical assistance on the

power source, contact the power source manufac

turer's local dealer or representative.

If there are any questions regarding the pump or

its application which are not covered in this man

ual or in other literature accompanying this unit,

please contact your Gorman‐Rupp distributor, or

The Gorman‐Rupp Company:

The Gorman‐Rupp Company

P.O. Box 1217

Mansfield, Ohio 44901-1217

Phone: (419) 755-1011

or:

Gorman‐Rupp of Canada Limited

70 Burwell Road

St. Thomas, Ontario N5P 3R7

Phone: (519) 631-2870

Hazards or unsafe practices which COULD

result in minor personal injury or product

or property damage. These instructions

describe the requirements and the possi

ble damage which could result from failure

to follow the procedure.

NOTE

Instructions to aid in installation, operation, and

maintenance or which clarify a procedure.

PAGE I - 1INTRODUCTION

Page 6

PA SERIES OM-06525

SAFETY - SECTION A

This information applies to PA Series

basic pumps. Gorman‐Rupp has no

control over or particular knowledge of

the power source which will be used.

Refer to the manual accompanying the

power source before attempting to be

gin operation.

This manual will alert personnel to

known procedures which require spe

cial attention, to those which could

damage equipment, and to those which

could be dangerous to personnel. How

ever, this manual cannot possibly antici

pate and provide detailed instructions

and precautions for every situation that

might occur during maintenance of the

unit. Therefore, it is the responsibility of

the owner/maintenance personnel to

ensure that only safe, established main

tenance procedures are used, and that

any procedures not addressed in this

manual are performed only after estab

lishing that neither personal safety nor

pump integrity are compromised by

such practices.

This pump is designed to handle most

non‐volatile, non‐flammable liquids

containing specified entrained solids.

Do not attempt to pump volatile, corro

sive, or flammable materials which may

damage the pump or endanger person

nel as a result of pump failure.

After the pump has been positioned,

make certain that the pump and all pip

ing connections are tight, properly sup

ported and secure before operation.

Do not operate the pump without the

guards in place over the rotating parts.

Exposed rotating parts can catch cloth

ing, fingers, or tools, causing severe in

jury to personnel.

Before attempting to open or service the

pump:

1. Familiarize yourself with this man

ual.

2. Disconnect or lock out the power

source to ensure that the pump will

remain inoperative.

3. Allow the pump to completely cool

if overheated.

4. Check the temperature before

opening any covers, plates, or

plugs.

5. Close the suction and discharge

valves.

6. Vent the pump slowly and cau

tiously.

7. Drain the pump.

Do not remove plates, covers, gauges,

pipe plugs, or fittings from an over

heated pump. Vapor pressure within the

pump can cause parts being disen

gaged to be ejected with great force. Al

low the pump to cool before servicing.

Do not operate the pump against a

closed discharge valve for long periods

of time. If operated against a closed dis

charge valve, pump components will

deteriorate, and the liquid could come

PAGE A - 1SAFETY

Page 7

PA SERIESOM-06525

to a boil, build pressure, and cause the

pump casing to rupture or explode.

Use lifting and moving equipment in

good repair and with adequate capacity

to prevent injuries to personnel or dam

age to equipment. Suction and dis

charge hoses and piping must be re

moved from the pump before lifting.

Do not attempt to disengage any part of

an overheated pump unit. Vapor pres

sure within the pump casing can eject

these parts with great force when they

are disengaged. Allow the pump to

completely cool before servicing it.

rials which could cause illness through

direct exposure or emitted fumes. Wear

adequate protective clothing when

working on the pump or piping.

This pump may be equipped with an op

tional automatic starting system, and

therefore subject to automatic restart.

Keep hands and clothing away from the

unit to prevent injury during automatic

operation. Disconnect the positive bat

tery cable before performing any main

tenance. Failure to do so may result in

serious personal injury.

This pump may be used to handle mate

Pumps and related equipment must be in

stalled and operated according to all na

tional, local and industry standards.

PAGE A - 2 SAFETY

Page 8

INSTALLATION - SECTION B

OM-06525PA SERIES

Review all SAFETY information in Section A.

Since pump installations are seldom identical, this

section offers only general recommendations and

practices required to inspect, position, and ar

range the pump and piping.

Most of the information pertains to a standard

static lift application where the pump is posi

tioned above the free level of liquid to be pumped.

If installed in a flooded suction application where

the liquid is supplied to the pump under pressure,

some of the information such as mounting, line

configuration, and priming must be tailored to the

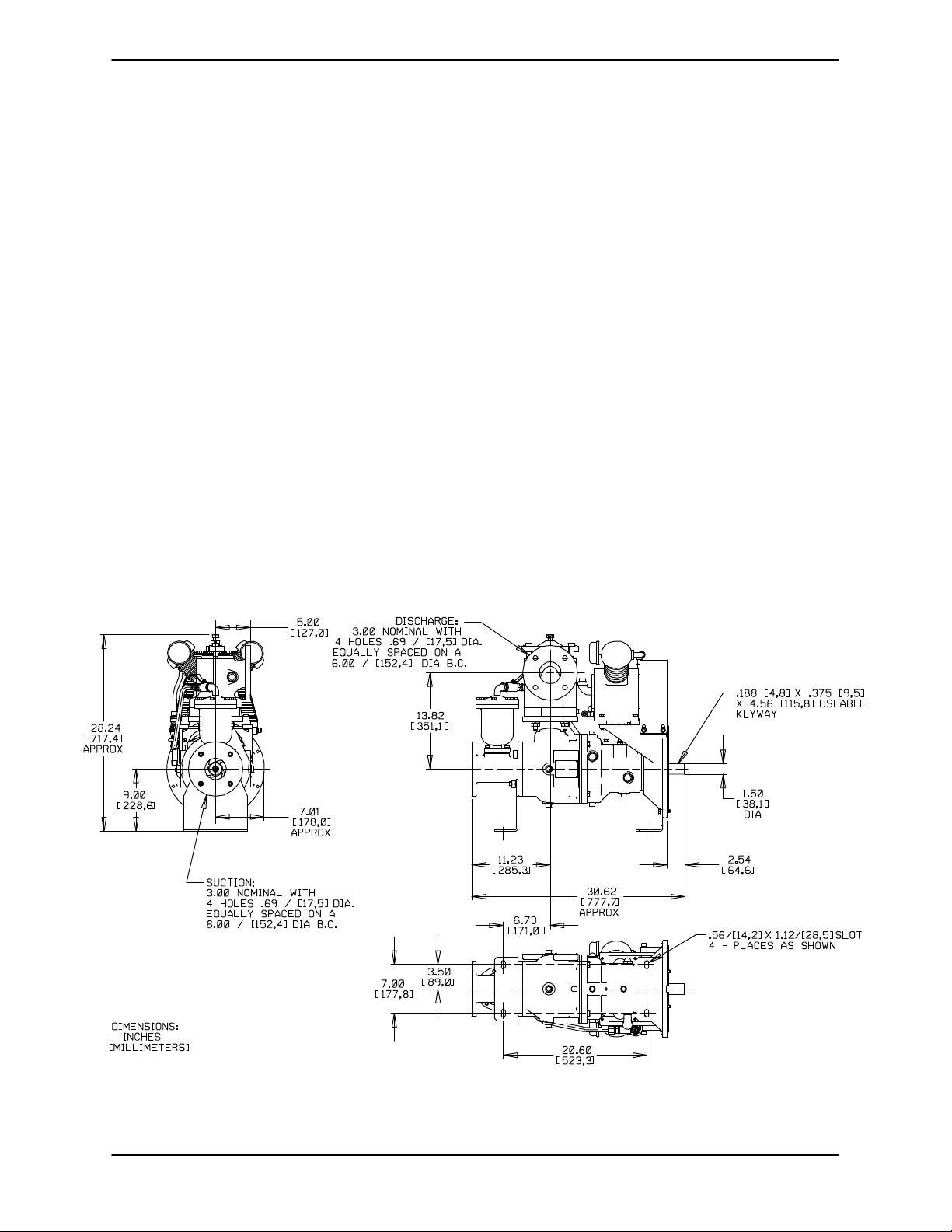

OUTLINE DRAWING

specific application. Since the pressure supplied

to the pump is critical to performance and safety,

be sure to limit the incoming pressure to 50% of

the maximum permissible operating pressure as

shown on the pump performance curve.

For further assistance, contact your Gorman‐Rupp

distributor or the Gorman‐Rupp Company.

Pump Dimensions

See Figure 1 for the approximate physical dimen

sions of this pump.

Figure 1. Pump Model PAV3A60C-B

PAGE B - 1INSTALLATION

Page 9

OM-06525 PA SERIES

PREINSTALLATION INSPECTION

The pump assembly was inspected and tested be

fore shipment from the factory. Before installation,

inspect the pump for damage which may have oc

curred during shipment. Check as follows:

a. Inspect the pump for cracks, dents, damaged

threads, and other obvious damage.

b. Check for and tighten loose attaching hard

ware. Since gaskets tend to shrink after dry

ing, check for loose hardware at mating sur

faces.

c. Carefully read all warnings and cautions con

tained in this manual or affixed to the pump,

and perform all duties indicated. Note the di

rection of rotation indicated on the pump.

Check that the pump shaft rotates counter

clockwise when facing the impeller.

POSITIONING PUMP

Lifting

Pump unit weights will vary depending on the

mounting and drive provided. Check the shipping

tag on the unit packaging for the actual weight, and

use lifting equipment with appropriate capacity.

Drain the pump and remove all customer‐installed

equipment such as suction and discharge hoses

or piping before attempting to lift existing, installed

units.

The pump assembly can be seriously

damaged if the cables or chains used to lift

and move the unit are improperly wrapped

around the pump.

Mounting

Only operate this pump in the direction in

dicated by the arrow on the pump body or

on the accompanying decal. Refer to RO

TATION in OPERATION, Section C.

d. Check levels and lubricate as necessary. Re

fer to LUBRICATION in the MAINTENANCE

AND REPAIR section of this manual and per

form duties as instructed.

e. If the pump and power source have been

stored for more than 12 months, some of the

components or lubricants may have ex

ceeded their maximum shelf life. These must

be inspected or replaced to ensure maxi

mum pump service.

If the maximum shelf life has been exceeded, or if

anything appears to be abnormal, contact your

Gorman‐Rupp distributor or the factory to deter

mine the repair or updating policy. Do not put the

pump into service until appropriate action has

been taken.

Locate the pump in an accessible place as close as

practical to the liquid being pumped. Level mount

ing is essential for proper operation.

The pump may have to be supported or shimmed

to provide for level operation or to eliminate vibra

tion.

SUCTION AND DISCHARGE PIPING

Pump performance is adversely effected by in

creased suction lift, discharge elevation, and fric

tion losses. See the performance curve and oper

ating range shown on Page E‐1 to be sure your

overall application allows pump to operate within

the safe operation range.

Materials

Either pipe or hose maybe used for suction and

discharge lines; however, the materials must be

compatible with the liquid being pumped. If hose is

used in suction lines, it must be the rigid‐wall, rein

forced type to prevent collapse under suction. Us

ing piping couplings in suction lines is not recom

mended.

PAGE B - 2 INSTALLATION

Page 10

OM-06525PA SERIES

Line Configuration

Keep suction and discharge lines as straight as

possible to minimize friction losses. Make mini

mum use of elbows and fittings, which substan

tially increase friction loss. If elbows are necessary,

use the long‐radius type to minimize friction loss.

Connections to Pump

Before tightening a connecting flange, align it ex

actly with the pump port. Never pull a pipe line into

place by tightening the flange bolts and/or cou

plings.

Lines near the pump must be independently sup

ported to avoid strain on the pump which could

cause excessive vibration, decreased bearing life,

and increased shaft and seal wear. If hose‐type

lines are used, they should have adequate support

to secure them when filled with liquid and under

pressure.

to avoid creating air pockets. Valves are not nor

mally used in suction lines, but if a valve is used,

install it with the stem horizontal to avoid air pock

ets.

Strainers

If a strainer is furnished with the pump, be certain

to use it; any spherical solids which pass through a

strainer furnished with the pump will also pass

through the pump itself.

If a strainer is not furnished with the pump, but is

installed by the pump user, make certain that the

total area of the openings in the strainer is at least

three or four times the cross section of the suction

line, and that the openings will not permit passage

of solids larger than the solids handling capability

of the pump.

This pump is designed to handle up to 3 inch (76,2

mm) diameter spherical solids.

Gauges

Most pumps are drilled and tapped for installing

discharge pressure and vacuum suction gauges. If

these gauges are desired for pumps that are not

tapped, drill and tap the suction and discharge

lines not less than 18 inches (457,2 mm) from the

suction and discharge ports and install the lines.

Installation closer to the pump may result in erratic

readings.

SUCTION LINES

To avoid air pockets which could affect pump prim

ing, the suction line must be as short and direct as

possible. When operation involves a suction lift, the

line must always slope upward to the pump from

the source of the liquid being pumped; if the line

slopes down to the pump at any point along the

suction run, air pockets will be created.

Fittings

Sealing

Since even a slight leak will affect priming, head,

and capacity, especially when operating with a

high suction lift, all connections in the suction line

should be sealed with pipe dope to ensure an air

tight seal. Follow the sealant manufacturer's rec

ommendations when selecting and applying the

pipe dope. The pipe dope should be compatible

with the liquid being pumped.

Suction Lines In Sumps

If a single suction line is installed in a sump, it

should be positioned away from the wall of the

sump at a distance equal to 1 1/2 times the diame

ter of the suction line.

If there is a liquid flow from an open pipe into the

sump, the flow should be kept away from the suc

tion inlet because the inflow will carry air down into

the sump, and air entering the suction line will re

duce pump efficiency.

Suction lines should be the same size as the pump

inlet. If reducers are used in suction lines, they

should be the eccentric type, and should be in

stalled with the flat part of the reducers uppermost

If it is necessary to position inflow close to the suc

tion inlet, install a baffle between the inflow and the

suction inlet at a distance 1 1/2 times the diameter

of the suction pipe. The baffle will allow entrained

PAGE B - 3INSTALLATION

Page 11

OM-06525 PA SERIES

air to escape from the liquid before it is drawn into

the suction inlet.

If two suction lines are installed in a single sump,

the flow paths may interact, reducing the efficiency

of one or both pumps. To avoid this, position the

suction inlets so that they are separated by a dis

tance equal to at least 3 times the diameter of the

suction pipe.

Suction Line Positioning

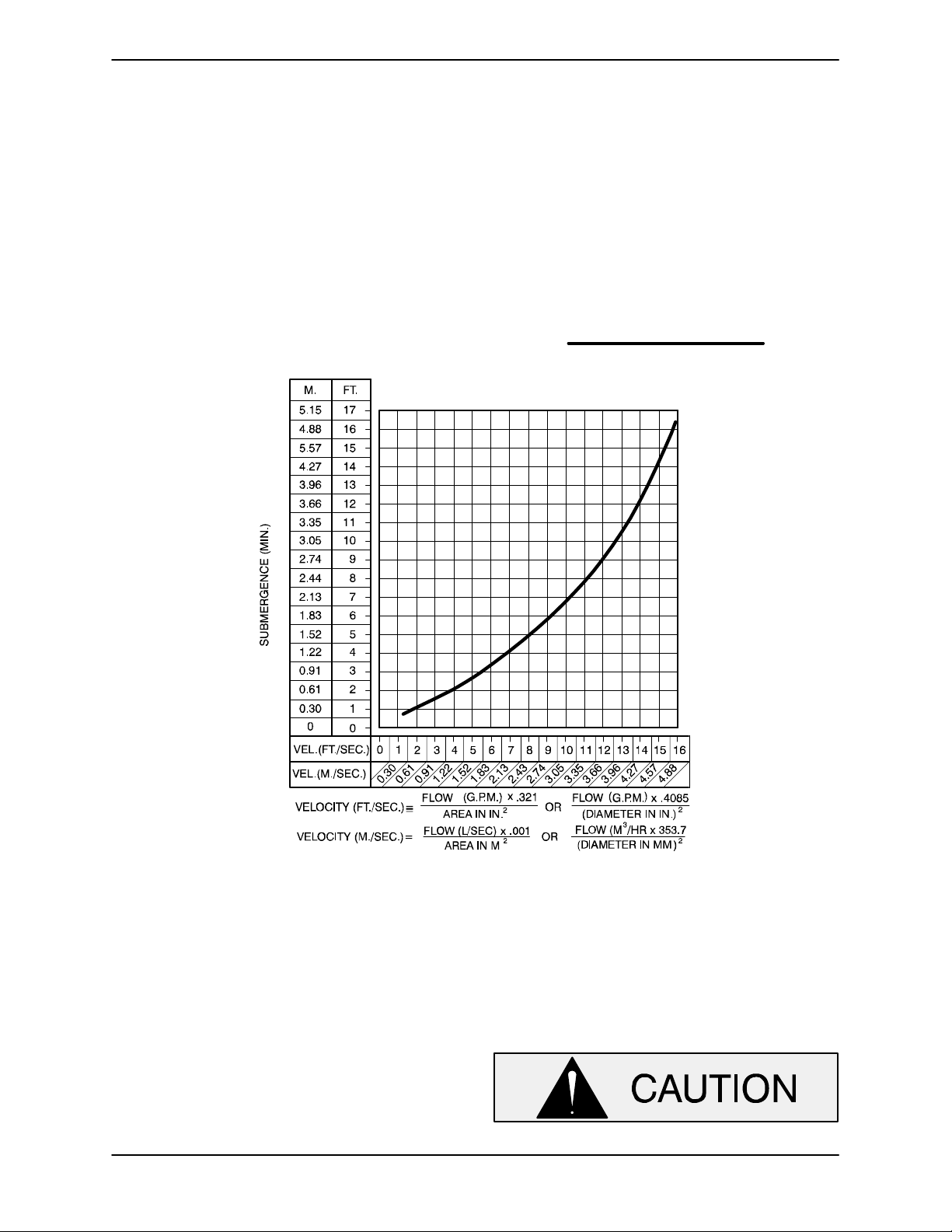

The depth of submergence of the suction line is

critical to efficient pump operation.

recommended minimum submergence vs. veloc

ity.

Figure 2 shows

NOTE

The pipe submergence required may be reduced

by installing a standard pipe increaser fitting at the

end of the suction line. The larger opening size will

reduce the inlet velocity. Calculate the required

submergence using the following formula based

on the increased opening size (area or diameter).

Figure 2. Recommended Minimum Suction Line Submergence vs. Velocity

DISCHARGE LINES

Siphoning

Do not terminate the discharge line at a level lower

than that of the liquid being pumped unless a si

phon breaker is used in the line. Otherwise, a si

phoning action causing damage to the pump

could result.

PAGE B - 4 INSTALLATION

Valves

If a throttling valve is desired in the discharge line,

use a valve as large as the largest pipe to minimize

friction losses. Never install a throttling valve in a

suction line.

If the application involves a high discharge

Page 12

OM-06525PA SERIES

head, gradually close the discharge

throttling valve before stopping the pump.

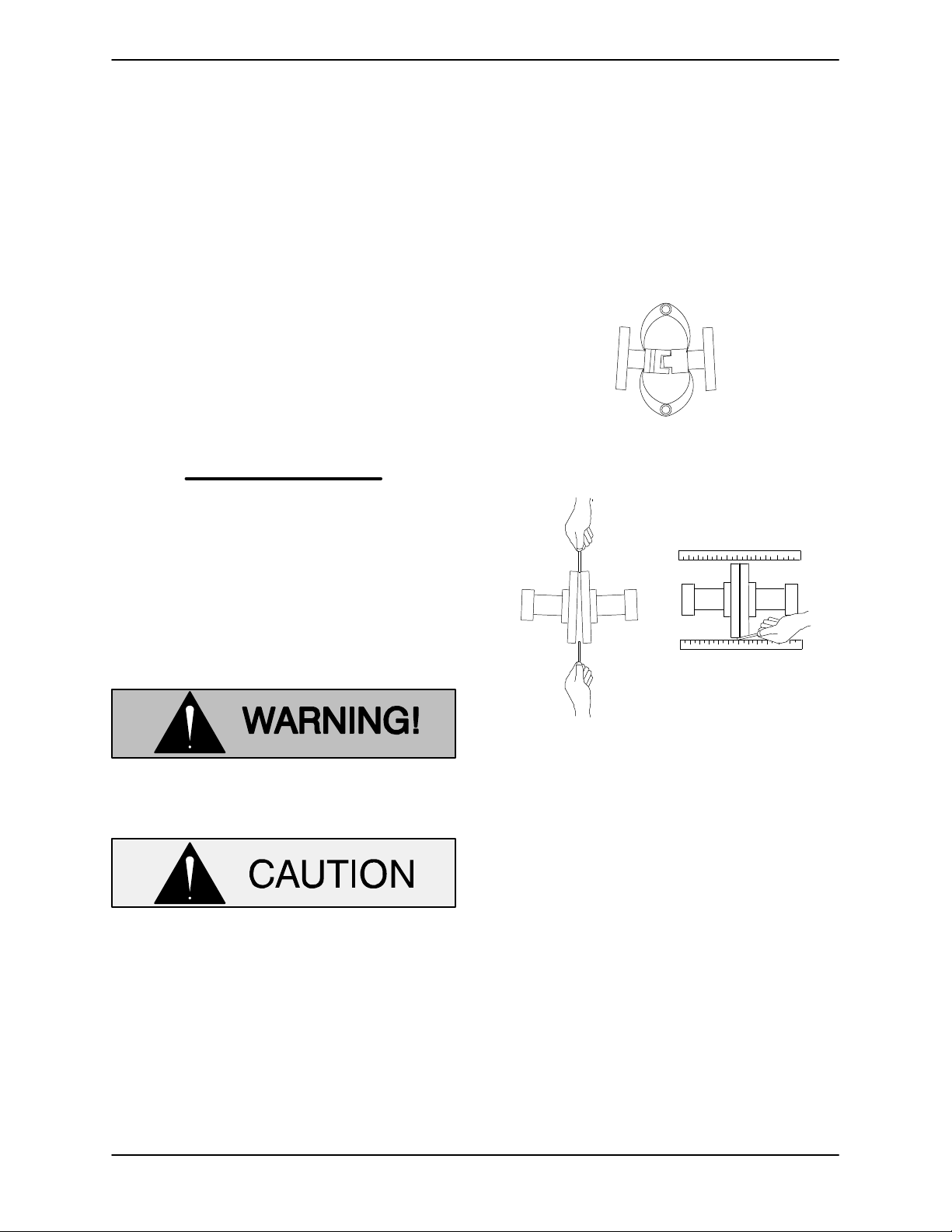

ALIGNMENT

The alignment of the pump and its power source is

critical for trouble‐free mechanical operation. In

either a flexible coupling or V‐belt driven system,

the driver and pump must be mounted so that their

shafts are aligned with and parallel to each other. It

is imperative that alignment be checked after the

pump and piping are installed, and before opera

tion.

NOTE

Check Rotation, Section C, before final alignment

of the pump.

When mounted at the Gorman‐Rupp factory, driver

and pump are aligned before shipment. Misalign

ment will occur in transit and handling. Pumps

must be checked and realigned before operation.

Before checking alignment, tighten the foundation

bolts. The pump casing feet and/or pedestal feet,

and the driver mounting bolts should also be tightly

secured.

between the driving and the driven shafts. Refer to

the coupling manufacturer's service literature.

Align spider insert type couplings by using calipers

to measure the dimensions on the circumference

of the outer ends of the coupling hub every 90.

The coupling is in alignment when the hub ends

are the same distance apart at all points (see Fig

ure 3).

Figure 3. Aligning Spider‐Type Couplings

When checking alignment, disconnect

the power source to ensure that the

pump will remain inoperative.

Adjusting the alignment in one direction

may alter the alignment in another direc

tion. check each procedure after altering

alignment.

Coupled Drives

When using couplings, the axis of the power

source must be aligned to the axis of the pump

shaft in both the horizontal and vertical planes.

Most couplings require a specific gap or clearance

Figure 4. Aligning Non‐Spider Type Couplings

Align non‐spider type couplings by using a feeler

gauge or taper gauge between the coupling halves

every 90. The coupling is in alignment when the

hubs are the same distance apart at all points (see

Figure 4).

Check parallel adjustment by laying a straightedge

across both coupling rims at the top, bottom, and

side. When the straightedge rests evenly on both

halves of the coupling, the coupling is in horizontal

parallel alignment. If the coupling is misaligned,

use a feeler gauge between the coupling and the

straightedge to measure the amount of misalign

ment.

Drive Belts

When using drive belts, the power source and the

pump must be parallel. Use a straightedge along

PAGE B - 5INSTALLATION

Page 13

OM-06525 PA SERIES

the sides of the pulleys to ensure that the pulleys

are properly aligned (see Figure 5). In drive sys

tems using two or more belts, make certain that the

belts are a matched set; unmatched sets will cause

accelerated belt wear.

Do not operate the pump without the

guard in place over the rotating parts.

exposed rotating parts can catch cloth

ing, fingers, or tools, causing severe in

jury to personnel.

DRIVE BELT TENSIONING

General Rules of Tensioning

For new drive belts, check the tension after 5, 20

and 50 hours of operation and re‐tension as re

MISALIGNED:

SHAFTS

NOT PARALLEL

MISALIGNED:

SHAFTS

NOT IN LINE

ALIGNED: SHAFTS

PARALLEL AND

SHEAVES IN LINE

Figure 5. Alignment of V‐Belt Driven Pumps

quired (see the following procedure for measuring

belt tension). Thereafter, check and re‐tension if re

quired monthly or at 500 hour intervals, whichever

comes first.

Tighten the belts in accordance with the belt manu

facturer's instructions. If the belts are too loose,

they will slip; if the belts are too tight, there will be

excessive power loss and possible bearing failure.

Select pulleys that will match the proper speed ra

tio; overspeeding the pump may damage both

pump and power source.

Ideal drive belt tension is the lowest tension at

which the belt will not slip under peak load condi

tions. Do not over‐tension drive belts. Over‐ten

sioning will shorten both drive belt and bearing life.

Under‐tensioning will cause belt slippage. Always

keep belts free from dirt, grease, oil and other for

eign material which may cause slippage.

PAGE B - 6 INSTALLATION

Page 14

PA SERIES

OM-06525

OPERATION - SECTION C

Review all SAFETY information in Section A.

Follow the instructions on all tags, labels and de

cals attached to the pump.

This pump is designed to handle most

non‐volatile, non‐flammable liquids

containing specified entrained solids.

Do not attempt to pump volatile, corro

sive, or flammable liquids which may

damage the pump or endanger person

nel as a result of pump failure.

Pump speed and operating conditions

must be within the performance range

shown on page E‐1.

STARTING

If an electric motor is used to drive the pump, re

move V‐belts, couplings, or otherwise disconnect

the pump from the motor before checking motor

rotation. Operate the motor independently while

observing the direction of the motor shaft, or cool

ing fan.

If rotation is incorrect on a three‐phase motor, have

a qualified electrician interchange any two of the

three phase wires to change direction. If rotation is

incorrect on a single‐phase motor, consult the liter

ature supplied with the motor for specific instruc

tions.

PRIMING

The pump will begin to prime upon startup. The air

in the suction line will be discharged from the prim

ing chamber discharge line. Complete priming is

indicated by a positive discharge pressure read

ing.

If full priming is not achieved, the discharge check

valve may be malfunctioning. If this occurs, shut

down the pump and consult the Maintenance and

Repair section of this manual for further details.

Install the pump and piping as described in IN

STALLATION. Make sure that the piping connec

tions are tight, and that the pump is securely

mounted. Check that the pump is properly lubri

cated (see LUBRICATION in MAINTENANCE

AND REPAIR).

Consult the operations manual furnished with the

power source.

Rotation

The correct direction of pump rotation is counter

clockwise when facing the impeller. The pump

could be damaged and performance adversely af

fected by incorrect rotation. If pump performance

is not within the specified limits (see the curve on

page E‐1), check the direction of power source ro

tation before further troubleshooting.

OPERATION PAGE C - 1

OPERATION

Leakage

No leakage should be visible at pump mating sur

faces, or at pump connections or fittings. Keep all

line connections and fittings tight to maintain maxi

mum pump efficiency.

Liquid Temperature And Overheating

The maximum liquid temperature for this pump is

160F (71C). Do not apply it at a higher operating

temperature.

Overheating can occur if operated with the valves

in the suction or discharge lines closed. Operating

Page 15

PA SERIESOM-06525

against closed valves could bring the liquid to a

boil, build pressure, and cause the pump to rup

ture or explode. If overheating occurs, stop the

pump and allow it to cool before servicing it. Refill

the pump casing

with cool liquid.

Allow an over‐heated pump to com

pletely cool before servicing. Do not re

move plates, covers, gauges, or fittings

from an over‐heated pump. Liquid with

in the pump can reach boiling tempera

tures, and vapor pressure within the

pump can cause parts being disen

gaged to be ejected with great force. Af

ter the pump completely cools, drain

the liquid from the pump by removing

the casing drain plug. Use caution when

removing the plug to prevent injury to

personnel from hot liquid.

As a safeguard against rupture or explosion due to

heat, this pump is equipped with a pressure relief

valve which will open if vapor pressure within the

pump casing reaches a critical point. If overheating

does occur, stop the pump immediately and allow

it to cool before servicing it. Approach any over

heated pump cautiously. It is recommended that

the pressure relief valve assembly be replaced at

each overhaul, or any time the pump casing over

heats and activates the valve. Never replace this

valve with a substitute which has not been speci

fied or provided by the Gorman‐Rupp Company.

Never introduce air or steam pressure into the

pump casing or piping to remove a blockage. This

could result in personal injury or damage to the

equipment. If backflushing is absolutely neces

sary, liquid pressure must be limited to 50% of the

maximum permissible operating pressure shown

on the pump performance curve.

Pump Vacuum Check

Read the vacuum gauge with the pump primed

and at operation speed. Shut off the pump. The

vacuum gauge reading will immediately drop pro

portionate to static suction lift, and should then sta

bilize. If the vacuum reading falls off rapidly after

stabilization, an air leak exists. Before checking for

the source of the leak, check the point of installa

tion of the vacuum gauge.

Priming Chamber Discharge Line

Check the priming chamber discharge line for liq

uid bypass. If bypass occurrs, shut down the

pump. Refer to the Maintenance and Repair sec

tion of this manual and disassemble and clean the

float and valve assembly inside the priming cham

ber.

STOPPING

Consult the operations manual furnished with the

power source.

After stopping the pump, lock out or disconnect

the power source to ensure that the pump will re

main inoperative.

Strainer Check

If a suction strainer has been shipped with the

pump or installed by the user, check the strainer

regularly, and clean it as necessary. The strainer

should also be checked if pump flow rate begins to

drop. If a vacuum suction gauge has been in

stalled, monitor and record the readings regularly

to detect strainer blockage.

Do not operate the pump against a

closed discharge throttling valve for

long periods of time. If operated against

a closed discharge throttling valve,

pump components will deteriorate, and

the liquid could come to a boil, build

pressure, and cause the pump casing to

rupture or explode.

OPERATIONPAGE C - 2

Page 16

PA SERIES

OM-06525

PERIODIC CHECKS

Seal And Bearing Cavity Lubrication

Both the seal and bearing cavities were fully lubri

cated at the factory. Check the lubrication levels

before startup, and regularly thereafter as indi

cated in the Maintenance and Repair section of

this manual. When lubrication is required, use only

SAE No. 30 non‐detergent oil.

Cold Weather Preservation

In below freezing conditions, drain the pump to

prevent damage from freezing. Also, clean out any

solids by flushing with a hose. Operate the pump

for approximately one minute; this will remove any

remaining liquid that could freeze the pump rotat

ing parts. If the pump will be idle for more than a

few hours, or if it has been pumping liquids con

taining a large amount of solids, drain the pump,

and flush it thoroughly with clean water. To prevent

large solids from clogging the drain port and pre

venting the pump from completely draining, insert

a rod or stiff wire in the drain port, and agitate the

liquid during the draining process. Clean out any

remaining solids by flushing with a hose.

BEARING TEMPERATURE CHECK

Bearings normally run at higher than ambient tem

peratures because of heat generated by friction.

Temperatures up to 160F (71C) are considered

normal for bearings and they can operate safely to

at least 180F (82C).

Checking bearing temperatures by hand is inaccu

rate. Bearing temperatures can be measured ac

curately by placing a contact‐type thermometer

against the housing. Record this temperature for

future reference.

A sudden increase in bearing temperature is a

warning that the bearings are at the point of failing

to operate properly. Make certain that the bearing

lubricant is of the proper viscosity and at the cor

rect level (see LUBRICATION in MAINTENANCE

AND REPAIR). Bearing overheating can also be

caused by shaft misalignment and/or excessive vi

bration.

When pumps are first started, the bearings may

seem to run at temperatures above normal. Con

tinued operation should bring the temperatures

down to normal levels.

OPERATION PAGE C - 3

Page 17

PA SERIES

TROUBLESHOOTING - SECTION D

Review all SAFETY information in Section A.

Before attempting to open or service the

pump:

1. Familiarize yourself with this manual.

2. Lock out or disconnect the power

source to ensure that the pump will

remain inoperative.

3. Allow the pump to completely cool if

overheated.

4. Check the temperature before open

ing any covers, plates, or plugs.

5. Close the suction and discharge

valves.

6. Vent the pump slowly and cautiously.

7. Drain the pump.

OM-06502

TROUBLE POSSIBLE CAUSE PROBABLE REMEDY

PUMP FAILS TO

PRIME

PUMP STOPS OR

FAILS TO DELIVER

RATED FLOW OR

PRESSURE

Discharge check valve contami

nated, damaged, or unable to seat.

Air leak in suction line. Correct leak.

Lining of suction hose collapsed. Replace suction hose.

Leaking or worn seal or pump gasket. Check pump vacuum. Replace

Suction lift or discharge head too high. Check piping installation and install

Air compressor damaged/belts broken. Check and repair/replace.

Strainer clogged. Check strainer and clean if neces

Eductor clogged. Check and clean eductor.

Air leak in suction line. Correct leak.

Lining of suction hose collapsed. Replace suction hose.

Leaking or worn seal or pump gasket. Check pump vacuum. Replace

Clean or replace check valve.

leaking or worn seal or gasket.

bypass line if needed. See INSTAL

LATION.

sary.

leaking or worn seal or gasket.

TROUBLESHOOTING PAGE D - 1

Page 18

OM-06502

Pump Troubleshooting (Cont'd)

TROUBLE POSSIBLE CAUSE PROBABLE REMEDY

PA SERIES

PUMP STOPS OR

FAILS TO DELIVER

RATED FLOW OR

PRESSURE (cont.)

PUMP REQUIRES

TOO MUCH

POWER

Strainer clogged.

Discharge check valve clogged.

Suction intake not submerged at

proper level or sump too small.

Impeller or other wearing parts worn

or damaged.

Discharge head too high.

Suction lift too high.

Pump speed too slow. Check driver output; consult driver

Belt or flexible coupling broken. Check and replace as necessary.

Pump speed too high. Check driver output; check that

Check strainer and clean if neces

sary.

Check and clean check valve.

Check installation and correct

submergence as needed.

Replace worn or damaged parts.

Check that impeller is properly

centered and rotates freely.

Free impeller of debris.Impeller clogged.

Install bypass line.

Measure lift w/vacuum gauge. Re

duce lift and/or friction losses in

suction line.

operation manual.

sheaves or couplings are correctly

sized.

PUMP CLOGS

FREQUENTLY

EXCESSIVE NOISE

Extreme ambient temperature. Reduce pump output.

Discharge head too low.

Bearing(s) frozen. Disassemble, check and replace

Discharge flow too slow.

Suction check valve or foot valve

clogged or binding.

Liquid solution too thick.

Cavitation in pump. Reduce suction lift and/or friction

Pumping entrained air.

Adjust discharge valve.

Dilute if possible.Liquid solution too thick.

bearing(s) as required..

Open discharge valve fully to in

crease flow rate, and run power

source at maximum speed.

Clean valve.

Dilute if possible.

losses in suction line. Record vac

uum and pressure gauge readings

and consult local representative or

factory.

Locate and eliminate source of air

bubble.

Secure mounting hardware.Pump or drive not securely mounted.

Impeller clogged or damaged.

Clean out debris; replace damaged

parts.

TROUBLESHOOTINGPAGE D - 2

Page 19

PA SERIES

Pump Troubleshooting (Cont'd)

TROUBLE POSSIBLE CAUSE PROBABLE REMEDY

OM-06502

BEARINGS RUN

TOO HOT

Bearing temperature is high, but

within limits.

Low or incorrect lubricant.

Suction and discharge lines not prop

erly supported.

Excessive tension on drive belt.

PUMP PREVENTIVE MAINTENANCE

Since pump applications are seldom identical, and

pump wear is directly affected by such things as

the abrasive qualities, pressure and temperature

of the liquid being pumped, this section is intended

only to provide general recommendations and

practices for preventive maintenance. Regardless

of the application however, following a routine pre

ventive maintenance schedule will help assure

trouble‐free performance and long life from your

Gorman‐Rupp pump. For specific questions con

cerning your application, contact your Gorman‐

Rupp distributor or the Gorman‐Rupp Company.

Record keeping is an essential component of a

good preventive maintenance program. Changes

in suction and discharge gauge readings (if so

Check bearing temperature regu

larly to monitor any increase.

Check for proper type and level of

lubricant.

Check piping installation for proper

support.

Align drive properly.Drive misaligned.

Check belt tension. Adjust as

required.

equipped) between regularly scheduled inspec

tions can indicate problems that can be corrected

before system damage or catastrophic failure oc

curs. The appearance of wearing parts should also

be documented at each inspection for comparison

as well. Also, if records indicate that a certain part

(such as the seal) fails at approximately the same

duty cycle, the part can be checked and replaced

before failure occurs, reducing unscheduled down

time.

For new applications, a first inspection of wearing

parts at 250 hours will give insight into the wear rate

for your particular application. Subsequent inspec

tions should be performed at the intervals shown

on the chart below. Critical applications should be

inspected more frequently.

TROUBLESHOOTING PAGE D - 3

Page 20

OM-06502

PA SERIES

Preventive Maintenance Schedule

Service Interval*

Item

General Condition (Temperature, Unusual

Noises or Vibrations, Cracks, Leaks,

Loose Hardware, Etc.) I

Pump Performance (Gauges, Speed, Flow) I

Bearing Lubrication I R

Seal Lubrication (And Packing Adjustment,

If So Equipped) I R

V‐Belts (If So Equipped) I

Air Release Valve Plunger Rod (If So Equipped) I C

Front Impeller Clearance (Wear Plate) I

Rear Impeller Clearance (Seal Plate) I

Check Valve I

Pressure Relief Valve (If So Equipped) C

Pump and Driver Alignment I

Shaft Deflection I

Bearings I

Bearing Housing I

Piping I

Driver Lubrication - See Mfgr's Literature

Daily Weekly Monthly Semi‐

Annually

Annually

Legend:

I = Inspect, Clean, Adjust, Repair or Replace as Necessary

C = Clean

R = Replace

* Service interval based on an intermittent duty cycle equal to approximately 4000 hours annually.

Adjust schedule as required for lower or higher duty cycles or extreme operating conditions.

TROUBLESHOOTINGPAGE D - 4

Page 21

PA SERIES

OM-06525

PUMP MAINTENANCE AND REPAIR - SECTION E

MAINTENANCE AND REPAIR OF THE WEARING PARTS OF THE PUMP WILL MAINTAIN PEAK

OPERATING PERFORMANCE.

STANDARD PERFORMANCE FOR PUMP MODEL PAV3A60C‐B

Based on 70F (21C) clear water at sea level

with minimum suction lift. Since pump installations

are seldom identical, your performance may be dif

ferent due to such factors as viscosity, specific

gravity, elevation, temperature, and impeller trim.

Contact the Gorman‐Rupp Company to verify per

formance or part numbers.

Pump speed and operating condition

If your pump serial number is followed by an “N”,

your pump is NOT a standard production model.

MAINTENANCE & REPAIR PAGE E - 1

points must be within the continuous per

formance range shown on the curve.

Page 22

OM-06525 PA SERIES

PARTS PAGE

ILLUSTRATION

SEE FIGURE 2

Figure 1. Pump Model PAV3A60C-B

MAINTENANCE & REPAIRPAGE E - 2

Page 23

PA SERIES

OM-06525

PARTS LIST

Pump Model PAV3A60C-B

(From S/N 1511107 Up)

If your pump serial number is followed by an “N”, your pump is NOT a standard production model. Contact

the Gorman‐Rupp Company to verify part numbers.

ITEM

PART NAME PART

NO.

NUMBER

MAT'L

CODE

QTY ITEM

NO.

PART NAME PART

NUMBER

MAT'L

CODE

QTY

1 PUMP CASING 38224-517 10000 1

2 REPAIR ROTATING ASSY 44163-534 --- 1

3 PIPE PLUG P12 15079 3

4 GASKET 25113-033 --- 2

5 LOCK WASHER 21171-514 --- 8

6 STUD MC1670 15991 4

7 SUCTION SPOOL 38642-013 10000 1

8 STRAINER SCREEN 38661-205 17040 1

9 HOPPER GASKET 38687-581 18000 1

10 LOCK WASHER 21171-511 --- 12

11 HEX HEAD CAP SCREW 22645-166 --- 4

12 HOPPER CAP 33282-033 15080 1

13 CLOSE PIPE NIPPLE T16 15079 1

14 PRIMING VALVE 26664-009 --- 1

15 SUCTION FLANGE 11412 10010 1

16 CHECK VALVE PIN 11557A 17010 1

17 BALL VALVE 26631-052 --- 1

18 FLAP VALVE ASSY 46411-060 --- 1

19 CONNECTOR S1598 --- 1

20 HOSE BARB FTG 26523-047 --- 1

21 SUCT FLANGE GASKET 11412G 19370 1

22 1/2” I.D. X 18” LG HOSE 18513-113 --- 1

23 DISCHARGE ELBOW 38647-641 10000 1

24 PIPE PLUG P04 15079 1

25 STUD 22641-023 --- 4

26 AIR COMPRESSOR ASSY 46181-908 --- 1

27 BELT 24186-011 --- 1

28 FAN GUARD 42381-510 2415X 1

29 SOCKET HD CAP SCREW 22644-215 --- 4

INDICATES PARTS RECOMMENDED FOR STOCK

30 HEX HEAD CAP SCREW 22645-168 --- 4

31 U‐BOLT 21751-019 --- 1

32 LOCK WASHER J04 15991 2

33 HEX NUT D04 15991 2

34 LOCK WASHER 21171-512 --- 4

35 HEX HEAD CAP SCREW 22644-224 --- 4

36 O‐RING S1874 --- 1

37 HEX NUT 22647-012 --- 8

38 PIPE PLUG P16 10009 1

39 STREET ELBOW RS08 11999 1

40 DRIVE SCREW BM#04-03 17000 4

41 NAMEPLATE 38818-155 13000 1

42 SPACER 31131-098 15000 4

43 SPROCKET 24271-118 --- 1

44 BUSHING 24131-211 --- 1

45 KEY N0404 15990 REF

46 COVER PLT ASSY 42111-344 --- 1

47 CLAMP BAR 38111-004 11010 1

48 MACHINE BOLT A1012 15991 2

49 HEX HD CAPSCREW B1010S 15991 1

50 FLANGE SUPPORT 34265-054 15080 1

51 SUCTION SUPPORT 34265-055 15080 1

52 G‐R DECAL GR-03 --- 1

53 DISCHARGE STICKER 6588BJ --- 1

54 SUCTION STICKER 6588AG --- 1

55 OIL LEVEL DECAL 38816-123 --- 1

56 LUBRICATION DECAL 38816-074 --- 1

57 GUARD WARNING DECAL 38816-063 --- 1

58 INSTRUCTION TAG 38817-085 --- 1

MAINTENANCE & REPAIR PAGE E - 3

Page 24

OM-06525 PA SERIES

ILLUSTRATION

Figure 2. Pump Model PAV3C60C-B (Cont'd)

MAINTENANCE & REPAIRPAGE E - 4

Page 25

PA SERIES

OM-06525

PARTS LIST

Pump Model Pump Model PAV3C60C-B (Cont'd)

(From S/N Up)

If your pump serial number is followed by an “N”, your pump is NOT a standard production model. Contact

the Gorman‐Rupp Company to verify part numbers.

ITEM

PART NAME PART

NO.

NUMBER

MAT'L

CODE

QTY ITEM

NO.

PART NAME PART

NUMBER

MAT'L

CODE

QTY

1 PUMP CASING 38224-517 10000 1

2 REPAIR ROTATING ASSY 44163-534 --- 1

3 PIPE PLUG P12 15079 3

4 GASKET 25113-033 --- 2

5 LOCK WASHER 21171-514 --- 8

6 STUD MC1670 15991 4

7 SUCTION SPOOL 38642-013 10000 1

8 STRAINER SCREEN 38661-205 17040 1

9 HOPPER GASKET 38687-581 18000 1

10 LOCK WASHER 21171-511 --- 12

11 HEX HEAD CAP SCREW 22645-166 --- 4

12 HOPPER CAP 33282-033 15080 1

13 CLOSE PIPE NIPPLE T16 15079 1

14 PRIMING VALVE 26664-009 --- 1

15 SUCTION FLANGE 11412 10010 1

16 CHECK VALVE PIN 11557A 17010 1

17 BALL VALVE 26631-052 --- 1

18 FLAP VALVE ASSY 46411-060 --- 1

19 CONNECTOR S1598 --- 1

20 HOSE BARB FTG 26523-047 --- 1

21 SUCT FLANGE GASKET 11412G 19370 1

22 1/2” I.D. X 18” LG HOSE 18513-113 --- 1

23 DISCHARGE ELBOW 38647-641 10000 1

24 PIPE PLUG P04 15079 1

25 STUD 22641-023 --- 4

26 AIR COMPRESSOR ASSY 46181-908 --- 1

27 BELT 24186-011 --- 1

28 FAN GUARD 42381-510 2415X 1

29 SOCKET HD CAP SCREW 22644-215 --- 4

INDICATES PARTS RECOMMENDED FOR STOCK

30 HEX HEAD CAP SCREW 22645-168 --- 4

31 U‐BOLT 21751-019 --- 1

32 LOCK WASHER J04 15991 2

33 HEX NUT D04 15991 2

34 LOCK WASHER 21171-512 --- 4

35 HEX HEAD CAP SCREW 22644-224 --- 4

36 O‐RING S1874 --- 1

37 HEX NUT 22647-012 --- 8

38 PIPE PLUG P16 10009 1

39 STREET ELBOW RS08 11999 1

40 DRIVE SCREW BM#04-03 17000 4

41 NAMEPLATE 38818-155 13000 1

42 SPACER 31131-098 15000 4

43 SPROCKET 24271-118 --- 1

44 BUSHING 24131-211 --- 1

45 KEY N0404 15990 REF

46 COVER PLT ASSY 42111-344 --- 1

47 CLAMP BAR 38111-004 11010 1

48 MACHINE BOLT A1012 15991 2

49 HEX HD CAPSCREW B1010S 15991 1

50 FLANGE SUPPORT 34265-054 15080 1

51 SUCTION SUPPORT 34265-055 15080 1

52 G‐R DECAL GR-03 --- 1

53 DISCHARGE STICKER 6588BJ --- 1

54 SUCTION STICKER 6588AG --- 1

55 OIL LEVEL DECAL 38816-123 --- 1

56 LUBRICATION DECAL 38816-074 --- 1

57 GUARD WARNING DECAL 38816-063 --- 1

58 INSTRUCTION TAG 38817-085 --- 1

MAINTENANCE & REPAIR PAGE E - 5

Page 26

OM-06525 PA SERIES

ILLUSTRATION

Figure 3. 44163-534 Repair Rotating Assembly

MAINTENANCE & REPAIRPAGE E - 6

Page 27

PA SERIES

OM-06525

PARTS LIST

44163-534 Repair Rotating Assembly

ITEM

NO.

1 BEARING HOUSING 38251-426 10000 1

2 BALL BEARING 23287-009 --- 1

3 IMPELLER SHAFT 38514-842 16000 1

4 SEAL PLATE 38272-425 11010 1

5 RETAINING RING S442 --- 1

6 OIL SEAL S1452 --- 1

6A OIL SEAL S1452 --- 1

7 LIP SEAL HOLDER 38242-709 11010 1

8 LOCK WASHER 21171-511 --- 16

9 GASKET 38683-480 18000 1

10 MOUNTING FLANGE 38545-014 10000 1

11 HEX HEAD CAP SCREW 22645-382 --- 8

12 SOCKET HEAD CAP SCREW 22644-216 --- 4

13 BEARING CAVITY SIGHT GAUGE S1471 --- 1

13A SEAL CAVITY SIGHT GAUGE S1471 --- 1

14 REDUCER PIPE BUSHING AP0802 15079 1

15 AIR VENT S1530 --- 1

16 PIPE PLUG P08 15079 1

16A BEARING CAVITY DRAIN PLUG P08 15079 1

16B SEAL CAVITY DRAIN PLUG P08 15079 1

17 VENTED PIPE PLUG 4823A 15079 1

18 PIPE PLUG P12 15079 2

19 CART SEAL ASSEMBLY 46513-151 --- 1

20 ADJ SHIM SET 2X 17090 REF

21 IMPELLER 38614-749 11010 1

22 FLAT HEAD CAP SCREW 22644-166 --- 2

23 IMPELLER WASHER 31514-016 17000 1

24 SOCKET HEAD CAP SCREW 22644-217 --- 1

25 O‐RING 25152-265 --- 1

26 GASKET 38687-582 18000 1

27 COVER 33659-062 15080 1

28 HEX HEAD CAP SCREW 22645-162 --- 4

29 O‐RING 25154-151 --- 1

30 O‐RING 25154-148 --- 1

31 KEY 24113-601 --- 1

32 STREET ELBOW RS12 11999 1

33 BALL BEARING S1080 --- 1

34 SHAFT KEY N0607 15990 1

35 SHAFT KEY N0607 15990 1

36 SHAFT SLEEVE O‐RING 25154-022 --- REF

37 SHIPPING PLUG 11495B 15079 2

38 O‐RING S1874 --- 1

39 OIL SEAL 25227-485 --- 1

NOT SHOWN:

PART NAME

INSTRUCTION TAG 6588U --- 1

PART

NUMBER

MAT'L

CODE

QTY

INDICATES PARTS RECOMMENDED FOR STOCK

MAINTENANCE & REPAIR PAGE E - 7

Page 28

OM-06525 PA SERIES

ILLUSTRATION

Figure 4. 46181-908 Air Compressor Assembly

MAINTENANCE & REPAIRPAGE E - 8

Page 29

PA SERIES

OM-06525

PARTS LIST

46181-908 Air Compressor Assembly

ITEM

NO.

1 AIR COMPRESSOR 26813-113 --- 1

2 PIPE PLUG P04 15079 1

3 STREET ELBOW RS04 11999 1

4 TUBE 31962-001 14090 1

5 COMPRESSION FITTING 26311-067 --- 1

6 PRESSURE RELIEF VALVE 26662-028 --- 1

7 HOSE BARB FITTING 26523-446 --- 1

8 CHECK VALVE 26641-092 --- 1

9 PIPE TEE U08 11999 1

10 PIPE COUPLING AE08 15079 1

11 REDUCER PIPE BUSHING AP0804 15079 1

12 VENTURI 26817-003 --- 1

13 ADAPTER HUB 31531-023 16000 1

14 KEY N0604 15990 1

15 SOCKET HEAD CAP SCREW 22644-211 --- 1

16 FAN 26813-951 --- 1

17 MACHINE SCREW X#10-01-1/2 15991 5

18 SPROCKET 24271-117 --- 1

19 BUSHING 24131-039 --- 1

20 HYD HOSE ADAPTER 26813-952 --- 1

INDICATES PARTS RECOMMENDED FOR STOCK

PART NAME

PART

NUMBER

MAT'L

CODE

QTY

MAINTENANCE & REPAIR PAGE E - 9

Page 30

PA SERIESOM-06525

PUMP AND SEAL DISASSEMBLY AND REASSEMBLY

Review all SAFETY information in Section A.

Follow the instructions on all tags, label and de

cals attached to the pump.

This pump requires little service due to its rugged,

minimum‐maintenance design. However, if it be

comes necessary to inspect or replace the wearing

parts, follow these instructions which are keyed to

the illustrations (see Figures 1 through 4) and the

corresponding Parts Lists. Maintenance and repair

instructions for the air compressor are covered

separately in specific literature available from the

manufacturer.

Before attempting to service the pump, lock out

and tag out incoming power to the control box and

take precautions to ensure that it will remain inop

erative. Close all valves in the suction and dis

charge lines and drain the pump casing by remov

ing the casing drain plug (3, Figure 1). Clean and

reinstall the drain plug.

pump integrity are compromised by

such practices.

Before attempting to open or service the

pump:

1. Familiarize yourself with this man

ual.

2. Disconnect or lock out the power

source to ensure that the pump will

remain inoperative.

3. Allow the pump to completely cool

if overheated.

4. Check the temperature and make

sure it is cool before opening any

covers, plates, gauges, or plugs.

5. Close the suction and discharge

valves.

6. Vent the pump slowly and cau

tiously.

7. Drain the pump.

This manual will alert personnel to

known procedures which require spe

cial attention, to those which could

damage equipment, and to those which

could be dangerous to personnel. How

ever, this manual cannot possibly antici

pate and provide detailed instructions

and precautions for every situation that

might occur during maintenance of the

unit. Therefore, it is the responsibility of

the owner/maintenance personnel to

ensure that only safe, established main

tenance procedures are used, and that

any procedures not addressed in this

manual are performed only after estab

lishing that neither personal safety nor

This pump may be equipped with an op

tional automatic starting system, and

therefore subject to automatic restart.

Keep hands and clothing away from the

unit to prevent injury during automatic

operation. Lock out the power from the

control box to ensure that the pump will

remain inoperative. Failure to do so

may result in serious personal injury.

Use only replacement parts provided or

approved by Gorman‐Rupp. Use of non‐

authorized parts may result in damage to

the equipment and/or injury to personnel

and will invalidate the warranty.

MAINTENANCE & REPAIRPAGE E - 10

Page 31

PA SERIES

OM-06525

Priming Valve Removal And Disassembly

(Figure 1)

Liquid within the priming hopper may be

pressurized. When draining liquid from the

priming hopper, use caution to avoid con

tact with the liquid. Otherwise, injury to ser

vice personnel may occur.

Disconnect the air discharge hose (22) from the

priming valve (14). Liquid will remain in the priming

valve. To drain the liquid, slowly remove the pipe

plug (not shown) in the valve body.

Gasket

Float

Arm

Orifice

Button

Figure 5. Priming Valve

If excessive liquid continues to bypass through the

priming valve after the pump is fully primed, the ori

fice button may require replacement. Remove the

old orifice button from the hole in float arm and

install a new one.

Cover

Float

Body

If draining is slow or difficult, the orifice in the valve

may be clogged (valve requires service).

Remove the hardware (10 and 11) and separate

the priming valve and hopper cap (12) from the

suction spool (7). Remove the gasket (9) and

strainer (8) from the suction spool and clean the

strainer as necessary.

It is not necessary to separate the priming valve

from the hopper cap unless complete replacement

of the priming valve is required. If replacement is

required, unscrew the priming valve from the nip

ple (13).

(Figure 5)

Remove the hardware securing the priming valve

cover to the priming valve body. Carefully lift the

valve cover and components from the priming

valve. Remove the priming valve gasket and clean

the mating surfaces.

Flap Valve Removal

(Figure 1)

Remove the discharge piping from the discharge

elbow (23).

Disengage the hardware (5 and 37) and remove

the discharge elbow (it may be necessary to tap on

the flange (15) with a soft‐faced mallet in order to

separate the discharge elbow from the flange).

With the discharge elbow removed, remove the

gasket (21). Unscrew the pin (16) from the flange.

Lift the flap valve assembly (18) out of the flange.

NOTE

Further disassembly of the flap valve is not required

since it must be replaced as a complete unit. Indi

vidual parts are not sold separately.

Remove the flange if the gasket (4) requires re

placement.

Pump Casing Removal

(Figures 1 and 2)

Support the pump casing using a suitable hoist

If the priming valve float is stuck, it can usually be

cleaned without further disassembly.

MAINTENANCE & REPAIR PAGE E - 11

and sling. Use caution to not to damage the pump

casing.

Page 32

Use lifting and moving equipment in

good repair and with adequate capacity

to prevent injuries to personnel or dam

age to equipment. If slings or chains are

used to move the pump or components,

make sure that the load is balanced;

otherwise serious personal injury or

death could result. Suction and dis

charge hoses and piping must be re

moved from the pump before lifting.

Disengage the hardware (34 and 35, Figure 2) se

curing the pump casing (1, Figure 1) to the rotating

assembly (2, Figure 2). Separate the pump casing

from the rotating assembly by pulling the casing

straight away. Use a soft‐faced mallet to tap on the

pump casing as necessary to separate the compo

nents. Remove and discard the O‐ring (36).

PA SERIESOM-06525

until the impeller comes free of the shaft. Retain the

impeller key (31).

Remove the impeller adjusting shims (20); tie and

tag the shims, or measure and record their thick

ness for ease of reassembly.

Seal Removal

(Figure 3)

Slide the integral shaft sleeve and rotating portion

of the seal off the shaft as a unit.

Use a pair of stiff wires with hooked ends to remove

the stationary element and seat.

An alternate method of removing the stationary

seal components is to remove the flat head caps

crews (22) and slide the seal plate off the shaft (3).

Remove the O‐ring (38) from the seal plate shoul

der.

Draining Oil From Seal Cavity

(Figure 3)

If any further disassembly is to be performed on the

pump, the seal oil cavity must be drained to pre

vent the oil in the seal cavity from escaping as the

impeller is removed.

Position a large, clean container under the seal

cavity drain plug (16B). Remove the plug and drain

the oil from the seal cavity into the container. For

shorter drain time, remove the vented plug (17).

Clean and reinstall the drain plug and vent plug. In

spect the oil for water, dirt or a cloudy condition

which could indicate seal failure.

Impeller Removal

(Figure 3)

Immobilize the impeller (21) with a strap wrench

and use an impact wrench to remove the impeller

screw and washer (23 and 24). Use caution not to

damage the impeller with the strap wrench.

Position two wedges opposite each other behind

the impeller, and tap the wedges carefully in turn

Position the seal plate on a flat surface with the im

peller side Use a wooden dowel or other suitable

tool to press on the back side of the stationary seat

until the seat, O‐rings, and stationary element can

be removed.

Remove the shaft sleeve O‐ring (36).

If no further disassembly is required, refer to Seal

Installation.

Removing Air Compressor Assembly

(Figure 2)

Further pump disassembly requires removal of the

air compressor assembly (26). Disengage the

hardware (10 and 29) and remove the guard (28).

Remove the hardware (10 and 30) and use a pry

bar to raise the air compressor high enough to re

move the spacers (42). Remove the belt (27) from

the air compressor drive pulley (18, Figure 4).

Disengage the hardware (32 and 33) and remove

the U‐bolt (31).

Disconnect all hoses and fittings from the air com

pressor and use a suitable hoist and sling to re

move the air compressor assembly.

MAINTENANCE & REPAIRPAGE E - 12

Page 33

PA SERIES

OM-06525

Separating Rotating Assembly From Driver

(Figures 1, 2 and 3)

The rotating assembly must be separated from the

driver before further disassembly.

Support the rotating assembly using a hoist and

sling. Disengage the coupling from the driver and

remove the coupling components and drive key

from the impeller shaft.

See Figure 2 and remove the air compressor drive

belt (27). Remove the hardware securing the drive

flange (10, Figure 3) to the flange support (50, Fig

ure 1) and move the rotating assembly to a clean,

well equipped shop area for further disassembly.

Loosen the setscrews in the bushing (44) and slide

the sprocket (43), bushing and key (45) off the

shaft.

Place a block of wood against the impeller end of

the shaft (3) and tap the shaft and assembled bear

ings (5 and 33) from the bearing housing.

After removing the shaft and bearings, clean and

inspect the bearings in place as follows.

To prevent damage during removal from

the shaft, it is recommended that bearings

be cleaned and inspected in place. It is

strongly recommended that the bearings

be replaced any time the shaft and bear

ings are removed.

Clean the bearing housing, shaft and all compo

nent parts (except the bearings) with a soft cloth

soaked in cleaning solvent. Inspect the parts for

wear or damage and replace as necessary.

Shaft and Bearing Removal and Disassembly

(Figure 5)

When the pump is properly operated and main

tained, the bearing housing should not require dis

assembly. Disassemble the shaft and bearings

only when there is evidence of wear or damage.

Shaft and bearing disassembly in the field

is not recommended. These operations

should be performed only in a properly

equipped shop by qualified personnel.

Remove the bearing housing drain plug (16A) and

drain the lubricant. Clean and reinstall the drain

plug.

Disengage the hardware (8 and 11) and remove

the mounting flange (20), gasket (9) and oil seal

(6B). Press the oil seal from the mounting flange.

Disengage the hardware (8 and 12) and pull the lip

seal holder (7) out of the bearing housing (1). Re

move the O‐rings (29 and 30) from the shoulders

on the seal holder. Pry or press the oil seals (6 and

6A) from the seal holder.

Most cleaning solvents are toxic and

flammable. Use them only in a well ven

tilated area free from excessive heat,

sparks, and flame. Read and follow all

precautions printed on solvent contain

ers.

Clean the bearings thoroughly in fresh cleaning

solvent. Dry the bearings with filtered compressed

air and coat with light oil.

Bearings must be kept free of all dirt and

foreign material. Failure to do so will great

ly shorten bearing life. Do not spin dry

bearings. This may scratch the balls or

races and cause premature bearing fail

ure.

Rotate the bearings by hand to check for rough

ness or binding and inspect the bearing balls. If ro

tation is rough or the bearing balls are discolored,

replace the bearings.

The bearing tolerances provide a tight press fit

onto the shaft and a snug slip fit into the bearing

MAINTENANCE & REPAIR PAGE E - 13

Page 34

PA SERIESOM-06525

housing. Replace the bearings, shaft, or bearing

housing if the proper bearing fit is not achieved.

If bearing replacement is required, remove the

snap ring (5) and use a bearing puller to remove

the inboard and outboard bearings from the shaft.

Shaft and Bearing Reassembly and Installation

(Figure 5)

Inspect the shaft (29) for distortion, nicks or

scratches, or for thread damage on the impeller

end. Dress small nicks and burrs with a fine file or

emery cloth. Replace the shaft if defective.

Clean and inspect the bearings as indicated in

Shaft And Bearing Removal And Disassembly.

To prevent damage during removal from

the shaft, it is recommended that bearings

be cleaned and inspected in place. It is

strongly recommended that the bearings

be replaced any time the shaft and bear

ings are removed.

The bearings may be heated to ease installation.

An induction heater, hot oil bath, electric oven, or

hot plate may be used to heat the bearings. Bear

ings should never be heated with a direct flame or

directly on a hot plate.

done quickly, in one continuous motion, to prevent

the bearings from cooling and sticking on the shaft.

After the bearings have been installed and allowed

to cool, check to ensure that they have not moved

away from the shaft shoulders in shrinking. If

movement has occurred, use a suitably sized

sleeve and a press to reposition the bearings

against the shaft shoulders.

If heating the bearings is not practical, use a suit

ably sized sleeve and an arbor (or hydraulic) press

to install the bearings on the shaft.

When installing the bearings onto the

shaft, never press or hit against the outer

race, balls, or ball cage. Press only on the

inner race.

Secure the outboard bearing to the shaft with the

snap ring (5)

When installing the shaft and bearings into

the bearing bore, push against the outer

race. Never hit the balls or ball cage.

Slide the shaft and assembled bearings into the

bearing housing until the retaining ring on the out

board bearing seats against the bearing housing.

NOTE

If a hot oil bath is used to heat the bearings, both the

oil and the container must be absolutely clean. If

the oil has been previously used, it must be thor

oughly filtered.

NOTE

Position the outboard bearing (35) on the shaft with

the retaining ring on the bearing O.D. toward the

drive end of the shaft.

Heat the bearings to a uniform temperature no

higher than 250F (120C) and slide the bearings

onto the shaft, one at a time, until they are fully

seated against the shaft shoulders. This should be

Apply a light coating of oil to the lip of the oil seal

(6B) and press it into the mounting flange (10) with

the lip positioned as shown in Figure 3. The face of

the oil seal should be flush with the chamfer on the

mounting flange bore.

Install the mounting flange gasket (9) and secure

the mounting flange to the bearing housing with

the hardware (8 and 11). Be careful not to damage

the lip of the oil seal on the shaft keyway. Torque the

capscrews (11) to 41 ft. lbs. (5,6 m. kg.).

Apply a light coating of oil to the lip of the oil seals (6

and 6A) and press them into the lip seal holder (7)

with the lips positioned as shown in Figure 3.

Slide the assembled lip seal holder and lip seals

over the shaft, using caution not to roll the lip of the

MAINTENANCE & REPAIRPAGE E - 14

Page 35

PA SERIES

OM-06525

inboard oil seal on the shaft shoulder. Secure the

lip seal holder to the bearing housing with the hard

ware (8 and 12).

Lubricate the bearings as indicated in LUBRICA

TION at the end of this section.

Securing Rotating Assembly to Driver

(Figures 1, 2 and 3)

See Figure 3 and install the key (34) in the shaft

keyway, making sure to leave room in the keyway

for the drive key (35). Install the sprocket (43, Fig

ure 2) and bushing (44, Figure 2) on the shaft to the

dimension shown in Figure 6.

(25, Figure 3). Slide the belt (27) over the air com

pressor sprocket (43). Use a pry bar to raise the

compressor high enough to install the spacers (42)

between the compressor and the mounting flange.

Secure the compressor to the mounting flange

with the hardware (10 and 30).

Reinstall the U‐bolt and hardware (31, 32 and 33).

Install the coupling guard (28) and secure it with

the previously removed hardware (10 and 29).

Seal and Impeller Installation

(Figures 3, 7, 8 and 9)

Figure 6. Drive Sprocket Positioning

Secure the bushing and sprocket to the shaft by

torqueing the bushing screws to (55 in. lbs. or 6,3

m. kg.). Install the belt (27) over the sprocket and

up through the slot in the mounting flange (25, Fig

ure 3).

Install the drive key (35, Figure 3) in the shaft key

way.

Using a suitable lifting device, position the rotating

assembly on the base and secure the flange to the

support (50, Figure 1) with the previously removed

hardware. Reinstall and align the coupling.

Installing Air Compressor Assembly

Most cleaning solvents are toxic and

flammable. Use them only in a well ven

tilated area free from excessive heat,

sparks, and flame. Read and follow all

precautions printed on solvent contain

ers.

Clean the seal cavity and shaft with a cloth soaked

in fresh cleaning solvent. Inspect the stationary

seat bore in the seal plate for dirt, nicks and burrs,

and remove any that exist. The stationary seat bore

must be completely clean before installing the

seal.

A new seal assembly should be installed

any time the old seal is removed from the

pump. Wear patterns on the finished faces

cannot be realigned during reassembly.

Reusing an old seal could result in prema

ture failure.

(Figure 2)

Use a suitable hoist and sling to position the air

compressor assembly (26) on the mounting flange

MAINTENANCE & REPAIR PAGE E - 15

To ease installation of the seal, lubricate the shaft

sleeve O‐ring and the external stationary seat O‐

ring with a very small amount of light lubricating oil.

See Figure 7 for seal part identification.

Page 36

PA SERIESOM-06525

SPRING

IMPELLER

IMPELLER

SHIMS

IMPELLER

SHAFT

BELLOWS

SPRING

CENTERING

WASHER

RETAINER

ROTATING

ELEMENT

STATIONARY

ELEMENT

SEAL PLATE

O‐RINGS

SLEEVE

O‐RING

INTEGRAL

SHAFT

SLEEVE

SHEAR

RING

(SHEARED)

STATIONARY

SEAT

Figure 7. Cartridge Seal Assembly

This seal is not designed for operation at

temperatures above 160F (71C). Do not

use at higher operating temperatures.

If the seal plate (4) was removed, install the seal

plate O‐ring (25) and lubricate it with oil. Position

the seal plate over the shaft and secure it to the

bearing housing with the flat head capscrews (22).

To prevent damaging the shaft sleeve O‐ring (36)

on the shaft threads, cover the threads with electri

cal or duct tape. Slide the O‐ring over the shaft until

it seats against the shaft shoulder. Remove the

tape covering the threads. Check to ensure that

the shaft threads are free of any tape residue and

clean as required before proceeding with seal

installation.

Lubricate the external stationary seat O‐ring with

light oil. Slide the seal assembly onto the shaft until

the external stationary seat O‐ring engages the

bore in the seal plate.

Inspect the impeller, and replace it if cracked or

badly worn. Inspect the impeller screw (24) and

shaft threads for dirt or damage, and clean or dress

the threads as required.

Install the set of impeller shims (20) provided with

the seal and install the impeller key (31) in the shaft

keyway. Position the impeller keyway over the im

peller key and press the impeller onto the shaft until

it is seated against the seal (see Figure 8).

MAINTENANCE & REPAIRPAGE E - 16

Page 37

PA SERIES

OM-06525

O‐RING ENGAGED

WITH SEAL PLATE

BORE

SHEAR RING

(UNSHEARED)

Figure 8. Seal Partially Installed

Immobilize the impeller shaft by wedging a block of

wood between one of the impeller vanes and the

ground.

STATIONARY SEAT

FULLY SEATED IN

SEAL PLATE BORE

SHEAR RING

(SHEARED)

Figure 9. Seal Fully Installed

A clearance of .025 to .040 inch (0,64 to 1,02 mm)