Page 1

ACE

PUBLICATION NUMBER OM−03984

December 9, 1994

Rev. D: 04−28−98

HS AND HSV SERIES

HYDRAULIC SUBMERSIBLE

PUMPS

THE GORMAN-RUPP COMPANY D MANSFIELD, OHIO

GORMAN-RUPP OF CANADA LIMITED D ST. THOMAS, ONTARIO, CANADA Printed in U.S.A.

eCopyright by the Gorman-Rupp Company

Page 2

OM−03984 HS AND HSV SERIES

INTRODUCTION

Thank You for purchasing a Gorman-Rupp Hy-

draulic Submersible Pump. Read this manual

carefully to learn how to safely install and operate

your pump. Failure to do so could result in personal

injury or damage to the pump.

A set of manuals accompanies your pump. Each

set consists of three parts; the Installation/Operation Manual contains essential information on installing and operating the pump. However, since

pump installations are seldom identical, some of

the information only summarizes general recommendations and practices required to inspect, position, and arrange the pump and piping.

The Parts List Manual provides a performance

curve, pump model cross-section drawing, and

parts list for your pump.

The Maintenance and Repair Manual provides

troubleshooting and maintenance instructions required to properly diagnose operational problems,

and to service the pump components.

The pump is a hydraulic motor-driven submersible

model, capable of handling liquids that may be volatile or flammable, and which could cause serious

illness or injury through direct exposure or emitted

fumes.

The pump is designed to be driven only by an

open-center type hydraulic power source with

flows and pressures not exceeding the nominal

specifications shown for your pump in Table 1,

Section B. Do not use closed-center valves or

operate the pump at higher flows or pressures.

Closed-center valves or operation at higher flows

or pressures will damage the pump motor and/or

seal, and void the pump warranty. Consult the

factory for additional information concerning the

appropriate hydraulic power source.

If there are any questions regarding the pump

which are not covered in this manual or in other literature accompanying the unit, please contact

your Gorman-Rupp distributor or the GormanRupp Company:

The Gorman-Rupp Company

P.O. Box 1217

Mansfield, Ohio 44901−1217

or:

Gorman-Rupp of Canada Limited

70 Burwell Road

St. Thomas, Ontario N5P 3R7

CONTENTS

SAFETY − SECTION A

INSTALLATION − SECTION B

PREINSTALLATION INSPECTION PAGE B − 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lubrication PAGE B − 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PUMP INSTALLATION PAGE B − 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pump and Power Source Specifications PAGE B − 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lifting PAGE B − 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hydraulic Power Source Connections PAGE B − 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rotation PAGE B − 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Positioning the Pump PAGE B − 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PIPING PAGE B − 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

OPERATION − SECTION C

STARTING PAGE C − 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

OPERATIONAL CHECKS PAGE C − 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hydraulic Oil Level/Temperature PAGE C − 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Low Oil Shutdown PAGE C − 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Oil Cooler PAGE C − 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Leaks PAGE C − 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

STOPPING PAGE C − 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

BEARING TEMPERATURE CHECK PAGE C − 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PAGE I − 1INTRODUCTION

Page 3

OM−03984HS AND HSV SERIES

RECORDING MODEL AND

SERIAL NUMBERS

Please record the model and serial number for

your Hydraulic Submersible Pump in the spaces

provided below. Your Gorman-Rupp distributor

needs this information when you require parts or

service.

Model:

Serial Number:

the equipment be abused or modified to change its

performance beyond the original factory specifications, the warranty will become void and any claim

will be denied.

If the pump is to be powered by any source other

than a Gorman-Rupp hydraulic submersible power source, contact the Gorman-Rupp Company

before installing and operating the equipment.

Gorman-Rupp assumes no responsibility for damage to the pump or any other hydraulic equipment

due to misapplication of the pump, or use with a

non-approved power source.

WARRANTY INFORMATION

NOTICE

The warranty provided with your Hydraulic Submersible Pump is part of Gorman-Rupp’s support

program for customers who operate and maintain

their equipment as described in this and the other

accompanying literature. Please note that should

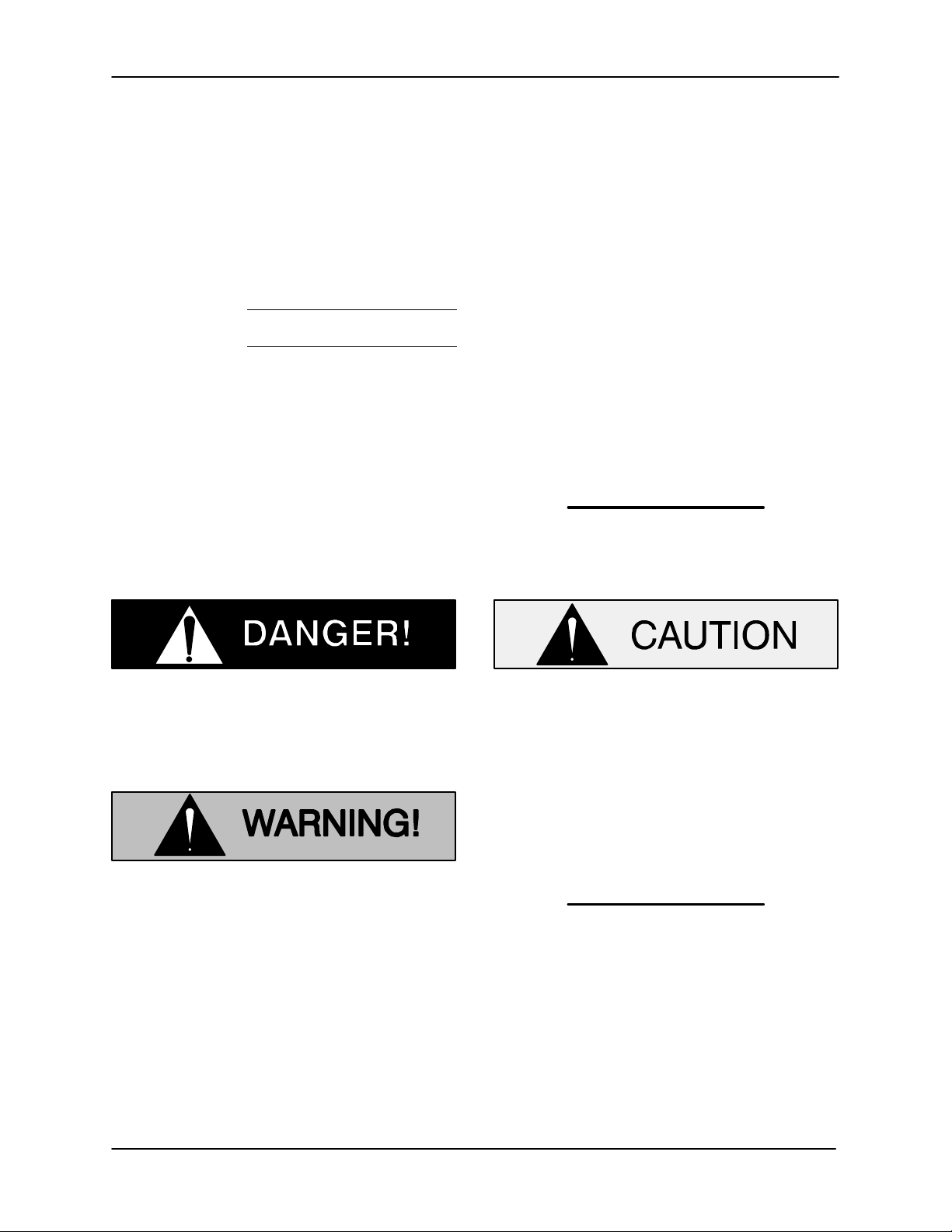

The following are used to alert personnel to procedures which require special attention, to those which

could damage equipment, and to those which could be dangerous to personnel:

Gorman-Rupp assumes no responsibility, either expressed or implied, for environmental damage resulting from leakage or spills which may occur during operation or storage of this equipment.

Immediate hazards which WILL result in

severe personal injury or death. These

instructions describe the procedure required and the injury which will result

from failure to follow the procedure.

Hazards or unsafe practices which

COULD result in severe personal injury

or death. These instructions describe

the procedure required and the injury

which could result from failure to follow

the procedure.

Hazards or unsafe practices which COULD

result in minor personal injury or product or

property damage. These instructions describe the requirements and the possible

damage which could result from failure to

follow the procedure.

NOTE

Instructions to aid in installation, operation, and

maintenance or which clarify a procedure.

PAGE I − 2 INTRODUCTION

Page 4

HS AND HSV SERIES

SAFETY - SECTION A

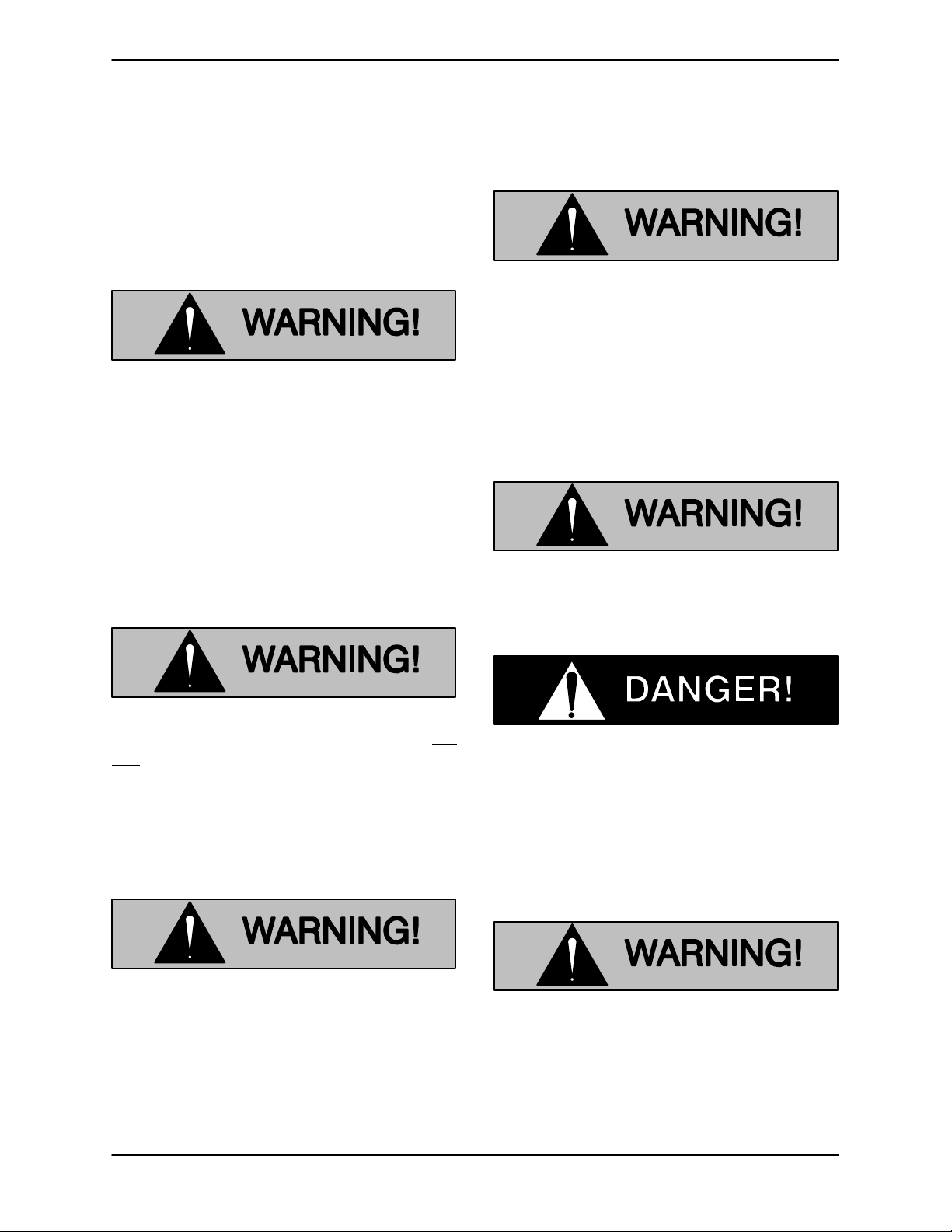

This information applies to HS and HSV

Series submersible hydraulic motor

driven pumps.

Before attempting to service the hydraulic power source or pump:

1. Familiarize yourself with this manual.

2. Shut down the hydraulic power

source and take precautions to ensure that it will remain inoperative.

3. Allow the hydraulic oil to cool before attempting to disconnect or

service the pump.

OM−03984

Use lifting and moving equipment in

good repair and with adequate capacity

to prevent injuries to personnel or damage to equipment. Attach adequate lifting equipment only to the lifting device

on the pump. Hydraulic hoses to the

power source must be removed before

lifting. Make certain that all personnel

are clear of the area before lifting.

After the pump has been installed, make

certain that the pump and all piping or

hose connections are tight, properly

supported and secure before operation.

This pump is designed to pump materials that may be volatile or flammable. Do

not attempt to pump any liquids for

which the pump is not designed, or

which may damage the pump or endanger personnel as a result of pump failure. Consult the factory for specific

application data.

This pump is designed to pump materials which could cause serious illness or

injury through direct exposure or

emitted fumes. Wear protective clothing, such as rubber gloves, face mask

and rubber apron, as necessary, before

disconnecting or servicing the pump or

piping.

Do not operate an internal combustion

engine in an explosive atmosphere.

When operating internal combustion

engines in an enclosed area, make certain that exhaust fumes are piped to the

outside. These fumes contain carbon

monoxide, a deadly gas that is colorless, tasteless, and odorless.

Fuel used by internal combustion engines presents an extreme explosion

and fire hazard. Make certain that all

fuel lines are securely connected and

free of leaks. Never refuel a hot or running engine. Avoid overfilling the fuel

tank, and clean up any fuel spills imme-

PAGE A − 1SAFETY

Page 5

diately. Always use the correct type of

fuel.

If using a customer-installed power

source, do not use closed-center

valves. Return flow from the hydraulic

motor must be allowed to return directly

to the oil reservoir to enable the pump

impeller to gradually slow to a stop. Closed-center valves will block this flow,

causing damage to the hydraulic motor

and/or the pump seal.

HS AND HSV SERIESOM−03984

Make sure hydraulic hose connections

are fully tightened. Hydraulic hoses are

equipped with check valves in each end to

prevent oil from escaping when

disconnected. Hose connections must be

tight to fully open these check valves.

Failure to tighten connections can cause

excessive hydraulic system pressure,

resulting in damage to the hydraulic motor

and/or other components.

PAGE A − 2 SAFE-

TY

Page 6

INSTALLATION − SECTION B

OM−03984HS AND HSV SERIES

Review all SAFETY information in Section A.

This section is intended only to summarize recommended installation practices for the pump. If there

are any questions concerning your specific application, contact your Gorman-Rupp distributor or

the Gorman-Rupp Company.

PREINSTALLATION INSPECTION

The pump was inspected and tested before shipment. Before installation, inspect the pump for

damage which may have occurred during shipment. Check as follows:

a. Inspect the pump assembly for cracks, dents,

damaged threads on the hydraulic connecting hoses, and other obvious damage.

b. Check for and tighten loose attaching hard-

ware. Since gaskets tend to shrink after drying, check for loose hardware at mating surfaces.

c. If the pump was shipped with hydraulic

hoses, inspect the hoses for cuts or damage

to the threaded ends.

not put the pump into service until appropriate action has been taken.

Lubrication

The pump was fully lubricated when shipped from

the factory. However, always check the lubricant

level before installing the pump (see LUBRICA-

TION in MAINTENANCE AND REPAIR).

PUMP INSTALLATION

Pump and Power Source Specifications

The Gorman-Rupp Company manufactures a hydraulic power unit specifically designed to power

the hydraulic pump. Only open-center valves

may be used in a customer-supplied power

source, with flows and pressures not exceeding

the nominal specifications shown for your pump in

Table 1. Do not use closed-center valves, or op-

erate the pump at higher flows or pressures.

Closed-center valves or operation at higher flows

or pressures will damage the pump motor and/or

seal, and void the pump warranty.

d. Check the pump hydraulic motor for any oil

leaks, and tighten any hardware as required.

e. Carefully read all tags, decals, and markings

on the pump assembly, and perform all duties

as indicated.

f. Check that the hydraulic power source pro-

vides the required horsepower and flow to

properly and safely operate the pump (see

Table 1).

If anything on the pump appears to be abnormal,

contact your Gorman-Rupp distributor or the factory to determine the repair or updating policy. Do

Do not use closed-center valves. Return

flow from the hydraulic motor must be

allowed to return directly to the oil reservoir to enable the pump impeller to

gradually slow to a stop. Closed-center

valves will block this flow, causing damage to the hydraulic motor and/or the

pump seal.

See Figure 1 for a typical hydraulic schematic for a

customer-supplied power source. Consult the factory for additional information concerning the appropriate hydraulic power source.

PAGE B − 1INSTALLATION

Page 7

OM−03984 HS AND HSV SERIES

1

Do not use closed-center valves. Return

flow from the hydraulic motor must be

allowed to return directly to the oil reservoir to enable the pump impeller to

2

2

gradually slow to a stop. Closed-center

valves will block this flow, causing damage to the hydraulic motor and/or the

pump seal.

4

3

2

Submersible Pump

Figure 1. Typical Hydraulic Schematic for Customer-Supplied Power Source

(Including Hydraulic Pump)

5

Legend

1) 4-Way Open-Center Directional Valve

(Must be operated in forward direction

2

only or use check valve (4) to prevent

reversing.)

2) Valved Quick Disconnect Coupling

3) Hydraulic Motor Driven

Submersible Pump

4) Check Valve (Recommended)

5) Flow Control (Recommended if hydraulic

flow is greater than flow required by

submersible pump.)

PAGE B − 2 INSTALLATION

Page 8

Table 1. Pump and Nominal Hydraulic Power Source Specifications

OM−03984HS AND HSV SERIES

Pump

Model

HSV4A31−HYD

HSV6A31−HYD

HSV6B31−HYD

HSV3A1−HYD

HSV3B31−HYD

Lifting

Use lifting and moving equipment with a capacity

of at least 5 times the weight of the pump, not including the weight of any customer installed accessories. Customer-installed equipment such as

discharge piping must be removed before attempting to lift. Refer to the Pump Specification

Data Sheet or contact the Gorman-Rupp Company

for the approximate weight of your pump.

Min.

Power Source

Horsepower

60

10

Max.

Hydraulic

Output

32 GPM

(7260 LPH)

8 GPM

(1817 LPH)

Max.

Operating

Pressure

2900 PSI

(205 kg/cm@)

2500 PSI

(176 kg/cm@)

Min.

Reservoir

Capacity

45 U.S. Gal

(170 L)

4 U.S. Gal

(15 L)

Make sure hydraulic hose connections

are fully tightened. Hydraulic hoses are

equipped with check valves in each end.

Hose connections must be tight to fully

open these check valves. Failure to tighten

connections can cause excessive hydraulic pressure, resulting in damage to the hydraulic motor and/or other components.

Do not attempt to lift the pump by the hydraulic hoses or the piping. Attach proper

lifting equipment to the lifting device fitted

to the pump. If chains or cable are

wrapped around the pump to lift it, make

certain that they are positioned so as not to

damage the pump, and so that the load will

be balanced.

Hydraulic Power Source Connections

The hydraulic connections on the hoses supplied

with the pump are male and female. The threads

on these hoses must be kept clean and protected.

Be sure hydraulic hoses and connections are

clean before making connections at the pump and

power source. Check connections to be sure they

are tight before starting the power source.

Rotation

Before putting the pump into service, check pump

rotation.

While checking impeller rotation, secure

the pump to prevent rolling.

Suspend the pump by the lifting handle. Quickly

apply power and note the direction of pump kickback. As viewed from the top, the pump should

kickback in a counterclockwise direction (see

Figure 2); this will indicate that impeller rotation is

correct.

If the pump kicks back in a clockwise direction, impeller rotation is incorrect. Consult the Mainte-

nance and Repair manual and make sure pressure is supplied to correct port of the hydraulic motor. Recheck pump kickback; it should now be in a

counterclockwise direction.

PAGE B − 3INSTALLATION

Page 9

OM−03984 HS AND HSV SERIES

Positioning the Pump

NOTE

Refer to OPERATION, Section C and perform a test

on dry land before submerging the pump.

This pump is designed to operate fully or partially

submerged. It may also be operated in air for extended periods.

The pump will operate if positioned on its side, but

this is not recommended because the hydraulic

motor torque could cause the pump to roll during

operation.

The pump should be independently secured and

supported by the lifting device fitted on the pump. If

the application involves a lot of debris, protect the

pump from excessive wear and clogging by suspending it in a perforated barrel or culvert pipe. If

DIRECTION OF KICKBACK

Figure 2. Kickback Direction (All Models)

the bottom is heavily sludge-covered, rest the

pump on support blocks or suspend it from a raft or

similar device near the surface of the liquid. See

Figure 2 for typical pump installations.

BY BAIL IN PERFORATED CULVERT PIPE ON SUPPORTS

Figure 3. Typical Pump Installations

PIPING

No suction piping is required in a standard submerged application. The pump is provided with a

PAGE B − 4 INSTALLATION

suction strainer to prevent large solids from clogging the impeller. All liquid entering the pump must

pass through the strainer. Any spherical solids

Page 10

OM−03984HS AND HSV SERIES

which pass through the strainer will pass through

the pump.

Either hose or rigid pipe may be used for discharge piping. To facilitate mobility and maintenance, it is recommended that the discharge line

be fitted with a quick disconnect fitting near the

pump. The discharge line must be independently

supported to avoid strain and vibration on the

pump.

For maximum pumping capacity, keep the discharge as short and straight as possible. Minimize

the use of elbows and fittings which increase friction losses through the discharge piping system.

It is recommended that a check valve or throttling

valve be installed in the discharge line to control siphoning or back flow when the pump is shut off.

PAGE B − 5INSTALLATION

Page 11

HS AND HSV SERIES

OM−03984

OPERATION − SECTION C

Review all SAFETY information in Section A.

The Gorman-Rupp Company manufactures a

hydraulic power unit specifically designed to

power the hydraulic pump. A customer-installed power source may be used to operate the

pump; however, since operating procedures

vary with the power source used, the following

instructions apply to operation with a GormanRupp power unit. Consult the factory for specific information using a customer-installed power

source.

Refer to the INSTALLATION section of this manual before startup.

Follow the instructions on all tags, labels and

decals attached to the power source.

motor must be allowed to return directly

to the oil reservoir to enable the pump

impeller to gradually slow to a stop. Closed-center valves will block this flow,

causing damage to the hydraulic motor

and/or the pump seal.

STARTING

1. Position the submersible pump away from personnel for a dry test on land.

2. Refer to the engine operation manual, start the

engine and allow it to warm up for one or two

minutes. (On units equipped with a 45 gallon

[170 liter] hydraulic tank, adjust engine speed

to 1500 RPM after warm up.)

NOTE

If the engine is equipped with a shutdown system,

hold the reset button in until the engine starts and

the engine oil pressure is maintained.

Do not operate an internal combustion

engine in an explosive atmosphere.

When operating internal combustion

engines in an enclosed area, make certain that exhaust fumes are piped to the

outside. These fumes contain carbon

monoxide, a deadly gas that is colorless, tasteless, and odorless.

Never tamper with the governor to gain

more power. The governor establishes

safe operating limits that should not be

exceeded. Consult the factory or the

power unit specification data sheet for

the maximum continuous operating

speed.

If using a customer-installed power

source, do not use closed-center

valves. Return flow from the hydraulic

3. Turn the hydraulic pressure control valve clockwise until it stops. This energizes the hydraulic

system.

Do not use the hydraulic pressure control

valve to regulate hydraulic pressure; this

valve is on/off only.

4. Check the hydraulic submersible pump to be

sure it is operating.

5. Check all connections and the pump hydraulic

motor for any oil leaks, and correct as required.

Make sure hydraulic hose connections

are fully tightened. Hydraulic hoses are

equipped with check valves in each end to

prevent oil from escaping when

disconnected. Hose connections must be

tight to fully open these check valves.

OPERATION PAGE C − 1

Page 12

OM−03984

HS AND HSV SERIES

Failure to tighten connections can cause

excessive hydraulic system pressure,

resulting in damage to the hydraulic motor

and/or other components.

6. De-energize the hydraulic system. Connect the

discharge hose and install the pump as described in INSTALLATION, Section B. Energize

the hydraulic system again and adjust the engine speed to achieve the desired pump output.

7. If full volume is not required, the engine speed

may be slowed down as necessary to conserve

fuel. Do not increase engine speed once the

factory-set system operating pressure is

achieved.

NOTE

Some pump models are equipped with a vented

screw (see the Parts Identification List in the MAIN-

TENANCE AND REPAIR MANUAL) which is de-

signed to relieve trapped air in the pump casing.

The pump will not operate if this trapped air is not

removed. If the pump does not produce flow, deenergize the hydraulic system, remove the pump

from the wet well or sump, and check to ensure that

the hole in the vented screw is not clogged.

170_F (77_C). If the temperature becomes excessive, shut down the system and allow the oil

to cool. Check for insufficient oil in the reservoir,

kinked hydraulic hoses, inadequate ventilation

of the reservoir or oil cooler, a clogged return

line filter (on models equipped with a 45 gallon

[170 liter] hydraulic tank, the gauge on the filter

will read in the red or above 40 PSI), or the submersible pump may be running dry for extended periods of time.

Low Oil Shutdown

1. The low oil shutdown switch is mounted on the

front of the hydraulic oil reservoir (on units

equipped with emergency shutdown packages). It will shut down the engine in the event

of loss of hydraulic oil to protect against damage to the system.

Oil Cooler

1. If your hydraulic power unit is equipped with an

engine-mounted air/oil cooler to cool the hydraulic oil, be sure the cooling fins are kept

clean so air can circulate freely through it.

System Leaks

OPERATIONAL CHECKS

Hydraulic Oil Level/Temperature

1. Maintain the hydraulic oil level to the top of the

sight glass on the side of the hydraulic reservoir.

2. After initial startup, check the hydraulic oil level

in the reservoir. Filling the hydraulic hoses initially will cause the level to drop.

3. During operation, check to be sure the hydraulic oil operating temperature never exceeds

1. Check all system components regularly for

leaks. When checking the relief valve, check the

control valve and tubing. Replace the valve,

and repair or replace tubing, fittings, oil cooler

or any other components at the first sign of leakage.

STOPPING

1. To stop the pump, de-energize the system (turn

the control valve counter-clockwise).

2. Reduce the engine speed slowly before stopping to prevent possible system damage.

OPERATIONPAGE C − 2

Page 13

For U.S. and International Warranty Information,

Please Visit www.grpumps.com/warranty

or call:

U.S.: 419−755−1280

International: +1−419−755−1352

For Canadian Warranty Information,

Please Visit www.grcanada.com/warranty

or call:

519−631−2870

THE GORMAN-RUPP COMPANY D MANSFIELD, OHIO

GORMAN-RUPP OF CANADA LIMITED D ST. THOMAS, ONTARIO, CANADA

Loading...

Loading...