GORMAN-RUPP PUMPS GMS Series Installation, Operation And Maintenance Manual

TVXY

OM-04910

August 12, 1998

Rev. B 01/25/00

INSTALLATION, OPERATION,

AND MAINTENANCE MANUAL

ROTARY GEAR PUMPS

MODELS

GMSSERIESPUMPS

S&TSIZES

THE GORMAN-RUPP COMPANY D MANSFIELD, OHIO

GORMAN-RUPP OF CANADA LIMITED D ST.THOMAS, ONTARIO, CANADA Printed in U.S.A.

ECopyright by the Gorman-Rupp Company

TABLE OF CONTENTS

INTRODUCTION PAGE I --- 1...................................................

SA FE T Y --- SE CT I ON A PA G E A --- 1............................................

IN STA L LAT ION --- SE CTI ON B PA G E B --- 1.....................................

PUMP MODEL DESIGNATION PAGE B---1..................................................

PREINSTALLATION INSPECTION PAGE B---2................................................

STORAGE PA GE B --- 2....................................................................

Flushing PA GE B --- 2..................................................................

PUMP INSTALLATION P AGE B---3..........................................................

Lifting PA GE B --- 3.....................................................................

Positioning The Pump PA GE B --- 3......................................................

Mounting PA GE B --- 3.................................................................

Piping PA GE B --- 3....................................................................

Strainers PA GE B --- 4..................................................................

Gauges PA GE B --- 4...................................................................

Sealing PA GE B --- 4...................................................................

Valves PAGE B --- 4....................................................................

ALIGNMENT PAGE B --- 4..................................................................

Coupled Drives PA GE B --- 4............................................................

V-Belt Drives PA GE B --- 5...............................................................

V-BELT TENSIONING PAGE B---5..........................................................

General Rules of Tensioning PAGE B---5.................................................

Tension Measurement PAGE B---6......................................................

OPER AT IO N --- SE CT I ON C PA G E C --- 1.......................................

PU MP OPERATION PA GE C --- 1............................................................

PRE-OPERATION PAGE C---1..............................................................

Before Starting The Pump PAGE C---1...................................................

Checking Pump Rotation PAGE C---1...................................................

STARTING PA GE C --- 2....................................................................

OPERATION PAGE C --- 2..................................................................

Liquid Temperature PA GE C --- 2.........................................................

Overheating PA GE C --- 2...............................................................

Checking Gauges PAGE C---2..........................................................

Strainer Check PAGE C---3.............................................................

Leakage PAGE C --- 3..................................................................

PRESSURE RELIEF VALVE ADJUSTMENT PAGE C---3........................................

Cracking Pressure PAGE C---3.........................................................

Complete By-Pass Pressure PAGE C---3.................................................

STOPPING PA GE C --- 3....................................................................

TR OUB LES HOO TI NG --- S E CT ION D PA G E D --- 1...............................

TROUBLESHOOTING WITH GAUGES P AGE D---1............................................

TROUBLESHOOTING CHART P AGE D---2...................................................

PREVENTIVE MAINTENANCE PAGE D---4...................................................

PUMP MAINTENANCE AND REPAIR --- SECTION E PAGE E --- 1.................

PARTS KEY:

TypicalGMSS&TSizePumpModel PAGEE---3.........................................

i

TABLE OF CONTENTS

(continued)

ASSEMBLED GMS S & T SIZE PUMP MODEL ILLUSTRATION PAGE E---4......................

PU MP DISASSEMBLY PA GE E --- 5..........................................................

Preparing for Disassembly PA GE E---5..................................................

Pressure Relief Valve (10) PAGE E---6...................................................

Foot Bracket Kit - S Size Only (08) PAGE E---6...........................................

Coverplate Kit (11) PAGE E---6.........................................................

Head/Idler Kit (01/02) PAGE E---6.......................................................

Seal Gland Removal (06I) PAGE E---7...................................................

Rotor/Shaft Removal (03) PAGE E---7...................................................

Backhead Assembly (06) PAGE E---7...................................................

PUMP REASSEMBLY PAGE E---7..........................................................

Cleaning and Inspection PAGE E---7....................................................

Bushing Preparation PAGE E---8........................................................

Backhead Kit (06) PAGE E---8..........................................................

Rotor/Shaft Assembly (03) PAGE E---8..................................................

Head/Idler Kit (01/02) PAGE E---8.......................................................

Coverplate Kit (11) PAGE E---9.........................................................

Seal Gland Installation (06I) PAGE E---9.................................................

Foot Bracket Kit - S Size Only (06I) P AGE E- --9..........................................

SETTING END CLEARANCE PAGE E---9....................................................

RELIEF VALVE DISASSEMBLY (S Hydraulic Size Only) PAGE E---10............................

RELIEF VALVE REASSEMBLY (S Hydraulic Size Only) PAGE E---11.............................

RELIEF VALVE DISASSEMBLY (T Hydraulic Size Only) PAGE E---12............................

RELIEF VALVE REASSEMBLY (T Hydraulic Size Only) PAGE E---13.............................

RELIEF VALVE INSTALLATION PAGE E---13.................................................

SEAL APPENDIX --- SECTION F P AGE F---1...................................

Standard Friction Drive And Option 61M Mechanical Seals PAGE F---1...........................

Option 60N Positive Drive Seal PAGE F---3...................................................

Standard 65 And Option 65Q Packing Seals PAGE F---5.......................................

ii

INTRODUCTION

OM--04910GMS SERIES

Thank You for purchasing a Gorman-RuppRotary

Gear Pump. This manual is designed to help you

achievethebest performanceand longest lifefrom

your Gorman-Rupp Rotary Gear pump. Read this

manual carefully to learn how to safely install, operate and repair your pump. Failure to do so could

result in personal injury or damage to the pump.

This manual will alert personnel to known procedures which require special attention, to those

which could damage equipment, and to those

whichcould be dangerous to personnel. However,

this manual cannot possibly provide detailed instructions and precautions for each specific application or for every situation that might occur during maintenance of the unit. Therefore, it is the responsibility of the owner, installer and/or maintenance personnel to ensure that applications and/

or maintenance procedures not addressed in this

manual are performed only

neither personal safety nor pump integrity are

compromisedbysuchapplicationsorprocedures.

after establishing t hat

If there a re any questions regarding the pump or

drive unit which are not covered in this manual or

in other literature accompanying this unit, please

contact your Gorman-Rupp distributor or the Gorman-Rupp Company:

The Gorman-Rupp Company

P.O. Box 1217

Mansfield, Ohio 44901-- 1217

or:

Gorman-Rupp of Canada Limited

70 Burwell Road

St. Thomas, Ontario N5P 3R7

RECORDING MODEL AND

SERIAL NUMBERS

Please record the pump modeland serial number

in the spaces provided below. Your Gorman-Rupp

distributorneeds thisinformationw hen yourequire

parts or service.

In addition to this manual, a separate Parts List is

shippedwiththepump.RefertothePartsListwhen

ordering parts.

If your pump is furnished with a drive unit, refer to

the drive unit manufacturer’ s installationand operation instructions in the literature accompanying

the pump.

These pumps can transfer a wide range of light,

medium, a nd heavy viscosity liquids, depending

on design and components. Some models are

not recommended for use with water; others

when fitted with specific options, may be used

with water; consult the factory.

Pump Model:

Serial Number:

WARRANTY INFORMATION

The warranty provided with your pump is part of

Gorman-Rupp’s support program for customers

who operate and maintain their equipment as described in this and the other accompanying literature. Please note that should the equipment be

abused or modified to change its performance beyond the original factory specifications, the warranty will become void and any claim will be denied.

INTRODUCTION

PAGE I -- 1

GMS SERIESOM--04910

The following are used to alert personnel to procedures which require special attention, to those which

could damage equipment, and to those which could be dangerous to personnel:

Immediate hazards which will result in

severe personal injury or death. These

instructions describe the procedure required and the injury which will result

from failure to follow the procedure.

Hazards or unsafe practices which

COULDresult in severe personal injury

or death. These instructions describe

the procedure required and the injury

which could result fromfailure to follow

the procedure.

HazardsorunsafepracticeswhichCOULD

resultinminorpersonalinjuryorproductor

property damage. These instructions describe the requirements and the possible

damage which could result from failure to

follow the procedure.

NOTE

Instructions to aid in installation, operation, and

maintenance or which clarify a procedure.

PAGE I -- 2

INTRODUCTION

GMS SERIES OM--04910

SAFETY --- SECTION A

This information is specific to Gorman-Rupp GMS

Series Rotary Gear Pumps.It appliesthroughout

this manual and any manual or literature accompanying the pump.

In addition to this manual, see the separate literature covering the drive unit used to operate this

pump.

Pumps and relatedequipmentmust be installed and operated according to all national, local and industry standards.

This manual will alert personnel to

known procedures which require special attention, to those which could

damage equipment, and to thosewhich

could be dangerousto personnel. However, this manual cannot possibly provide detailed instructions and precautionsfor each specificapplication or for

every situation that might occur during

maintenance of the unit. Therefore, it is

the responsibility of the owner, installer

and/or maintenance personnel to ensure that applications and/or maintenanceproceduresnot addressedin this

manual are performed only after establishing that neither personal safety nor

pump integrity are compromised by

such applications or procedures.

coveredin thismanualcouldleadto destruction of equipment, injury, or death.

The standard versionofthis pump isdesigned to handle a wide range of light,

medium, and heavy viscosity liquid, depending on design and components,

and a range oftemperatures when fitted

with different seals. Do not apply at

higher temperatures than the seal will

handle. Do not attempt to pump liquids

which may damage the pump or endanger personnel as a result of pump failure; consult the factory for chemical

compatibility.

If the pump and motor are furnished

mountedon abase,make certainthat all

lifting devices have adequate capacity.

If chains or cables are used in lifting,

makecertain that they are positioned so

as not to damage components, and so

that the load will be balanced.

Afterthe pump hasbeen installed,make

certain that the pump and all piping or

hoseconnec t ionsare sec ure beforeoperation.Looseconnectionscan resultin

damage to the equipment and serious

injury to personnel.

Before attempting to install, operate, or

service this pump, familiarize yourself

withthismanual,and withall otherliterature shipped with the pump. Unfamiliarity with all aspects ofpumpoperation

SAFETY

Neveroperatethe pump without a pressure relief valve installed on the pump

orin the discharge piping. Make certain

that pump-mounted pressure relief

PAGE A -- 1

OM--04910 GMS SERIES

valves are installed with their adjusting

ends toward the suction port.Ifbi-rotational operation is required, a pressure

relief device must be provided for both

directions of flow. Operation without a

pressure relief valve or with an improperly installed relief valve could cause

the pump to explode, resulting in serious injury or death to personnel.

Beforeattempting toopenorservic e the

pump:

1. Familiarize yourself with this manual.

2. Lock out incoming power to the

drive unit to ensure that the pump

will remain inoperative.

3. Allow the pump tocompletelycool

if overheated.

4. Close the discharge and suction

valve (if used).

3. Refer to the instructions in this

manual before restarting the

pump.

Do not remove plates, covers, gauges,

pipe plugs or fittings from an overheated pump. Vaporpressure within the

pump can cause parts being disengagedto be ejected withgreatforce.Allowthe pump to completely coolbefore

servicing.

Do not operate this pump without

guards in place over the rotating parts.

Exposed rotating parts can catch clothing, fingers or tools, causing severe injury to personnel.

An overheated pump can cause severe

burns and injury.If overheating occurs:

1. Stop the pump immediately.

2. Allowthepumptocompletelycool.

This pump may be used to handle liquidswhichmay cause serious illne ss or

injury through direct exposure or

emitted fumes. Wear protective clothing, such as rubber gloves, face mask

and rubber apron, as necessary, before

disconnecting or servicing the pump or

piping.

PAGE A -- 2

SAFETY

GMS SERIES

OM--04910

INSTALLATION --- SECTION B

Review all SAFETY information in Section A.

Pumps and relatedequipmentmust be installed and operated according to all national, local and industry standards.

Since pump installations areseldom identical,this

sectionis intended only to summarize generalrecommendations and practices required to inspect,

position,and arrangethepump andpiping.Ifthere

are any questions concerning your specific installation, contact your Gorman-Rupp distributor or

the Gorman-Rupp Company.

Mostof theinformation applies toa floodedsuction

installation where liquid is supplied under pressure.

Typical Pump Model

GHS 1 1/2 GF 32

Design

Style

Design Style: Gorman-Rupp rotary gear pumps

are available in five basic designs:

S GMC --- Medium Duty --- Compact

S GMS --- Medium Duty

S GHC --- Heavy Duty --- Compact

S GHS --- Heavy Duty

S GHA --- Abrasive Duty

Port Size: Gorman-Rupp rotary gear pumps are

available in port sizes from 1 to 6 inches, depending on the design style. Consult your GormanRupp distributoror the factory for additional sizes.

Port

Size

Hydraulic

Size

Construction

Code

Ifthepumpis positioned above the liquidin astatic

lift installation, information such as mounting, piping configuration and priming must be tailored to

specific conditions.

Thesepumpsarenotrecommendedfor

use with water. Some models, when fitted

withspecificoptions,maybeusedwithwater; consult the factory.

PUMP MODEL DESIGNATION

Following is a description of the modelnumbering

system for Gorman-Rupp rotary gear pumps.

Rotary gear pump model numbers includedesign

style, port size, hydraulic size and construction

code.

Hydraulic Size: The first letterin the hydraulicsize

is a rotor diameter code. The second letter indicates tooth length.

Construction Code: Construction Codes for Gorman-Rupp rotary gear pumps are as follows:

Code Description

3 Iron w/Mechanical Seal(s)

4Ironw/PackingorLipSeal(s)

9 316 SST w/ M echanical Seal(s)

10 316 SST w/Packing or Lip Seal(s)

32 Steel w/Mechanical Seal(s)

38 Steel w/Packing or Lip Seal(s)

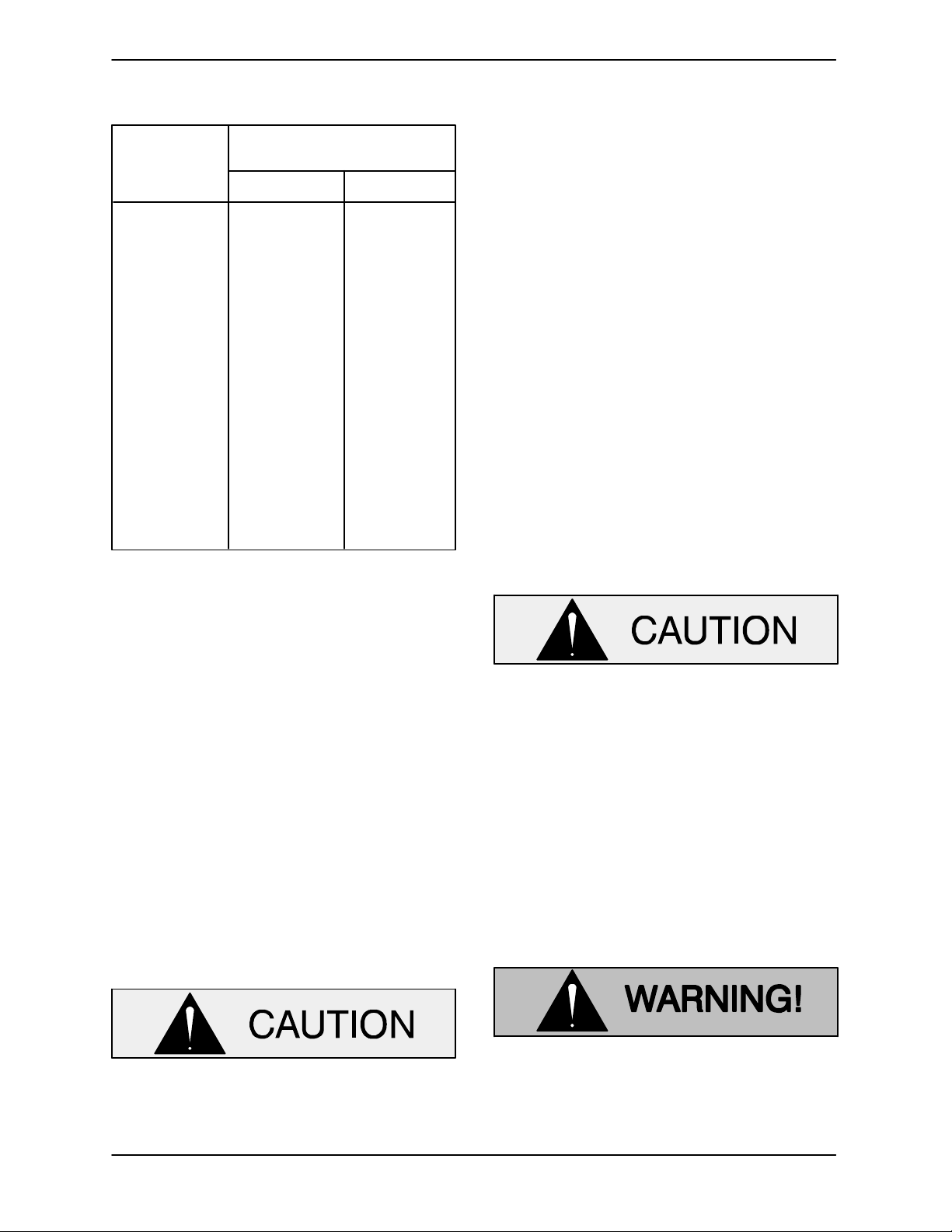

Theoretical Displacement: Table B-1 indicates

theoreticaldisplacement values for each hydraulic

size.

NOTE

Actual capacities and recommended shaft speeds

vary according to application. Consult your Gorman-Rupp distributor or the factory for additional

information.

INSTALLATION

PAGE B -- 1

GMS SERIESOM--04910

Table B-1. Theoretical Displacement

Theoretical Displacement

Hydraulic

Size

DC 0.00568 21.486

DE 0.00704 26.646

GC 0.00967 36.619

GF 0.01405 53.186

GH 0.01915 72.479

GJ 0.02317 87.700

JG 0.03579 135.49

JJ 0.05159 195.28

JL 0.07078 267.94

JP 0.10078 381.48

NK 0.10665 403.71

NM 0.14173 536.51

NP 0.17681 669.31

RM 0.24030 909.65

RP 0.29979 1134.8

RR 0.35927 1360.0

RS 0.41876 1585.1

SR 0.65752 2489.0

SU 1.10240 4173.2

TU 1.91280 7240.7

Per Revolution

Gallons Centimeters

Ifthe pump willnot beimmediately installed, follow

these procedures or damage t o the pump will occur.

a. Do not flush the pump. Ensure that the port

3

plugs shipped with the pump remain in place

until piping is installedto help prevent dust or

other foreignobjects from entering the pump.

b. Pumps that will not be installed for an ex-

tended period should be stored indoors if

possible. The factory-installed port plugs will

not ensure protection from excessive humidity, splash w ater or rain. In very humid or wet

conditions, install air-tight plugs in the ports

andfillthepump completelywith a lubricating

preservative liquid that is compatible with the

liquid to be pumped.

c. Pumps stored outdoors must be fully pre-

servedasdescribedabove, completelycovered with plastic or other water-tightmaterial,

and the covering anchored to ensure that it

will not be blown off.

PREINSTALLATION INSPECTION

Thepump assembly wasinspected and tested before shipment from the factory. Before installation,

check for damage which may have occurred during shipment. Check as follows:

a. Inspectthe pumpassemblyfor cracks, dents,

damaged threads, and other obvious damage.

b. Check for loose attaching hardware. Since

gaskets tend to shrink after drying, check for

loosehardwareatthematingsurfaces.

c. Carefully read all tags, decals, and markings

onthepump assembly,and performallduties

indicated.

STORAGE

Flushing

Cleanpiping is essentialbecauseofclosetolerancemoving partsinthis pump.Flush

all dirt, grit, weld beads or scale from the

suction piping before installing the pump.

Damage to the pump because of debris in

thesuctionlineisnotcoveredbythepump

warranty.

The pump may have been tested using a petroleum-based preservative, or a preservative may

havebeenused for long-term storage of thepump.

Ifflushing is required, do not do so untiljust before

installation; the test oil protects close-tolerance

pump parts from corrosion.

Due to the extreme close machining tolerances within rotary gear pumps, proper

storage before installation is essential to

prevent damage to the pump.

PAGE B -- 2

Most cleaning solvents are toxic and

flammable. Use themonly in a wellventilated area free from flame, sparks, and

excessiveheat. Read and followallprecautions printed on solvent containers.

INSTALLATION

GMS SERIES

OM--04910

To flush the pump, use an approved solvent compatible with the liquid being pumped. Make cer-

tain that the solvent will not attack pump components, particularly seals and gaskets.

PUMP INSTALLATION

Pump dimensions are shown in the separate

Pump Specification Bulletin.

Neveroperatethe pump without a pressure relief valve installed on the pump

orin the discharge piping. Make certain

that pump-mounted pressure relief

valves are installed with their adjusting

ends toward the suction port.Ifbi-rotational operation is required, a pressure

relief device must be provided for both

directions of flow. Operation without a

pressure relief valve or with an improperly installed relief valve could cause

the pump to explode, resulting in serious injury or death to personnel.

Lifting

heavy enough to absorb any vibration, strain or

shock.

Piping

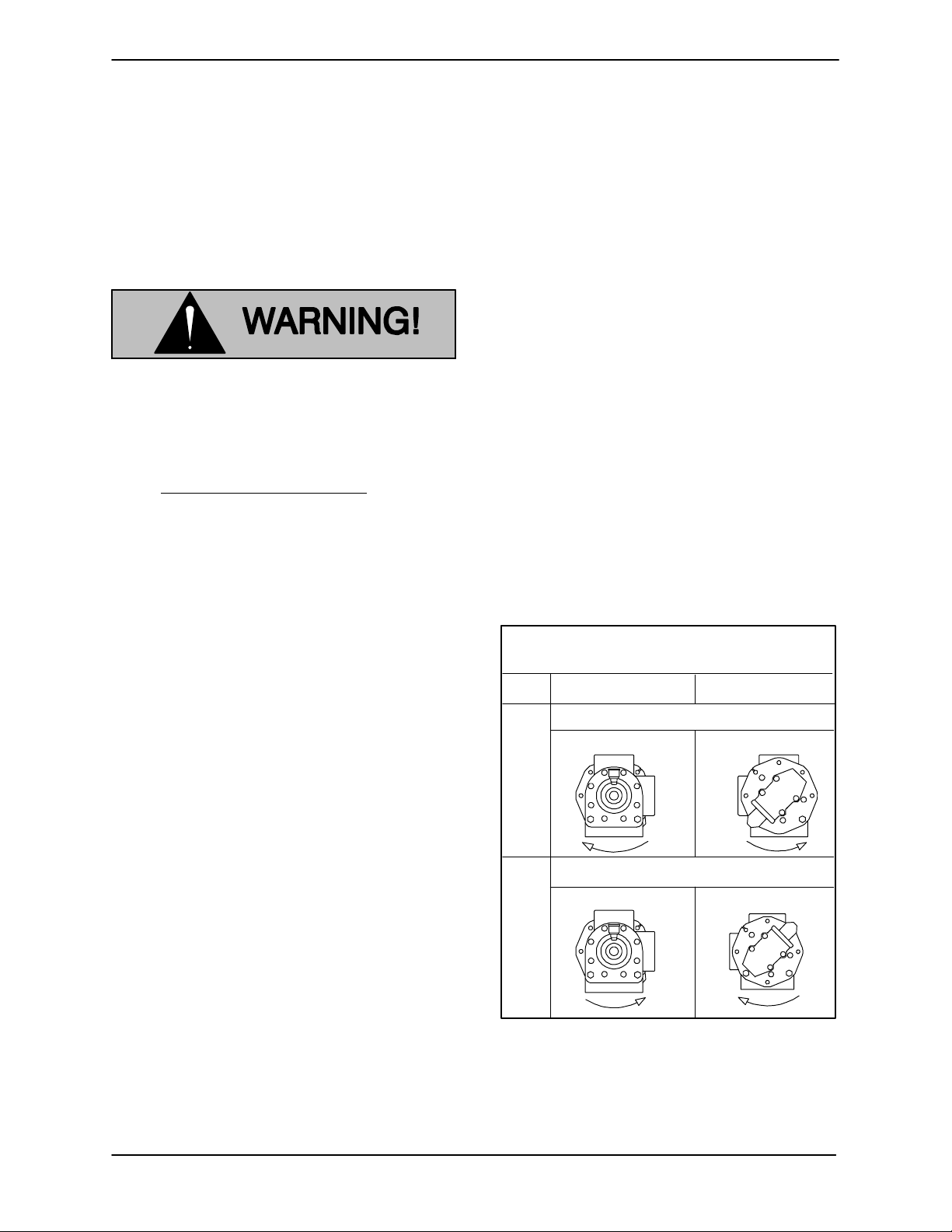

Before establishing suction and discharge lines,

determine pump port positions and rotation. Figure B-1 shows typical port positions for the standard 90_ housing; if you have selected a 180_

housing port option, your port positionswill bedifferent.

Eitherhoseor rigid pipe maybe used to makeconnections. If rigid piping is used, install expansion

joints to protect t he pump from vibration and thermal expansion in the piping. Donot useexpansion

joints or flexible connectors to adjust misaligned

piping.

Begin piping layout at the pump, and work toward

the source of s upply and the point of discharge. If

an obstacle is in the way of a suction or discharge

line, run the piping around the obstruction, not

over it. Running piping over an obstruction will

create anair pocket which willmake primingmore

difficult.

Housing Position Std. 90_ Pump

(3---12 O’clock) Head Mounted Relief Valve

OPT.

Drive End

Front End

Remove suction and discharge hose and piping

beforeattemptingto liftthepump.Useliftingequipment with a capacity of at least five times the total

weight of the equipment being lifted.

Positioning The Pump

Locatethe pump as closeas possible to the liquid

being pumped. Locating the pump below the liquid source will help self-priming and reduce the

possibility of cavitation.

Mounting

The pump may be shipped alone, mounted on a

base,or w ith pumpand motormountedona base.

Install the pump and motor on a base before

mounting the base on a foundation.

Mount the base on a foundation that will provide

permanent, rigid support for the pump, and willbe

Rotation Clockwise

D

STD.

Rotation Counter-clockwise

S

01A

Figure B-1. Typical Port Positions & Rotation

Ifpossible,slopethe pipingtoward thepumpsono

air or liquid is trapped in the piping. If a long horizontal suction line is necessary, install the line below the liquid level whenever possible in order to

S

D

S

D

D

S

INSTALLATION

PAGE B -- 3

GMS SERIESOM--04910

keep the piping fullof liquid. This will make priming

easier because the pump will not have to remove

as much air in the line.

The discharge and suction lines must be independently supported to avoid vibration and strain

on the pump. For maximum pumping capacity,

keepthe lines as shortand straightas possible.Elbows and fittings used in the lines increase friction

losses; minimize their use. Reducers used in suction lines should be the eccentric type installed

with the flat part uppermost to avoid creating air

pockets.

Before tightening a connection or flange, align it

exactly w ith the pump port. Never pull a pipe line

into place by tightening the flange bolts and/or

couplings.

Strainers

Valves

To avoid air pockets, install piping valves with the

stem horizontal.

Topreventleakageduringshutdown, installa shutoff valve in the discharge line, particularly on a

floodedsuction application. Shutoff valves are not

recommended for suction lines.

Itisnot recommended thata foot valve beinstalled

at the end of the suction line. If desired to install a

foot valve, consult the factory.

When handling very hot or cold liquids, install a

pressure relief valve in any part of the system that

can bevalvedoff orisolated; this will protect piping

against damage from liquid thermal expansion or

contraction from temperature changes during

shutdown.

ALIGNMENT

Because of the close-tolerance moving parts of

thispump, it is recommended that a strainer be in stalled in the suction line. The strainer should be

large enough to prevent excessive vacuum, and

capable of operating under high vacuum without

collapsing. The net open area of the strainer

screen depends on liquid viscosity and desired

flowrate; inany case, the sum of the area of all the

holesinthescreenshouldbe three tofivetimesthe

area of the suction pipe.

Gauges

Tomonitoroperationandassistin troubleshooting,

a vacuum gauge and a pressure gauge shouldbe

installed on the pump.

Sealing

Make certain that power to the driveunit

is disconnecte d before attempting to

connectthep ump driv e;otherwise,personal injury may result.

NOTE

See ROTATION in Section C before mounting the

pump on the base.

Coupled Drives

When using couplings, the axis of the power

source must be aligned to the axis of the pump

shaft in both the horizontal and vertical planes.

Mostcouplingsrequire a specific gap or clearance

between the driving and the driven shafts. Refer to

the coupling manufacturer’s service literature.

Even a slight leak will affect priming, head, and capacity, especially in a suction lift application. Seal

all piping joints, valves and gauges with pipe dope

orteflontape. The sealingmaterialshould be compatible with the liquid being pumped.

PAGE B -- 4

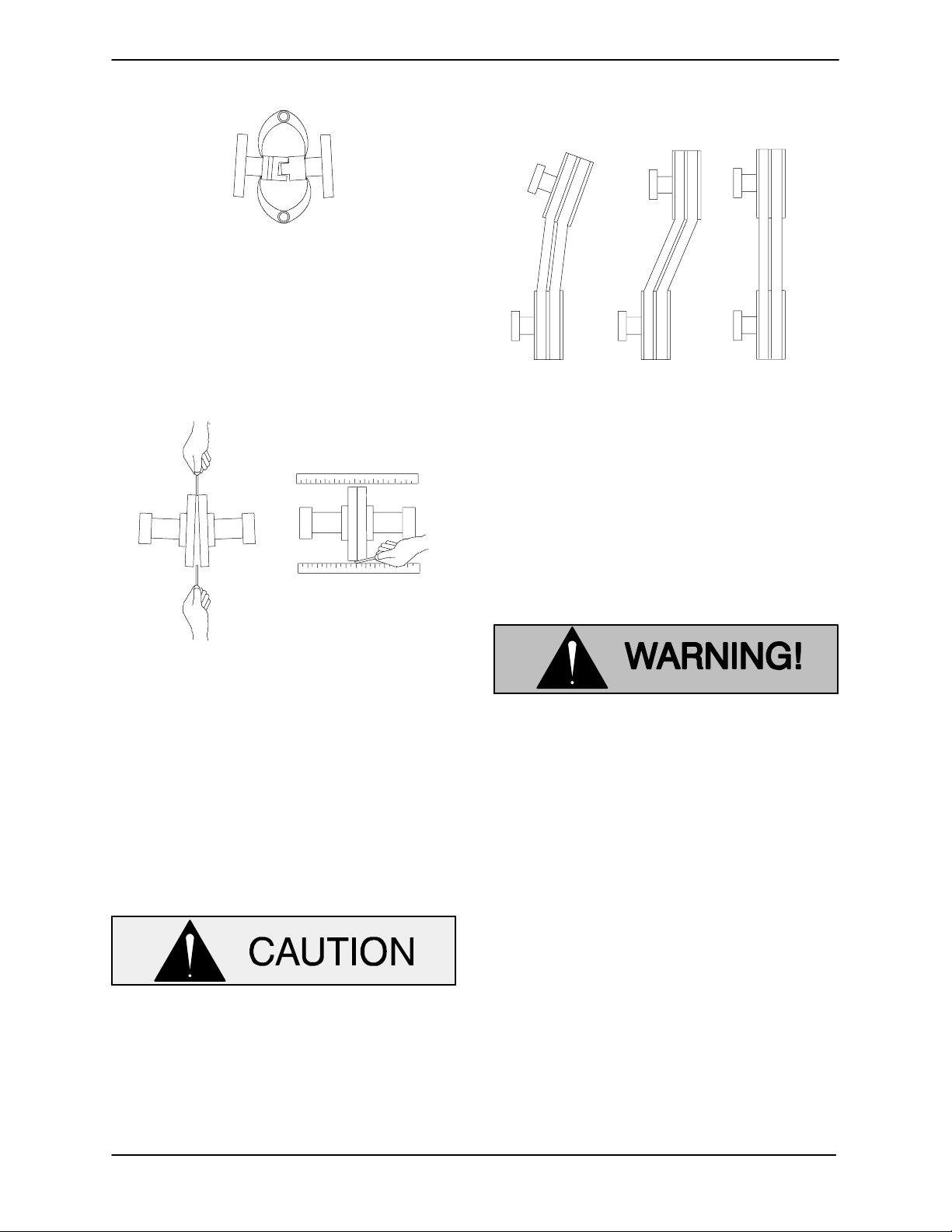

Alignspiderinserttypecouplingsbyusingcalipers

to measure the dimensions on the circumference

of the outer ends of the coupling hub every 90_.

The coupling is in alignment when the hub ends

are the same distance apart at all points (see Figure B-2).

INSTALLATION

GMS SERIES

ARA

A

V

Figure B-2. Spider-type Couplings

Align non-spider type couplings by using a feeler

gaugeortapergaugebetweenthecouplinghalves

every 90_. The coupling is in alignment when the

hubs are the same distanceapart at allpoints (see

Figure B-3).

OM--04910

beltsareamatchedset; unmatched setswillcause

accelerated belt wear.

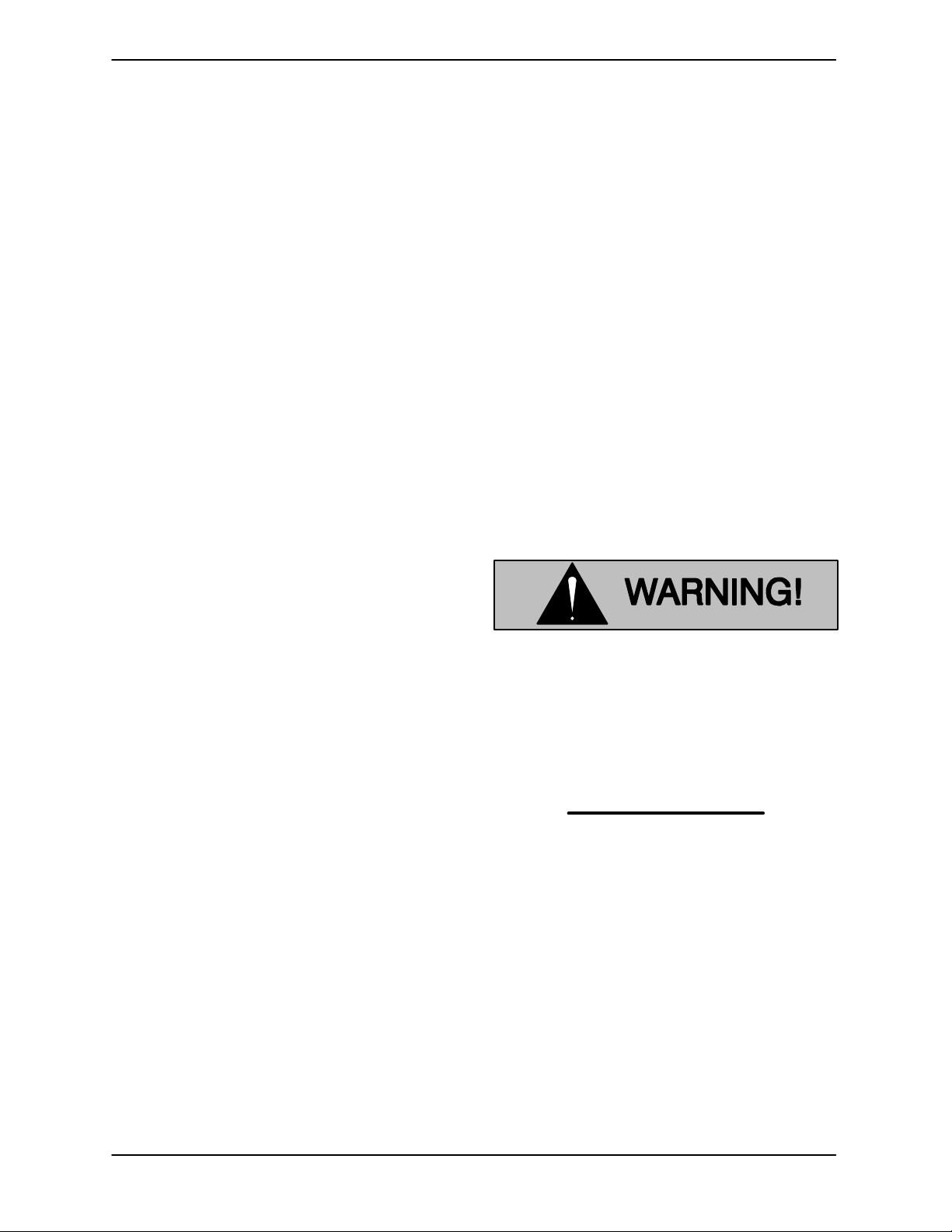

MISALIGNED:

SHAFTS

NOT P

LLEL

MISALIGNED:

SHAFTS

NOT IN LINE

ALIGNED:SHAFTS

PARALLEL AND

SHE

ES IN LINE

Figure B-4. V- belt Alignment

Tighten the belts in accordance with the belt manufacturer’s instructions. If the belts are too loose

they will slip; if they are too tight, there will be excessive power loss and possible bearing failure.

Figure B-3. Aligning Non-Spider Type Coupling

Checkparalleladjustmentbylayingastraightedge

across both coupling rims at the top, bottom, and

side. When the straightedge rests evenly on both

halves of the coupling, the couplingis in horizontal

parallel alignment. If the coupling is misaligned,

use a feeler gauge between the coupling and the

straightedge to measure the amount of misalignment.

V-Belt Drives

GMS style pumps will require an external

bearing support when using V-belt drives.

Select pulleys to match the proper speed ratio;

overspeeding the pump may damage both pump

and power source.

Do not operate this pump without

guards in place over the rotating parts.

Exposed rotating parts can catch clothing, fingers or tools, causing severe injury to personnel.

V-BELT TENSIONING

General Rules of Tensioning

For new v-belts, check the tension after 5, 20 and

50 hours of operation and re-tension as required

(see the following procedure for measuring belt

tension). Thereafter, check a nd re-tension if required monthlyor at 500 hour intervals, whichever

comes first.

When using V-belt drives, the power source and

the pump must be parallel. Use a straightedge

along the sides of the pulleys to ensure that they

are properly aligned (see Figure B-4). In drive systemsusingtwoormorebelts,make certainthatthe

INSTALLATION

Ideal v-belt tension is the lowest tension at which

the belt willnot slip under peak load conditions.Do

notover-tensionv-belts.Over-tensioningwill shorten both v-belt and bearing life. Under-tensioning

will cause belt slippage. Always keep belts free

PAGE B -- 5

GMS SERIESOM--04910

from dirt, grease, oil and other foreign material

which may cause slippage.

Tension Measurement

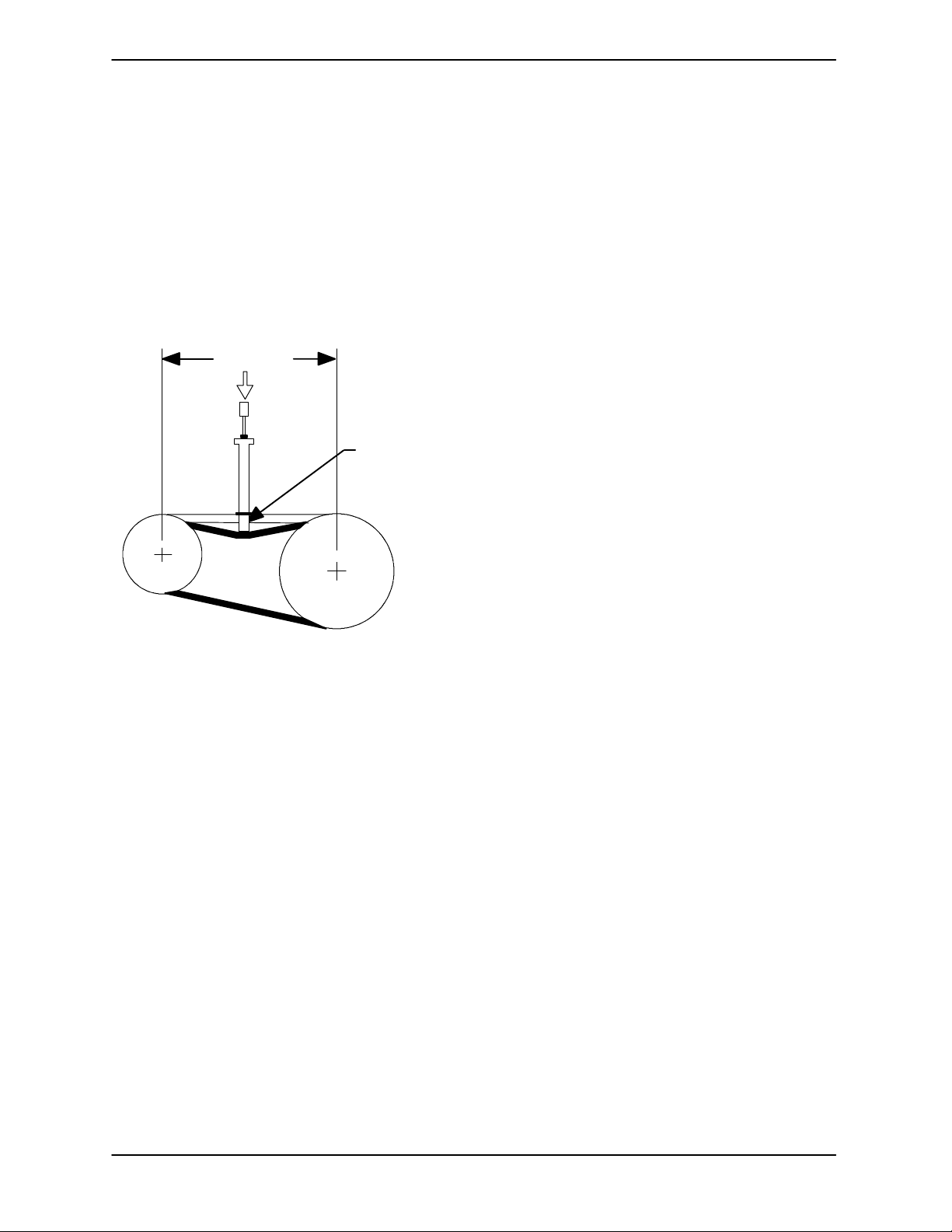

Correct v-belt tension can be achieved using a vbelt tension tester and Table B-2 or B-3. Use the

tables to find the v-belt size (cross-section), the

smallestsheavediameter,the belttypeforyourapplication. The corresponding deflection force requiredfor new orused belts is shown opposite the

RPM range of the pump.

Belt Span

Deflection

Forexample,ifthespan asmeasured in FigureB-5

is32inches(813mm),the v-beltcross-sectionisC,

thesmallestsheavediameteris8inches,thepump

speed is 1250 RPM, and the belts are uncogged

Yy-Ttype, then 11.5 lbs. of force on the tensioner

should show 1/2-inch (12,7 mm) of deflection.

A tension tester is availableas an option fromGorman-Rupp (P/N 29513---001). Other tension testers are available from your local belt/sheave distributor, and work on a similar principal.

To use the Gorman-Rupp t ensioner, measure the

belt span as shown in Figure B-5. Position the bottomofthelargeO-ringonthespanscaleofthetensioner at the measured belt span. Setthe small Oring on the deflection force scale to zero.

Placethe tension tester squarely on the belt at the

center of the beltspan. Apply forceon theplunger,

perpendicular to the belt span, until the bottom of

thelargeO-ringisevenwith the top ofthenextbelt,

orwiththebottomofastraight edge laidacrossthe

sheaves.

Figure B-5. Belt Tension Measurement

The ratio of deflection to belt span is 1:64 for both

ASA and metric units. Therefore, a beltwith aspan

of 64 inches w ould require a deflection of 1 inch at

the force shown on the Tables for your particular

application.

Readtheforceappliedfromthe bottomofthesmall

O-ring on the deflection force scale. Compare this

forcewiththevalueshowninTableB-2orB-3and

adjust the tension accordingly. Note that the ten-

sion for new belts is higher than that for used

belts to allow for expected belt stretching. Do not

over-tension used belts t o the higher deflection

forces shown for new belts.

PAGE B -- 6

INSTALLATION

Loading...

Loading...