GORMAN-RUPP PUMPS GHC SERIES Installation, Operation And Maintenance Manual

TVXY

OM---04352---01

September 2, 1996

INSTALLATION, OPERATION,

AND MAINTENANCE MANUAL

ROTARY GEAR PUMPS

MODELS

GHC SERIES

IRON AND STEEL

PUMPS

THE GORMAN-RUPP COMPANY MANSFIELD, OHIO

GORMAN-RUPP OF CANADA LIMITED ST. THOMAS, ONTARIO, CANADA Printed in U.S.A.

Copyright by the Go rman-Rupp Company

TABLE OF CONTENTS

INTRODUCTION PAGE I --- 1...................................................

S A F E T Y --- S E C T I O N A PA G E A --- 1............................................

I N S T A L L A T I O N --- S E C T I O N B PA G E B --- 1.....................................

GENERAL INFORMATION PAGE B--- 1......................................................

PUMP MODEL DESIGNATION PAGE B ---1..................................................

PREINSTALLATION INSPECTION PAGE B ---2................................................

STORAGE PA G E B --- 2....................................................................

Flushing PA G E B --- 2..................................................................

PUMP INSTALLATION P AGE B --- 3..........................................................

Lifting PA G E B --- 3.....................................................................

Po s i t io n i n g T h e Pu m p PA G E B --- 3......................................................

Mounting PA G E B --- 3.................................................................

Piping PA G E B --- 3....................................................................

Gauges PA G E B --- 4...................................................................

Strainers PA G E B --- 4..................................................................

Sealing PA G E B --- 4...................................................................

Valves PA G E B --- 4....................................................................

Barrier Liquids for Dual Seals PAGE B---4................................................

ALIGNMENT PA G E B --- 5..................................................................

C o u p l e d Dr i v e s PA G E B --- 5............................................................

V-Belt Drives PA G E B --- 5...............................................................

V-BELT TENSIONING PAGE B--- 6..........................................................

General Rules of Tensioning PAGE B---6.................................................

Tensioning Measurement PAGE B ---6...................................................

ELECTRICAL CONNECTIONS PAGE B--- 7...................................................

O P E R A T I O N --- S E C T I O N C PA G E C --- 1.......................................

P U M P O P E R AT I O N PA G E C --- 1............................................................

PRE-OPERATION PAGE C ---1..............................................................

Before Starting The Pump PAGE C --- 1...................................................

Checking Pump Rotation PAGE C ---1...................................................

STARTING PA G E C --- 1....................................................................

OPERATION PA G E C --- 2..................................................................

L i q u i d Te m p e r a t u r e PA G E C --- 2.........................................................

Overheating PA G E C --- 2...............................................................

Checking Gauges PA GE C --- 2..........................................................

Strainer Check PAGE C --- 2.............................................................

Leakage PA G E C --- 3..................................................................

PRESSURE RELIEF VALVE ADJUSTMENT PAGE C ---3........................................

Cracking Pressure PAGE C ---3.........................................................

Complete By-Pass Pressure PAGE C --- 3.................................................

STOPPING PA G E C --- 3....................................................................

T R O U B L E S H O O T I N G --- S E C T I O N D PA G E D --- 1...............................

PREVENTIVE MAINTENANCE PAGE D ---4...................................................

PUMP MAINTENANCE AND REPAIR --- SECTION E PAGE E --- 1.................

PART S KE Y:

Typical GHC Pump Model PAGE E ---3...................................................

i

TABLE OF CONTENTS

(continued)

ASSEMBLED GHC PUMP MODEL ILLUSTRATIONS PAGE E ---4...............................

P U M P D I S A S S E M B LY PA G E E --- 5..........................................................

Pressure Relief Valve (10) P AGE E --- 5...................................................

Rotor Adjusting Sleeve (07) PAGE E---6.................................................

Coverplate Kit (11) PAGE E--- 6.........................................................

Head/Idler Kit (01) PAGE E---6..........................................................

Seal Removal (05) PAGE E --- 7..........................................................

Rotor/Shaft Removal (08) PAGE E --- 7...................................................

Foot Bracket Kit (06) P AGE E -- -7........................................................

Backhead Kit Removal (06) PAGE E --- 7..................................................

Housing Assembly (04) PAGE E ---7.....................................................

PUMP REASSEMBLY PAGE E --- 8..........................................................

Cleaning and Inspection PAGE E ---8....................................................

Bushing Preparation PAGE E ---8........................................................

Housing Assembly (04) PAGE E ---8.....................................................

Backhead Kit (06) PAGE E---9..........................................................

Rotor/Shaft Assembly (03) PAGE E--- 9..................................................

Seal Installation (05) P AGE E --- 9........................................................

H e a d / I d le r K i t PA G E E --- 9..............................................................

Coverplate Kit (11) PAGE E---10........................................................

Foot Bracket Kit (08) PAGE E---10.......................................................

Rotor Adjusting Sleeve (07) PAGE E---10................................................

SETTING END CLEARANCE PAGE E--- 10...................................................

R E L I E F VA LV E DI S A S S E M B LY PA G E E --- 1 1.................................................

RELIEF VALVE REASSEMBLY PAGE E ---12..................................................

Relief Valve Installation (10) PAGE E --- 13................................................

SEAL APPENDIX --- SECTION F P AGE F--- 1...................................

Standard Friction Drive And Optional 60A, 60B And 61J Mechanical Seals PAGE F--- 1.............

StandardLip(AndOptional65C)Seal PAGEF---3.............................................

Positive Drive (Option 60D) And Metal Bellows (Option 60F, 61K) Seals PAGE F--- 5................

Double Friction Drive (Options 60J And 60K) Seals PAGE F--- 8.................................

Cartridge (Options 60M, 60N, 60P And 61L) Seals PAGE F--- 11.................................

Balanced Seal (Option 60Q) PAGE F---13....................................................

Friction Drive Mechanical Seal With Flush (Options 60T And 60U) P AGE F --- 15...................

ii

INTRODUCTION

OM--04352GHC SERIES

Thank You for purchasing a Gorman-Rupp Rotary

Gear Pump. This manual is designed to help you

achieve the best performance and longest life from

your Gorman-Rupp Rotary Gear pump. Read this

manual carefully to learn how to safely install, operate and repair your pump. Failure to do so could

result in personal injury or damage to the pump.

This manual will alert personnel to known procedures which require special attention, to those

which could damage equipment, and to those

which could be dangerous to personnel. However,

this manual cannot possibly provide detailed instructions and precautions for each specific application or for every situation that might occur during maintenance of the unit. Therefore, it is the responsibility of the owner, installer and/or maintenance personnel to ensure that applications and/

or maintenance procedures not addressed in this

manual are performed only

neither personal safety nor pump integrity are

compromised by such applications or procedures.

after establishing that

If there are any questions regarding the pump or

drive unit which are not covered in this manual or

in other literature accompanying this unit, please

contact your Gorman-Rupp distributor or the Gorman-Rupp Company:

The Gorman-Rupp Company

P.O. Box 1217

Mansfield, Ohio 44901-- 1217

or:

Gorman-Rupp of Canada Limited

70 Burwell Road

St. Thomas, Ontario N5P 3R7

RECORDING MODEL AND

SERIAL NUMBERS

Please record the pump model and serial number

in the spaces provided below. Your Gorman-Rupp

distributor needs this information when yourequire

parts or service.

In addition to this manual, a separate Parts List is

shipped with the pump. Refer to the Parts List when

ordering parts.

If your pump is furnished with a drive unit, refer to

the drive unit manufacturer’s installation and operation instructions in the literature accompanying

the pump.

These pumps can transfer a wide range of light,

medium, a nd heavy viscosity liquids, depending

on design and components. Some models are

not recommended for use with water; others

when fitted with specific options, may be used

with water; consult the factory.

Pump Model:

Serial Number:

WARRANTY INFORMATION

The warranty provided with your pump is part of

Gorman-Rupp’s support program for customers

who operate and maintain their equipment as described in this and the other accompanying literature. Please note that should the equipment be

abused or modified to change its performance beyond the original factory specifications, the warranty will become void and any claim will be denied.

INTRODUCTION

PAGE I -- 1

GHC SERIESOM--04352

The following are used to alert personnel to procedures which require special attention, to those which

could damage equipment, and to those which could be dangerous to personnel:

Immediate hazards which will result in

severe personal injury or death. These

instructions describe the procedure required and the injury which will result

from failure to follow the procedure.

Hazards or unsafe practices which

COULD result in severe personal injury

or death. These instructions describe

the procedure required and the injury

which could result from failure to follow

the procedure.

Hazards or unsafe practices whichCOULD

result in minor personal injury or productor

property damage. These instructions describe the requirements and the possible

damage which could result from failure to

follow the procedure.

NOTE

Instructions to aid in installation, operation, and

maintenance or which clarify a procedure.

PAGE I -- 2

INTRODUCTION

GHC SERIES OM--04352

SAFETY --- SECTION A

This information is specific to Gorman-Rupp GHC

Series Rotary Gear Pumps. It applies throughout

this manual and any manual or literature accompanying the pump.

In addition to this manual, see the separate literature covering the drive unit used to operate this

pump.

Pumps and related equipment must be installed and operated according to all national, local and industry standards.

This manual will alert personnel to

known procedures which require special attention, to those which could

damage equipment, and to those which

could be dangerous to personnel. However, this manual cannot possibly provide detailed instructions and precautions for each specific application or for

every situation that might occur during

maintenance of the unit. Therefore, it is

the responsibility of the owner, installer

and/or maintenance personnel to ensure that applications and/or maintenance procedures not addressed in this

manual are performed only after establishing that neither personal safety nor

pump integrity are compromised by

such applications or procedures.

covered in this manual could lead to destruction of equipment, injury, or death.

The standard version of this pump is designed to handle a wide range of light,

medium, and heavy vi scosity liquid, depending on design and components,

and a range of temperatures when fitted

with different seals. Do not apply at

higher temperatures that the seal will

handle. Do not attempt to pump liquids

which may damage the pump or endanger personnel as a result of pump failure; consult the factory for chemical

compatibility.

If the pump and motor are furnished

mountedon a base, make certain that all

lifting devices have adequate capacity.

If chains or cables are used in lifting,

make certain that they are positioned so

as not to damage components, and so

that the load will be balanced.

After the pump has been installed, make

certain that the pump and all piping or

hose connections are secure before operation. Loose connections can result in

damage to the equipment and serious

injury to personnel.

Before attempting to install, ope rate , or

service this pump, familiarize yourself

with this manual, and with all other liter ature ship ped with the pump. Unfamil iarity with all aspects of pump operation

SAFETY

Never operate the pump without a pressure relief valve installed on the pump

or in the discharge piping. Make certain

that pump-mounted pressure relief

PAGE A -- 1

OM--04352 GHC SERIES

valves are installed with their adjusting

ends toward the suction port.Ifbi-rotational operation is required, a pressure

relief device must be provided for both

directions of flow. Operation without a

pressure relief valve or with an improperly installed relief valve could cause

the pump to explode, resulting in serious injury or death to personnel.

An overheated pump can cause severe

burns and injury. If overheating occurs:

1. Stop the pump immediately.

2. Allow the pump to completely cool.

3. Refer to the instructions in this

manual before restarting the

pump.

Before attempti ng to open or service the

pump:

1. Familiarize yourself with this manual.

2. Lock out incoming power to the

drive unit to ensure that the pump

will remain inoperative.

3. Allow the pump to completely cool

Do not remove plates, covers, gauges,

pipe plugs or fittings from an overheated pump. Vapor pressure within the

pump can cause parts being disen gaged to be ejected with great force. Allow the pump to completely cool before

servicing.

if overheated.

4. Close the discharge and suction

valve (if used).

Do not operate this pump without

guards in place over the rotating parts.

Exposed rotating parts can catch clothing, fingers or tools, causing severe injury to personnel.

PAGE A -- 2

SAFETY

GHC SERIES

OM--04352

INSTALLATION --- SECTION B

GENERAL INFORMATION

Review all SAFETY information in Section A .

Pumps and related equipment must be installed and operated according to all national, local and industry standards.

Since pump installations are seldom identical, this

section is intended only to summarize general recommendations and practices required to inspect,

position, and arrange the pump and piping. If there

are any questions concerning your specific installation, contact your Gorman-Rupp distributor or

the Gorman -Rupp Company.

Most of the information applies to a flooded suction

installation where liquid is supplied under pressure.

Typ ica l Pu m p M o d e l

GHS 1 1/2 GF 32

Design

Style

Design Style: Gorman-Rupp rotary gear pumps

are available in five basic designs:

S G M C --- M e d i u m D u t y --- C o m p a c t

S G M S --- M e d i u m Du t y

S G H C --- H e a v y D u t y --- C o m p a c t

S G H S --- H e a v y Du t y

S G H A --- A b r a s i v e D u t y

Port Size: Gorman-Rupp rotary gear pumps are

available in port sizes from 1 to 6 inches, depending on the design style. Consult your GormanRupp distributor or the factory for additional sizes.

Port

Size

Hydraulic

Size

Construction

Code

If the pump is positioned above the liquid in a static

lift installation, information such as mounting, piping configuration and priming must be tailored to

specific conditions.

Thesepumpsarenotrecommendedfor

usewithwater.Somemodelswhenfitted

with specific options may be used with water; consult the factory.

PUMP MODEL DESIGNATION

Following is a description of the model numbering

system for Gorman-Rupp rotary gear pumps.

Rotary gear pump model numbers include design

style, port size, hydraulic size and construction

code.

Hydraulic Size: The first letter in the hydraulic size

is a rotor diameter code. The second letter indicates tooth length.

Construction Code: Construction Codes for Gorman-Rupp rotary gear pumps are as follows:

Code Description

3 Iron w/Mechanical Seal(s)

4Ironw/PackingorLipSeal(s)

9 316 SST w/Mechanical Seal(s)

10 316 SST w/Packing or Lip Seal(s)

32 Steel w/Mechanical Seal(s)

38 Steel w/Packing or Lip Seal(s)

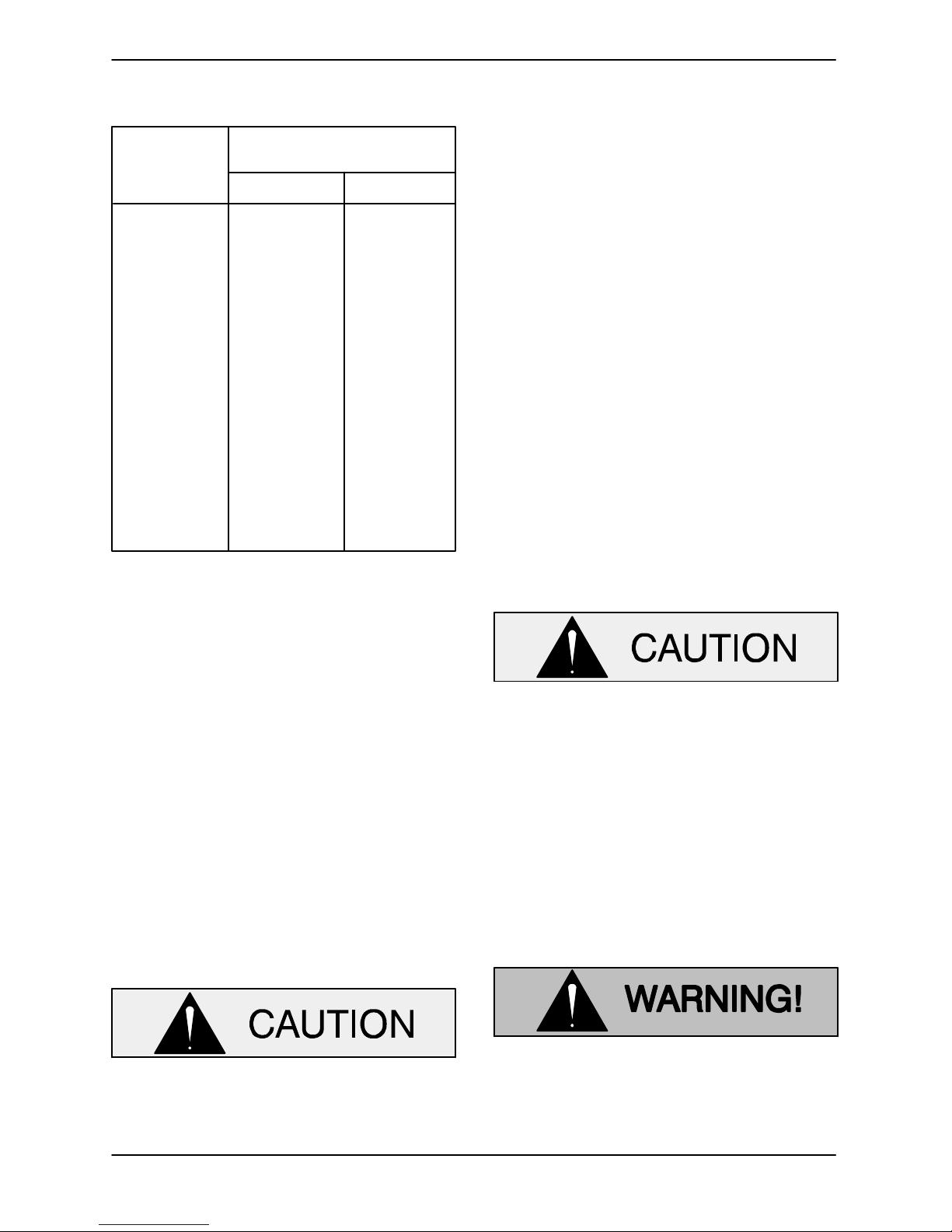

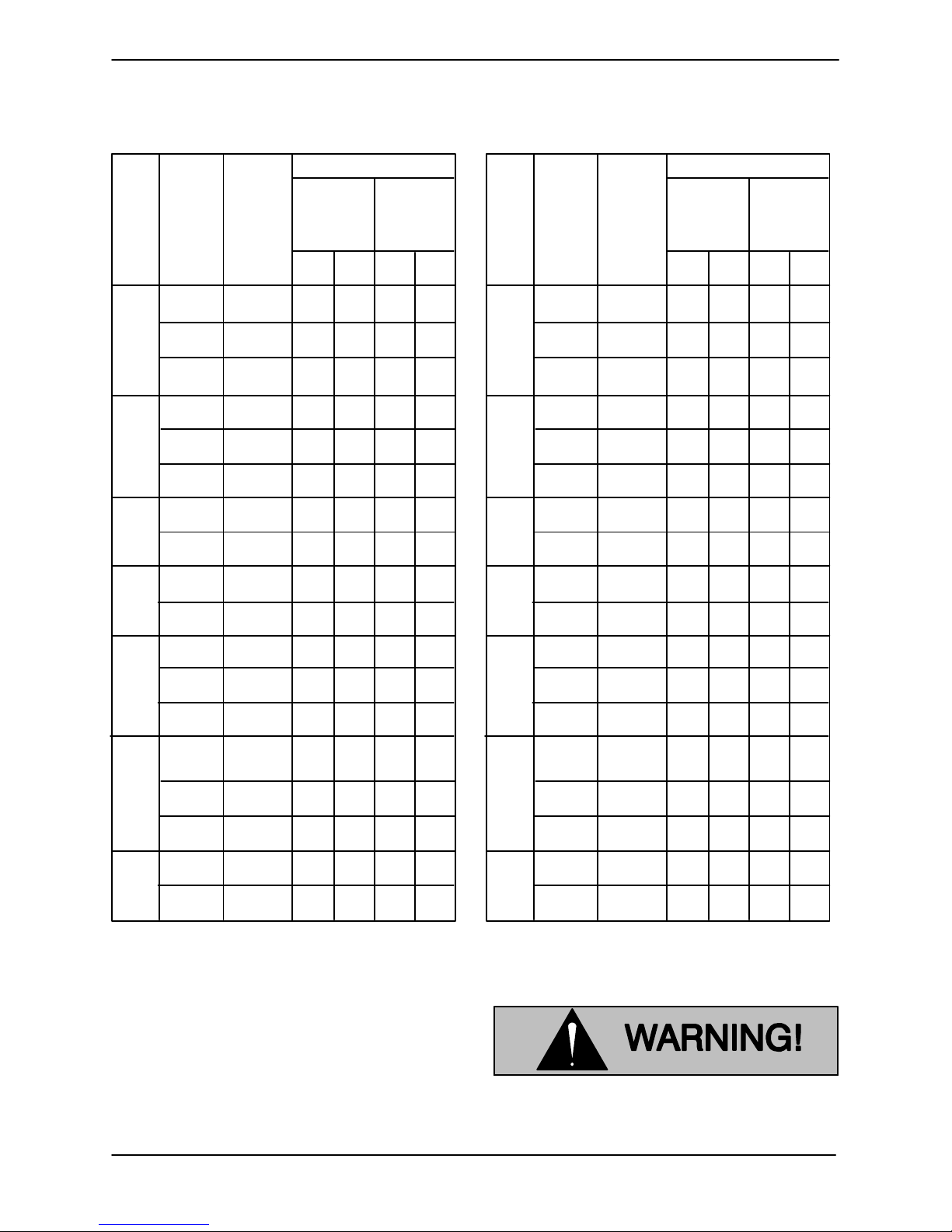

Theoretical Displacement: Table B-1 indicates

theoretical displacement values for each hydraulic

size.

NOTE

Actual capacities and recommended shaft speeds

vary according to application. Consult your Gorman-Rupp distributor or the factory for addtional information.

INSTALLATION

PAGE B -- 1

GHC SERIESOM--04352

Ta b l e B -1 . T h eo r e ti c a l Di s p l a ce m e nt

Theoretical Displacement

Hydraulic

Size

DC 0.00568 21.486

DE 0.00704 26.646

GC 0.00967 36.619

GF 0.01405 53.186

GH 0.01915 72.479

GJ 0.02317 87.700

JG 0.03579 135.49

JJ 0.05159 195.28

JL 0.07078 267.94

JP 0.10078 381.48

NK 0.10665 403.71

NM 0.14173 536.51

NP 0.17681 669.31

RM 0.24030 909.65

RP 0.29979 1134.8

RR 0.35927 1360.0

RS 0.41876 1585.1

SR 0.65752 2489.0

SU 1.10240 4173.2

TU 1.91280 7240.7

Per Revolution

Gallons Centimeters

If the pump will not be immediately installed, follow

these procedures or damage to the pump will occur.

a. Do not flush the pump. Ensure that the port

3

plugs shipped with the pump remain in place

until piping is installed to help prevent dust or

other foreign objects from entering the pump.

b. Pumps that will not be installed for an ex-

tended period should be stored indoors if

possible. The factory-installed port plugs will

not ensure protection from excessive humidity, splash water or rain. In very humid or wet

conditions, install air-tight plugs in the ports

and fill the pump completelywith a lubricating

preservative liquid that is compatible with the

liquid to be pumped.

c. Pumps stored outdoors must be fully pre-

served as described above, completely covered with plastic or other water-tight material,

and the covering anchored to ensure that it

will not be blown off.

PREINSTALLATION INSPECTION

The pump assembly was inspected and tested before shipment from the factory. Before installation,

check for damage which may have occurred during shipment. Check as follows:

a. Inspect the pump assembly for cracks, dents,

damaged threads, and other obvious damage.

b. Check for loose attaching hardware. Since

gaskets tend to shrink after drying, check for

loose hardware at t he mating surfaces.

c. Carefully read all tags, decals, and markings

on the pump assembly, and perform all duties

indicated.

STORAGE

Flushing

Clean piping is essential because of closetolerance moving parts in this pump. Flush

all dirt, grit, weld beads or scale from the

suction piping before installing the pump.

Damage to the pump because of debris in

the suction line is not covered by the pump

warranty.

Before shipment, the pump may have been tested

using a petroleum-based preservative. If flushingis

required, do not do so until just before installation;

the test oil protects close-tolerance pump parts

from corrosion.

Due to the extreme close machining tolerances within rotary gear pumps, proper

storage before installation is essential to

prevent damage to the pump.

PAGE B -- 2

Most cleaning solvents are toxic and

flammable. Use them only in a well ventilated area free from flame, sparks, and

excessive heat. Read and follow all pre cautions printed on solvent containers.

INSTALLATION

GHC SERIES

OM--04352

To flush the pump, use an approved solvent compatible with the liquid being pumped. Make cer-

tain that the solvent will not attack pump components, particularly seals and gaskets.

PUMP INSTALLATION

Pump dimensions are shown in the separate

Pump Specification Bulletin.

Never operate the pump without a pressure relief valve installed on the pump

or in the discharge piping. Make certain

that pump-mounted pressure relief

valves are installed with their adjusting

ends toward the suction port.Ifbi-rotational operation is required, a pressure

relief device must be provided for both

directions of flow. Operation without a

pressure relief valve or with an improperly installed relief valve could cause

the pump to explode, resulting in serious injury or death to personnel.

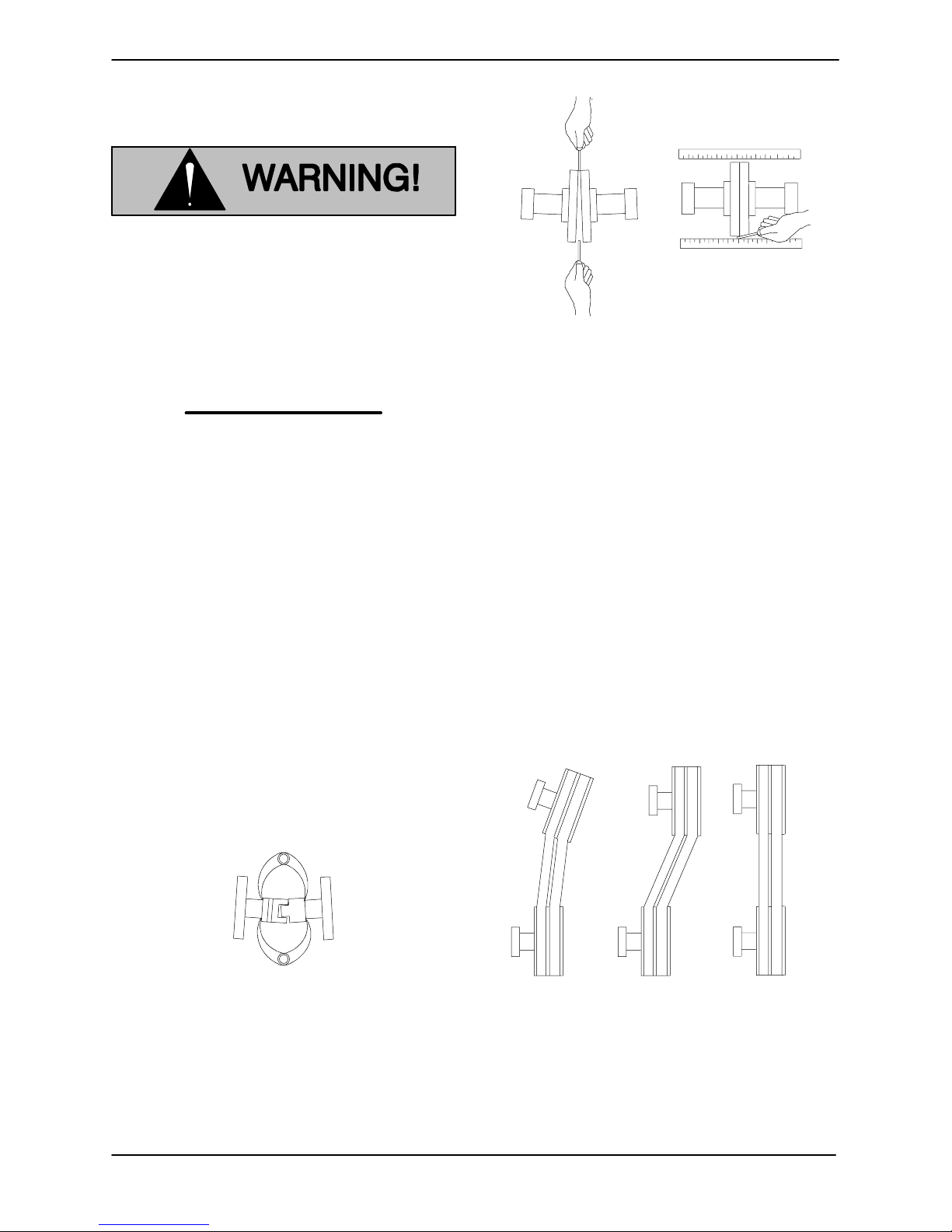

Lifting

Remove suction and discharge hose and piping

before attempting to lift the pump. Use liftingequipment with a capacity of a t least five times the total

weight of the equipment being lifted.

Positioning The Pump

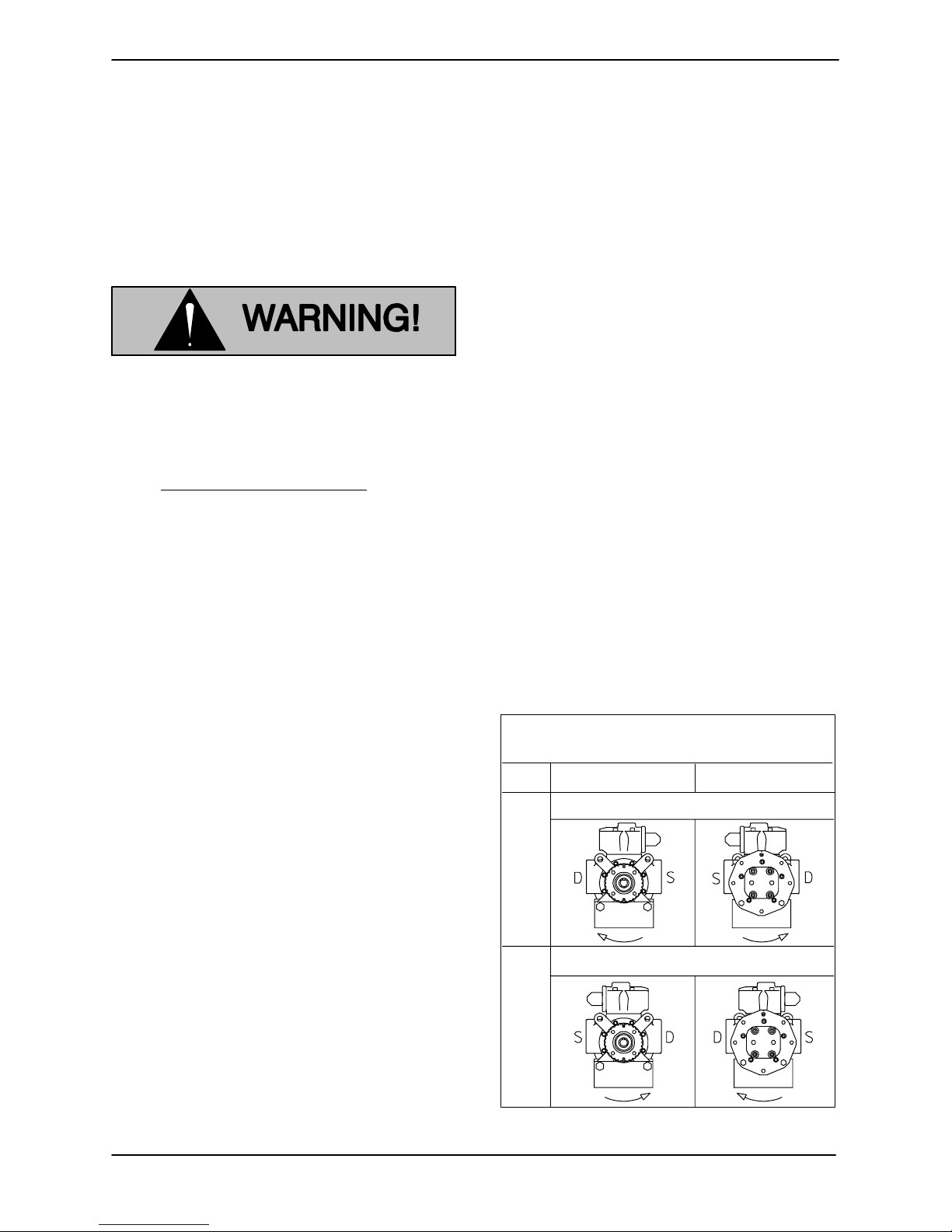

Piping

Before establishing suction and discharge lines,

determine pump port positions and rotation. Figure B ---1 shows typical port positions for the standard 180_ housing; if you have selected a 90_

housing port option, your port positions will be different.

Either hose or rigid pipe may be used to make connections. If rigid piping is used, install expansion

joints to protect the pump from vibration and thermal expansion in the piping. Do not use expansion

joints or flexible connectors to adjust misaligned

piping.

Begin piping layout at the pump, and work toward

the source of supply and the point of discharge. If

an obstacle is in the way of a suction or discharge

line, run the piping around the obstruction, not

over it. Running piping over an obstruction will

creat an air pocket which will make priming more

difficult.

If possible, slope the piping toward the pump so no

air or liquid is trapped in the piping. If a long horizontal suction line is necessary, install the line below the liquid level whenever possible in order to

keep the piping full of liquid. This will make priming

easier because the pump will not have to remove

as much air in the line.

Housing Position Std. 180_ Pump

(3---9 O’clock) Housing Mounted Relief Valve

OPT.

Drive End Front End

Rotation Clockwise

Locate the pump as close as possible to the liquid

being pumped. Locating the pump below the liquid source will help self-priming and reduce the

possibility of cavitation.

Mounting

The pump may be shipped alone, mounted on a

base, or with pump and motor mounted on a base.

Install the pump and motor on a base before

mounting the base on a foundation.

Mount the base on a foundation that will provide

permanent, rigid support for the pump, and will be

heavy enough to absorb any vibration, strain or

shock.

INSTALLATION

STD.

Rotation Counter-clockwise

01A

Figure B-1. Typical Port Positions & Rotation

PAGE B -- 3

GHC SERIESOM--04352

The discharge and suction lines must be independently supported to avoid vibration and strain

on the pump. For maximum pumping capacity,

keep the lines as short and straight as possible. Elbows and fittings used in the lines increase friction

losses; minimize their use. Reducers used in suction lines should be the eccentric type installed

with the flat part uppermost to avoid creating air

pockets.

Before tightening a connection or flange, align it

exactly with the pump port. Never pull a pipe line

into place by tightening the flange bolts and/or

couplings.

Gauges

Install a vacuum gauge in the suction line and a discharge pressure gauge in the discharge line (both

should be as close as possible to the pump) to

monitor operation and assist in troubleshooting.

Toprevent leakage during shutdown, install a shut off valve in the discharge line, particularly on a

flooded suction application. Shutoff valves are not

recommended for suction lines.

It is not recommended that a foot valve be installed

at the end of the suction line. If desired to install a

foot valve, consult the factory.

When handling very hot or cold liquids, install a

pressure relief valve in any part of the system that

can be valved off or isolated; this will protect piping

against damage from liquid thermal expansion or

contraction from temperature changes during

shutdown.

Barrier Liquids for Dual Mechanical Seals

Pumps equipped with dual (tandem) mechanical

seals require a barrier liquid to prevent contamination of the seal assembly by the liquid being

pumped. The barrier liquid must have the following

characteristics:

Strainers

Because of the close-tolerance moving parts of

this pump, it is recommended that a strainer be installed in the suction line. The strainer should be

large enough to prevent excessive vacuum, and

capable of operating under high vacuum without

collapsing. The net open area of the strainer

screen depends on liquid viscosity and desired

flow rate; in any case, the sum of the area of all the

holes in the screen should be three to five times the

area of the suction pipe.

Sealing

Even a slight leak will affect priming, head, and capacity, especially in a suction lift application. Seal

all piping joints, valves and gauges with pipe dope

or teflon tape. The sealing material s hould be compatible with the liquid being pumped.

Val ves

a. The barrier liquid must have sufficient lubricat-

ing characteristics, including an optimum viscosity of 1 to 5 cSt at the temperature of the

liquid being pumped.

b. The barrier liquid must be compatible in all re-

spects with all pump and seal components to

which it will be exposed.

c. The barrier liquid must be compatible in all re-

spects w ith the liquid being pumped.

Pumps equipped with dual mechanical seals require the barrier liquid to be supplied at a continuous pressure equivalent to the maximum dis charge pressure in order to avoid inboard seal face

separation. The maximum barrier liquid pressure

that can be applied depends primarily on the maximum seal design pressure (consult the factory).

Do not pressurize tandem seals. Pressurizing a

tandem seal w ill cause the seal faces to separate,

resulting in leakage and/or damage to the seal.

To avoid air pockets, install piping valves with the

stem horizontal.

PAGE B -- 4

Refer to the appropriate section in Seal Appendix,

Section F for your specific seal option for operating

instructions for the barrier liquid reservoir kit.

INSTALLATION

GHC SERIES

ARA

A

V

ALIGNMENT

Make certain that power to the drive unit

is disconnected be fore attempting to

connect the pump drive; otherwise, personal injury may result.

OM--04352

NOTE

See ROTATION in Section C before mounting the

pump on the base.

Coupled Drives

When using couplings, the axis of the power

source must be aligned to the axis of the pump

shaft in both the horizontal and vertical planes.

Most couplings require a specific gap or clearance

between the driving and the driven shafts. Refer to

the coupling manufacturer’s service literature.

Align spider insert type couplings by using calipers

to measure the dimensions on the circumference

of the outer ends of the coupling hub every 90_.

The coupling is in alignment when the hub ends

are the same distance apart at all points (see Figure B-2).

Figure B-3. Aligning Non-Spider Type Coupling

Check parallel adjustment by laying a straightedge

across both coupling rims at the top, bottom, and

side. When the straightedge rests evenly on both

halves of the coupling, the coupling is in horizontal

parallel alignment. If the coupling is misaligned,

use a feeler gauge between the coupling and the

straightedge to measure the amount of misalignment.

V-Belt Drives

When using V-belt drives, the power source and

the pump must be parallel. Use a straightedge

along the sides of the pulleys to ensure that they

are properly aligned (see Figure B-4). In drive systems using two or more belts, make cert ain that the

belts are a matched set; unmatched sets will cause

accelerated belt wear.

Figure B-2. Spider-type Couplings

Align n on-spider t ype couplings by using a feeler

gauge or taper gauge between the couplinghalves

every 90_. The coupling is in alignment when the

hubs are the same distance apart at all points (see

Figure B-3).

INSTALLATION

MISALIGNED:

SHAFTS

NOT P

LLEL

MISALIGNED:

SHAFTS

NOT IN LINE

ALIGNED: SHAFTS

PARALLEL AND

SHE

ES IN LINE

Figure B-4. V-belt Alignment

Tighten t he belts in accordance with the belt manufacturer’s instructions. If the belts are too loose

they will slip; if they are too tight, there will be excessive power loss and possible bearing failure.

PAGE B -- 5

GHC SERIESOM--04352

Select pulleys to match the proper speed ratio;

overspeeding the pump may damage both pump

and power source.

Do not operate this pump without

guards in place over the rotating parts.

Exposed rotating parts can catch clothing, fingers or tools, causing severe injury to personnel.

V-BELT TENSIONING

General Rules of Tensioning

For new v-belts, check the tension after 5, 20 and

50 hours of operation and re-tension as required

(see the following procedure for measuring belt

tension). Thereafter, check and re-tension if required monthly or at 500 hour intervals, whichever

comes first.

Ideal v-belt tension is the lowest tension at which

the belt will not slip under peak load conditions. Do

not over-tension v-belts. Over-tensioning will shorten both v-belt and bearing life. Under-tensioning

will cause belt slippage. Always keep belts free

from dirt, grease, oil and other foreign material

which may cause slippage.

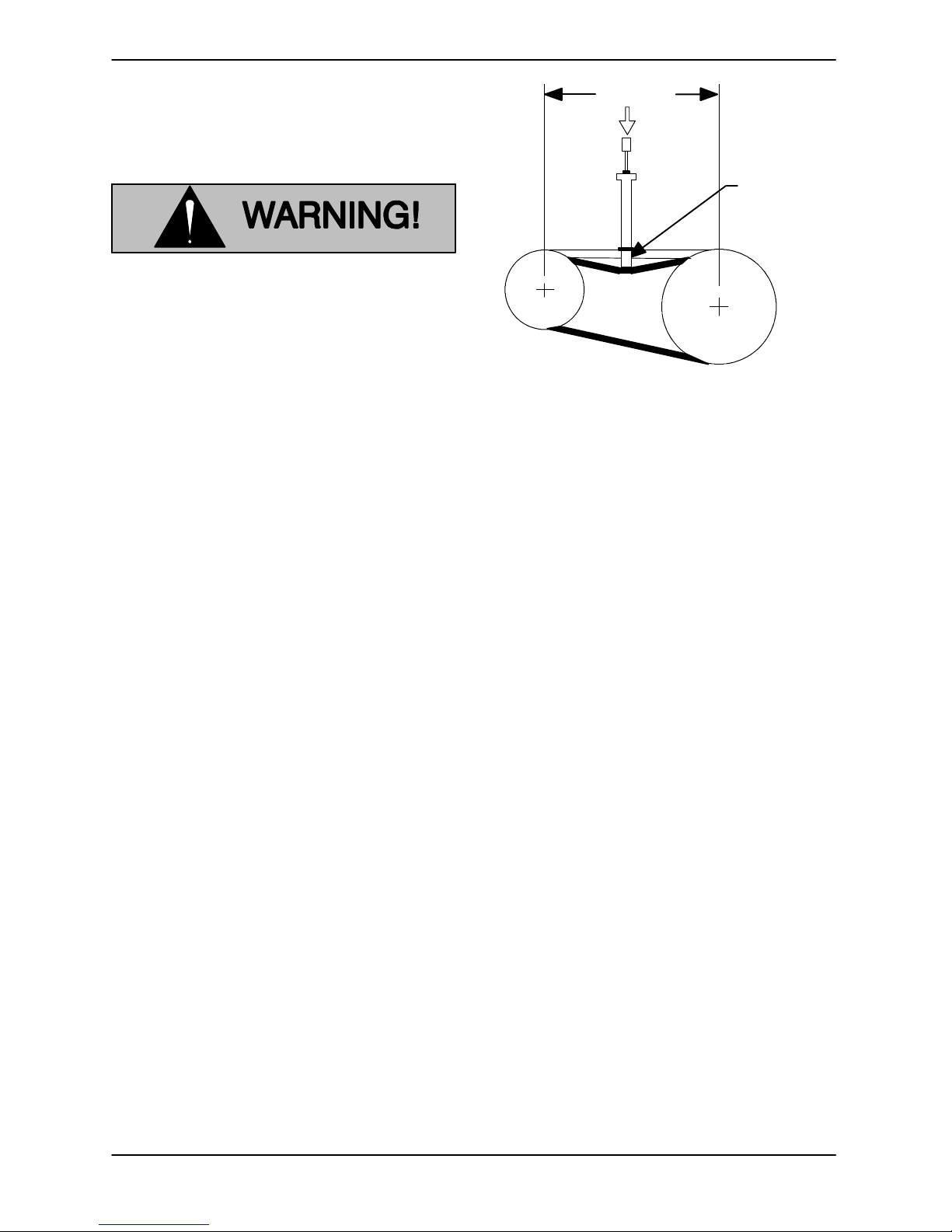

Tension Measurement

Belt Span

Deflection

Figure B-5. Belt Tension Measurement

The ratio of deflection to belt span is 1:64 for both

ASA and metric units. Therefore, a belt with a span

of 64 inches would require a deflection of 1 inch at

the force shown on the Tables for your particular

application.

For example, if the span as measured in Figure B-5

is 32 inches (813 mm), the v-belt cross-section is C,

the smallest sheave diameter is 8 inches, the pump

speed is 1250 RPM, a nd the belts are uncogged

Yy-T type, then 11.5 lbs. of force on the tensioner

should show 1/2-inch (12,7 mm) of deflection.

A tension tester is available as an option from Gorman-Rupp (P/N 29513---001). Other tension tes ters are available from your local belt/sheave distributor, and work on a similar principal.

To use the Gorman-Rupp tensioner, measure the

belt span as shown in Figure B-5. Position the bottom of the large O-ring on the span scale of the tensioner at the measured belt span. Set the small Oring on the deflection force scale to zero.

Place the tension tester squarely on the belt at the

center of the belt span. Apply force on the plunger,

perpendicular to the belt span, until the bottom of

the large O-ring is even with the top of the next belt,

or with the bottom of a straight edge laid across the

sheaves.

Correct v-belt tension can be achieved using a vbelt tension tester and Table B-2 or B-3. Use the

tables to find the v-belt size (cross-section), the

smallest sheave diameter, the belt type for your application. The corresponding deflection force required for new or used belts is shown opposite the

RPM range of the pump.

PAGE B -- 6

Read the force applied from the bottom of the small

O-ring on the deflection force scale. Compare this

forcewiththevalueshowninTableB-2orB-3and

adjust the tension accordingly. Note that the ten-

sion for new belts is higher than that for used

belts to allow for expected belt stretching. Do not

over-tension used belts to the higher deflection

forces shown for new belts.

INSTALLATION

GHC SERIES

OM--04352

TableB-2.SheaveDiameter (In.)

Smallest

Cross

Section

Sheave

Diameter

Range

3.0 - 3.6

A,AX

B,BX

C,CX

3V,

3VX

5V,

5VX

8V

3.8 - 4.8

5.0 - 7.0

3.4 - 4.2

4.4 - 5.6

5.8 - 8.6

7.0 - 9.0

9.5 - 16.0

12.0 - 16.0

D

18.0 - 20.0

2.2 - 2.4

2.65 - 3.65

4.12 - 6.90

4.4 - 6.7

7.1 - 10.9

11.8 - 16.0 500-1740

12.5 - 17.0

18.0 - 22.4

Deflection Force (Lbs.)

Belt Deflection Force

Uncogged

Hy-T Belts &

Uncogged

Hy-T Torque

Tea m

R.P.M.

Range

1000-2500

2501-4000

1000-2500

2501-4000

1000-2500

2501-4000

860-2500

2501-4000

860-2500

2501-4000

860-2500

2501-4000

500-1740

1741-3000

500-1740

1741-3000

200-850

851-1500

200-850

851-1500

1000-2500

2501-4000

1000-2500

2501-4000

1000-2500

2501-4000

500-1749

1750-3000

3001-4000

500-1740

1741-3000

1741-3000

200-850

851-1500

200-850

851-1500

Used

Belt

3.7

2.8

4.5

3.8

5.4

4.7

5.3

4.5

6.3

6.0

11.5

9.4

14.1

12.5

11.5

9.4

30.4

25.6

3.6

3.0

4.9

4.4

12.7

11.2

15.5

14.6

33.0

26.8

39.6

35.3

New

Belt

5.5

4.2

6.8

5.7

8.0

7.0

7.9

6.7

9.4

8.9

17.0

13.8

21.0

18.5

17.0

13.8

45.2

38.0

5.1

4.4

7.3

6.6

18.9

16.7

23.4

21.8

49.3

39.9

59.2

52.7

Cogged

Tor q u e - F le x

&Machined

Edge torque

Tea m B e lt s

Used

New

Belt

Belt

4.1

6.1

3.4

5.0

5.0

7.4

4.3

6.4

5.7

9.4

5.1

7.4

4.9

7.2

4.2

6.2

10.5

7.1

9.1

7.1

8.5

12.6

7.3

10.9

21.8

14.7

17.5

11.9

15.9

23.5

14.6

21.6

21.8

14.7

17.5

11.9

3.3

4.9

2.9

4.3

6.2

4.2

5.6

3.8

5.3

7.9

4.9

7.3

10.2

15.2

8.8

13.2

5.6

8.5

22.1

14.8

20.1

13.7

17.1

25.5

16.8

25.0

TableB-3.SheaveDiameter (Mm.)

Deflection Force (Kg.)

Belt Deflection Force

Uncogged

Hy-T Belts &

Uncogged

Hy-T Torque

Tea m

Used

Belt

1.7

1.3

2.0

1.7

2.4

2.1

2.4

2.0

2.9

2.7

5.2

4.3

6.4

5.7

11.3

9.6

13.8

11.6

1.6

1.4

2.2

2.0

5.8

5.1

7.0

6.6

15.0

12.2

18.0

16.0

Cross

Section

A,AX

B,BX

C,CX

D

3V,

3VX

5V,

5VX

8V

Smallest

Sheave

Diameter

Range

75 - 90

91 - 120

125 - 175

85 - 105

106 - 140

141 - 220

175 - 230

231 - 400

305 - 400

401 - 510

55 - 60

61 - 90

91 - 175

110 - 170

171 - 1275

276 - 400 500-1740

315 - 430

431 - 570

R.P.M.

Range

1000-2500

2501-4000

1000-2500

2501-4000

1000-2500

2501-4000

860-2500

2501-4000

860-2500

2501-4000

860-2500

2501-4000

500-1740

1741-3000

500-1740

1741-3000

200-850

851-1500

200-850

851-1500

1000-2500

2501-4000

1000-2500

2501-4000

1000-2500

2501-4000

500-1749

1750-3000

3001-4000

500-1740

1741-3000

1741-3000

200-850

851-1500

200-850

851-1500

New

Belt

2.5

1.9

3.1

2.6

3.6

3.2

3.6

3.0

4.3

4.0

7.7

6.3

9.5

8.4

16.8

14.2

20.5

17.2

2.3

2.0

3.3

3.0

8.6

7.6

10.6

9.9

22.4

18.1

26.8

23.9

Cogged

Tor q u e - F le x

&Machined

Edge torque

Tea m B e lt s

Used

New

Belt

Belt

1.9

2.8

1.5

2.3

2.3

3.4

2.0

2.9

2.6

4.3

2.3

3.4

2.2

3.3

1.9

2.8

4.8

3.2

4.1

3.2

3.9

5.7

3.3

4.9

9.9

6.7

7.9

5.4

7.2

10.7

6.6

9.8

1.5

2.2

1.3

2.0

2.8

1.9

2.5

1.7

2.4

3.6

2.2

3.3

4.6

6.9

4.0

6.0

2.5

3.9

10.0

6.7

9.1

6.2

7.8

11.6

7.6

11.3

ELECTRICAL CONNECTIONS

Before connecting an electric motor to incoming

power, check that the electrical service available

matches the pump motor requirements stamped

on the motor nameplate.

INSTALLATION

The electrical power used to operate

this pump is high enough to cause injury or death. Obtain the services of a qu-

PAGE B -- 7

GHC SERIESOM--04352

alified electrician to make all electrical

connections.

Do not install and operate a non-explosion proof motor in an explosive atmo-

sphere. Install, connect, and operate

the motor in accordance with The National Electrical Code and all local

codes. If there is a conflict between the

instructions in the manual accompanying the unit and The Nati onal Electrical

Code or the applicable local c ode, The

National or local code shall take precedence.

PAGE B -- 8

INSTALLATION

GHC SERIES OM--04352

OPERATION --- SECTION C

Review all SAFETY information in Section A .

Follow the instructions on all tags, labels and

decals attached to the pump.

PUMP OPERATION

Never use a pressure relief valve to regulate liquid flow. Pressure relief valves

are designed as safety devices only

.Attempting to regulate flow with a pres sure relief valve may cause the pump or

piping to explode, causing severe personal injury or death.

PRE-OPERATION

Make certain that all instructions in INSTALLATION, Section B have been carried out.

Open all valves in the suction and discharge lines,

and close all drain valves.

If your pump is equipped with a packing seal, loosen the gland nuts before starting the pump until the

packing gland may be moved slightly. If leakage

seems excessive after starting, wait until the pump

has run long enough to reach its normal operating

temperature before adjusting the gland nuts. Do

not over-tighten the gland nuts. Packing pumps

must leak slightly to cool and lubricate the shaft

and to allow the shaft to turn freely.

Consult the drive manufacturer’s operating manual before attempting to start t he drive.

In a suction lift application, fill the pump housing

with liquid to seal clearances and to lubricate the

pump.

Checking Pump Rotation

Correct rotation of your pump is shown on the

pump serial plate or direction arrow plate.

The standard version of the pump is designed to handle a wide range of light, medium, and heavy viscosity liquids, depending on design and components. Do notoperate the pump with higher liquid temperatures than what it was designed; otherwise,

pump components and operation may be

affected. For temperature range consult

The Gorman-Rupp Company.

Before Starting The Pump

Never operate the pump against a

closed suction or discharge valve. The

pump will overheat, and may rupture or

explode, causing personal i njury or

death.

In applications with a single direction of

flow and a single pump-mounted pressure

relief valve, make certain that the drive unit

turns the pump in the correct direction of

rotation. Otherwise, the pump-mounted

pressure relief valve will not function.

Follow the drive unit manufacturer’s instructions,

jog the pump motor briefly, and check rotation.

If a 3-phase motor is being used and rotation is incorrect, have a qualified electrician interchange

any two of the 3-phase wires to change the direction of rotation. If a 1-phase motor is being used

and rotation is incorrect, consult the motor manufacturer’s literature.

STARTING

Start the drive unit as indicated in the manufacturer’s instructions and observe the suction and discharge gauges. If the pump does not deliver liquid

OPERATION

PAGE C -- 1

Loading...

Loading...