Page 1

ACEG

OM---05171---OE01

January 5, 2001

INSTALLATION, OPERATION,

AND MAINTENANCE MANUAL

WITH P ARTS LIST

60 SERIES PUMP

MODEL

62 1/2D1---CH23 S/G

THE GORMAN-RUPP COMPANY D MANSFIELD, OHIO

GORMAN-RUPP OF CANADA LIMITED D ST.THOMAS, ONTARIO, CANADA Printed in U.S.A.

ECopyright by the Gorman-Rupp Company

Page 2

The engine exhaust from this

product contains chemicals

known to the State ofCaliforniato

cause cancer, birth defects or

other reproductive harm.

Page 3

TABLE OF CONTENTS

INTRODUCTION PAGE I --- 1...................................................

SA F E TY --- S E CTIO N A PA G E A --- 1............................................

IN S TA LLATIO N --- SECTIO N B PA G E B --- 1.....................................

Pump Dimensions PAGE B --- 1.....................................................

PREINSTALLATION INSPECTION PAGE B --- 1............................................

POSITIONING PUMP PA GE B --- 2.......................................................

Mounting PA GE B --- 2.............................................................

SUCTION AND DISCHARGE PIPING PAGE B --- 2.........................................

Materials PA GE B --- 2..............................................................

Line Configuration PAGE B --- 2......................................................

Connections to Pump PAGE B --- 2..................................................

Gauges PA GE B --- 2...............................................................

SUCTION LINES PAGE B --- 3...........................................................

Fittings PA GE B --- 3...............................................................

Strainers PA GE B --- 3..............................................................

Sealing PAGE B --- 3...............................................................

Suction Lines In Sumps PAGE B --- 3.................................................

Suction Line Positioning PAGE B --- 3................................................

DISCHARGE LINES PA GE B --- 4........................................................

Siphoning PA GE B --- 4.............................................................

Valves PA GE B --- 4................................................................

OP E R AT ION --- S E CTIO N C PA G E C --- 1.......................................

PRIMING PA GE C --- 1.................................................................

Exhaust Primer PAGE C --- 1........................................................

STARTING PA GE C --- 1................................................................

OPERATION PA GE C --- 2..............................................................

Leakage PAGE C --- 2..............................................................

Liquid Temperature And Overheating PAGE C --- 2.....................................

Strainer Check PAGE C --- 2.........................................................

Pump Vacuum Check PAGE C --- 2..................................................

STOPPING PA GE C --- 2................................................................

Cold Weather Preservation PAGE C --- 3..............................................

TROU BLESH OOT I NG --- S E CTIO N D PA G E D --- 1...............................

PREVENTIVE MAINTENANCE PAGE D --- 2..................................................

PUMP MAINTENANCE AND REPAIR --- SECTION E PAGE E --- 1.................

STANDARD PERFORMANCE CURVE FOR PUMP MODEL 62 1/2D1---CH23 S/G PAGE E --- 1..

PARTS LIST:

Pump Model PA GE E --- 3..........................................................

Pump End Assembly PAGE E --- 5...................................................

Exhaust Primer Assembly PAGE E --- 6...............................................

PUMP AND SEAL DISASSEMBLY AND REASSEMBLY PAGE E --- 7.........................

i

Page 4

TABLE OF CONTENTS

(continued)

Discharge Check Valve Disassembly PAGE E --- 7.....................................

Exhaust Primer Disassembly PAGE E --- 7............................................

Pump Disassembly PAGE E --- 7.....................................................

Seal Removal and Disassembly PAGE E --- 8..........................................

Seal Reassembly and Installation P AGE E --- 8........................................

Impeller Installation P AGE E --- 10.....................................................

Pump Reassembly PAGE E --- 10.....................................................

Exhaust Primer Reassembly PAGE E --- 10.............................................

Discharge Check Valve Reassembly PAGE E --- 11......................................

LUBRICATION PA GE E --- 11.............................................................

Seal Assembly PAGE E --- 11.........................................................

Engine PA GE E --- 11................................................................

ii

Page 5

60 SERIES

OM--05171

INTRODUCTION

This Installation, Operation, and Maintenance

manual is designed to help you achieve the best

performance and longest life from your GormanRupp pump.

This pump is a 60 Series, single-stage centrifugal

model designed for agriculturalor fire fighting service.Itis close-coupledto aKohler CH23v-twin cylinder O.H.V. air cooled gasoline engine and protected by a wrap-around roll cage with rubber

mounting feet. The pump features compact, light

The Gorman-Rupp Company or Gorman-Rupp of Canada Limited

P.O. Box 1217 70 B urwell Road

Mansfield, Ohio 44901-- 1217 St. Thomas, Ontario N5P 3R7

For information or technical assistance on the engine, contact the engine manufacturer’s local dealer or

representative.

The following are used to alert maintenance personnel to procedures which require special attention, to

those which could damage equipment, and to those which could be dangerous to personnel:

weight design for portability, as well as rugged

construction for easy, low-cost maintenance. The

basic material of construction for wetted parts is

aluminum w ith bronze wear ring, and a self lubricated mechanical seal.

Ifthereare anyquestionsregardingt he pumporits

applicationwhichare notcovered inthis manualor

in other literature accompanying this unit, please

contact your Gorman-Rupp distributor, or write:

Immediate hazards whichWILL result in

severe personal injury or death. These

instructions describe the procedure required and the injury which will result

from failure to follow the procedure.

Hazards or unsafe practices which

COULDresult in severe personal injury

or death. These instructions describe

the procedure required and the injury

which could result from failure to follow

the procedure.

HazardsorunsafepracticeswhichCOULD

result in minor personal injury or product

or property damage. These instructions

describe the requirements and the possibledamage which couldresult fromfailure

to follow the procedure.

NOTE

Instructions to aid in installation, operation,and

maintenance, or which clarify a procedure.

PAGE I -- 1INTRODUCTION

Page 6

60 SERIES OM--05171

SAFETY --- SECTION A

This information applies to 60 Series

Engine Drivenpumps. Refer to themanual accompanying the engine be fore attempting to beg in operation.

This manual will alert personnel to

known procedures which require special attention, to those which c ould

damage equipment, and to thosewhich

could be dangerous to personnel.However, thismanualcannotpossiblyanticipate and provide detailed instructions

and precautions for every situationthat

might occur during maintenance of the

unit.Therefore,itisthe responsibility of

the owner/maintenance personnel to

ensurethatonlysafe, established maintenance procedures are used, and that

any procedures not addressed in this

manual are performed only after establishing that neither personal safety nor

pump integrity are compromised by

such practices.

Beforeattemptingto openorservicethe

pump:

This pump is designed to handle clear

water for high pressure distribution. Do

not attempt to pump volatile,corrosive,

or flammable liquids which may damagethepump orendanger personnel as

a result of pump failure.

Do not operate the pump against a

closed discharge valve for long periods

of time. This could bring the liquid to a

boil, build pressure, and cause the

pump casing to rupture or explode.

Do not remove plates, covers, gauges,

pipe plugs, or fittings from an overheated pump. Vaporpressure withinthe

pump can cause parts being disengagedtobe ejectedwith great force.Allow the pump to cool before servicing.

1. Familiarize yourself with thismanual.

2. Shutdown the engine and disconnect the park plug wires to ensure

that the pump will remain inoperative.

3. Allowthe pump tocompletely cool

if overheated.

4. Check the temperature before

opening any covers, plates, or

plugs.

5. Close the suction and discharge

valves.

6. Vent the pump slowly and cautiously.

7. Drain the pump.

Do not operate an internal combustion

engine in an explosive atmosphere.

When operating internal combustion

engines in an enclosed area, make certain that exhaust fumes are piped tothe

outside. These fumes contain carbon

monoxide, a deadly gas that is colorless, tasteless, and odorless.

Fuel used by internal combustion engines presents an extreme explosion

PAGE A -- 1SAFETY

Page 7

OM--05171

and fire hazard. Make certain that all

fuel lines are securely connected and

free of leaks. Never refuel a hot or running engine. Avoid overfilling the fuel

tank.Alwaysusethe correcttype offuel.

60 SERIES

Never tamper with the governor to gain

more power. The governor establishes

safe operating limits that should not be

exceeded.

PAGE A -- 2 SAFETY

Page 8

INSTALLATION --- SECTION B

OM--0517160 SERIES

Review all SAFETY information in Section A .

Since pump installations are seldom identical,this

section offers only general recommendations and

practices required to inspect, position, and arrange the pump and piping.

Most of the information pertains to a standard

static lift application where the pump is positionedabovethefreelevelofliquidto bepumped.

If installed in a flooded suction application where

the liquid is supplied to the pump under pressure,

some of the information such as mounting, line

configuration, and priming must be tailored to the

OUTLINE DRAWING

specific application. Since the pressure supplied

to the pump is critical to performance and safety,

be sure to limit the incoming pressure to 50% of

the maximum permissible operating pressure as

shownon thepump performance curve. (SeeSection E, Page 1.)

Forfurtherassistance, contact yourGorman-Rupp

distributor or the Gorman-Rupp Company.

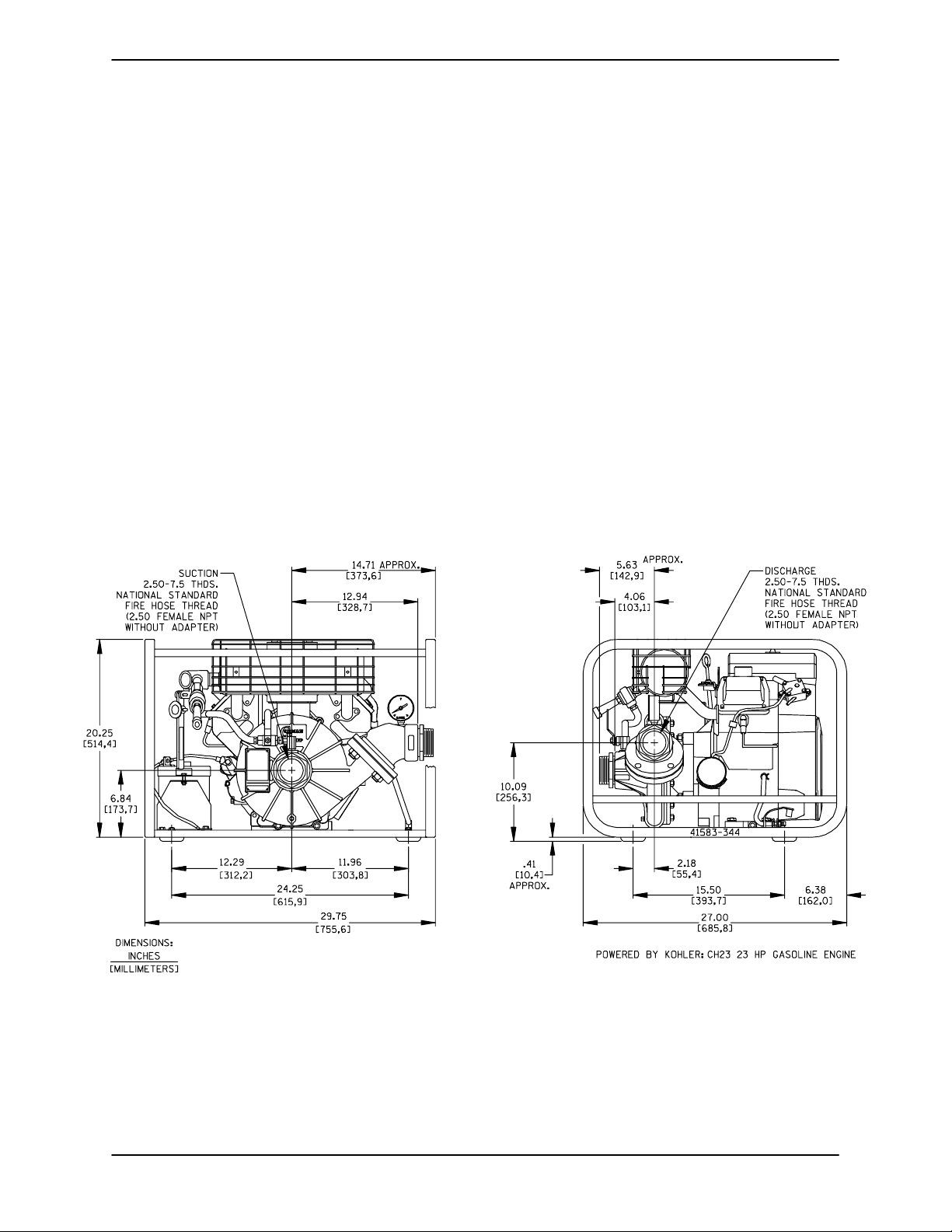

Pump Dimensions

SeeFigure1fortheapproximatephysicaldimensions of this pump and engine.

Figure 1. Pump Model 62 1/2D1--CH23 S/G

PREINSTALLATION INSPECTION

Thepump assemblywas inspectedandtested before shipment from the factory. Before installation,

inspect the pump for damage which may haveoc curred during shipment. Check as follows:

a. Inspect thepumpforcracks, dents,damaged

threads, and other obvious damage.

b. Check for and tighten loose attaching hard-

ware. Since gaskets tend to shrink after drying, check for loose hardware at mating surfaces.

PAGE B -- 1INSTALLATION

Page 9

OM--05171 60 SERIES

c. Carefully read all tags, decals and markings

onthepumpassembly,andfollowtheinstructions indicated.

d. Check all lubricant levels and lubricate as

necessary. Refer to LUBRICATION in the

MAINTENANCE AND REP AIRsectionof this

manual and perform duties as instructed.

e. If the pump and engine have been stored for

more than 12 months, some of the components or lubricants may have exceeded their

maximumshelflife.These mustbeinspected

or replaced to ensure maximum pump service.

f. Check to ensure the following standard

equipment items are included with the pump

assembly:

S Portable 6.5 gallon fuel tank complete with

quick-connect fitting.

S Suction strainer.

S Rubber foot mounting kit (must be

installed). Toinstall feet, positionflatwashers on capscrews, slide the capscrews

through the rubber feet and holes in the

base,and secure withtheflanged hexnut.

If the maximum shelf life has been exceeded, or if

anything appears to be abnormal, contact your

Gorman-Rupp distributor or the factory to determine the repair or updating policy. Do not put the

pump into service until appropriate action has

been tak en.

POSITIONING PUMP

This pump is designed to be very light-weightand

portable. The total pump weight is approximately

240 pounds (109 kg), not including accessories

orengine fuel.Customer installedequipment such

as suctionand discharge hoses must be removed

before attempting to lift.

Mounting

Locatethepump inanaccessibleplaceascloseas

practicalto the liquidbeingpumped. Levelmounting is essential for proper operation.

To ensure sufficient lubrication and fuel supply to

the engine, do not position the pump and engine

morethan 15_ off horizontal for continuous operation. The pump and engine may be positioned up

to 30_ off horizontal for intermittent operation

only;however,theengine manufacturershould be

consulted for continuous operation at angles

greater than 15_.

SUCTION AND DISCHARGE PIPING

Pump performance is adversely effected by increased suction lift, discharge elevation, and friction losses. See the performance curve and operating range shown on Page E-1 to be sure your

overall application allows pump to operate within

thesafeoperationrange.

Materials

Either pipe or hose maybe used for suction and

discharge lines; however, the materials must be

compatiblewiththe liquidbeingpumped. Ifhoseis

used in suction lines, it must be the rigid-wall, reinforced type to prevent collapse under suction. Using piping couplings in suction lines is not recommended.

Line Configuration

Keep suction and discharge lines as straight as

possible to minimize friction losses. Make minimum use of elbows and fittings, which substantiallyincreasefrictionloss. Ifelbows arenecessary,

use the long-radius type to minimize friction loss.

Connections to Pump

Before tightening a connecting flange, align it exactlywith the pump port. Never pulla pipe lineinto

place by tightening the flange bolts and/or couplings.

Lines near the pump must be independently supported to avoid strain on the pump which could

cause excessive vibration, decreased bearing life,

and increased shaft and seal wear. If hose-type

linesare used,they shouldhaveadequatesupport

to secure them when filled with liquid and under

pressure.

The pump may have to be supported orshimmed

to provide for level operation or to eliminate vibration.

PAGE B -- 2 INSTALLATION

Gauges

Most pumps are drilled and tapped for installing

dischargepressureandvacuumsuctiongauges.If

Page 10

OM--0517160 SERIES

these gauges are desired for pumps that are not

tapped, drill and tap the suction and discharge

lines not less than 18 inches (457,2 mm) from the

suction and discharge ports and install the lines.

Installationcloserto the pump may result inerratic

readings.

SUCTION LINES

Toavoidair pocketswhichcouldaffectpump priming, thes uction line must be as short and direct as

possible.Whenoperationinvolvesasuctionlift,the

line must always slope upward to the pump from

the source of the liquid being pumped; if the line

slopes down to the pump at any point along the

suction run, air pockets will be created.

The maximum vertical suction lift for this pump is

20 feet (6,1 meters). It is not designed to be operated at a higher lift.

Fittings

Suction lines should be the same size as the pump

inlet. If reducers are used in suction lines, they

should be the eccentric type, and should be installedwith the flat part of the reducers uppermost

to avoid creating air pockets. Valves are not normally used in suction lines, but if a valve is used,

install it with the stem horizontal to avoid air pock ets.

Strainers

Sealing

Since even a slight leak will affect priming, head,

and capacity, especially when operating with a

high suction lift, all connections in the suction line

should be sealed with pipe dope to ensure an airtight seal. Follow the sealant manufacturer’s recommendations when selecting and applying the

pipe dope. The pipe dope should be compatible

with the liquid being pumped.

Suction Lines In Sumps

If a single suction line is installed in a sump, it

should be positioned away from the wall of the

sumpata distance equal to1 1/2 times the diameter of the suction line.

If there is a liquid flow from an open pipe into the

sump, the flow should be kept away from the suctioninlet because theinflowwillcarryair downinto

the sump, and air entering the s uction line will reduce pump efficiency.

Ifitis necessary to positioninflowclose to the suctioninlet, installa bafflebetween theinflowandthe

suction inlet at a distance 1 1/2 times the diameter

of the suction pipe. The baffle will allow entrained

air to escape from the liquid before it is drawn into

the suction inlet.

If two suction lines are installed in a single sump,

theflow pathsmay interact,reducing theefficiency

of one or both pumps. To avoid this, position the

suction inlets so that they are separated by a distance equal to at least 3 times the diameter of the

suction pipe.

If a strainer is furnished with the pump, be certain

touse it;any sphericalsolidswhichpassthrougha

strainer furnished with the pump will also pass

through the pump itself.

If a strainer is not furnished with the pump, but is

installed by the pump user, make certain that the

total area of the openings in the strainer is at least

three or four times the cross section of the suction

line,and that the openings willnot permit passage

of solids larger than the solids handling capability

of the pump.

This pump is designed to handle up to 5/ 16-inch

(7,9 mm) diameter spherical solids.

Suction Line Positioning

The depth of submergence of the suction line is

critical to efficient pump operation. Figure 2shows

recommended minimum submergence vs. veloc-

ity.

NOTE

The pipe submergence required may be reduced

by installing a standard pipe increaserfitting at the

endof the suctionline. The largeropening size will

reduce the inlet velocity. Calculate the required

submergence using the following formula based

on the increased opening size (area or diameter).

PAGE B -- 3INSTALLATION

Page 11

OM--05171 60 SERIES

Figure 2. Recommended Minimum Suction Line Submergence vs. Velocity

DISCHARGE LINES

Siphoning

Donot terminate the discharge lineat a level lower

than that of the liquid being pumped unless a siphon breaker is used in the line. Otherwise, a siphoning action causing damage to the pump

could result.

Valves

A check valveinthedischargelineis normally recommended, but it is not necessary in low discharge head applications.

If a throttlingvalve is desired inthe discharge line,

useavalveaslargeasthelargestpipetominimize

friction losses. Never install a throttling valve in a

suction line.

Withhighdischarge heads,itis recommendedthat

a throttling valve and a system check valve be installed in the discharge line to protect the pump

from excessive shock pressure and reverse rotation when it is stopped.

PAGE B -- 4 INSTALLATION

Page 12

60 SERIES

OM--05171

OPERATION --- SECTION C

Review all SAFETY information in Section A .

Follow the instructions on all tags, labels and

decals attached to the pump.

This pump is designed to handle clear

water in high pressure distribution. Do

not attempt to pump volatile,corrosive,

or flammable liquids which may damagethepump orendanger personnel as

a result of pump failure.

Never tamper with the governor to gain

more power. The governor establishes

safe operating limits that should not be

exceeded.

The exhaust primer utilizes engine exhaust gases,

directedthrough a venturi,to createa vacuum and

draw air out of the suction line and pump casing.

The exhaust primer is capable of priming a pump

with a maximum priming lift of 15 feet (4,6 meters)

within 90 seconds; less time will be required for

priming ata lesser lift.Ifthe pump doesnotprimein

a reasonablelengthoftime, check the suctionline

for leaks.

Toprime the pump, closethe throttling valve inthe

discharge line.

Close the exhaust primer handle (see Figure 1),

and open the cock in the priming line. Consult the

starting instructions in this manual as well as the

engine operating manual, and start the engine.

Operate the engine at maximum governed speed

and allow the pump to prime untilliquid flows continuously from the exhaust primer nozzle. When

the pump is fullyprimed, open the exhaust primer

handle, and close the cock in the priming line.

PRIMING

Install the pump and piping as described in INSTALLATION. Make sure that the piping connec-

tions are tight, and that the pump is securely

mounted. Check that the pump is properly lubricated (see LUBRICATION in MAINTENANCE

AND REPAIR).

Exhaust Primer

Since this pump is not self-priming, it is equipped

with an exhaust primer assembly (Figure 1).

HANDLE

GAS COCK

Once fully primed, reduce the engine speed and

partially open the discharge throttling valve. The

discharge line should be filled slowly to prevent

damage tothe piping, gaskets, and other devices,

resulting from the initial shock of liquid filling the

lines. When the discharge line is completely filled,

adjust the discharge throttling valveto the desired

flow rate.

STARTING

Consult the operations manual furnished with the

engine.

Attach the fuel line to the quick-connect fitting locatedon theengine. Positiontheportable fueltank

atthesamelevelasthepump,orslightlyhigher.

Squeezetheprimingbulbuntilthefuelcanbeseen

in the transparent fuel line at the carburetor inlet.

The transparent fuel line need not be completely

full. Fuel will be pulled into the carburetor while

cranking the engine w ith the choke on.

Figure 1. Exhaust Primer Assembly

OPERATION PAGE C -- 1

Set the ignition toggle switch to the ON position.

Page 13

60 SERIESOM--05171

Set the twist-lock throttle control at approximately

half open position. Start the engine and follow engine manufacturer’s recommendations for carburetoradjustmentsto obtainoptimumperformance.

NOTE

Hard starting may be experienced after connecting

a new tank of fuel. This can be caused by air

trapped in the fuel line. It is recommended that the

fuel line be vented and filled by depressing the

valve in the female quick connect fitting prior to

installing it on the pump.

OPERATION

Pump speed and operating condition

points must be within the continuous performance range shown on the curve. (See

Section E, Page 1.)

heated pump. Vaporpressure withinthe

pump can cause parts being disengagedtobe ejectedwith great force.Allowthe pump to completely coolbefore

servicing.

Strainer Check

If a suction strainer has been shipped with t he

pump or installed by the user, check the strainer

regularly, and clean it as necessary. The strainer

shouldalsobe checkedifpumpflowratebeginsto

drop. If a vacuum suction gauge has been installed, monitor and record the readings regularly

to detect strainer blockage.

Never introduce air or steam pressure into the

pump casingor piping to removea blockage.This

could result in personal injury or damage t o the

equipment. If backflushing is absolutely necessary, liquid pressure must be limited to 50% of the

maximum permissible operating pressure shown

on the pump performance curve. (See Section E,

Page 1.)

Leakage

No leakage should be visibleat pump mating surfaces, or at pump connections or fittings. Keepall

lineconnectionsand fittingstight tomaintain maximum pump efficiency.

Liquid Temperature And Overheating

The maximum liquid temperature for this pump is

160_F(71_C). Do not applyit ata higher operating

temperature than is recommended.

Overheating can occur if operated with the valves

in the suction or discharge lines closed. Operating

against closed valves could bring the liquid to a

boil, build pressure, and cause the pump to rupture or explode. If overheating occurs, stop the

pumpand allowit tocompletelycool beforeservicing it. Refill the pump casing with cool liquid.

Pump Vacuum Check

Withthe pump inoperative,installa vacuumgauge

in the system, using pipe dope on the threads.

Block the suction lineandstart thepump. Atoperating speed the pump should pull a vacuum of 20

inches (508,0 mm) or more of mercury. If it does

not, check for air leaks in the seal, gasket, or discharge valve.

Openthe suctionline,andread thevacuum gauge

with the pump primed and at operation speed.

Shut offthe pump. The vacuumgaugereading will

immediately drop proportionate to static suction

lift,andshouldthenstabilize. Ifthe vacuum reading

falls off rapidly after stabilization, an air leak exists.

Before checking for the source of the leak, check

the point of installation of the vacuum gauge.

STOPPING

Do not remove plates, covers, gauges,

pipe plugs, or fittings from an over-

Never halt the flow of liquid suddenly. If the liquid

being pumped is stopped abruptly, damaging

shock waves can be transmitted to the pump and

piping system. Close all connectingvalvesslowly.

OPERATIONPAGE C -- 2

Page 14

60 SERIES

If the application involves a high discharge

head, gradually close the discharge

throttling valve before stopping the pump.

Afterstoppingthe pump,switchoffthe engineignition and remove or ground the spark plug to ensure that the pump will remain inoperative.

Cold Weather Preservation

In below freezing conditions, drain the pump to

OM--05171

preventdamagefrom freezing. Also,clean outany

solids by flushing with a hose. Operate the pump

for approximatelyone minute; this willremoveany

remaining liquid that could freeze the pump rotating parts. If the pump will be idle for more than a

few hours, or if it has been pumping liquids containing a large amount of solids, drain the pump,

and flush it thoroughly with clean water. Toprevent

large solids from clogging the drain port and preventing the pump from completely draining, insert

a rod or stiff wire in the drain port, and agitate the

liquid during the draining process. Clean out any

remaining solids by flushing with a hose.

OPERATION PAGE C -- 3

Page 15

60 SERIES

OM--05171

TROUBLESHOOTING --- SECTION D

Review all SAFETY information in Section A .

Beforeattemptingto openorservicethe

pump:

1. Familiarize yourself with thismanual.

2. Shutdown the engine and remove

thesparkplug wires toensurethat

the pump will remain inoperative.

Table B-1 Troubleshooting Chart

TROUBLE

ENGINE FAILS TO

START

CAUSE REMEDY

Auxiliary priming device faulty

or improperly installed.

Integral discharge check

valve clogged or binding.

Spark plug contaminated.

3. Allowthe pump tocompletely cool

if overheated.

4. Vent the pump slowly and cautiously.

5. Close the suction and discharge

valves.

6. Check the temperature before

opening any covers, plates, or

plugs.

7. Drain the pump.

Forspecificinstructionson enginetroubleshooting

or repair, see the engine manual.

Repair priming device or check installation.

Clean valve.

Clean and replace plug; reset gap.

PUMP FAILS T O

PRIME

No fuel to engine or fuel contaminated.

Engine flooded.

Auxiliary priming device faulty

or improperly installed.

Integral discharge check

valve clogged or binding.

Air leak in suction line.

Lining of suction hose col-

lapsed.

Leakingorwornsealorpump

gasket.

Suction lift or discharge head

to high.

Strainer clogged.

Check fuel tank level; vent t ank; purge air

from fuel lie; clean fuel filters. Check fuel for

proper oil mix; check for contamination.

Dry spark plug; a djust carburetor; see engine

manual.

Repair priming device or check installation.

Clean valve.

Correct leak.

Replace suction hose.

Check pump vacuum. Replace leaking or

worn seal or gasket.

Check piping installation and reduce suction

lift and/or discharge head.

Check strainer and clean if necessary.

TROUBLESHOOTING PAGE D -- 1

Page 16

OM--05171

TROUBLE

PUMP STOPS OR

FAILS TO DELIVER

RATED FLOW OR

PRESSURE

Table B-1 Troubleshooting Chart (continued)

CAUSE REMEDY

Air leak in suction line.

Suction intake not submerged

at proper level or sump too

small.

Correct leak.

Checkinstallationand correct submergenceas

needed.

60 SERIES

Lining of suction hose collapsed.

Dischargelinecloggedorrestricted; hose kinked.

Impellerorotherwearingparts

worn or damaged.

Impeller clogged.

Pump speed too slow.

Suction lift or discharge head

to high.

Leakingorwornsealorpump

gasket.

PUMP REQUIRES

TOO MUCH POWER

Exceeding operating limits.

Liquid solution too thick.

PREVENTIVE MAINTENANCE

Sincepump applicationsareseldomidentical,and

pump wear is directly affected by such things as

the abrasive qualities, pressure and temperature

oftheliquidbeingpumped, thissection isintended

only to provide general recommendations and

practices for preventive maintenance. Regardless

of the application however,following a routine preventive maintenance schedule will help assure

trouble-free performance and long life from your

Gorman-Rupp pump. For specific questions concerning your application, contact your GormanRupp distributor or the Gorman-Rupp Company.

Record keeping is an essential component of a

good preventive maintenance program. Changes

in suction and discharge gauge readings (if so

Replace suction hose.

Check discharge lines; straighten hose.

Replace worn or damaged parts. Check that

impelleris properlycentered and rotates freely.

Free impeller of debris.

Check engineoutput; consult engineoperation

manual.

Check pipinginstallationand reduce suctionlift

and/or discharge head.

Check pump vacuum. Replace leaking orworn

seal or gasket.

See performance curve in Pump Maintenance

And Repair.

Dilute if possible.

equipped) between regularly scheduled inspections can indicate problems that can be corrected

before system damage or catastrophic failure occurs.The appearanceof wearingpartsshouldalso

bedocumented ateach inspectionfor comparison

as well. Also, if records indicate that a certain part

(such as the seal) fails at approximately the same

duty cycle, the part can be checked and replaced

beforefailureoccurs,reducing unscheduleddown

time.

For new applications, a first inspection of wearing

partsat250 hourswillgiveinsightintothewearrate

foryourparticularapplication.Subsequentinspections should be performed at the intervals shown

on the chart below. Critical applications should be

inspected more frequently.

TROUBLESHOOTINGPAGE D -- 2

Page 17

60 SERIES

OM--05171

Preventive Maintenance Schedule

Service Interval*

Item

General Condition (Temperature, Unusual

Noises or Vibrations, Cracks, Leaks,

Loose Hardware, Etc.) I

Pump Performance (Gauges, Speed, Flow) I

Bearing Lubrication I R

Seal Lubrication (And Packing Adjustment,

If So Equipped) I R

V-Belts (If So Equipped) I

Air Release Valve Plunger Rod (If So Equipped) I C

Front Impeller Clearance (Wear Plate) I

Rear Impeller Clearance (Seal Plate) I

Check Valve I

Pressure Relief Valve (If So Equipped) C

Pump and Driver Alignment I

Shaft Deflection I

Bearings I

Bearing Housing I

Piping I

Driver Lubrication - -- See Mfgr’s Literature

Daily Weekly Monthly Semi-

Annually

Annually

Legend:

I = Inspect, Clean, Adjust, Repair or Replace as Necessary

C= Clean

R= Replace

* Service interval based on an intermittent duty cycle equal to approximately 4000 hours annually.

Adjust schedule as required for lower or higher duty cycles or extreme operating conditions.

TROUBLESHOOTING PAGE D -- 3

Page 18

60 SERIES

OM--05171

PUMP MAINTENANCE AND REPAIR --- SECTION E

MAINTENANCE AND REPAIR OF THE WEARING PARTS OF THE PUMP WILL MAINTAIN PEAK

OPERATING PERFORMANCE.

STANDARD PERFORMANCE FOR PUMP MODEL 62 1/2D1--CH23 S/G

Based on 70_ F(21_ C) clear water at sea level

with minimumsuction lift.Since pump installations

areseldomidentical,yourperformancemaybe different due to such factors as viscosity, specific

gravity, elevation, temperature, and impeller trim.

formance or part numbers.

Never tamper with the governor to gain

If your pump serial number is followed by an “N”,

your pump is NOT astandardproductionmodel.

Contact the Gorman-Rupp Company to verifyper-

MAINTENANCE & REPAIR PAGE E -- 1

more power. The governor establishes

safe operating limits that should not be

exceeded.

Page 19

SECTION DRAWING

60 SERIESOM--05171

Figure 1. Pump Model 62 1/D1---CH23 S/G

MAINTENANCE & REPAIRPAGE E -- 2

Page 20

60 SERIES

OM--05171

PARTS LIST

Pump Model 62 1/2D1---CH23 S/G

(From S/N 1211015 up)

Ifyourpump serialnumber is followedby an “N”,your pumpis NOT a standard production model.Contact

the Gorman-Rupp Company to verify part numbers.

ITEM

PART NAME PART

NO.

NUMBER

MAT’L

CODE

QTY ITEM

NO.

PART NAME PART

NUMBER

MAT’L

CODE

QTY

1 PUMP END ASSY 62 1/2D1---(CH23) 1

2 KOHLER CH23PS ENGINE 29127---303 --- --- --- 1

3 ROLLOVER BASE 41583---344 24150 1

4 MUFFLER ASSY 46211---029 24150 1

5 MUFFLER GUARD KIT 29187---111 ------ --- 1

6 PR ESSUR E G AUG E S1 80 --- --- --- 1

7 HAND CARRY DECAL 2613FT --------- 2

8 DISCHARGE STICKER 6588BJ --- --- --- 1

9 SUCTION STICKER 6588AG --- ------ 1

10 COUPLING 2469 14000 2

11 EXHAUST PRIMER ASSY 46112---706 --- --- --- 1

12 WARNING DECAL 2613FE --- --- --- 1

13 BRACKET 34144---036 15080 1

14 FLAT WASHER K06 15991 1

15 HEX HD CAPSCREW B0603 15991 1

16 HEX NUT D06 15991 1

17 DISCONNECT BUSHING 26534---082 --- --- --- 1

18 DUST CAP 26531---301 ------ --- 1

19 JAM NUT AT06S 15991 1

20 FUEL LINE 11308H --- ------ 1

21 HOSE CLAMP S1788 --- --- - -- 2

22 HEX HD CAPSCREW B0606 15991 4

23 FLAT WASHER K06 15991 4

24 FLANGED HEX NUT 21765---314 ------ --- 4

25 STUD C0709 15991 4

26 HEX NUT D07 15991 4

27 LOCKWASHER J07 15991 4

28 RUBBER FOOT MTG KIT 48152---603 ------ -- - 1

29 ---RUBBER BUMPER S1224 --- --- --- 4

30 ---HEX HD CAPSCREW B0504 15991 4

31 ---FLAT WASHER K05 15991 4

32 ---FLANGED HEX NUT 21765---312 --- -- ---- 4

33 NAME PLATE 2613BF 13990 1

34 DRIVE SCREW BM#04---03 17000 4

35 B AT TE R Y B OX A S SY GR P 40 --- 0 5 --- --- --- 1

36 ---HEX HD CAPSCREW B0503 15991 4

37 ---T TYPE LOCKWASHER BL05 15991 1

38 ---FLANGED HEX NUT 21765---312 --- -- ---- 4

39 ---BATTERY BOX 11281 24000 1

40 ---BATTERY S1680 - -- ------ REF

41 ---BATTERY TAG 38818---680 ------ --- 1

42 ---BATTERY BOX COVER 11870 24000 1

43 ---HEX HD CAPSCREW B0504 15991 2

44 ---FLANGED HEX NUT 21765---312 --- -- ---- 2

45 ---GROUND CABLE 47311---542 --- ------ 1

46 ---POS BATTERY CABLE 47311---502 --------- 1

47 FUEL TANK ASSY 46711---086 --- --- -- - 1

NOT SHOWN:

STRAINER 26841---010 - -- ------ 1

ADAPTOR 26115---011 --- --- --- 1

EXHAUST PRIMER TAG 6588X --- - -- --- 1

INSTRUCTION TAG 38817---045 ------ --- 1

ENG START---UP TAG 38816---269 --- --- --- 1

INDICATES PARTSRECOMMENDED FOR STOCK

MAINTENANCE & REPAIR PAGE E -- 3

Page 21

SECTION DRAWING

60 SERIESOM--05171

Figure 2. 62 1/2D1---(CH23) Pump End Assembly

MAINTENANCE & REPAIRPAGE E -- 4

Page 22

60 SERIES

OM--05171

PARTS LIST

62 1/2D1---(CH23) Pump End Assembly

ITEM

NO.

1 PUMP CASING 11013 13040 1

2

3

4 STUD C0605 1/2 15991 12

5 HEX NUT D06 15991 12

6 INTERMEDIATE 38264---331 13040 1

7

8

9

10

11 CASING DRAIN PLUG P04 15079 1

12

13 CHECK VALVE BODY 6323 13000 1

14

15 CHECK VALVE ARM 6324 14000 1

16 STUD C1009 15991 4

17 HEX NUT D10 15991 4

18 SPRING HOLDER 25273---273 ------ --- 1

PART NAME

IMPELLER 38623---034 13047 1

SEAL ASSEMBLY 25271---903 ------ --- 1

IMPELLER ADJUSTING SHIM 37J 17090 1

SHAFT SLEEVE 3428D 16000 1

BALANCE RING 62ZL6 14000 1

CASING GASKET 11013G 18000 1

WEAR RING 11017 14050 1

CHECK VALVE BODY GASKET 6323G 19060 1

PART

NUMBER

MAT’L

CODE

QTY

INDICATES PARTS RECOMMENDED FOR STOCK

MAINTENANCE & REPAIR PAGE E -- 5

Page 23

60 SERIESOM--05171

Figure 3. Exhaust Primer Detail

ITEM

NO.

1 EXHAUST PRIMER VALVE BODY 3643 10010 1

2

3

4 EJECTOR BODY 3552 14000 1

5 VENTURI 2345B 14000 1

6 HEX NIPPLE 26112---053 --- ------ 1

7 SWIVEL FITTING 26571---002 ------ --- 1

8 HOSE ADAPTOR 26523---334 ------ --- 2

9 1 FT HOSE 18513---302 ------ --- 1

10 GAS COCK S2 --- --- --- 1

11 VALVE HAND 1458A 15990 1

12 EXH PRIMER DECAL 6588AS --- ------ 1

13 EXHAUST PRIMER VALVE 1467 10010 1

14 COTTER PIN M0406 15990 2

15 SPRING WASHER S165 --- --- --- 3

PART NAME

PIPE NIPPLE T08 15079 1

EJECTOR JET 3645B 14000 1

PART

NUMBER

MAT’L

CODE

MAINTENANCE & REPAIRPAGE E -- 6

QTY

Page 24

60 SERIES

OM--05171

PUMP AND SEAL DISASSEMBLY

AND REASSEMBLY

Review all SAFETY information in Section A .

Followtheinstructionsonall tags,label anddecals attached to the pump.

This pump requires little service due to its rugged,

minimum-maintenance design. However, if it becomesnecessarytoinspect orreplacethe wearing

parts, followthese instructionswhichare keyed to

thesectionalview (seeFigure1)andthe accompanying parts list.

Most service functions, such as wear plate, impeller, and seal replacement, may be performed by

draining the pump and removing the back cover

assembly. However, the following instructions assume complete disassembly is required.

As described in the SAFETY Section, this manual

willalert personnel toknown procedures which require special attention, to those which could damage equipment, and to those whichcould be dangerousto personnel. However,this manualcannot

possibly anticipate and provide detailed precautions for every situation that might occur during

maintenanceof theunit. Therefore,itis theresponsibilityof the owner/maintenance personnel toensure that only safe, established shop procedures

are used, and that any procedures not addressed

in this manual are performed only after establishing that neither personal safety nor pumpintegrity

are compromised by such practices.

2. Shut down the engine and remove

the spark plug wires to ensurethat

the pump will remain inoperative.

3. Allowthe pump tocompletely cool

if overheated.

4. Check the temperature before

opening any covers, plates, or

plugs.

5. Close the suction and discharge

valves.

6. Vent the pump slowly and cautiously.

7. Drain the pump.

Discharge Check Valve Disassembly

(Figure 2)

Removethenuts(17)andseparatethecheckvalve

body(13)fromthe pumpcasing(1). Pullthe rubber

gasket (14) fromthe flangestuds (16),andpull the

check valve arm (15) from the check valve body.

Unscrewthepressuregaugeandfirehoseadaptor

if required.

Clean the mating surfaces of both flanges and inspectall partsfor wearor damage. Ifno furtherdisassembly is required, refer to Discharge Check

Valve Reassembly.

Exhaust Primer Disassembly

(Figure 3)

Removethe hoseadaptor (8)fromtheswivelfitting

(7). If necessary, remove the gas cock valve (10)

andpipenipple(6).

Before attempting to service the pump, switch off

the engine ignition and remove the spark plug, or

take other precautions to ensure thatit will remain

inoperative. Close all valves in the suction and discharge lines.

Forengine disassembly and repair, consult the literature supplied with the engine, or contact your

local Kohler engine representative.

To remove the exhaust primer body (1) unscrew

the body from the muffler (4). To disassemble the

exhaust primer, remove the handle (11) and unscrew the various primer components.

If no further disassembly is required, refer to Ex-

haust Primer Reassembly.

Pump Disassembly

(Figure 2)

After disconnecting the exhaust primer, remove

the casing drain plug (11) and drain the pump casing. Clean and reinstall the plug.

Beforeattemptingto openorservicethe

pump:

1. Familiarize yourself with thismanual.

MAINTENANCE & REPAIR PAGE E -- 7

For access to the impeller (2) and seal assembly

(3), removethe nuts (5) securingthe pumpcasing

totheintermediate(6).Removethecasinggasket

(10) and clean the contacting surfaces.

Page 25

60 SERIESOM--05171

Inspect the wear ring (12) for excessive wear or

damage.Thewearringissecuredinthepumpcasing by a press fit. If replacement is required, use a

small bit to drill two holes horizontally through the

ring, 180_ apart. Use a chisel or other suitable tool

to complete the cuts through the ring and remove

thering fromthe casing.Be carefulnotto damage

the casing bore w hen removing the ring.

Toremovethe impeller,insert a steel baror drift pin

between the vanes, and turn the impeller in a

counter-clockwise direction (when facing the impeller)whileholdingthe enginecrankshaft stationary. Be careful notto damage the impeller vanes.

Use caution when unscrewing the impeller; tension on the seal spring will be released as the impeller is removed.

Inspect t he balance ring (9) for excessive wear or

damage. The balance ring is secured in the intermediate by a press fit. If replacement is required,

use a small bit to drill two holes horizontally

through the ring, 180_ apart. Use a chisel or other

suitable toolto completethe cuts through the ring

and remove t he ring from the intermediate. Be

careful notto damagethe intermediatebore when

removing the ring.

Seal Removal and Disassembly

(Figure 2 And 4)

Removethe springholder(18) andthe impelleradjustingshims(7). Tieandtag theshims ormeasure

and record their thickness for ease ofreassembly.

Removethe seals pring, then slidethe shaft sleeve

and rotating portion of the seal off the engine shaft

as a unit. Apply oil to the sleeve and work it up under the bellows. Slide the rotating portion of the

sealoff the sleeve. Use two stiff wires with hooked

ends to pullthe stationary seat from the intermediate bore.

NOTE

Analternatemethodof removing thestationaryseat

istoremove thehardware(26 and27,Figure 1)and

separate the intermediate from the engine. Use a

dowel to press the stationary seat from the intermediate.

If no further disassembly is required, refer to Seal

Reassembly And Installation.

Seal Reassembly and Installation

(Figure 2 And 4)

Cleanthe seal cavityandshaft witha cloth soaked

in fresh cleaning solvent.

Most cleaning solvents are toxic and

flammable. Usethem only in a well ven tilated area free from excessive heat,

sparks, and flame. Read and follow all

precautions printed on solventcontainers.

The sealis not normallyreused because wear patterns on the finished faces cannot be realigned

during reassembly. This could result in premature

failure.Ifnecessary toreuse anoldsealinanemergency, carefully wash all metallic parts in fresh

cleaning solvent and allow to dry thoroughly.

Handlethe seal parts with extreme care to prevent

damage. Be careful not to contaminate precision

finished faces; even fingerprints on the faces can

shortenseallife.Ifnecessary,cleanthefaceswitha

non-oilbased solvent and a clean, lint-free tissue.

Wipe lightly in a concentric pattern to avoid

scratching the faces.

Inspect the seal components for wear, scoring,

grooves,and otherdamage that mightcauseleakage.Clean andpolishtheshaft sleeve,or replaceit

if there are cuts or nicks on either end. If any components are worn, replace the complete seal;

never mix old and new seal parts.

If a replacement seal is being used, remove itfrom

the container and inspect the precision finished

faces to ensure that they are free of any foreign

matter.

To ease installation of the seal, lubricate the rotating element O-ring with water or a very small

amount of oil, and apply a drop of light lubricating

oil on the finishedfaces. Assemble the seal as follows,(seeFigure4).

MAINTENANCE & REPAIRPAGE E -- 8

Page 26

60 SERIES

OM--05171

IMPELLER

IMPELLER

SHIM SET

SPRING

RETAINER

BELLOWS

O-RING

INTERMEDIATE

SHAFT

SLEEVE

IMPELLER

SHAFT

STATIONARY

ELEMENT

ROTATING

ELEMENT

Figure 4. 25271--903 Seal Assembly

This seal is not designed for operation at

temperatures above 160_F(71_C). Donot

use at higher operating temperatures.

If the balance ring (9) was removed, the replacement ring should be pressed into the intermediate

beforeinstallingthe seal. Positionthe ring inthe intermediatebore withthechamferedendtoward toward the bore shoulder and press it into the bore

until fully seated.

NOTE

The balance ring must be fully seated in the intermediate bore, otherwise binding and/or excessive

wear could result.

Lubricate the stationary seat O-ring with light oil

andinstallit inthestationary seat.Use thumbpressure to press this subassembly into the intermediateboreuntilfullyseated.Be carefulnottodamage

thesealface.Afterinstallation,wipethesealfacein

a concentric pattern with a clean, lint-free cloth to

remove any fingerprints.

Secure the intermediate to the engine with the

hardware (26 and 27). Be careful not to damage

the stationary seat on the shaft threads.

Slide the rotating portion of the seal (consisting of

theretainer,bellowsand rotatingelement)ontothe

sleeve(8)untiltherotatingfaceisjust flush with

the chamfered end of the sleeve. Slide the sleeve

ontotheshaftuntilthesealfaces contact.Continue

topushthesleevethroughthesealuntilitseats

against the shaft shoulder.

Iftheintermediatewasremoved,layitonaflatsurface with the impeller side facing up.

MAINTENANCE & REPAIR PAGE E -- 9

Install the seal spring. Make sure that all components of the seal are seated squarely.

Page 27

60 SERIESOM--05171

Impeller Installation

(Figures 2 and 5)

Inspectthe impeller(2), and replace itif cracked or

badly worn.

CD

B

2

AB

B

+

A

2

For maximum pump efficiency, the impeller must

becentered withinthe volutescroll. Toverifyimpeller positioning, measure the pump casing and impeller as shown in Figure 5. Use these measurements to calculate the required impeller location

(dimension E). Add or remove impeller adjusting

shims (55) to obtain dimension E.

D

2

E

Step 2Step 1 Step 3

C

+

D

2

=

E

---

Figure 5. Centering Impeller Within Pump Casing

NOTE

After the impeller has been properly positioned,

check for free rotation. Correct any scraping or

binding before further reassembly.

Pump Reassembly

(Figure 2)

If the wear ring (12) was removed, apply ‘Loctite

No. 242 Threadlocker’ or equivalent compound)

between thecasing andthewearring. Positionthe

replacement ring in the casing bore so that chamfer on the I.D. faces toward the impeller. Press the

ringinto the bore until fullyseatedagainst the casing shoulder.

NOTE

The wear ring must be fully seated in the casing

bore, otherwise binding and/or excessive wear

could result.

Install the pump casing gasket (10). Carefully

guidethewearringintotheeyeoftheimpeller,and

securethecasing to the intermediatewith the nuts

(5).

NOTE

After the pump casing has been install check the

impeller for free rotation. Correct any scraping or

binding before further reassembly.

Exhaust Primer Reassembly

(Figure 3)

NOTE

Before assembly, apply pipe sealant on all

threaded joints.

To install t he exhaust primer body (1) screw the

body intothe muffler(4). To assemble theexhaust

primer,installthehandle(11)and installthevarious

primer components.

Screw the hose adaptor (8) into the swivel fitting

(7). Install the gas cock valve (10) and pipenipple

(6).

MAINTENANCE & REPAIRPAGE E -- 10

Page 28

60 SERIES

OM--05171

Discharge Check Valve Reassembly

(Figure 2)

Position the pivot of the check valve arm (15) in the

slotinthevalvebody (13).Installtherubber gasket

(14), and secure the assembly to the casing with

the nuts (17). Check for free operation of the valve

arm.Inspectthepressuregaugeandhoseadaptor

forwearordamagebeforeinstallationandreplace

as required.

LUBRICATION

Seal Assembly

(Figure 2)

Theseal assemblyis lubricatedbythemediumbeing pumped. No addition lubrication is required.

Engine

(Figure 1)

Refer to the literature provided with the engine, or

contact your local Kohler engine representative.

MAINTENANCE & REPAIR PAGE E -- 11

Page 29

For U.S. and International Warranty Information,

Please Visit www.grpumps.com/warranty

or call:

U.S.: 419−755−1280

International: +1−419−755−1352

For Canadian Warranty Information,

Please Visit www.grcanada.com/warranty

or call:

519−631−2870

THE GORMAN-RUPP COMPANY D MANSFIELD, OHIO

GORMAN-RUPP OF CANADA LIMITED D ST. THOMAS, ONTARIO, CANADA

Loading...

Loading...