GORMAN-RUPP PUMPS 80 Series, 84A2-QSF2.8P FT4, 86A2-QSF2.8P FT4 Installation, Operation, And Maintenance Manual With Parts List

OM-06752-01

March 23, 2015

INSTALLATION, OPERATION,

AND MAINTENANCE MANUAL

WITH PARTS LIST

80 SERIES PUMP

MODEL

84A2-QSF2.8P FT4

GORMAN‐RUPP PUMPS

www.grpumps.com

e2015 Gorman‐Rupp Pumps Printed in U.S.A.

Register your new

Gorman‐Rupp pump online at

www.grpumps.com

Valid serial number and e‐mail address required.

The engine exhaust from this

product contains chemicals

known to the State of California to

cause cancer, birth defects or

other reproductive harm.

RECORD YOUR PUMP MODEL AND SERIAL NUMBER

Please record your pump model and serial number in the

spaces provided below. Your Gorman‐Rupp distributor

needs this information when you require parts or service.

Pump Model:

Serial Number:

TABLE OF CONTENTS

INTRODUCTION PAGE I - 1.................................................

SAFETY ‐ SECTION A PAGE A - 1............................................

INSTALLATION - SECTION B PAGE B - 1....................................

Pump Dimensions PAGE B - 1.....................................................

PREINSTALLATION INSPECTION PAGE B - 1............................................

Battery Specifications And Installation PAGE B - 2....................................

POSITIONING PUMP PAGE B - 2.......................................................

Lifting PAGE B - 2.................................................................

Mounting PAGE B - 2.............................................................

SUCTION AND DISCHARGE PIPING PAGE B - 3.........................................

Materials PAGE B - 3..............................................................

Line Configuration PAGE B - 3......................................................

Connections to Pump PAGE B - 3..................................................

Gauges PAGE B - 3...............................................................

SUCTION LINES PAGE B - 3...........................................................

Fittings PAGE B - 3...............................................................

Sealing PAGE B - 3...............................................................

Suction Line Positioning PAGE B - 3................................................

DISCHARGE LINES PAGE B - 5........................................................

Siphoning PAGE B - 5.............................................................

Valves PAGE B - 5................................................................

Bypass Lines PAGE B - 5..........................................................

ALIGNMENT PAGE B - 5..............................................................

OPERATION - SECTION C PAGE C - 1......................................

PRIMING PAGE C - 1.................................................................

STARTING PAGE C - 2................................................................

Starting PAGE C - 2...............................................................

OPERATION PAGE C - 2..............................................................

Lines With a Bypass PAGE C - 2....................................................

Lines Without a Bypass PAGE C - 2.................................................

Leakage PAGE C - 3..............................................................

Liquid Temperature And Overheating PAGE C - 3.....................................

Strainer Check PAGE C - 3.........................................................

Pump Vacuum Check PAGE C - 3..................................................

STOPPING PAGE C - 3................................................................

Stopping PAGE C - 3..............................................................

Safety Shutdown System PAGE C - 4...............................................

OPERATION IN EXTREME HEAT PAGE C - 4............................................

BEARING TEMPERATURE CHECK PAGE C - 4..........................................

Cold Weather Preservation PAGE C - 5..............................................

TROUBLESHOOTING - SECTION D PAGE D - 1..............................

PREVENTIVE MAINTENANCE PAGE D - 3...............................................

i

TABLE OF CONTENTS

(continued)

PUMP MAINTENANCE AND REPAIR ‐ SECTION E PAGE E - 1.................

STANDARD PERFORMANCE CURVE PAGE E - 1........................................

PARTS LISTS:

Pump Model PAGE E - 3..........................................................

Pump End Assembly PAGE E - 5...................................................

Drive Assembly PAGE E - 6........................................................

PUMP AND SEAL DISASSEMBLY AND REASSEMBLY PAGE E - 7.........................

Suction Check Valve Removal PAGE E - 7...........................................

Separating Pump And Intermediate From Engine PAGE E - 7..........................

Loosening Impeller PAGE E - 8.....................................................

Pump Casing and Wear Plate Removal PAGE E - 8...................................

Impeller Removal PAGE E - 9......................................................

Seal Removal PAGE E - 9..........................................................

Shaft and Bearing Removal and Disassembly PAGE E - 9.............................

Shaft and Bearing Reassembly and Installation PAGE E - 10............................

Seal Reassembly and Installation PAGE E - 11........................................

Impeller Installation PAGE E - 13.....................................................

Securing Intermediate And Drive Assembly To Engine PAGE E - 13......................

Pump Casing and Wear Plate Installation PAGE E - 14.................................

Suction Check Valve Installation PAGE E - 14.........................................

Final Pump Reassembly PAGE E - 14................................................

LUBRICATION PAGE E - 15.............................................................

Seal Assembly PAGE E - 15.........................................................

Bearings PAGE E - 15..............................................................

Engine PAGE E - 15................................................................

ii

80 SERIES

OM-06752

INTRODUCTION

Thank You for purchasing a Gorman‐Rupp pump.

Read this manual carefully to learn how to safely

install and operate your pump. Failure to do so

could result in personal injury or damage to the

pump.

Because pump installations are seldom identical,

this manual cannot possibly provide detailed in

structions and precautions for every aspect of

each specific application. Therefore, it is the re

sponsibility of the owner/installer of the pump to

ensure that applications not addressed in this

manual are performed only after establishing that

neither operator safety nor pump integrity are com

promised by the installation. Pumps and related

equipment must be installed and operated ac

cording to all national, local and industry stan

dards.

If there are any questions regarding the pump or

its application which are not covered in this man

ual or in other literature accompanying this unit,

please contact your Gorman‐Rupp distributor, or

The Gorman‐Rupp Company:

HAZARD AND INSTRUCTION

DEFINITIONS

The following are used to alert maintenance per

sonnel to procedures which require special atten

tion, to those which could damage equipment, and

to those which could be dangerous to personnel:

Immediate hazards which WILL result in

severe personal injury or death. These

instructions describe the procedure re

quired and the injury which will result

from failure to follow the procedure.

Hazards or unsafe practices which

COULD result in severe personal injury

or death. These instructions describe

the procedure required and the injury

which could result from failure to follow

the procedure.

The Gorman‐Rupp Company

P.O. Box 1217

Mansfield, Ohio 44901-1217

Phone: (419) 755-1011

or:

Gorman‐Rupp of Canada Limited

70 Burwell Road

St. Thomas, Ontario N5P 3R7

Phone: (519) 631-2870

For information or technical assistance on the

power source, contact the power source manufac

turer's local dealer or representative.

Hazards or unsafe practices which COULD

result in minor personal injury or product

or property damage. These instructions

describe the requirements and the possi

ble damage which could result from failure

to follow the procedure.

NOTE

Instructions to aid in installation, operation, and

maintenance or which clarify a procedure.

PAGE I - 1INTRODUCTION

80 SERIES

OM-06752

SAFETY - SECTION A

This information applies to 80 Series en

gine driven pumps. Refer to the manual

accompanying the engine before at

tempting to begin operation.

Because pump installations are seldom

identical, this manual cannot possibly

provide detailed instructions and pre

cautions for each specific application.

Therefore, it is the owner/installer's re

sponsibility to ensure that applications

not addressed in this manual are per

formed only after establishing that nei

ther operator safety nor pump integrity

are compromised by the installation.

Before attempting to open or service the

pump:

1. Familiarize yourself with this man

ual.

2. Switch off the engine ignition and

disconnect the positive battery

cable to ensure that the pump will

remain inoperative.

3. Allow the pump to completely cool

if overheated.

4. Check the temperature before

opening any covers, plates, or

plugs.

5. Close the suction and discharge

valves.

6. Vent the pump slowly and cau

tiously.

7. Drain the pump.

This pump is designed to handle most

non‐volatile, non‐flammable liquids

containing specified entrained solids.

Do not attempt to pump volatile, corro

sive, or flammable materials, or any liq

uids which may damage the pump or en

danger personnel as a result of pump

failure.

Death or serious personal injury and

damage to the pump or components

can occur if proper lifting procedures

are not observed. Make certain that

hoists, chains, slings or cables are in

good working condition and of suffi

cient capacity and that they are posi

tioned so that loads will be balanced

and the pump or components will not be

damaged when lifting. Suction and dis

charge hoses and piping must be re

moved from the pump before lifting. Lift

the pump or component only as high as

necessary and keep personnel away

from suspended objects.

After the pump has been positioned,

make certain that the pump and all pip

ing or hose connections are tight, prop

erly supported and secure before oper

ation.

Do not operate the pump against a

closed discharge valve for long periods

of time. If operated against a closed dis

charge valve, pump components will

deteriorate, and the liquid could come

to a boil, build pressure, and cause the

pump casing to rupture or explode.

Do not remove plates, covers, gauges,

pipe plugs, or fittings from an over

PAGE A - 1SAFETY

heated pump. Vapor pressure within the

pump can cause parts being disen

gaged to be ejected with great force. Al

low the pump to completely cool before

servicing.

Do not operate an internal combustion

engine in an explosive atmosphere.

When operating internal combustion

engines in an enclosed area, make cer

tain that exhaust fumes are piped to the

outside. These fumes contain carbon

monoxide, a deadly gas that is color

less, tasteless, and odorless.

80 SERIESOM-06752

Allow an over‐heated pump to com

pletely cool before servicing. Do not re

move plates, covers, gauges, or fittings

from an over‐heated pump. Liquid with

in the pump can reach boiling tempera

tures, and vapor pressure within the

pump can cause parts being disen

gaged to be ejected with great force. Af

ter the pump completely cools, drain the

liquid from the pump by removing the

casing drain plug. Use caution when re

moving the plug to prevent injury to per

sonnel from hot liquid.

Never tamper with the governor to gain

more power. The governor establishes

safe operating limits that should not be

exceeded. The maximum continuous

operating speed for this pump is 2100

RPM.

Pumps and related equipment must be in

stalled and operated according to all na

tional, local and industry standards.

Fuel used by internal combustion en

gines presents an extreme explosion

and fire hazard. Make certain that all

fuel lines are securely connected and

free of leaks. Never refuel a hot or run

ning engine. Avoid overfilling the fuel

tank. Always use the correct type of fuel.

PAGE A - 2 SAFETY

80 SERIES OM-06752

INSTALLATION - SECTION B

Review all SAFETY information in Section A.

Since pump installations are seldom identical, this

section offers only general recommendations and

practices required to inspect, position, and ar

range the pump and piping.

Most of the information pertains to a standard

static lift application where the pump is positioned

above the free level of liquid to be pumped.

If installed in a flooded suction application where

the liquid is supplied to the pump under pressure,

some of the information such as mounting, line

configuration, and priming must be tailored to the

OUTLINE DRAWING

specific application. Since the pressure supplied

to the pump is critical to performance and safety,

be sure to limit the incoming pressure to 50% of the

maximum permissible operating pressure. If the

pump is fitted with a Gorman‐Rupp double grease

lubricated seal, the maximum incoming pressure

must be reduced to 10 p.s.i.

For further assistance, contact your Gorman‐Rupp

distributor or the Gorman‐Rupp Company.

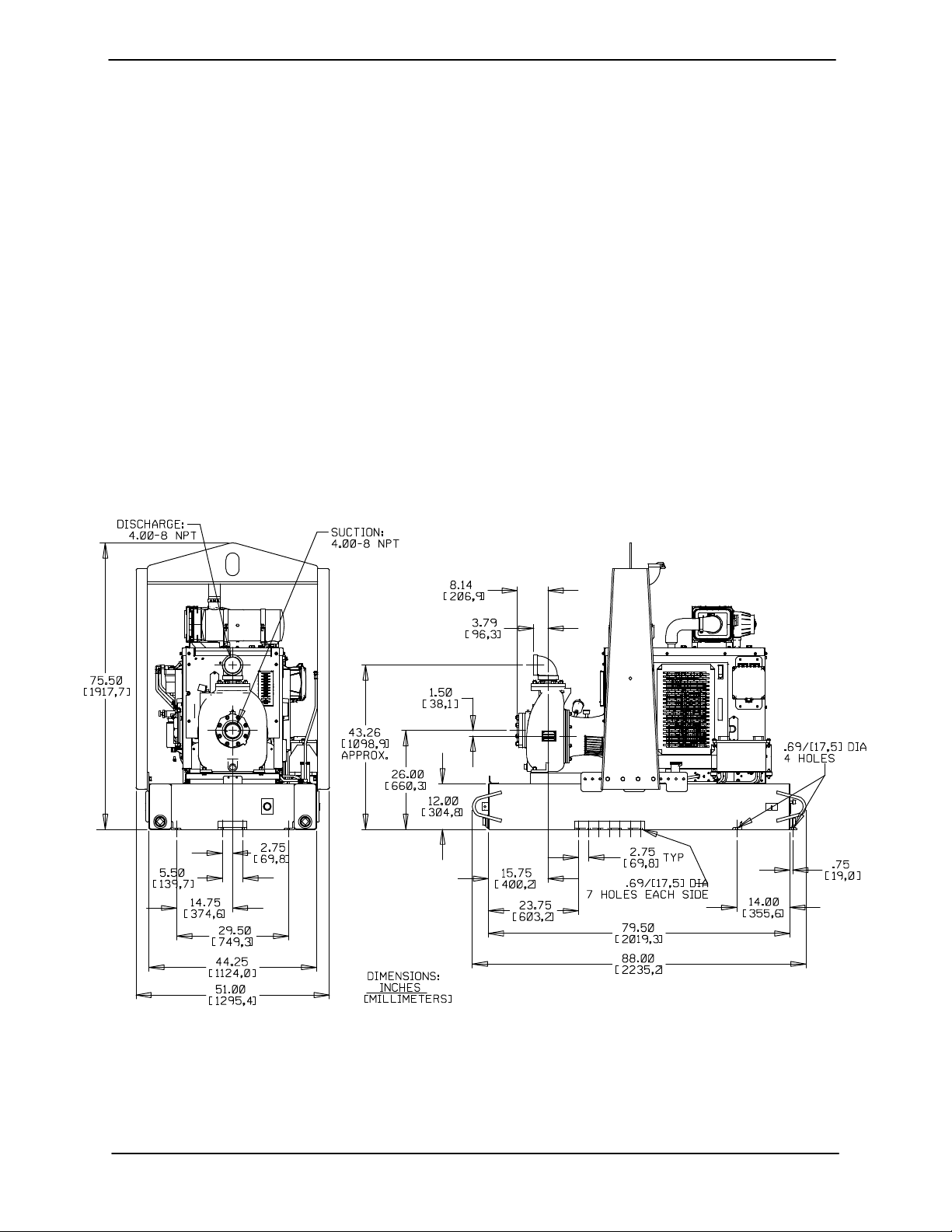

Pump Dimensions

See Figure 1 for the approximate physical dimen

sions of this pump.

Figure 1. Pump Model 84A2-QSF2.8P FT4

PAGE B - 1INSTALLATION

OM-06752 80 SERIES

PREINSTALLATION INSPECTION

The pump assembly was inspected and tested be

fore shipment from the factory. Before installation,

inspect the pump for damage which may have oc

curred during shipment. Check as follows:

a. Inspect the pump and engine for cracks,

dents, damaged threads, and other obvious

damage.

b. Check for and tighten loose attaching hard

ware. Since gaskets tend to shrink after dry

ing, check for loose hardware at mating sur

faces.

c. Carefully read all tags, decals, and markings

on the pump assembly, and perform all duties

indicated.

Table 1. Battery Specifications

Cold Reserve Approx.

Crank Capacity Amp/ Overall

Voltage

12 Volts 960‐975 365 175 8.75W

Refer to the information accompanying the battery

and/or electrolyte solution for activation and charg

ing instructions.

Before installing the battery, clean the positive and

negative cable connectors, and the battery termi

nals. Secure the battery by tightening the

holddown brackets. The terminals and clamps

may be coated with petroleum jelly to retard corro

sion. Connect and tighten the positive cable first,

then the negative cable.

Amps @80°F Hr. Dims.

@ 0°F (Minutes) Rating (Inches)

20.5L

x

x

9.75H

POSITIONING PUMP

d. Check levels and lubricate as necessary. Re

fer to LUBRICATION in the MAINTENANCE

AND REPAIR section of this manual and per

form duties as instructed.

e. If the pump end has been stored for more than

12 months, some of the components or lubri

cants may have exceeded their maximum

shelf life. These must be inspected or re

placed to ensure maximum pump service.

If the maximum shelf life has been exceeded, or if

anything appears to be abnormal, contact your

Gorman‐Rupp distributor or the factory to deter

mine the repair or updating policy. Do not put the

pump into service until appropriate action has

been taken.

Battery Specifications And Installation

Unless otherwise specified on the pump order, the

engine battery was not included with the unit. Re

fer to the following specifications when selecting a

battery.

Death or serious personal injury and

damage to the pump or components

can occur if proper lifting procedures

are not observed. Make certain that

hoists, chains, slings or cables are in

good working condition and of suffi

cient capacity and that they are posi

tioned so that loads will be balanced

and the pump or components will not be

damaged when lifting. Suction and dis

charge hoses and piping must be re

moved from the pump before lifting. Lift

the pump or component only as high as

necessary and keep personnel away

from suspended objects.

Lifting

Pump unit weights will vary depending on the

mounting and drive provided. Check the shipping

tag on the unit packaging for the actual weight, and

use lifting equipment with appropriate capacity.

Drain the pump and remove all customer‐installed

equipment such as suction and discharge hoses

or piping before attempting to lift existing, installed

units.

PAGE B - 2 INSTALLATION

80 SERIES OM-06752

Mounting

Locate the pump in an accessible place as close as

practical to the liquid being pumped. Level mount

ing is essential for proper operation.

The pump may have to be supported or shimmed

to provide for level operation or to eliminate vibra

tion.

If the pump has been mounted on a moveable

base, make certain the base is stationary by setting

the brake and blocking the wheels before attempt

ing to operate the pump.

To ensure sufficient lubrication and fuel supply to

the engine, do not position the pump and engine

more than 15

tion. The pump and engine may be positioned up

to 30_ off horizontal for intermittent operation

only; however, the engine manufacturer should be

consulted for continuous operation at angles

greater than 15_.

_

off horizontal for continuous opera

SUCTION AND DISCHARGE PIPING

Materials

Lines near the pump must be independently sup

ported to avoid strain on the pump which could

cause excessive vibration, decreased bearing life,

and increased shaft and seal wear. If hose‐type

lines are used, they should have adequate support

to secure them when filled with liquid and under

pressure.

Gauges

Most pumps are drilled and tapped for installing

discharge pressure and vacuum suction gauges. If

these gauges are desired for pumps that are not

tapped, drill and tap the suction and discharge

lines not less than 18 inches (457 mm) from the

suction and discharge ports and install the lines.

Installation closer to the pump may result in erratic

readings.

SUCTION LINES

To avoid air pockets which could affect pump prim

ing, the suction line must be as short and direct as

possible. When operation involves a suction lift, the

line must always slope upward to the pump from

the source of the liquid being pumped; if the line

slopes down to the pump at any point along the

suction run, air pockets will be created.

Either pipe or hose maybe used for suction and

discharge lines; however, the materials must be

compatible with the liquid being pumped. If hose is

used in suction lines, it must be the rigid‐wall, rein

forced type to prevent collapse under suction. Us

ing piping couplings in suction lines is not recom

mended.

Line Configuration

Keep suction and discharge lines as straight as

possible to minimize friction losses. Make mini

mum use of elbows and fittings, which substan

tially increase friction loss. If elbows are necessary,

use the long‐radius type to minimize friction loss.

Connections to Pump

Before tightening a connecting flange, align it ex

actly with the pump port. Never pull a pipe line into

place by tightening the flange bolts and/or cou

plings.

Fittings

Suction lines should be the same size as the pump

inlet. If reducers are used in suction lines, they

should be the eccentric type, and should be in

stalled with the flat part of the reducers uppermost

to avoid creating air pockets. Valves are not nor

mally used in suction lines, but if a valve is used,

install it with the stem horizontal to avoid air pock

ets.

Strainers

If a strainer is furnished with the pump, be certain

to use it; any spherical solids which pass through a

strainer furnished with the pump will also pass

through the pump itself.

If a strainer is not furnished with the pump, but is

installed by the pump user, make certain that the

total area of the openings in the strainer is at least

three or four times the cross section of the suction

line, and that the openings will not permit passage

PAGE B - 3INSTALLATION

OM-06752 80 SERIES

of solids larger than the solids handling capability

of the pump.

This pump is designed to handle up to 1‐1/8 inch

(28,6 mm) diameter spherical solids.

Sealing

Since even a slight leak will affect priming, head,

and capacity, especially when operating with a

high suction lift, all connections in the suction line

should be sealed with pipe dope to ensure an air

tight seal. Follow the sealant manufacturer's rec

ommendations when selecting and applying the

pipe dope. The pipe dope should be compatible

with the liquid being pumped.

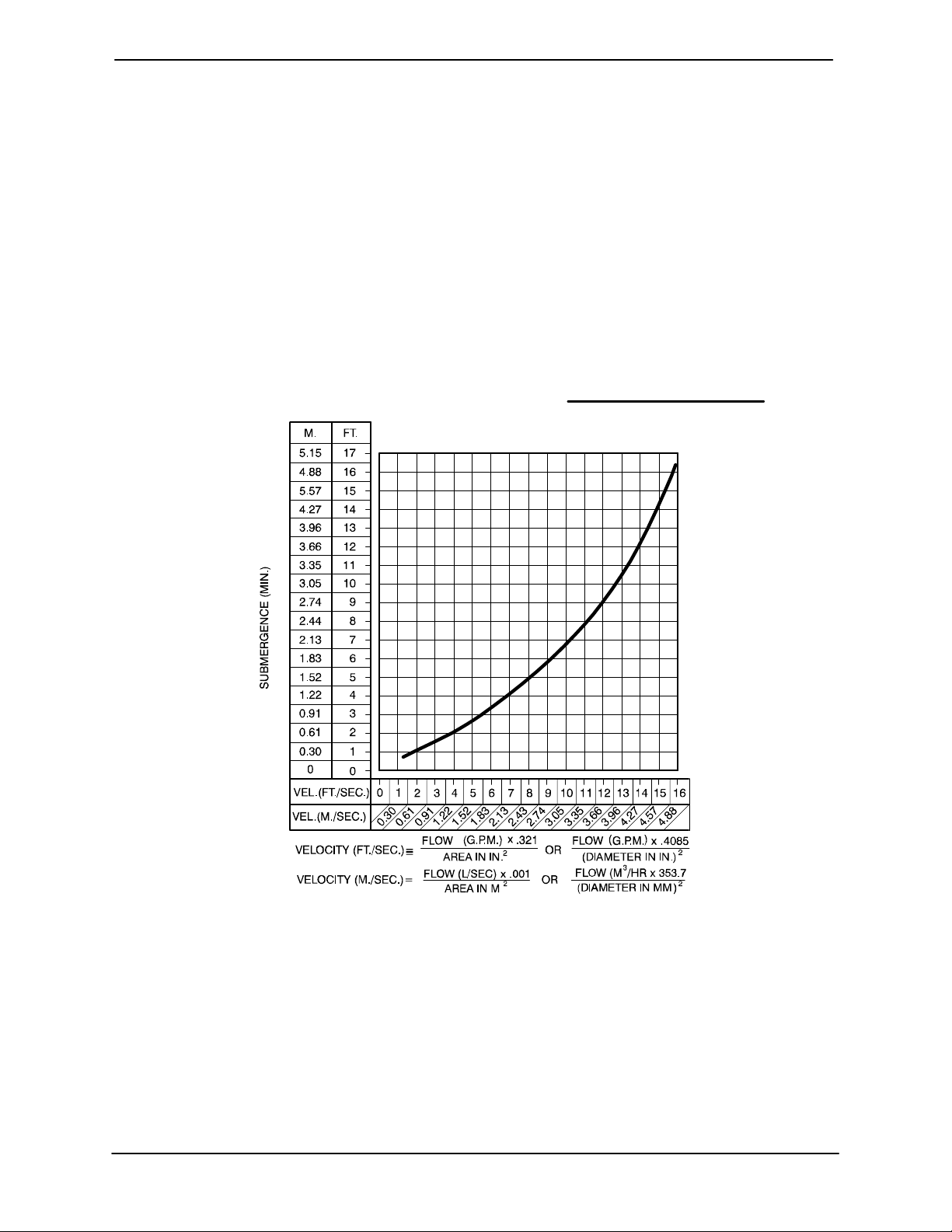

Suction Line Positioning

The depth of submergence of the suction line is

critical to efficient pump operation.

recommended minimum submergence vs. veloc

ity.

Figure 2 shows

NOTE

The pipe submergence required may be reduced

by installing a standard pipe increaser fitting at the

end of the suction line. The larger opening size will

reduce the inlet velocity. Calculate the required

submergence using the following formula based

on the increased opening size (area or diameter).

Figure 2. Recommended Minimum Suction Line Submergence vs. Velocity

DISCHARGE LINES

Siphoning

Do not terminate the discharge line at a level lower

than that of the liquid being pumped unless a si

phon breaker is used in the line. Otherwise, a si

phoning action causing damage to the pump

could result.

PAGE B - 4 INSTALLATION

Valves

If a throttling valve is desired in the discharge line,

use a valve as large as the largest pipe to minimize

friction losses. Never install a throttling valve in a

suction line.

With high discharge heads, it is recommended that

a throttling valve and a system check valve be in

stalled in the discharge line to protect the pump

80 SERIES OM-06752

from excessive shock pressure and reverse rota

tion when it is stopped.

If the application involves a high discharge

head, gradually close the discharge

throttling valve before stopping the pump.

Bypass Lines

If a system check valve is used due to high dis

charge head, it may be necessary to vent trapped

air from the top of the pump during the priming

process. This may be accomplished by installing a

bypass line from the top of the pump, back to the

source of liquid. The end of the bypass line must be

submerged. The line must be large enough to pre

vent clogging, but not so large as to affect pump

discharge capacity.

ALIGNMENT

The alignment of the pump and engine are critical

for trouble‐free performance. See Section E, Se

curing Intermediate And Drive Assembly To En

gine in MAINTENANCE AND REPAIR, for details.

PAGE B - 5INSTALLATION

Loading...

Loading...